Abstract

We report a scalable route to hybrid aluminum matrix composites (AMCs) based on Al6060 (as-fabricated condition) reinforced with 2 wt.% TiB2 and 1 wt.% microsilica, fabricated by ultrasonically assisted stir casting (UASC) followed by radial-shear rolling (RSR). Premixing and preheating of powders combined with acoustic cavitation/streaming during UASC ensured uniform, non-sedimentary particle dispersion and low-defect cast billets. X-ray diffraction of the as-cast composite shows fcc-Al with weak TiB2 reflections and no reaction products; microsilica remains amorphous. Electron microscopy and EBSD after RSR reveal full erasure of cast dendrites, fine equiaxed grains, weakened texture, and a high fraction of high-angle boundaries due to the concurrent action of particle-stimulated nucleation (micron-scale TiB2) and Zener pinning/Orowan strengthening (50–350 nm microsilica). Mechanical testing shows that, in the cast state—comparing cast monolithic Al6060 to the cast hybrid-reinforced composite—yield strength (YS) increases from 61.7 to 77.2 MPa and ultimate tensile strength (UTS) from 103.4 to 130.7 MPa, without loss of ductility. After RSR to Ø16 mm (cumulated true strain ≈ 0.893), the hybrid attains YS 101.2 MPa, UTS 150.6 MPa, and elongation ≈ 22.0%, i.e., comparable strength to rolled Al6060 (UTS 145.1 MPa) while restoring/raising ductility by ~9.7 percentage points. Microhardness follows the same trend, increasing from 50.2 HV0.2 to 73.1 HV0.2 when comparing the base cast condition with the rolled hybrid. The route from UASC to RSR thus achieves a favorable mechanical strength–ductility balance using an economical, eco-friendly oxide/boride hybrid reinforcement, making it attractive for formable AMC bar and rod products.

1. Introduction

Aluminum matrix composites (AMCs) continue to attract sustained interest as a class of materials that combine low density with high specific strength and excellent wear resistance—attributes that are critical in transportation and aerospace applications [1,2]. Their properties can be flexibly tailored through the choice of matrix alloy, the type, size, and volume fraction of the dispersed reinforcement, and the processing route and subsequent post-processing. Contemporary reviews consistently indicate that AMCs constitute the most mature branch of metal-matrix composites in terms of technology readiness level and breadth of industrial deployment [3,4,5].

A conventional distinction is made between binary AMCs, which incorporate a single reinforcement [6,7], and hybrid AMCs, which incorporate multiple reinforcements [8,9]. Hybridization enables the concurrent operation of several strengthening mechanisms [10,11]: load sharing by particles of differing modulus and size; more effective dislocation pinning; and stabilization of the microstructure under thermal and tribological loads. The combined action yields synergistic gains in strength and stiffness while retaining acceptable fracture toughness and wear resistance. Comprehensive reviews of hybrid aluminum composites indicate both an increasing prevalence of these systems and a widening range of processing routes [12,13].

Among liquid-state fabrication routes for AMCs, the most widely used is stir casting, i.e., mechanical stirring of the melt while introducing the particulate reinforcement. The method is simple, scalable, and cost-effective, accommodates large castings, and yields properties that are sensitive to controllable processing parameters such as stirring rate and duration, melt temperature, alloying and melt modifiers, and melt refining/degassing practices [14,15,16]. However, the baseline scheme frequently encounters particle aggregation, gas pickup, and reinforcement segregation—problems that are especially pronounced for nano- and submicron-scale additions—which degrade microstructural uniformity and promote local stress concentrations [17,18]. Ultrasonic melt treatment has been demonstrated as an effective countermeasure: acoustic cavitation and streaming facilitate degassing, break up agglomerates, distribute particles uniformly, and refine the matrix grain structure [19,20,21].

The choice of reinforcement system is fundamental. Titanium diboride (TiB2) particles are widely used in AMCs because they combine high stiffness and hardness with chemical stability toward aluminum, which favors clean interfaces during casting [22,23]. At moderate TiB2 loadings, multiple studies report measurable gains in hardness [24,25]. Strength improvements under similar conditions are likewise documented for TiB2-reinforced aluminum matrix composites produced by stir casting. Enhanced wear resistance with TiB2 additions has also been demonstrated on wrought and cast aluminum grades [26]. In parallel, microsilica (silica fume/nanodispersed SiO2)—an environmentally and economically attractive source of silica obtained as a by-product of silicon and ferroalloy production [27,28]—offers ultrafine particle size and high specific surface area, enabling it to function as a reinforcement and/or a melt modifier; for aluminum alloys, small additions have been shown to improve the overall property suite [29,30]. Combining carbide or boride particulates with amorphous, nanodispersed SiO2 in hybrid AMCs is promising because it couples mechanical strengthening—via load transfer to stiff particles—with structural stabilization, through the barrier effect of the dispersed oxide and the potential promotion of heterogeneous nucleation of α-Al. Synthesizing assessments of hybrid systems in the literature [31] reinforce this trajectory.

In recent years, interest has intensified in post-casting treatments of stir-castings: ultrasonic treatment, heat treatment [32,33], and deformation-based (including severe plastic deformation)—to stabilize particle distributions and produce fine-grained matrices with high dislocation densities and gradients [34,35]. For bulk billets and long products, continuous severe-shear rolling variants are particularly attractive [36,37]. Radial-shear rolling (RSR)—a stationary screw-rolling process in a three-roll mill at large feed angles—imposes an intense, complex stress state characterized by compressive pressure with very high shear, promoting rapid breakdown of cast dendrites, accelerated grain refinement, and favorable textures with reduced necking propensity [38]. However, despite its progress for monolithic alloys and other systems, RSR remains relatively underexplored for AMCs, especially hybrid ones—leaving open questions about reinforcement redistribution under RSR’s unique strain path, the integrity of brittle particles under severe shear, and the achievable strength–ductility balance.

In this context, Al6060 provides a relevant matrix platform: it is representative of 6xxx alloys with established heat-treatable response and good manufacturability. In Al–Mg–Si (6xxx) alloys such as Al6060, strengthening arises primarily from precipitation of metastable β″/β′ phases during heat treatment [39], while common ceramic reinforcements are effectively insoluble in Al and contribute via load transfer, Orowan strengthening, and boundary pinning mechanisms, with dispersion and wetting at the interface being critical [40]. Recent demonstrations combining ultrasonically assisted stir casting with RSR [41,42] have shown promising microstructural refinement and property improvements in Al6060-based composites, including systems reinforced with TiB2 alone or hybridized with other phases—yet comprehensive understanding of hybrid reinforcement fractions, spatial distributions through casting and rolling, and the consequent mechanical response remains limited.

Although ultrasonically assisted stir casting (UASC) and severe-shear rolling are individually well established, there remains a lack of (i) systematic evidence on oxide/boride hybrid reinforcement (2 wt.% TiB2 and 1 wt.% microsilica) in a heat-treatable Al-Mg-Si matrix (Al6060) processed by a continuous severe-shear route (radial-shear rolling, RSR); (ii) microstructure-mechanism linkage that combines particle-stimulated nucleation (PSN) by micron-scale TiB2 with pervasive Zener pinning/Orowan contributions from 50 to 350 nm microsilica under RSR; and (iii) quantitative benchmarking of the strength–ductility balance vs. monolithic Al6060 and prior AMC variants made by the same UASC to RSR route.

Accordingly, this study (1) fabricates an Al6060 composite with 2 wt.% TiB2 and 1 wt.% microsilica by UASC with premixing and preheating under controlled acoustic cavitation and streaming; (2) verifies the as-cast phase constitution and dispersion uniformity; (3) applies RSR to a diameter of 16 mm and maps grain refinement, texture weakening, and the high-angle grain boundary fraction by EBSD on orthogonal sections; (4) quantifies yield strength, ultimate tensile strength, elongation, and microhardness in cast and rolled states against monolithic Al6060; and (5) elucidates the synergistic mechanism in which TiB2 drives PSN and microsilica provides boundary pinning and Orowan strengthening, thereby underpinning the observed property improvements.

2. Materials and Methods

2.1. Preparation of Raw Materials

Commercial Al6060 alloy (Metall-Komplekt LLP, Karaganda, Kazakhstan) was used as the metallic matrix. The nominal chemical composition of Al6060 is given in Table 1.

Table 1.

Chemical composition of Al6060 alloy (wt.%).

