A Survey on Topologies and Modulation Strategies of Dual Inverters in Industrial Applications

Abstract

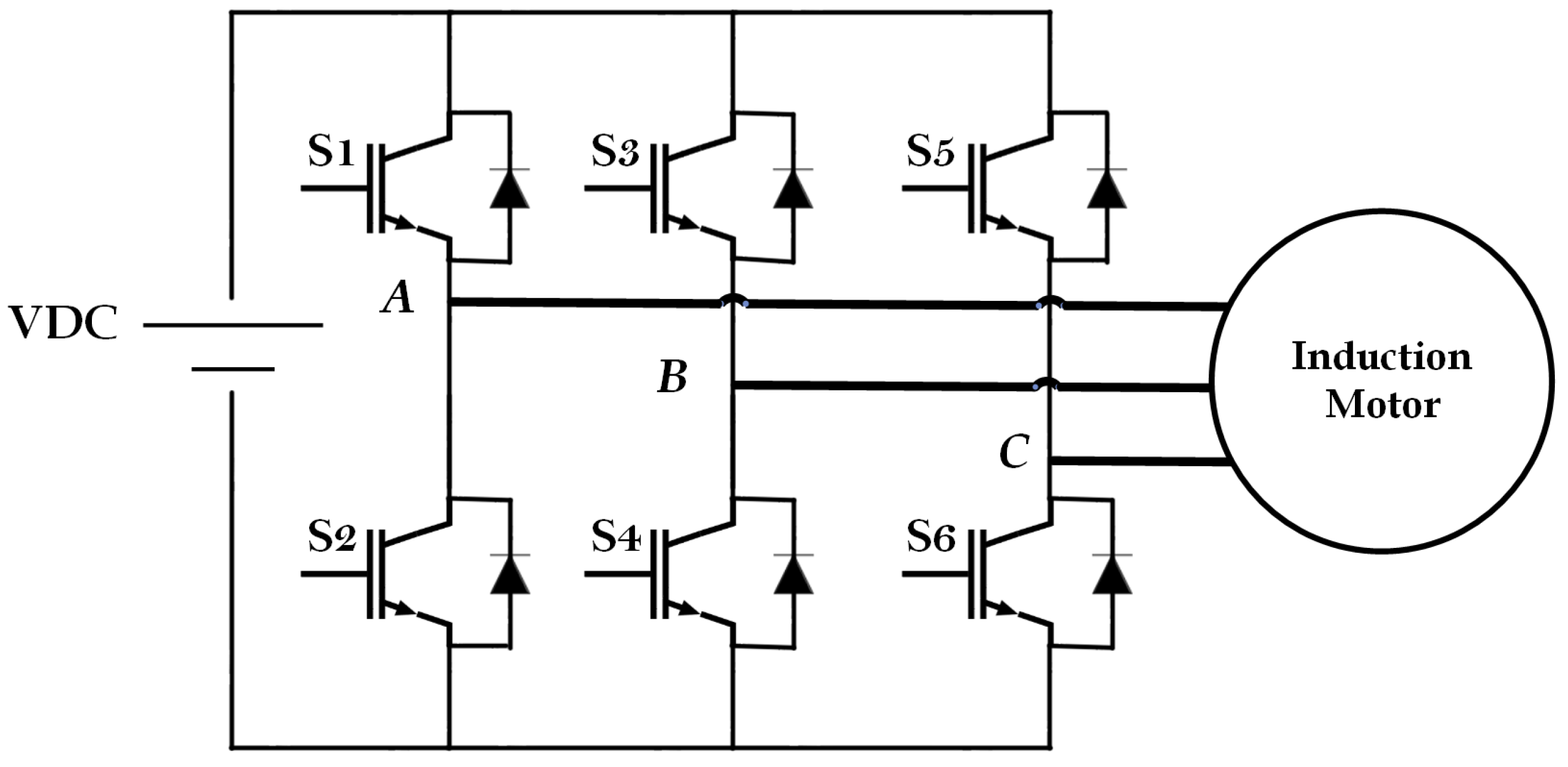

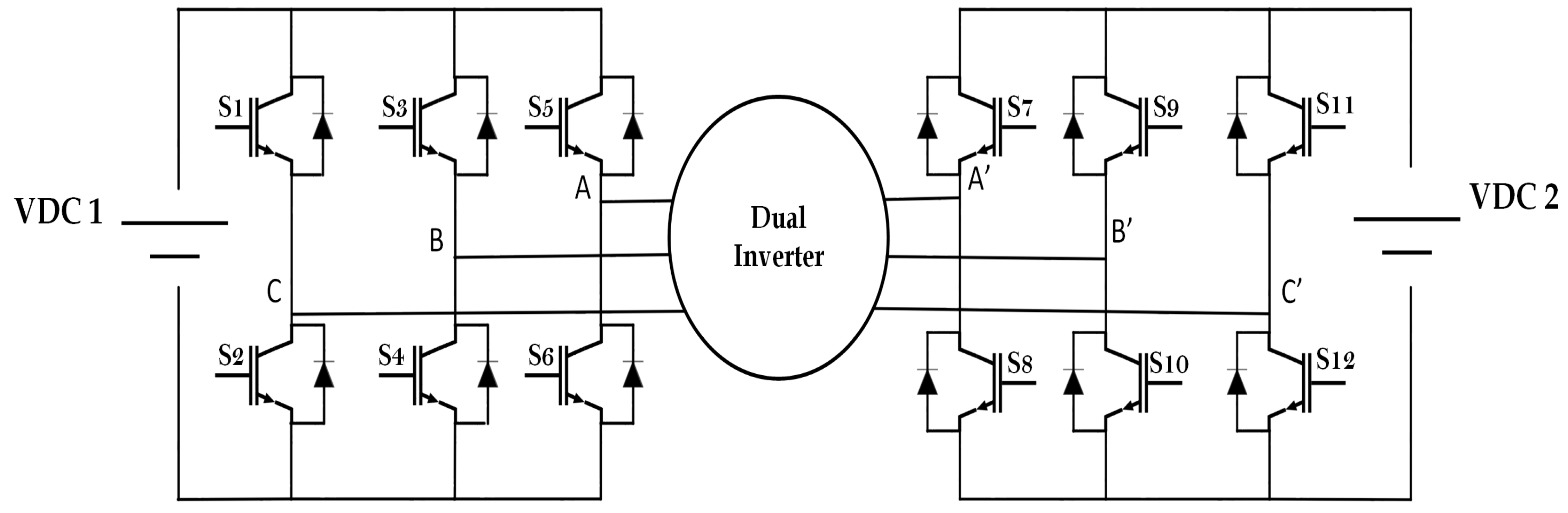

1. Introduction

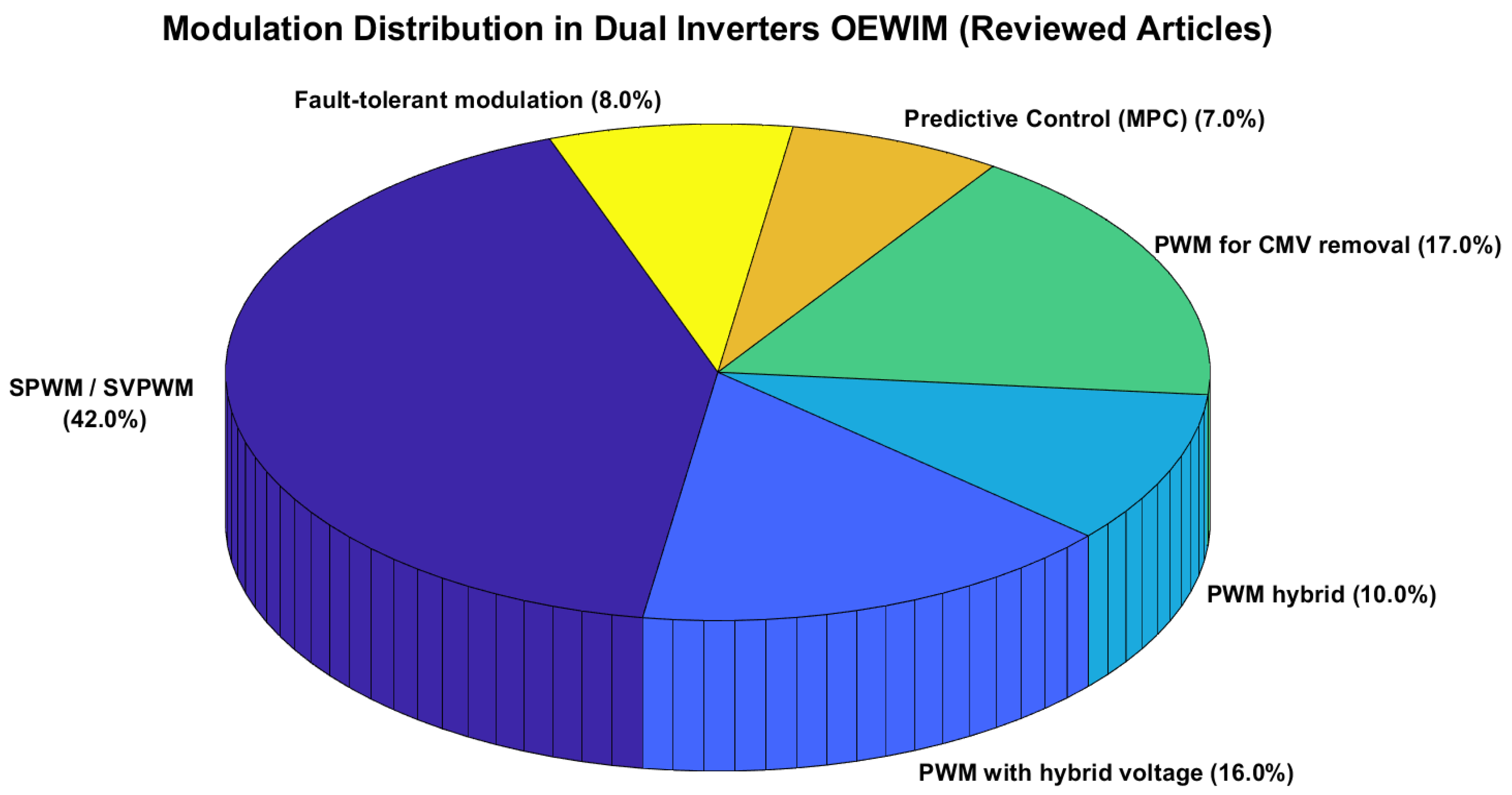

| Characteristic | SPWM (Sinusoidal PWM) | SVPWM (Space Vector PWM) | Hybrid (DPWM-SVPWM or SHE-PWM) |

|---|---|---|---|

| Operating Principle | Comparison of sinusoidal reference wave with a triangular carrier. | Voltage representation as a space vector within the switching | Combines techniques: reduces switching losses. |

| Voltage Utilization Factor | Low (≈78% of the DC bus). | Alto (≈90–92% del bus de CD). | Very high (≈92–96%, depending on implementation). |

| THD (Total Harmonic Distortion) | Higher THD, especially in high-power loads. | Lower THD, spectrum more concentrated in higher-order harmonics. | Very low THD, better natural filtering at the output. |

| Implementation Complexity | Simple, easy to implement on a microcontroller or FPGA. | Moderate, requires vector calculations and switching time computation. | High, requires advanced algorithms, numerical optimization, or predefined tables. |

| Robustness in OEWIM | Less efficient, requires additional filter to improve waveform quality [5]. | Very suitable, maximizes DC bus utilization in dual inverters and improves symmetry [6]. | Excellent, especially for critical applications (EVs, electric traction, renewable energy) [7]. |

| Typical Applications | Low power systems, simple motor control [8]. | Electric vehicles, traction, medium/high-power industrial applications [9]. | Next-generation EVs, high-efficiency inverters, applications where low THD and high efficiency are prioritized [10]. |

