1. Introduction

Natural gas has been extensively utilized globally as a low-carbon emission fossil energy source and is widely regarded as the optimal complementary option to renewable energy sources for reducing carbon emissions in energy systems [

1]. In recent years, global natural gas demand has exhibited a steady annual increase. In 2020, global demand reached 3840 billion cubic meters (bcm), with projections indicating a rise to 5625 bcm by 2050 [

2]. As natural gas exists in a gaseous state at ambient temperature, rendering it inconvenient for transportation, it undergoes liquefaction for transit and is stored in tanks to achieve a significant volume reduction [

3]. Over recent decades, global LNG (liquefied natural gas) trade volume has progressively expanded. In 2024, global LNG trade volumes reached 411.24 million tons, with China solidifying its position as the world’s largest importer at 76.65 million tons, while the United States remained the dominant exporter with 88.30 million tons. LNG must first be transported to storage tanks at coastal LNG-receiving terminals. When needed, it is regasified and delivered to end-users. Due to its extremely low initial temperature (approximately −162 °C), seawater is typically used as the heat source for regasification. During this process, a substantial amount of cold exergy is released, reaching up to 830 kJ/kg [

4]. Recovering this cold energy offers significant economic benefits. Consequently, with the continued growth in LNG trade volume, LNG cold energy recovery is poised for substantial development prospects [

5,

6].

Currently, the primary techniques for recovering cold energy from LNG include electricity production [

7,

8], air separation [

9], desalination of seawater [

10], cryogenic energy storage using liquid air [

11], and capture of carbon dioxide [

12]. Among these, power generation has emerged as the most widely adopted method for LNG cold energy utilization, owing to its negligible environmental effects, operational adaptability, and considerable economic advantages [

13]. Among the various LNG cold-to-power conversion technologies—such as direct expansion [

14], Rankine cycle [

15,

16], Organic Rankine Cycle (ORC) [

17], Brayton cycle [

18], and Kalina cycle [

19]—the Organic Rankine Cycle stands out as the most widely adopted solution in practical applications due to its operational simplicity, system stability, and high reliability [

20]. In a conventional LNG cold energy power generation (LNG-CEPG) system based on ORC technology, the organic working fluid undergoes the following continuous process: it is first condensed into liquid state within the condenser, pressurized by the organic working fluid pump, and subsequently directed to the evaporator where it absorbs thermal energy from heat sources such as seawater and undergoes vaporization. The resulting vapor then expands through a turbine to generate electricity before finally returning to the condenser, thus completing the thermodynamic cycle [

21].

In recent decades, significant research efforts have been devoted to the study of LNG cold energy power generation systems utilizing the Organic Rankine Cycle (ORC), primarily focusing on heat source selection, cycle configuration (single vs. multi-stage), and organic working fluid optimization. Zhen Tian et al. [

22] utilized waste heat from marine engine exhaust gases and jacket cooling water as the ORC heat source for LNG cold energy recovery. Their results indicated that reducing evaporation pressure and increasing condensation pressure enhanced both energy efficiency and economic performance, while optimizing the expander could reduce system capital costs. Bao, J.J. [

23] et al. investigated the impact of different ORC stages and Combined Cycle (CC) configurations integrating direct expansion with ORC on LNG cold energy recovery system performance. They found that for the same number of stages, systems employing ORC incurred higher costs than CC systems but delivered higher net power output; moreover, increasing the number of stages significantly raised investment costs. Li, B. et al. [

24] investigated a dual-loop ORC-LNG configuration, reporting enhancements in thermal and exergy efficiencies by 43.3% and 63.7%, respectively, relative to traditional single-loop ORC systems. Their analysis further highlighted R134a as the most effective working fluid for simultaneously optimizing thermal and exergy performance within the proposed dual-loop framework. Rao et al. [

25] evaluated the performance of various working fluids in an LNG cold energy power generation system utilizing solar thermal energy to drive the ORC process. Their findings indicated that R143a, R290, and R1270 demonstrated the most favorable thermodynamic characteristics for this specific application. He et al. [

26], researching ORC systems for LNG cold energy recovery, determined that R236fa achieved higher thermal efficiency. Liu, Q. et al. [

27] investigated working fluid selection for seawater-driven ORC cold energy recovery systems, finding R32 and R1270 more suitable for single-stage ORC, while R170, R41, R744, and R1123 were better suited for multi-stage ORC configurations. He, T.B. et al. [

28] analyzed the influence of LNG-side fluid types on the performance of single-stage ORC systems recovering LNG cold energy. Their results showed that using pure R1270 yielded the highest thermal and exergy efficiency. Critically, they noted that in practical applications, zeotropic mixtures frequently exhibit suboptimal thermal matching with the LNG vaporization curve, leading to increased exergy destruction within the evaporator.

The aforementioned research landscape reveals that regarding cycle configuration, increasing the number of ORC stages within LNG cold energy power generation (LNG-CEPG) systems enhances thermal efficiency but incurs the significant drawback of elevated costs [

29]. Concerning working fluid selection, pure fluids remain the predominant choice in practical applications, as zeotropic mixtures frequently encounter challenges in achieving optimal thermal matching with the LNG vaporization curve. In terms of heat sources, clean energy sources like geothermal energy are commonly utilized for the ORC [

30]. However, geographical constraints often limit the availability of such heat sources at most LNG-receiving terminals [

28,

31]. Type II Absorption Heat Transformers (AHTs), widely employed for district heating in industrial parks, utilize substantial amounts of medium-temperature heat to generate high-temperature heat [

32]. Nevertheless, a significant portion of heat is dissipated via cooling water in the AHT condenser. The current literature primarily focuses on areas such as working fluid pair selection in AHT [

33], system structure optimization [

34], the impact of various system parameters on AHT performance [

35], and the integration of clean energy sources (e.g., solar energy) with AHT for building heating systems [

32]. However, research on utilizing the cooling water from the AHT condenser remains unexplored. If this resource can be effectively harnessed—for instance, as a heat source for LNG-CEPG—it would present broad prospects for future research.

Building upon this background and the current research status, this study establishes an integrated AHT-LNG-CEPG system combining AHT with LNG-CEPG. A steady-state mathematical model of the system is developed. An optimized organic working fluid is selected for the LNG-CEPG subsystem. The influence of varying AHT condensation temperatures and LNG-CEPG evaporation temperatures on system performance is analyzed. Finally, an economic assessment of the system under optimal operating conditions is conducted. The results presented in this study are derived from simulation software, which, to some extent, facilitates further design optimization of the LNG-CEPG system and is expected to provide valuable insights for practical engineering applications of LNG cold energy recovery.

