Driving Green Through Lean: A Structured Causal Analysis of Lean Practices in Automotive Sustainability

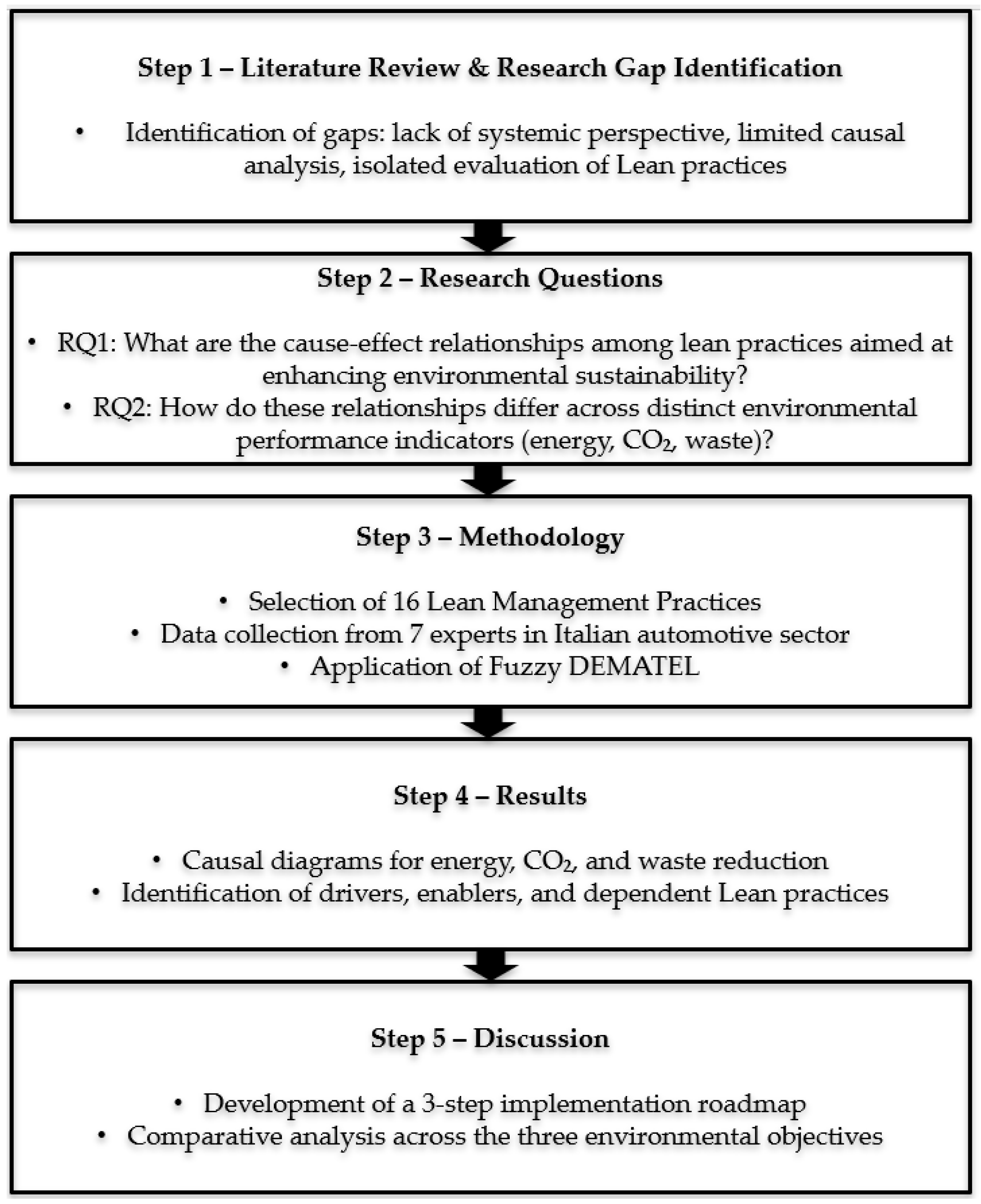

Abstract

1. Introduction

2. Literature Review

2.1. Systematic Literature Review on Lean and Environmental Performance

2.2. Research Gaps and Emerging Questions

- RQ1: What are the cause–effect relationships among lean practices aimed at enhancing environmental sustainability?

- RQ2: How do these relationships differ when evaluating distinct environmental performance indicators: energy consumption, CO2 emissions, and waste generation?

3. Methodology

3.1. Expert Selection

- Industry Experience: All experts had a minimum of 8 years of professional experience in the automotive industry, ensuring deep knowledge of sector-specific processes, challenges, and dynamics.

- Lean Management Specialization: Each expert was a recognized specialist in Lean Management within the automotive sector, providing informed insights into the implementation of lean practices and their environmental implications.

- Supply Chain Diversification: Experts were selected from different points along the automotive supply chain, including both component manufacturers and final product assemblers. This diversification enabled a comprehensive perspective across various operational contexts.

- Nationality and Contextual Consistency: Only Italian experts were included to maintain cultural and regulatory consistency. This helped ensure homogeneity in the responses and a focused analysis of Lean Management practices in the Italian automotive industry.

3.2. DEMATEL Computation

- How much more impactful is practice X than practice Y in reducing energy consumption?

- How much more impactful is practice X than practice Y in reducing CO2 emissions?

- How much more impactful is practice X than practice Y in reducing waste generation?

- Normalization:

- Step 1: Generation of average matrix

- Step 2: Normalized initial direct-relation matrix (X)

- Step 3: The total relation matrix (T)

- Step 4: Prominence and Relevance

- Step 5: Set a threshold and draw the cause–effect diagram.

