Neuro-Fuzzy Framework with CAD-Based Descriptors for Predicting Fabric Utilization Efficiency

Abstract

1. Introduction

2. Materials and Methods

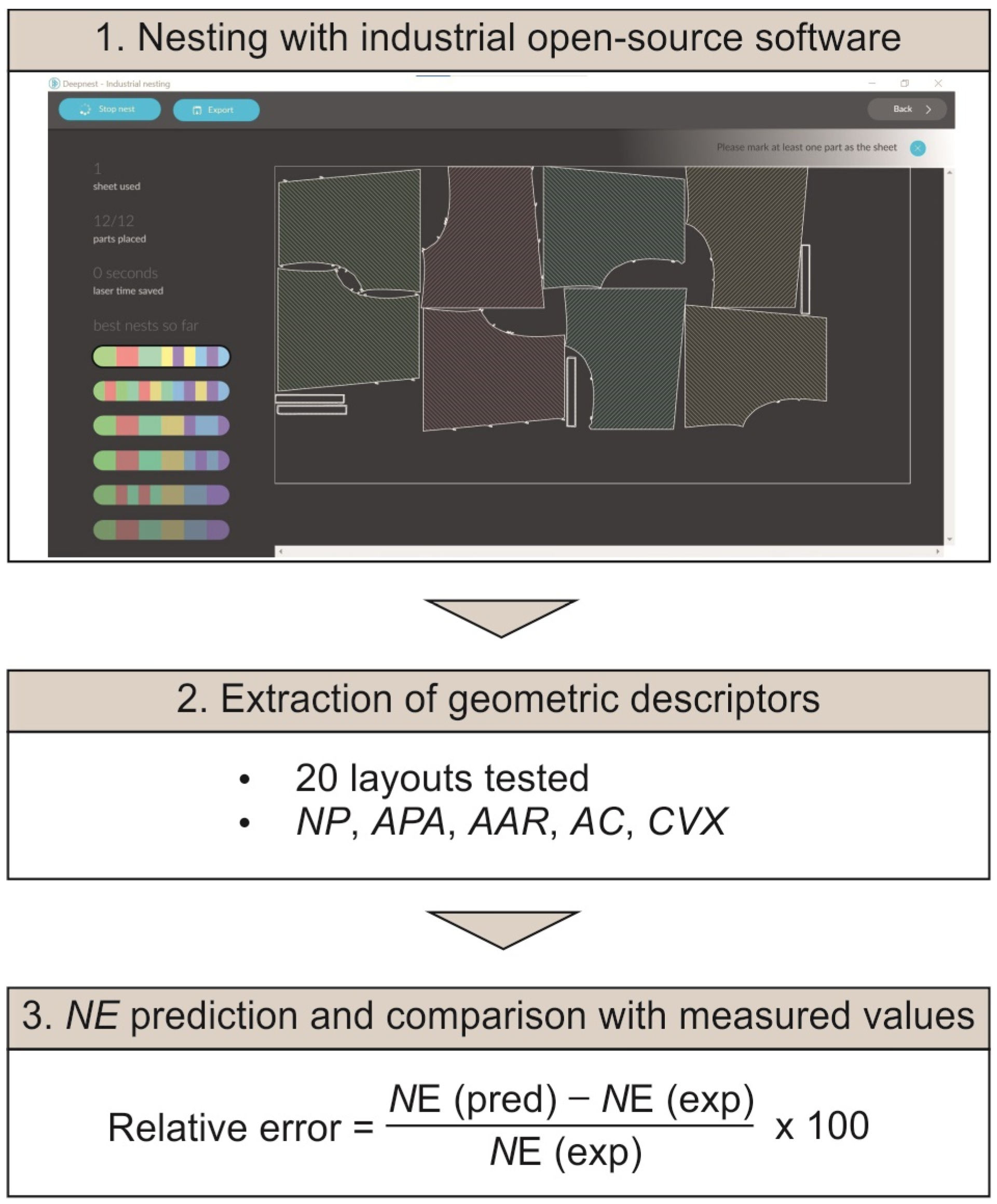

2.1. Framework of This Study, Tools and Methodologies

