Reviewing Critical Logistics and Transport Models in Stainless-Steel Fluid Storage Tanks

Abstract

1. Introduction

| Property | Typical Value | Units | Notes |

|---|---|---|---|

| Density, ρ | 7900–8000 | kg·m−3 | Austenitic stainless steel, corrosion-resistant |

| Specific heat (at 300 K), cₚ | ~500 | J·kg−1·K−1 | Increase slightly with temperature |

| Thermal conductivity, λ | ~16 | W·m−1·K−1 | Lower than carbon steel; relevant for jacket design |

| Viscosity (solid metal), η | Not applicable | Pa·s | Metals are solids; viscosity not defined |

| Elastic modulus, E | ~193 | GPa | Used for stress and deformation calculations |

| Poisson’s ratio, ν | ~0.30 | – | Typical for isotropic metals |

| Thermal expansion coefficient, α | 16 × 10−6 | K−1 | Important for thermal cycling and expansion allowances |

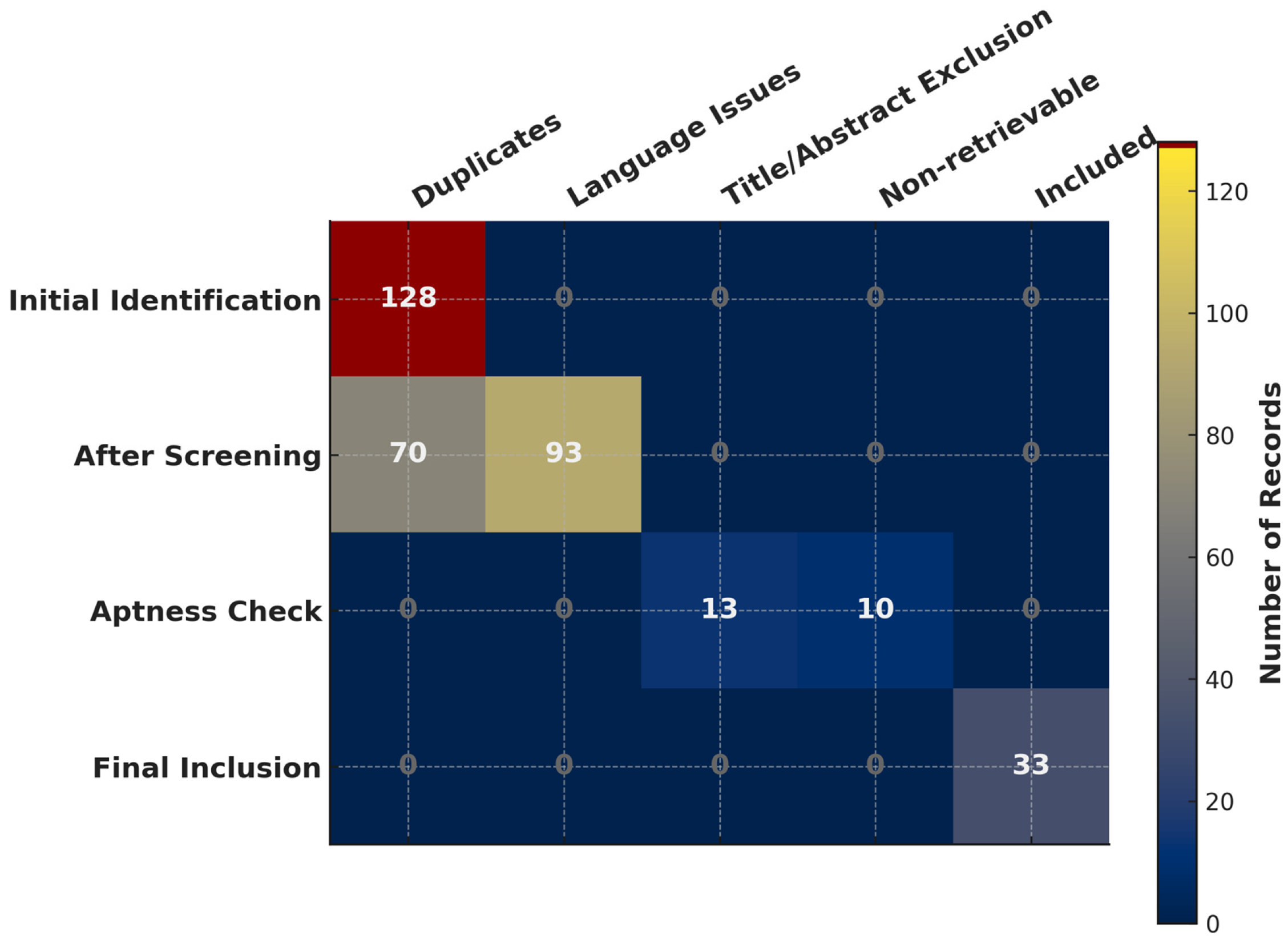

