Performance Monitoring of a Double-Slope Passive Solar-Powered Desalination System Using Arduino Programming

Abstract

1. Introduction

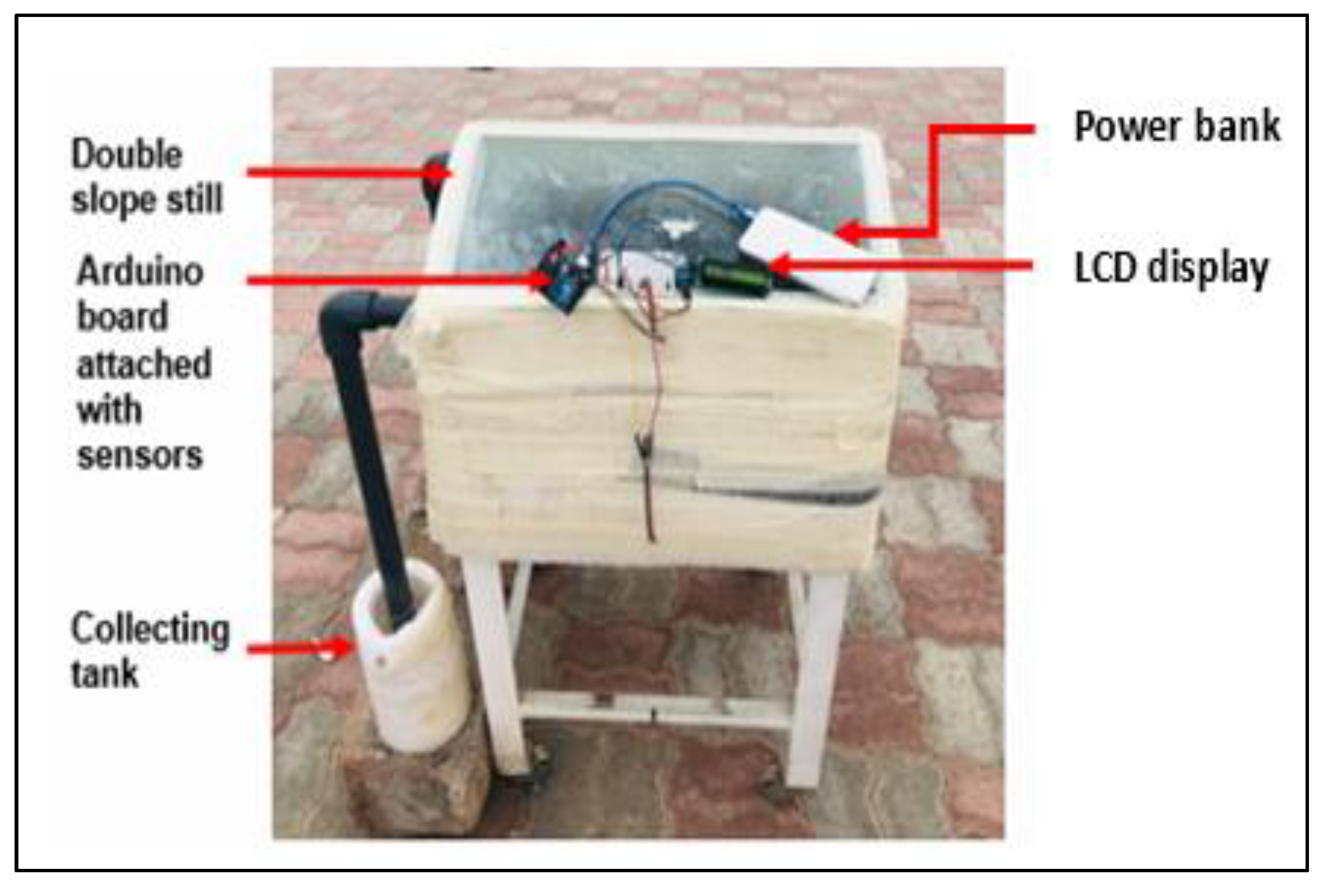

2. Experimentation

| #include <LiquidCrystal_I2C.h> |

| LiquidCrystal_I2C lcd(0x27,16,2); void setup() { |

| lcd.init(); |

| lcd.clear(); lcd.backlight(); |

| } |

| #include <DFRobot_DHT11.h> |

| DFRobot_DHT11 DHT; |

| #define DHT11a_PIN 6 |

| #define DHT11b_PIN 10 |

| #define DHT11c_PIN 11 |

| #define DHT11d_PIN 12 void loop() |

| { |

| loop1(); |

| loop2(); |

| loop3(); |

| loop4(); |

| } |

| void loop1() |

| { |

| DHT.read(DHT11a_PIN); |

| lcd.setCursor(0,0); lcd.print(“T1:”); lcd.println(DHT.temperature); lcd.setCursor(0,1); lcd.print(“H1:”); lcd.println(DHT.humidity); |