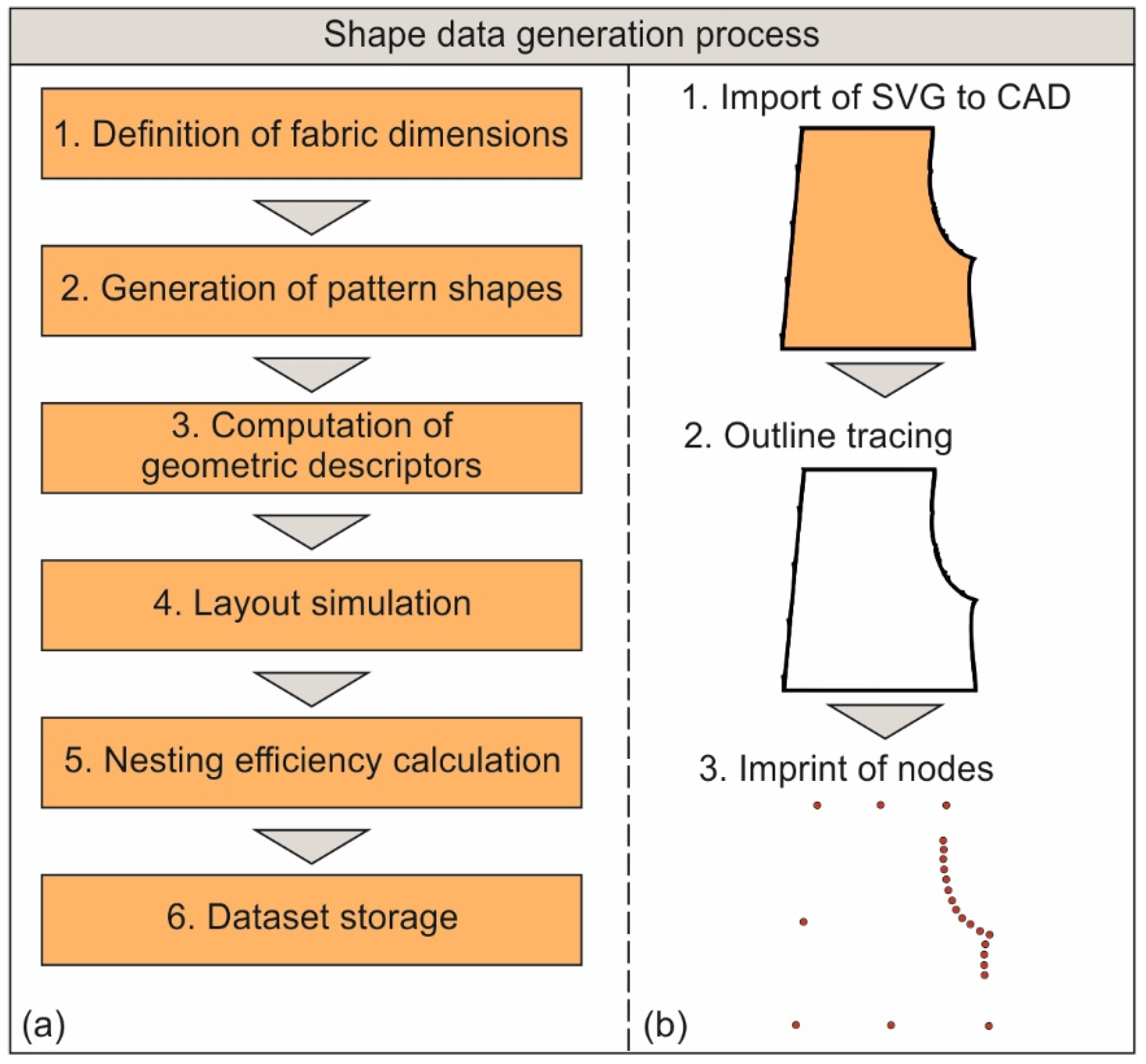

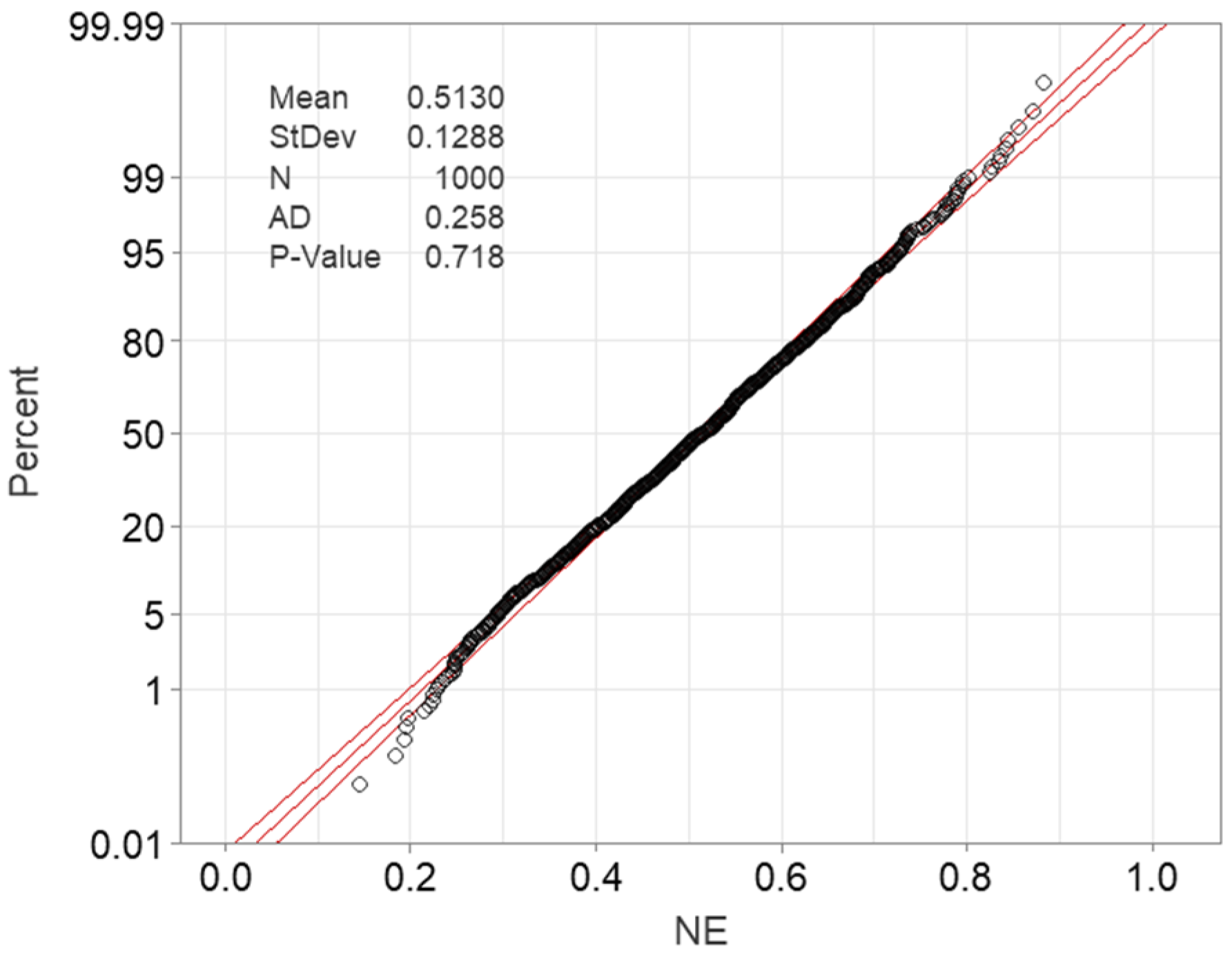

2.2. Generation of the Data Points

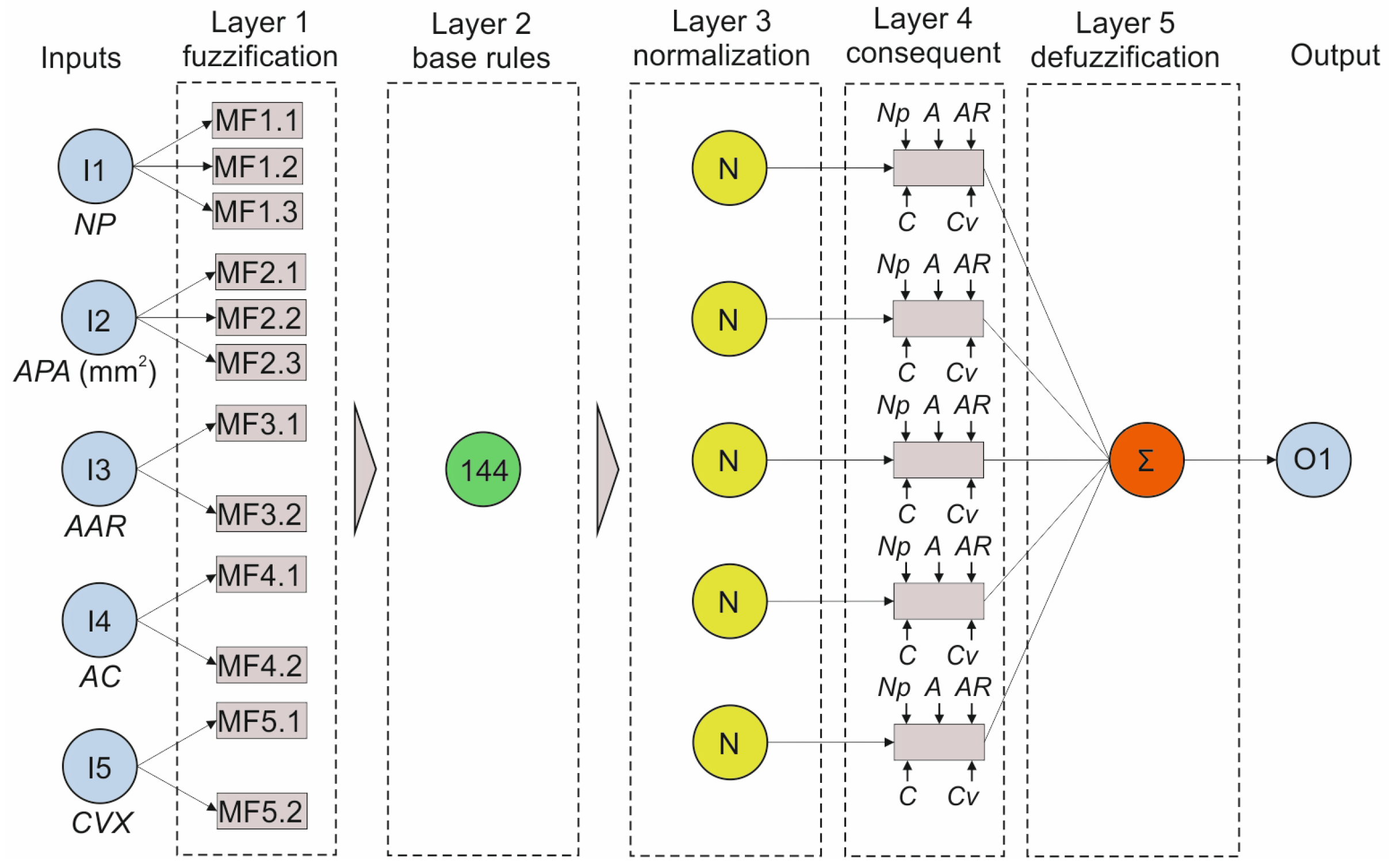

3. Adaptive Neuro-Fuzzy Modeling

4. Results and Discussion

| Test | NP | APA (mm2) | AAR | AC | CVX | NEpred | NEexp | Relative Error (%) | Sensitivity Class |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 12 | 628 | 1.52 | 0.78 | 0.93 | 0.49 | 0.59 | −16.9 | High |

