Characterization of Matrix Pore Structure of a Deep Coal-Rock Gas Reservoir in the Benxi Formation, NQ Block, ED Basin

Abstract

1. Introduction

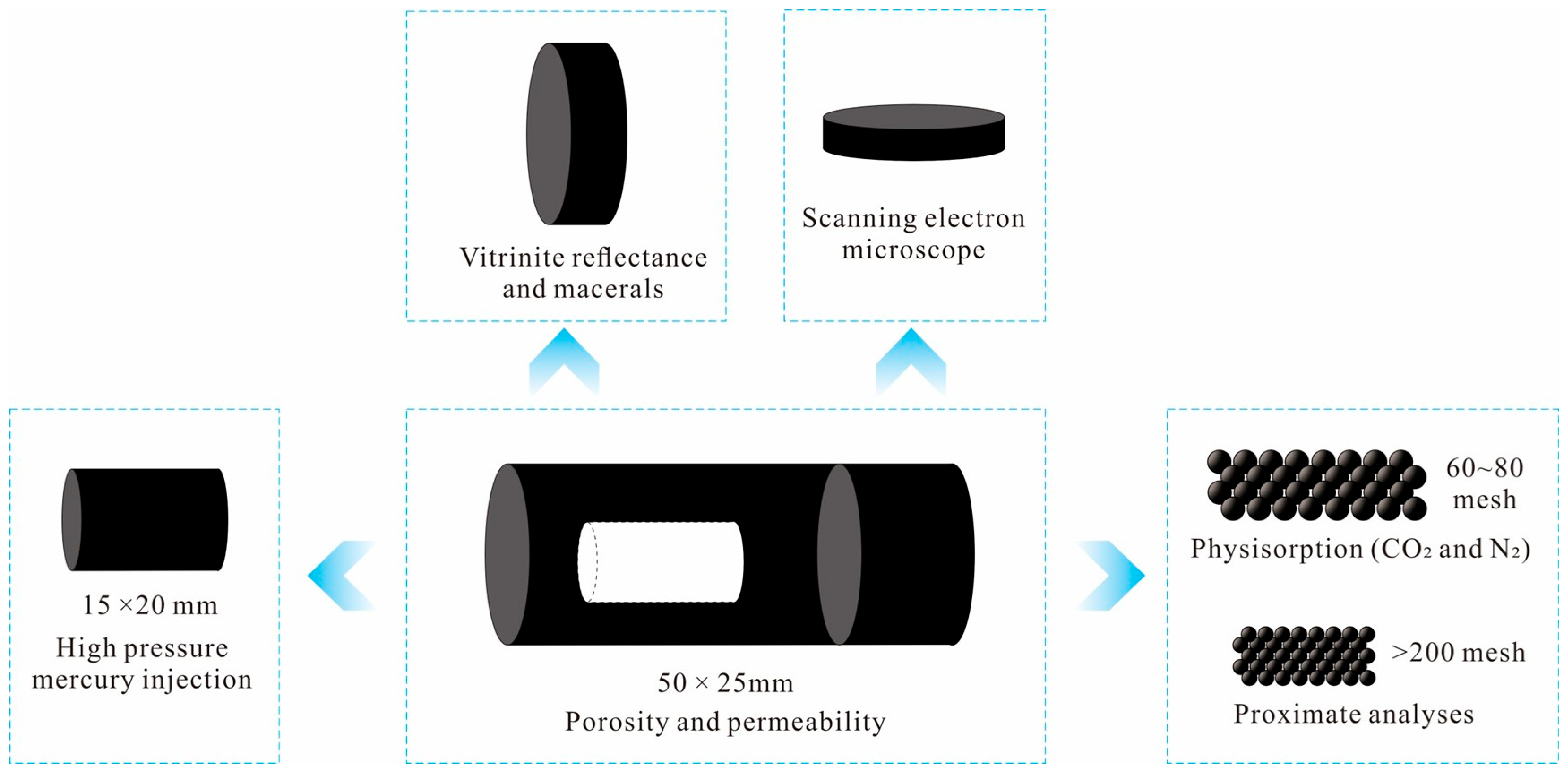

2. Experimental

2.1. Materials

2.2. Experimental Setup

2.3. Experimental Procedures

2.3.1. Proximate Analysis

2.3.2. Vitrinite Reflectance Analysis

2.3.3. Maceral Composition Analysis

2.3.4. SEM Analysis

2.3.5. Physisorption Experiments

2.3.6. HPMI Tests

3. Results and Discussion

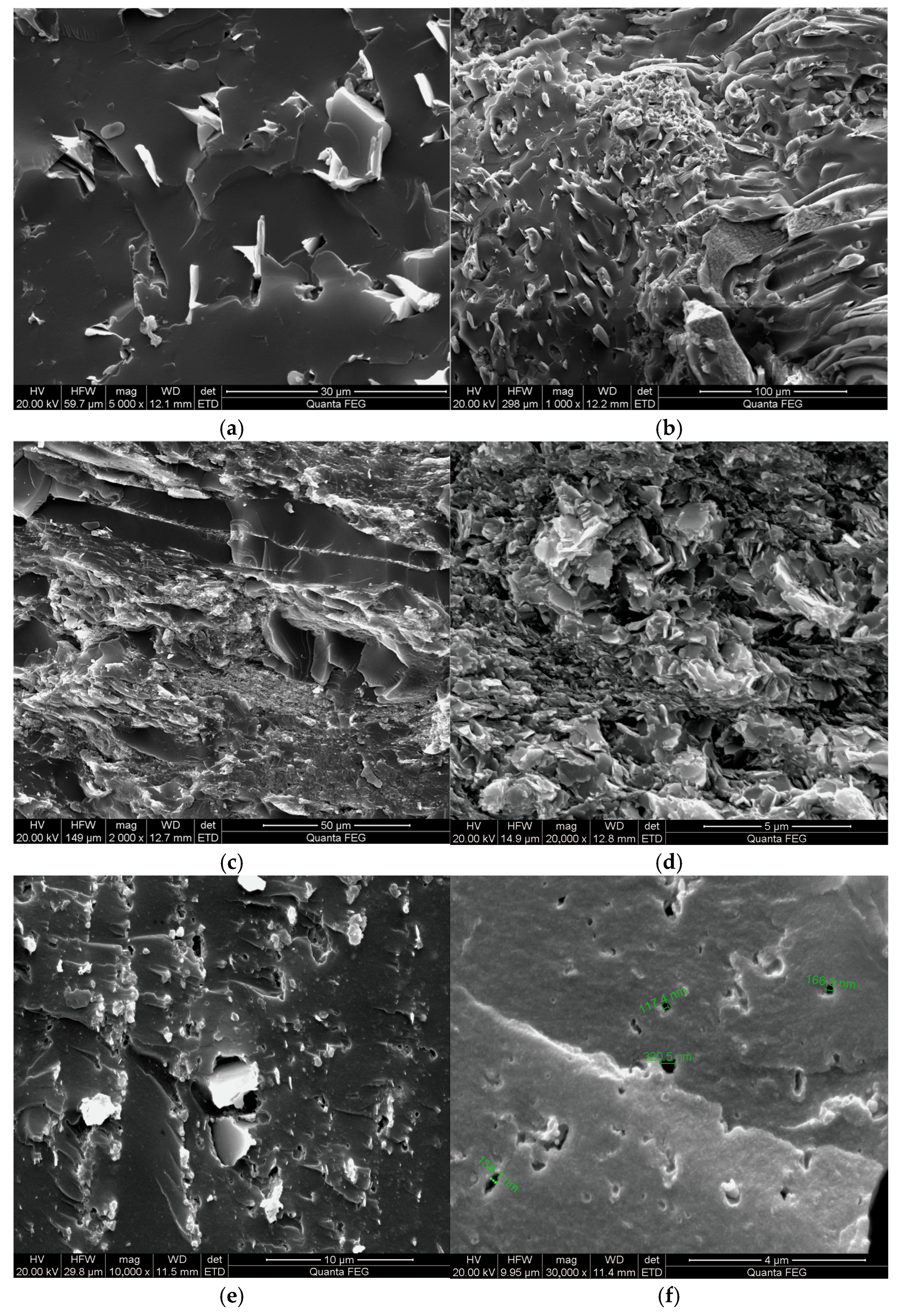

3.1. Mineral Characteristics and Coal Morphology

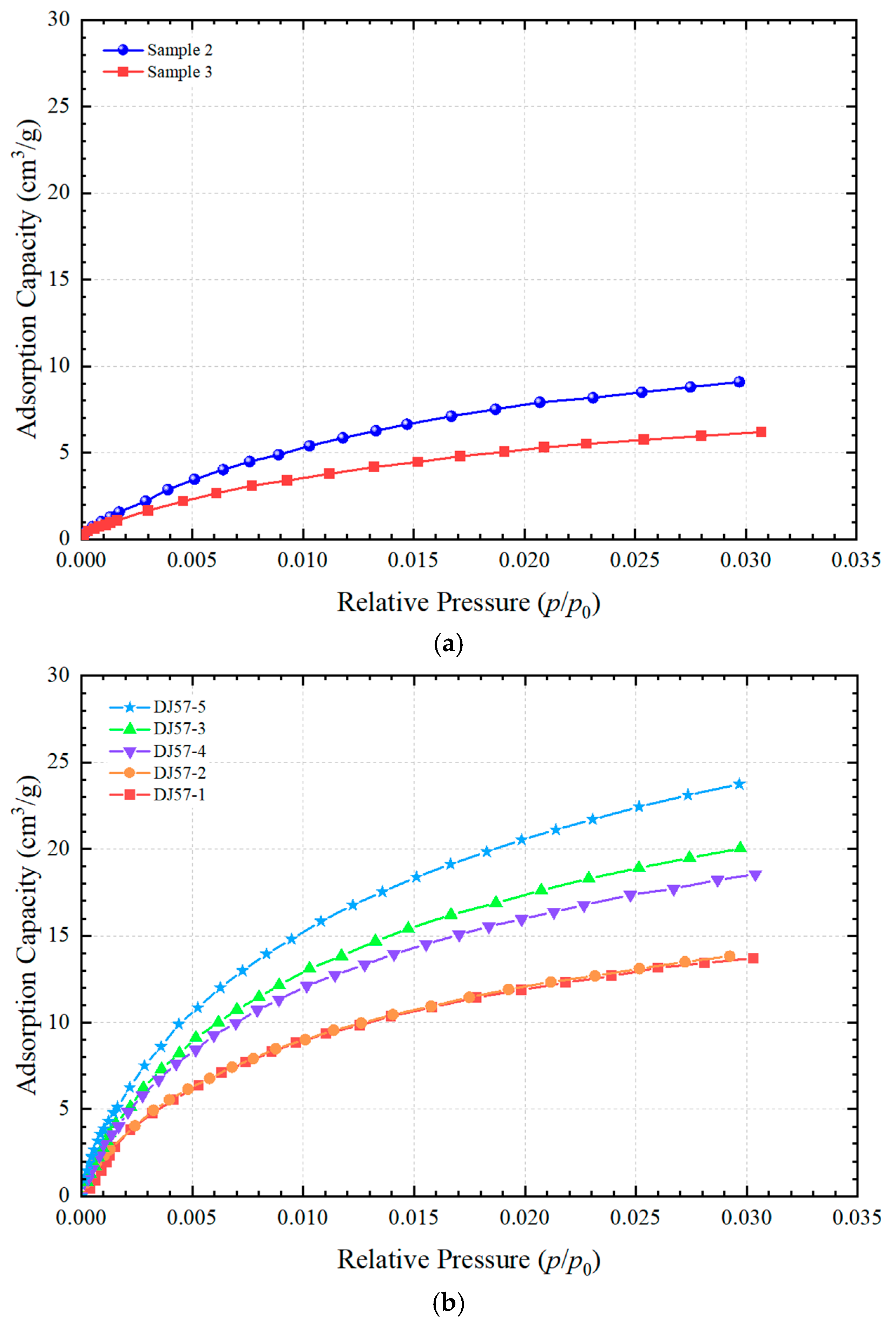

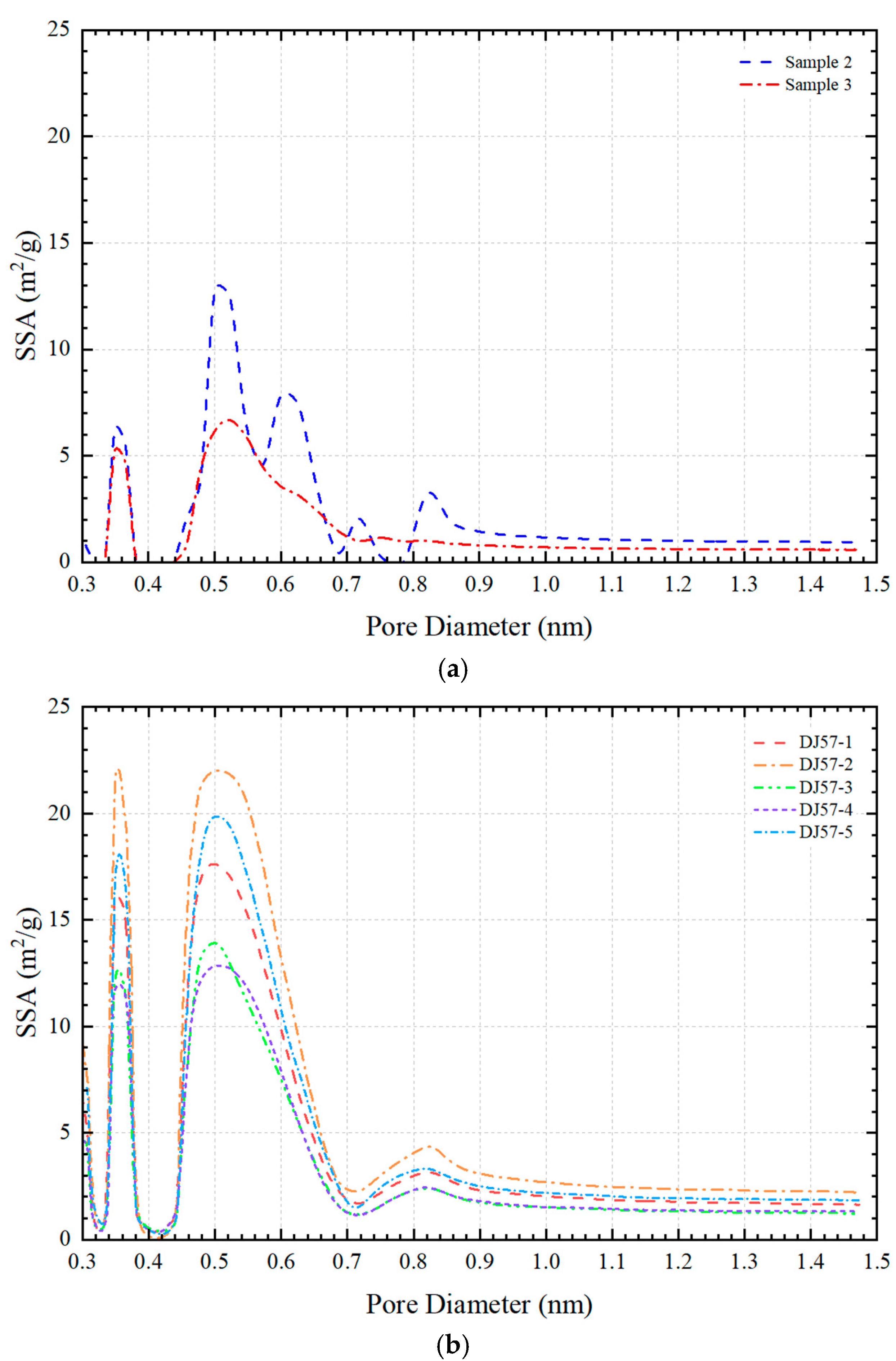

3.2. Micropore Distribution Characteristics

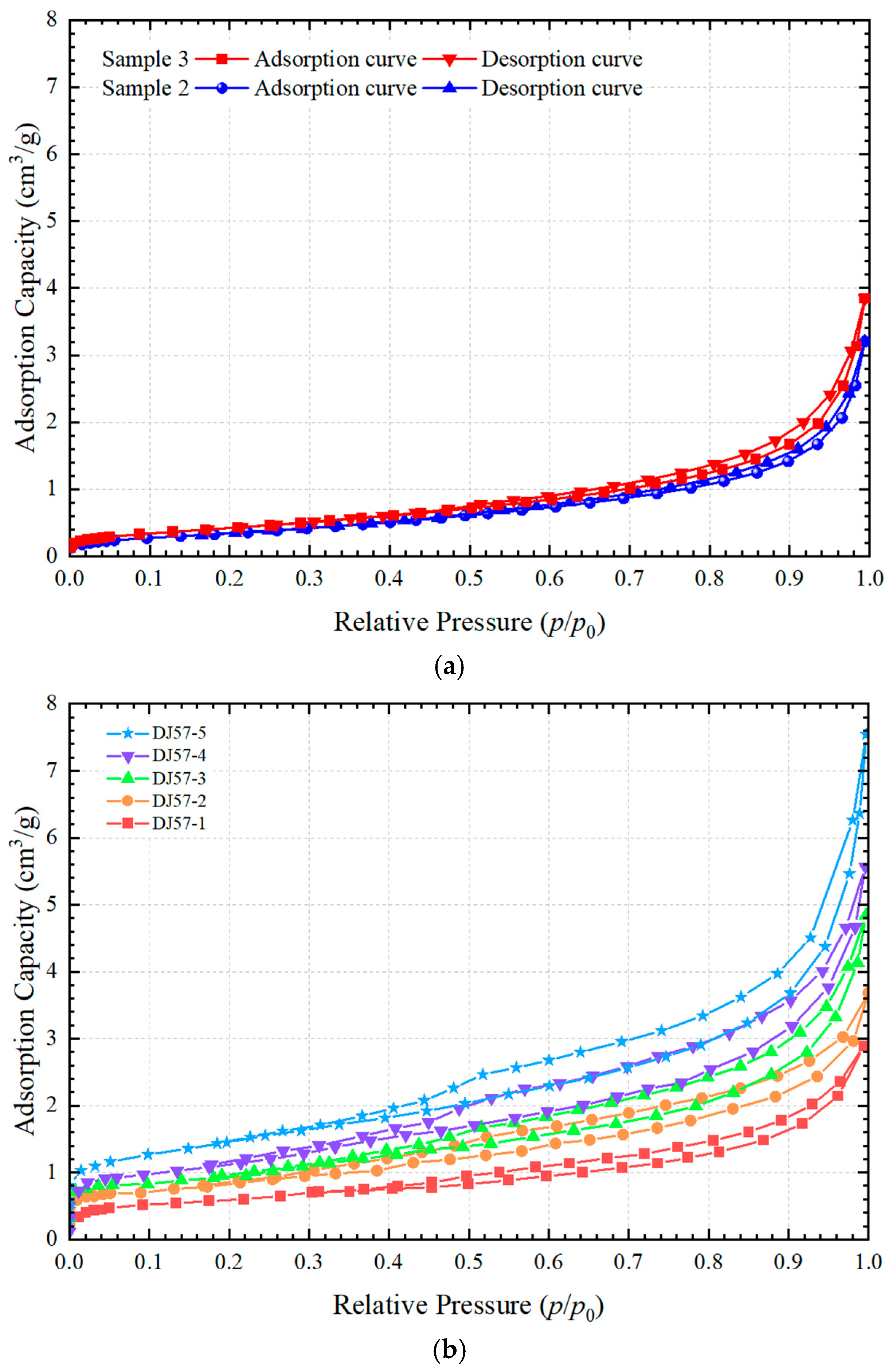