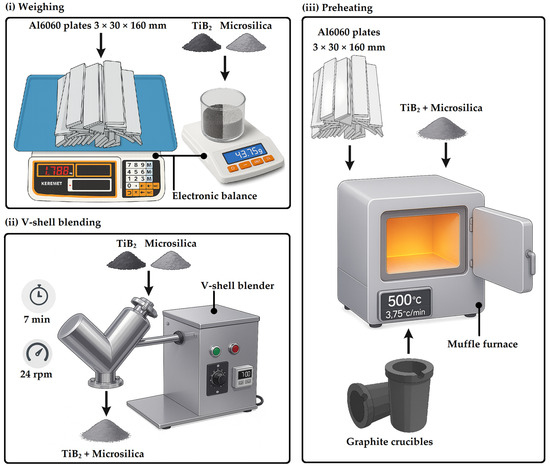

The alloy was cut into plates of 3 × 30 × 160 mm, deburred, and weighed on an electronic balance. Reinforcement powders—TiB2 (Luoyang Tongrun Info Technology Co., Ltd., Luoyang, China) and microsilica (YDD Corporation, Karaganda, Kazakhstan)—were proportioned to achieve a nominal composition of 2 wt.% TiB2 and 1 wt.% microsilica in the final composite. Consequently, the combined powder charge equaled 3 wt.% of the total batch, maintaining a fixed TiB2:microsilica mass ratio of 2:1. The overall workflow is illustrated in Figure 1.

Figure 1.

Workflow for preparing raw materials for the Al6060/2 wt.% TiB2/1 wt.% microsilica composite.

Prior to melting, TiB2 and microsilica were dry-blended in a V-shell blender (Xinxiang Dongzhen Machinery Co., Ltd., Xinxiang, China) to promote premixing and disrupt soft agglomerates. Blending was carried out for 7 min at 24 rpm. When required to break loose clusters without altering particle size distribution, the powders were gently passed through a stainless-steel laboratory sieve and re-blended for the remaining time. To remove adsorbed moisture/volatiles and improve wetting during melt processing, the Al6060 plates, the premixed TiB2 and microsilica powders, and graphite crucibles (Ø84 × 181 mm) were preheated separately in a PM-5 muffle furnace (Plavka.Pro, Korolev, Russia) to 500 °C at ~3.75 °C min−1. Upon reaching temperature, items were held to thermal equilibrium (≥15 min for plates and crucibles; ≥10 min for powders), kept hot, and then transferred promptly to the melt-processing station to minimize re-adsorption of moisture.

Metal plates were brushed and wiped with ethanol before weighing. Masses of matrix and reinforcements were verified to within ±0.05 wt.% of target for each batch.

2.2. UASC/RSR Procedure

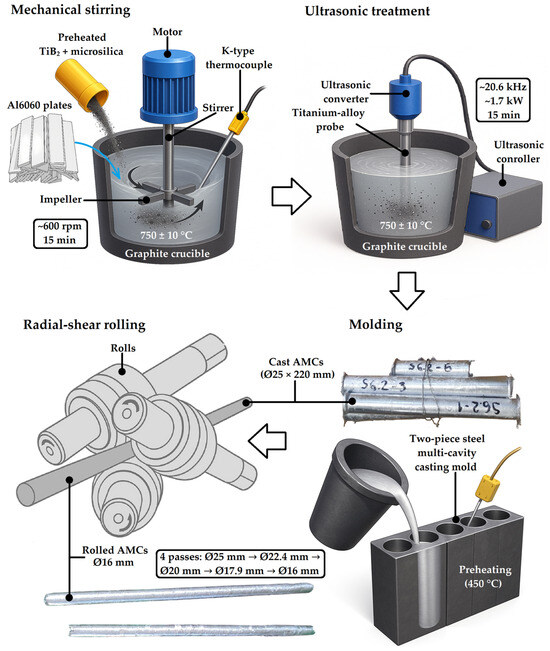

Processing followed the “UASC followed by RSR” route illustrated in Figure 2. Melting (JC-S-220-4 electric resistance furnace, Zibo JC Eco-Tech Co., Ltd., Zibo, China) was carried out in a graphite crucible at 750 ± 10 °C under K-type thermocouple control. UASC began with mechanical stirring using a four-blade impeller at ~600 rpm for 15 min. During this period the preheated TiB2 and microsilica blend was meter-fed into the surface vortex to enhance wetting and primary dispersion; dross was skimmed as needed. Without interrupting the thermal regime, the melt was then subjected to ultrasonic treatment (JH-LRT30 system, Hangzhou Precision Machinery Co., Ltd., Hangzhou, China) using an immersed titanium-alloy probe (converter set ~20.6 kHz, nameplate power ~1.7 kW, duration 15 min).

Figure 2.

UASC/RSR processing route for Al6060/2 wt.% TiB2/1 wt.% microsilica AMC.

Cavitation and acoustic streaming promoted deagglomeration and homogenization of particulates throughout the melt. The impeller was immersed to ~2/3 of melt depth with clearance to the crucible wall; the ultrasonic probe was positioned below the free surface and laterally offset from the impeller to avoid acoustic shadowing. Immediately after UASC, the refined melt was poured into a two-piece steel multi-cavity mold preheated to 450 °C, producing billets of Ø25 × 220 mm nominal geometry. Billets were subsequently RSR-processed on a three-roll mill in four passes with stepwise diameter reductions from Ø25 mm to Ø22.4 mm, then to Ø20 mm, then to Ø17.9 mm, and finally to Ø16 mm. The resulting Ø16 mm rods were straight and suitable for subsequent characterization. Between RSR passes, transfers were prompt to maintain a consistent thermal state; lubricant and roll settings were kept constant across passes.

For comparability, deformation metrics are reported. Assuming axisymmetric flow, the per-pass true strain (, based on diameter) and the cross-section area reduction () are:

where and are the inlet and exit diameters of pass i. For the adopted schedule: 25 to 22.4 mm (1st pass): ≈ 0.220, ≈ 19.7%; 22.4 to 20 mm (2nd pass): ≈ 0.227, ≈ 20.3%; 20 to 17.9 mm (3rd pass): ≈ 0.222, ≈ 19.9%; 17.9 to 16 mm (4th pass): ≈ 0.224, ≈ 20.1%. The cumulative values to Ø16 mm are: = 2 ln(25/16) ≈ 0.893, = 1 − (16/25)2 ≈ 59%.

2.3. Material Characterization

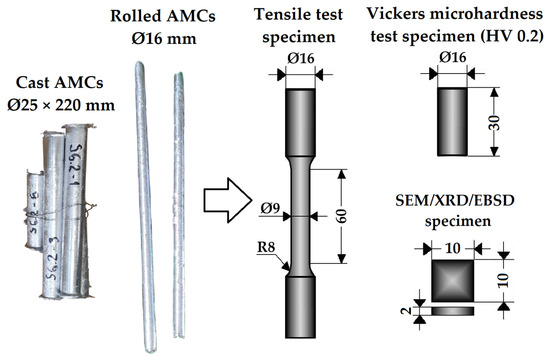

The microstructure and properties were characterized for both conditions—as-cast billets (Ø25 × 220 mm) and RSR-rolled rods (Ø16 mm)—using SEM, XRD, EBSD, tensile testing, and Vickers microhardness measurement (Figure 3). Tensile dog-bones, hardness cylinders, and metallographic/XRD/EBSD coupons were machined from each condition.

Figure 3.

Sampling and test geometry.

Tensile specimens were machined to a dog-bone geometry (gauge diameter 9 mm, gauge length L0 = 60 mm) in accordance with ASTM E8 [43]. For each condition, three specimens were tested to ensure reproducibility. Tests were conducted on a WDW-100 kN universal testing machine (Jinan Xinluchang Testing Machine Co., Ltd., Jinan, China) at a constant crosshead speed of = 1 mm min−1 until failure at room temperature. The nominal engineering strain rate was:

From the stress–strain curves we determined yield strength (YS), ultimate tensile strength (UTS), and elongation (%). The short-range “waviness” confined to the very early portion of the engineering stress–strain curves (up to ≈0.7–1.0% nominal strain) is an instrumental artifact of how the axial strain was acquired and of inevitable specimen/grip settling, rather than a material anomaly.

For each condition, cylindrical samples were machined to Ø16 × 30 mm and tested per ASTM E384 [44] on an HVT-1000A microhardness tester (Laizhou Laihua Testing Instrument Factory, Laizhou, China) with a Vickers diamond pyramid indenter (included angle 136°). A load of F = 0.2 kgf (~1.961 N) with a 15 s dwell was applied; ≥5 indents at separated locations were taken per specimen. Vickers microhardness was calculated as:

where is the mean diagonal.