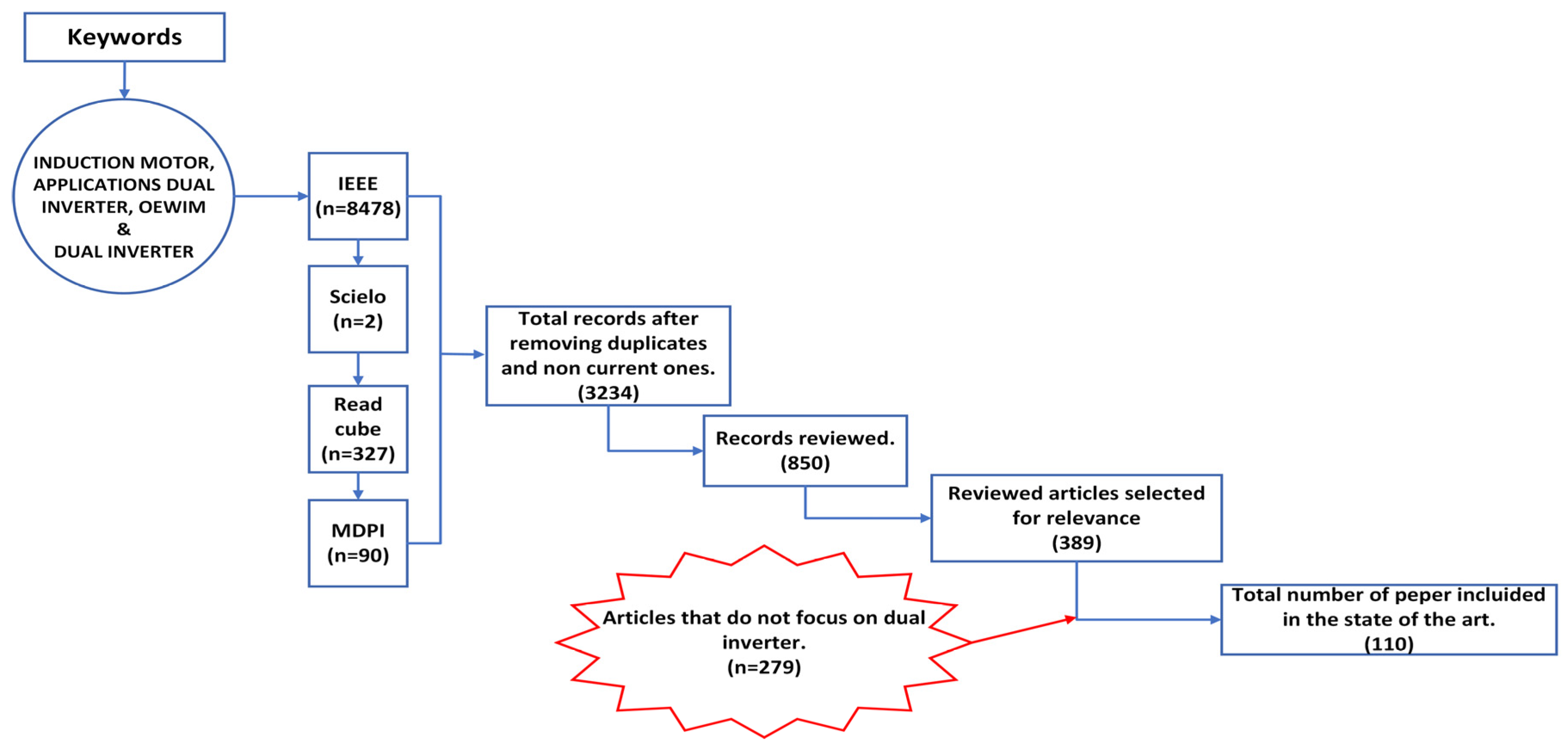

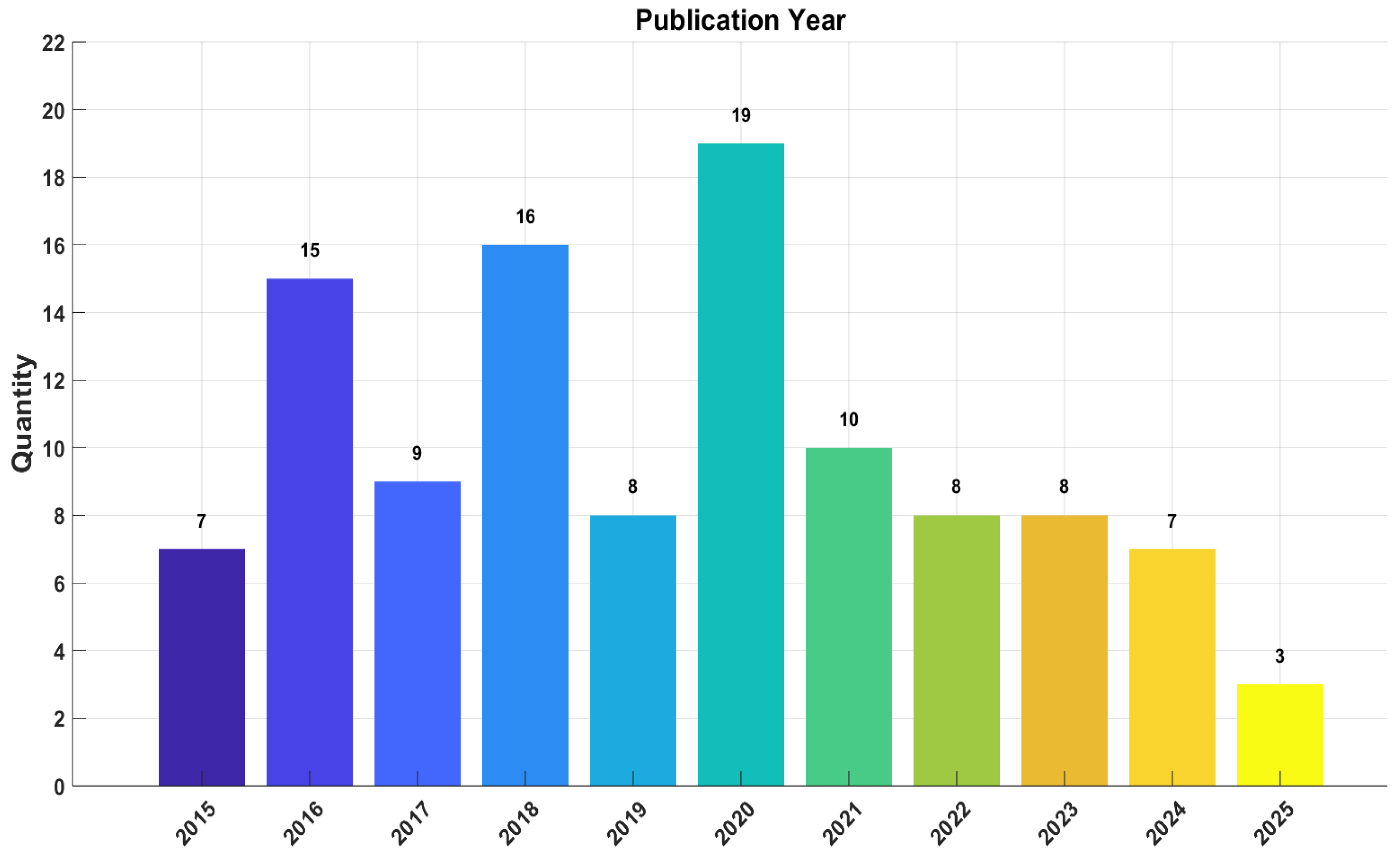

2. Materials and Methods

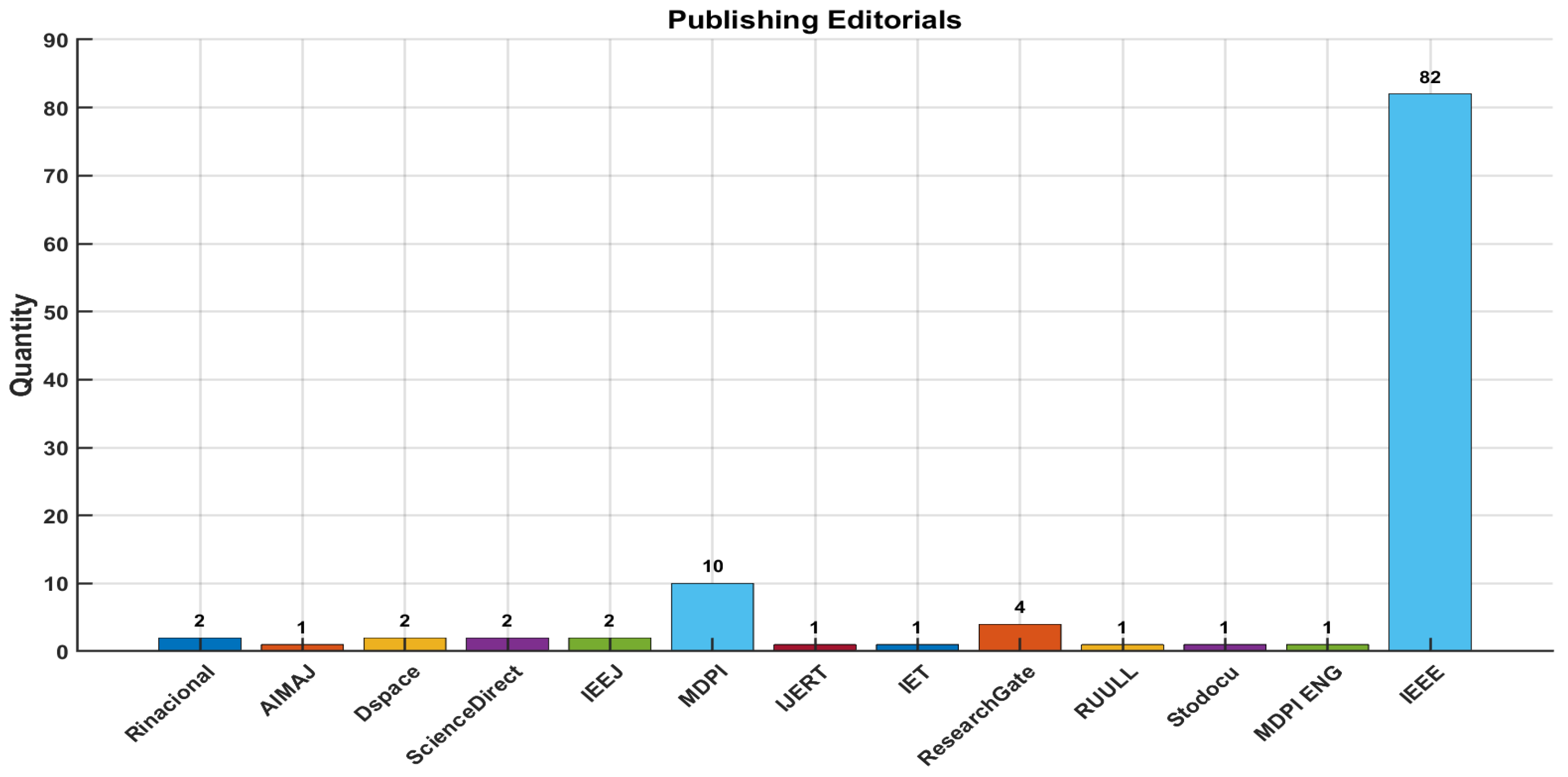

3. Results

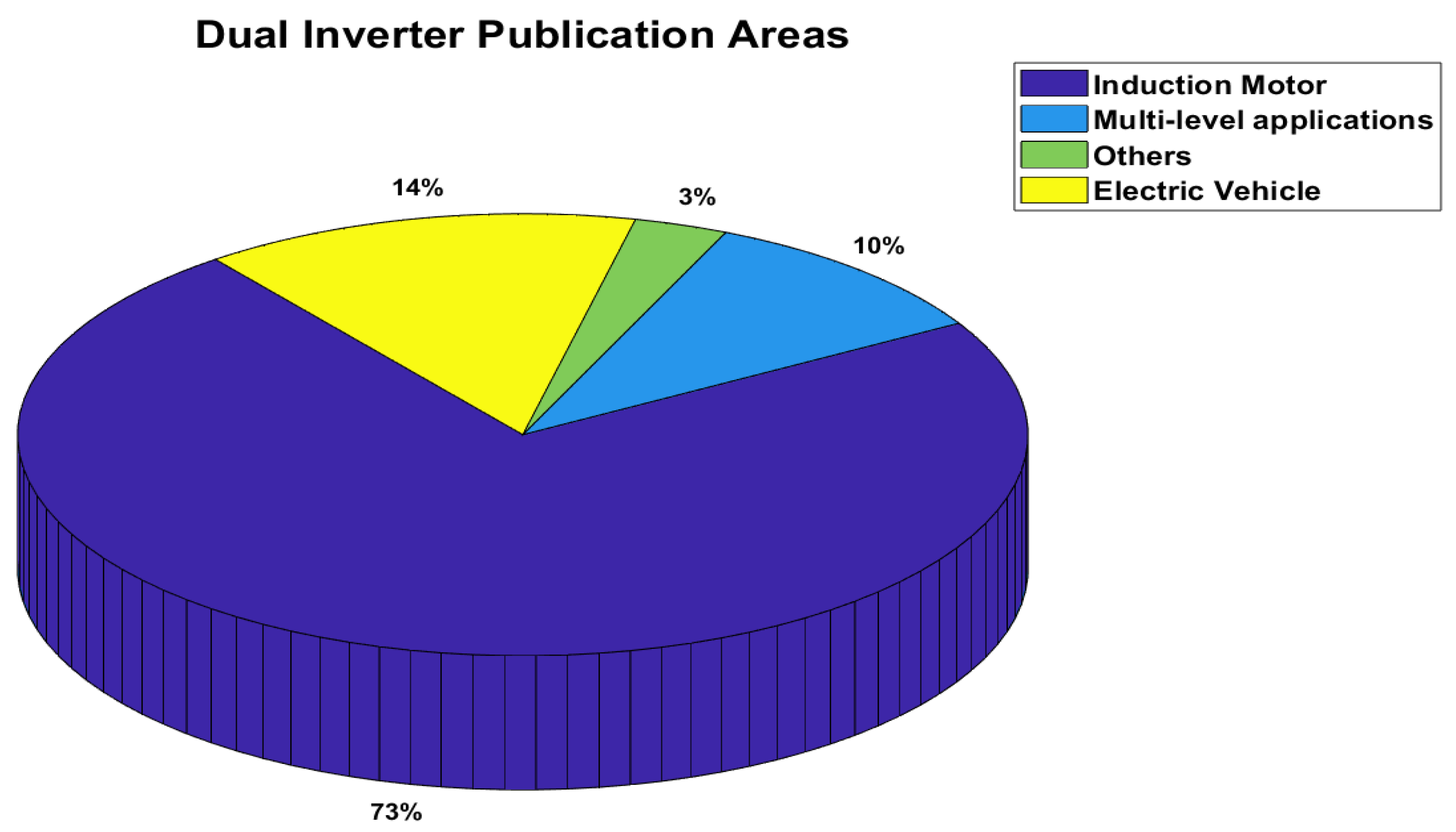

3.1. Applications