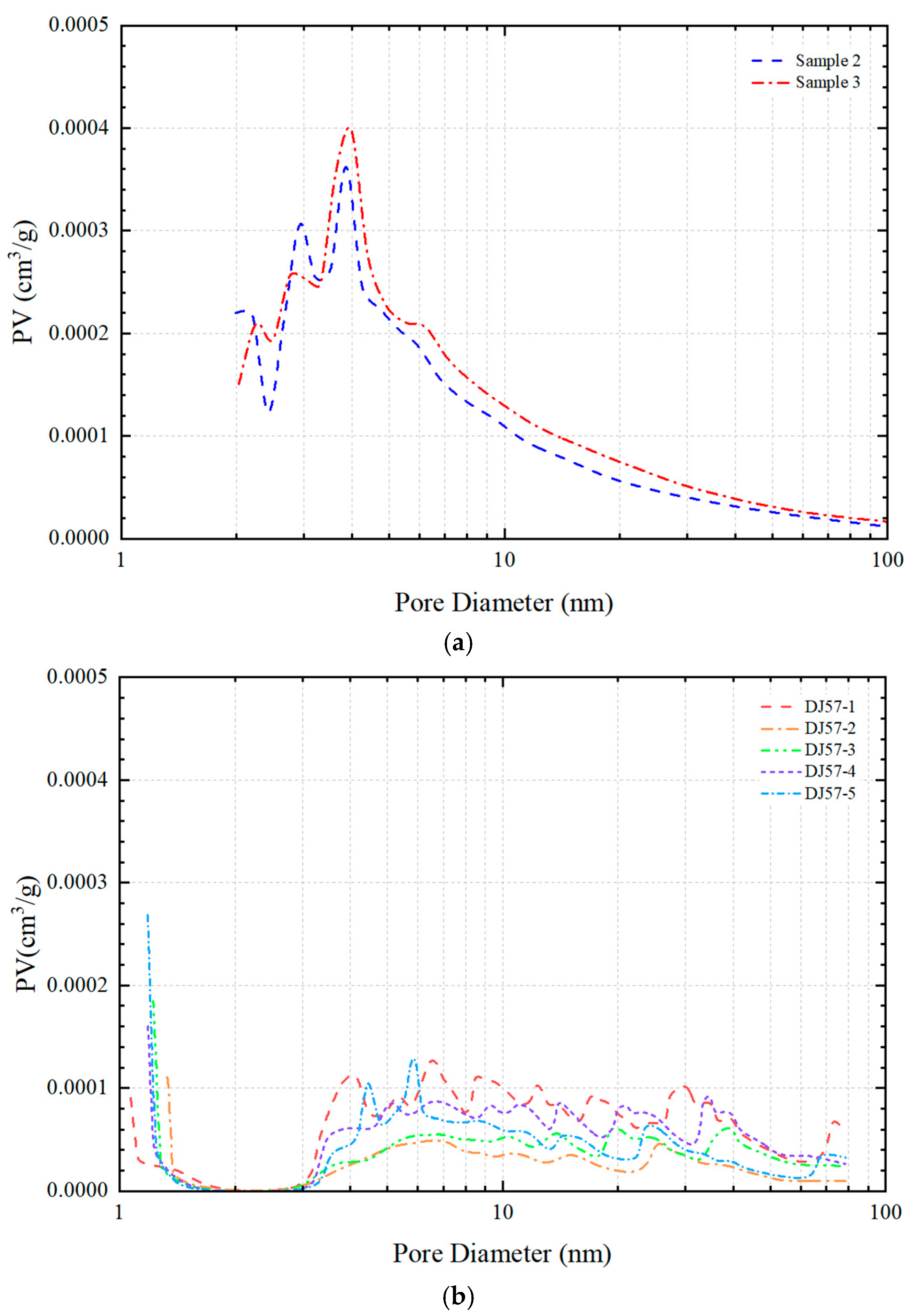

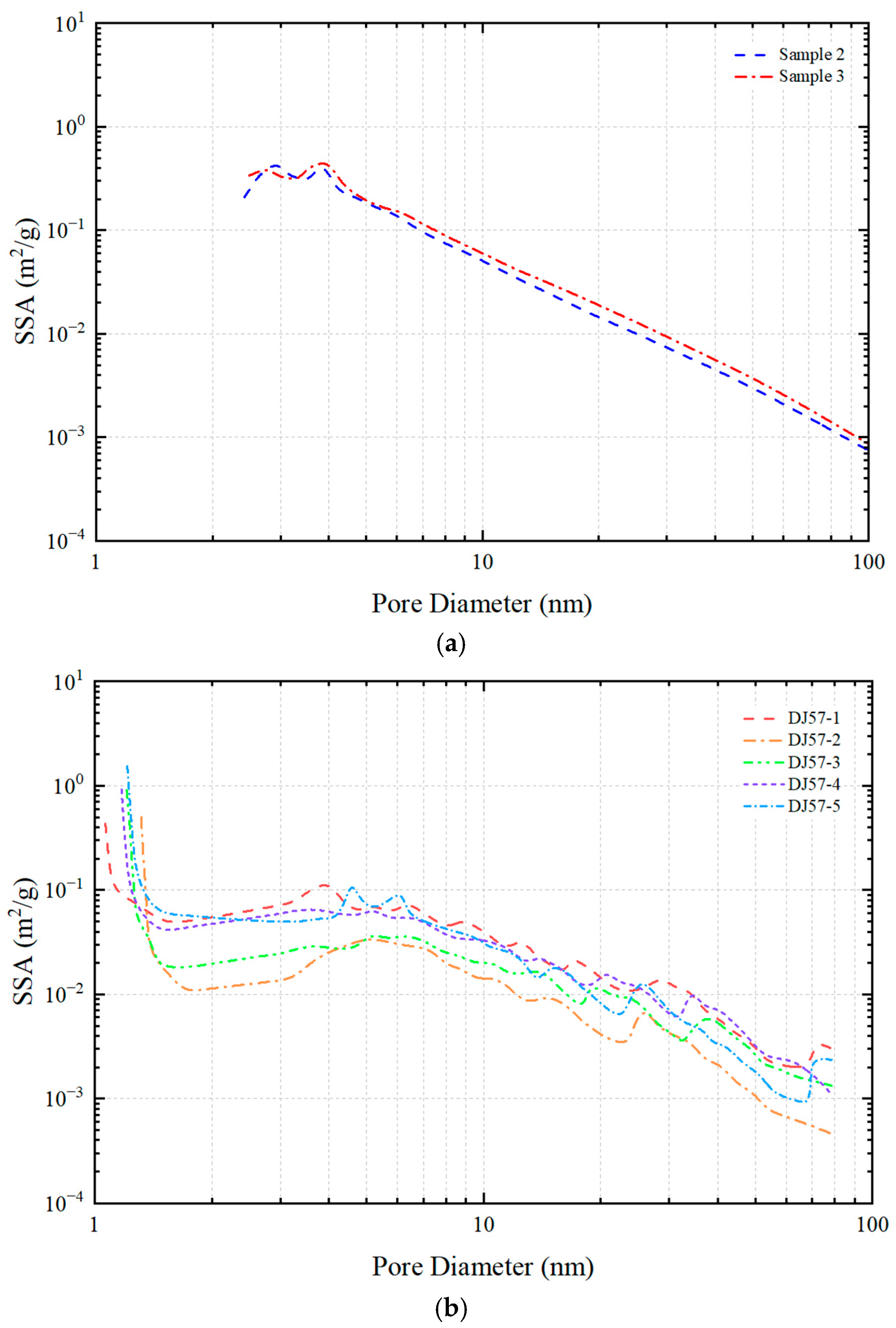

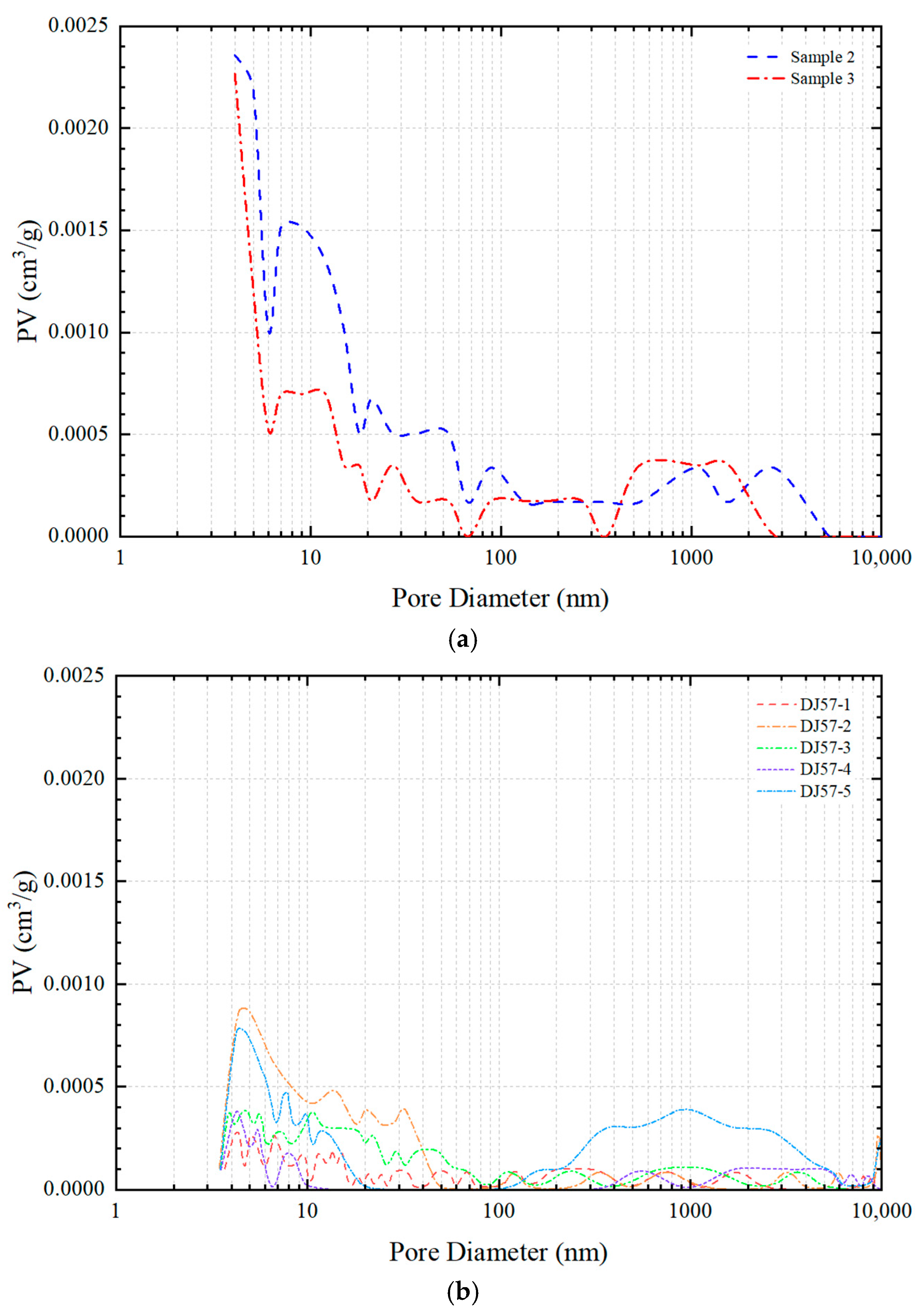

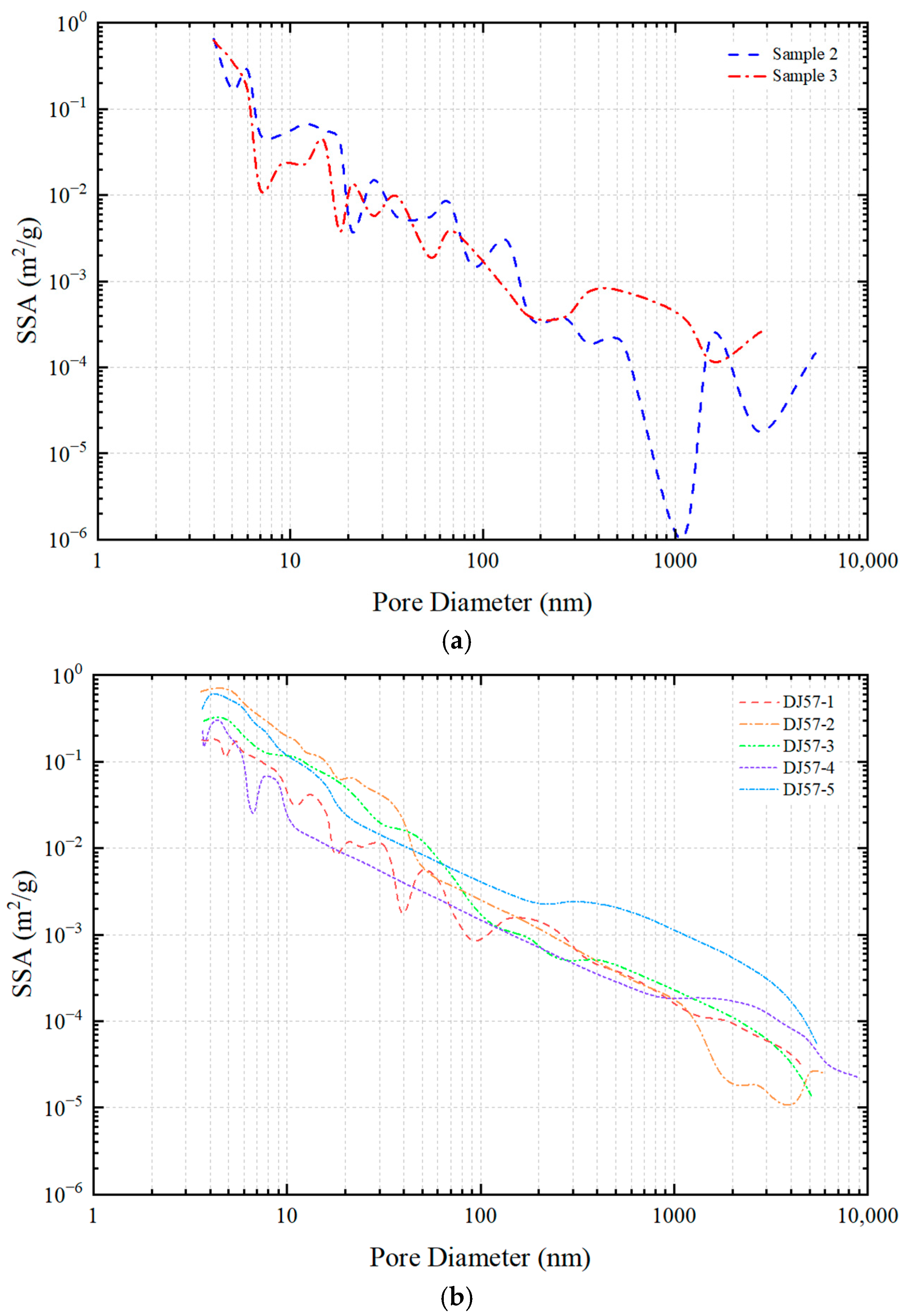

3.3. Mesopore Distribution Characteristics

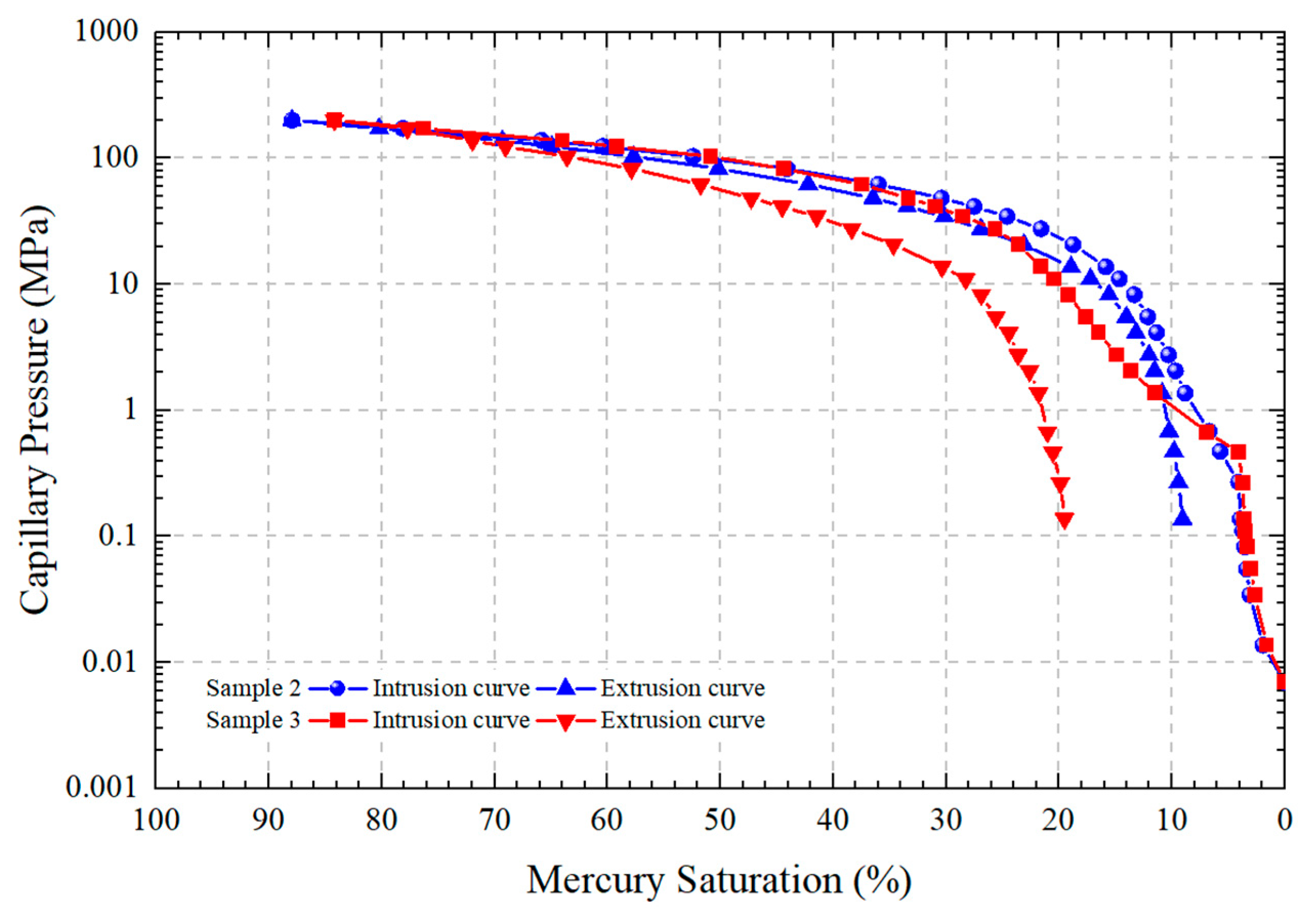

3.4. Macropore Distribution Characteristics

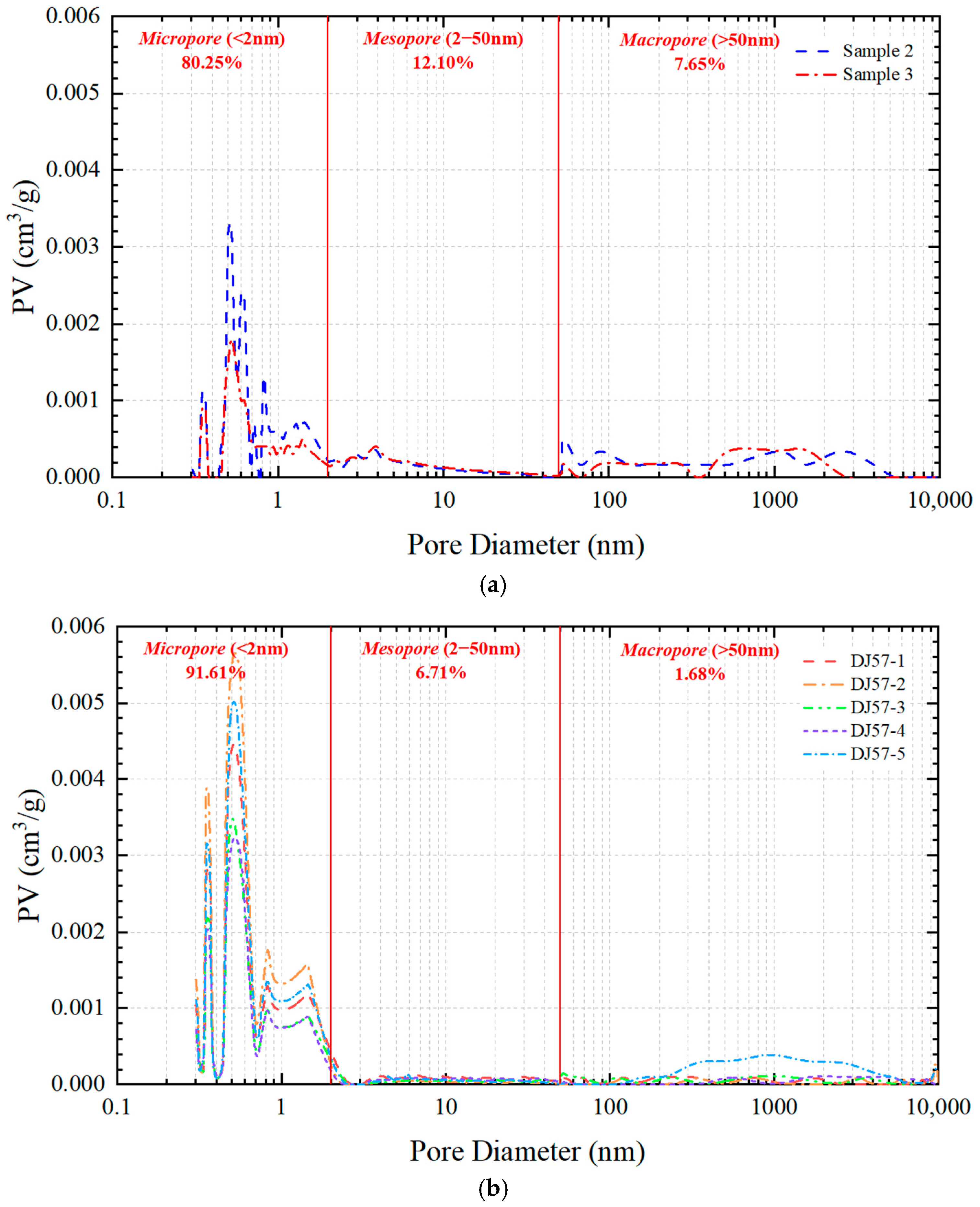

3.5. Multi-Scale Pore Distribution Characteristics

4. Conclusions

- (1)

- The DCR in the NQ Block is predominantly composed of vitrinite, accounting for approximately 77.75%, followed by inertinite. The pore space is predominantly characterized by cellular pores with minor contributions from intercrystalline and dissolution pores, but porosity development is relatively limited as most of these pores are extensively filled with clay minerals.

