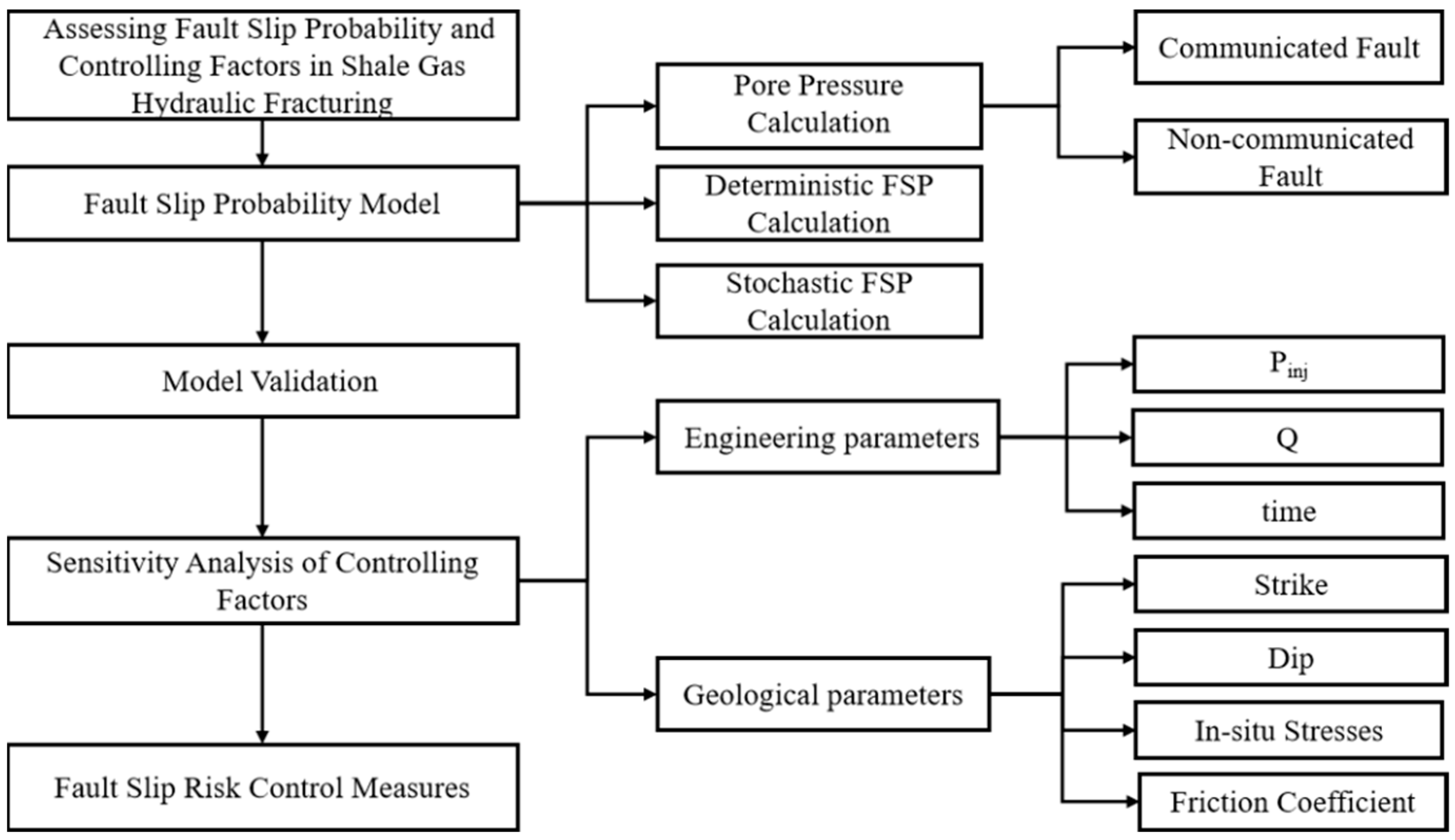

Assessing Fault Slip Probability and Controlling Factors in Shale Gas Hydraulic Fracturing