4. Results

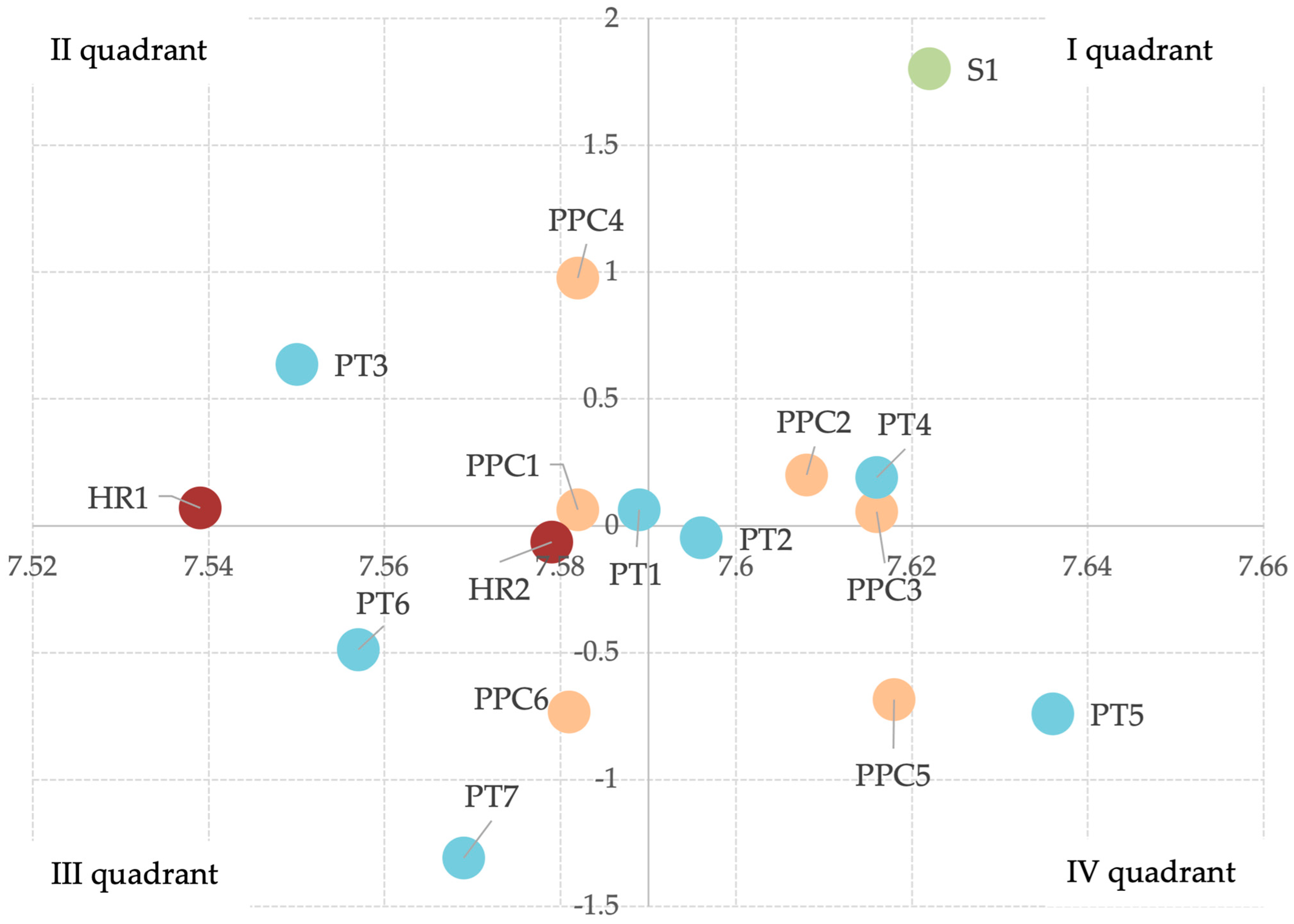

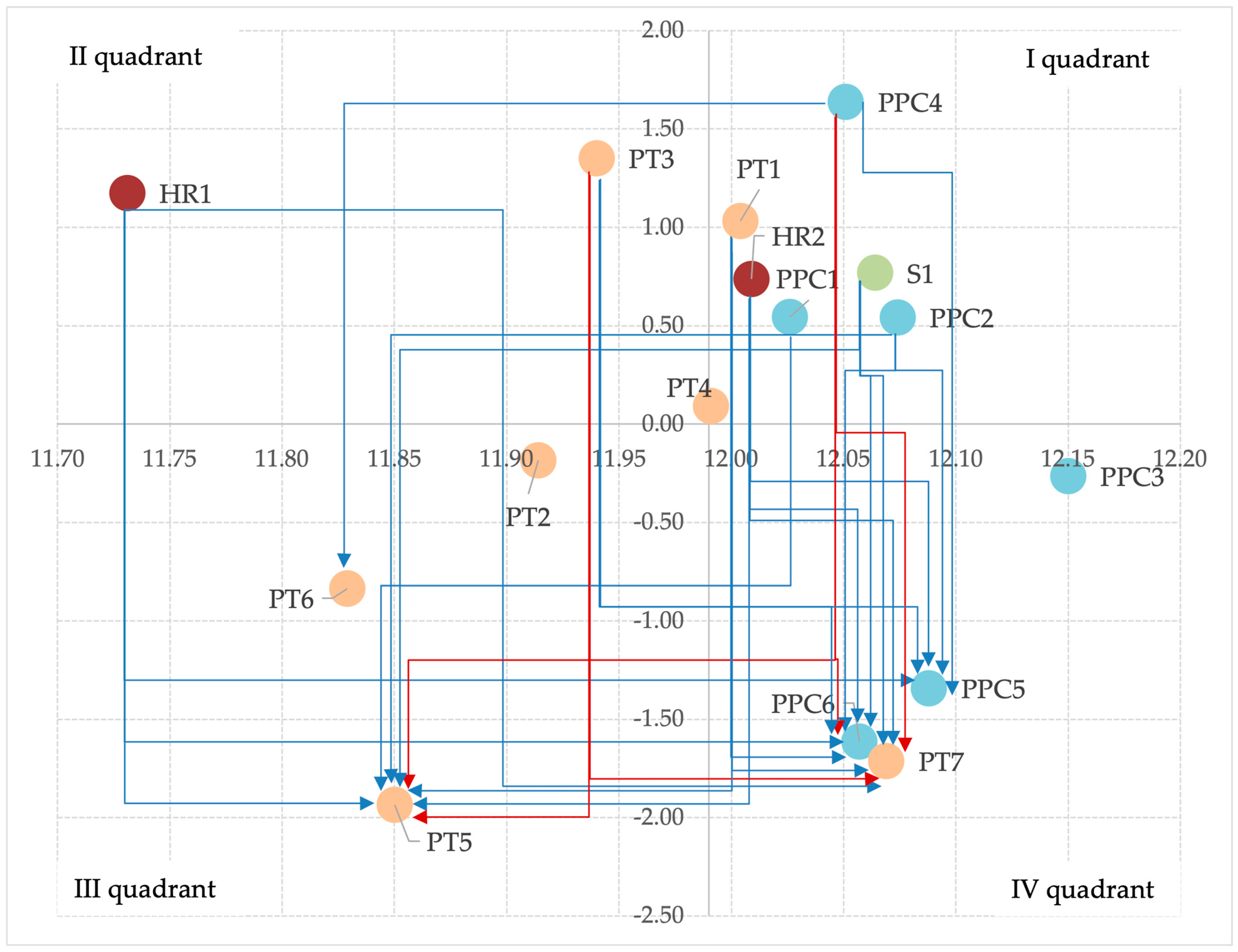

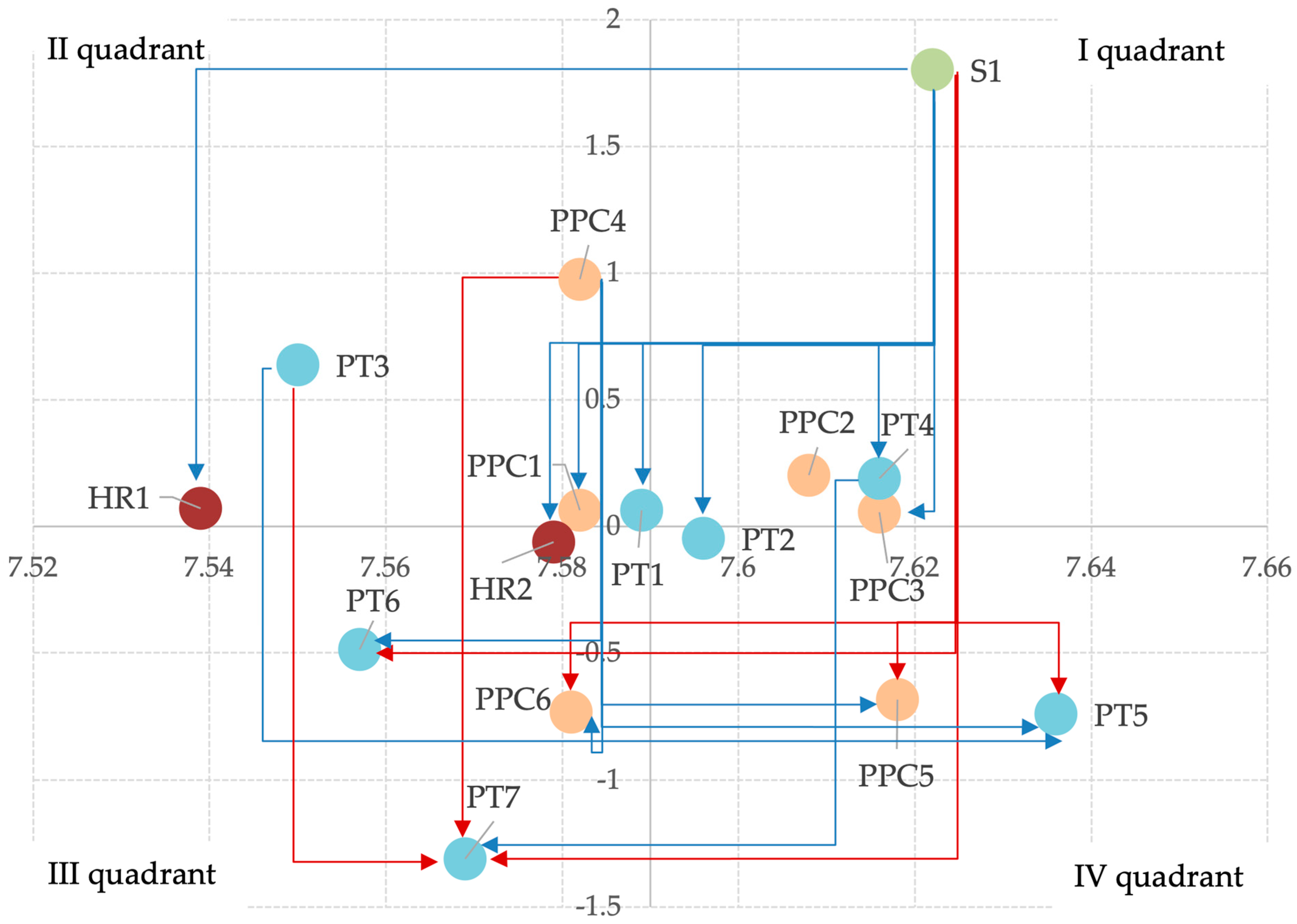

4.1. Results Related to Energy Reduction

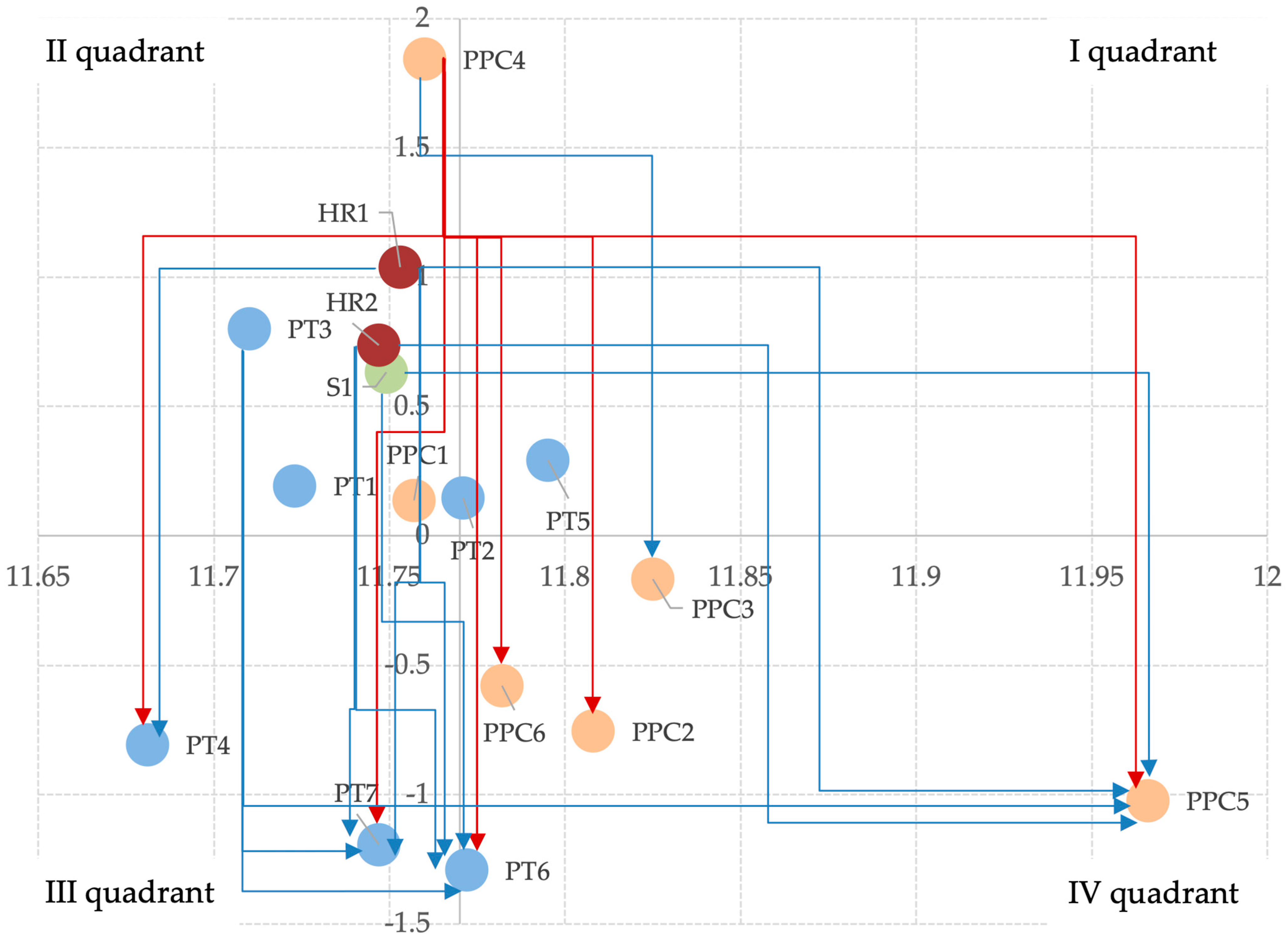

4.2. Results Related to CO2 Emission Reduction

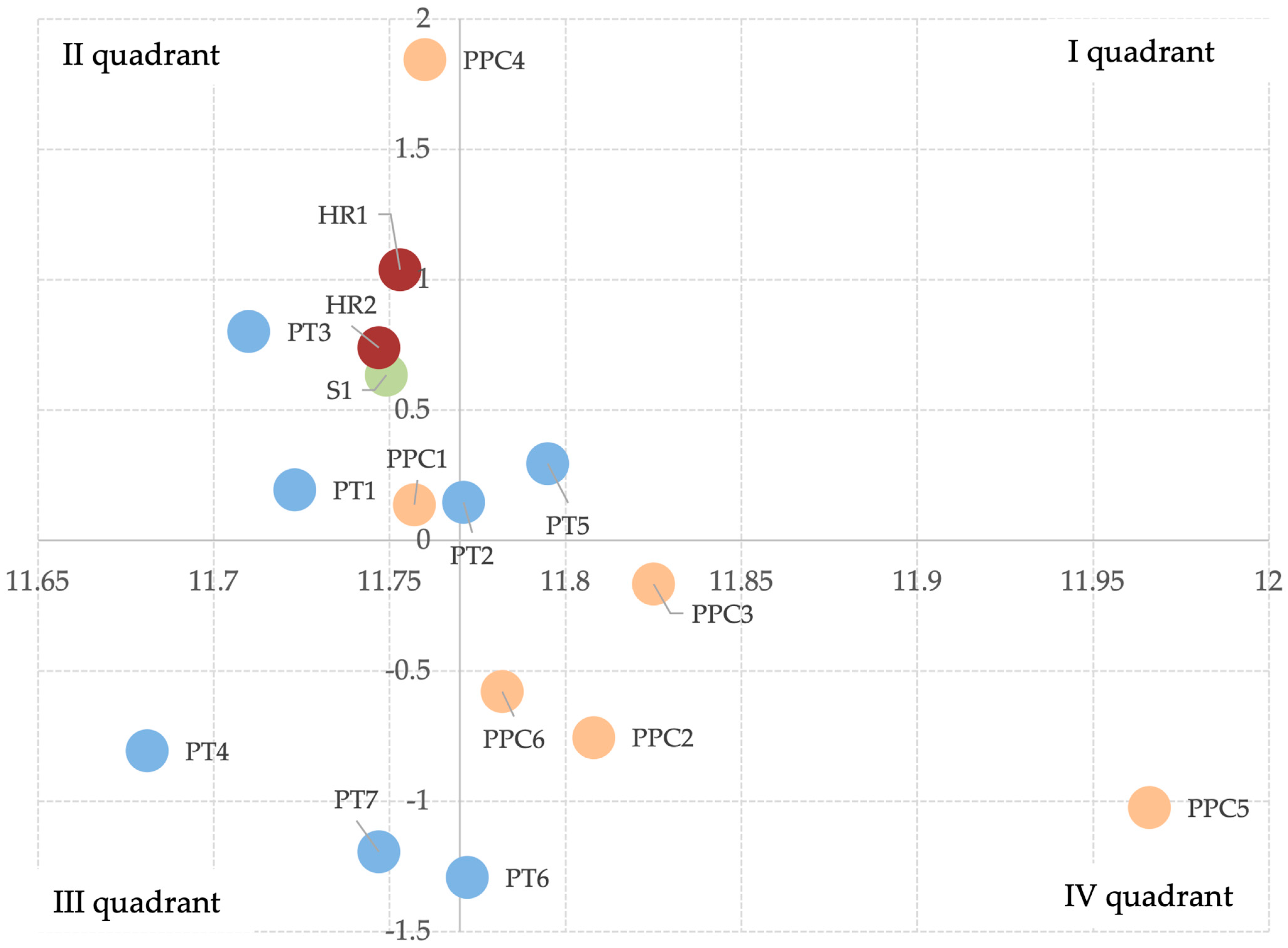

4.3. Results Related to Waste Reduction

5. Discussion

5.1. Energy Reduction Discussion

5.2. CO2 Emission Reduction Discussion