- (2)

- The PV and SSA of micropores in the NQ Block and the eastern part of the Basin exhibit multi-peak distribution characteristics. Notably, there are substantial differences in SSA and PV between the NQ Block and the eastern part of the Basin. In the DJ Block located in the eastern part of the Basin, the SSA and PV for the micropores per unit mass of DCR are 186.045 m2/g and 0.055 cm3/g, respectively, while t-tests confirm that the micropore SSA of the DJ Block is 2.4 times higher (p < 0.01). The degree of micropore development in the NQ Block is relatively comparable to that of the SF Block but significantly differs from that of the DJ Block, which is potentially attributable to variations in the DCR pore structure.

- (3)

- The PV of the mesopores per unit mass of DCR in the NQ Block is 0.004 cm3/g, which is comparable to that of the SF Block and the DJ Block located in the eastern part of the Basin; however, the SSA of the mesopores per unit mass of DCR in the NQ Block is significantly higher at 3.445 m2/g compared to 0.596 m2/g and 1.869 m2/g for the SF Block and the DJ Block, respectively, indicating a marked disparity in the SSA of the mesopores among these blocks. For macropores, the distribution of macropores in the NQ Block shows relatively close resemblance to that of the DJ Block in the eastern part of the Basin.

- (4)

- The SSA and PV per unit mass of DCR of the NQ Block and the DJ Block exhibit an L-shape distribution characteristic. Micropores dominate as the primary pore type, contributing significantly to both the SSA and PV. The NQ Block has a total SSA per unit mass of DCR of 81.215 m2/g and a PV of 0.030 cm3/g, whereas the DJ Block exhibits a total SSA per unit mass of DCR of 187.926 m2/g and a PV of 0.060 cm3/g. Notably, the SSA of the DJ Block was 2.3 times greater than that of the NQ Block; this was primarily due to differences in the SSA of micropores.

- (5)

- For the coal seams targeted for development, particularly in regions where the clay content is <20% (Table 2) and the vitrinite content >60%, large-scale hydraulic fracturing should be implemented to improve the accessibility of micropores and enhance the gas production rate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, D.; Chen, G.; Chen, Z.; Liu, Z. Exploration and development progress, key evaluation parameters and prospect of deep CBM in China. Nat. Gas Ind. 2022, 42, 43–51. [Google Scholar]

- Xu, F.; Xiao, Z.; Chen, D.; Yan, X.; Wu, N.; Li, X.; Miao, Y. Current status and development direction of coalbed methane exploration technology in China. Coal Sci. Technol. 2019, 47, 205–215. [Google Scholar]

- Li, S.; Tang, D.; Pan, Z.; Xu, H.; Tao, S.; Liu, Y.; Ren, P. Geological conditions of deep coalbed methane in the eastern margin of the Ordos Basin, China: Implications for coalbed methane development. J. Nat. Gas Sci. Eng. 2018, 53, 394–402. [Google Scholar] [CrossRef]