| delay(5000); |

| } |

| void loop2() |

| { |

| DHT.read(DHT11b_PIN); |

| lcd.setCursor(0,0); lcd.print(“T2:”); lcd.println(DHT.temperature); lcd.setCursor(0,1); lcd.print(“H2:”); lcd.println(DHT.humidity); |

| delay(5000); |

| } |

| void loop3() |

| { |

| DHT.read(DHT11c_PIN); |

| lcd.setCursor(0,0); lcd.print(“T3:”); lcd.println(DHT.temperature); lcd.setCursor(0,1); lcd.print(“H3:”); |

| lcd.println(DHT.humidity); |

| delay(5000); |

| } |

| void loop4() |

| { |

| DHT.read(DHT11d_PIN); |

| lcd.setCursor(0,0); lcd.print(“T4:”); lcd.println(DHT.temperature); lcd.setCursor(0,1); lcd.print(“H4:”); lcd.println(DHT.humidity); |

| delay(5000); |

| } |

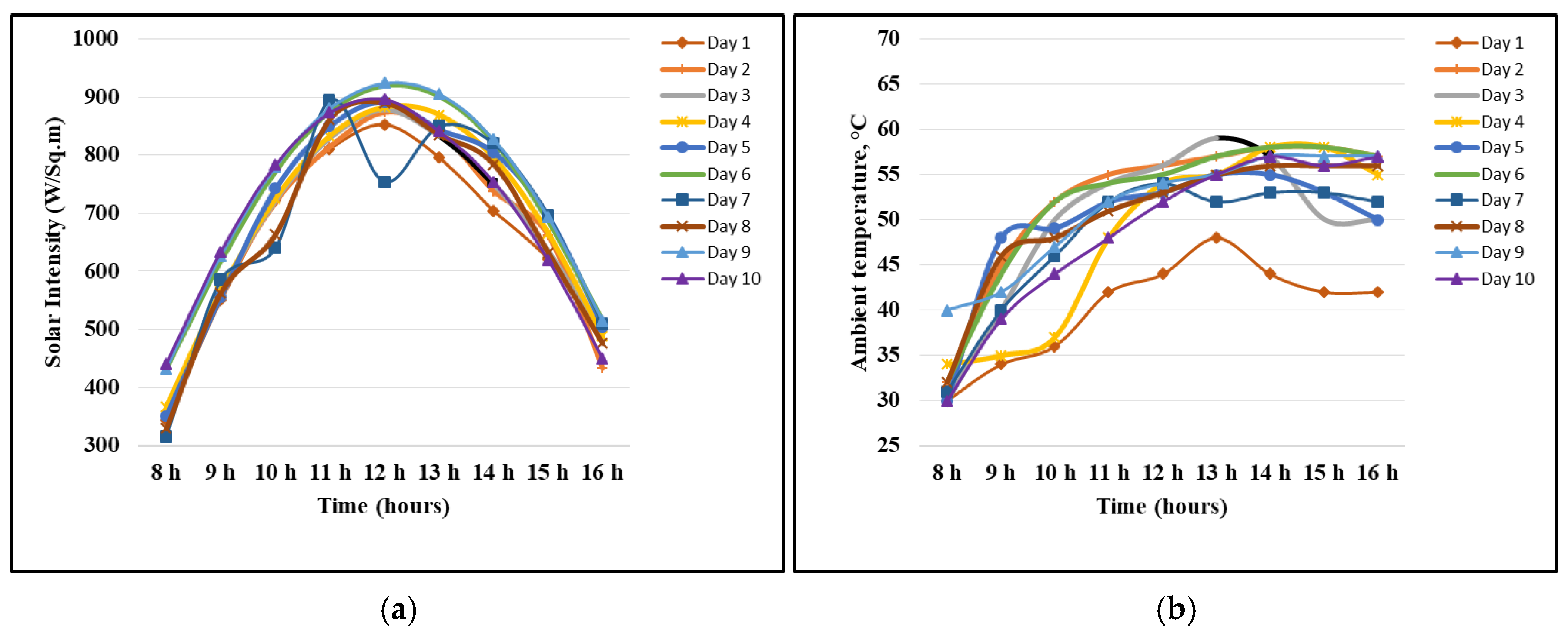

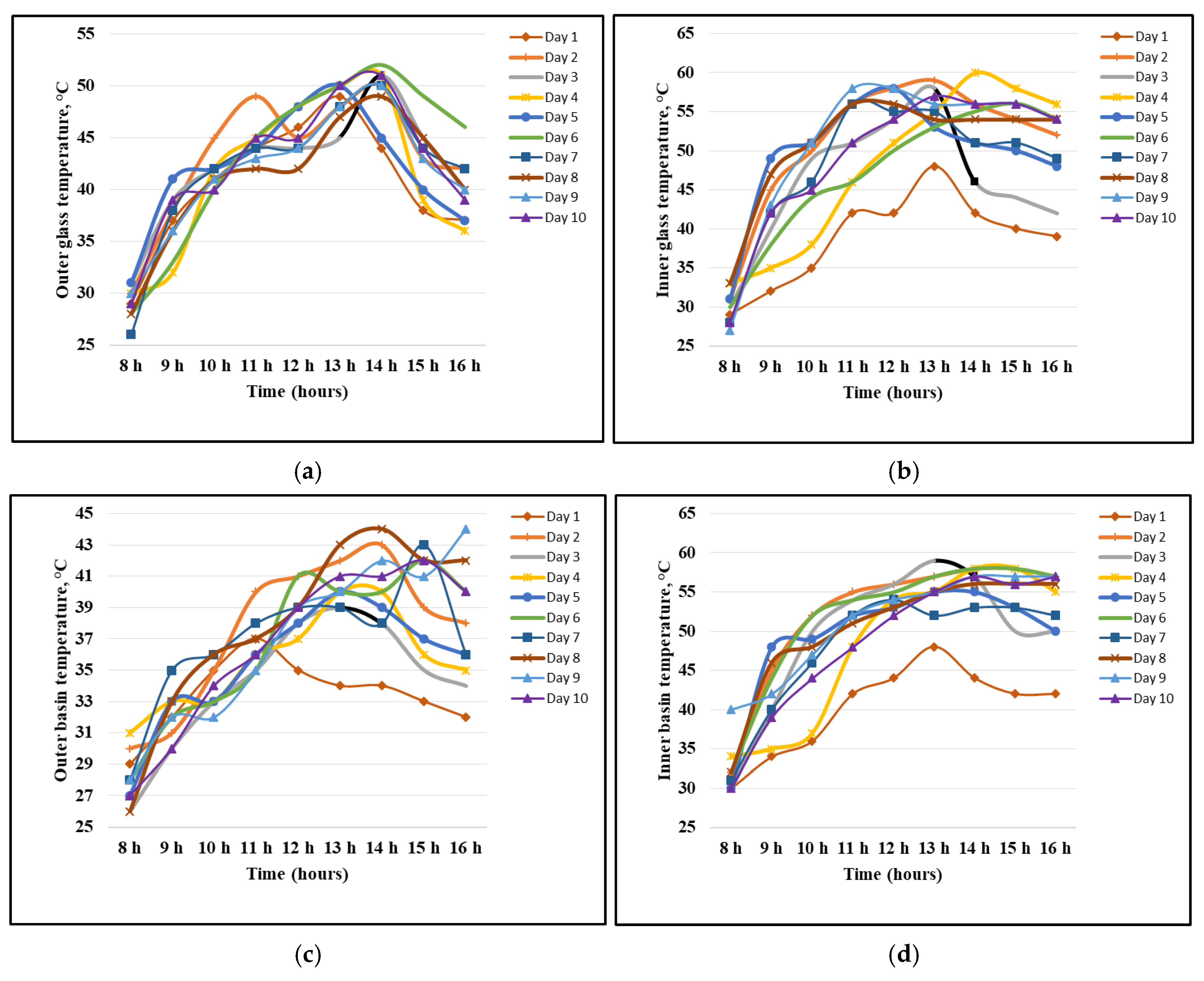

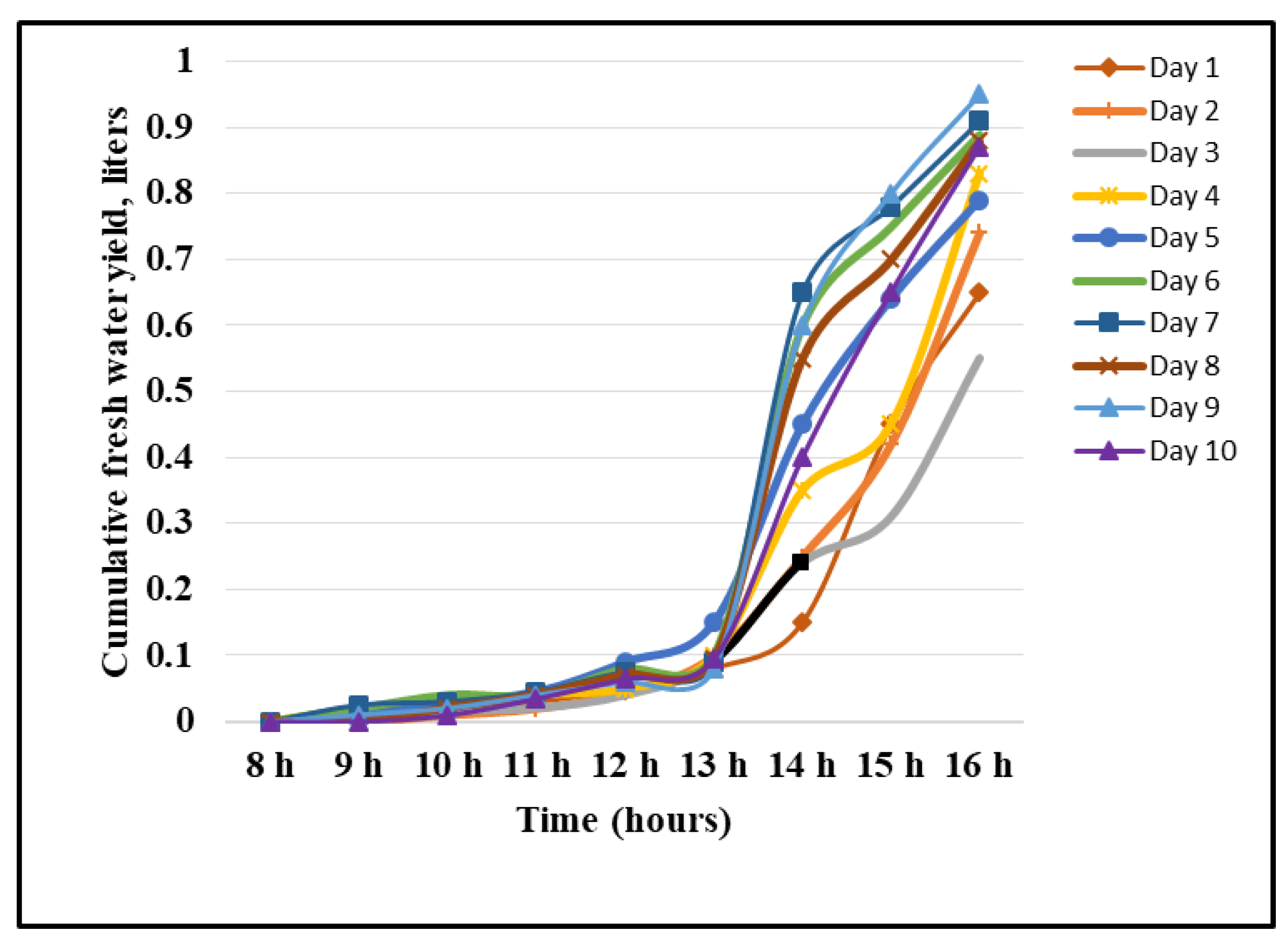

3. Results and Discussions

4. Conclusions

- ➣

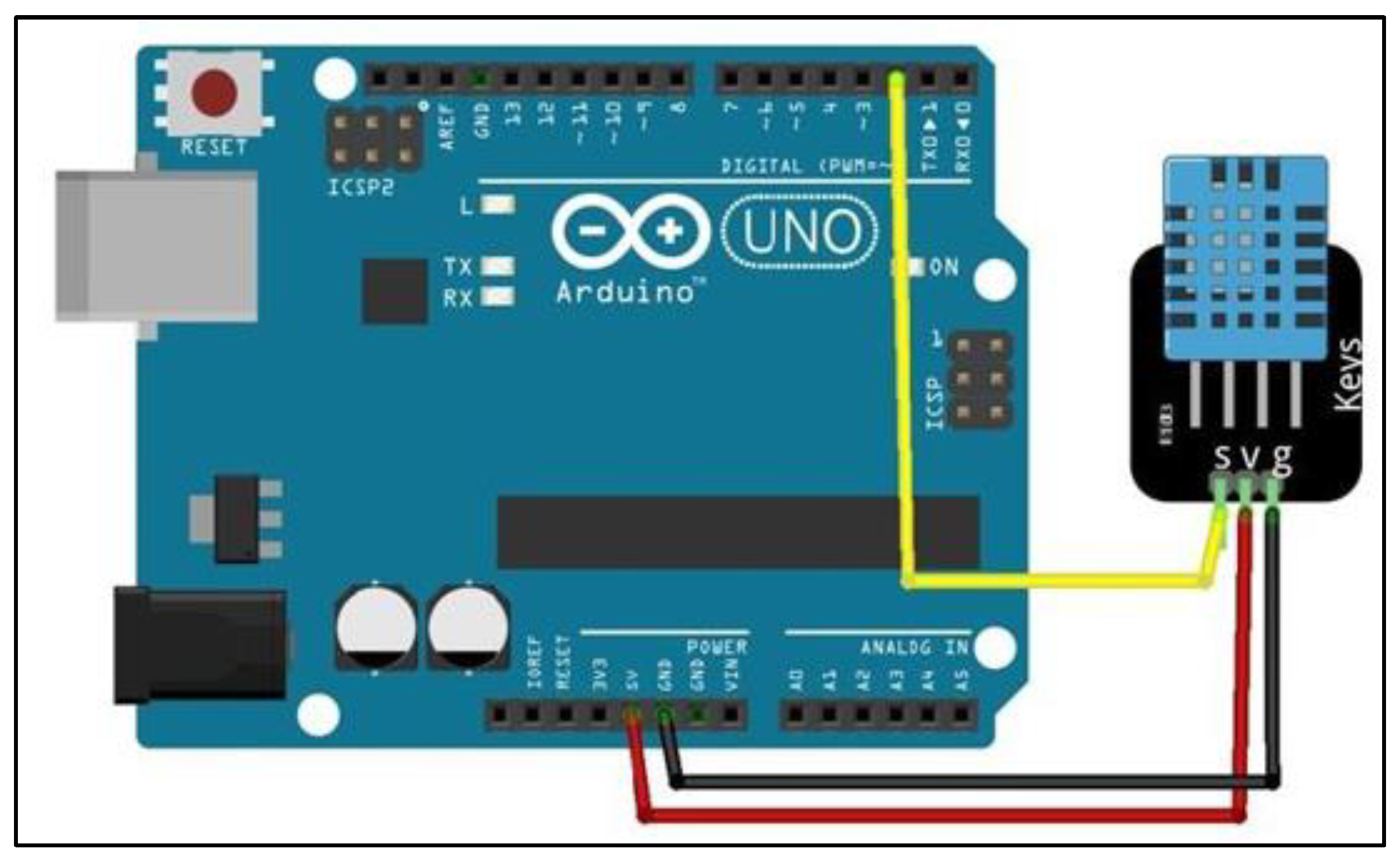

- Arduino programming with an Arduino UNO interface board was used and recorded the temperatures with less effort.

- ➣

- No abnormality was observed during the experimentation in the temperature readings recorded by the program.

- ➣

- The solar radiation intensity followed by the ambient temperature affected the thermal performance of the desalination system significantly.