2. System Description

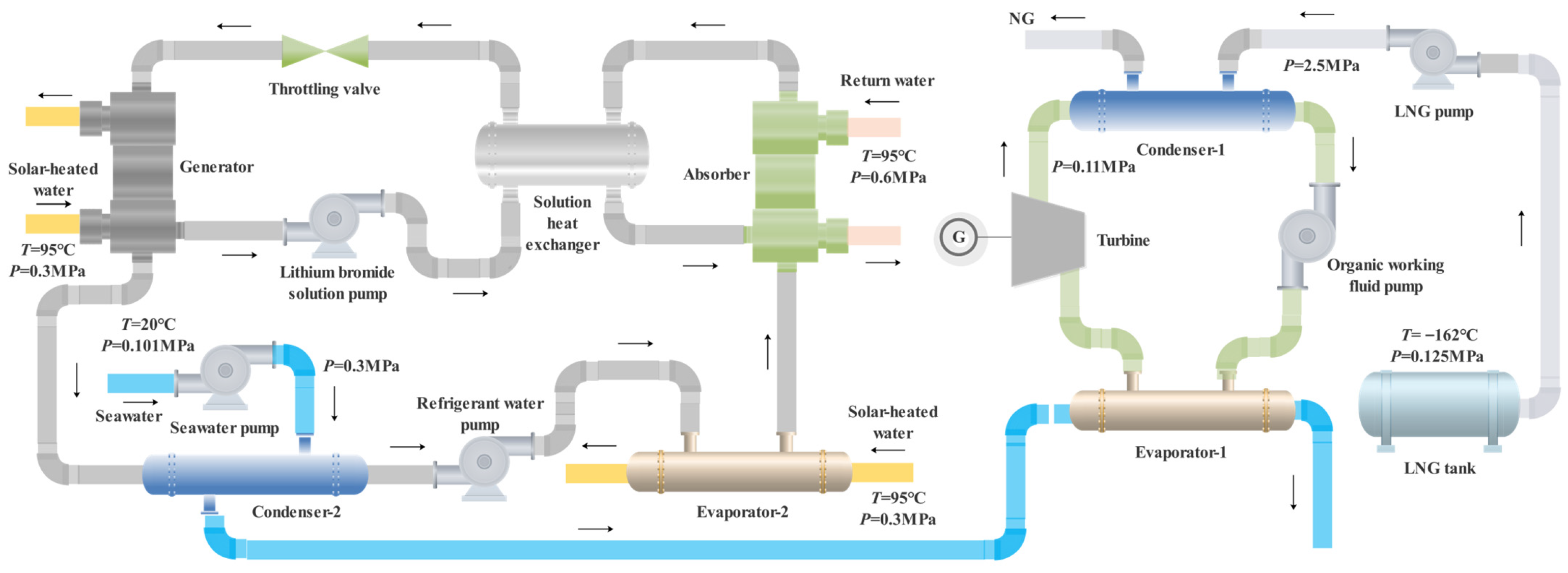

The integration architecture of the proposed system, which combines a Type II Absorption Heat Transformer (AHT) with a liquefied natural gas cold energy power generation (LNG-CEPG) unit, is illustrated schematically in

Figure 1. The overall system comprises two primary subsystems: an ORC-based LNG cold energy power generation system and a Type II Absorption Heat Transformer (AHT) system.

The LNG cold energy power generation subsystem primarily consists of a single ORC. LNG flows from the storage tank and is pressurized to the required delivery pressure by the LNG pump. It then passes through Condenser-1 of the ORC, where it absorbs heat and subsequently exits the system as warmed natural gas (NG). The working process within the ORC proceeds as follows: initially, saturated liquid organic working fluid is pressurized by the refrigerant pump and enters Evaporator-1. Within Evaporator-1, the fluid is heated by seawater, transforming it into a saturated vapor state. This saturated vapor then expands through the turbine, generating mechanical work that is converted into electrical energy. Finally, the expanded vapor enters Condenser-1, where the cold energy from the LNG stream causes it to condense back into saturated liquid, thereby completing the cycle.

The second-type absorption heat pump heating system employs a lithium bromide–water mixture as the working pair and typically utilizes clean energy as the medium-temperature heat source. In this study, solar-heated water serves as the input heat source, with a temperature range generally around 95 °C [

32,

36], supplying thermal energy to both the generator and Evaporator-2. Seawater acts as the cooling medium, providing cold energy to Condenser-2. A significant portion of the heat released within the absorber is transferred to the district heating return water, elevating its temperature for subsequent heating applications. The internal working process of the AHT proceeds as follows: dilute LiBr solution is heated by solar-heated water within the generator, causing the evaporation of low-pressure water vapor and resulting in a concentrated solution. The generated water vapor flows to the AHT’s Condenser-2, where it is condensed into saturated liquid water by seawater cooling. This liquid water is then pressurized by the liquid water pump and delivered to Evaporator-2. Within Evaporator-2, the water is heated and evaporated by solar-heated water, transforming into high-temperature, high-pressure vapor which subsequently enters the absorber. Meanwhile, the concentrated solution from the generator is pressurized by the solution pump and passes through the solution heat exchanger for recuperative heating. It then enters the absorber, where it absorbs the incoming high-pressure vapor from Evaporator-2. This absorption process releases substantial heat into the district heating return water. Following absorption, the solution reverts to a dilute state and flows through the solution heat exchanger, transferring heat to the incoming concentrated solution stream. Finally, the diluted solution passes through a throttling valve to reduce its pressure before re-entering the generator to commence the next cycle.

The integration between the LNG-CEPG and AHT systems is achieved through seawater acting as an intermediary heat transfer medium. Seawater first serves as the cooling fluid entering Condenser-2 of the AHT. After being warmed within Condenser-2, this seawater then acts as the thermal source, flowing into Evaporator-1 of the ORC subsystem to transfer heat to the organic working fluid.