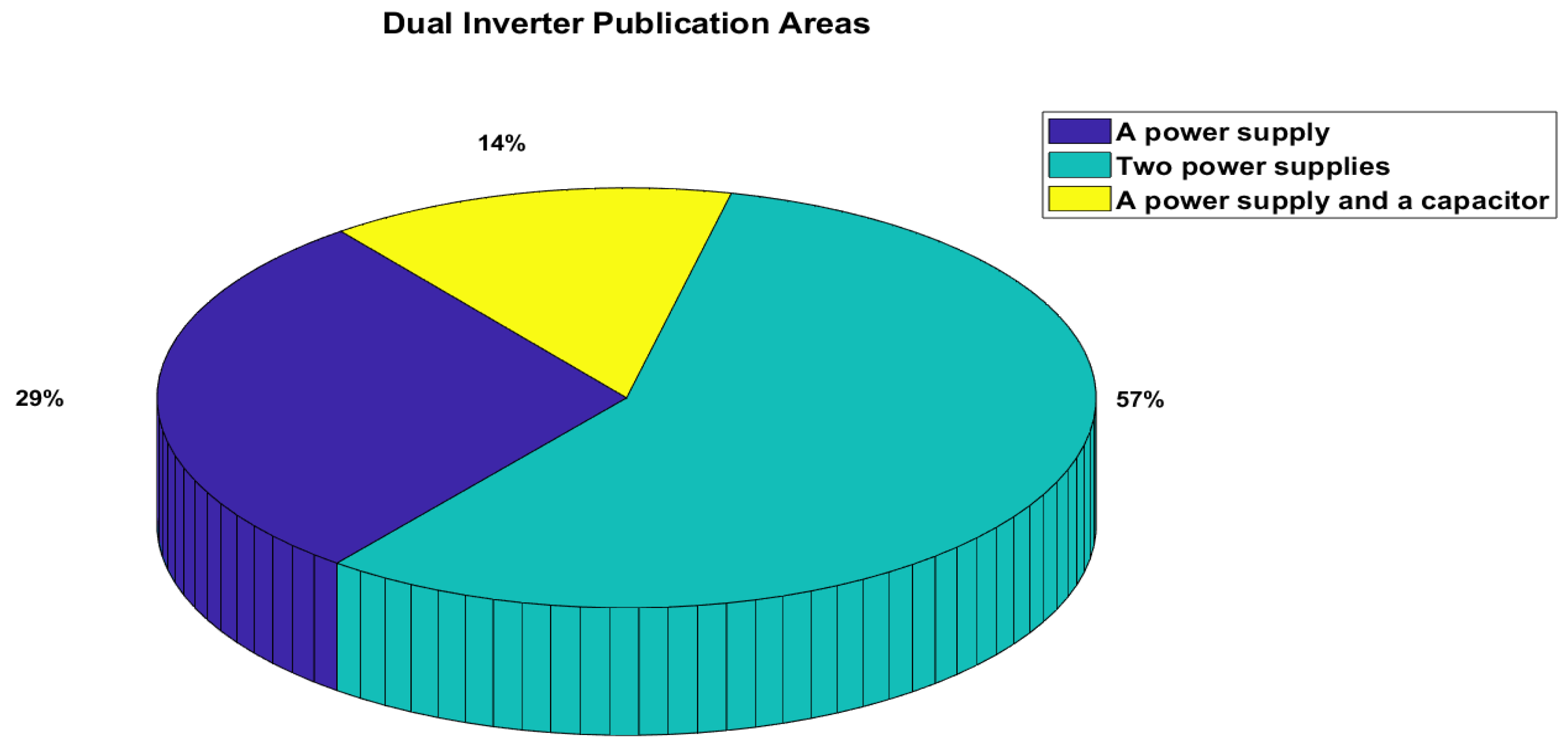

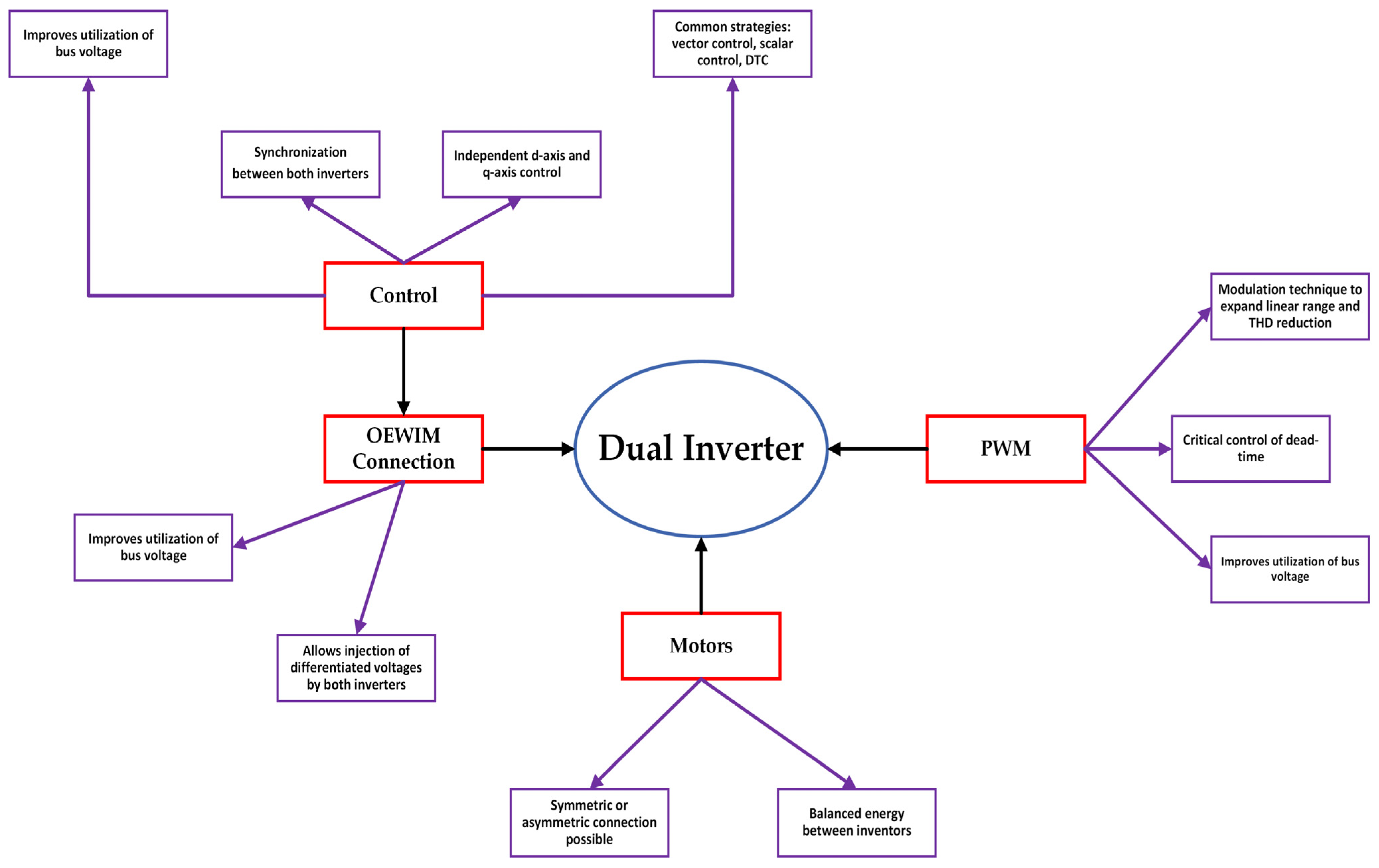

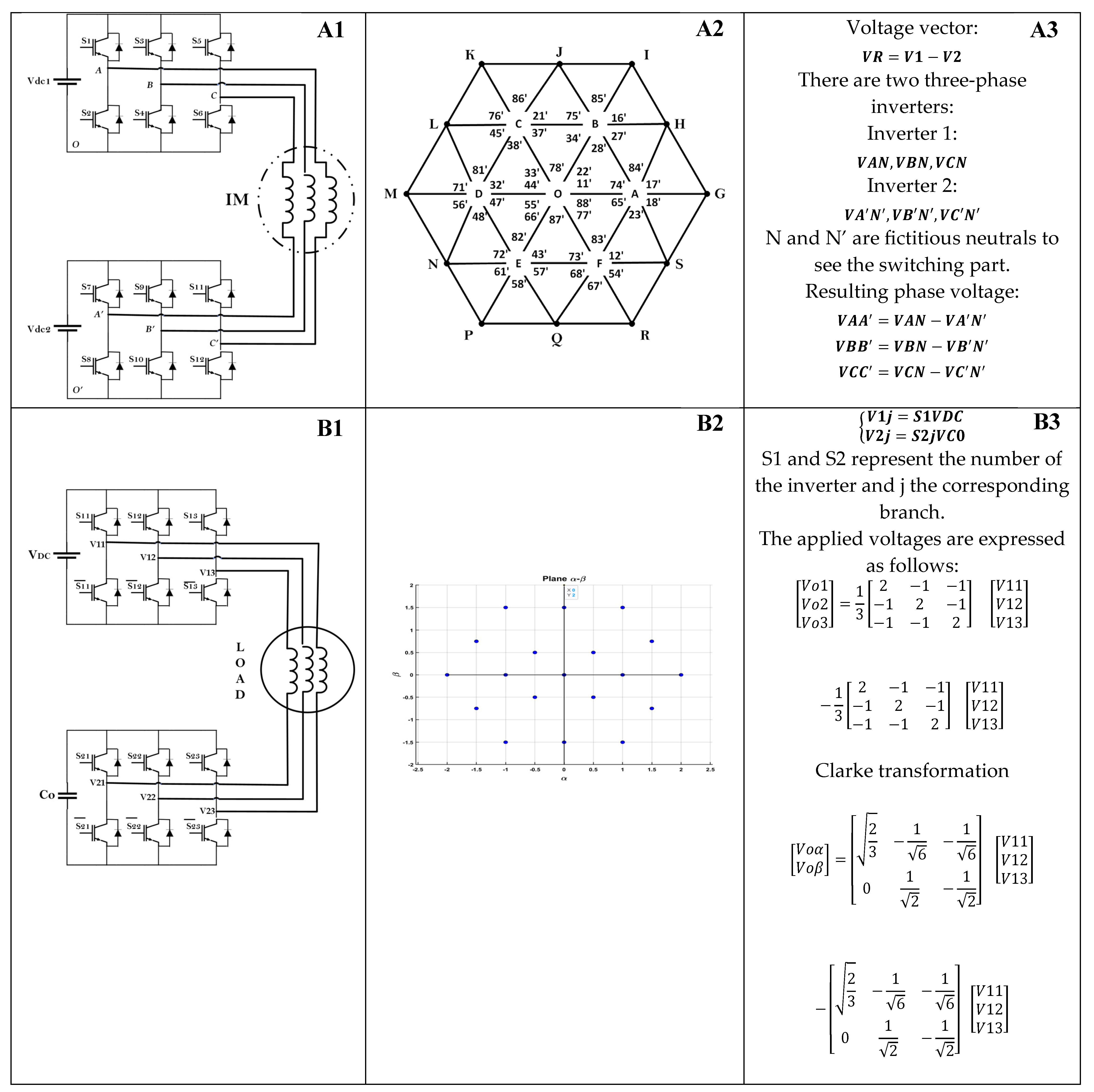

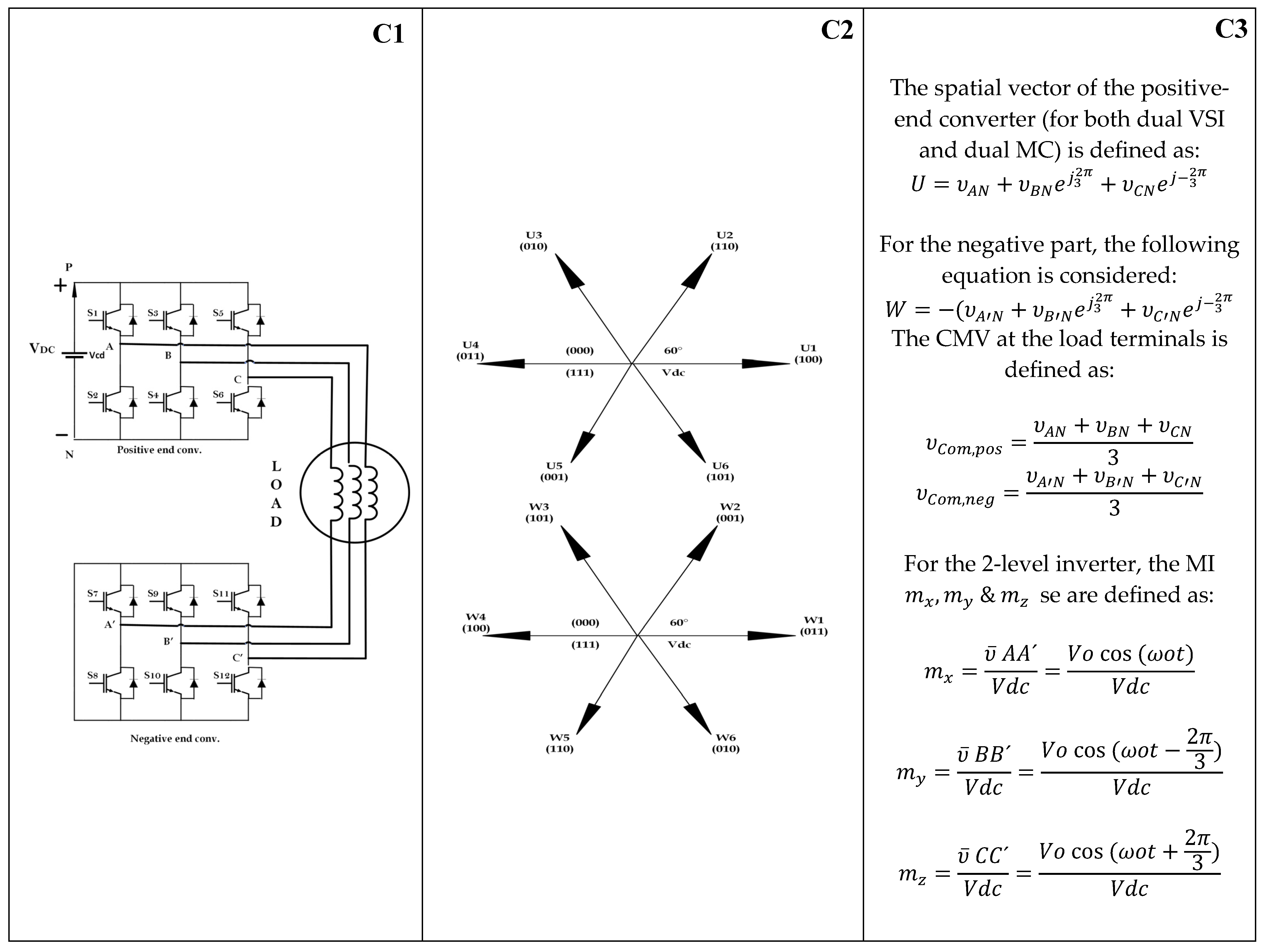

3.2. Architecture of Dual Inverters

3.3. Future Trends

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vasquez Libreros, I. Convertidor Fuente Z Como Técnica de Reconfiguración en el Inversor Multinivel en Cascada; Secretaría de Educación Pública: Mexico City, Mexico, 2018. [Google Scholar]