| 2 | 10 | 752 | 1.05 | 0.85 | 0.97 | 0.60 | 0.62 | −3.2 | Low |

| 3 | 16 | 1092 | 0.79 | 0.81 | 0.91 | 0.79 | 0.78 | 1.3 | Low |

| 4 | 9 | 420 | 1.12 | 0.92 | 0.90 | 0.57 | 0.53 | 7.5 | Low |

| 5 | 12 | 889 | 1.25 | 0.73 | 0.97 | 0.68 | 0.77 | −11.7 | Moderate |

| 6 | 11 | 400 | 1.34 | 0.71 | 0.94 | 0.33 | 0.37 | −12.2 | Moderate |

| 7 | 16 | 613 | 1.58 | 0.78 | 0.93 | 0.63 | 0.64 | −1.7 | Moderate |

| 8 | 10 | 1000 | 1.40 | 0.70 | 0.96 | 0.65 | 0.67 | −3.0 | Moderate |

| 9 | 14 | 920 | 0.89 | 0.74 | 0.95 | 0.86 | 0.85 | 1.2 | Low |

| 10 | 17 | 710 | 1.82 | 0.72 | 0.94 | 0.79 | 0.80 | −1.3 | Low |

| 11 | 11 | 998 | 0.71 | 0.73 | 0.94 | 0.73 | 0.71 | 2.8 | Moderate |

| 12 | 7 | 1543 | 0.98 | 0.76 | 0.95 | 0.88 | 0.87 | 1.0 | Low |

| 13 | 13 | 610 | 0.84 | 0.77 | 0.94 | 0.52 | 0.55 | −5.5 | Moderate |

| 14 | 11 | 766 | 1.06 | 0.74 | 0.94 | 0.57 | 0.53 | 8.4 | Moderate |

| 15 | 17 | 523 | 1.74 | 0.80 | 0.95 | 0.61 | 0.60 | 1.7 | Moderate |

| 16 | 11 | 1157 | 1.55 | 0.80 | 0.98 | 0.86 | 0.86 | 0.6 | Moderate |

| 17 | 9 | 1266 | 1.20 | 0.76 | 0.95 | 0.86 | 0.87 | −1.1 | Low |

| 18 | 7 | 895 | 1.16 | 0.76 | 0.98 | 0.41 | 0.45 | −8.9 | Moderate |

| 19 | 20 | 413 | 1.37 | 0.71 | 0.96 | 0.52 | 0.59 | −11.9 | High |

| 20 | 10 | 945 | 1.68 | 0.80 | 0.94 | 0.64 | 0.65 | −0.8 | Low |

5. Conclusions

- The finalized ANFIS model, structured 3-3-2-2-2, achieved high predictive reliability, with an overall mean relative error of −0.1%, demonstrating excellent agreement between the predicted and observed values.

- The generalization capability of the model was further assessed through validation against twenty real nesting layouts generated using Deepnest.io software. The obtained relative errors ranged from 8.4% to −16.9%, indicating satisfactory predictive consistency and robustness. These findings confirm that the selected geometric descriptors effectively capture the essential characteristics influencing nesting efficiency, while the developed ANFIS framework provides a reliable and computationally efficient tool for assessing and optimizing material utilization in apparel manufacturing.

