Abstract

Natural fibers have been widely used for reinforcing polymers, attributed to their sustainable nature, light weight, biodegradability, and low cost compared with synthetic fibers, for example, carbon or glass fibers. The objective of this research was to promote the use of natural resource-blended polypropylene (PP) to reduce greenhouse gas emissions and to explore the potential of using grain by-products, such as coconut shell (CS), as fillers for thermoplastic materials. CS (30 wt%) is embedded in the PP matrix of the composite. Thereafter, CS/PP composites were produced utilizing a hot press compounding machine to produce the specimens and a high-speed mixer set at 3000 rpm for five minutes. The impact of coconut shell content on the mechanical and thermal properties of CS/PP composites was examined. The results show the CS/PP composite’s tensile strength and tensile modulus improved by 36% and 30%, respectively. In the meantime, the CS/PP composite’s flexural strength and flexural modulus increased by 16% and 13%, respectively. At a maximum temperature of 260 °C, the CS/PP composite demonstrated thermal stability. Due to the unprocessed particles, the coconut fiber appeared on the surface as homogenous particles. Researchers and industry professionals can use these results to help create new products.

1. Introduction

As a vital natural resource that sustains millions of humans, the coconut tree (Cocos nucifera), which belongs to the palm family, is a prominent player in the small islands of the Pacific [1]. The tough lignocellulose agricultural waste that constitutes the coconut shell is not edible. Coconut shell makes up 15–20% of the coconut [2]. One popular way to remove coconut shells is to burn them openly. However, the biocomposites industry can develop new manufacturing methods using coconut shells as a raw material [3]. These innovative methods can lead to the creation of sustainable products, such as biodegradable packaging and construction materials. By repurposing coconut shells, we not only reduce waste but also promote eco-friendly practices in various industries. Natural-organic fillers are increasingly utilized in the production of polymer composites due to their characteristics, including low density, cost-effectiveness, availability, non-abrasiveness, and renewability [4,5,6,7].

In 2023, Doss et al. [8] investigated the impact of varying coconut fiber content (0–50 wt%) on thermoplastic starch/beeswax composites. Results indicated that higher fiber content enhanced thermal stability and mechanical properties. Notably, the composite with 50 wt% coconut fiber exhibited a tensile strength of 20.7 MPa and a flexural strength of 30.3 MPa, demonstrating the potential of coconut fiber as a reinforcement in biodegradable thermoplastic composites. Meanwhile, Jha & Mishra [9] explored the effects of chemically modifying coconut fibers with alkoxysilanes on poly(lactic acid) (PLA) composites. The study found that silanization improved interfacial bonding, increased crystallinity, and enhanced thermal and dynamic mechanical properties. For instance, the composite with VTMS-modified fibers exhibited a 325% increase in elastic modulus compared to unmodified PLA. In a copolymer of acrylonitrile and butadiene rubber, coconut shell (CS) is a proven cost-effective filler. The composites containing 25 wt% and 50 wt% CS had superior hardness and tensile strength properties compared to those containing 25 wt% of CS [10]. Okpala et al. [11] reported that the tensile strength of the composite improved with the incorporation of coir fiber, reaching a maximum value of 32 MPa at 8 wt% fiber loading. This indicates that the addition of treated coir fiber enhances the tensile properties of the composite up to an optimal concentration. Beyond this level, however, a further increase in fiber content resulted in a significant reduction in tensile strength, likely due to poor fiber dispersion and weak interfacial bonding. Flexural and impact tests further demonstrated similar trends, leading to the conclusion that the incorporation of coir fiber generally enhances the overall mechanical performance of the composite. Senthil et al. [12] investigated the mechanical performance of banana/coir fiber-reinforced epoxy composites. Optimization results revealed that the composite with a 65:35 fiber-to-matrix volume ratio, 10 mm fiber length, and a 75:25 banana-to-coir proportion exhibited superior tensile, compressive, impact, and flexural properties compared to other formulations. This improvement is attributed to the synergistic effect of combining banana fibers, which provide high tensile strength, with coir fibers, which enhance toughness and energy absorption. The optimized fiber length of 10 mm facilitated effective stress transfer while minimizing fiber pull-out and agglomeration. Furthermore, surface morphology analysis confirmed strong interfacial adhesion between the chemically treated fibers and the epoxy matrix, reducing void formation and improving load distribution. These findings highlight that proper fiber ratio, treatment, and length are critical factors in achieving enhanced mechanical performance in hybrid natural fiber composites.