- ➣

- A drastic rise in yield was observed after 12 h every day, as the rate of condensation was higher after this time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Compain, P. Solar Energy for water desalination. Procedia Eng. 2012, 46, 220–227. [Google Scholar] [CrossRef]

- Gude, V.G.; Nirmalakhandan, N. Sustainable desalination using solar energy. Energy Convers. Manag. 2010, 51, 2245–2251. [Google Scholar] [CrossRef]

- Hafs, H.; Zaaoumi, A.; Bouramdane, Z.; Ansari, O.; Bah, A.; Asbik, M.; Malha, M. A Performance Analysis Study of a Single Slope Solar Still with Integrating Fins and Nanofluid for Productivity Enhancement. In Proceedings of the 1st International Conference of Computer Science and Renewable Energies (ICCSRE 2018), Ouarzazate, Morocco, 22–24 November 2018; pp. 342–348. [Google Scholar]

- Al Shabibi, A.M.; Tahat, M. Thermal Performance of a Single Slope Solar Water Still with Enhanced Solar Heating System. In Proceedings of the International conference on Renewable energies and power quality, La Coruña, Spain, 25–27 March 2015; pp. 585–590. [Google Scholar]

- Radhakrishnan, G.; Breaz, D.; Al Riyami, K.A.A.; Al Nadabi, W.S.; Al Nadabi, T.Y.; Karthikeyan, K.R. Performance Investigation on a Double slope passive solar desalination system targeting towards sustainable development of Oman. Energies 2023, 16, 5917. [Google Scholar] [CrossRef]

- Tarawneh, M.S.K. Effect of Water Depth on the Performance Evaluation of Solar Still. Jordan J. Mech. Ind. Eng. 2007, 1, 23–29. [Google Scholar]

- El-Agouz, S.A.; El-Aziz, G.B.A.; Awad, A.M. Solar desalination system using spray evaporation. Energy 2014, 76, 276–283. [Google Scholar] [CrossRef]

- Gude, V.G.; Nirmalakhandan, N.; Deng, S. Desalination using solar energy: Towards sustainability. Energy 2010, 36, 78–85. [Google Scholar] [CrossRef]

- Ullah, M.A.; Ali, A.; Asla, M.; Khan, K.H. Brackish Water Desalination Using Solar Desalination Panel. Curr. Investig. Agric. Curr. Res. 2018, 3, 1–5. [Google Scholar]

- Suraparaju, S.K.; Natarajan, S.K. Performance analysis of single slope solar desalination setup with natural fiber. Desalination Water Treat. 2020, 193, 64–71. [Google Scholar] [CrossRef]

- Savithiri, V.; El Hadi Attia, M.; Kabeel, A.E.; Vaithilingam, S.; Radhakrishnan, G. Enhancing the productivity of hemispherical solar distillation by using energy storage (rubber) and wick materials at different thickness. Sol. Energy Mater. Sol. Cells 2022, 248, 112006. [Google Scholar] [CrossRef]

- El-Maaty, A.E.A.; Awad, M.M.; Sultan, G.I.; Hamed, A.M. Solar powered fog desalination system. Desalination 2019, 472, 114130. [Google Scholar] [CrossRef]

- Hawlader, M.N.A.; Dey, P.K.; Diab, S.; Chung, C.Y. Solar assisted heat pump desalination system. Desalination 2004, 168, 49–54. [Google Scholar] [CrossRef]

| S. No. | Component | Material | Specifications |

|---|---|---|---|

| 1 | Basin | Mild steel | 15 L capacity |

| 2 | Solar collector | Glass | 48.5 × 26 × 0.6 cm—2 nos. |

| 3 | Insulating material | Polyurethane foam | 20 mm thick for required length |