Prior to testing, surfaces were ground with SiC papers from P400 to P1500 and polished on cloth with alumina suspensions from 1 µm to 0.3 µm; specimens were then cleaned in ethanol and dried with compressed air.

SEM and XRD specimens (2 × 10 × 10 mm) were sectioned along a diametral plane using a Brilliant 220 precision cutting machine (ATM Qness GmbH, Mammelzen, Germany) to ~2 mm thickness, hot-mounted in carbon-filled resin with a Citopress-5 (Struers, Cleveland, OH, USA), then mechanically prepared: SiC grinding P320 to P2000, diamond polishing 9 to 3 to 1 µm, and final polishing with Eposil M colloidal silica (0.06 µm, pH 9.5, ATM Qness GmbH, Mammelzen, Germany). SEM imaging—including micrographs of the as-cast monolithic and hybrid composites—was performed with a Crossbeam 540 microscope (Carl Zeiss, Oberkochen, Germany) at an accelerating voltage of 20 kV using a secondary electron (SE) detector. The as-received reinforcing powders were characterized on the same instrument under identical settings. Phase analysis used XRD (Rigaku SmartLab high-resolution X-ray diffractometer, Rigaku Corporation, Tokyo, Japan): Cu Kα, λ = 1.5406 Å, 2θ = 5–75°, step 0.05°. EBSD [45] was conducted on a Thermo Fisher Helios 5 UX (Waltham, MA, USA) to obtain inverse-pole-figure (IPF) maps in the RD–ND (longitudinal) and TD–ND (transverse) planes.

3. Results and Discussion

3.1. Microstructural Observations

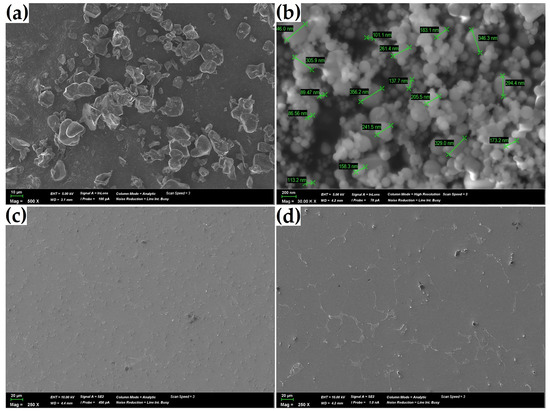

Figure 4 assembles four SEM panels that trace the path from reinforcement feedstock to the as-cast microstructure obtained after UASC. Figure 4a shows the commercial TiB2 powder as fractured, angular particulates with sharp ridges and facets [46,47]. The modal particle size lies in the low-micrometer regime (≈5–15 µm), with irregular outlines typical of milled boride ceramics. This morphology is beneficial in two complementary ways. First, micron-scale, high-modulus inclusions act as potent particle-stimulated nucleation (PSN) sites during subsequent radial-shear rolling (RSR), where steep local strain gradients accumulate at the particle–matrix interface [48]. Second, the rough surface topography and faceting are favorable for mechanical interlocking and strong interfacial bonding once the surface contaminants are burned off by preheating and the triple line is periodically “scrubbed” by acoustic pressure during UASC. The main risk for TiB2—face-to-face agglomeration by van der Waals attraction [49]—is precisely the failure mode that ultrasound is designed to defeat via cavitation-induced micro-jets and bulk acoustic streaming.

Figure 4.

SEM characterization of feed powders and as-cast microstructures: (a) angular TiB2 particles; (b) polydisperse microsilica nanoparticles (annotated sizes, ~46–356 nm); (c) as-cast Al6060 after UASC showing low porosity and clean interdendritic regions; (d) as-cast Al6060/2 wt.% TiB2/1 wt.% microsilica composite with uniform, non-sedimentary dispersion.

Figure 4b depicts the microsilica as polydisperse, near-spherical particles that form loose, mist-like flocculates [50,51]. Using the dimensional annotations visible in the micrograph, the measured diameters (n = 17) span 46–356 nm with mean 201.7 nm, median 183.1 nm, Q1 ≈ 113 nm, and Q3 ≈ 294 nm. This right-skewed distribution places the oxide firmly in the Orowan regime for Al (the Burgers vector for Al: b ≈ 0.286 nm), where strengthening scales with the inverse of the inter-particle spacing on the active {111}⟨110⟩ slip systems rather than with particle size per se [52,53]. Even at a modest loading (1 wt.% here), a population of 50–350 nm obstacles establishes a high number density of barriers to dislocation glide and—critically—provides widespread Zener pinning to stabilize subgrain and grain boundaries during hot deformation and inter-pass holds [54,55,56]. Compared with TiB2, the microsilica has a lower elastic modulus; its principal role is therefore indirect strengthening (via spacing control and boundary pinning) rather than load carrying. The powder’s spherical habit also helps it infiltrate interdendritic liquid during solidification and distribute uniformly under acoustic streaming, provided weak flocs are broken by cavitation.

Figure 4c shows the as-cast monolithic Al6060 produced under the same melt-conditioning protocol. The field of view is largely free of shrinkage cavities or oxide stringers; only small, isolated pores are visible. Dendrite arms and interdendritic channels are recognizable but comparatively clean, consistent with effective hydrogen removal and the suppression of oxide entrainment by the combined stirring–ultrasound sequence and the warm-mold pour [57,58,59]. This “clean cast state” is a necessary precondition for the microstructural transformations targeted during RSR: uniform recrystallization, texture weakening, and fine, equiaxed grains without crack-initiating defects.

Figure 4d presents the as-cast hybrid composite. Several features attest to good dispersion quality. No gravitational segregation is apparent: there is no radial gradient, banding, or particle-rich “floors/ceilings” that would indicate TiB2 sedimentation or microsilica flotation. No long rafts or oxide films are present; clusters are small and equiaxed rather than lamellar, implying that acoustic deagglomeration and streaming prevented particle capture in entrained biofilms [60,61]. Tight particle–matrix interfaces are inferred from the absence of debonded halos at this scale, in line with the preheat-and-ultrasound wetting strategy [62]. The resulting microstructure can be described as micron-scale TiB2 crystals separated by a high-number-density, sub-micron oxide “mist” [63,64]. This architecture is precisely what is needed to combine PSN (driven by TiB2) with pervasive Zener pinning (from microsilica), thus promoting a fine, stable grain structure under the high-shear RSR kinematics.

In summary, Figure 4 confirms that the feedstocks possess the morphology and scale needed for a complementary strengthening–refinement strategy, and that the UASC step successfully translates those attributes into a uniform, low-defect as-cast microstructure.

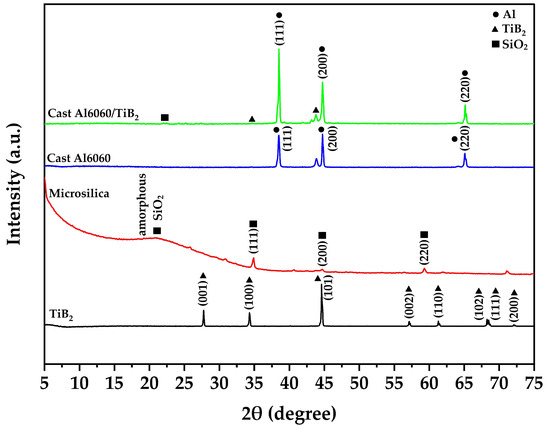

Figure 5 consolidates XRD patterns for the four constituents of interest: the hybrid composite in the as-cast state (green), the monolithic Al6060 cast under identical melt-conditioning (blue), the microsilica feedstock (red), and the TiB2 feedstock (black).

Figure 5.

X-ray diffraction (Cu Kα) of feed powders and as-cast materials. Black—TiB2 powder: sharp hexagonal TiB2 reflections; Red—microsilica: broad amorphous halo (no crystalline SiO2 peaks); Blue—cast Al6060: fcc-Al peaks only (no detectable coarse intermetallics); Green—cast Al6060/2 wt.% TiB2/1 wt.% microsilica composite: Al peaks with weak TiB2 reflections; no new reaction phases detected, indicating amorphous silica retention and interfacial stability.