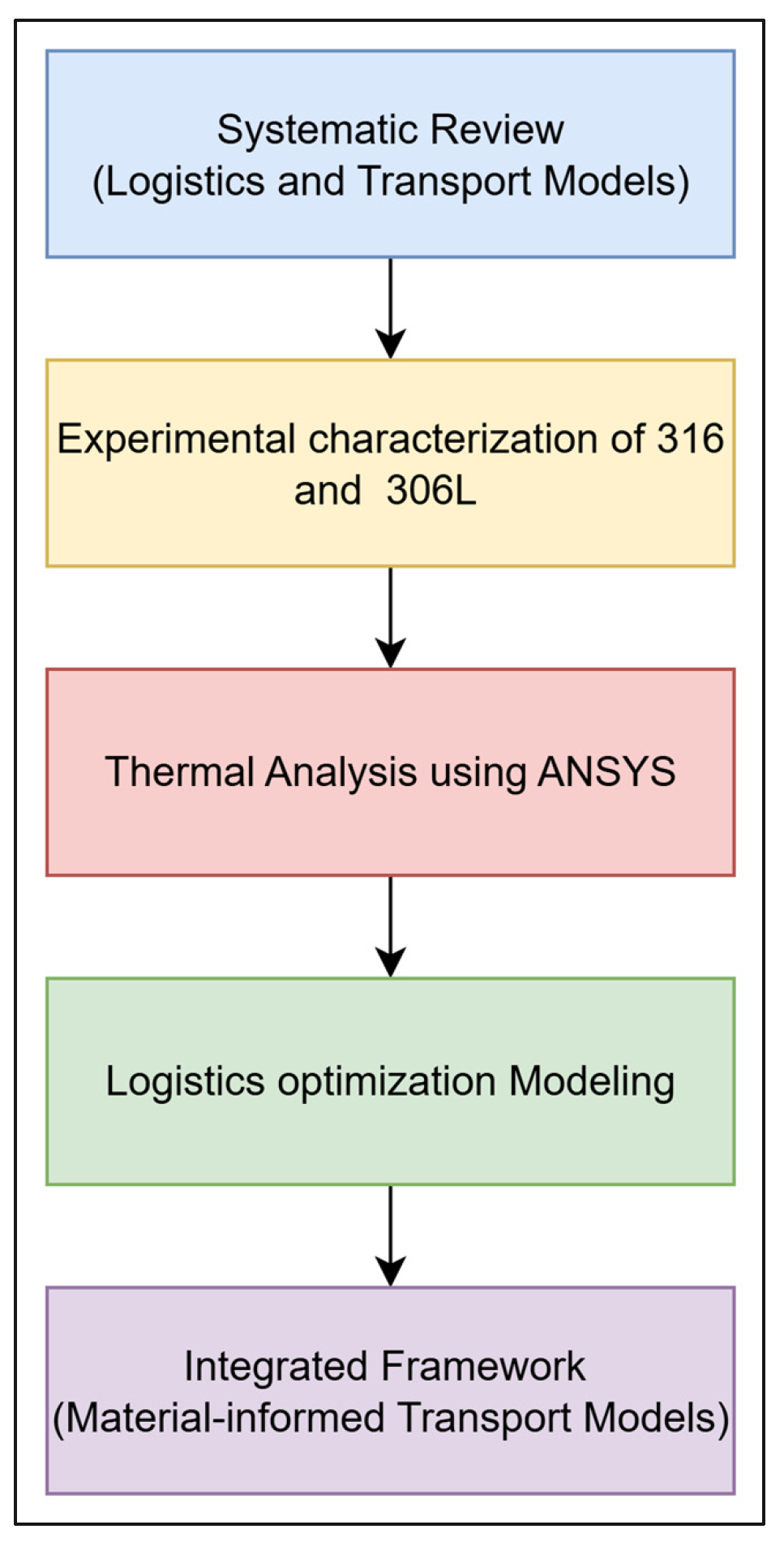

2. Materials and Methods

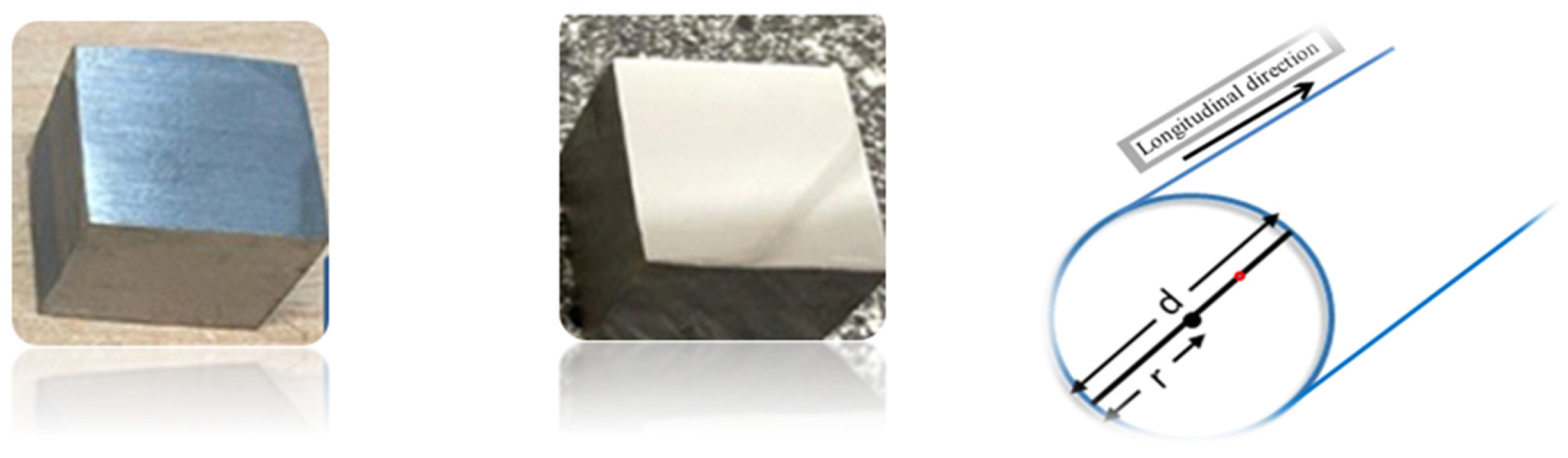

2.1. Material Selection and Process

2.2. Methodology

- (a)

- What variables in the modeling of logistics and transport should be considered to optimize stainless-steel fluid storage tank design?

- (b)

- What effects does an isothermal annealing at 700 °C for 1 h in a bench furnace have on the elemental compositions of stainless-steel grades 316 and 304L?

Integration of Framework

2.3. Statistical and Uncertainty Analysis

Acquisition Parameters (EDS)

- Beam current: ∼1 nA (Faraday-cup referenced).

- Working distance/take-off angle: ~10 mm/~35°.

- Live time per spectrum: 60–100 s; 3–5 repeat spectra per spot; 3 spots per sample.

- Detector: silicon drift detector (SDD); energy resolution ~125–135 eV at Mn Kα.