5.3. Waste Reduction Discussion

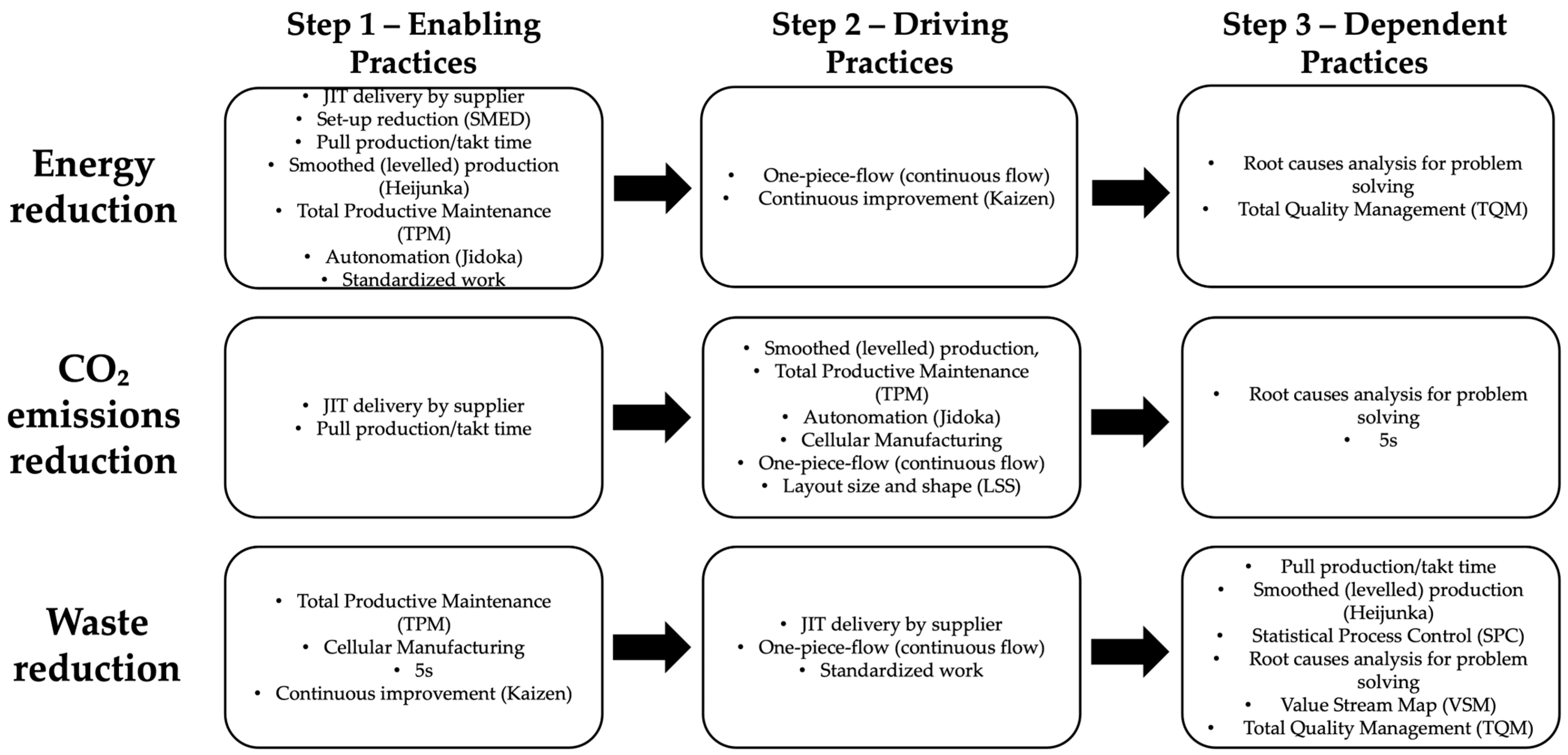

5.4. Cross-Analysis of Lean Practices Across Environmental Performance

6. Conclusions

Limitations and Directions for Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Acerbi, F.; Sassanelli, C.; Terzi, S.; Taisch, M. A Systematic Literature Review on Data and Information Required for Circular Manufacturing Strategies Adoption. Sustainability 2021, 13, 2047. [Google Scholar] [CrossRef]

- Sarkar, B.; Ullah, M.; Sarkar, M. Environmental and Economic Sustainability through Innovative Green Products by Remanufacturing. J. Clean. Prod. 2022, 332, 129813. [Google Scholar] [CrossRef]

- Transforming Our World: The 2030 Agenda for Sustainable Development Transforming Our World: The 2030 Agenda for Sustainable Development Preambl; United Nations: New York, NY, USA, 2015.