- Jain, S.; Ramulu, C.; Padmanaban, S.; Ojo, J.O.; Ertas, A.H. Dual MPPT algorithm for dual PV source fed open-end winding induction motor drive for pumping application. Eng. Sci. Technol. Int. J. 2016, 19, 1771–1780. [Google Scholar] [CrossRef]

- Lee, S.S.; Lim, C.S.; Siwakoti, Y.P.; Lee, K.-B. Dual-T-type five-level cascaded multilevel inverter with double voltage boosting gain. IEEE Trans. Power Electron. 2020, 35, 9522–9529. [Google Scholar] [CrossRef]

- Baia, G.; De Caro, S.; Foti, S.; Khan, H.; Testa, A. Efficiency Assessment of an Open-End Winding Inverter Exploiting a Mixed Si/GaN Technology. In Proceedings of the 2023 25th European Conference on Power Electronics and Applications (EPE’23 ECCE Europe), Aalborg, Denmark, 4–8 September 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–9. [Google Scholar]

- Rizki, F.R.M.; Riyadi, S.; Pratomo, L.H. A SPWM Controlled Input in Dual Buck DC-DC Converter–Full Bridge for Single-Phase Five-Level Inverter. J. Phys. Conf. Ser. 2020, 1444, 012031. [Google Scholar] [CrossRef]

- Wang, Y.; Ge, H.; Yin, H.; Wu, B.; Yang, F. Improved SVPWM modulation method for three-phase dual-input dual-buck inverters. J. Power Electron. 2023, 23, 736–745. [Google Scholar] [CrossRef]

- Verma, A.; Gaikwad, P.; Hussein, L.; Goyal, H.R.; Kumar, M.; Michaelson, J.; Kumar, Y. Performance and Analysis of PWM Strategy with PV-Based Multilevel Hybrid Inverter. In Proceedings of the 2024 1st International Conference on Sustainable Computing and Integrated Communication in Changing Landscape of AI (ICSCAI), Greater Noida, India, 4–6 July 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–7. [Google Scholar]

- Zúñiga Kalab, E.J. Bobinado de Motor Asíncrono Trifásico de c.a. 2020. Available online: http://riull.ull.es/xmlui/handle/915/20408 (accessed on 25 September 2025).

- Merizalde, Y.; Hernández-Callejo, L.; Duque-Perez, O. State of the art and trends in the monitoring, detection and diagnosis of failures in electric induction motors. Energies 2017, 10, 1056. [Google Scholar] [CrossRef]

- Jia, Y.-F.; Chu, L.; Xu, N.; Li, Y.-K.; Zhao, D.; Tang, X. Power sharing and voltage vector distribution model of a dual inverter open-end winding motor drive system for electric vehicles. Appl. Sci. 2018, 8, 254. [Google Scholar] [CrossRef]

- Gudhe, S.; Singh, S.; Rezkallah, M.; Chandra, A. Dynamic control of traction motor for EV fed via dual source inverter with a two battery system. Energies 2023, 16, 1754. [Google Scholar] [CrossRef]

- Lei, J.; Feng, G.; Liu, C.; Xia, Y.; Hua, W. A dual inverter topology with quasi-isolated power supplies for more electric aircraft applications. IEEE Trans. Power Electron. 2022, 38, 2889–2895. [Google Scholar] [CrossRef]

- Mizukoshi, A.; Haga, H. Reduction of voltage harmonics in an open-end winding induction motor driven by a dual-inverter with a floating capacitor in a partial-load condition. IEEJ J. Ind. Appl. 2021, 10, 564–574. [Google Scholar] [CrossRef]

- Chakrabarti, A.; Saha, A.; Biswas, S.K. Winding open-circuit fault-tolerant operation of single DC-link dual-inverter fed three-phase open-end induction motor drive. IET Power Electron. 2021, 14, 1256–1270. [Google Scholar] [CrossRef]

- Bahena, A.; De León Aldaco, S.E.; Alquicira, J. Simulation for a dual inverter feeding a three-phase open-end winding induction motor: A comparative study of PWM techniques. Eur. J. Electr. Eng. 2020, 22, 13–21. [Google Scholar] [CrossRef]

- Xu, D.; Zhao, W.; Cheng, Y.; Chen, Q.; Xu, L. Power factor improvement of permanent-magnet linear vernier motor by using dual-inverter with hybrid discontinuous PWM. IET Power Electron. 2019, 12, 3438–3446. [Google Scholar] [CrossRef]

- Reddy, B.P.; Keerthipati, S. A multilevel inverter configuration for an open-end-winding pole-phase-modulated-multiphase induction motor drive using dual inverter principle. IEEE Trans. Ind. Electron. 2017, 65, 3035–3044. [Google Scholar] [CrossRef]

- Janssen, T.; Krishnaswami, H. Fault-tolerant control for a modular cascaded NPC inverter configuration. In Proceedings of the 2016 IEEE 17th Workshop on Control and Modeling for Power Electronics (COMPEL), Trondheim, Norway, 27–30 June 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–7. [Google Scholar]

- Harsha, N.S.; Anitha, G.; Sreedevi, A. Modified Dual Three-Pulse Modulation technique for single-phase inverter topology. In Proceedings of the 2015 International Conference on Green Computing and Internet of Things (ICGCIoT), Greater Noida, India, 8–10 October 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1418–1423. [Google Scholar]

- Srinivas, S. Predictive current control of an open end winding induction machine using a dual two-level inverter drive. In Proceedings of the 2019 IEEE 28th International Symposium on Industrial Electronics (ISIE), Vancouver, BC, Canada, 12–14 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 378–383. [Google Scholar]

- Rakesh, T.; Suresh, K. Bearing Currents and Shaft Voltage Reduction in Dual-Inverter-Fed Open-End Winding Induction Motor With CMV PWM Methods Employing PID. Int. J. Eng. Dev. Res. 2016, 4, 1899–1904. [Google Scholar]

- Jia, Y.-F.; Xu, N.; Chu, L.; Zhang, L.-F.; Zhao, D.; Li, Y.-K.; Yang, Z.-H. Power flow control strategy based on the voltage vector distribution for a dual power electric vehicle with an open-end winding motor drive system. IEEE Access 2018, 6, 54910–54926. [Google Scholar] [CrossRef]

- Khan, M.A.; Gupta, S.K.; Singh, O. Pulse width modulation switching analysis for three phase dual inverter system using artificial neural network. In Proceedings of the 2018 Australasian Universities Power Engineering Conference (AUPEC), Auckland, New Zealand, 27–30 November 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar]

- Zheng, J.; Yang, S.; Xie, Z.; Zhang, X.; Chang, L. Multi-Objective PWM Strategy with Independent ZSC Suppression, CMV Variation Elimination, and NPV Balance for OEWIM Fed by Dual Three-Level VSI. IEEE J. Emerg. Sel. Top. Power Electron. 2025, 13, 1-1. [Google Scholar] [CrossRef]

- Perera, C.; Salmon, J.; Kish, G.J. Multiport converter with enhanced port utilization using multitasking dual inverters. IEEE Open J. Power Electron. 2021, 2, 511–522. [Google Scholar] [CrossRef]

- Khadar, S.; Kaddouri, A.M.; Kouzou, A.; Hafaifa, A.; Kennel, R.; Abdelrahem, M. Experimental validation of different control techniques applied to a five-phase open-end winding induction motor. Energies 2023, 16, 5288. [Google Scholar] [CrossRef]

- Eswar, K.M.R.; Kumar, K.V.P.; Kumar, T.V. A simplified predictive torque control scheme for open-end winding induction motor drive. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 7, 1162–1172. [Google Scholar] [CrossRef]

- Chowdhury, S.; Wheeler, P.W.; Gerada, C.; Patel, C. Model predictive control for a dual-active bridge inverter with a floating bridge. IEEE Trans. Ind. Electron. 2016, 63, 5558–5568. [Google Scholar] [CrossRef]

- Kumar, N.; Saha, T.K.; Dey, J. Sliding mode control, implementation and performance analysis of standalone PV fed dual inverter. Sol. Energy 2017, 155, 1178–1187. [Google Scholar] [CrossRef]

- Lodi, K.A.; Beig, A.R.; Al Jaafari, K.A.; Aung, Z. Ann-based improved direct torque control of open-end winding induction motor. IEEE Trans. Ind. Electron. 2024, 71, 12030–12040. [Google Scholar] [CrossRef]

- Wu, D.; Wu, X.; Su, L.; Yuan, X.; Xu, J. A dual three-level inverter-based open-end winding induction motor drive with averaged zero-sequence voltage elimination and neutral-point voltage balance. IEEE Trans. Ind. Electron. 2016, 63, 4783–4795. [Google Scholar] [CrossRef]

- Lakhimsetty, S.; Surulivel, N.; Somasekhar, V. Improvised SVPWM strategies for an enhanced performance for a four-level open-end winding induction motor drive. IEEE Trans. Ind. Electron. 2016, 64, 2750–2759. [Google Scholar] [CrossRef]

- Lim, Y.-S.; Lee, J.-S.; Lee, K.-B. Advanced speed control for a five-leg inverter driving a dual-induction motor system. IEEE Trans. Ind. Electron. 2018, 66, 707–716. [Google Scholar] [CrossRef]