3. Computational Analysis and Validation

3.1. Variables in Logistics of Transport Modeling

- Inner container;

- Inner supports (synthetic materials);

- Outer container;

- Insulation;

- Radiation shields;

- Vacuum;

- Outer supports;

- Container frame;

- Accessories.

- (a)

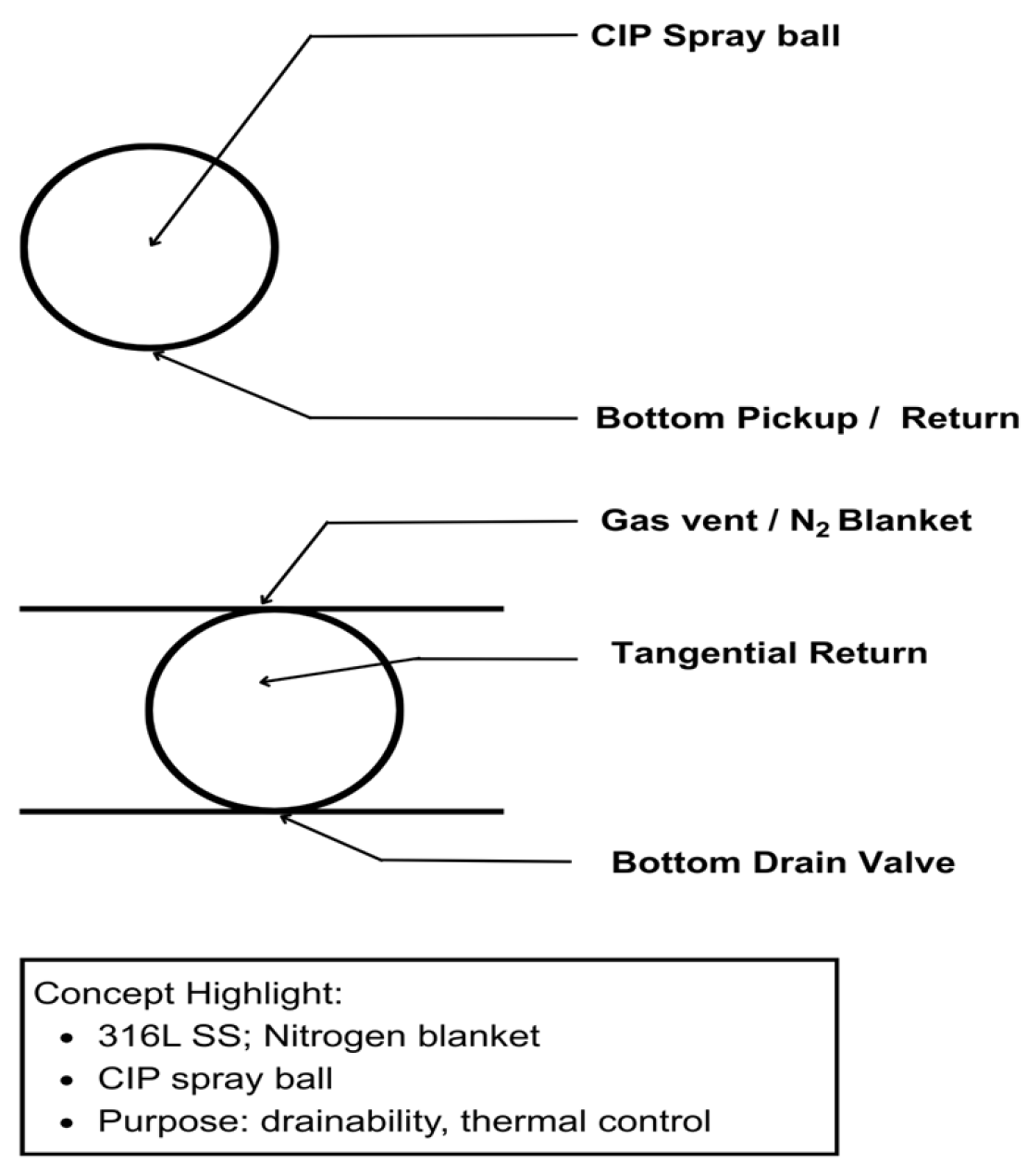