| 4 | Distillate tank | Plastic | 5 L capacity—2 nos. |

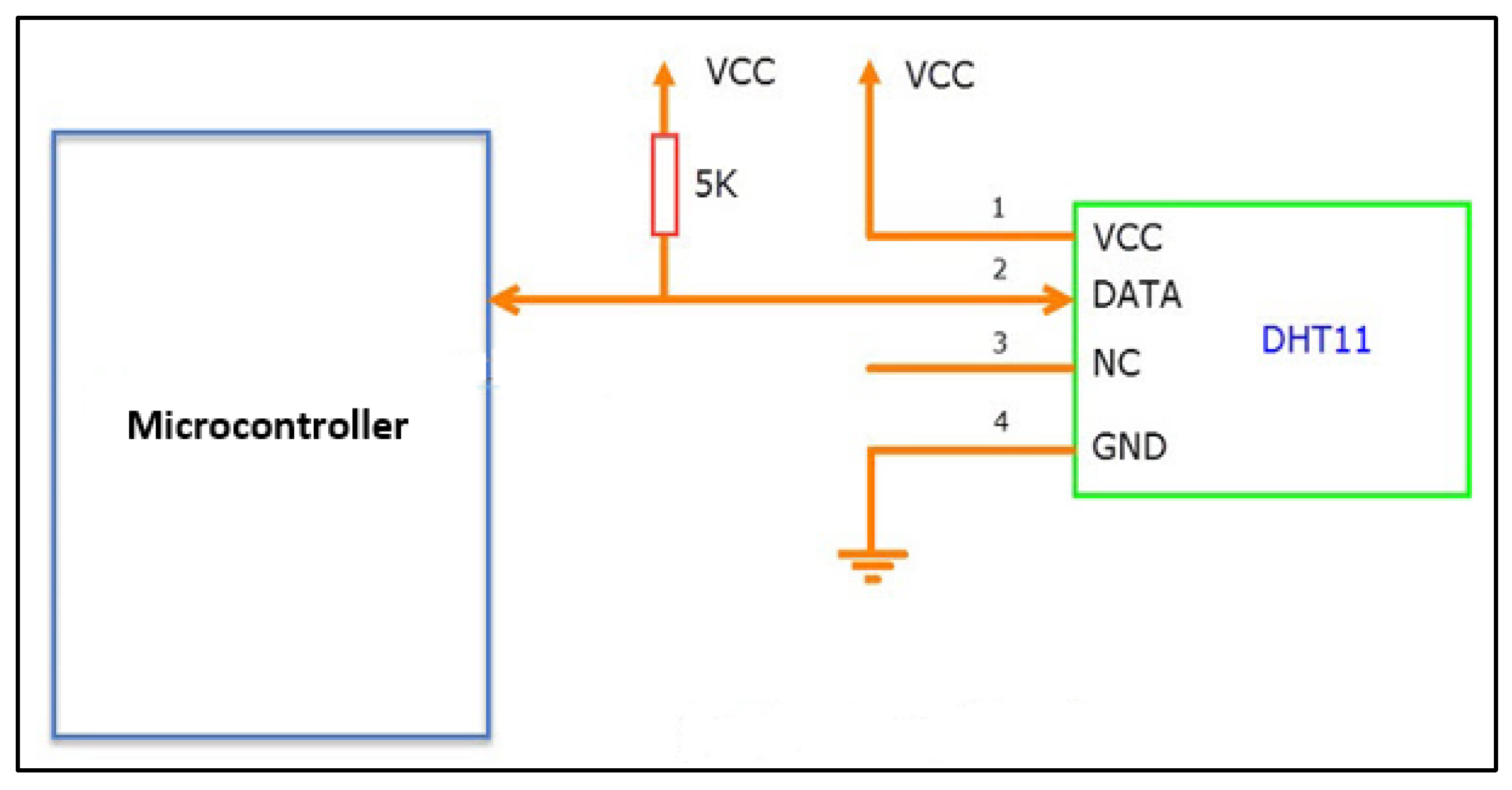

| 5 | Temperature sensor | DHT11 | Voltage: 3.5–5.5 V; Current: 0.3 mA Temperature: 0–50 °C; Humidity: 20–90%; Accuracy: ±1 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radhakrishnan, G.; Karthikeyan, K.R. Performance Monitoring of a Double-Slope Passive Solar-Powered Desalination System Using Arduino Programming. Eng 2025, 6, 39. https://doi.org/10.3390/eng6020039

Radhakrishnan G, Karthikeyan KR. Performance Monitoring of a Double-Slope Passive Solar-Powered Desalination System Using Arduino Programming. Eng. 2025; 6(2):39. https://doi.org/10.3390/eng6020039

Chicago/Turabian StyleRadhakrishnan, Ganesh, and Kadhavoor R. Karthikeyan. 2025. "Performance Monitoring of a Double-Slope Passive Solar-Powered Desalination System Using Arduino Programming" Eng 6, no. 2: 39. https://doi.org/10.3390/eng6020039

APA StyleRadhakrishnan, G., & Karthikeyan, K. R. (2025). Performance Monitoring of a Double-Slope Passive Solar-Powered Desalination System Using Arduino Programming. Eng, 6(2), 39. https://doi.org/10.3390/eng6020039