- Zhang, L.; Bian, L.; Hou, W.; Li, Y.; Li, Y.; Wu, P.; Li, W.; Li, X.; Li, C. Pore structure characteristics and exploration significance of deep coal reservoirs: A case study of Daning-Jixian block in the eastern margin of Ordos Basin. Acta Pet. Sin. 2023, 44, 1867–1878. [Google Scholar]

- Guo, X.; Wang, L.; Yao, X.; Li, X.; Zhang, L.; Wang, X. Geological characteristics of deep coal rock and main geological factors controlling coalbed methane enrichment: A case study of the M area in the eastern Ordos Basin. Pet. Geol. Exp. 2025, 47, 17–26. [Google Scholar]

- Tang, S.; Tang, D.; Yang, J.; Deng, Z.; Li, S.; Chen, S.; Feng, P.; Huang, C.; Li, Z. Pore structure characteristics and gas storage potential of deep coal reservoirs in Daning-Jixian Block of Ordos Basin. Acta Pet. Sin. 2023, 44, 1854–1866+1902. [Google Scholar]

- Deng, Z.; Wang, H.; Jiang, Z.; Ding, R.; Li, Y.; Wang, T. Influence of deep coal pore and fracture structure on occurrence of coalbed methane: A case study of Daning-Jixian Block in eastern margin of Ordos Basin. Coal Sci. Technol. 2024, 52, 106–123. [Google Scholar]

- Bustin, A.M.M.; Bustin, R.M. Coal reservoir saturation: Impact of temperature and pressure. AAPG Bull. 2008, 92, 77–86. [Google Scholar] [CrossRef]

- Wang, Y.; Tao, C.; Ni, X.; Gao, X.; He, Y. Amount of adsorbed gas in deep coal reservoir based on adsorption potential theory. J. China Coal Soc. 2018, 43, 1547–1552. [Google Scholar]

- Liu, D.; Liu, Z.; Cai, Y. Research progress on accumulation mechanism and formation geological conditions of coalbed methane. Coal Sci. Technol. 2020, 48, 1–16. [Google Scholar]

- Zhao, W.; Liu, H.; Wang, H.; Liu, D.; Li, X. Microscopic pore characteristics of coal seam and the controlling effect of sedimentary environment on pore structure in No.8 coalseam of the Ordos Basin. Coal Sci. Technol. 2024, 52, 142–154. [Google Scholar]

- Yang, X.; Song, B.; Chen, G.; He, R.; Zhao, H.; Yang, X. Characteristics of multi-scale pore-fracture structure of deep coal rocks in the Daning-Jixian Block. Spec. Oil Gas Reserv. 2022, 29, 94–100. [Google Scholar]

- Du, Q.; Liu, X.; Wang, E.; Zuo, J.; Wang, W.; Zhu, Y. Effects of CO2–water interaction with coal on mineral content and pore characteristics. J. Rock Mech. Geotech. Eng. 2020, 12, 326–337. [Google Scholar] [CrossRef]

- Qin, L.; Ma, C.; Li, S.; Lin, H.; Wang, P.; Long, H.; Yan, D. Mechanical damage mechanism of frozen coal subjected to liquid nitrogen freezing. Fuel 2022, 309, 122124. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, X.; Liu, J.; Pang, S.; Zhu, K.; Zheng, Z. Multi-scale quantitative characterization of three-dimensional pores and fissures in deep coal and study of the evolution laws. Constr. Build. Mater. 2024, 449, 138449. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Zhang, L.; Hou, J. Characterization on pore structure of tectonic coals based on the method of mercury intrusion, carbon dioxide adsorption and nitrogen adsorption. J. China Coal Soc. 2019, 44, 1188–1196. [Google Scholar]

- Clarkson, C.; Haghshenas, B.; Ghanizadeh, A.; Qanbari, F.; Williams-Kovacs, J.; Riazi, N.; Debuhr, C.; Deglint, H. Nanopores to megafractures: Current challenges and methods for shale gas reservoir and hydraulic fracture characterization. J. Nat. Gas Sci. Eng. 2016, 31, 612–657. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, Y.; Chen, S.; Zhang, H.; Fu, C. Qualitative-quantitative multiscale characterization of pore structures in shale reservoirs: A case study of Longmaxi Formation in the Upper Yangtze area. Earth Sci. Front. 2016, 23, 154–163. [Google Scholar]

- Chen, Y.; Zou, C.; Maria, M.; Zhu, R.; Bai, B.; Yang, Z. Porosity and fractal characteristics of shale across a maturation gradient. Nat. Gas Geosci. 2015, 26, 1646–1656. [Google Scholar]

- GB/T 30732-2014; National Technical Committee on Coal Standardization of Standardization Administration of China (SAC/TC 42). Proximate Analysis of Coal—Instrumental Method. China Standards Press: Beijing, China, 2014; Volume 16.

- GB/T 6948-2008; National Technical Committee on Coal Standardization of Standardization Administration of China (SAC/TC 42). Method of Determining Microscopically the Reflectance of Vitrinite in Coal. China Standards Press: Beijing, China, 2008; Volume 16.

- GB/T 8899-2013; National Technical Committee on Coal Standardization of Standardization Administration of China (SAC/TC 42). Determination of Maceral Group Composition and Minerals in Coal. China Standards Press: Beijing, China, 2013; Volume 12.

- Liu, G.; Bai, Y.; Gu, D.; Lu, Y.; Yang, D. Determination of static and dynamic characteristics of microscopic pore-throat structure in a tight oil-bearing sandstone formation. AAPG Bull. 2018, 102, 1867–1892. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, R.; Cai, Y.; Yin, T.; Qiu, F.; Xu, S. CH4 adsorption capacity of coalbed methane reservoirs induced by microscopic differences in pore structure. Unconv. Resour. 2024, 4, 100097. [Google Scholar] [CrossRef]

- Woodd, D. Complex interactions between coal maceral fractions, thermal maturity, reaction kinetics, fractal dimensions and pore-size distributions: Implications for gas storage. Int. J. Coal Geol. 2025, 305, 104788. [Google Scholar] [CrossRef]

- Liu, G.; Yin, H.; Lan, Y.; Fei, S.; Yang, D. Experimental determination of dynamic pore-throat structure characteristics in a tight gas sandstone formation with consideration of effective stress. Mar. Pet. Geol. 2020, 113, 104170. [Google Scholar] [CrossRef]

- Li, G.; Zhang, S.; He, H.; He, X.; Zhao, Z.; Niu, X.; Xiong, X.; Zhao, Q.; Guo, X.; Hou, Y.; et al. Coal-rock gas: Concept, connotation and classification criteria. Pet. Explor. Dev. 2024, 51, 897–911. [Google Scholar] [CrossRef]

- Li, G.; Yao, Y.; Wang, H.; Meng, L.; Li, P.; Zhang, Y.; Wang, J.; Ma, L. Deep coalbed methane resources in the Shenmu-Jiaxian block, Ordos Basin, China: Geological characteristics and potential for exploration and exploitation. Coal Geol. Explor. 2024, 52, 70–80. [Google Scholar]

- Liu, X.; Huang, D.; Hu, J.; Zhou, G.; Du, X.; Dai, X. Reservoir characteristics of Carboniferous Benxi Formation coal-rock gas in the central and eastern Ordos Basin. Nat. Gas Ind. 2024, 44, 51–62. [Google Scholar]

- Huo, Z.; Xi, Z.; Guo, J.; Wang, D. Pore characteristics of tectonic coal based on nitrogen adsorption and SEM. Coal Eng. 2024, 56, 149–156. [Google Scholar]

- Zhao, D.; Guo, Y.; Mao, X.; Lu, C.; Li, M.; Qian, F. Characteristics of macro-nanopores in anthracite coal based on mercury injection, nitrogen adsorption and FE-SEM. J. China Coal Soc. 2017, 42, 1517–1526. [Google Scholar]