Abstract

1. Introduction

2. Fault Slip Probability Calculation Model

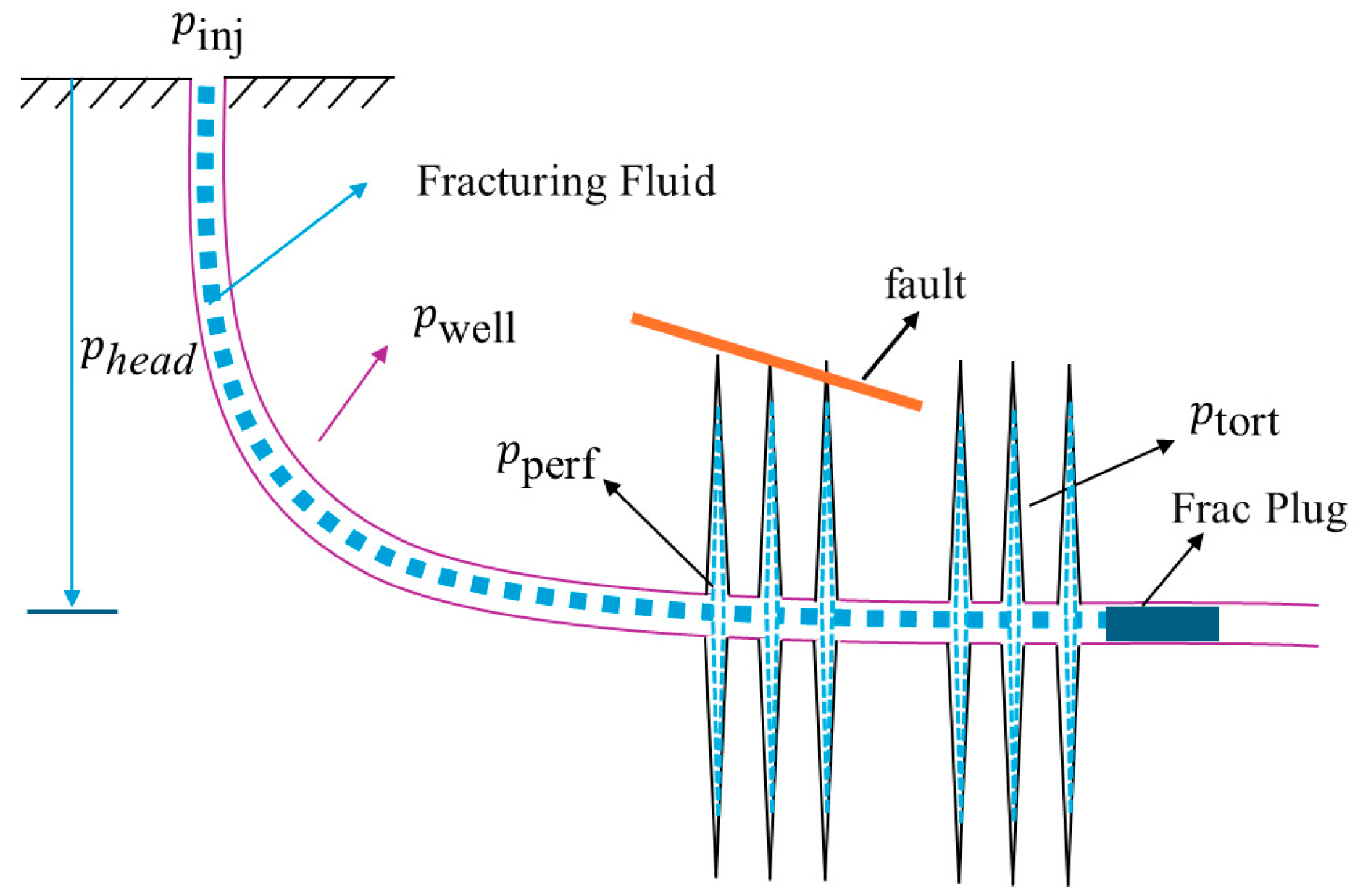

2.1. Calculation of Fault Pressure

- 1.

- Wellbore friction loss :

- 2.

- Perforation friction loss :

- 3.

- Near-wellbore tortuosity friction loss :