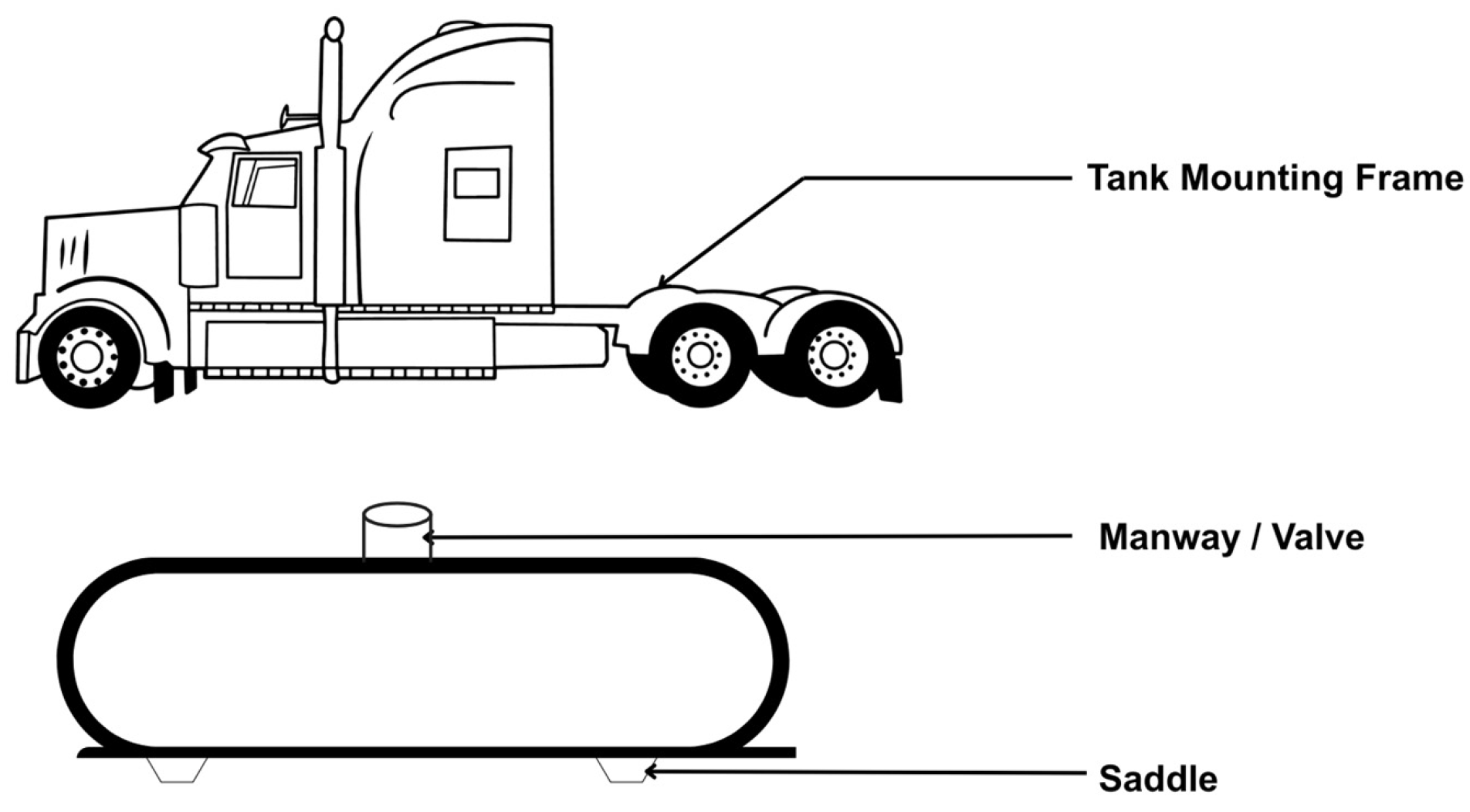

- The structural configuration of the designed stainless-steel vessel;

- (b)

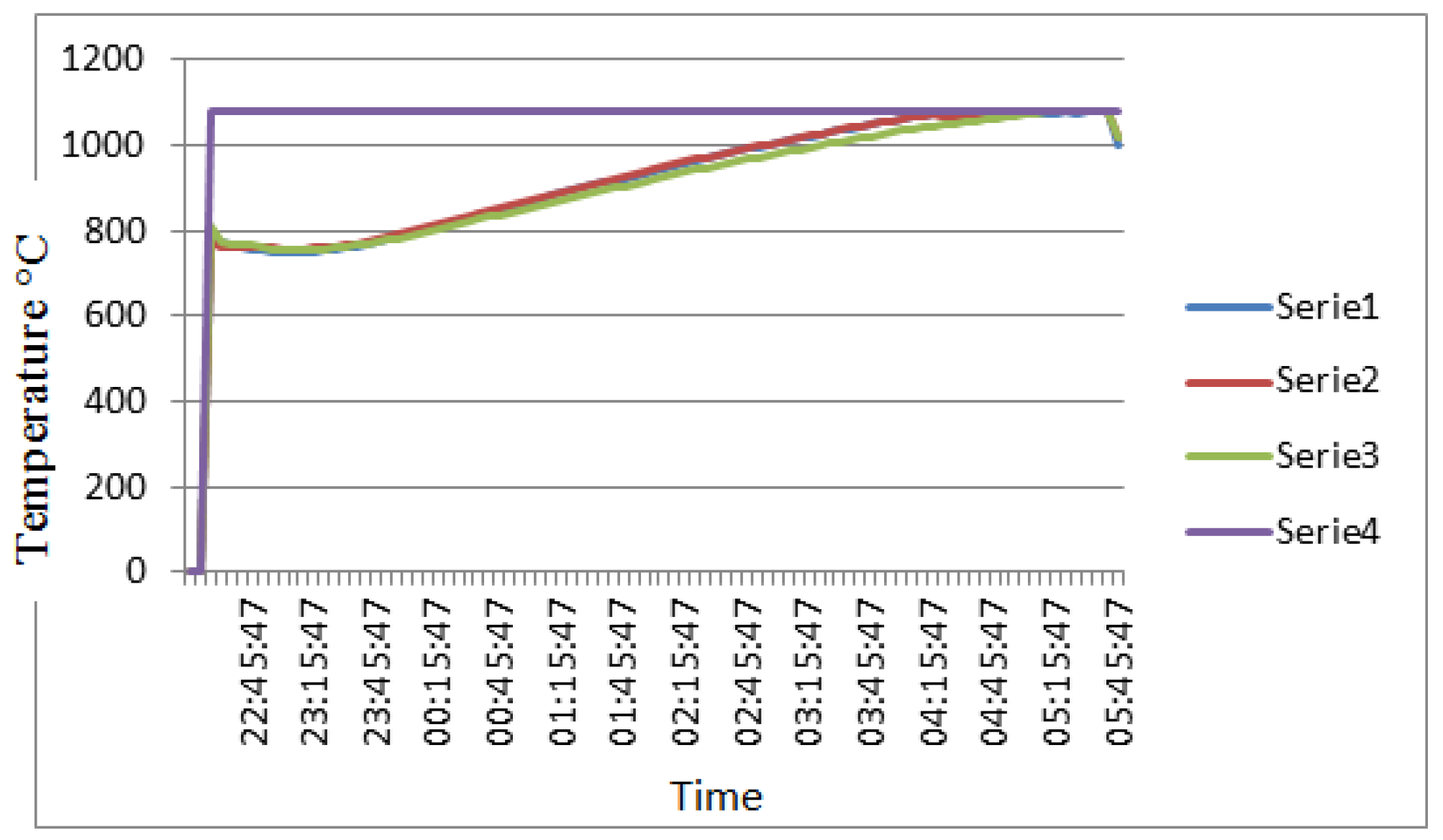

- Thermal performance calculations of mobile tanks intended for the transport and storage of liquefied natural gas (LNG).