Kumar & Ramesh [13] investigated the thermo-mechanical performance of 3D-printed coir fiber powder/PLA biocomposites. Specimens containing 0.1–0.5 wt% coir fiber were annealed at 90 °C for 120 min. The annealed composite with 0.1 wt% coir fiber exhibited a 13.5% higher tensile strength and a 12.7% higher flexural strength than neat PLA, along with improved crystallinity and thermal stability. Singh et al. [14] developed coir fiber-reinforced composites using glycidyl methacrylate (GMA)-functionalized ethylene butylene acrylate (EBA). The study found that the composites exhibited higher tensile properties than pristine EBA, with increased storage and loss moduli. The 30 wt% coir fiber/EBA composite showed the highest tensile strength of 10.93 MPa. These studies underscore the growing interest in utilizing coconut fiber as a sustainable reinforcement in thermoplastic composites, offering enhanced mechanical properties and environmental benefits. To create high-performance composite materials with the best qualities and ensure the wide use of composite materials, further research and development must be performed on the combination of CS with other natural fibers. In this sense, CS is a perfect filler material because it is widely accessible, affordable, and abundant [15]. Sumesh et al. [16] employed Taguchi-based gray relational analysis to optimize parameters affecting the tensile, flexural, and impact strengths of banana/coir composites. The optimal combination of 20% banana, 15% coir, 3% alkali treatment, 16 MPa pressure, and 100 °C yielded the highest mechanical performance. Moreover, NaOH-treated hybrids exhibited enhanced interfacial bonding, as confirmed by SEM observations. Similarly, Costa et al. [17] investigated epoxy composites reinforced with 10–30 wt% mallow fibers. The 30 wt% composite showed the best overall performance, achieving the highest energy absorption, flexural strength, and modulus of rupture. Consequently, such findings reinforce the potential of plant-based fiber-reinforced polymer composites as sustainable alternatives to synthetic materials due to their renewability, cost-effectiveness, and environmental benefits [18,19]. In a related study, tensile tests revealed that incorporating coir fiber increased composite strength, peaking at 32 MPa at 8 wt% fiber loading, beyond which further addition led to a decline in strength [11]. Furthermore, Costa et al. [20] enhanced the tensile and impact resistance of jute/aramid/HDPE hybrid nanocomposites through the addition of 0.10 wt% graphene nanoplatelets (GNP). The optimized hybrid, consisting of 10 jute and 10 aramid layers, exhibited remarkable improvements: 24.3% in toughness, 59.1% in tensile strength, and a 46.2% reduction in ductility if compared to neat jute/HDPE composites. SEM analysis further confirmed the role of GNP nano-functionalization in strengthening interfacial adhesion and improving failure mechanisms.

In previous years, natural resources, e.g., oil palm, straw, cornstalk, and bagasse, have been used for making composites with acrylonitrile butadiene styrene, polypropylene, polyethylene, polyester, polyurethane, polyvinyl acetate, and polylactic acid [21]. Coconut fiber has been extensively studied in PLA, starch, and EBA matrices; CS has not been adequately explored in a PP matrix. Previous CS composite studies are limited and do not cover thermal and mechanical behavior. Furthermore, there is a limited investigation into how CS affects PP composites specifically, particularly for thermal stability and mechanical reinforcement. Thus, this study’s objective is to investigate how reinforced material affects the mechanical and thermal properties of a CS/PP composite. Some techniques were used to characterize the properties of the blends, including a scanning electron microscope (SEM), thermo-gravimetric analysis (TGA), tensile testing, and flexural testing. It is anticipated that the study’s findings will give researchers and industry practitioners comprehensive information and data on the CS/PP composite, enabling the use of the knowledge gained in a variety of fields, particularly packaging, automotive components, and medical devices.