The scans were collected over 5–75° 2θ (Cu Kα), which spans the principal reflections of fcc-Al and hexagonal TiB2 and captures the amorphous halo characteristic of fumed silica. The figure addresses three questions central to the process–structure–property link in this work: (i) which crystalline phases are present after ultrasonically assisted stir casting (UASC); (ii) whether any reaction products form between the matrix and the reinforcements under the chosen thermal exposure; and (iii) whether the oxide second phase remains largely amorphous (as intended) so that it acts primarily as a dispersive pinning/Orowan agent rather than as a brittle crystalline inclusion.

The TiB2 trace exhibits a set of narrow, instrument-limited peaks at positions typical of hexagonal TiB2 (e.g., reflections near ~28°, ~34°, ~45°, ~57°, ~61°, ~68°, and ~72° 2θ [65]). The absence of low-angle shoulders or anomalous broadening indicates that the ceramic feedstock contains well-crystallized TiB2 without detectable secondary borides or oxides. The microsilica trace (red) is dominated by a broad amorphous hump extending roughly from the mid-teens to the high-20s in 2θ, tapering toward ~40–45°. This is the expected signature of fumed silica [66]; sharp Bragg peaks of crystalline SiO2 polymorphs (quartz, cristobalite, tridymite) are not resolved, confirming that the feedstock is predominantly amorphous. This amorphousness is important for two reasons: (1) it maximizes specific surface area (hence the effectiveness of Zener pinning per unit mass), and (2) it minimizes the risk of introducing hard, brittle crystalline planes that could act as micro-cleavage sites.

The cast Al6060 pattern (blue) shows the canonical fcc-Al reflections—intense peaks in the ~38–45° region and higher-order peaks near ~65–70° 2θ—without additional lines attributable to coarse intermetallics [67]. In particular, there are no resolved peaks assignable to Mg2Si or Al–Fe–Si phases at the scan’s step width and counting statistics. Given the limited thermal budget of UASC (minutes at casting temperature) and the immediate warm-mold pour, this is consistent with a solid solution matrix with only fine, XRD-subdetectable precipitation, matching the intention to defer any precipitation reactions until after deformation/heat treatment if desired [68,69].

The hybrid composite spectrum (green) is dominated by the fcc-Al peaks, as expected for a low total reinforcement fraction (3 wt.%). Superimposed on the Al pattern, weak TiB2 reflections are discernible at the same 2θ positions seen in the reference trace [70,71]; their low intensity relative to Al is fully consistent with (i) the small TiB2 volume fraction (≈2 wt.%), (ii) the high absorption/penetration contrast of Cu Kα in Al vs. dense borides, and (iii) random particle orientation [72]. Crucially: no new peaks appear beyond those attributable to Al and TiB2. Within the detection limits of laboratory XRD, there is no evidence for reaction products such as Al–O–Si crystalline phases, TiOₓ oxides, or complex borides formed by melt reactions. The amorphous hump characteristic of microsilica is, at most, barely perceptible against the Al background—again expected at 1 wt.% and given the dominance of Al scattering.

In summary (Figure 5): the composite’s XRD signature is a linear superposition of fcc-Al and weak TiB2 peaks over an Al background, with no new crystalline phases and with microsilica remaining amorphous. This establishes that the UASC processing window enables dispersion and wetting without interfacial reaction penalties, setting favorable boundary conditions for the grain refinement, texture weakening, and strength–ductility balance demonstrated after radial-shear rolling.

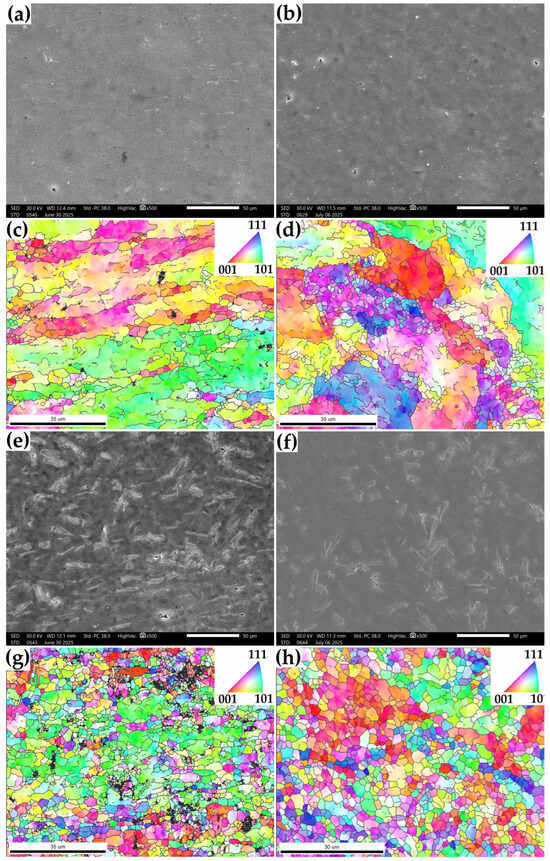

Figure 6 compares the post-RSR microstructures of the monolithic Al6060 and the Al6060/2 wt.% TiB2/1 wt.% microsilica hybrid on orthogonal cross-sections. Panels (a–b, e–f) are secondary-electron (SEM) views that emphasize morphology and defect content; panels (c–d, g–h) are EBSD inverse pole figure (IPF) maps keyed to the standard triangle (⟨001⟩–⟨101⟩–⟨111⟩).

Figure 6.

SEM morphology and EBSD-IPF maps of RSR-processed samples on orthogonal sections. (a,b) Al6060, SEM on RD–ND and TD–ND planes (50 µm scale); (c,d) Al6060, EBSD-IPF (RD–ND and TD–ND); (e,f) Al6060/2 wt.% TiB2/1 wt.% microsilica, SEM (RD–ND and TD–ND); (g,h) hybrid composite, EBSD-IPF (RD–ND and TD–ND).

Two planes are examined for each material: RD–ND (rolling direction—normal direction) and TD–ND (transverse direction—normal direction). Together they show that RSR erases the cast dendritic memory, generates a fine, equiaxed grain structure with a HAGB fraction, and weakens texture—effects that are enhanced in the hybrid due to particle-stimulated nucleation (PSN) and Zener pinning.

SEM (a,b). At 50 µm scale, both sections of the monolithic alloy are free of macroscopic tearing, with only sparse pores/pull-outs. Faint elongated features and shallow shear traces follow the helical flow typical of three-roll RSR, but there are no continuous banded defects. The surface is clean, reflecting the degassed, low-oxide starting billet.

EBSD-IPF (c,d). The RD–ND and TD–ND maps reveal a fine, largely equiaxed grain assembly with scattered shear-aligned strings of smaller grains where local strain peaked. Grain orientations are broadly distributed across the IPF triangle, with no dominant rolling/cube component; RD and TD sections are visually similar in color dispersion, indicating weakened anisotropy relative to plane-strain rolling. Misorientation contrast suggests numerous HAGBs partitioning subgrains formed during dynamic/recrystallization under the high-shear path of RSR. Occasional orientation clusters track the shear lines seen in SEM, consistent with progressive continuous recrystallization rather than a single nucleation-and-growth event.

SEM (e,f). The hybrid exhibits the same macroscopic integrity but with more numerous fine lamellar/feathered traces aligned with the RSR shear—typical of PSN zones around hard particles. There is no evidence of particle rafting or fracture; instead, bright contrast speckles distributed uniformly hint at the TiB2 sites, while the absence of large pull-out cavities indicates tight particle–matrix bonding. Both RD–ND and TD–ND planes show homogeneous morphology at 50 µm scale.

EBSD-IPF (g,h). Compared with the monolithic alloy, the hybrid maps contain a denser population of small, equiaxed grains and more isotropic color mosaics. The texture appears further weakened: colors fill the IPF triangle more uniformly, with no strong elongation of specific components.

The prevalence of small grains near presumed particle locations (dark/low-indexing spots) indicates PSN triggered by micron-scale TiB2, while the uniformly fine background points to Zener pinning by the nanoscale oxide that suppresses boundary migration during inter-pass holds. The RD–ND and TD–ND sections are again similar, reinforcing the conclusion that RSR plus hybrid pinning yields a quasi-isotropic recrystallized matrix at the mesoscale.

Implication. The hybrid achieves a higher HAGB density and narrower grain-size spread than the monolithic alloy—microstructural conditions that (i) raise yield/UTS via Hall–Petch and Orowan contributions and (ii) help retain elongation by distributing slip across many orientations and delaying localized necking.