4. Results and Discussion

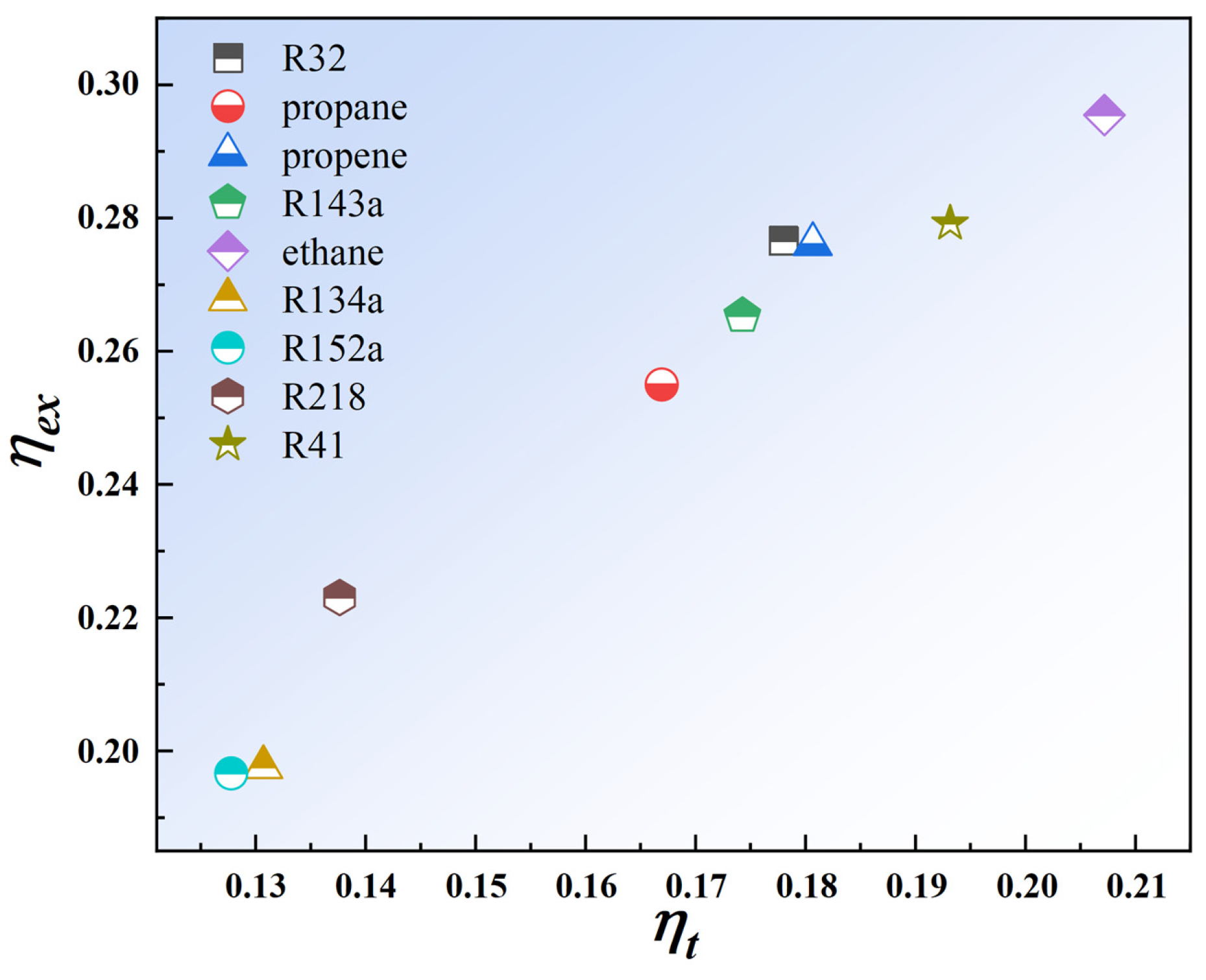

4.1. Selection of Organic Working Fluids

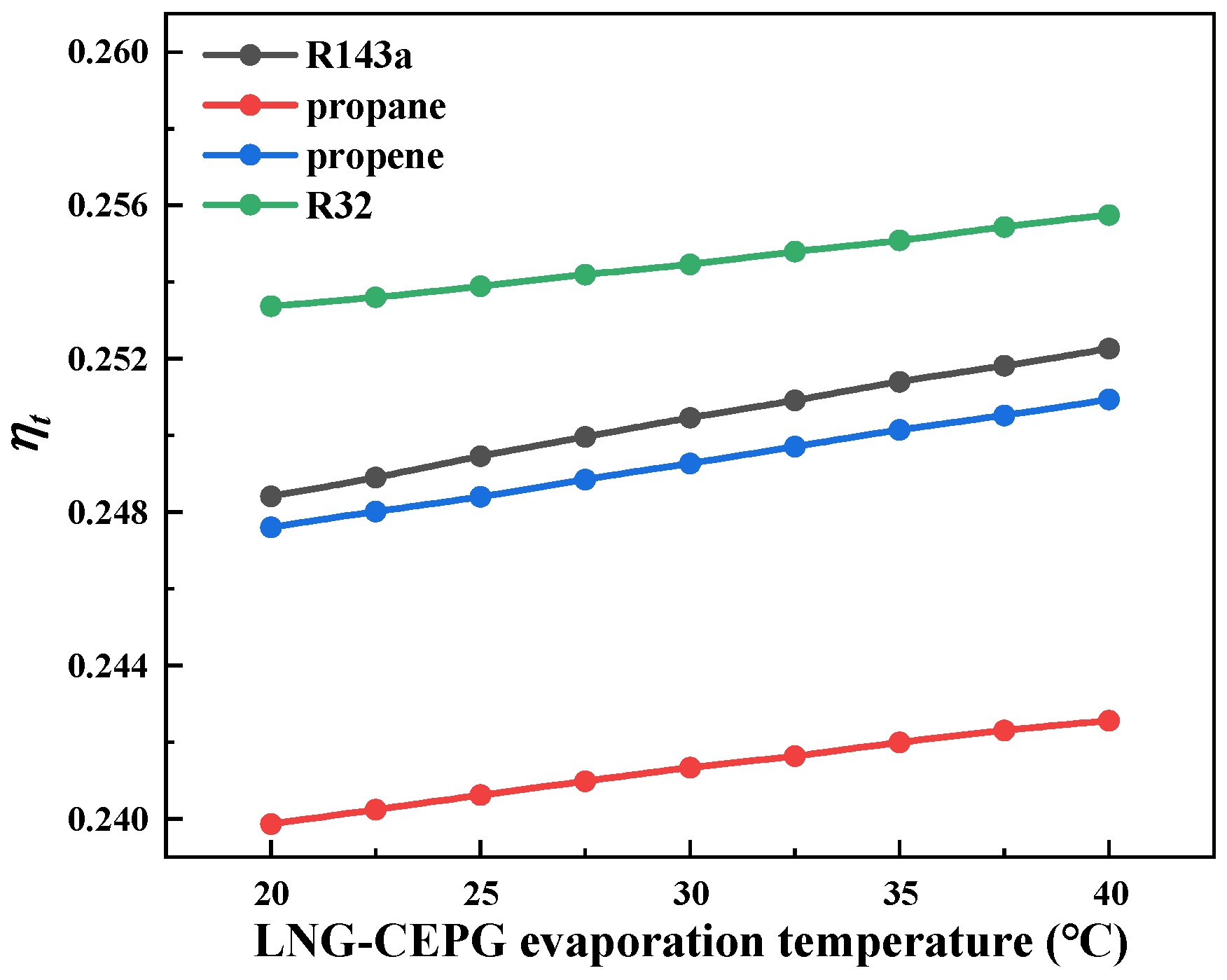

Owing to distinct physical properties among different organic working fluids, their operational temperature ranges vary significantly. To enhance ORC efficiency and minimize exergy destruction, an optimal working fluid must be selected from the 10 preliminarily screened candidates to improve cold energy recovery. Since working fluids pertain exclusively to the ORC subsystem, this section focuses solely on the LNG cold energy power generation (LNG-CEPG) system excluding the AHT subsystem. For Evaporator-1, the heat source is substituted with 20 °C seawater. The

and

of the LNG-CEPG system across the 10 candidate working fluids are presented in

Figure 2, while

and

are shown in

Figure 3.

As evidenced in

Figure 2 and

Figure 3, system

,

,

, and

exhibit considerable variation across working fluids. This divergence primarily stems from differences in physical properties, particularly condensation temperature, which affects thermal matching between the working fluid and LNG during heat exchange, consequently impacting all performance metrics.