- Skalli, D.; Charkaoui, A.; Cherrafi, A.; Shokri, A.; Garza-Reyes, J.A.; Antony, J. Analysis of Factors Influencing Circular-Lean-Six Sigma 4.0 Implementation Considering Sustainability Implications: An Exploratory Study. Int. J. Prod. Res. 2024, 62, 3890–3917. [Google Scholar] [CrossRef]

- Ferrazzi, M.; Frecassetti, S.; Bilancia, A.; Portioli-Staudacher, A. Investigating the Influence of Lean Manufacturing Approach on Environmental Performance: A Systematic Literature Review. Int. J. Adv. Manuf. Technol. 2024, 136, 4025–4044. [Google Scholar] [CrossRef]

- Ferrazzi, M.; Tortorella, G.L.; Li, W.; Costa, F.; Portioli-Staudacher, A. From People to Performance: Leveraging Soft Lean Practices for Environmental Sustainability in Large-Scale Production. Sustainability 2025, 17, 3955. [Google Scholar] [CrossRef]

- Frecassetti, S.; Bassel, K.; Kaustav, K.; Matteo, F.; Portioli-Staudacher, A. Introducing Lean Practices through Simulation: A Case Study in an Italian SME. Qual. Manag. J. 2023, 30, 90–104. [Google Scholar] [CrossRef]

- Ferrazzi, M.; Li, W.; Tortorella, G.L.; Costa, F.; Portioli-Staudacher, A. Assessing the Environmental Benefits of Lean Practices in the Manufacturing Industry: An Interpretive Ranking Process Analysis. J. Clean. Prod. 2025, 525, 146405. [Google Scholar] [CrossRef]

- Siegel, R.; Antony, J.; Garza-Reyes, J.A.; Cherrafi, A.; Lameijer, B. Integrated Green Lean Approach and Sustainability for SMEs: From Literature Review to a Conceptual Framework. J. Clean. Prod. 2019, 240, 118205. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A. Lean and Green-a Systematic Review of the State of the Art Literature. J. Clean. Prod. 2015, 102, 18–29. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Zhang, H. Construction of Lean-Green Coordinated Development Model from the Perspective of Personnel Integration in Manufacturing Companies. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2020, 234, 1460–1470. [Google Scholar] [CrossRef]

- Sunmola, F.; Mbafotu, O.R.; Salihu-Yusuf, M.L.; Sunmola, H.O. Lean Green Practices in Automotive Components Manufacturing. Procedia Comput. Sci. 2024, 232, 2001–2008. [Google Scholar] [CrossRef]

- Mamat, R.C.; Md Deros, B.; Ab Rahman, M.N.; Omar, M.K.; Abdullah, S. Soft Lean Practices for Successful Lean Production System Implementation in Malaysia Automotive Smes: A Proposed Framework. J. Teknol. 2015, 77, 141–150. [Google Scholar] [CrossRef]

- Abu, F.; Gholami, H.; Saman, M.Z.M.; Zakuan, N.; Streimikiene, D.; Kyriakopoulos, G.L. An Sem Approach for the Barrier Analysis in Lean Implementation in Manufacturing Industries. Sustainability 2021, 13, 1978. [Google Scholar] [CrossRef]

- Rossini, M.; Costa, F.; Staudacher, A.P.; Tortorella, G. Industry 4.0 and Lean Production: An Empirical Study. IFAC-PapersOnLine 2019, 52, 42–47. [Google Scholar] [CrossRef]

- Dieste, M.; Panizzolo, R.; Garza-Reyes, J.A. Evaluating the Impact of Lean Practices on Environmental Performance: Evidences from Five Manufacturing Companies. Prod. Plan. Control 2020, 31, 739–756. [Google Scholar] [CrossRef]

- Dieste, M.; Panizzolo, R.; Garza-Reyes, J.A.; Anosike, A. The Relationship between Lean and Environmental Performance: Practices and Measures. J. Clean. Prod. 2019, 224, 120–131. [Google Scholar] [CrossRef]

- Ferrazzi, M.; Costa, F.; Frecassetti, S.; Portioli-Staudacher, A. Unlocking Synergies in Lean Manufacturing for Enhanced Environmental Performance: A Cross-Sector Investigation through Fuzzy DEMATEL. Clean. Logist. Supply Chain. 2025, 15, 100219. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Lean Manufacturing: Context, Practice Bundles, and Performance. J. Oper. Manag. 2003, 21, 129–149. [Google Scholar] [CrossRef]

- Bai, C.; Satir, A.; Sarkis, J. Investing in Lean Manufacturing Practices: An Environmental and Operational Perspective. Int. J. Prod. Res. 2019, 57, 1037–1051. [Google Scholar] [CrossRef]

- Ferrazzi, M.; Portioli-Staudacher, A. Applying the Value Stream Map to Streamline Energy Consumption: Analysis of an Italian Company. In Advances in Production Management Systems. Production Management Systems for Responsible Manufacturing, Service, and Logistics Futures; Alfnes, E., Romsdal, A., Strandhagen, J.O., von Cieminski, G., Romero, D., Eds.; APMS 2023; IFIP Advances in Information and Communication Technology; Springer: Cham, Switzerland, 2023; Volume 689. [Google Scholar] [CrossRef]

- Ferrazzi, M.; Frecassetti, S.; Staudacher, A.P. Influence of the Lean Approach on Corporate Environmental Sustainability: A Case Study. In Lean, Green and Sustainability; McDermott, O., Rosa, A., Sá, J.C., Toner, A., Eds.; ELEC 2022; IFIP Advances in Information and Communication Technology; Springer: Cham, Switzerland, 2023; Volume 668. [Google Scholar] [CrossRef]

- Dieste, M.; Panizzolo, R.; Garza-Reyes, J.A. A Systematic Literature Review Regarding the Influence of Lean Manufacturing on Firms’ Financial Performance. J. Manuf. Technol. Manag. 2021, 32, 101–121. [Google Scholar] [CrossRef]

- Abualfaraa, W.; Salonitis, K.; Al-Ashaab, A.; Ala’raj, M. Lean-Green Manufacturing Practices and Their Link with Sustainability: A Critical Review. Sustainability 2020, 12, 981. [Google Scholar] [CrossRef]

- Gaikwad, L.; Sunnapwar, V. Development of an Integrated Framework of LGSS Strategies for Indian Manufacturing Firms to Improve Business Performance: An Empirical Study. TQM J. 2021, 33, 257–291. [Google Scholar] [CrossRef]

- Ben Ruben, R.; Vinodh, S.; Asokan, P. Implementation of Lean Six Sigma Framework with Environmental Considerations in an Indian Automotive Component Manufacturing Firm: A Case Study. Prod. Plan. Control 2017, 28, 1193–1211. [Google Scholar] [CrossRef]

- Singh, C.; Singh, D.; Khamba, J.S. Analyzing Barriers of Green Lean Practices in Manufacturing Industries by DEMATEL Approach. J. Manuf. Technol. Manag. 2020, 32, 176–198. [Google Scholar] [CrossRef]

- Ben Ruben, R.; Vinodh, S.; Asokan, P. ISM and Fuzzy MICMAC Application for Analysis of Lean Six Sigma Barriers with Environmental Considerations. Int. J. Lean Six Sigma 2018, 9, 64–90. [Google Scholar] [CrossRef]

- Ferrazzi, M.; Ye, F.; Frecassetti, S.; Portioli-Staudacher, A. Investigating the Relationship Among Lean Manufacturing Practices to Improved Eco-Efficiency Performance: A Fuzzy DEMATEL Analysis. In Challenging the Future with Lean; van Kollenburg, T., Kokkinou, A., McDermott, O., Eds.; ELEC 2023; IFIP Advances in Information and Communication Technology; Springer: Cham, Switzerland, 2024; Volume 681. [Google Scholar] [CrossRef]

- Costa, F.; Lispi, L.; Staudacher, A.P.; Rossini, M.; Kundu, K.; Cifone, F.D. How to Foster Sustainable Continuous Improvement: A Cause-Effect Relations Map of Lean Soft Practices. Oper. Res. Perspect. 2019, 6, 100091. [Google Scholar] [CrossRef]

- Frecassetti, S.; Rossini, M.; Portioli-Staudacher, A. Unleashing Industry 4.0: Leveraging Lean Practices to Overcome Implementation Barriers. IEEE Trans. Eng. Manag. 2024, 71, 10797–10814. [Google Scholar] [CrossRef]

- Lin, R.-J. Using Fuzzy DEMATEL to Evaluate the Green Supply Chain Management Practices. J. Clean. Prod. 2013, 40, 32–39. [Google Scholar] [CrossRef]

- Wu, W.-W.; Lee, Y.-T. Developing Global Managers’ Competencies Using the Fuzzy DEMATEL Method. Expert. Syst. Appl. 2007, 32, 499–507. [Google Scholar] [CrossRef]