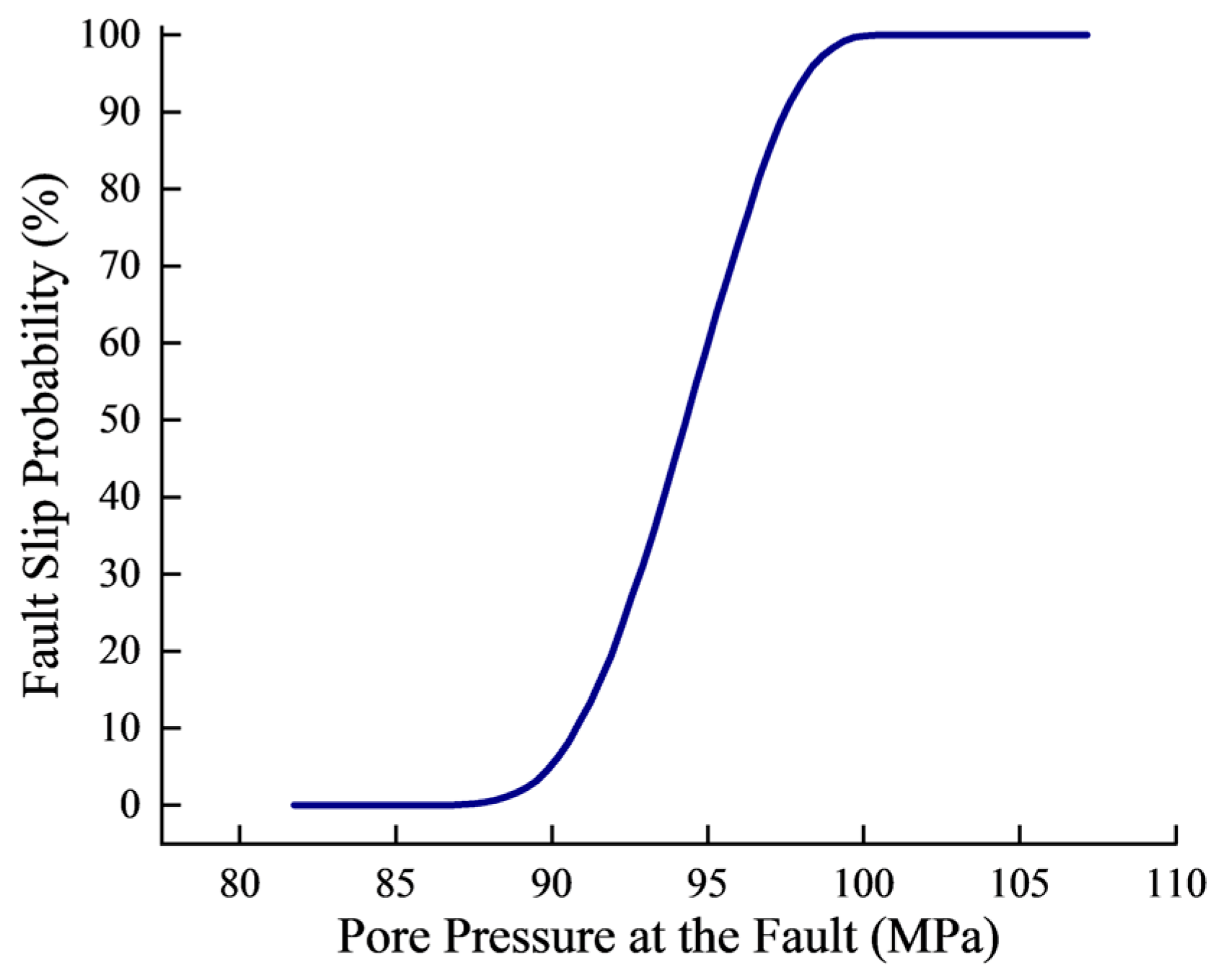

2.2. Deterministic Probability Calculation of Fault Slip

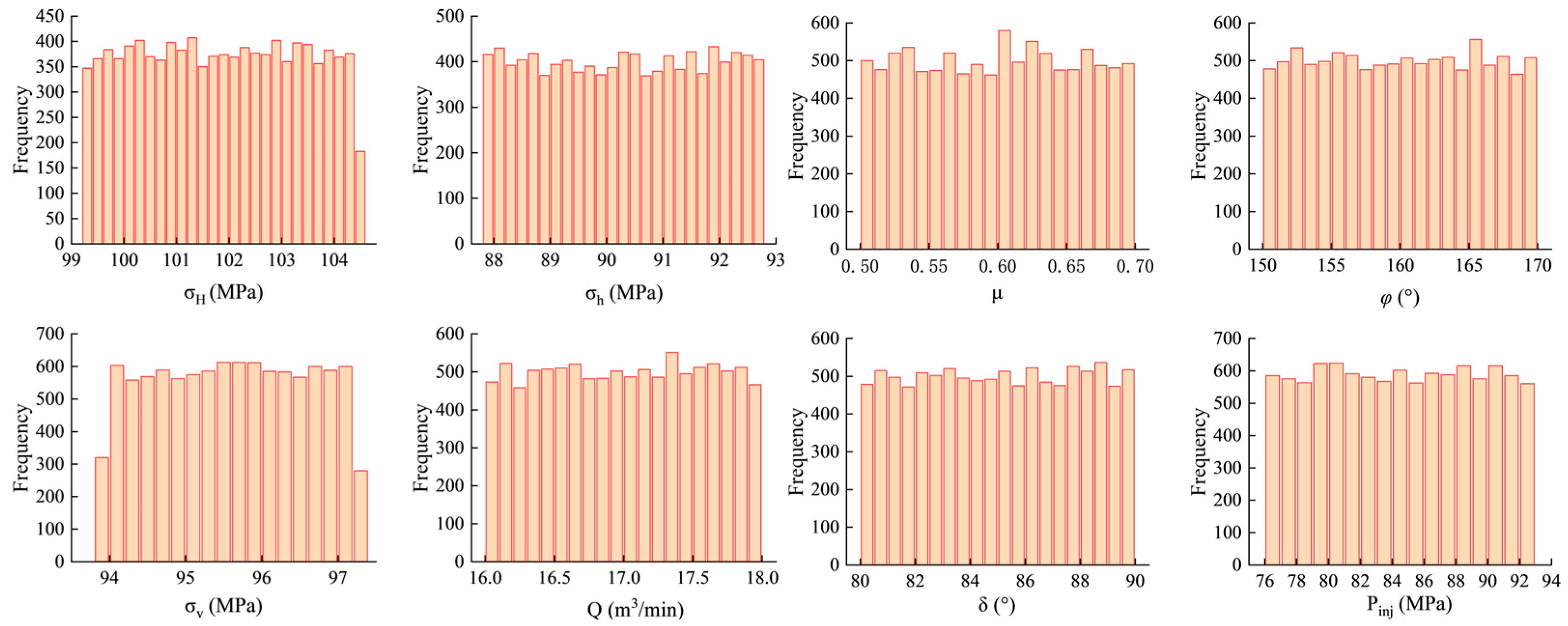