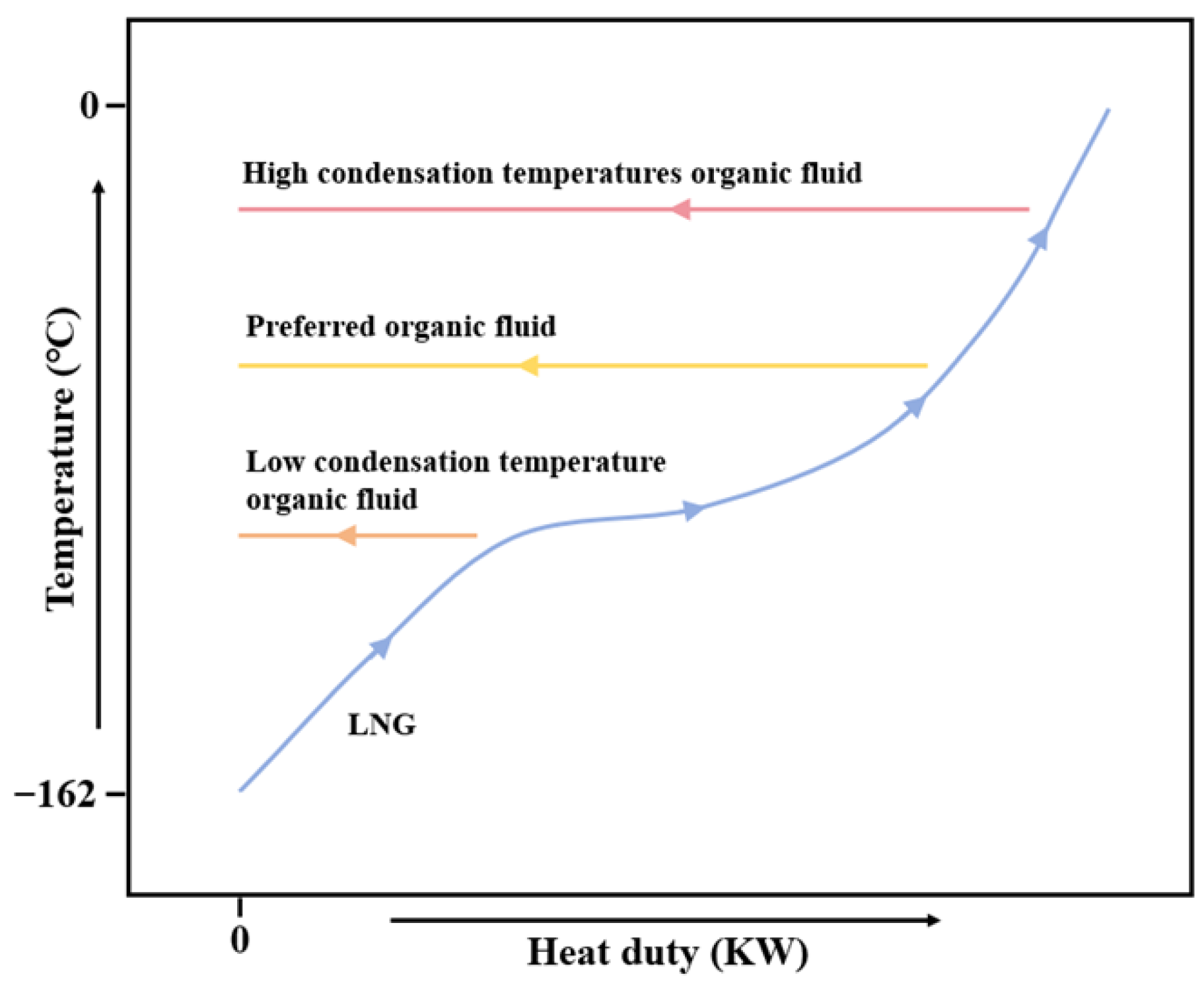

Figure 4 demonstrates that fluids with higher condensation temperatures expand the LNG cold energy recovery temperature range. However, they incur excessive heat exchange temperature differences with LNG, resulting in poor thermal profile matching, increased exergy destruction, and degraded system performance. Conversely, fluids with lower condensation temperatures reduce the heat exchange temperature difference with LNG but narrow the effective cold energy recovery temperature range, diminishing overall recovery efficiency.

As observed in

Figure 3, system

and

vary substantially among fluids. Candidates positioned near the top-right quadrant of the plot should be prioritized, while R134a, R152a, and R218 exhibit significantly inferior performance and are excluded from consideration. Similarly,

Figure 4 indicates that

and

differ considerably across fluids. Following the same selection principle, ethane and R41 are eliminated. Synthesizing both figures, R32, propane, propene, and R143a are identified as optimal working fluids for further analysis.

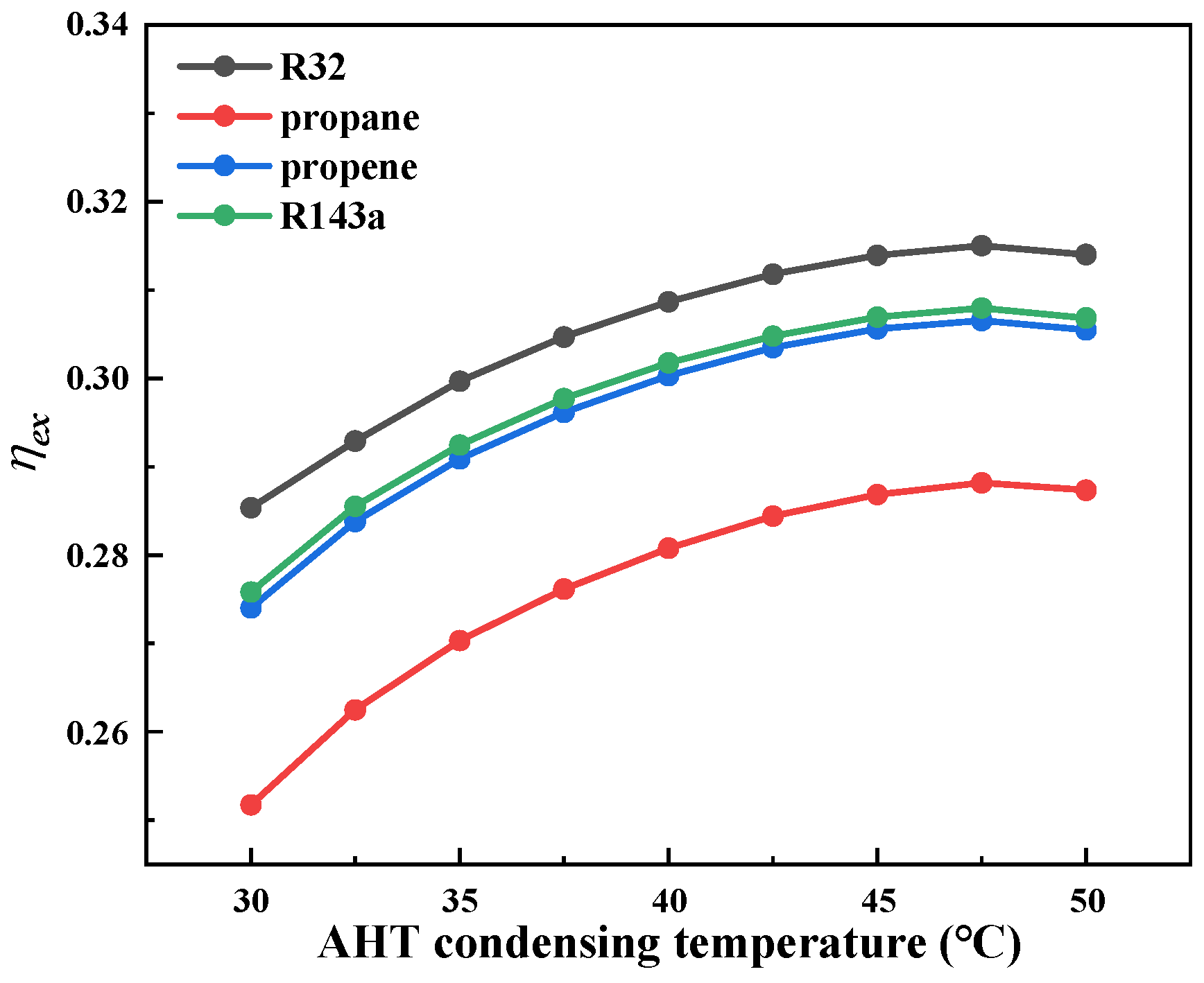

4.2. Impact of AHT Condensation Temperature on System Performance

To better understand the impact of different parameters on system performance, this section builds upon the four preferred working fluids identified in