- Zuo, Y.; Zhu, X.; Si, X.; Lee, C.H. Fault-tolerant control for multiple open-leg faults in open-end winding permanent magnet synchronous motor system based on winding reconnection. IEEE Trans. Power Electron. 2020, 36, 6068–6078. [Google Scholar] [CrossRef]

- Pires, V.F.; Cordeiro, A.; Foito, D.; Pires, A.; Silva, J.F.; Chen, H. Multilevel Inverter Based on a Dual Two-Level Nine-Switch Converter for a Dual Three-Phase or Six-Phase Motor Drive System. IEEE Access 2025, 13, 37263–37277. [Google Scholar] [CrossRef]

- Sankarrao, R.; Pramanick, S. Dodecagonal Voltage Space Vector-Based Hybrid PWM Technique for the Reduction of Torque Ripple in OEWIM Drive. IEEE Trans. Energy Convers. 2025, 40, 1274–1287. [Google Scholar] [CrossRef]

- Mizukoshi, A.; Haga, H.; Sakasegawa, E. Evaluation of the Output Voltage Harmonics of Typical PWM Methods in a Dual-inverter Fed Open-End Winding Induction Motor with a Floating-capacitor. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Singapore, 24–27 May 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 4896–4901. [Google Scholar]

- Chowdhury, S.; Wheeler, P.W.; Patel, C.; Gerada, C. A multilevel converter with a floating bridge for open-end winding motor drive applications. IEEE Trans. Ind. Electron. 2016, 63, 5366–5375. [Google Scholar] [CrossRef]

- Reddy, M.H.V.; Reddy, T.B.; Reddy, B.R.; Kalavathi, M.S. Discontinuous PWM technique for the asymmetrical dual inverter configuration to eliminate the overcharging of DC-link capacitor. IEEE Trans. Ind. Electron. 2017, 65, 156–166. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, X.; Cao, R. A zero-sequence steerable CBPWM strategy for eliminating zero-sequence current of dual-inverter fed open-end winding transformer based PV grid-tied system with common DC bus. IEEE Access 2020, 8, 81220–81231. [Google Scholar] [CrossRef]

- Oto, Y.; Noguchi, T.; Sasaya, T.; Yamada, T.; Kazaoka, R. Space vector modulation of dual-inverter system focusing on improvement of multilevel voltage waveforms. IEEE Trans. Ind. Electron. 2018, 66, 9139–9148. [Google Scholar] [CrossRef]

- Zhao, W.; Zhao, P.; Xu, D.; Chen, Z.; Zhu, J. Hybrid modulation fault-tolerant control of open-end windings linear vernier permanent-magnet motor with floating capacitor inverter. IEEE Trans. Power Electron. 2018, 34, 2563–2572. [Google Scholar] [CrossRef]

- Mizukoshi, A.; Haga, H. Reduction of voltage harmonics in an open-end winding induction motor driven by a dual-inverter with floating-capacitor in the low-speed region. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 2656–2661. [Google Scholar]

- Chowdhury, S.; Wheeler, P.; Gerada, C.; Arevalo, S.L. A dual inverter for an open end winding induction motor drive without an isolation transformer. In Proceedings of the 2015 IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 283–289. [Google Scholar]

- Perera, C.; Leng, S.; Kish, G.J.; Salmon, J. Robust floating capacitor voltage control of dual inverter drive for open-ended winding induction motor. In Proceedings of the 2019 IEEE Applied Power Electronics Conference and Exposition (APEC), Anaheim, CA, USA, 17–21 March 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 249–256. [Google Scholar]

- Kumar, A.; Bhat, A.; Agarwal, P. Comparative evaluation of SPS and EPS based dual active bridge converter based on transistor-clamped H-bridge inverter. In Proceedings of the 2022 1st International Conference on Sustainable Technology for Power and Energy Systems (STPES), Srinagar, India, 4–6 July 2022; Curran Associates, Inc.: Red Hook, NY, USA, 2022; pp. 1–6. [Google Scholar]

- Lakhimsetty, S.; Somasekhar, V. A four-level open-end winding induction motor drive with a nested rectifier–inverter combination with two DC power supplies. IEEE Trans. Power Electron. 2018, 34, 8894–8904. [Google Scholar] [CrossRef]

- Khan, A.A.; Cha, H. Dual-buck-structured high-reliability and high-efficiency single-stage buck–boost inverters. IEEE Trans. Ind. Electron. 2017, 65, 3176–3187. [Google Scholar] [CrossRef]

- Can, E. A new multi-level inverter with reverse connected dual dc to dc converter at simulation. Int. J. Model. Simul. 2022, 42, 34–46. [Google Scholar] [CrossRef]

- Nesrin, A.N.; Sukanya, M.; Joseph, K. Switched dual input buckboost inverter for continuous power operation with single stage conversion. In Proceedings of the 2020 International Conference on Power Electronics and Renewable Energy Applications (PEREA), Kannur, India, 27–28 November 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6. [Google Scholar]

- Tanigawa, Y.; Tanaka, H.; Fuji, K.; Shibako, Y.; Neba, Y. Steady-state characteristics of PWM dual current source inverter-fed induction motor with constant dc voltage source. In Proceedings of the 2020 23rd International Conference on Electrical Machines and Systems (ICEMS), Hamamatsu, Japan, 24–27 November 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1464–1467. [Google Scholar]

- Heo, S.; Han, J.; Park, W.-K. Energy storage system with dual power Inverters for islanding operation of microgrid. In Proceedings of the 2020 IEEE International Symposium on Circuits and Systems (ISCAS), Virtual, 10–21 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–4. [Google Scholar]

- Nemade, R.V.; Pandit, J.K.; Aware, M.V. Reconfiguration of T-type inverter for direct torque controlled induction motor drives under open-switch faults. IEEE Trans. Ind. Appl. 2016, 53, 2936–2947. [Google Scholar] [CrossRef]

- Dewangan, N.; Jalhotra, M.; Sahu, L.K.; Gautam, S.P.; Gupta, S. Fault tolerant analysis of single phase multilevel inverter. In Proceedings of the 2018 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Chennai, India, 18–21 December 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–6. [Google Scholar]

- Zhang, T.; Wei, J.; Tao, W.; Zhou, B.; Shi, L. A fault-tolerant strategy for the dual stator doubly salient electro-magnet motor drives with the dual inverter topology. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–7. [Google Scholar]

- An, Q.; Liu, J.; Peng, Z.; Sun, L.; Sun, L. Dual-space vector control of open-end winding permanent magnet synchronous motor drive fed by dual inverter. IEEE Trans. Power Electron. 2016, 31, 8329–8342. [Google Scholar] [CrossRef]

- Vasuda, K.; Johny, L.K.; Mathew, J. Effective DC link utilization of multilevel dual inverter with single source in the maximal distention mode. IEEE Access 2024, 12, 26212–26221. [Google Scholar] [CrossRef]

- Lamine, B.M.; Abdelkader, B.; Abdellah, K.; Mohamed, E.; Korich, B. Comparative Analysis of Two SVPWM Strategies for Dual Two-Level Inverter Control in Open-End Winding Induction Motors. In Proceedings of the 2024 2nd International Conference on Electrical Engineering and Automatic Control (ICEEAC), Setif, Algeria, 12–14 May 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–5. [Google Scholar]

- Schiedermeier, M.; Schlamp, F.; Rettner, C.; März, M. Analytical calculation of the RMS value and the spectrum of the DC-link current of a dual-inverter. IEEE Trans. Power Electron. 2021, 37, 782–794. [Google Scholar] [CrossRef]

- Smith, I.J.; Salmon, J. High-efficiency operation of an open-ended winding induction motor using constant power factor control. IEEE Trans. Power Electron. 2018, 33, 10663–10672. [Google Scholar] [CrossRef]

- Mizukoshi, A.; Haga, H. Improvement of output voltage waveform in dual inverter fed open-winding induction motor at low speed area. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 5422–5427. [Google Scholar]

- Mizukoshi, A.; Haga, H. Control method for reducing the motor loss of dual-inverter fed open-end winding induction motor in the low-speed region. IEEJ J. Ind. Appl. 2020, 9, 27–35. [Google Scholar] [CrossRef]

- Darijevic, M.; Jones, M.; Dordevic, O.; Levi, E. Decoupled PWM control of a dual-inverter four-level five-phase drive. IEEE Trans. Power Electron. 2016, 32, 3719–3730. [Google Scholar] [CrossRef]

- Nirsha, K.; Rajeevan, P. A direct torque control scheme for dual inverter fed induction motor drive with a common dc voltage source. In Proceedings of the IECON 2017-43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1674–1679. [Google Scholar]

- Okumura, R.; Haga, H. Low-Speed Operation of a Motor Drive System Using Dual Inverters to Reduce Input Current Harmonics. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 2662–2667. [Google Scholar]

- Kumar, G.N.; Srinivas, S. Carrier based PWM methods for CMV elimination in open-end winding induction motor drive. In Proceedings of the 2018 IEEE 12th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG 2018), Doha, Qatar, 10–12 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–6. [Google Scholar]

- Hotchkiss, E.; Chen, W.; Bazzi, A. Control-Strategy-Based Reconfiguration to Mitigate Short Circuit Faults in NPC Inverters. In Proceedings of the 2018 IEEE Transportation Electrification Conference and Expo (ITEC), Long Beach, CA, USA, 13–15 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 783–787. [Google Scholar]

- Liu, C.; Lei, J.; Hua, W.; Zhang, H.; Xi, Y.; Wang, S. A modulation scheme to suppress common-mode voltage of four-level dual inverter. In Proceedings of the 2022 IEEE 5th International Electrical and Energy Conference (CIEEC), Nanjing, China, 27–29 May 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 3613–3619. [Google Scholar]

- Chowdhury, S.; Wheeler, P.; Gerada, C.; Rivera, M. Modulated model predictive control of assymetric source dual inverter system for open end winding induction motor drive. In Proceedings of the 2017 IEEE Southern Power Electronics Conference (SPEC), Puerto Varas, Chile, 4–7 December 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–7. [Google Scholar]

- Piao, C.; Hung, J.Y. A novel SVPWM overmodulation technique for three-level NPC VSI. In Proceedings of the 2015 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 14–17 June 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–6. [Google Scholar]