- Logesh, B.; Balaji, M. Experimental Investigations to Deploy Green Manufacturing through Reduction of Waste Using Lean Tools in Electrical Components Manufacturing Company. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 365–374. [Google Scholar] [CrossRef]

| Bundles | Lean Manufacturing Practices | Practices ID |

|---|---|---|

| Supplier | JIT delivery by supplier | S1 |

| Production Planning and Control | Single-Minute Exchange of Dies (SMED) | PPC1 |

| Pull production/takt time | PPC2 | |

| Smoothed (leveled) production (Heijunka) | PPC3 | |

| Total Productive Maintenance (TPM) | PPC4 | |

| Statistical Process Control (SPC) | PPC5 | |

| Root cause analysis for problem solving | PPC6 | |

| Process Technology | Autonomation (Jidoka) | PT1 |

| One-piece-flow (continuous flow) | PT2 | |

| Cellular Manufacturing | PT3 | |

| Layout size and shape | PT4 | |

| 5S | PT5 | |

| Value Stream Maps (VSMs) | PT6 | |

| Total Quality Management (TQM) | PT7 | |

| Human Resources | Continuous improvement | HR1 |

| Standardized work | HR2 |

| Expert ID | Role | Supply Chain Positioning | Years of Experience |

|---|---|---|---|

| 1 | Associate Director | Final assembly | 10+ |

| 2 | Senior Project Manager | Final assembly | 10+ |

| 3 | Lean Manager | Component production | 10+ |

| 4 | Quality Manager | Component production | 10+ |

| 5 | Continuous Improvement Manager | Component production | 10+ |

| 6 | Program Manager | Component production | 8 |

| 7 | Head of Operations | Component production | 8 |

| Linguistic Variable | Influence Score | Corresponding Triangular Fuzzy Numbers (l,m,r) |

|---|---|---|

| much less impactful | 0 | (0,0,0.25) |

| less impactful | 1 | (0,0.25,0.5) |

| equally impactful | 2 | (0.25,0.5,0.75) |

| more impactful | 3 | (0.5,0.75,1) |

| much more impactful | 4 | (0.75,1,1) |

| Practices ID | Lean Manufacturing Practices | R | D | D + R | D − R |

|---|---|---|---|---|---|

| S1 | JIT delivery by supplier | 6.42 | 5.65 | 12.06 | 0.77 |

| PPC1 | Single-Minute Exchange of Dies (SMED) | 6.29 | 5.74 | 12.03 | 0.54 |

| PPC2 | Pull production/takt time | 6.31 | 5.77 | 12.07 | 0.54 |

| PPC3 | Smoothed (leveled) production (Heijunka) | 5.94 | 6.21 | 12.15 | −0.26 |

| PPC4 | Total Productive Maintenance (TPM) | 6.84 | 5.21 | 12.05 | 1.64 |

| PPC5 | Statistical Process Control (SPC) | 5.37 | 6.71 | 12.09 | −1.34 |

| PPC6 | Root cause analysis for problem solving | 5.22 | 6.84 | 12.06 | −1.61 |

| PT1 | Autonomation (Jidoka) | 6.52 | 5.49 | 12.00 | 1.03 |

| PT2 | Cellular Manufacturing | 5.87 | 6.05 | 11.91 | −0.18 |

| PT3 | One-piece-flow (continuous flow) | 6.65 | 5.29 | 11.94 | 1.35 |

| PT4 | Layout size and shape | 6.04 | 5.95 | 11.99 | 0.09 |

| PT5 | 5S | 4.96 | 6.89 | 11.85 | −1.93 |

| PT6 | Value Stream Maps (VSMs) | 5.50 | 6.33 | 11.83 | −0.84 |

| PT7 | Total Quality Management (TQM) | 5.18 | 6.89 | 12.07 | −1.71 |

| HR1 | Continuous improvement (Kaizen) | 6.45 | 5.28 | 11.73 | 1.18 |

| HR2 | Standardized work | 6.37 | 5.64 | 12.01 | 0.74 |

| Practices ID | Lean Manufacturing Practices | R | D | D + R | D − R |

|---|---|---|---|---|---|

| S1 | JIT delivery by supplier | 2.91 | 4.71 | 7.62 | 1.80 |

| PPC1 | Single-Minute Exchange of Dies (SMED) | 3.76 | 3.82 | 7.58 | 0.06 |

| PPC2 | Pull production/takt time | 3.70 | 3.91 | 7.61 | 0.20 |

| PPC3 | Smoothed (leveled) production (Heijunka) | 3.78 | 3.84 | 7.62 | 0.06 |

| PPC4 | Total Productive Maintenance (TPM) | 3.30 | 4.28 | 7.58 | 0.98 |

| PPC5 | Statistical Process Control (SPC) | 4.15 | 3.47 | 7.62 | −0.68 |

| PPC6 | Root cause analysis for problem solving | 4.16 | 3.42 | 7.58 | −0.73 |

| PT1 | Autonomation (Jidoka) | 3.76 | 3.83 | 7.59 | 0.06 |

| PT2 | Cellular Manufacturing | 3.82 | 3.77 | 7.60 | −0.05 |

| PT3 | One-piece-flow (continuous flow) | 3.46 | 4.09 | 7.55 | 0.64 |

| PT4 | Layout size and shape | 3.71 | 3.90 | 7.62 | 0.19 |

| PT5 | 5S | 4.19 | 3.45 | 7.64 | −0.74 |

| PT6 | Value Stream Maps (VSMs) | 4.02 | 3.54 | 7.56 | −0.49 |

| PT7 | Total Quality Management (TQM) | 4.44 | 3.13 | 7.57 | −1.31 |

| HR1 | Continuous improvement (Kaizen) | 3.73 | 3.81 | 7.54 | 0.07 |

| HR2 | Standardized work | 3.82 | 3.76 | 7.58 | −0.06 |

| Practices ID | Lean Manufacturing Practices | R | D | D + R | D − R |

|---|---|---|---|---|---|

| S1 | JIT delivery by supplier | 5.56 | 6.19 | 11.75 | 0.63 |

| PPC1 | Single-Minute Exchange of Dies (SMED) | 5.81 | 5.95 | 11.76 | 0.14 |

| PPC2 | Pull production/takt time | 6.28 | 5.53 | 11.81 | −0.76 |

| PPC3 | Smoothed (leveled) production (Heijunka) | 6.00 | 5.83 | 11.83 | −0.17 |

| PPC4 | Total Productive Maintenance (TPM) | 4.96 | 6.80 | 11.76 | 1.84 |

| PPC5 | Statistical Process Control (SPC) | 6.50 | 5.47 | 11.97 | −1.02 |

| PPC6 | Root cause analysis for problem solving | 6.18 | 5.60 | 11.78 | −0.58 |

| PT1 | Autonomation (Jidoka) | 5.77 | 5.96 | 11.72 | 0.19 |

| PT2 | Cellular Manufacturing | 5.81 | 5.96 | 11.77 | 0.15 |

| PT3 | One-piece-flow (continuous flow) | 5.46 | 6.26 | 11.71 | 0.80 |

| PT4 | Layout size and shape | 6.24 | 5.44 | 11.68 | −0.81 |

| PT5 | 5S | 5.75 | 6.04 | 11.80 | 0.29 |

| PT6 | Value Stream Maps (VSMs) | 6.53 | 5.24 | 11.77 | −1.29 |

| PT7 | Total Quality Management (TQM) | 6.47 | 5.28 | 11.75 | −1.19 |

| HR1 | Continuous improvement (Kaizen) | 5.36 | 6.40 | 11.75 | 1.04 |

| HR2 | Standardized work | 5.50 | 6.24 | 11.75 | 0.74 |

| S1 | PPC1 | PPC2 | PPC3 | PPC4 | PPC5 | PPC6 | PT1 | PT2 | PT3 | PT4 | PT5 | PT6 | PT7 | HR1 | HR2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 0.33 | 0.40 | 0.39 | 0.42 | 0.34 | 0.45 | 0.46 | 0.37 | 0.40 | 0.35 | 0.41 | 0.47 | 0.43 | 0.46 | 0.36 | 0.38 |