Section 4.1. Under the condition of an LNG-CEPG evaporation temperature of 20 °C, the influence of different AHT condensation temperatures on system performance is investigated to identify the optimal AHT condensation temperature for improved system performance.

Figure 5,

Figure 6 and

Figure 7 illustrate the variations in system

,

, and

for different working fluids and AHT condensation temperatures.

Figure 5 and

Figure 6 show the changes in

and

with respect to the AHT condensation temperature for different working fluids. It can be observed that as the condensation temperature increases, both

and

for all working fluids initially rise and then decline. The condensation temperature of the AHT increased from 30 °C to 47.5 °C, with average growth rates of 6.60% and 3.27% for

and

, respectively. Among them, the working fluid R32 demonstrates superior performance, followed by R143a and propene, while propane performs the poorest. When R32 is used as the working fluid, both

and

reach their maximum values of 24.0% and 31.50%, respectively.

Figure 5 and

Figure 6 also reveal that the growth trends of

and

gradually slow down as the AHT condensation temperature increases and begin to decline after the AHT condensation temperature exceeds 47.5 °C. This is primarily because the increase in AHT condensation temperature raises the temperature of seawater after passing through Condenser-2, thereby increasing the seawater inlet temperature of the LNG-CEPG Evaporator-1. The increase in the average temperature difference between seawater and the working fluid enhances heat transfer. According to the heat transfer equation

, under a fixed heat transfer area, a larger average temperature difference significantly improves heat transfer efficiency. This leads to an increase in the mass flow rate of the working fluid, resulting in higher turbine output work. However, as the AHT condensation temperature continues to rise, the AHT condensation pressure and generation pressure also increase, which deteriorates the water evaporation effect in the generator, reduces generation capacity, decreases heat exchange at Condenser-2, and lowers the circulating water flow rate. Consequently, the heating capacity of the AHT decreases significantly. Although the average heat transfer temperature difference at Evaporator-1 continues to increase, it is insufficient to offset the negative impact caused by the reduction in the AHT’s generation capacity. As a result, the growth in both the

and

of the system slows down and even declines.

Figure 7 shows that as the AHT condensation temperature increases, the

under different working fluids first rises and then declines. This is primarily because the increase in AHT condensation temperature weakens the AHT generation capacity, leading to a significant reduction in heat supply and a decrease in the system’s net output power. Meanwhile, the input exergy increases due to the higher seawater inlet temperature at the LNG-CEPG Evaporator-1, which enhances the exergy obtained by the working fluid, thereby reducing the system’s

.

At a condensation temperature of 40 °C, the exergy work ratio for all working fluids reaches its maximum value, with propene exhibiting the highest

of 0.667. Based on the growth trends of

and

, when the AHT condensation temperature increases from 30 °C to 40 °C,

and

show average increases of 5.51% and 2.61%, respectively. However, when the temperature further rises from 40 °C to 50 °C, the average increases are only 1.09% and 0.66%. For the same 10 °C increment in AHT condensation temperature, the growth rates of

and

differ by approximately fourfold and threefold, respectively. This indicates that as the AHT condensation temperature increases, the marginal gains in

and

diminish. Additionally, since

reaches its maximum value at an AHT condensation temperature of 40 °C, it can be concluded that the system achieves optimal performance when the AHT condensation temperature is set at 40 °C.