3.2. Modeling for Logistics of Transport

- Let t ϵ T≔ [ , T] represent the location range.

- Let d(t) denote the product demand density at each location t and let D(t) represent the cumulative demand from t0 to t.

- Facilities are built at locations t = f(t), … , each associated with opening cost f(t).

- Once facilities are in place, each demand point is served by its closest facility.

- The transportation cost to serve each unit demand at the location t is modeled as the product of the distance to its nearest facility and a constant scalar c, i.e.,

- Demand can be approximated by d(t).

- The discrete area function As() can be replaced by a continuous service area function A(t). This leads to the continuous approximation (CA) of Equation (4) as:

- 0.376 for circular areas;

- 0.377 for hexagonal;

- 0.382 for square;

- 0.403 for triangular zones.

- represents the specific heat of air at constant pressure [J/(kg K)];

- represents the specific heat of air at constant pressure volume [J/(kg K)];

- , represent heat transfer coefficients for the surface of the inner tank and the outer tank;

- A1, A2 represent an area of inner tank walls and outer tank walls [m2];

- represents the gas constant [J/(mol K)];

- represents the molar mass of the residual gas [kg/mol];

- represents temperature in the pressure measurement point (on the outer tank) [K];

- P represents the pressure of the residual gas [Pa];

- T2, T1 represent the temperature of outer wall of inner tank and outer shield of inner tank insulation [K].

- Qc represents average heat flux on the outer surface of the tank [W/m2];

- A represents an area of the outer surface of the tank [m2];

- h represents the latent heat of vaporization [J/];

- F represents the total mass of LNG in the tank [].

- and

- α represents the enthalpic factor;

- β represents the entropic factor;

- po represents the saturation pressure of the bulk gas;

- p represents the operating pressure.

- p represents the equilibrium pressure (Pa) and the heterogeneous parameter.

- n represents n0 + αT, depending on temperature.

- are parameters that are factored into the experimental data of the hydrogen adsorption on the cubic metal–organic framework compound (MOF-5). In conclusion, Sridhar, and Kaisare [10] believe that making a proper choice among the adsorption isotherm models is important. The effect of temperature on the physical properties of gas, adsorbent, and walls is also crucial for consideration.

3.3. Finite Element Modeling

Case Study with an Example of the LNG Storage Tank in Logistics

3.4. Continuous Approximation (UFL)—Numerical Example and Sensitivity

- Corridor length L 200 km.

- Demand density λ 500 kg day−1 km−1 (total 100,000 kg day−1).

- Transport cost cₜ 0.02 USD (kg·km)−1.

- Facility fixed cost F 2000 USD day−1.

- Facility cost ≈ 14,000 USD/day.

- Transport cost ≈ 14,142 USD/day.

- Total ≈ 28,142 USD/day.