2. Materials and Methods

2.1. Sample Preparation

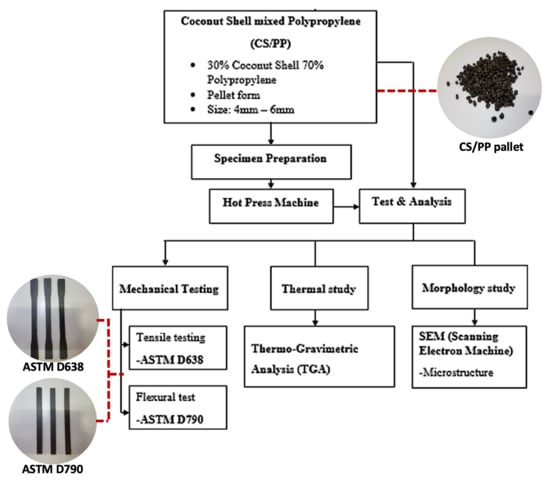

The husk of a coconut and the flesh are separated by the coconut shell (CS). Figure 1a illustrates the virgin PP thermoplastic granules supplied by a Chinese manufacturer (Chi Mei Corporation, Tainan, China) with MFI 3.6 g/10 min, whereas Figure 1b depicts CS fiber in powder form with an 80-mesh size. Figure 2 shows a flowchart of the research methodology for CS/PP composites. To remove the unwanted soluble cellulose, lignin, hemicellulose, and moisture, the CS was immersed in water for two days and in a sodium hydroxide (NaOH) solution for two hours. It then spent a day drying in the sun. An amount of 30 wt% of CS and 70 wt% of PP was used to create the CS/PP composite. Pre-mixing with a high-speed mixer set to 3000 rpm for five minutes was the next step. Gotech hot press machines with specialized molds were utilized to obtain tensile and flexural samples in compliance with ASTM D638 [22] and ASTM D790 [23]. The CS/PP composite was hot-pressed for 30 min at 240 °C, and virgin PP was hot-pressed for 20 min at 160 °C. Hot-press compression molding was selected due to its suitability for incorporating natural fibers into the thermoplastic matrix. Compression molding allows better control over fiber distribution, minimizes fiber degradation caused by high shear stresses in injection molding, and is more cost-effective for small-scale experimental work. Additionally, this method is frequently reported in the literature for fabricating natural fiber-reinforced thermoplastic composites, making it an appropriate choice for the scope of this study. The next methods performed were the mechanical testing (tensile and flexural), thermal testing, and microstructure evaluation.

Figure 1.

(a) PP pallets (2.5–3.0 mm size) and (b) CS fiber in powder (80 mesh size).

Figure 2.

Flowchart of research methodology for CS/PP composites.

2.2. Thermo-Gravimetric Analysis (TGA)

A thermo-gravimetric analyzer was used to generate the thermal analysis data for the CS/PP composite. The temperature range for the test was 25 °C to 600 °C, with the heating rate set at 10 °C per minute. The test’s primary objective is to continually assess the material’s weight loss in relation to temperature and time.

2.3. Mechanical Testing

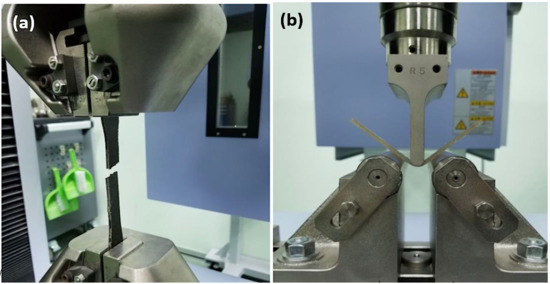

Figure 3 shows the tensile and flexural test setup as per ASTM 638 and ASTM D790. The tests were performed using the universal testing machine (Shimadzu Autograph AGSX, Shimadzu Corporation, Kyoto, Japan) at a temperature of 23 °C and relative humidity of 50 ± 5%. Three samples were measured with a 5 kN load cell and 5 mm/min crosshead speed. The tensile strength formula can be found in Equation (1), where A is the material’s initial cross-sectional area, P is the force needed to break it, and σt is the tensile strength. In essence, it determines the stress at which a material will break under a tensile force. The flexural strength and modulus are calculated using Equations (2) and (3), where σf indicates the flexural strength, Ef indicates the flexural modulus, S is for the dimension between load sites, b is for sample width, L and d are the length and thickness of the support span, P is the load at yield, and t is for sample thickness.

σt = P/A

σf = 3PS/2bt2

Et = L3P/4bd3

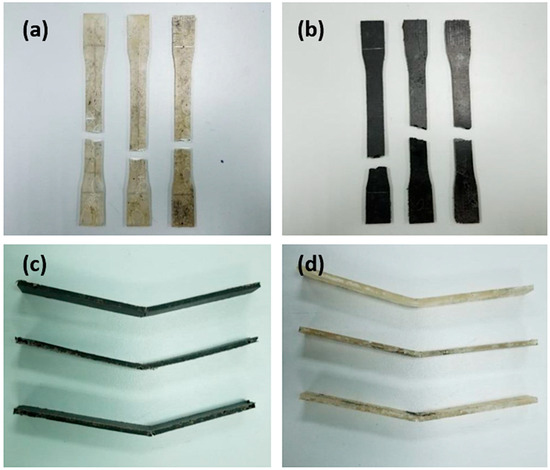

Figure 3.

Mechanical testing of CS/PP composite and pure PP: (a) tensile test and (b) flexural test.

2.4. Morphological Analysis

A scanning electron microscope (SEM), model JEOL (JSM-6010PLUS/LV, JEOL Ltd., Tokyo, Japan), with platinum coating and 20 kV acceleration, was used to examine the morphology of the CS/PP composite.

2.5. One-Way ANOVA

One-way ANOVA was used to determine the significant difference in the main variables. It is used to determine whether the means of two or more independent groups differ significantly when you have a continuous dependent variable and one independent variable with many levels.