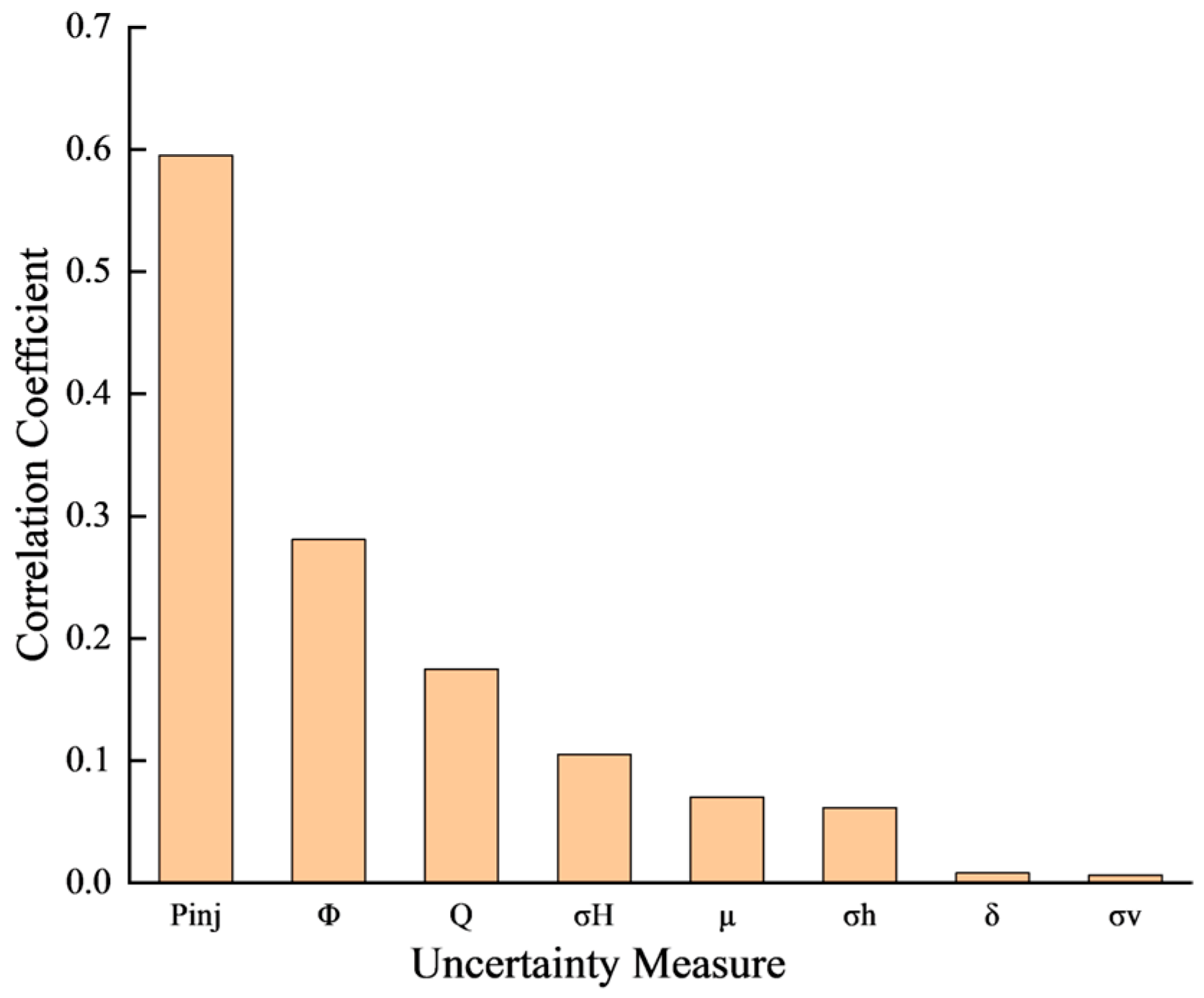

2.3. Probabilistic Calculation of Fault Slip Uncertainty