4. Experimental Results and Analysis

4.1. Elemental Compositions of Stainless Steels (EDS Mapping)

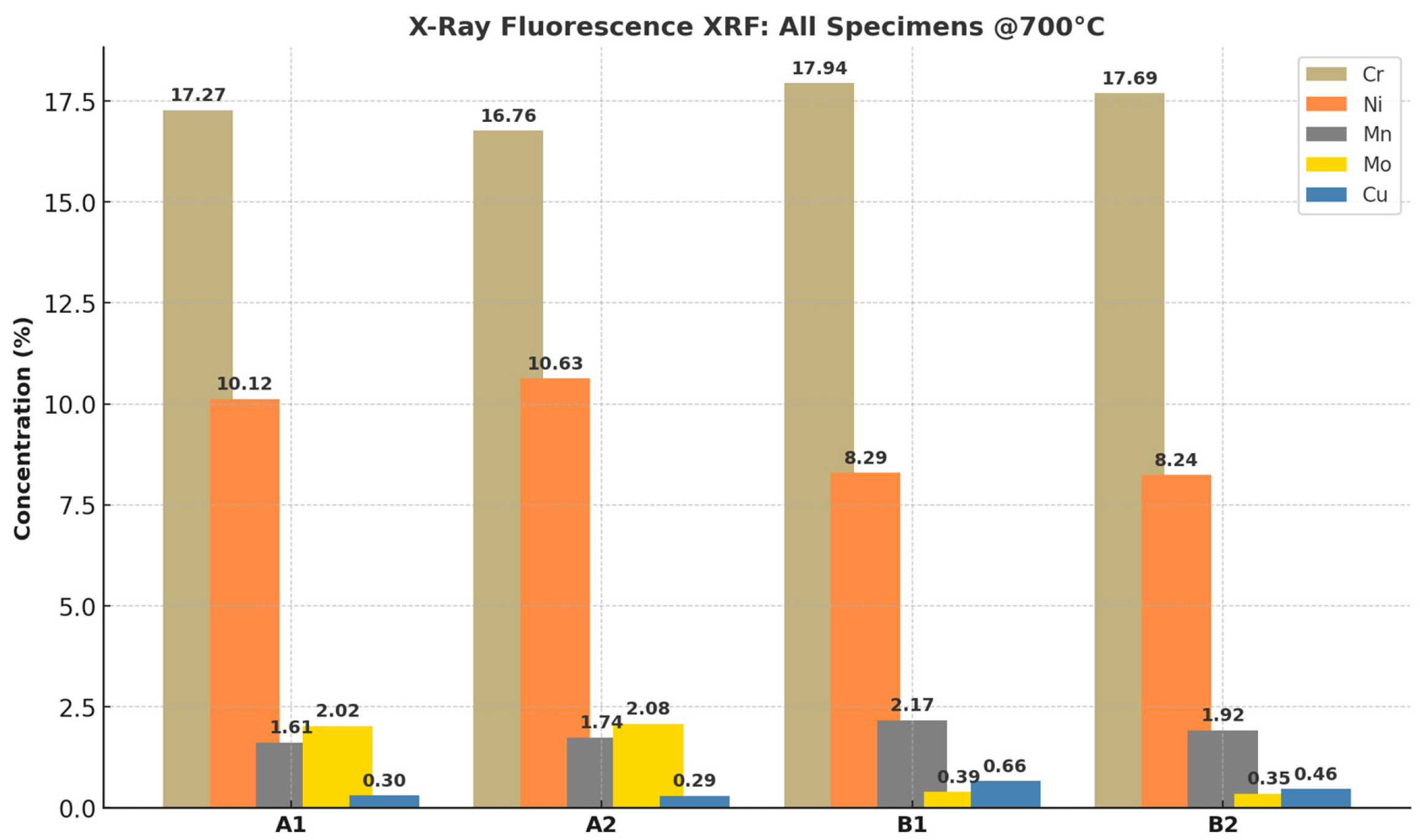

4.2. Elemental Compositions of Stainless Steels (X-Ray Fluorescence)

4.3. XRF Statistical Analysis

4.4. Europium Detection in 304L (EDS Mapping)

5. Discussion

5.1. Technical Interaction of Stainless-Steel Properties with Logistics Modeling

5.2. Limitations

5.3. Future Research Directions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Verma, A.; Shankar, R.; Shaik, A.M.; Reddy, B.V.S.; Sastry, C.C.; Shaik, N.; Abouel Nasr, E. Comprehensive design and analysis of a 300L steel fuel tank for heavy off-road vehicles: Numerical and experimental insights. Front. Mech. Eng. 2024, 10, 1360590. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Afshan, S.; Hjalmarsson, J. A review of metallic tanks for H2 storage with a view to application in future green shipping. Int. J. Hydrogen Energy 2021, 46, 6151–6179. [Google Scholar] [CrossRef]

- Wang, X.; Xu, Y.; Wang, S.; Xu, Q.; Ho, T.C. Comprehensive study on boil-off gas generation from LNG road tankers under simultaneous impacts of heat leakage and transportation vibration. Fuel 2020, 275, 117876. [Google Scholar] [CrossRef]

- Lee, D.Y.; Jo, J.S.; Nyongesa, A.J.; Lee, W.J. Fatigue analysis of a 40 ft LNG ISO tank container. Materials 2023, 16, 428. [Google Scholar] [CrossRef]

- Bojinov, M.; Chang, L.; Saario, T.; Que, Z. Corrosion of 316L stainless steel produced by laser powder bed fusion and powder metallurgy in pressurized water reactor primary coolant. Materialia 2024, 34, 102055. [Google Scholar] [CrossRef]

- Contreras-Fortes, J.; Rodríguez-García, M.I.; Sales, D.L.; Sánchez-Miranda, R.; Almagro, J.F.; Turias, I. A machine learning approach for modelling cold-rolling curves for various stainless steels. Materials 2023, 17, 147. [Google Scholar] [CrossRef] [PubMed]

- Alshoaibi, A.M.; Bashiri, A.H. Fatigue crack growth studies under mixed-mode loading in AISI 316 stainless steel. Appl. Sci. 2023, 13, 9446. [Google Scholar] [CrossRef]

- Krivtsun, I.; Khoshnaw, F.; Polishko, G.; Schwab, S.; Selin, R. (Eds.) Welding and Related Technologies: Proceedings of the VIIth International Conference on Welding and Related Technologies (WRT 2024, 7–10 October 2024, Yaremche, Ukraine); CRC Press: Boca Raton, FL, USA, 2025. [Google Scholar] [CrossRef]

- Godshall, G.F.; Rau, D.A.; Williams, C.B.; Moore, R.B. Additive manufacturing of poly (phenylene sulfide) aerogels via simultaneous material extrusion and thermally induced phase separation. Adv. Mater. 2024, 36, 2307881. [Google Scholar] [CrossRef] [PubMed]

- Sridhar, P.; Kaisare, N.S. A critical analysis of transport models for refueling of MOF-5 based hydrogen adsorption system. J. Ind. Eng. Chem. 2020, 85, 170–180. [Google Scholar] [CrossRef]

- Lisowski, E.; Czyżycki, W. Transport and storage of LNG in container tanks. J. KONES 2011, 18, 193–201. [Google Scholar]

- Ejeh, C.J.; Akhabue, G.P.; Agyeibi, I. Effect of transient temperature on 304 stainless steel LPG tank structure using numerical simulation approach. SN Appl. Sci. 2019, 1, 1690. [Google Scholar] [CrossRef]

- Wan, C.; Shi, C.; Zhu, S.; Fang, S.; Qiu, L.; Shi, G.; Wang, K. Comprehensive design and preliminary experiments of liquid hydrogen storage tank for trucks. Int. J. Refrig. 2024, 169, 279–293. [Google Scholar] [CrossRef]

- Wiberg, E.; Wiberg, N. Inorganic Chemistry; Academic Press: Cambridge, MA, USA, 2001. [Google Scholar]

- Divyasri, K.S.; Hema, M.N.; Manish, R.K.; Mirdula, R.; Pandiaraj, S.; Subiksha, M.; Balakumar, P. Study of structural behaviour of SS 316 water tank using ANSYS Workbench under hydrostatic pressure. Int. J. Adv. Eng. Manag. 2022, 4, 324–330. [Google Scholar] [CrossRef]

- Fukunaga, A. Hydrogen embrittlement behaviors during SSRT tests in gaseous hydrogen for cold-worked type 316 austenitic stainless steel and iron-based superalloy A286 used in hydrogen refueling station. Eng. Fail. Anal. 2024, 160, 108158. [Google Scholar] [CrossRef]

- Ansari, S.; Başdere, M.; Li, X.; Ouyang, Y.; Smilowitz, K. Advancements in continuous approximation models for logistics and transportation systems: 1996–2016. Transp. Res. Part B 2018, 107, 229–252. [Google Scholar] [CrossRef]

- Carkovs, J.; Matvejevs, A.; Matvejevs, A.; Kubzdela, A. Stochastic modeling for transport logistics. Procedia Comput. Sci. 2019, 149, 457–462. [Google Scholar] [CrossRef]