3. Results and Discussion

3.1. Thermo-Gravimetric Analysis (TGA)

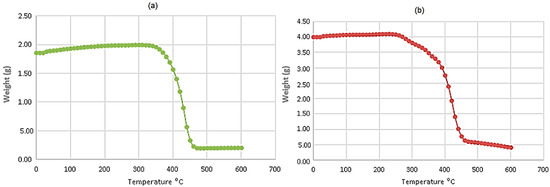

Figure 4 shows the TGA results for both the CS/PP composite and plain PP. TGA was used to identify the properties of composite materials that show mass gain or loss primarily as the outcome of oxidation, breakdown, and volatile loss. Each PP and CS/PP composite curve shows an endothermic reaction and a single-stage breakdown. The analysis reveals that the CS/PP composite exhibits enhanced thermal stability compared to plain PP, indicating that the incorporation of fiber significantly influences its degradation behavior. This improved performance suggests potential applications in environments where thermal resistance is crucial. The oil palm fiber composite discovered by Ahmad et al. [24] displayed a trend that was comparable to the TGA graph. Increasing the temperature in TGA thermograms causes the sample’s weight to decrease due to deterioration. The thermal decomposition temperature rose in tandem with the heating rate. The point at which weight loss abruptly grew was used to determine the degradation temperature. Both the CS/PP and plain PP completely disintegrated at 600 °C and 460 °C, respectively, leaving approximately 1.9 and 2.0% residue. The longer it takes to respond, the more filler there is in the composition. This observation highlights the significant influence of filler materials on the thermal stability of the composites. As the filler content increases, the thermal degradation process becomes more complex, potentially leading to variations in both the degradation temperature and the residue left behind after burning.

Figure 4.

TGA graph of (a) pure PP and (b) CS/PP composite.

3.2. Mechanical Properties

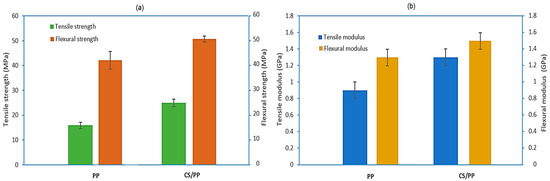

Figure 5 displays the tensile and flexural test samples (post-testing) of the CS/PP composite and pure PP. These tests were carried out to evaluate the mechanical properties of the CS/PP composite. Figure 6a,b show the tensile strength, tensile modulus, flexural strength, and flexural modulus of pure PP and CS/PP composites. The tensile strength and tensile modulus of the CS/PP composite had improved 36% and 30%, respectively, when compared to pure PP. Meanwhile, the flexural strength and flexural modulus of the CS/PP composite improved 16% and 13%, respectively, when compared to pure PP. As compared to pure PP (0 wt%), the tensile strength for the CS/PP composite was slightly greater. The tensile strength graph and the tensile modulus results show a similar pattern. These enhancements indicate that the incorporation of CS into the PP matrix significantly influences the mechanical properties of the composite. Future studies could explore the effects of varying CS content and processing conditions to further optimize these characteristics. The tensile modulus of the oil CS/PP composite increased compared to pure PP. According to Osman and Atia [25], the maximum flexural stress and Young’s modulus significantly dropped as the percentage of rice straw in the ABS matrix rose. As compared to a previous study by Bledzki [26], it shows the tensile strength for the CS/PP composite varies between 20 and 25 MPa. The tensile result was slightly different from pure PP because they used CS fiber in powder form (100–200 µm). This variation highlights the influence of fiber morphology on mechanical properties. Additionally, it suggests that optimizing the fiber size and distribution could further enhance the performance of CS/PP composites in practical applications. The tensile strength of the 30 wt% coconut shell/PP composite developed in this study was measured at 26 MPa. This value is consistent with results reported for other natural fiber-reinforced thermoplastics. For example, coir/PP composites at 10 wt% fiber achieved a tensile strength of 24.21 MPa, although further fiber addition reduced performance due to poor fiber–matrix adhesion [27]. Similarly, hybrid coir/glass fiber composites in PP have shown tensile strength values ranging from 26.08 to 36.68 MPa, depending on glass fiber content and compatibilizer use [28]. In comparison, rice husk/PP composites exhibit slightly higher tensile strength values. Untreated rice husk/PP systems reached 31.1–37.4 MPa [29], while the use of maleic anhydride polypropylene (MAPP) compatibilizer improved interfacial bonding and raised tensile strength to approximately 27.1 MPa, which is comparable to the present study [30]. Conversely, certain formulations showed a tensile strength reduction of nearly 10% when 15 wt% rice husk was incorporated into PP, highlighting the sensitivity of mechanical properties to filler dispersion and adhesion [31]. Banana/coir hybrid composites in PP have also demonstrated promising performance, with tensile strength values around 31.3 MPa at a 15 wt% banana-to-coir ratio, outperforming single-fiber systems [32]. This suggests that hybridization strategies may further enhance mechanical properties by combining the high tensile capacity of banana fibers with the toughness of coir fibers. Overall, the present tensile strength (26 MPa) compares favorably with several natural fiber/thermoplastic composites, particularly when proper compatibilization or hybrid reinforcement is not applied. However, it is lower than certain optimized systems (e.g., rice husk/PP or banana/coir/PP), indicating that future improvements may be achieved by optimizing filler loading, applying surface treatments, or exploring hybrid fiber systems. Previous studies [11,16,17,20] consistently demonstrate that the mechanical performance of natural fiber-reinforced composites can be significantly enhanced through optimal fiber composition, surface modification, and hybridization with nanomaterials. Alkali treatment effectively improves fiber–matrix adhesion, while appropriate fiber loading maximizes tensile and flexural strength. Moreover, the incorporation of nanofillers such as graphene nanoplatelets further strengthens interfacial bonding and mechanical integrity. These findings collectively affirm that the synergistic optimization of natural fibers, surface treatments, and nanofiller reinforcement offers a promising pathway toward developing high-performance, sustainable composite materials suitable for advanced engineering and additive manufacturing applications.