- Wang, T.; Tian, F.; Deng, Z.; Hu, H. The characteristic development of micropores in deep coal and its relationship with adsorption capacity on the eastern margin of the Ordos Basin, China. Minerals 2023, 13, 302. [Google Scholar] [CrossRef]

- Li, B.; Guo, Y.; Hu, X.; Wang, T.; Wang, R.; Chen, X.; Fan, W.; Deng, Z. Pore structure and heterogeneity characteristics of deep coal reservoirs: A case study of the Daning–Jixian Block on the southeastern margin of the Ordos Basin. Minerals 2025, 15, 116. [Google Scholar] [CrossRef]

- Wang, K.; Qiao, P.; Wang, Z.; Liu, X.; Li, Y. Multiple scale pore size characterization of coal based on carbon dioxide and liquid nitrogen adsorption, high-pressure mercury intrusion and low field nuclear magnetic resonance. China Min. Mag. 2017, 26, 146–152. [Google Scholar]

- Ma, L.; Wu, P.; Yang, J.; Hu, W.; Huang, Y.; Liu, C.; Niu, Y.; Wang, Z.; Ren, D. Microscopic pore structure characteristics and implications of deep coal measure reservoirs in eastern Ordos Basin. Pet. Reserv. Eval. Dev. 2025, 15, 217–226. [Google Scholar]

- Chen, S.; Zhu, Y.; Wang, H.; Liu h Wei w Fang, J. Structure characteristics and accumulation significance of nanopores in Longmaxi shale gas reservoir in the southern Sichuan Basin. J. China Coal Soc. 2012, 37, 438–444. [Google Scholar]

- Xu, F.; Wang, C.; Xiong, X.; Li, S.; Wang, Y.; Guo, G.; Yan, X.; Chen, G.; Yang, Y.; Wang, H.; et al. Deep (layer) coalbed methane reservoir forming modes and key technical countermeasures: Taking the eastern margin of Ordos Basin as an example. China Offshore Oil Gas 2022, 34, 30–42+262. [Google Scholar]

- Jiang, J.; Yang, W.; Cheng, Y.; Zhao, K.; Zheng, S. Pore structure characterization of coal particles via MIP, N2 and CO2 adsorption: Effect of coalification on nanopores evolution. Powder Technol. 2019, 354, 136–148. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.; Olivier, J.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

| Coal Samples | Porosity (%) | Permeability (mD) | Qt-Ar (cm3/g) |

|---|---|---|---|

| 1 | 3.40 | 0.19 | 6.69 |

| 2 | 6.60 | 0.33 | 7.76 |

| 3 | 4.40 | 0.28 | 6.47 |

| 4 | 5.20 | 0.12 | 8.44 |

| Coal Samples | Mad (%) | Aad (%) | Vad (%) | FCad (%) | Ro,max (%) | Maceral (%) | ||

|---|---|---|---|---|---|---|---|---|

| Vitrinite | Inertinite | Other | ||||||

| 2 | 0.64 | 25.85 | 10.75 | 62.76 | 1.86 | 76.20 | 20.20 | 3.60 |

| 3 | 054 | 38.11 | 12.02 | 49.33 | 1.87 | 78.20 | 19.40 | 2.40 |

| 4 | 0.63 | 22.45 | 10.80 | 66.12 | 1.87 | 77.20 | 19.40 | 2.80 |

| Parameter | Pore Type | Western ED Basin | Eastern ED Basin | |

|---|---|---|---|---|

| NQ Block (n = 2) | DJ Block (n = 5) | SF Block (n = 4) | ||

| SSA (m2/g) | Micropore | 77.754 ± 16.1140 | 186.045 ± 19.8858 | 91.519 ± 8.8930 |

| Mesopore | 3.445 ± 0.1080 | 1.869 ± 0.3220 | 0.596 ± 0.0153 | |

| Macropore | 0.016 ± 0.0040 | 0.012 ± 0.0050 | N/A | |

| Total PV (cm3/g) | Micropore | 0.024 ± 0.0050 | 0.055 ± 0.0060 | 0.036 ± 0.0030 |

| Mesopore | 0.004 ± 0.0001 | 0.004 ± 0.0007 | 0.003 ± 0.0010 | |

| Macropore | 0.002 ± 0.0010 | 0.001 ± 0.0003 | N/A | |

| Coal Samples | MMS (%) | MEE (%) | Pt (MPa) | P50 (MPa) | α | Sp |

|---|---|---|---|---|---|---|

| 2 | 87.9 | 89.7 | 0.270 | 100.7 | 0.095 | 2.245 |

| 3 | 84.2 | 76.8 | 0.465 | 97.4 | 0.156 | 2.674 |

| ED Basin | Coal Samples | Measured Micropores with CO2 Adsorption | Measured Mesopores with N2 Adsorption | Measured Macropores with HPMI Tests | |||

|---|---|---|---|---|---|---|---|

| Total PV (cm3/g) | SSA (m2/g) | Total PV (cm3/g) | SSA (m2/g) | Total PV (cm3/g) | SSA (m2/g) | ||

| NQ Block | 2 | 0.029 | 93.868 | 0.004 | 3.337 | 0.003 | 0.020 |

| 3 | 0.019 | 61.641 | 0.004 | 3.553 | 0.001 | 0.012 | |

| Mean (n = 2) | 0.024 ± 0.0050 | 77.754 ± 16.1140 | 0.004 ± 0.0001 | 3.445 ± 0.1080 | 0.002 ± 0.0010 | 0.016 ± 0.0040 | |

| DJ Block | DJ57-1 | 0.056 | 190.433 | 0.006 | 2.865 | 0.001 | 0.028 |

| DJ57-2 | 0.073 | 246.819 | 0.002 | 1.044 | 0.000 | 0.003 | |

| DJ57-3 | 0.042 | 143.664 | 0.003 | 1.335 | 0.001 | 0.018 | |

| DJ57-4 | 0.041 | 141.940 | 0.005 | 2.208 | 0.001 | 0.001 | |

| DJ57-5 | 0.061 | 207.370 | 0.004 | 1.892 | 0.002 | 0.010 | |

| Mean (n = 5) | 0.055 ± 0.0060 | 186.045 ± 19.8858 | 0.004 ± 0.0007 | 1.869 ± 0.3220 | 0.001 ± 0.0003 | 0.012 ± 0.0050 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Wang, D.; Peng, X.; Zhang, Q.; Liu, B.; Luo, Z.; Zhang, Z.; Yang, D. Characterization of Matrix Pore Structure of a Deep Coal-Rock Gas Reservoir in the Benxi Formation, NQ Block, ED Basin. Eng 2025, 6, 142. https://doi.org/10.3390/eng6070142

Liu G, Wang D, Peng X, Zhang Q, Liu B, Luo Z, Zhang Z, Yang D. Characterization of Matrix Pore Structure of a Deep Coal-Rock Gas Reservoir in the Benxi Formation, NQ Block, ED Basin. Eng. 2025; 6(7):142. https://doi.org/10.3390/eng6070142

Chicago/Turabian StyleLiu, Guangfeng, Dianyu Wang, Xiang Peng, Qingjiu Zhang, Bofeng Liu, Zhoujun Luo, Zeyu Zhang, and Daoyong Yang. 2025. "Characterization of Matrix Pore Structure of a Deep Coal-Rock Gas Reservoir in the Benxi Formation, NQ Block, ED Basin" Eng 6, no. 7: 142. https://doi.org/10.3390/eng6070142

APA StyleLiu, G., Wang, D., Peng, X., Zhang, Q., Liu, B., Luo, Z., Zhang, Z., & Yang, D. (2025). Characterization of Matrix Pore Structure of a Deep Coal-Rock Gas Reservoir in the Benxi Formation, NQ Block, ED Basin. Eng, 6(7), 142. https://doi.org/10.3390/eng6070142