- Shammazov, I.; Karyakina, E. The LNG flow simulation in stationary conditions through a pipeline with various types of insulating coating. Fluids 2023, 8, 68. [Google Scholar] [CrossRef]

- Friel, J.J.; Lyman, C.E. Tutorial review: X-ray mapping in electron-beam instruments. Microsc. Microanal. 2006, 12, 2–25. [Google Scholar] [CrossRef] [PubMed]

- Emrani, A.; Berrada, A. Structural behavior and flow characteristics assessment of gravity energy storage system: Modeling and experimental validation. J. Energy Storage 2023, 72, 108277. [Google Scholar] [CrossRef]

- Wang, Z.; Qian, C.; Li, W. Study on impact process of a large LNG tank container for trains. Appl. Sci. 2023, 13, 1351. [Google Scholar] [CrossRef]

- An, N.Y.; Yang, J.H.; Song, E.; Hwang, S.H.; Byun, H.G.; Park, S. Digital twin-based hydrogen refueling station (HRS) safety model: CNN-based decision-making and 3D simulation. Sustainability 2024, 16, 9482. [Google Scholar] [CrossRef]

- Srinivasan, R.; Singh, S.P.; Deshpande, D.; Saripalli, S.D.; Venkataramanan, V.S.; Nagrale, S.; Karimi, I.A. Liquefied Natural Gas (LNG) Supply Chains: Recent Advances and Future Opportunities. Ind. Eng. Chem. Res. 2024, 63, 6481–6503. [Google Scholar] [CrossRef]

- Rao, B.S.C.; Madeswaran, R.; Chandramohan, R. In-fabrication and pre-service care on stainless steel pressure vessels. Int. J. Press. Vessel. Pip. 1997, 73, 53–57. [Google Scholar] [CrossRef]

- Su, M.; Zhao, J.; Gu, C. Investigation of the high-temperature oxidation behavior of Fe-14Cr-9Mn-2.5 Ni austenitic stainless steel in N2-21 vol% O2 environment. Corros. Sci. 2023, 220, 111294. [Google Scholar] [CrossRef]

- Li, T.; Qu, S.; Zang, Q.; Dong, C.; Fu, C.; Zhang, Z. Leakage failure analysis of a 60 m3 LNG storage tank. Eng. Fail. Anal. 2023, 153, 107591. [Google Scholar] [CrossRef]

- Drake, D.M. Best practices for metallography in a powder testing laboratory. Adv. Mater. Process. 2025, 183, 17–20. [Google Scholar] [CrossRef]

- Al-Mohannadi, A.A.; Ertogral, K.; Erkoc, M. Alternative Fuels in Sustainable Logistics—Applications, Challenges, and Solutions. Sustainability 2024, 16, 8484. [Google Scholar] [CrossRef]

- Fariña, E.A.; Panait, M.; Lago-Cabo, J.M.; Fernández-González, R. Energy Analysis of Standardized Shipping Containers for Housing. Inventions 2024, 9, 106. [Google Scholar] [CrossRef]

- Bitar, M.; Friederici, V.; Imgrund, P.; Brose, C.; Bruinink, A. In vitro bioactivity of micro metal injection moulded stainless steel with defined surface features. Eur. Cells Mater. 2012, 23, 333–347. [Google Scholar] [CrossRef]

- American Society of Mechanical Engineers. ASME Boiler and Pressure Vessel Code Section II, Materials, Part D Properties (Metric); BPVC Committee on Materials, Ed.; Standard No. BPVC-IID-2017; ASME: New York, NY, USA, 2017. [Google Scholar]

- Wells, S.; Thomas, B.G. Uncertainty quantification in modeling mold heat transfer in steel continuous slab casting with CON1D. Steel Res. Int. 2024, 95, 2400118. [Google Scholar] [CrossRef]

| AISI (UNS) | Fe* | Cu | C | Si | Mn | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|---|---|

| 316 (UNS S31600) | - | 0.3 | 0.08 | 1.0 | 2.00 | 0.045 | 0.030 | 16.0–18.0 | 10.0–14.0 | 2.0–3.0 |

| 304L (UNS S30403) | - | 0.3 | 0.03 | 1.0 | 2.00 | 0.045 | 0.030 | 18.0–20.0 | 8.0–12.0 | 0.40 |

| Sample | AISI 316 | 304L |

|---|---|---|

| As received, water quenched | A1 | B1 |

| Heat-treated and air-cooled | A2 | B2 |

| Search Assists | Logistics Model | Transport Model | Stainless-Steel Tanks |

|---|---|---|---|

| Alternative expressions | Variables Influencing factors | Gas transport Gas flow Fluid Transfer rate | Temperature Heat exchange Thermally induced. Cryogenic |

| Keywords | Optimization Variables Gas storage and or Delivery | Gas transport Flow-through system. Location | Materials and experimental validation Chemical or elemental compositions Designed tanks. Finite element method (FEM) |

| Reference | Focus/Contribution | Key Innovation | Relevance to SS Tank Logistics |

|---|---|---|---|

| An et al. (2024) [23] | Digital twin–based hydrogen refueling station safety model using CNN + 3D simulation | Integration of AI-driven decision-making with real-time digital twins | Demonstrates how digital twins and deep learning can be used for tank safety assessment and predictive modeling in hydrogen and cryogenic storage systems |

| Srinivasan et al. (2024) [24] | Review of LNG supply chains: advances and opportunities | Comprehensive mapping of LNG logistics networks, highlighting optimization and decarbonization | Extends traditional models by embedding sustainability and network-wide efficiency, directly relevant to SS tanks for LNG transport |

| Al-Mohannadi et al. (2024) [29] | Alternative fuels in sustainable logistics | Identification of challenges and solutions for integrating alternative fuels | Shows how fuel choices interact with logistics frameworks, relevant for SS tanks used in LNG/H2 transitions |