A numerical partition of ‘PSN-derived’ vs. ‘non-PSN’ grains was deliberately not reported because two boundary-generating pathways act concurrently during RSR (PSN at micron-scale TiB2 and recrystallization stabilized by nanoscale SiO2 pinning). With EBSD not acquired in a particle-segmented mode and PSN nuclei rapidly impinging/coarsening under ongoing deformation, any percentage would be method-dependent (particle proximity, size thresholds, misorientation cut-offs) and risk over-interpretation. Instead, we document unambiguous qualitative PSN signatures (corona-like refinement near TiB2) together with system-wide refinement from Zener pinning, consistent across RD–ND and TD–ND maps in Figure 6.

Mechanistic synthesis from Figure 6:

- (A)

- Mechanism of cast-memory erasure. During radial-shear rolling (RSR), the three-roll kinematics impose a torsion-like shear combined with compressive hydrostatic pressure, which fragments dendrites and disrupts the as-cast substructure [73]. In the hybrid composite, micron-scale TiB2 particles act as potent sites for particle-stimulated nucleation (PSN), promoting the formation of new grain orientations during deformation and recrystallization [74]. Concurrently, sub-micron microsilica particles pin migrating boundaries (Zener pinning), stabilizing the refined structure as it forms [75]. Together, these effects erase the cast memory and produce the equiaxed mosaics observed in panels (g,h).

- (B)

- Texture weakening and ductility retention. The inverse pole figure (IPF) maps show a broad spread of orientations—most pronounced in the hybrid material—which indicates weakened texture and reduced earing/planar anisotropy. This texture state favors a more uniform activation of the {111}⟨110⟩ slip systems across grains [76], supporting extended work-hardening and the preserved elongation seen in the tensile curves.

- (C)

- Defect control and toughness. SEM observations reveal a scarcity of pores and pull-outs and an absence of particle-fracture cavities, consistent with clean interfaces and minimal oxide stringers inherited from UASC processing. By delaying void nucleation and slowing void coalescence, these microstructural features enhance damage tolerance at a given strength.

3.2. Mechanical Properties

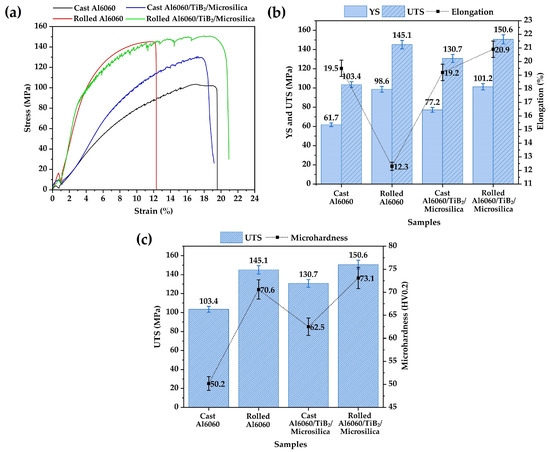

The tensile and hardness results in Figure 7 show that both the processing route and the hybrid reinforcement (2 wt.% TiB2 and 1 wt.% microsilica) contribute additively to performance.

Figure 7.

Mechanical properties of Al6060 and Al6060/TiB2/microsilica composites in as-cast and rolled states: (a) engineering stress–strain curves; (b) yield strength (YS), ultimate tensile strength (UTS), and elongation; (c) comparison of UTS and microhardness (HV0.2).

Cast state. Baseline Al6060 exhibits YS 61.7 MPa, UTS 103.4 MPa, εf (elongation) ≈ 19.5%, HV0.2 50.2. Introducing the hybrid increases strength without a ductility penalty: YS rises to 77.2 MPa (an increase of 15.5 MPa), UTS to 130.7 MPa (an increase of 27.3 MPa), elongation to ≈21.2% (an increase of 1.7 percentage points), and HV0.2 to 62.5 (an increase of 12.3). The gain reflects load transfer from micron-scale TiB2 and an Orowan contribution from sub-micron microsilica.

After RSR. The monolithic alloy strengthens, as expected for grain refinement and texture evolution, but loses ductility: YS 98.6 MPa, UTS 145.1 MPa, εf ≈ 12.3%, HV0.2 70.6. The rolled hybrid achieves the best overall balance: YS 101.2 MPa, UTS 150.6 MPa, εf ≈ 22.0%, HV0.2 73.1. Relative to rolled Al6060, this corresponds to an increase of 2.6 MPa in YS, an increase of 5.5 MPa in UTS, and an increase of 9.7 percentage points in elongation, indicating that PSN (micron TiB2) plus Zener pinning (nanoscale microsilica) mitigate the ductility loss typically seen after severe shear rolling.

Strength–hardness scaling. Across all four conditions, HV0.2 scales nearly linearly with UTS (Cast Al6060: 50.2 HV—103.4 MPa; Rolled hybrid: 73.1 HV—150.6 MPa), confirming that barrier-controlled mechanisms—grain refinement, Orowan looping, and interfacial load transfer—dominate.

Within a PSP (process–structure–property) perspective, the weak anisotropy observed after RSR arises from torsion-like shear coupled with PSN (TiB2) and Zener pinning (SiO2), which promote orientation randomization and stabilize equiaxed grains. Practical levers for tuning anisotropy include per-pass reduction/cumulative shear, inter-pass thermal budget, roll speed, and particle state/dispersion: more shear, tighter transfers, higher speed, and well-dispersed TiB2 and SiO2 generally reduce anisotropy; the converse tends to increase it.

Comparison with our prior studies that use the route from UASC to RSR.

- TiB2-only composite [41]: YS ≈ 108.6 MPa, UTS ≈ 156.9 MPa, HV0.2 ≈ 76.3, εf ≈ 9% in the rolled state. The present rolled hybrid is within ~5–7 MPa of these strength levels at a much higher ductility (~22% vs. ~9%), thus shifting the strength–ductility frontier favorably.

- TiB2–MWCNT hybrid [42]: YS > 115 MPa, UTS ≈ 164 MPa, HV0.2 ≈ 82, εf ≈ 14% after RSR. Our oxide-assisted hybrid attains comparable class strength (UTS ≈ 151 MPa) while delivering ~8 percentage points higher elongation and avoiding the cost/chemistry complexities of CNT networks.

Mechanistic reading. The hybrid’s ability to raise or maintain strength while restoring/boosting ductility stems from (i) PSN by micron TiB2 that accelerates recrystallization, (ii) pervasive Zener pinning by 50–350 nm microsilica that stabilizes a fine grain size during/after RSR, (iii) clean interfaces (XRD shows no new reaction phases), and (iv) weakened, broadened textures that distribute slip more uniformly—features consistent with our EBSD and XRD observations for this batch.

Net outcome. The Al6060/TiB2/microsilica system reaches UTS ≈ 151 MPa at εf ≈ 22% after RSR, essentially matching the TiB2-only strength while doubling its elongation, and approaching the TiB2–MWCNT strength with higher ductility—an attractive balance for formable AMC bar stock produced by a scalable UASC to RSR route.

Limitations of the study. While qualitative SEM observations of the as-cast billets indicated a low apparent defect background, we did not perform a dedicated quantitative characterization of casting defects (e.g., Archimedes density, metallographic image analysis for area porosity, or X-ray computed tomography for 3D pore/void mapping). Accordingly, the possible presence of sub-visual porosity, shrinkage cavities, or entrained biofilm-related voids cannot be ruled out and should be considered a limitation of this work.

4. Conclusions

Fabrication and phase stability. The UASC route with premixing/preheating followed by warm-mold casting produces a uniform, non-sedimentary dispersion of 2 wt.% TiB2 and 1 wt.% microsilica in Al6060 at a low defect background. XRD shows fcc-Al with weak TiB2 reflections and no parasitic reaction products; the amorphous state of SiO2 is retained, confirming interfacial integrity after ultrasonic melt treatment.

Microstructural evolution under RSR. Radial-shear rolling (to Ø16 mm; cumulative true strain ≈ 0.893) erases the cast dendritic memory and yields a fine-grained, quasi-isotropic matrix with an increased HAGB fraction and weakened texture on RD–ND and TD–ND sections. The higher share of small, equiaxed grains together with feather-like shear traces indicates particle-stimulated nucleation (PSN) from micron-scale TiB2, while 50–350 nm microsilica provides persistent Zener pinning and Orowan barriers that stabilize grain size between passes.