Figure 5.

Mechanical test specimens for (a) pure PP—tensile, (b) CS/PP composite—tensile, (c) CS/PP composite—flexural, and (d) pure PP—flexural.

Figure 6.

(a) Tensile strength and flexural strength, and (b) tensile modulus and flexural modulus of PP and CS/PP composite.

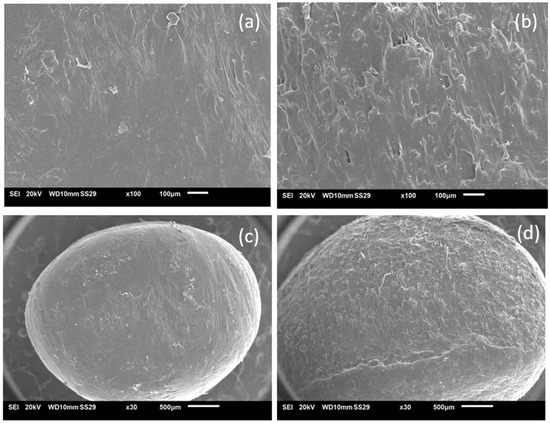

In this study, the mechanical characterization was limited to tensile and flexural properties, which were selected as primary indicators of stiffness and load-bearing capacity of the coconut shell/PP composite. While impact and hardness properties would provide a more complete mechanical profile, these were not within the scope of the present work and are recommended for future studies. The SEM micrographs provided further insight into the relationship between microstructure and mechanical behavior. At moderate fiber loadings, relatively uniform fiber distribution and improved interfacial bonding contributed to enhanced tensile and flexural strengths. However, at higher fiber contents, the SEM images revealed the presence of voids, fiber agglomeration, and fiber pull-out, which disrupted the continuity of the matrix and reduced effective stress transfer. These microstructural defects explain the decline in mechanical performance observed at elevated filler loadings, confirming that interfacial adhesion and fiber dispersion play a decisive role in determining the composite’s mechanical response.

3.3. Analysis of Variance (ANOVA)

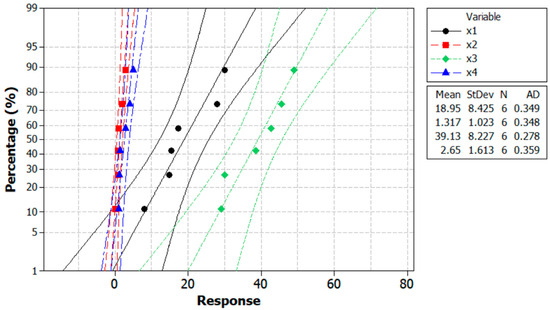

The one-way ANOVA results presented in Table 1 evaluate the influence of a single factor (e.g., material type and fiber content) on four responses: tensile strength, tensile modulus, flexural strength, and flexural modulus. The statistical analysis using one-way ANOVA was conducted with three replicates (n = 3) for each experimental group. The analysis was performed using Minitab-16 software. The results were statistically significant, with p-values indicating clear differences between the groups. Although three replicates provide a preliminary level of statistical insight, we recognize that increasing the number of replicates would improve the robustness of the findings. Future studies will incorporate a larger sample size to strengthen the statistical reliability and provide more comprehensive results. Notably, all four properties have p-values less than 0.05, indicating statistically significant differences between the groups for each property tested. The flexural modulus stands out with a very high F-value, indicating a strong effect of the tested factor. The low p-value confirms this significance with high confidence. This suggests that the material’s stiffness during bending is highly sensitive to the experimental variable, such as fiber reinforcement. For flexural strength, the results show that the factor significantly affected the bending strength of the samples. This is important in applications where materials undergo bending or flexural loading, indicating improved structural behavior under such stress. Overall, all responses exhibit statistically significant differences, reinforcing the conclusion that the factor studied (e.g., natural fiber reinforcement, filler percentage, etc.) has a consistent and measurable effect on the mechanical performance of the material. The strongest effect is seen on the flexural modulus, followed by moderate effects on tensile and flexural strengths. These findings provide a strong foundation for optimizing the material design, especially for applications that require enhanced stiffness and strength under various loading conditions. Figure 7 illustrates that the experimental data exhibit strong agreement with the fitted regression line across all measured responses. The low Anderson–Darling (AD) statistics confirm adherence to a normal distribution. Normal probability plots further demonstrate that the residuals are evenly distributed and closely aligned with the reference line, with no observable outliers. This distribution pattern indicates that the error terms are normally and independently distributed, thereby satisfying one of the fundamental assumptions of the regression model. Additionally, the consistent spread of residuals across the experimental runs suggests homoscedasticity, further supporting the validity of the model.