| Fariña et al. (2024) [30] | Energy analysis of standardized shipping containers | Quantitative assessment of thermal and energy performance in modular containers | Illustrates how containerized designs and energy trade-offs can be applied to SS tank insulation and transport optimization |

| Tank Capacity | Length of the Tank | Inner Diameter | Outer Diameter | Inner Tank Thickness | Outer Tank Thickness | Aerogel Layer Thickness | Vacuum Gap Between Aerogel Layer and Outer Layer |

|---|---|---|---|---|---|---|---|

| 50,000 m3 | 70 m | 25 m | 28 m | 40 mm | 40 mm | 1.25 m | 160 mm |

| Material | Property | 293 K | 77 K | Notes/Source |

|---|---|---|---|---|

| 304L SS | Elastic modulus (GPa) | ~193 | ~210 | Slight increase at cryogenic T [32] |

| 304L SS | Thermal conductivity (W/m·K) | ~16 | ~8 | Decreases with falling T [3,32] |

| 304L SS | Charpy toughness (J) | ~200 | <50 | Sharp reduction, embrittlement [16] |

| 316 SS | Thermal expansion (µm/m·K) | ~16 | ~9 | Reduced at cryogenic T [32] |

| 316 SS | Specific heat (J/kg·K) | ~500 | ~310 | Lower heat capacity at low T [32] |

| Aerogel | Thermal conductivity (W/m·K) | ~0.020 | ~0.012 | Consistent with cryogenic aerogel behavior [9] |

| GFRP supports | Thermal conductivity (W/m·K) | ~0.3 | ~0.12 | Reduced parasitic heat ingress [3] |

| Scenario | Parameter Change | s* (km) | n* (≈) | Facility Cost (USD/Day) | Transport Cost (USD/Day) | Total (USD/Day) |

|---|---|---|---|---|---|---|

| Baseline | – | 28.3 | 7 | 14,000 | 14,142 | 28,142 |

| Higher facility cost | F = 2500 (+25%) | 31.6 | 6 | 15,000 | 15,811 | 30,811 |

| Lower facility cost | F = 1500 (−25%) | 24.5 | 8 | 12,000 | 12,248 | 24,248 |

| Higher transport cost | cₜ = 0.025 (+25%) | 25.3 | 8 | 16,000 | 15,811 | 31,811 |

| Lower transport cost | cₜ = 0.015 (−25%) | 32.7 | 6 | 12,000 | 12,247 | 24,247 |

| Higher demand density | λ = 625 (+25%) | 25.3 | 8 | 16,000 | 15,811 | 31,811 |

| Lower demand density | λ =375 (−25%) | 32.7 | 6 | 12,000 | 12,247 | 24,247 |

| Element | Mean (wt.%) | SD | 95% CI | n |

|---|---|---|---|---|

| Cr | 17.42 | 0.52 | 16.59–18.24 | 4 |

| Ni | 9.32 | 1.24 | 7.35–11.29 | 4 |

| Mn | 1.86 | 0.24 | 1.47–2.25 | 4 |

| Mo | 1.26 | 0.92 | −0.20–2.72 | 4 |

| Cu | 0.43 | 0.17 | 0.15–0.70 | 4 |

| Element | Group A Mean | Group B Mean | Difference (B−A) | Hedges’ g | Effect Size |

|---|---|---|---|---|---|

| Cr | 17.02 | 17.82 | +0.80 | +1.61 | Large |

| Ni | 10.38 | 8.27 | −2.11 | −4.71 | Very large |

| Mn | 1.68 | 2.05 | +0.37 | +1.50 | Large |

| Mo | 2.05 | 0.47 | −1.58 | −7.30 | Very large |

| Cu | 0.30 | 0.56 | +0.27 | +1.51 | Large |

| Element | 316 (wt.%) | 316 (at%) | 304L (wt.%) | 304L (at%) | Typical 95% CI (wt.%) | LOD (wt.%) |

|---|---|---|---|---|---|---|

| Cr | 17.6 ± 0.5 | 18.9 | 17.2 ± 0.4 | 18.4 | 16.8–18.4 | 0.1 |

| Ni | 10.1 ± 0.6 | 9.1 | 8.3 ± 0.5 | 7.5 | 7.5–10.8 | 0.2 |

| Mn | 1.7 ± 0.2 | 1.9 | 2.0 ± 0.3 | 2.3 | 1.5–2.3 | 0.2 |

| Mo | 2.0 ± 0.3 | 1.1 | 0.5 ± 0.1 | 0.3 | 0.3–2.3 | 0.3 |

| Cu | 0.3 ± 0.1 | 0.2 | 0.6 ± 0.1 | 0.4 | 0.2–0.7 | 0.3 |

| C | <LOD | <LOD | <LOD | <LOD | — | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Emele, J.; Sliva, A.; Nainaragaram Ramasamy, M.; Fusek, M.; Besta, P.; Dižo, J. Reviewing Critical Logistics and Transport Models in Stainless-Steel Fluid Storage Tanks. Eng 2025, 6, 275. https://doi.org/10.3390/eng6100275

Emele J, Sliva A, Nainaragaram Ramasamy M, Fusek M, Besta P, Dižo J. Reviewing Critical Logistics and Transport Models in Stainless-Steel Fluid Storage Tanks. Eng. 2025; 6(10):275. https://doi.org/10.3390/eng6100275

Chicago/Turabian StyleEmele, Jude, Ales Sliva, Mahalingam Nainaragaram Ramasamy, Martin Fusek, Petr Besta, and Ján Dižo. 2025. "Reviewing Critical Logistics and Transport Models in Stainless-Steel Fluid Storage Tanks" Eng 6, no. 10: 275. https://doi.org/10.3390/eng6100275

APA StyleEmele, J., Sliva, A., Nainaragaram Ramasamy, M., Fusek, M., Besta, P., & Dižo, J. (2025). Reviewing Critical Logistics and Transport Models in Stainless-Steel Fluid Storage Tanks. Eng, 6(10), 275. https://doi.org/10.3390/eng6100275