- Yang, S.; Sun, X.; Ma, M.; Zhang, X.; Chang, L. Fault detection and identification scheme for dual-inverter fed OEWIM drive. IEEE Trans. Ind. Electron. 2019, 67, 6112–6123. [Google Scholar] [CrossRef]

- Maddugari, S.K.; Borghate, V.B.; Sabyasachi, S.; Sanjeevini, G. A Reliable Fault Tolerant Inverter. In Proceedings of the 2020 IEEE First International Conference on Smart Technologies for Power, Energy and Control (STPEC), Nagpur, India, 25–26 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–5. [Google Scholar]

- Kim, S.-M.; Lee, J.-S.; Lee, K.-B. Fault-tolerant strategy using neutral-shift method for cascaded multilevel inverters based on level-shifted PWM. In Proceedings of the 2015 9th International Conference on Power Electronics and ECCE Asia (ICPE-ECCE Asia), Seoul, Republic of Korea, 1–5 June 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1327–1332. [Google Scholar]

- Shen, Z.; Jiang, D.; Zou, T.; Qu, R. Dual-segment three-phase PMSM with dual inverters for leakage current and common-mode EMI reduction. IEEE Trans. Power Electron. 2018, 34, 5606–5619. [Google Scholar] [CrossRef]

- Ohno, Y.; Haga, H. Control Method of Electrolytic Capacitor-less Dual Inverter Fed IPMSM for Reducing Torque Ripple under Grid Disturbance. IEEJ J. Ind. Appl. 2022, 11, 623–633. [Google Scholar] [CrossRef]

- Safsouf, K.; Sawma, J.; Kanaan, H.Y. Adaptive Dynamic Power Allocation for Enhanced Performance in Fuel Cell-Supercapacitor OEWIM Systems. In Proceedings of the IECON 2024—50th Annual Conference of the IEEE Industrial Electronics Society, Chicago, IL, USA, 3–6 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar]

- Hota, A.; Agarwal, V. Novel three-phase H10 inverter topology with zero or constant common-mode voltage for three-phase induction motor drive applications. IEEE Trans. Ind. Electron. 2021, 69, 7522–7525. [Google Scholar] [CrossRef]

- Jahan, S.; Kibria, M.F.; Biswas, S.P.; Islam, M.R.; Rahman, M.A.; Muttaqi, K.M. H9 and H10 transformer-less solar photovoltaic inverters for leakage current suppression and harmonic current reduction. IEEE Trans. Ind. Appl. 2022, 59, 2446–2457. [Google Scholar] [CrossRef]

- Gandhi, K.; Gupta, S. Operation Strategies and Energy Market Structure for Hybrid Microgrid Using Intelligent Techniques. In Proceedings of the 2023 9th IEEE India International Conference on Power Electronics (IICPE), Sonipat, India, 28–30 November 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–5. [Google Scholar]

- Muduli, U.R.; Beig, A.R.; Al Jaafari, K.; Alsawalhi, J.Y.; Behera, R.K. Interrupt-free operation of dual-motor four-wheel drive electric vehicle under inverter failure. IEEE Trans. Transp. Electrif. 2020, 7, 329–338. [Google Scholar] [CrossRef]

- Kimura, T.; Yamada, T.; Kazaoka, R.; Noguchi, T. Control method of dual inverter system for EV with one battery. IEEJ J. Ind. Appl. 2023, 12, 376–383. [Google Scholar] [CrossRef]

- Drisya, V.; Samina, T. Supply voltage boosting in a 3 level space vector modulated dual inverter fed open end winding induction motor drive for hybrid electric vehicles. In Proceedings of the 2015 IEEE Recent Advances in Intelligent Computational Systems (RAICS), Trivandrum, India, 10–12 December 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 330–334. [Google Scholar]

- Khaneghah, M.Z.; Alzayed, M.; Chaoui, H. Fault detection and diagnosis of the electric motor drive and battery system of electric vehicles. Machines 2023, 11, 713. [Google Scholar] [CrossRef]

- Kumar, A.; Sahoo, S.B.; Behera, R.K.; Al Hosani, K.; Muduli, U.R. Robust OEWIM Drive for Optimized EV Powertrain Performance with DTC and ZSV Mitigation. In Proceedings of the 2024 IEEE Energy Conversion Congress and Exposition (ECCE), Phoenix, AZ, USA, 20–24 October 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 5899–5904. [Google Scholar]

- Said, N.M.; Xiao, D.; Dutta, R.; Fletcher, J. Control strategy of post-fault operation in dual inverter-fed, PMSM considering zero sequence and back-emf harmonic. In Proceedings of the 8th IET International Conference on Power Electronics, Machines and Drives (PEMD 2016), Glasgow, UK, 19–21 April 2016; Curran Associates, Inc.: Red Hook, NY, USA, 2016; pp. 1–6. [Google Scholar]

- Oto, Y.; Noguchi, T. Fault-tolerant function of DC-bus power source in a dual inverter drive system and its operation characteristics. IEEJ J. Ind. Appl. 2019, 8, 953–959. [Google Scholar] [CrossRef]

- Lv, K.; Dong, X.; Zhu, C. Research on fault-tolerant operation strategy of permanent magnet synchronous motor with common dc bus open winding phase-breaking fault. Energies 2022, 15, 2927. [Google Scholar] [CrossRef]

- Jiang, X.; Huang, W.; Cao, R.; Hao, Z.; Jiang, W. Fault tolerant control of dual-winding fault-tolerant permanent magnet motor drive with three-phase four-leg inverter. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–6. [Google Scholar]

- Yang, S.-H.; Yang, Y.-H.; Chen, K.-H.; Lin, Y.-H.; Tsai, T.-Y.; Lin, S.-R.; Lee, C.-C. A low-THD class-D audio amplifier with dual-level dual-phase carrier pulsewidth modulation. IEEE Trans. Ind. Electron. 2015, 62, 7181–7190. [Google Scholar] [CrossRef]

- Monisha, M.A.; Jacob, B. Space vector pulse density modulation scheme for zero sequence voltage elimination in dual inverter fed open end winding induction motor drive. In Proceedings of the IECON 2020 the 46th Annual Conference of the IEEE Industrial Electronics Society, Phoenix, AZ, USA, 20–24 October 2024; IEEE: Piscataway, NJ, USA, 2020; pp. 1096–1101. [Google Scholar]

- Kim, T.-H.; Lee, J.-H.; Yoon, B.-R.; Lee, J.-S. Clamping modulation technique for balancing power losses of dual inverter with isolated dc bus. IEEE Access 2023, 11, 41868–41879. [Google Scholar] [CrossRef]

- Chen, M.; Sun, D. A unified space vector pulse width modulation for dual two-level inverter system. IEEE Trans. Power Electron. 2016, 32, 889–893. [Google Scholar] [CrossRef]

- Menon, R.; Williamson, S.S.; Azeez, N.A.; Kadam, A.H. A fault tolerant modulation strategy for dual inverter traction drives. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 5856–5861. [Google Scholar]

- Huang, Z.; Yang, T.; Giangrande, P.; Galea, M.; Wheeler, P. Technical review of dual inverter topologies for more electric aircraft applications. IEEE Trans. Transp. Electrif. 2021, 8, 1966–1980. [Google Scholar] [CrossRef]

- Abuzyarov, T.; Plekhov, A. Algorithm of Field-Oriented Control of a Dual Inverter-Fed Stepper Drive with Use of the Lookup Table. In Proceedings of the 2021 3rd International Conference on Control Systems, Mathematical Modeling, Automation and Energy Efficiency (SUMMA), Lipetsk, Russia, 10–12 November 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1061–1065. [Google Scholar]

- Kiadehi, A.D.; Drissi, K.E.K.; Pasquier, C. Voltage THD reduction for dual-inverter fed open-end load with isolated DC sources. IEEE Trans. Ind. Electron. 2016, 64, 2102–2111. [Google Scholar] [CrossRef]

- Vaicys, J.; Norkevicius, P.; Baronas, A.; Gudzius, S.; Jonaitis, A.; Peftitsis, D. Efficiency evaluation of the dual system power inverter for on-grid photovoltaic system. Energies 2021, 15, 161. [Google Scholar] [CrossRef]

- Singh, A.; Grant, B.; DeFour, R.; Sharma, C.; Bahadoorsingh, S. A review of induction motor fault modeling. Electr. Power Syst. Res. 2016, 133, 191–197. [Google Scholar] [CrossRef]

- Diab, A.A.Z.; Al-Sayed, A.-H.M.; Abbas Mohammed, H.H.; Mohammed, Y.S. Literature review of induction motor drives. In Development of Adaptive Speed Observers for Induction Machine System Stabilization; SpringerBriefs in Electrical and Computer Engineering; Springer: Singapore, 2020; pp. 7–18. [Google Scholar] [CrossRef]

- Xiao, Q.; Jin, Y.; Jia, H.; Tang, Y.; Cupertino, A.F.; Mu, Y.; Teodorescu, R.; Blaabjerg, F.; Pou, J. Review of fault diagnosis and fault-tolerant control methods of the modular multilevel converter under submodule failure. IEEE Trans. Power Electron. 2023, 38, 12059–12077. [Google Scholar] [CrossRef]

- Ma, J.; Xue, Y.; Han, Q.; Li, X.; Yu, C. Motor bearing damage induced by bearing current: A Review. Machines 2022, 10, 1167. [Google Scholar] [CrossRef]

- Tautz-Weinert, J.; Watson, S.J. Using SCADA data for wind turbine condition monitoring—A review. IET Renew. Power Gener. 2017, 11, 382–394. [Google Scholar] [CrossRef]

- Pires, V.F.; Cordeiro, A.; Silva, J.F. Dual inverter with a floating bridge controlled by a vectorial voltage modulator. In Proceedings of the 2018 16th Biennial Baltic Electronics Conference (BEC), Tallinn, Estonia, 8–10 October 2018; Curran Associates, Inc.: Red Hook, NY, USA, 2018; pp. 1–4. [Google Scholar]

- Kumar, V.; Kumar, S. A 3-level inverter based induction motor drive for cane preparation in sugar industry. In Proceedings of the 2019 2nd International Conference on Power Energy, Environment and Intelligent Control (PEEIC), Greater Noida, India, 18–19 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 190–195. [Google Scholar]

- Mousavi, M.S.; Davari, S.A.; Nekoukar, V.; Norambuena, M.; Rodriguez, J.; Wang, F. Four-Stage Cascaded Predictive Control for Zero-Sequence Current Suppression of Open-End Winding Induction Motor. In Proceedings of the 2020 11th Power Electronics, Drive Systems, and Technologies Conference (PEDSTC), Tehran, Iran, 4–6 February 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6. [Google Scholar]