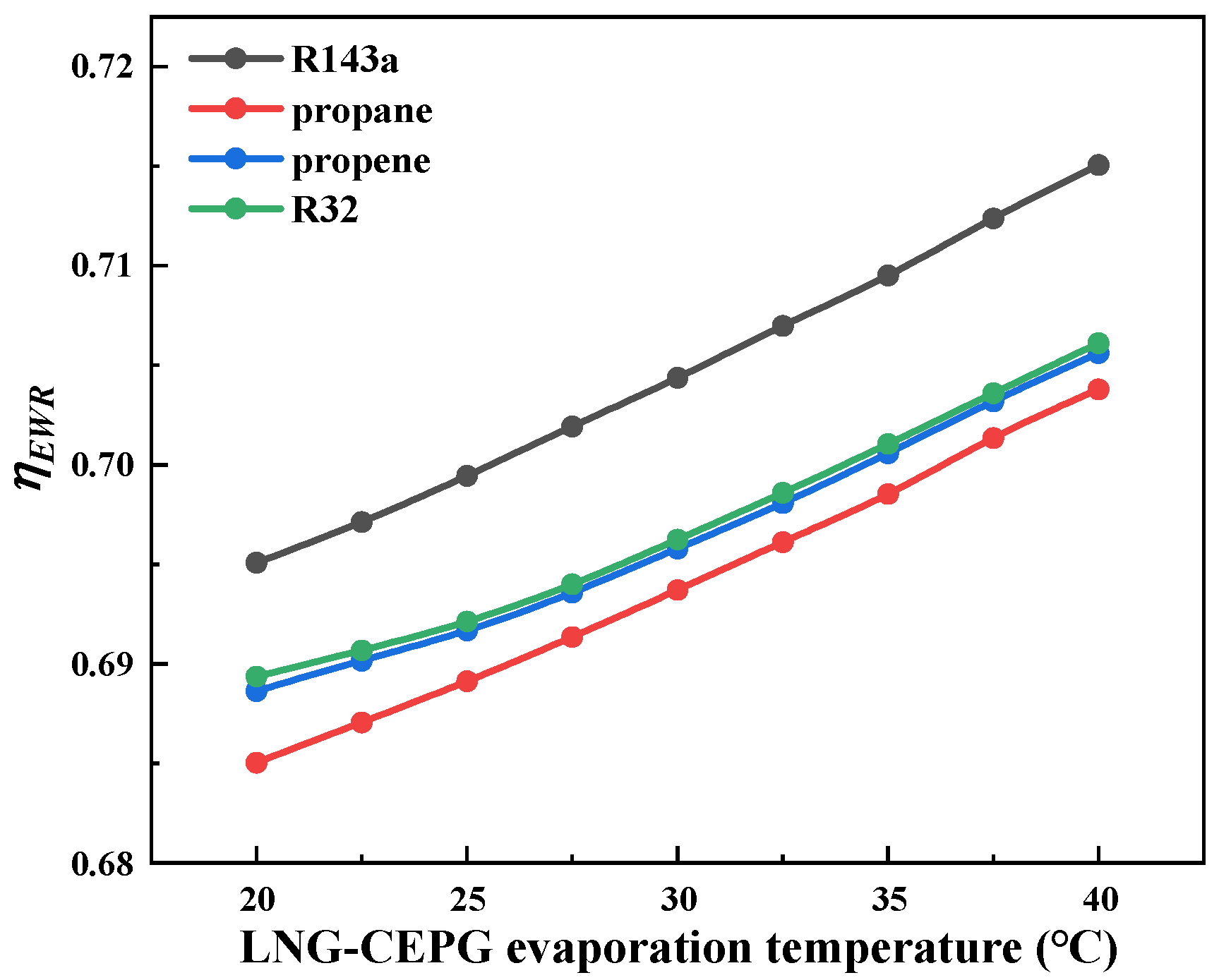

4.3. Impact of LNG-CEPG Evaporation Temperature on System Performance

Based on four selected working fluids, this section examines the influence of different LNG-CEPG evaporation temperatures on system performance.

Figure 8,

Figure 9 and

Figure 10, respectively, demonstrate the variations in system

,

, and

with LNG-CEPG evaporation temperature for different working fluids. The results show that

,

, and

all increase with rising evaporation temperature, though

exhibits relatively slower growth. When the LNG-CEPG evaporation temperature increases from 20 °C to 40 °C, the average improvements in

,

, and

for the four working fluids reach 1.23%, 3.90%, and 2.38%, respectively. This phenomenon primarily occurs because the working fluid at the hot side of LNG-CEPG Evaporator-1 becomes superheated after evaporation. As the degree of superheat increases, the superheated heat transfer section expands, reducing the overall heat transfer coefficient. With fixed heat transfer area in Evaporator-1, this leads to decreased thermal load and reduced organic working fluid flow rate. However, the increased working fluid temperature at turbine inlet ultimately enhances output power, thereby improving overall system thermal efficiency. Nevertheless, due to the relatively low superheat and short superheated section in Evaporator-1, the reduction in thermal load remains limited, resulting in only modest

improvement. Higher LNG-CEPG evaporation temperatures introduce superheat at Evaporator-1 outlet, which reduces the average heat transfer temperature difference between seawater and working fluid in Evaporator-1, consequently decreasing exergy destruction and improving both

and

. The improvement in

and

is significantly greater than that of

, with increases higher by 217% and 93%, respectively. However, excessive superheat may potentially cause turbine surge risks and increase system instability. Based on the conclusion presented in

Section 4.2 that the system performance is optimal when the AHT condensation temperature is 40 °C, it can be determined that the system exhibits superior performance when the LNG-CEPG evaporation temperature is set at 30 °C.

As evidenced in

Figure 8,

Figure 9 and

Figure 10, the R32 working fluid demonstrates superior

and

, followed by R143a and propene, while propane exhibits the lowest performance in both metrics. Regarding

, R143a achieves optimal performance, with propene and propane ranking second and third, respectively.

For the AHT subsystem, its coefficient of performance (

COP) across all operating conditions in this study ranges from 0.49 to 0.52. Compared with Reference [

35], the AHT component in our system also demonstrates favorable thermodynamic performance.