Mechanical properties and strength–ductility balance. In the as-cast state, the hybrid raises YS from ~61.7 to ~77.2 MPa and UTS from ~103.4 to ~130.7 MPa without loss of elongation, reflecting combined load transfer from TiB2 and submicron Orowan control. After RSR, the hybrid attains YS ≈ 101.2 MPa, UTS ≈ 150.6 MPa, elongation ≈ 22%, matching or exceeding the strength of rolled monolithic Al6060 (UTS ≈ 145.1 MPa) while delivering a ~9.7 percentage-point increase in ductility. The near-linear HV0.2–UTS correlation indicates that the dominant barrier mechanisms are Hall–Petch strengthening, Orowan strengthening, and interfacial load transfer.

Benchmarking against prior systems. Relative to our TiB2-only AMC after RSR, the hybrid preserves the strength class while achieving ~2× higher elongation; versus TiB2–MWCNT, it delivers comparable strength with higher ductility and lower materials/process risk. The oxide–boride hybrid therefore offers a practical techno-economic advantage.

Overall engineering significance. The route from UASC to RSR for Al6060/2%TiB2/1% microsilica yields scalable rod stock with a favorable strength–ductility balance enabled by the synergy of particle-stimulated nucleation and Zener/Orowan mechanisms, alongside verified phase purity and a low defect background, making it a promising candidate for formable AMC components in transportation applications.

Author Contributions

Conceptualization, M.A. and I.T.; methodology, M.A., I.T. and N.L.; validation, N.L. and Z.A.; formal analysis, N.L. and Z.A.; investigation, K.N. and S.K.; resources, M.A. and I.T.; data curation, Z.A. and S.K.; writing—original draft preparation, M.A. and I.T.; writing—review and editing, N.L. and K.N.; visualization, Z.A. and S.K.; supervision, M.A.; project administration, M.A.; funding acquisition, M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. AP19677907).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All the relevant data are contained within the article itself. Additional data may be shared by the authors following a reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AMCs | Aluminum matrix composites |

| UASC | Ultrasonically assisted stir casting |

| RSR | Radial-shear rolling |

| SEM | Scanning electron microscopy |

| EBSD | Electron backscatter diffraction |

| XRD | X-ray diffraction |

| ASTM | American Society for Testing and Materials |

References

- Oyewo, A.T.; Oluwole, O.O.; Ajide, O.O.; Omoniyi, T.E.; Hussain, M. A summary of current advancements in hybrid composites based on aluminium matrix in aerospace applications. Hybrid Adv. 2024, 5, 100117. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Sáenz-Nuño, M.A. Sustainable Processes in Aluminium, Magnesium, and Titanium Alloys Applied to the Transport Sector: A Review. Metals 2022, 12, 9. [Google Scholar] [CrossRef]

- Kar, A.; Sharma, A.; Kumar, S. A Critical Review on Recent Advancements in Aluminium-Based Metal Matrix Composites. Crystals 2024, 14, 412. [Google Scholar] [CrossRef]

- Ujah, C.O.; Kallon, D.V.V. Trends in Aluminium Matrix Composite Development. Crystals 2022, 12, 1357. [Google Scholar] [CrossRef]

- Ramanathan, A.; Krishnan, P.K.; Muraliraja, R. A review on the production of metal matrix composites through stir casting–Furnace design, properties, challenges, and research opportunities. J. Manuf. Process. 2019, 42, 213–245. [Google Scholar] [CrossRef]

- Rutecka, A.; Makowska, K.; Kowalewski, Z.L. Mechanical and Microstructural Investigations of AA2124/SiC Metal Matrix Composites After Creep. Materials 2025, 18, 4495. [Google Scholar] [CrossRef]

- Zubcak, M.; Soltes, J.; Zimina, M.; Weinberger, T.; Enzinger, N. Investigation of Al-B4C Metal Matrix Composites Produced by Friction Stir Additive Processing. Metals 2021, 11, 2020. [Google Scholar] [CrossRef]

- Channar, H.R.; Ullah, B.; Naseem, M.S.; Akhter, J.; Mehmood, A.; Aamir, M. Mechanical Properties and Microstructural Investigation of AA2024-T6 Reinforced with Al2O3 and SiC Metal Matrix Composites. Eng 2024, 5, 3023–3032. [Google Scholar] [CrossRef]

- Mustafa, S.; Haider, J.; Matteis, P.; Murtaza, Q. Synthesis and Wear Behaviour Analysis of SiC- and Rice Husk Ash-Based Aluminium Metal Matrix Composites. J. Compos. Sci. 2023, 7, 394. [Google Scholar] [CrossRef]

- Ravindran, S.; Mani, N.; Balaji, S.; Abhijith, M.; Surendaran, K. Mechanical Behaviour of Aluminium Hybrid Metal Matrix Composites—A Review. Mater. Today Proc. 2019, 16, 1020–1033. [Google Scholar] [CrossRef]

- Kareem, A.; Qudeiri, J.A.; Abdudeen, A.; Ahammed, T.; Ziout, A. A Review on AA 6061 Metal Matrix Composites Produced by Stir Casting. Materials 2021, 14, 175. [Google Scholar] [CrossRef]

- Patel, S.K.; Shi, L. Recent Advances in Ceramic-Reinforced Aluminum Metal Matrix Composites: A Review. Alloys 2025, 4, 18. [Google Scholar] [CrossRef]

- Yadav, P.; Ranjan, A.; Kumar, H.; Mishra, A.; Yoon, J. A Contemporary Review of Aluminium MMC Developed through Stir-Casting Route. Materials 2021, 14, 6386. [Google Scholar] [CrossRef]

- Sharma, S.K.; Gajević, S.; Sharma, L.K.; Pradhan, R.; Sharma, Y.; Miletić, I.; Stojanović, B. Progress in Aluminum-Based Composites Prepared by Stir Casting: Mechanical and Tribological Properties for Automotive, Aerospace, and Military Applications. Lubricants 2024, 12, 421. [Google Scholar] [CrossRef]

- Monteiro, B.; Simões, S. Recent Advances in Hybrid Nanocomposites for Aerospace Applications. Metals 2024, 14, 1283. [Google Scholar] [CrossRef]

- Sarmah, P.; Gupta, K. Recent Advancements in Fabrication of Metal Matrix Composites: A Systematic Review. Materials 2024, 17, 4635. [Google Scholar] [CrossRef] [PubMed]

- Shivalingaiah, K.; Nagarajaiah, V.; Selvan, C.P.; Kariappa, S.T.; Chandrashekarappa, N.G.; Lakshmikanthan, A.; Chandrashekarappa, M.P.G.; Linul, E. Stir Casting Process Analysis and Optimization for Better Properties in Al-MWCNT-GR-Based Hybrid Composites. Metals 2022, 12, 1297. [Google Scholar] [CrossRef]

- Grilo, J.; Carneiro, V.H.; Teixeira, J.C.; Puga, H. Manufacturing Methodology on Casting-Based Aluminium Matrix Composites: Systematic Review. Metals 2021, 11, 436. [Google Scholar] [CrossRef]

- Mantha, S.R.V.; Kumar, G.B.V.; Pramod, R.; Rao, C.S.P. Investigations on Microstructure, Mechanical, and Wear Properties, with Strengthening Mechanisms of Al6061-CuO Composites. J. Manuf. Mater. Process. 2024, 8, 245. [Google Scholar] [CrossRef]

- Abishkenov, M.; Tavshanov, I.; Lutchenko, N.; Amanzholov, N.; Kalmyrzayev, D.; Ashkeyev, Z.; Nogaev, K.; Kydyrbayeva, S.; Abdirashit, A. Improving Mechanical Properties of Low-Quality Pure Aluminum by Minor Reinforcement with Fine B4C Particles and T6 Heat Treatment. Appl. Sci. 2024, 14, 10773. [Google Scholar] [CrossRef]

- Maddaiah, K.C.; Kumar, G.B.V.; Pramod, R. Studies on the Mechanical, Strengthening Mechanisms and Tribological Characteristics of AA7150-Al2O3 Nano-Metal Matrix Composites. J. Compos. Sci. 2024, 8, 97. [Google Scholar] [CrossRef]

- Bhowmik, A.; Sen, B.; Beemkumar, N.; Singh Chohan, J.; Bains, P.S.; Singh, G.; Kumar, A.V.; Santhosh, A.J. Development and wear resistivity performance of SiC and TiB2 particles reinforced novel aluminium matrix composites. Results Eng. 2024, 24, 102981. [Google Scholar] [CrossRef]

- Alfattani, R.; Yunus, M. Explorations of mechanical and corrosion resistance properties of AA6063/TiB2/Cr2O3 hybrid composites produced by stir casting. J. Sci. Adv. Mater. Devices 2024, 9, 100790. [Google Scholar] [CrossRef]