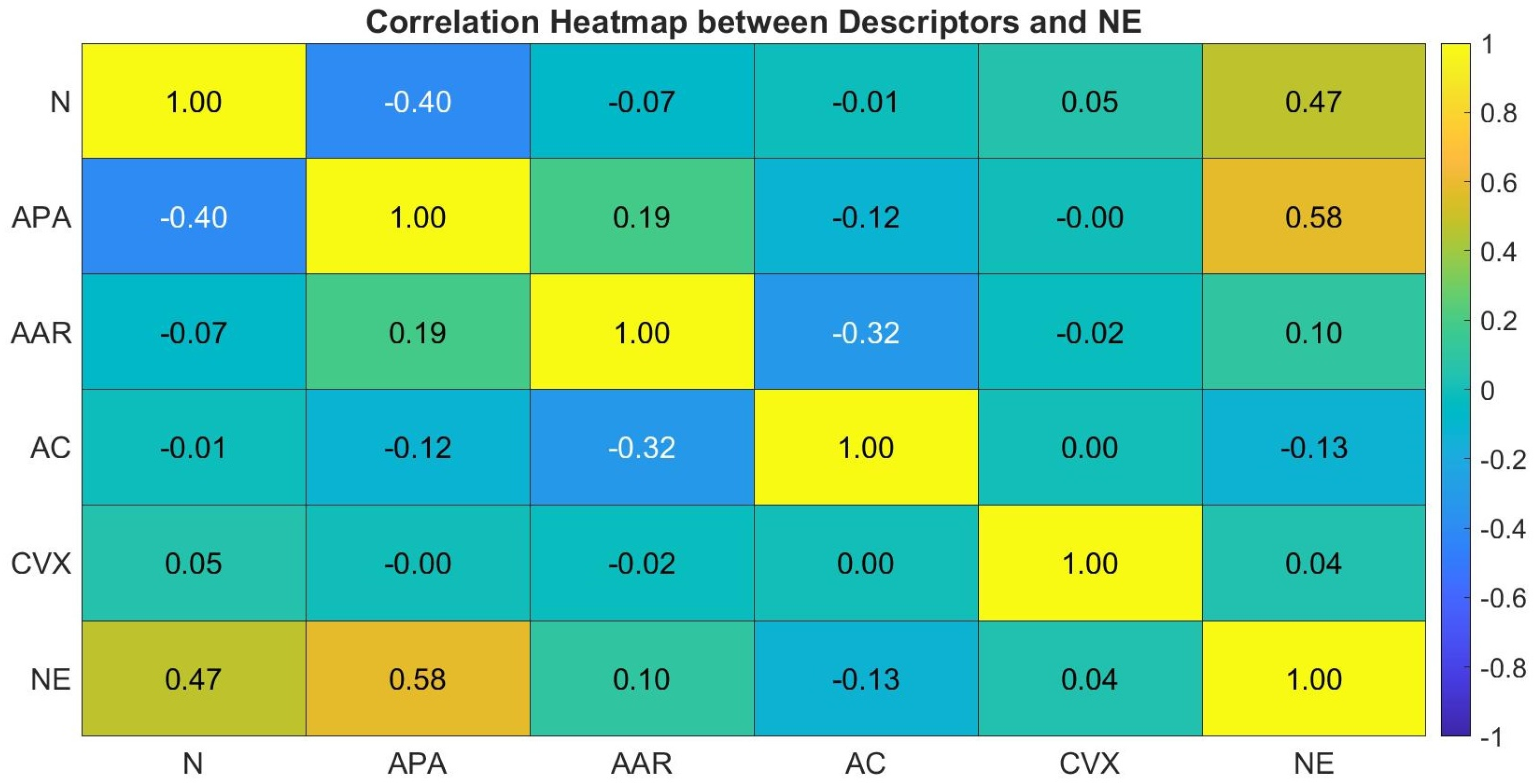

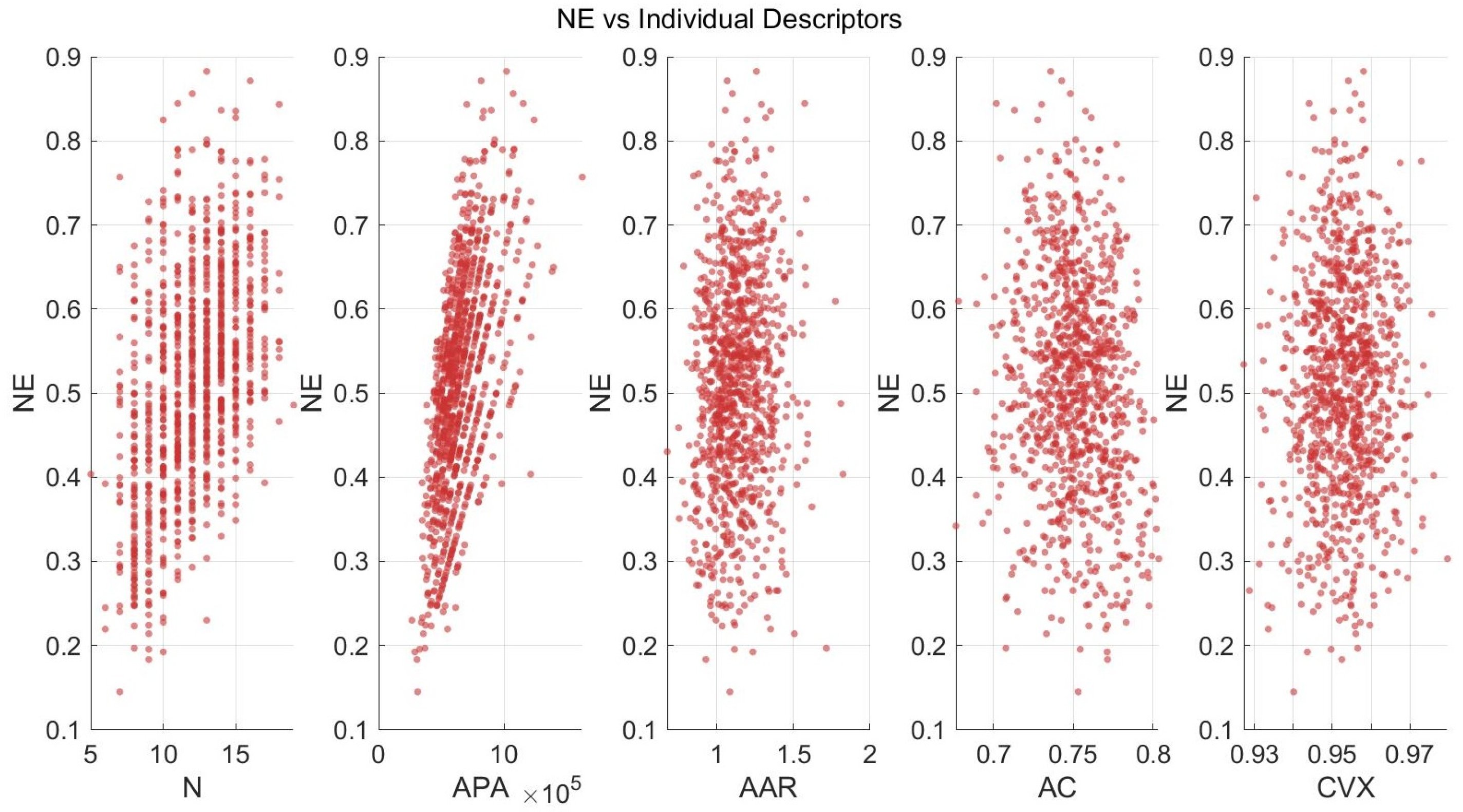

- Analysis of descriptor influence revealed that NP and APA were the most dominant factors affecting NE, as layouts with a higher number of smaller pieces tended to produce lower efficiency due to increased fragmentation.

- Conversely, AAR values closer to unity, indicating more regular and rectangular shapes, correlated positively with NE.

- AC and CVX presented positive effects as well, as more compact and convex shapes enable tighter packing with fewer voids. These relationships highlight the geometric dependencies that govern material utilization during nesting.

6. Future Work and Limitations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vilumsone-Nemes, I.; Pešić, M.; Csanák, E. Flexible Design of Garment Styles to Support the Minimal Waste Concept in the Fashion Industry. FIBRES Text. East. Eur. 2023, 31, 64–73. [Google Scholar] [CrossRef]

- Papachristou, E.; Kalaitzi, D.; Pissas, V. A Methodological Framework for the Integration of 3D Virtual Prototyping into the Design Development of Laser-Cut Garments. J. Eng. Fiber. Fabr. 2023, 18, 15589250231194621. [Google Scholar] [CrossRef]

- Papachristou, E.; Bilalis, N. How to Integrate Recent Development in Technology with Digital Prototype Textile and Apparel Applications. Marmara J. Pure Appl. Sci. 2015, 27, 32–39. [Google Scholar] [CrossRef][Green Version]

- Tufan Tolmaç, N.; İşmal, Ö.E. A New Era: 3D Printing as an Aesthetic Language and Creative Tool in Fashion and Textile Design. Res. J. Text. Appar. 2023, 28, 656–670. [Google Scholar] [CrossRef]

- Minaoglou, P.; Oancea, G.; Gupta, M.; Kyratsis, P. Use of Computational Design Technology to Automate Sew Pattern. In Digital Product Design and Manufacturing; CRC Press: Boca Raton, FL, USA, 2025; p. 19. [Google Scholar]

- Xiao, Y.; Kan, C. Review on Development and Application of 3D-Printing. Coatings 2022, 12, 267. [Google Scholar] [CrossRef]

- Li, S. Development and Application of Fused Deposition Molding 3D Printing Technology in Textile and Fashion Design. J. Eng. Fiber. Fabr. 2024, 19, 15589250241266977. [Google Scholar] [CrossRef]

- Jeong, J.; Park, H.; Lee, Y.; Kang, J.; Chun, J. Developing Parametric Design Fashion Products Using 3D Printing Technology. Fash. Text. 2021, 8, 22. [Google Scholar] [CrossRef]