Table 1.

Summary of one-way ANOVA for mechanical properties.

Figure 7.

Probability graph of x1 is tensile strength, x2 is tensile modulus, x3 is flexural strength, and x4 is flexural modulus.

3.4. Scanning Electron Microscope (SEM)

Figure 8a,b represent the CS/PP composite and pure PP surface morphology, respectively. It shows that the surface of pure PP is relatively smooth compared to the CS/PP surface. It is comparable to the findings of Nukala et al. [33], who discovered that the pure recycled PP had a fine surface microstructure and no distinct characteristics. The virgin PLA surface was smoother than the wood fiber/PLA composite surface [34]. Nehel et al. [35] also discovered that the ABS-palm leaf fiber composite surface was rougher than the neat ABS surface. There were some cracks, defects, voids, and some damage on the fiber surface. It is due to the presence of inhomogeneous-sized fibers and larger particles. Hence, it shows that the bonding between fiber and thermoplastic matrix was less strong. Furthermore, an agglomeration was seen in the CS/PP composite, and the phase separation shown in both images was further emphasized because of the immiscible polymers [36]. Young’s modulus, tensile, flexural, and impact strength were among the mechanical performance metrics that were significantly impacted by the quantity of agglomerations. This phenomenon was also observed by Shahar et al. [37], who conducted research on creating a composite filament. They asserted that the PLA composite reinforced with kenaf fibers had a lower tensile strength due to agglomerations in the composite matrix. Obasi et al. [38] reported the aggregation of coconut shell particles with the matrix. This is feasible because when there is a lot of filler, the fibers tend not to interact with the matrix, which produces holes and gaps.

Figure 8.

SEM micrograph of (a) pure PP, magnification of 100 µm, (b) CS/PP composite under 100 µm magnification, (c) pure PP, magnification of 500 µm, and (d) CS/PP composite, magnification of 500 µm.

4. Conclusions

This study demonstrated the potential of utilizing grain by-products, specifically coconut shell (CS), as substitute fillers for reinforcement in composite materials. At the highest test temperature of 260 °C, the CS/PP composite maintained good thermal stability, exhibiting greater resistance to degradation compared to plain PP. Mechanical testing revealed notable improvements over pure PP, with tensile strength and tensile modulus increasing by 36% and 30%, respectively, and flexural strength and flexural modulus increasing by 16% and 13%, respectively. Surface analysis indicated the presence of inhomogeneous regions due to unrefined coconut shell particles. Beyond performance benefits, incorporating agricultural waste such as coconut shell into composites offers a sustainable approach that reduces landfill waste and supports circular economy practices, thereby lowering the environmental footprint of material production. These findings highlight the viability of CS/PP composites for applications in sectors such as automotive components and medical devices. For future work, it is recommended to use coconut shell fiber in finely powdered form as a filler during the compounding process with thermoplastic matrices to enhance uniformity and performance.

Author Contributions

Conceptualization, M.N.A.; methodology, M.N.A. and M.N.P.; software, M.N.A.; validation, M.N.A.; formal analysis, M.N.A.; investigation, M.N.A. and M.N.P.; resources, M.N.A.; data curation, M.N.A.; writing—original draft preparation, M.N.A.; writing—review and editing, M.N.A.; visualization, M.N.A.; supervision, M.N.A.; project administration, M.N.A.; funding acquisition, M.N.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

This research was financially supported by the Centre of Research and Innovation Management, University Teknikal Malaysia Melaka, for supporting this research work. Special appreciation and gratitude to the Faculty of Mechanical and Manufacturing Engineering Technology for giving full cooperation towards this research.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CS | Coconut Shell |

| PP | Polypropylene |

| PLA | Poly(lactic acid) |

| EBA | Ethylene Butylene Acrylate |

| GMA | Glycidyl Methacrylate |

| TGA | Thermo-gravimetric Analysis |

| SEM | Scanning Electron Microscope |

| ANOVA | Analysis of Variance |

| AD | Anderson–Darling |

| GNP | Graphene Nanoplatelets |

References

- Gunasekaran, K.; Annadurai, R.; Kumar, P. Long term study on compressive and bond strength of coconut shell aggregate concrete. Constr. Build. Mater. 2012, 28, 208–215. [Google Scholar] [CrossRef]