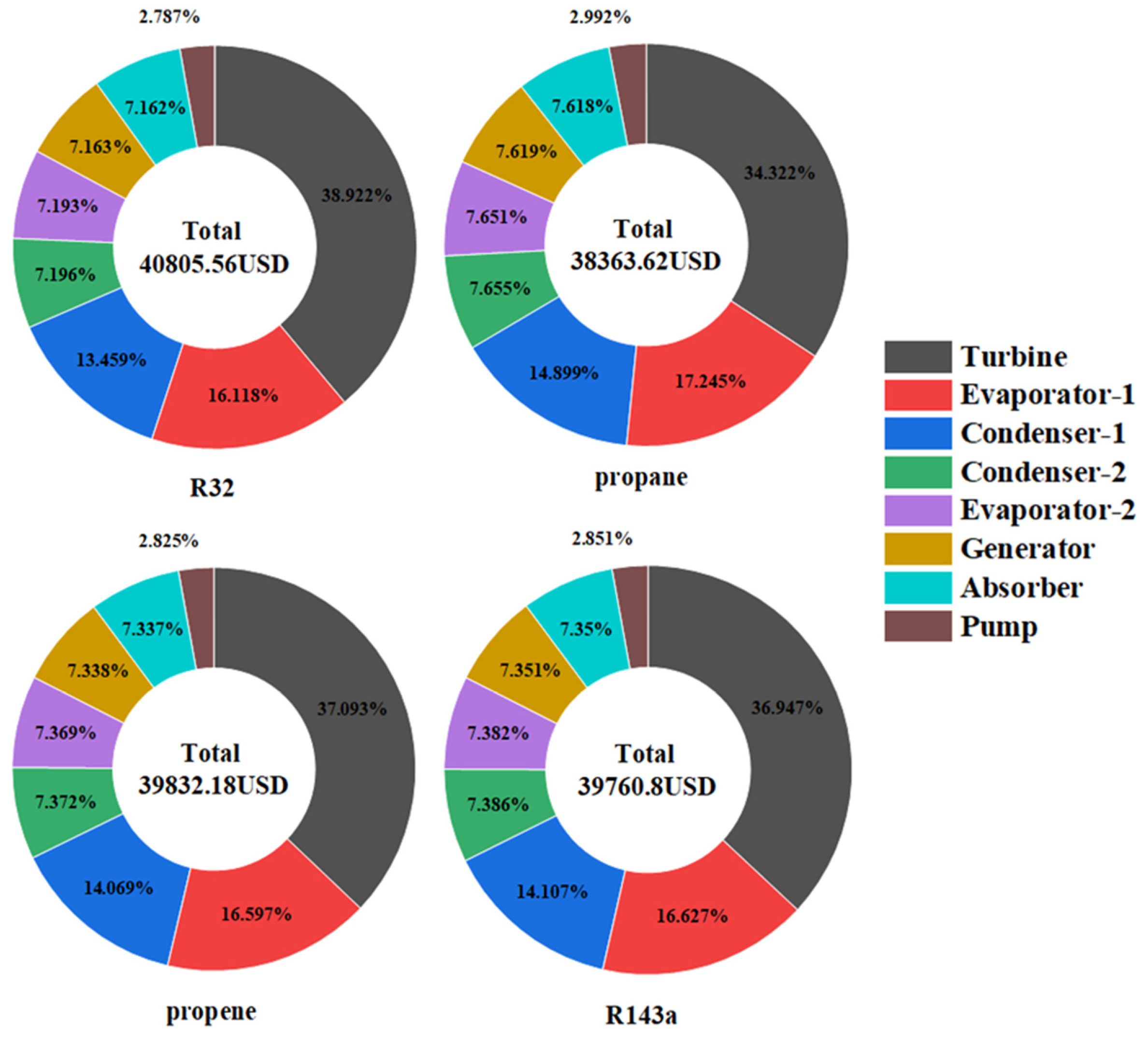

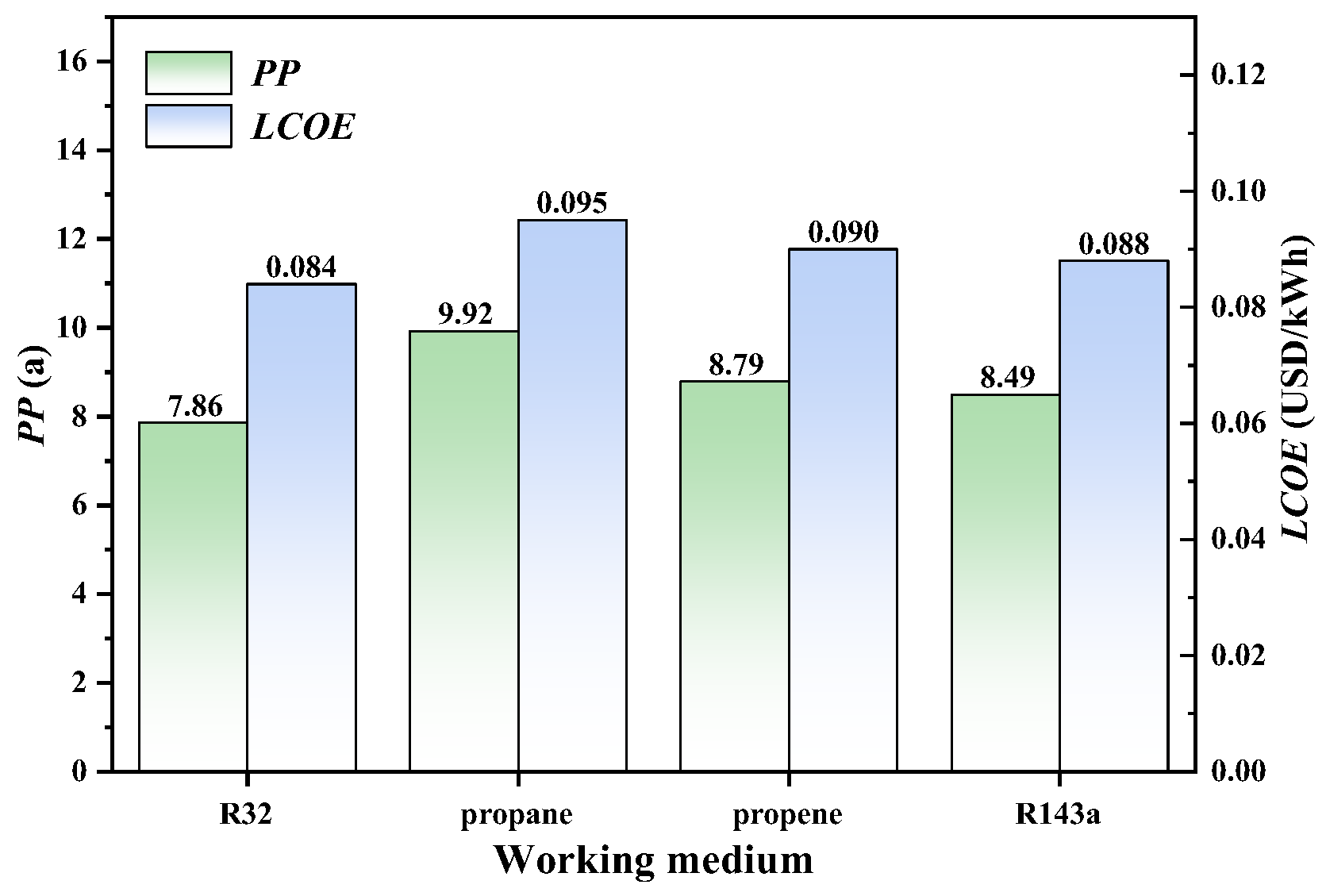

4.4. Economic Analysis

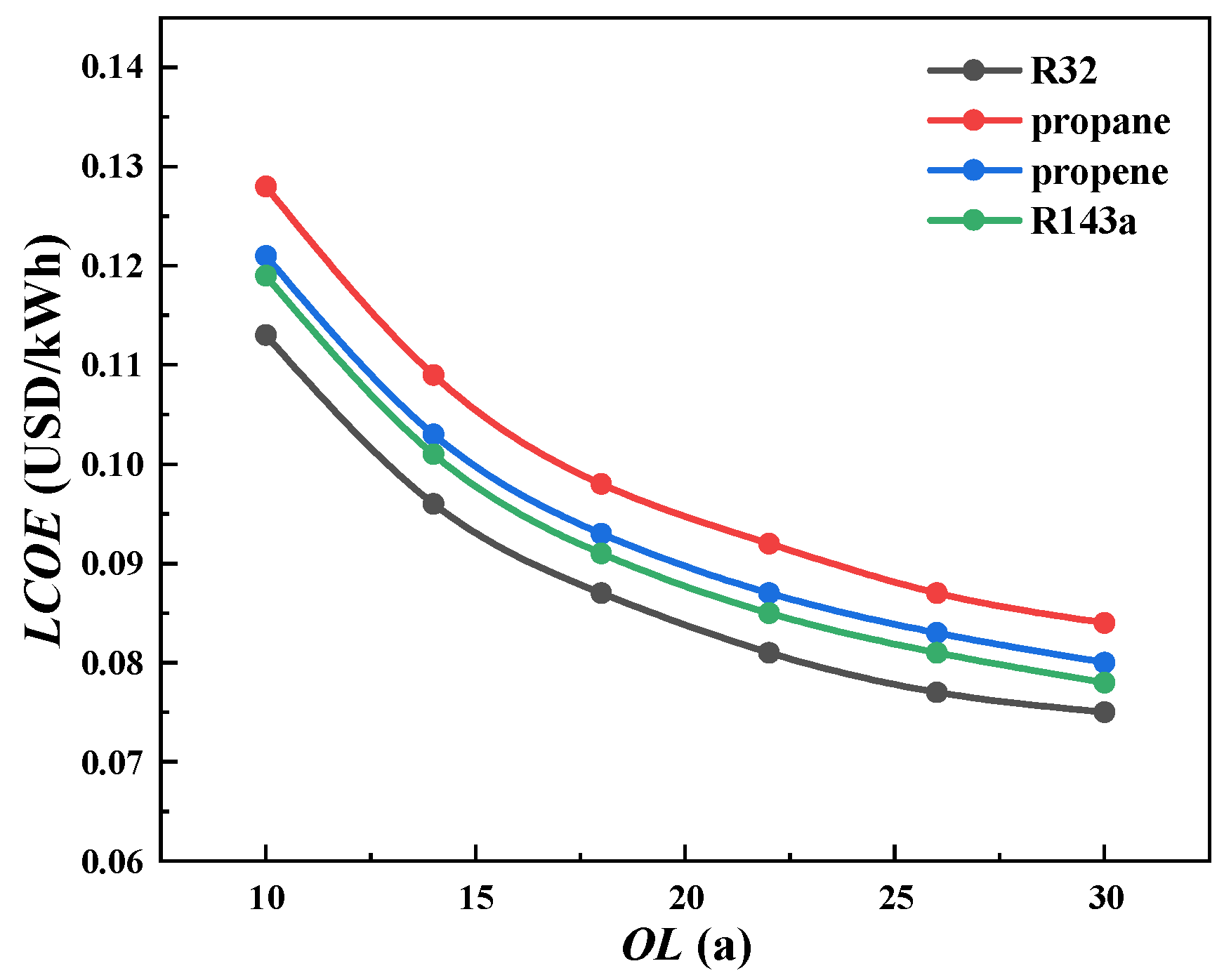

To assess the economic feasibility and scalability potential of the proposed system, this section conducts an economic evaluation focusing on the cost composition, Levelized Cost of Electricity (LCOE), and static Payback Period (PP). The variation in LCOE with system design life is examined under different optimized working fluids, with the AHT condensation temperature held constant at 40 °C and the LNG-CEPG evaporation temperature set at 30 °C.