- Thi Hai, V.N.; Phu, S.N.; Essomba, T.; Lai, J.-Y. Development of a Multicolor 3D Printer Using a Novel Filament Shifting Mechanism. Inventions 2022, 7, 34. [Google Scholar] [CrossRef]

- Chan, I.; Au, J.; Ho, C.; Lam, J. Creation of 3D Printed Fashion Prototype with Multi-Coloured Texture: A Practice-Based Approach. Int. J. Fash. Des. Technol. Educ. 2021, 14, 78–90. [Google Scholar] [CrossRef]

- Habib, A.; Alam, S. A Comparative Study of 3D Virtual Pattern and Traditional Pattern Making. J. Text. Sci. Technol. 2024, 10, 1–24. [Google Scholar] [CrossRef]

- Marin, I.-E.; Bocancea, V.; Loghin, M.C. Developing a Zero-Waste Pattern Drafting Method Suitable for Mass Production. Ind. Textila 2024, 75, 171–176. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Z.; Yang, C.; Wang, S.; Zhang, Z.; Yang, C. 3D Digital Clothing Design of Chu-Style Lacquerware Patterns Based on Style3D Technology. Text. Leather Rev. 2025, 8, 539–568. [Google Scholar] [CrossRef]

- Mostafa, S.; Mohamed, A. The Benefits of Using 3D CAD Software to Modify Clothing Virtual Prototype. Int. Des. J. 2025, 15, 415–426. [Google Scholar]

- Zhang, R.; Mueller, S.; Bernstein, G.; Schulz, A.; Leake, M. WasteBanned: Supporting Zero Waste Fashion Design with Linked Edits. In Proceedings of the 37th Annual ACM Symposium on User Interface Software and Technology, San Francisco, CA, USA, 29 October–1 November 2024; pp. 1–13. [Google Scholar]

- Buso, A.; Mcquillan, H. A Design Space for Animated Textile-Forms through Shuttle Weaving: A Case of 3D Woven Trousers. In Proceedings of the 2025 ACM Designing Interactive Systems Conference, Funchal, Portugal, 5–9 July 2025; pp. 2465–2484. [Google Scholar]

- Montusiewicz, J.; Miłosz, M.; Kęsik, J.; Żyła, K. Structured—Light 3D Scanning of Exhibited Historical Clothing—A First—Ever Methodical Trial and Its Results. Herit. Sci. 2021, 9, 74. [Google Scholar] [CrossRef]

- Papachristou, E.; Kyratsis, P.; Bilalis, N. A Comparative Study of Open-Source and Licensed CAD Software to Support Garment. Machines 2019, 7, 30. [Google Scholar] [CrossRef]

- Brad, R. A New Reality: Smart Fabrics and Wearable Technology. Ann. Univ. Oradea. Fascicle Text. Leatherwork 2022, 23, 5–22. [Google Scholar]

- Salama, W.M.; Aly, M.H.; Abed, A.M.; Eladly, A.M. Efficiency Marker Evaluation Based on Optimized Deep Learning Supported by Bayesian Optimization Technique. Text. Res. J. 2023, 93, 4273–4289. [Google Scholar] [CrossRef]

- Eladly, A.M.; Abed, A.M.; Aly, M.H.; Salama, W.M. Results in Engineering Enhancing Circular Economy via Detecting and Recycling 2D Nested Sheet Waste Using Bayesian Optimization Technique Based-Smart Digital Twin. Results Eng. 2023, 20, 101544. [Google Scholar] [CrossRef]

- Abdou, K.; Mohammed, O.; Eskandar, G.; Ibrahim, A.; Huber, M.F.; Matt, P. Smart Nesting: Estimating Geometrical Compatibility in the Nesting Problem Using Graph Neural Networks. J. Intell. Manuf. 2024, 35, 2811–2827. [Google Scholar] [CrossRef]

- Kuzmichev, V. Clothing Design in the Era of Artificial Intelligence. J. Comput. Commun. 2025, 13, 121–136. [Google Scholar] [CrossRef]

- Lamia, N.J.; Mim, S.A. Transforming Fashion with AI: A Comparative Study of Large Language Models in Apparel Design. In Proceedings of the 3rd International Conference on Textile Science and Engineering, Dhaka, Bangladesh, 24 May 2025; p. 10. [Google Scholar]

- Sagar, A.V. Studying the Role of Ai-Driven Algorithms in Assisting the Creation of Sustainable Fashion by Optimizing Material Usage and Reducing Waste in The Design and Production Process. J. Text. Eng. Fash. Technol. 2023, 5, 16–24. [Google Scholar]

- Wang, Z.; Tao, X.; Zeng, X.; Xing, Y.; Xu, Z.; Bruniaux, P. A Machine Learning-Enhanced 3D Reverse Design Approach to Personalized Garments in Pursuit of Sustainability. Sustainability 2023, 15, 6235. [Google Scholar] [CrossRef]

- Liu, K.; Zeng, X.; Bruniaux, P.; Tao, X.; Kamalha, E.; Wang, J. Garment Fit Evaluation Using Machine Learning Technology [M]//Artificial Intelligence for Fashion Industry in the Big Data Era; Springer Singapore: Singapore, 2018; pp. 273–288. [Google Scholar] [CrossRef]

- Thomassey, S.; Zeng, X. Artificial Intelligence for Fashion Industry in the Big Data Era; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 9789811300790. [Google Scholar]

- Chiurco, A.; Augusta, V.D.; La Rosa, A.; Nicoletti, L.; Solina, V. Literature Overview on AI-Based Garment Sizing Systems under a Sustainable Perspective. In Proceedings of the 35th European Modeling & Simulation Symposium, Athens, Greece, 18–20 September 2023; p. 7. [Google Scholar]

- Solis, M.; Tonini, D.; Scheutz, C.; Napolano, L. Contribution of Waste Management to a Sustainable Textile Sector. Waste Manag. 2024, 189, 389–400. [Google Scholar] [CrossRef]

- Duta, E.; Jimeno-morenilla, A. An Approach to Apply the Jaya Optimization Algorithm to the Nesting of Irregular Patterns. J. Comput. Des. Eng. 2024, 11, 112–121. [Google Scholar] [CrossRef]

- Lallier, C.; Blin, G.; Pinaud, B.; Vézard, L. Graph Neural Network Comparison for 2D Nesting Efficiency Estimation. J. Intell. Manuf. 2024, 35, 859–873. [Google Scholar] [CrossRef]

- Korosteleva, M.; Lee, S.-H. Dataset of 3D Garments with Sewing Patterns. Available online: https://zenodo.org/records/5267549 (accessed on 1 November 2025).