- Rane, K.; Dhokey, N. On the Formation and Distribution of In Situ Synthesized TiB2 Reinforcements in Cast Aluminium Matrix Composites. J. Compos. Sci. 2018, 2, 52. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, X.; Fang, Y.; Guo, E.; Kang, H.; Hao, Z.; Li, J.; Du, G.; Liu, L.; Chen, Z.; et al. Multiscale microstructures, mechanical properties and electrical conductivity of in-situ dual-size TiB2 particles reinforced 6201 aluminum matrix composites. J. Mater. Res. Technol. 2023, 23, 5459–5473. [Google Scholar] [CrossRef]

- Farooq, S.A.; Mukhtar, S.H.; Raina, A.; Ul Haq, M.I.; Siddiqui, M.I.H.; Naveed, N.; Dobrota, D. Effect of TiB2 on the Mechanical and Tribological Properties of Marine Grade Aluminum Alloy 5052: An Experimental Investigation. J. Mater. Res. Technol. 2024, 29, 3749–3758. [Google Scholar] [CrossRef]

- Sharifov, D.; Niyazbekova, R.; Mirzo, A.; Shansharova, L.; Serekpayeva, M.; Aldabergenova, S.; Ibzhanova, A.; Machnik, R.; Bembenek, M. The Study of Composite Materials Properties Based on Polymers and Nano-Additives from Industrial Wastes from Kazakhstan. Materials 2024, 17, 2959. [Google Scholar] [CrossRef]

- Kenzhaliyev, B.; Biryukova, A.; Dzhienalyev, T.; Panichkin, A.; Imbarova, A.; Uskenbaeva, A.; Yusoff, A.H. Assessment of Microsilica as a Raw Material for Obtaining Mullite–Silica Refractories. Processes 2024, 12, 200. [Google Scholar] [CrossRef]

- Abishkenov, M.; Tavshanov, I.; Lutchenko, N.; Nogaev, K.; Kalmyrzayev, D.; Abdirashit, A.; Aikenbayeva, N. Effect of Minor Reinforcement with Ultrafine Industrial Microsilica Particles and T6 Heat Treatment on Mechanical Properties of Aluminum Matrix Composites. Appl. Sci. 2025, 15, 1329. [Google Scholar] [CrossRef]

- Kuz’min, M.P.; Larionov, L.M.; Chu, P.K.; Qasim, A.M.; Kuz’mina, M.Y.; Kondratiev, V.V.; Kuz’mina, A.S.; Ran, J.Q. New Methods of Obtaining Al–Si Alloys Using Amorphous Microsilica. Int. J. Met. 2020, 14, 207–217. [Google Scholar] [CrossRef]

- Fanani, E.W.A.; Surojo, E.; Prabowo, A.R.; Akbar, H.I. Recent Progress in Hybrid Aluminum Composite: Manufacturing and Application. Metals 2021, 11, 1919. [Google Scholar] [CrossRef]

- Ikumapayi, O.M.; Akinlabi, E.T.; Abegunde, O.O.; Ken-Ezihuo, P.; Benjamin, H.A.; Afolalu, S.A.; Akinlabi, S.A. Influence of Heat Treatment on the Corrosion Behaviour of Aluminium Silver Nano Particle/Calcium Carbonate Composite. J. Compos. Sci. 2021, 5, 280. [Google Scholar] [CrossRef]

- Bedolla-Becerril, E.; Garcia-Guerra, J.; Lopez-Morelos, V.H.; Garcia-Renteria, M.A.; Falcon-Franco, L.A.; Martinez-Landeros, V.H.; García-Villarreal, S.; Flores-Villaseñor, S.E. Tribological Behaviour of Al-2024/TiC Metal Matrix Composites. Coatings 2023, 13, 77. [Google Scholar] [CrossRef]

- Luo, Y.; Yi, J.; Chen, M.; Zhou, L.; Zhang, Z.; Huang, Z.; Sun, X.; Zhang, Y.; Wen, L.; Wu, Z. Effect of hot rolling on microstructures and mechanical properties of SiCp/A356 aluminum matrix composites. J. Mater. Res. Technol. 2024, 33, 1776–1784. [Google Scholar] [CrossRef]

- Wang, Z.J.; Zheng, Z.; Fu, M.W. Aluminum matrix composites: Structural design and microstructure evolution in the deformation process. J. Mater. Res. Technol. 2024, 30, 3724–3754. [Google Scholar] [CrossRef]

- Nogayev, K.; Kamarov, A.; Abishkenov, M.; Ashkeyev, Z.; Sembayev, N.; Kydyrbayeva, S. Finite Element-Based Multi-Objective Optimization of a New Inclined Oval Rolling Pass Geometry. Modelling 2025, 6, 110. [Google Scholar] [CrossRef]

- Abishkenov, M.; Ashkeyev, Z.; Nogaev, K.; Bestembek, Y.; Azimbayev, K.; Tavshanov, I. On the possibility of implementing a simple shear in the cross-section of metal materials during caliber rolling. Eng. Solid Mech. 2023, 11, 253–262. [Google Scholar] [CrossRef]

- Mashekov, S.; Nurtazaev, E.; Mashekova, A.; Abishkenov, M. Extruding aluminum bars on a new structure radial shear mill. Metalurgija 2021, 60, 427–430. [Google Scholar]

- Hennum, E.; Marthinsen, K.; Tundal, U.H. Effect of Microstructure on the Precipitation of β-Mg2Si during Cooling after Homogenisation of Al-Mg-Si Alloys. Metals 2024, 14, 215. [Google Scholar] [CrossRef]

- James, J.; Annamalai, A.R.; Muthuchamy, A.; Jen, C.-P. Effect of Wettability and Uniform Distribution of Reinforcement Particle on Mechanical Property (Tensile) in Aluminum Metal Matrix Composite—A Review. Nanomaterials 2021, 11, 2230. [Google Scholar] [CrossRef] [PubMed]

- Abishkenov, M.; Tavshanov, I.; Lutchenko, N.; Nogayev, K.; Ashkeyev, Z.; Kulidan, S. Microstructure and Mechanical Properties of Al6060/TiB2 Aluminum Matrix Composites Produced via Ultrasonically Assisted Stir Casting and Radial-Shear Rolling. J. Manuf. Mater. Process. 2025, 9, 309. [Google Scholar] [CrossRef]

- Abishkenov, M.; Tavshanov, I.; Lutchenko, N.; Nogayev, K.; Ashkeyev, Z.; Kulidan, S. Microstructural Evolution and Mechanical Properties of Hybrid Al6060/TiB2–MWCNT Composites Fabricated by Ultrasonically Assisted Stir Casting and Radial-Shear Rolling. Appl. Sci. 2025, 15, 10427. [Google Scholar] [CrossRef]

- ASTM E8; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM E384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Doddapaneni, S.; Kumar, S.; Sharma, S.; Shankar, G.; Shettar, M.; Kumar, N.; Aroor, G.; Ahmad, S.M. Advancements in EBSD Techniques: A Comprehensive Review on Characterization of Composites and Metals, Sample Preparation, and Operational Parameters. J. Compos. Sci. 2025, 9, 132. [Google Scholar] [CrossRef]

- Zheng, X.; Long, W.; Zhu, C.; Zhao, L.; Hu, X.; Liu, S.; Jiang, W.; Peng, Y. The Effect of Micron-Sized TiB2 Particles on the Properties of Al6061 Strengthened with 4% TiB2 Nano-TiB2. Materials 2024, 17, 182. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Li, C.; Xu, S.; Hu, Y.; Ji, G.; Wang, H. Microstructure and Microhardness of Ni/Al-TiB2 Composite Coatings Prepared by Cold Spraying Combined with Postannealing Treatment. Coatings 2019, 9, 565. [Google Scholar] [CrossRef]

- Wang, Z.; Ren, Z.; Li, Y.; Wang, Z.; Chen, J.; Sun, Z.; Wang, Z.; Wang, H.; Tang, H. Effect of TiC Particles on High-Temperature Properties of Al-Li Alloy and Coarsening of Al2CuLi(T1) Precipitates. Materials 2025, 18, 922. [Google Scholar] [CrossRef]

- Elkady, M.; Sörgel, T. Impact of Dry Chemical-Free Mechanical Pressing on Deagglomeration of Submicron-Sized Boron Carbide Particles. Nanomaterials 2025, 15, 611. [Google Scholar] [CrossRef]