Considering the relatively small thermal load of the solution heat exchanger, its cost is assumed negligible. The AHT-LNG-CEPG equipment costs primarily consists of the generator, Evaporator-2, Condenser-2, and absorber in the AHT section; and Condenser-1, Evaporator-1, turbine, and pump in the LNG-CEPG section.

Figure 11 displays the total system cost and individual equipment cost distributions across different working fluids. The turbine consistently emerges as the highest cost component, regardless of working fluid, commanding an average 36.821% of total costs, followed by Evaporator-1 at 16.647% and Condenser-1 at 14.134%. This cost distribution profile clearly indicates that the LNG-CEPG section constitutes the primary cost center of the integrated system.

Figure 12 presents the system’s

PP and

LCOE under four different working fluids with a 20-year design lifespan. The results demonstrate that using R32 as the working fluid achieves the most favorable economic performance, with the lowest

PP of 7.86 years and

LCOE of

$0.084/kWh. Propene and R143a show intermediate economic indicators, while propane yields the least favorable results with the highest

PP and

LCOE values among the four working fluids.

Figure 13 illustrates the variation in system

LCOE with design

OL for different working fluids. As the design life increases, the system

LCOE shows a gradual decline, attributable to the annual cost reduction and profit increase resulting from the amortization of initial investment costs over extended operational periods. When the

OL increases from 10 to 30 years, the system’s

LCOE decreases by an average of

$0.041 per kWh, representing an average reduction of 34.09%. Notably, the R32 working fluid demonstrates significantly lower

LCOE values compared to other alternatives, indicating superior economic performance. At the 30-year design life mark, the average

LCOE across all four working fluids reaches its minimum value of

$0.079/kWh.

In practical engineering applications, using solar-heated water as the heat source for the AHT system as described in this study will require additional initial investment in components such as solar collectors. For different regions, the literature [

48] indicates that variations in solar irradiance intensity also affect the total initial investment, Payback Period (

PP), and Levelized Cost of Energy (

LCOE). Regions with higher solar irradiance intensity tend to have lower total initial investment, while areas with lower irradiance may still achieve higher profitability. For large-scale industrial applications, the literature [

49] shows that although increasing the capacity of solar collectors leads to a significant rise in the total initial investment, the cost growth of components such as solar collectors is nonlinear. As a result, the lifecycle cost of the system can be reduced by up to approximately 34%. For the system described in this paper, taking the working fluid R32 and a 20-year

OL as an example, when additional components such as solar collectors are incorporated, the total initial investment increases significantly. According to Equation (29), for every 1% increase in the total initial investment, the system’s

LCOE increases by 0.51%. However, as the area of solar collectors expands, the revenue generated also rises substantially. This indicates that large-scale implementation of the system would achieve lower

LCOE and a shorter PP compared to the small-scale system discussed in this study.

4.5. A Comparison of Different LNG Cold Energy Power Generation Systems

Due to the novelty of the system proposed in this study, direct comparisons with identical systems are challenging. Therefore, the performance under the optimal operating condition identified in this work was compared with that of single-stage Organic Rankine Cycle (ORC) systems driven by different heat sources and utilizing LNG cold energy for power generation. The results are shown in

Table 7. Compared with the performance metrics under the optimal cost rate in Reference [

38] the thermal efficiency of the system proposed in this study is significantly higher, while the exergy efficiency is slightly lower than the results reported in Reference [

38]. This difference is attributed to the integration of the Absorption Heat Transformer (AHT), which enhances the heating output and thereby improves the overall thermal efficiency. In comparisons with references [

28,

50], both the thermal and exergy efficiencies of the proposed system are markedly superior. This is because the aforementioned references used seawater as the heat source, which has a lower temperature than the heat source employed in the ORC subsystem of our system, resulting in lower thermal and exergy efficiencies in those studies.

Overall, the innovative system presented in this paper demonstrates significant advantages in cold energy recovery for power generation and district heating compared to the results reported in the literature.

Table 7.

Comparison with different LNG cold energy power generation systems.

Table 7.

Comparison with different LNG cold energy power generation systems.

| Parameters | Present Work | Ref. [38] | Ref. [28] | Ref. [50] |

| Structure and composition | AHT-LNG-CEPG | GSF-ORC | SORC-LNG | ORC-DEC |

| Organic working fluid | R32 | R601 | R1270 | Propane |

| Thermal source type | AHT condenser cooling water | Geothermal water | Seawater | Seawater |

| ηt (%) | 24.8 | 12.8 | 10.4 | 11.2 |

| ηex (%) | 32.4 | 33.3 | 15.3 | 21.4 |

4.6. Limitations and Future Work

This study proposes a novel system that integrates an Absorption Heat Transformer (AHT) with an LNG cold energy power generation system, and conducts performance and economic analyses based on simulation software. Although the model has been developed in accordance with established thermodynamic principles, it is important to acknowledge its limitations and the uncertainties arising from various factors. Firstly, the research findings are derived from numerical simulations under specific assumptions; thus, the steady-state simulation results may differ from real-world engineering applications characterized by dynamic fluctuations. For example, the isentropic efficiencies of pumps and turbines are assumed constant in the simulations, whereas in practice, these values vary with changes in the thermodynamic properties of the organic working fluid. Secondly, the economic analysis relies on equipment cost estimates from the literature, and time-sensitive data such as electricity prices are subject to change over time. Actual capital investment and operational expenses can vary significantly depending on the timeframe, geographic location, market conditions, and specific project requirements. Lastly, the use of solar-heated water as the AHT heat source only considers daytime operation; nighttime conditions are not discussed in this study. Additionally, the operational scenario involving the addition of components such as solar collectors has not been discussed in this study.

To address these limitations and uncertainties and facilitate the transition from simulation to practical engineering application, future work will focus on the following directions: first, establishing a small-scale experimental platform to validate the simulation results under laboratory conditions, which will provide an empirical foundation for practical implementation. Second, incorporating thermal energy storage to enable nighttime operation and developing dynamic models to simulate fluctuations in solar irradiance. Third, conducting comprehensive, location-specific techno-economic analyses that include actual supplier quotations, installation costs, and detailed operational strategies will be essential for accurate pre-commercialization feasibility assessment. Despite these limitations and uncertainties, the innovative approach and systematic analysis presented in this study offer valuable insights, demonstrate the thermodynamic feasibility of the system, and establish a foundation for subsequent experimental and practical applications.