- Bennell, J.A.; Oliveira, J.F. The Geometry of Nesting Problems: A Tutorial. Eur. J. Oper. Res. 2008, 184, 397–415. [Google Scholar] [CrossRef]

- Berlinger, M.; Kolling, S.; Schneider, J. A Generalized Anderson—Darling Test for the Goodness-of-Fit Evaluation of the Fracture Strain Distribution of Acrylic Glass. Glas. Struct. Eng. 2021, 6, 195–208. [Google Scholar] [CrossRef]

- Enes, E.; Kipöz, Ş. The Role of Fabric Usage for Minimization of Cut-and-Sew Waste within the Apparel Production Line: Case of a Summer Dress. J. Clean. Prod. 2020, 248, 119221. [Google Scholar] [CrossRef]

- Marani, M.; Songmene, V.; Zeinali, M.; Kouam, J.; Zedan, Y. Neuro-Fuzzy Predictive Model for Surface Roughness and Cutting Force of Machined Al–20 Mg2Si–2Cu Metal Matrix Composite Using Additives. Neural Comput. Appl. 2020, 32, 8115–8126. [Google Scholar] [CrossRef]

- Tzotzis, A.; Nedelcu, D.; Mazurchevici, S.; Kyratsis, P. Investigating the Machining Behavior of the Additively Manufactured Polymer-Based Composite Using Adaptive Neuro-Fuzzy Learning. Appl. Sci. 2025, 15, 5373. [Google Scholar] [CrossRef]

- Luis-Pérez, C.J.; Buj-Corral, I. Multi-Objective Optimization of Surface Roughness, Dimensional Errors and Density in FFF 3D-Printed Glass Fiber-Reinforced PP Parts via Adaptive Neuro-Fuzzy Inference Modeling. Rapid Prototyp. J. 2025, 31, 1905–1932. [Google Scholar] [CrossRef]

- Li, Y.; Yuan, M.; Chadli, M.; Wang, Z.-P.; Zhao, D. Unknown Input Functional Observer Design for Discrete-Time Interval Type-2 Takagi–Sugeno Fuzzy Systems. IEEE Trans. Fuzzy Syst. 2022, 30, 4690–4701. [Google Scholar] [CrossRef]

- Li, Y.; Dong, J. Fault Detection for Discrete-Time Interval Type-2 Takagi–Sugeno Fuzzy Systems Using H_/L∞ Unknown Input Observer and Zonotopic Analysis. IEEE Trans. Fuzzy Syst. 2024, 32, 846–858. [Google Scholar] [CrossRef]

- Pérez-pérez, E.; Puig, V.; López-estrada, F. Robust Fault Diagnosis of Wind Turbines Based on MANFIS and Zonotopic Observers. Expert Syst. Appl. 2024, 235, 121095. [Google Scholar] [CrossRef]

- Takagi, T.; Sugeno, M. Fuzzy Identification of Systems and Its Applications to Modeling and Control. IEEE Trans. Syst. Man. Cybern. 1985, SMC-15, 116–132. [Google Scholar] [CrossRef]

- Karaboga, D.; Kaya, E. Adaptive Network Based Fuzzy Inference System (ANFIS) Training Approaches: A Comprehensive Survey. Artif. Intell. Rev. 2019, 52, 2263–2293. [Google Scholar] [CrossRef]

- Gkountakou, F.; Papadopoulos, B. The Use of Fuzzy Linear Regression and ANFIS Methods to Predict the Compressive Strength of Cement. Symmetry 2020, 12, 1295. [Google Scholar] [CrossRef]

- Okwu, M.O.; Adetunji, O. A Comparative Study of Artificial Neural Network (ANN) and Adaptive Neuro-Fuzzy Inference System (ANFIS) Models in Distribution System with Nondeterministic Inputs. Int. J. Eng. Bus. Manag. 2018, 10, 1847979018768421. [Google Scholar] [CrossRef]

- Burke, E.K.; Kendall, G.; Whitwell, G. A New Placement Heuristic for the Orthogonal Stock-Cutting Problem. Oper. Res. 2004, 52, 655–671. [Google Scholar] [CrossRef]

- Bennell, J.A.; Oliveira, J.F. A Tutorial in Irregular Shape Packing Problems. J. Oper. Res. Soc. 2009, 60, S93–S105. [Google Scholar] [CrossRef]

- Lodi, A.; Martello, S.; Vigo, D. Recent Advances on Two-Dimensional Bin Packing Problems. Discret. Appl. Math. 2002, 123, 379–396. [Google Scholar] [CrossRef]

- Dickinson, J.K.; Knopf, G.K. A Moment Based Metric for 2-D and 3-D Packing. Eur. J. Oper. Res. 2000, 122, 133–144. [Google Scholar] [CrossRef]

- Morio, J. Global and Local Sensitivity Analysis Methods for a Physical System Global and Local Sensitivity Analysis. Eur. J. Phys. 2011, 32, 1577–1583. [Google Scholar] [CrossRef]