- Nadh, G.; Nair, D. Modulation scheme with common mode and differential mode voltage elimination for a five level inverter fed open end winding induction motor drive. In Proceedings of the 2020 22nd European Conference on Power Electronics and Applications (EPE’20 ECCE Europe), Lyon, France, 7–11 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–8. [Google Scholar]

- Muduli, U.R.; Beig, A.R.; Behera, R.K.; Al Jaafari, K.; Alsawalhi, J.Y. Predictive control with battery power sharing scheme for dual open-end-winding induction motor based four-wheel drive electric vehicle. IEEE Trans. Ind. Electron. 2021, 69, 5557–5568. [Google Scholar] [CrossRef]

- Mousavi, M.S.; Davari, S.A.; Nekoukar, V.; Rodriguez, J. Robust predictive current control for a dual inverter fed open-end winding induction motor. In Proceedings of the 2019 10th International Power Electronics, Drive Systems and Technologies Conference (PEDSTC), Shiraz, Iran, 12–14 February 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 96–101. [Google Scholar]

- Safsouf, K.A.; Sawma, J.; Kanaan, H.Y. Mitigating Voltage Saturation in Multi-Source Open-End Winding Induction Motor Systems for Electric Vehicles. IEEE J. Emerg. Sel. Top. Ind. Electron. 2025, 6, 1534–1545. [Google Scholar] [CrossRef]

- Yan, C.; Zou, S.; Xu, D. Power control for dual-input DC/AC inverter. In Proceedings of the 2015 IEEE 6th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Aachen, Germany, 22–25 June 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–8. [Google Scholar]

- Dabour, S.M.; Aboushady, A.A.; Gowaid, I.; Elgenedy, M.A.; Farrag, M.E. Analysis and control of simplified dual-output single-phase split-source boost inverters. In Proceedings of the 2022 23rd International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 13–15 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–5. [Google Scholar]

- Yang, G.; Chen, M.; Guo, L.; Dou, Z.; Sun, Y.; Jin, N. A dual-vector modulated MPC method for grid-tied inverter: Visualization analysis and verification. In Proceedings of the 2021 IEEE International Conference on Predictive Control of Electrical Drives and Power Electronics (PRECEDE), Jinan, China, 20–22 November 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 765–769. [Google Scholar]

- Mousavi, M.S.; Davari, S.A.; Nekoukar, V.; Garcia, C.; Rodriguez, J. Computationally efficient model-free predictive control of zero-sequence current in dual inverter fed induction motor. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 11, 1332–1344. [Google Scholar] [CrossRef]

| Characteristic | Conventional Inverter | Dual Inverter |

|---|---|---|

| DC Bus Utilization | Medium (≤0.866 Vdc) | High (≈2 × Vdc/√3) |

| Waveform Quality (THD) | Moderate | Low (better filtering) |

| Control Complexity | Low | High |

| Fault Tolerance | Limited | High (redundant operation) |

| Typical Applications | Low-medium power, standard control | High power. EVs, renewables, advanced industrial systems |

| Structure | Reference | Voltage Utilization Factor | Switching Stress | Harmonic Spectrum (THD) | Fault Tolerance Robustness |

|---|---|---|---|---|---|

| Dual Isolated Source | [17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36] | High (almost twice that of a single inverter due to better utilization of the DC bus). | Medium (requires balancing both inverters). | Low THD, especially with SVPWM or advanced techniques. | High, allows power transfer in case of partial faults. |

| Single Source with Capacitor | [37,38,39,40,41,42,43,44,45] | Medium (limited by capacitor voltage). | Low-Medium (fewer devices under stress). | Moderate THD; more sensitive to low-order harmonics. | Medium, capacitor failure may affect stability, but degraded operation is possible. |

| Single Source | [46,47,48,49,50,51,52,53,54,55,56] | Medium-High (utilizing the single source). | Medium-High (greater complexity in energy management). | Low-Medium (due to modulation complexity). | Medium-High, as it combines partial redundancy with some fault tolerance. |

| Topologies | Topology 1 | Topology 2 | Topology 3 |

|---|---|---|---|

| References | [63] | [64] | [65] |

| Switches | 12 | 12 | 12 |

| Sources | 2 | 1 | 1 |

| Diodes | 12 | 12 | 12 |

| Capacitors | 0 | 1 | 0 |

| Utilization Factor | - | −33 | −15 |

| Phase Shift Angle (°) | Harmonic Content | DC Bus Utilization | Control Complexity | Typical Applications | Recommended Modulation Techniques | Reference |

|---|---|---|---|---|---|---|

| 0° | High | Low | Low | Basic control, prototypes, low-demand systems | Synchronized SPWM, Basic SVM | [66] |

| 60° | Medium | Medium | Medium | Industrial motors, HVAC, speed control | Phase-shifted SPWM, Coordinated SVM | [67] |

| 90° | Low | High | High | Electric vehicles, traction converters | Phase-shifted SPWM, Shifted SVM, Alternated DPWM | [68] |

| 120° | Very low | Very high | High | Multi-axis inverters, precision systems, robotics | Advanced SVM, 120° SPWM, Balanced DPWM | [69] |

| 180° | Variable (case-dependent) | Medium | Medium | Selective harmonic suppression, improved EMC | Inverted SPWM, Hybrid Modulation Strategies | [70] |

| Categories | Articles/Authors | Description |

|---|---|---|

| Electric Vehicles | [80] | It uses induction motors with open windings and two inverters connected to a dual-motor system (front and rear motor) in a D4WD configuration. |

| [81] | A control method is proposed for electric vehicles (EVs) with a dual inverter system and a battery. | |

| [82] | In this article, one of the inverters is powered by a floating capacitor, so that the supply voltage remains constant. | |

| [83] | It provides a comprehensive overview of potential faults in EV motor drive systems and batteries. | |

| [84] | This paper proposes an operating strategy for a frequency converter for an open-ended induction motor powered by MI and T-type inverters, using MATLAB/SIMULINK. | |

| Dual Inverter Failures | [85] | This article presents the ability of the open-end winding of a dual inverter to manage faults and continue operating when they occur. |

| [86] | This article proposes a fault tolerance function for the DC bus battery. | |

| [87] | A zero-sequence current suppression strategy is proposed for a common DC bus subjected to a phase break fault. | |

| [88] | It provides a robust predictive current control scheme for an induction motor (OEWIM). | |

| Modulation of dual inverters | [89] | A modulation method is proposed to maximize the output power of the inverter and motor with reduced losses and harmonics. |

| [90] | A space vector-based pulse density modulation scheme is presented to eliminate zero-sequence voltage. | |

| [91] | A clamping modulation technique is proposed to reduce and balance power losses in a dual inverter with an isolated DC bus. | |

| [92] | A unified modulation (SVPWM) is proposed for a dual inverter with two isolated DC voltage sources. | |

| [93] | A carrier-based modulation technique is proposed for fault-tolerant operation in a dual inverter drive system. | |

| Aircraft (MEA) | [94] | This article presents a comprehensive review of different dual inverter-based structures. To meet the stringent requirements of MEA applications, three performance aspects are considered: voltage, inverter output, and fault tolerance. |

| Industrial applications (Robotic systems) | [95] | The objective of this work is to develop a field-oriented control (FOC) algorithm for a stepper motor adapted to a dual inverter. |

| THD reduction | [96] | In this article, NSPWM adapted for a dual VSI inverter powered by isolated DC sources is proposed to minimize total harmonic distortion (THD) of the voltage. |

| Grid-connected photovoltaic system | [97] | This research analyzes the potential benefit of a novel three-phase dual-system power inverter over the conventional inverter used in a solar power plant. |

| Review of articles related to dual inverters | [98] | An overview of each type of model is provided, along with its respective advantages and disadvantages for modeling different types of faults. |

| [99] | This article provides a general overview of induction motor (IM) drive systems and analyzes various control methodologies, both in voltage and current. | |

| [100] | This article presents a detailed review of fault diagnosis and fault-tolerant control methods of the MMC in the event of SM faults. | |

| [101,102] | The possible damage caused to induction motors under different conditions is analyzed in detail. |

| Energy Sector | Current Problems | Benefit of Dual OEWIM Inverters |

|---|---|---|

| Renewables (solar/wind) | Generation variability, grid instability | Better voltage control, stable and flexible integration |

| Electric transportation | High maintenance costs, critical failures on the road | Continuous operation under faults, higher reliability and safety |

| Industry and manufacturing | Downtime due to failures, high energy consumption | Lower harmonic losses, operational continuity |

| Energy storage | Low efficiency in charge/discharge cycles | Dynamic optimization of energy flows |

| Smart grids and microgrids | Overloads and intermittency | Real-time adaptation, resilience, and efficient distribution |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adame Najera, E.Z.; De León Aldaco, S.E.; Aguayo Alquicira, J.; Lozoya-Ponce, R.E.; Pecina-Sánchez, J.Á.; Portillo Contreras, S. A Survey on Topologies and Modulation Strategies of Dual Inverters in Industrial Applications. Eng 2025, 6, 316. https://doi.org/10.3390/eng6110316

Adame Najera EZ, De León Aldaco SE, Aguayo Alquicira J, Lozoya-Ponce RE, Pecina-Sánchez JÁ, Portillo Contreras S. A Survey on Topologies and Modulation Strategies of Dual Inverters in Industrial Applications. Eng. 2025; 6(11):316. https://doi.org/10.3390/eng6110316

Chicago/Turabian StyleAdame Najera, Erick Zain, Susana Estefany De León Aldaco, Jesus Aguayo Alquicira, Ricardo Eliu Lozoya-Ponce, José Ángel Pecina-Sánchez, and Samuel Portillo Contreras. 2025. "A Survey on Topologies and Modulation Strategies of Dual Inverters in Industrial Applications" Eng 6, no. 11: 316. https://doi.org/10.3390/eng6110316

APA StyleAdame Najera, E. Z., De León Aldaco, S. E., Aguayo Alquicira, J., Lozoya-Ponce, R. E., Pecina-Sánchez, J. Á., & Portillo Contreras, S. (2025). A Survey on Topologies and Modulation Strategies of Dual Inverters in Industrial Applications. Eng, 6(11), 316. https://doi.org/10.3390/eng6110316