- Zohary, D.; Hopf, M. Domestication of Plants in the Old World: The Origin and Spread of Cultivated Plants in West Asia, Europe and the Nile Valley, 3rd ed.; Oxford University Press: Oxford, UK, 2000. [Google Scholar]

- Nadzri, S.N.I.H.A.; Sultan, M.T.H.; Shah, A.U.M.; Safri, S.N.A.; Talib, A.R.A.; Jawaid, M.; Basri, A.A. A comprehensive review of coconut shell powder composites: Preparation, processing, and characterization. J. Thermoplast. Compos. Mater. 2022, 35, 2641–2664. [Google Scholar] [CrossRef]

- Matuana, L.M.; Balatinecz, J.J.; Park, C.B. Effect of surface properties on the adhesion between PVC and wood veneer laminates. Polym. Eng. Sci. 1998, 38, 765–773. [Google Scholar] [CrossRef]

- Mengeloglu, F.; Matuana, L.M.; King, J.A. Effects of impact modifiers on the properties of rigid PVC/wood-fiber composites. J. Vinyl Addit. Technol. 2000, 6, 153–157. [Google Scholar] [CrossRef]

- Clemons, C. Wood-plastic composites in the United States: The interfacing of two industries. For. Prod. J. 2002, 52, 10–18. [Google Scholar]

- Clemons, C. Elastomer modified polypropylene–polyethylene blends as matrices for wood flour–plastic composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1559–1569. [Google Scholar] [CrossRef]

- Doss, R.M.; Muthuraj, R.; Parameswaran, M. Effect of Coconut Fiber Loading on the Morphological, Thermal, and Mechanical Properties of Coconut Fiber Reinforced Thermoplastic Starch/Beeswax Composites. Polymers 2023, 15, 875. [Google Scholar]

- Jha, P.; Mishra, D. Silanized Coconut Fiber Reinforced Poly (lactic acid) Composites: Interfacial Interaction, Crystallinity, and Thermomechanical Properties. J. Appl. Polym. Sci. 2023, 140, 52816. [Google Scholar]

- Keerthika, B.; Umayavalli, M.; Jeyalalitha, T.; Krishnaveni, N. Coconut shell powder as cost effective filler in copolymer of acrylonitrile and butadiene rubber. Ecotoxicol. Environ. Saf. 2016, 130, 1–3. [Google Scholar] [CrossRef]

- Okpala, C.; Chinwuko, E.; Ezeliora, C.; Awka, P.M.B. Mechanical properties and applications of coir fiber reinforced composites. Int. Res. J. Eng. Technol. 2021, 8. [Google Scholar] [CrossRef]

- Senthil Kumar, M.S.; Rajeshkumar, L.; Rangappa, S.M.; Siengchin, S. Mechanical behaviour analysis for banana/coir natural fiber hybrid epoxy composites through experimental modelling. J. Polym. Res. 2024, 31, 163. [Google Scholar] [CrossRef]

- Kumar, S.; Ramesh, K. Thermo-Mechanical Performance of 3D Printed Coir Fiber/PLA Biocomposites. Polym. Compos. 2024, 45, 2891–2901. [Google Scholar]

- Singh, S.; Kumar, R. Coir Fiber Reinforced Chemically Functionalized Ethylene Butylene Acrylate Composites: A Study on Mechanical and Thermal Properties. Polym. Eng. Sci. 2024, 64, 47–57. [Google Scholar]

- Islam, T.; Das, S.C.; Saha, J.; Paul, D.; Islam, M.T.; Rahman, M.; Khan, M.A. Effect of Coconut Shell Powder as Filler on the Mechanical Properties of Coir-polyester Composites. Chem. Mater. Eng. 2017, 5, 75–82. [Google Scholar] [CrossRef]

- Sumesh, K.R.; Kanthavel, K. Optimizing various parameters influencing mechanical properties of banana/coir natural fiber composites using grey relational analysis and artificial neural network models. J. Ind. Text. 2022, 51 (Suppl. S4), 6705S–6727S. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Bezerra, W.B.A.; Monteiro, S.N. Evaluation of Izod impact and bend properties of epoxy composites reinforced with mallow fibers. J. Mater. Res. Technol. 2020, 9, 373–382. [Google Scholar] [CrossRef]

- Mohanraj, C.M.; Rameshkumar, R.; Mariappan, M.; Mohankumar, A.; Rajendran, B.; Senthamaraikannan, P.; Suyambulingam, I.; Kumar, R. Recent Progress in Fiber Reinforced Polymer Hybrid Composites and Its Challenges-A Comprehensive Review. J. Nat. Fibers 2025, 22, 2495911. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Mohamad, A.R. Analysis on dimensional accuracy of 3D printed parts by Taguchi approach. In Lecture Notes in Mechanical Engineering; Springer: Singapore, 2020; pp. 219–231. [Google Scholar] [CrossRef]