- Karlina, A.I.; Karlina, Y.I.; Gladkikh, V.A. Analysis of Experience in the Use of Micro- and Nanoadditives from Silicon Production Waste in Concrete Technologies. Minerals 2023, 13, 1525. [Google Scholar] [CrossRef]

- Kim, J.-H.J.; You, Y.-J.; Jeong, Y.-J.; Choi, J.-H. Stable Failure-Inducing Micro-Silica Aqua Epoxy Bonding Material for Floating Concrete Module Connection. Polymers 2015, 7, 2389–2409. [Google Scholar] [CrossRef]

- Gallegos Orozco, V.; Santos Beltrán, A.; Santos Beltrán, M.; Medrano Prieto, H.; Gallegos Orozco, C.; Estrada Guel, I. Effect on Microstructure and Hardness of Reinforcement in Al–Cu with Al4C3 Nanocomposites. Metals 2021, 11, 1203. [Google Scholar] [CrossRef]

- Peng, Y.; Xie, Z.; Su, C.; Zhong, Y.; Tao, Z.; Zhuang, D.; Zeng, J.; Tang, H.; Xu, Z. Inhomogeneous Microstructure Evolution of 6061 Aluminum Alloyat High Rotating Speed Submerged Friction Stir Processing. Materials 2023, 16, 579. [Google Scholar] [CrossRef] [PubMed]

- Fu, H.; Yan, H.; Wei, B.; Sun, B.; Liu, Z.; Gao, W. Effect of Zr Additions on the Microstructure and Elevated-Temperature Mechanical Properties of Al–Cu–Mg–Ag–Zn–Mn–Zr Alloys. Materials 2025, 18, 4062. [Google Scholar] [CrossRef] [PubMed]

- Koju, R.K.; Mishin, Y. The Role of Grain Boundary Diffusion in the Solute Drag Effect. Nanomaterials 2021, 11, 2348. [Google Scholar] [CrossRef]

- Malaki, M.; Xu, W.; Kasar, A.K.; Menezes, P.L.; Dieringa, H.; Varma, R.S.; Gupta, M. Advanced Metal Matrix Nanocomposites. Metals 2019, 9, 330. [Google Scholar] [CrossRef]

- Hu, Y.; Jiang, R.; Li, X.; Hu, R. Effect of Ultrasonic-Assisted Casting on the Hydrogen and Lithium Content of Al-Li Alloy. Materials 2022, 15, 1081. [Google Scholar] [CrossRef]

- El-Sayed, M.A.; Essa, K.; Hassanin, H. Influence of Bifilm Defects Generated during Mould Filling on the Tensile Properties of Al–Si–Mg Cast Alloys. Metals 2022, 12, 160. [Google Scholar] [CrossRef]

- Fracchia, E.; Gobber, F.S.; Rosso, M.; Actis Grande, M.; Bidulská, J.; Bidulský, R. Junction Characterization in a Functionally Graded Aluminum Part. Materials 2019, 12, 3475. [Google Scholar] [CrossRef]

- Lazaro-Nebreda, J.; Patel, J.B.; Lordan, E.; Zhang, Y.; Karakulak, E.; Al-Helal, K.; Scamans, G.M.; Fan, Z. Degassing of Aluminum Alloy Melts by High Shear Melt Conditioning Technology: An Overview. Metals 2022, 12, 1772. [Google Scholar] [CrossRef]

- Grilo, J.; Puga, H.; Carneiro, V.H.; Tohidi, S.D.; Barbosa, F.V.; Teixeira, J.C. Effect of Hybrid Ultrasonic and Mechanical Stirring on the Distribution of m-SiCp in A356 Alloy. Metals 2020, 10, 610. [Google Scholar] [CrossRef]

- Malaki, M.; Tehrani, A.F.; Niroumand, B.; Abdullah, A. Ultrasonically Stir Cast SiO2/A356 Metal Matrix Nanocomposites. Metals 2021, 11, 2004. [Google Scholar] [CrossRef]

- Huang, J.; Xiang, Z.; Li, M.; Li, L.; Chen, Z. Hot Deformation Behavior and Microstructural Evolution of a TiB2/Al-Zn-Mg-Cu-Zr Composite. Materials 2024, 17, 1487. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; He, Y.; Peng, F.; Liu, Y. Influences of Second Phase Particle Precipitation, Coarsening, Growt.h or Dissolution on the Pinning Effects during Grain Coarsening Processes. Metals 2023, 13, 281. [Google Scholar] [CrossRef]

- Twardowska, A.; Podsiadło, M.; Sulima, I.; Bryła, K.; Hyjek, P. Microstructure and Properties of TiB2 Composites Produced by Spark Plasma Sintering with the Addition of Ti5Si3. Materials 2021, 14, 3812. [Google Scholar] [CrossRef]

- Arunachelam, N.; Maheswaran, J.; Chellapandian, M.; Murali, G.; Vatin, N.I. Development of High-Strength Geopolymer Concrete Incorporating High-Volume Copper Slag and Micro Silica. Sustainability 2022, 14, 7601. [Google Scholar] [CrossRef]

- Kim, Y.-M.; Choi, S.-W.; Kim, Y.-C.; Kang, C.-S.; Hong, S.-K. Influence of the Precipitation of Secondary Phase on the Thermal Diffusivity Change of Al-Mg2Si Alloys. Appl. Sci. 2018, 8, 2039. [Google Scholar] [CrossRef]

- Milkereit, B.; Starink, M.J.; Rometsch, P.A.; Schick, C.; Kessler, O. Review of the Quench Sensitivity of Aluminium Alloys: Analysis of the Kinetics and Nature of Quench-Induced Precipitation. Materials 2019, 12, 4083. [Google Scholar] [CrossRef]

- Zupanič, F.; Steinacher, M.; Žist, S.; Bončina, T. Microstructure and Properties of a Novel Al-Mg-Si Alloy AA 6086. Metals 2021, 11, 368. [Google Scholar] [CrossRef]

- Ko, S.; Park, H.; Lee, Y.-H.; Shin, S.; Jo, I.; Kim, J.; Lee, S.-B.; Kim, Y.; Lee, S.-K.; Cho, S. Fabrication of TiB2–Al1050 Composites with Improved Microstructural and Mechanical Properties by a Liquid Pressing Infiltration Process. Materials 2020, 13, 1588. [Google Scholar] [CrossRef]

- Gao, Q.; Yang, B.; Gan, G.; Zhong, Y.; Sun, L.; Zhai, W.; Qiang, W.; Wang, S.; Lu, Y. Microstructure and Wear Resistance of TiB2/7075 Composites Produced via Rheocasting. Metals 2020, 10, 1068. [Google Scholar] [CrossRef]

- Pingale, A.D.; Gautam, D.; Owhal, A.; Deshwal, D.; Belgamwar, S.U.; Rao, V.K.P. Development of Non-Destructive Dynamic Characterization Technique for MMCs: Predictions of Mechanical Properties for Al@Al2O3 Composites. NDT 2023, 1, 22–34. [Google Scholar] [CrossRef]

- Gamin, Y.V.; Belov, N.A.; Akopyan, T.K.; Timofeev, V.N.; Cherkasov, S.O.; Motkov, M.M. Effect of Radial-Shear Rolling on the Structure and Hardening of an Al–8%Zn–3.3%Mg–0.8%Ca–1.1%Fe Alloy Manufactured by Electromagnetic Casting. Materials 2023, 16, 677. [Google Scholar] [CrossRef] [PubMed]

- Arbuz, A.; Panichkin, A.; Popov, F.; Kawalek, A.; Ozhmegov, K.; Lutchenko, N. Modeling the Evolution of Casting Defect Closure in Ingots through Radial Shear Rolling Processing. Metals 2024, 14, 53. [Google Scholar] [CrossRef]

- Ozhmegov, K.; Kawalek, A.; Naizabekov, A.; Panin, E.; Lutchenko, N.; Sultanbekov, S.; Magzhanov, M.; Arbuz, A. The Effect of Radial-Shear Rolling Deformation Processing on the Structure and Properties of Zr-2.5Nb Alloy. Materials 2023, 16, 3873. [Google Scholar] [CrossRef] [PubMed]

- Muñoz, J.A.; Khelfa, T.; Duarte, G.A.; Avalos, M.; Bolmaro, R.; Cabrera, J.M. Plastic Behavior and Microstructure Heterogeneity of an AA6063-T6 Aluminum Alloy Processed by Symmetric and Asymmetric Rolling. Metals 2022, 12, 1551. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).