- Pineda, L.E.; Fregly, B.J.; Haftka, R.T.; Queipo, N. V Estimating Training Data Boundaries in Surrogate-Based Modeling. Struct. Multidiscip. Optim. 2010, 42, 811–821. [Google Scholar] [CrossRef]

| Function | Purpose | Explanation |

|---|---|---|

| polygon_area(coords) | Compute area | Calculates the area of a polygon using the shoelace formula, based on its vertex coordinates. |

| bounding_box(coords) | Determine dimensions | Finds the width and height of a polygon by computing the difference between its max and min x/y coordinates. |

| polygon_perimeter(coords) | Compute perimeter | Calculates the total perimeter length by summing distances between consecutive vertices. |

| compactness(area, perimeter) | Shape descriptor | Evaluates how efficiently a shape encloses its area. |

| convexity(area, convex_area) | Shape descriptor | Measures how close a shape is to being convex. |

| point_in_poly(point, poly) | Overlap detection | Uses the ray casting algorithm to check if a point lies inside a polygon. |

| polygons_overlap(poly1, poly2) | Collision checking | Detects if two polygons overlap by checking whether any vertex of one lies inside the other. |

| place_shapes() | Layout generation | Generates, scales, rotates, and randomly places multiple shapes within the fabric area while avoiding overlaps. Computes descriptors and NE for each layout. |

| random.choice() | Random selection | Randomly selects a shape or rotation angle during layout generation. |

| np.hypot() | Distance calculation | Computes Euclidean distances between consecutive polygon vertices for perimeter and overlap checks. |

| matplotlib.patches.Polygon() | Visualization | Draws filled polygons representing fabric pieces on the layout plot. |

| pd.DataFrame() | Data storage | Organizes calculated descriptors and NE values into a structured table for export. |

| df.to_csv() | Dataset export | Saves the generated dataset as a CSV file for further analysis and modeling. |

| NP | APA (mm2) | AAR | AC | CVX | NE | |

|---|---|---|---|---|---|---|

| Upper boundary | 20 | 1,621,769 | 1.823 | 0.803 | 0.979 | 0.883 |

| Lower boundary | 5 | 265,508 | 0.677 | 0.676 | 0.927 | 0.145 |

| MF Structure | Rules | MF Type | RMSE | R2 |

|---|---|---|---|---|

| 2-2-2-2-2 | 64 | Gaussian | 0.0188 | 0.9786 |

| Generalized bell-shaped | 0.0310 | 0.9420 | ||

| 3-2-2-2-2 | 96 | Gaussian | 0.0173 | 0.9819 |

| Generalized bell-shaped | 0.0337 | 0.9314 | ||

| 2-3-2-2-2 | 96 | Gaussian | 0.0121 | 0.9911 |

| Generalized bell-shaped | 0.0221 | 0.9704 | ||

| 2-2-3-2-2 | 96 | Gaussian | 0.0186 | 0.9791 |

| Generalized bell-shaped | 0.0333 | 0.9332 | ||

| 2-2-2-3-2 | 96 | Gaussian | 0.0185 | 0.9794 |

| Generalized bell-shaped | 0.0331 | 0.9340 | ||

| 2-2-2-2-3 | 96 | Gaussian | 0.0188 | 0.9788 |

| Generalized bell-shaped | 0.0344 | 0.9287 | ||

| 3-3-2-2-2 | 144 | Gaussian | 0.0112 | 0.9924 |

| Generalized bell-shaped | 0.0224 | 0.9667 | ||

| 3-2-3-2-2 | 144 | Gaussian | 0.0172 | 0.9821 |

| Generalized bell-shaped | 0.0343 | 0.9288 | ||

| 3-2-2-3-2 | 144 | Gaussian | 0.0181 | 0.9802 |

| Generalized bell-shaped | 0.0343 | 0.9290 | ||

| 3-2-2-2-3 | 144 | Gaussian | 0.0188 | 0.9786 |

| Generalized bell-shaped | 0.0366 | 0.9189 | ||

| 2-3-3-2-2 | 144 | Gaussian | 0.0117 | 0.9917 |

| Generalized bell-shaped | 0.0212 | 0.9728 | ||

| 2-3-2-2-3 | 144 | Gaussian | 0.0120 | 0.9914 |

| Generalized bell-shaped | 0.0218 | 0.9714 | ||

| 2-2-3-3-2 | 144 | Gaussian | 0.0181 | 0.9802 |

| Generalized bell-shaped | 0.0332 | 0.9336 | ||

| 2-2-3-2-3 | 144 | Gaussian | 0.0182 | 0.9800 |

| Generalized bell-shaped | 0.0340 | 0.9302 | ||

| 2-2-2-3-3 | 144 | Gaussian | 0.0182 | 0.9799 |

| Generalized bell-shaped | 0.0334 | 0.9326 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tzotzis, A.; Minaoglou, P.; Nedelcu, D.; Mazurchevici, S.-N.; Kyratsis, P. Neuro-Fuzzy Framework with CAD-Based Descriptors for Predicting Fabric Utilization Efficiency. Eng 2025, 6, 368. https://doi.org/10.3390/eng6120368

Tzotzis A, Minaoglou P, Nedelcu D, Mazurchevici S-N, Kyratsis P. Neuro-Fuzzy Framework with CAD-Based Descriptors for Predicting Fabric Utilization Efficiency. Eng. 2025; 6(12):368. https://doi.org/10.3390/eng6120368

Chicago/Turabian StyleTzotzis, Anastasios, Prodromos Minaoglou, Dumitru Nedelcu, Simona-Nicoleta Mazurchevici, and Panagiotis Kyratsis. 2025. "Neuro-Fuzzy Framework with CAD-Based Descriptors for Predicting Fabric Utilization Efficiency" Eng 6, no. 12: 368. https://doi.org/10.3390/eng6120368

APA StyleTzotzis, A., Minaoglou, P., Nedelcu, D., Mazurchevici, S.-N., & Kyratsis, P. (2025). Neuro-Fuzzy Framework with CAD-Based Descriptors for Predicting Fabric Utilization Efficiency. Eng, 6(12), 368. https://doi.org/10.3390/eng6120368