| PPC1 | 0.36 | 0.33 | 0.38 | 0.41 | 0.34 | 0.44 | 0.45 | 0.37 | 0.40 | 0.35 | 0.40 | 0.46 | 0.42 | 0.45 | 0.36 | 0.38 |

| PPC2 | 0.37 | 0.38 | 0.33 | 0.40 | 0.34 | 0.45 | 0.45 | 0.37 | 0.40 | 0.36 | 0.40 | 0.46 | 0.42 | 0.45 | 0.34 | 0.37 |

| PPC3 | 0.35 | 0.36 | 0.37 | 0.34 | 0.33 | 0.42 | 0.42 | 0.35 | 0.38 | 0.33 | 0.38 | 0.43 | 0.39 | 0.42 | 0.33 | 0.36 |

| PPC4 | 0.41 | 0.41 | 0.42 | 0.44 | 0.32 | 0.48 | 0.49 | 0.40 | 0.43 | 0.38 | 0.42 | 0.49 | 0.46 | 0.49 | 0.38 | 0.41 |

| PPC5 | 0.32 | 0.33 | 0.32 | 0.35 | 0.30 | 0.33 | 0.39 | 0.32 | 0.34 | 0.29 | 0.34 | 0.39 | 0.36 | 0.39 | 0.29 | 0.31 |

| PPC6 | 0.31 | 0.32 | 0.32 | 0.35 | 0.29 | 0.37 | 0.33 | 0.30 | 0.33 | 0.30 | 0.33 | 0.38 | 0.34 | 0.38 | 0.29 | 0.31 |

| PT1 | 0.39 | 0.39 | 0.39 | 0.42 | 0.36 | 0.45 | 0.47 | 0.33 | 0.42 | 0.37 | 0.41 | 0.48 | 0.44 | 0.48 | 0.36 | 0.38 |

| PT2 | 0.35 | 0.35 | 0.36 | 0.38 | 0.32 | 0.41 | 0.43 | 0.33 | 0.32 | 0.32 | 0.37 | 0.42 | 0.39 | 0.43 | 0.33 | 0.35 |

| PT3 | 0.40 | 0.40 | 0.40 | 0.43 | 0.37 | 0.47 | 0.47 | 0.38 | 0.43 | 0.32 | 0.41 | 0.48 | 0.44 | 0.49 | 0.37 | 0.39 |

| PT4 | 0.35 | 0.36 | 0.36 | 0.39 | 0.33 | 0.42 | 0.43 | 0.35 | 0.38 | 0.34 | 0.33 | 0.44 | 0.41 | 0.44 | 0.34 | 0.36 |

| PT5 | 0.29 | 0.30 | 0.29 | 0.33 | 0.28 | 0.35 | 0.36 | 0.28 | 0.32 | 0.27 | 0.31 | 0.31 | 0.34 | 0.37 | 0.27 | 0.29 |

| PT6 | 0.32 | 0.34 | 0.33 | 0.36 | 0.30 | 0.39 | 0.40 | 0.31 | 0.35 | 0.30 | 0.34 | 0.40 | 0.32 | 0.41 | 0.31 | 0.33 |

| PT7 | 0.31 | 0.32 | 0.32 | 0.34 | 0.28 | 0.36 | 0.38 | 0.29 | 0.33 | 0.28 | 0.32 | 0.38 | 0.34 | 0.32 | 0.29 | 0.31 |

| HR1 | 0.38 | 0.38 | 0.40 | 0.43 | 0.36 | 0.46 | 0.46 | 0.37 | 0.41 | 0.36 | 0.40 | 0.42 | 0.31 | 0.46 | 0.31 | 0.39 |

| HR2 | 0.38 | 0.38 | 0.39 | 0.41 | 0.35 | 0.46 | 0.46 | 0.37 | 0.41 | 0.36 | 0.39 | 0.42 | 0.35 | 0.46 | 0.35 | 0.33 |

| S1 | PPC1 | PPC2 | PPC3 | PPC4 | PPC5 | PPC6 | PT1 | PT2 | PT3 | PT4 | PT5 | PT6 | PT7 | HR1 | HR2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 0.18 | 0.30 | 0.28 | 0.29 | 0.26 | 0.33 | 0.33 | 0.29 | 0.30 | 0.27 | 0.29 | 0.34 | 0.32 | 0.34 | 0.30 | 0.30 |