- Costa, U.O.; Garcia Filho, F.D.C.; Rio, T.G.D.; Rodrigues, J.G.P.; Simonassi, N.T.; Monteiro, S.N.; Nascimento, L.F.C. Mechanical properties optimization of hybrid aramid and jute fabrics-reinforced graphene nanoplatelets in functionalized HDPE matrix nanocomposites. Polymers 2023, 15, 2460. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Ishak, M.R.; Taha, M.M.; Mustapha, F.; Leman, Z. Finite element analysis of oil palm fiber reinforced thermoplastic composites for fused deposition modeling. Mater. Today Proc. 2023, 74, 509–512. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D790-17; Standard test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Ahmad, M.N.; Ishak, M.R.; Taha, M.M.; Mustapha, F.; Leman, Z. Mechanical, thermal and physical characteristics of oil palm (Elaeis Guineensis) fiber reinforced thermoplastic composites for FDM–Type 3D printer. Polym. Test. 2023, 120, 107972. [Google Scholar] [CrossRef]

- Osman, M.A.; Atia, M.R. Investigation of ABS-rice straw composite feedstock filament for FDM. Rapid Prototyp. J. 2018, 24, 1067–1075. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Volk, J. Barley husk and coconut shell reinforced polypropylene composites: The effect of fibre physical, chemical and surface properties. Compos. Sci. Technol. 2010, 70, 840–846. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Terrones, L.A.H.; D’almeida, J.R.M. Mechanical performance of coir fiber/polyester composites. Polym. Test. 2008, 27, 591–595. [Google Scholar]

- Shrivastava, R.; Telang, A.; Rana, R.S.; Purohit, R. Mechanical properties of coir/glass fiber epoxy resin hybrid composite. Mater. Today Proc. 2017, 4, 3477–3483. [Google Scholar]

- Fuad, M.Y.; Ismail, Z.; Mansor, M.S.; Ishak, Z.A.; Omar, A.K. Mechanical properties of rice husk ash/polypropylene composites. Polym. J. 1995, 27, 1002–1015. [Google Scholar]

- Ezenkwaa, O.E.; Hassanb, A.; Samsudina, S.A. Tensile and Impact Properties of Rice Husk Filled Ethylene-Acrylic Ester Maleic Anhydride Compatibilized Polypropylene Composites. CET J.-Chem. Eng. Trans. 2021, 83, 511–516. [Google Scholar]

- Atuanya, C.U.; Olaitan, S.A.; Akagu, C.C.; Onukwuli, O.D.; Menkiti, M.C. Effect of rice husk filler on mechanical properties of polyethylene matrix composite. Int. J. Curr. Res. Rev. 2013, 5, 111–118. [Google Scholar]

- Bujjibabu, G.; Das, V.C.; Ramakrishna, M.; Nagarjuna, K. Development of Banana/Coir Natural Fibers Reinforced Polypropylene Hybrid Composites: The Effect of MA-g-PP (Maleic Anhydride Grafted Polypropylene) on Mechanical Properties and Thermal Properties. Nano Hybrids Compos. 2021, 32, 85–97. [Google Scholar]

- Nukala, S.G.; Kong, I.; Kakarla, A.B.; Tshai, K.Y.; Kong, W. Preparation and Characterisation of Wood Polymer Composites Using Sustainable Raw Materials. Polymers 2022, 14, 3183. [Google Scholar] [CrossRef]

- Guo, R.; Ren, Z.; Bi, H.; Song, Y.; Xu, M. Effect of toughening agents on the properties of poplar wood flour/poly (lactic acid) composites fabricated with Fused Deposition Modeling. Eur. Polym. J. 2018, 107, 34–45. [Google Scholar] [CrossRef]

- Neher, B.; Gafur, A.; Al-Mansur, M.A.; Bhuiyan, M.R.; Qadir, R.; Ahmed, F. Investigation of the Surface Morphology and Structural Characterization of Palm Fiber Reinforced Acrylonitrile Butadiene Styrene (PF-ABS) Composites. Mater. Sci. Appl. 2014, 05, 378–386. [Google Scholar] [CrossRef]

- Bi, H.; Ren, Z.; Guo, R.; Xu, M.; Song, Y. Fabrication of flexible wood flour/thermoplastic polyurethane elastomer composites using fused deposition molding. Ind. Crop. Prod. 2018, 122, 76–84. [Google Scholar] [CrossRef]

- Shahar, F.S.; Sultan, M.T.H.; Safri, S.N.A.; Jawaid, M.; Abu Talib, A.R.; Basri, A.A.; Shah, A.U.M. Physical, thermal and tensile behaviour of 3D printed kenaf/PLA to suggest its usability for ankle–foot orthosis—A preliminary study. Rapid Prototyp. J. 2022, 28, 1573–1588. [Google Scholar] [CrossRef]

- Obasi, H.C.; Mark, U.C.; Mark, U. Improving the mechanical properties of polypropylene composites with coconut shell particles. Compos. Adv. Mater. 2021, 30, 26349833211007497. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).