| PPC1 | 0.18 | 0.19 | 0.24 | 0.24 | 0.21 | 0.27 | 0.27 | 0.24 | 0.24 | 0.22 | 0.23 | 0.26 | 0.25 | 0.28 | 0.24 | 0.24 |

| PPC2 | 0.20 | 0.24 | 0.19 | 0.24 | 0.21 | 0.28 | 0.28 | 0.24 | 0.25 | 0.22 | 0.24 | 0.27 | 0.26 | 0.29 | 0.24 | 0.25 |

| PPC3 | 0.19 | 0.24 | 0.24 | 0.19 | 0.21 | 0.26 | 0.26 | 0.24 | 0.24 | 0.22 | 0.24 | 0.26 | 0.26 | 0.28 | 0.24 | 0.25 |

| PPC4 | 0.21 | 0.27 | 0.27 | 0.27 | 0.19 | 0.29 | 0.29 | 0.27 | 0.28 | 0.25 | 0.27 | 0.29 | 0.29 | 0.32 | 0.26 | 0.27 |

| PPC5 | 0.16 | 0.22 | 0.21 | 0.22 | 0.19 | 0.19 | 0.24 | 0.22 | 0.22 | 0.20 | 0.22 | 0.24 | 0.23 | 0.26 | 0.22 | 0.22 |

| PPC6 | 0.16 | 0.21 | 0.20 | 0.22 | 0.19 | 0.23 | 0.19 | 0.22 | 0.22 | 0.20 | 0.21 | 0.24 | 0.23 | 0.25 | 0.22 | 0.22 |

| PT1 | 0.19 | 0.24 | 0.24 | 0.24 | 0.21 | 0.26 | 0.19 | 0.23 | 0.25 | 0.22 | 0.23 | 0.27 | 0.26 | 0.28 | 0.24 | 0.24 |

| PT2 | 0.19 | 0.24 | 0.23 | 0.24 | 0.20 | 0.26 | 0.26 | 0.23 | 0.19 | 0.22 | 0.25 | 0.26 | 0.26 | 0.28 | 0.24 | 0.24 |

| PT3 | 0.20 | 0.25 | 0.25 | 0.26 | 0.23 | 0.28 | 0.28 | 0.26 | 0.26 | 0.19 | 0.25 | 0.29 | 0.27 | 0.31 | 0.25 | 0.26 |

| PT4 | 0.20 | 0.25 | 0.24 | 0.24 | 0.21 | 0.27 | 0.27 | 0.24 | 0.25 | 0.24 | 0.25 | 0.28 | 0.26 | 0.29 | 0.24 | 0.25 |

| PT5 | 0.16 | 0.22 | 0.22 | 0.22 | 0.19 | 0.21 | 0.24 | 0.21 | 0.23 | 0.20 | 0.22 | 0.19 | 0.23 | 0.26 | 0.22 | 0.21 |

| PT6 | 0.17 | 0.23 | 0.22 | 0.22 | 0.19 | 0.25 | 0.25 | 0.22 | 0.22 | 0.20 | 0.22 | 0.25 | 0.19 | 0.27 | 0.22 | 0.22 |

| PT7 | 0.15 | 0.20 | 0.20 | 0.20 | 0.17 | 0.22 | 0.21 | 0.20 | 0.20 | 0.17 | 0.20 | 0.19 | 0.19 | 0.19 | 0.19 | 0.20 |

| HR1 | 0.18 | 0.24 | 0.24 | 0.24 | 0.21 | 0.26 | 0.26 | 0.24 | 0.24 | 0.22 | 0.24 | 0.26 | 0.25 | 0.28 | 0.19 | 0.25 |

| HR2 | 0.18 | 0.24 | 0.23 | 0.23 | 0.21 | 0.26 | 0.26 | 0.24 | 0.22 | 0.22 | 0.23 | 0.27 | 0.23 | 0.27 | 0.23 | 0.19 |

| S1 | PPC1 | PPC2 | PPC3 | PPC4 | PPC5 | PPC6 | PT1 | PT2 | PT3 | PT4 | PT5 | PT6 | PT7 | HR1 | HR2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 0.32 | 0.39 | 0.42 | 0.40 | 0.33 | 0.44 | 0.40 | 0.37 | 0.38 | 0.36 | 0.41 | 0.38 | 0.44 | 0.42 | 0.36 | 0.37 |

| PPC1 | 0.35 | 0.32 | 0.40 | 0.38 | 0.31 | 0.42 | 0.40 | 0.36 | 0.37 | 0.34 | 0.39 | 0.37 | 0.42 | 0.42 | 0.35 | 0.36 |

| PPC2 | 0.32 | 0.35 | 0.32 | 0.36 | 0.30 | 0.39 | 0.37 | 0.34 | 0.34 | 0.32 | 0.36 | 0.34 | 0.39 | 0.38 | 0.32 | 0.33 |

| PPC3 | 0.34 | 0.37 | 0.39 | 0.32 | 0.31 | 0.40 | 0.38 | 0.36 | 0.36 | 0.34 | 0.40 | 0.37 | 0.41 | 0.40 | 0.34 | 0.34 |

| PPC4 | 0.40 | 0.43 | 0.45 | 0.43 | 0.31 | 0.47 | 0.45 | 0.43 | 0.43 | 0.40 | 0.46 | 0.42 | 0.48 | 0.47 | 0.39 | 0.40 |

| PPC5 | 0.33 | 0.34 | 0.37 | 0.36 | 0.30 | 0.33 | 0.37 | 0.34 | 0.34 | 0.32 | 0.34 | 0.33 | 0.38 | 0.38 | 0.31 | 0.32 |

| PPC6 | 0.34 | 0.35 | 0.37 | 0.37 | 0.29 | 0.38 | 0.32 | 0.35 | 0.35 | 0.33 | 0.34 | 0.34 | 0.39 | 0.39 | 0.32 | 0.33 |

| PT1 | 0.37 | 0.37 | 0.40 | 0.38 | 0.31 | 0.41 | 0.39 | 0.32 | 0.37 | 0.34 | 0.40 | 0.37 | 0.42 | 0.41 | 0.34 | 0.35 |

| PT2 | 0.36 | 0.37 | 0.40 | 0.38 | 0.31 | 0.41 | 0.39 | 0.32 | 0.35 | 0.32 | 0.40 | 0.37 | 0.42 | 0.41 | 0.34 | 0.35 |

| PT3 | 0.38 | 0.39 | 0.42 | 0.40 | 0.34 | 0.43 | 0.41 | 0.39 | 0.39 | 0.32 | 0.42 | 0.38 | 0.44 | 0.43 | 0.35 | 0.36 |

| PT4 | 0.33 | 0.34 | 0.37 | 0.34 | 0.29 | 0.38 | 0.36 | 0.33 | 0.33 | 0.32 | 0.38 | 0.33 | 0.38 | 0.38 | 0.31 | 0.32 |

| PT5 | 0.36 | 0.38 | 0.41 | 0.38 | 0.32 | 0.42 | 0.40 | 0.37 | 0.38 | 0.36 | 0.41 | 0.32 | 0.42 | 0.41 | 0.35 | 0.35 |

| PT6 | 0.31 | 0.32 | 0.35 | 0.34 | 0.28 | 0.37 | 0.35 | 0.32 | 0.33 | 0.31 | 0.35 | 0.33 | 0.32 | 0.37 | 0.30 | 0.31 |

| PT7 | 0.32 | 0.32 | 0.36 | 0.34 | 0.28 | 0.36 | 0.35 | 0.33 | 0.33 | 0.31 | 0.35 | 0.33 | 0.37 | 0.32 | 0.31 | 0.31 |

| HR1 | 0.38 | 0.39 | 0.43 | 0.41 | 0.34 | 0.44 | 0.42 | 0.39 | 0.40 | 0.38 | 0.44 | 0.40 | 0.44 | 0.44 | 0.32 | 0.38 |

| HR2 | 0.37 | 0.38 | 0.42 | 0.40 | 0.34 | 0.44 | 0.41 | 0.39 | 0.39 | 0.37 | 0.43 | 0.39 | 0.43 | 0.43 | 0.35 | 0.32 |

| Practices ID | Lean Manufacturing Practices | Energy Reduction | CO2 Emission Reduction | Waste Reduction |

|---|---|---|---|---|

| S1 | JIT delivery by supplier | Step 1 | Step 1 | Step 2 |

| PPC1 | Single-Minute Exchange of Dies (SMED) | Step 1 | - | - |

| PPC2 | Pull production/takt time | Step 1 | Step 1 | Step 3 |

| PPC3 | Smoothed (leveled) production (Heijunka) | Step 1 | Step 2 | Step 3 |

| PPC4 | Total Productive Maintenance (TPM) | Step 1 | Step 2 | Step 1 |

| PPC5 | Statistical Process Control (SPC) | Step 3 | Step 3 | Step 3 |

| PPC6 | Root cause analysis for problem solving | Step 3 | - | Step 3 |

| PT1 | Autonomation (Jidoka) | Step 1 | Step 2 | - |

| PT2 | Cellular Manufacturing | - | Step 2 | Step 1 |

| PT3 | One-piece-flow (continuous flow) | Step 2 | Step 2 | Step 2 |

| PT4 | Layout size and shape | - | Step 2 | - |

| PT5 | 5S | - | Step 3 | Step 1 |

| PT6 | Value Stream Maps (VSMs) | - | - | Step 3 |

| PT7 | Total Quality Management (TQM) | Step 3 | - | Step 3 |

| HR1 | Continuous improvement (Kaizen) | Step 2 | - | Step 1 |

| HR2 | Standardized work | Step 1 | - | Step 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrazzi, M.; Portioli-Staudacher, A. Driving Green Through Lean: A Structured Causal Analysis of Lean Practices in Automotive Sustainability. Eng 2025, 6, 296. https://doi.org/10.3390/eng6110296

Ferrazzi M, Portioli-Staudacher A. Driving Green Through Lean: A Structured Causal Analysis of Lean Practices in Automotive Sustainability. Eng. 2025; 6(11):296. https://doi.org/10.3390/eng6110296

Chicago/Turabian StyleFerrazzi, Matteo, and Alberto Portioli-Staudacher. 2025. "Driving Green Through Lean: A Structured Causal Analysis of Lean Practices in Automotive Sustainability" Eng 6, no. 11: 296. https://doi.org/10.3390/eng6110296

APA StyleFerrazzi, M., & Portioli-Staudacher, A. (2025). Driving Green Through Lean: A Structured Causal Analysis of Lean Practices in Automotive Sustainability. Eng, 6(11), 296. https://doi.org/10.3390/eng6110296