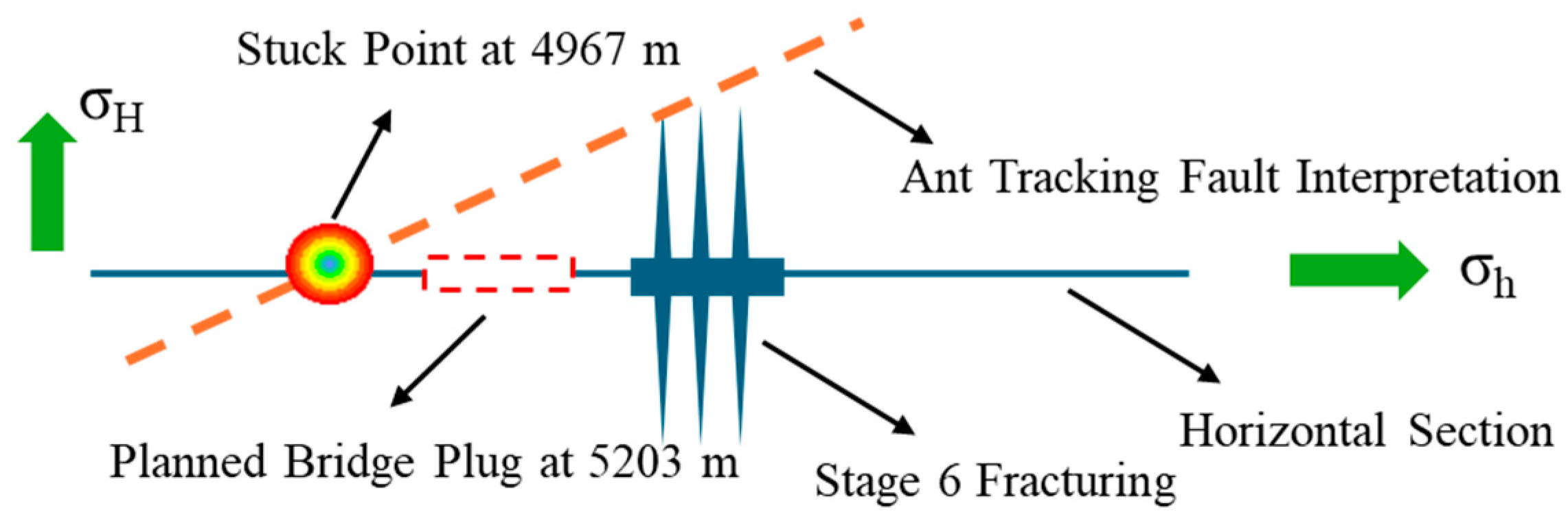

3. Model Validation

4. Analysis of Factors Influencing Fault Slip Probability

4.1. Engineering Factors

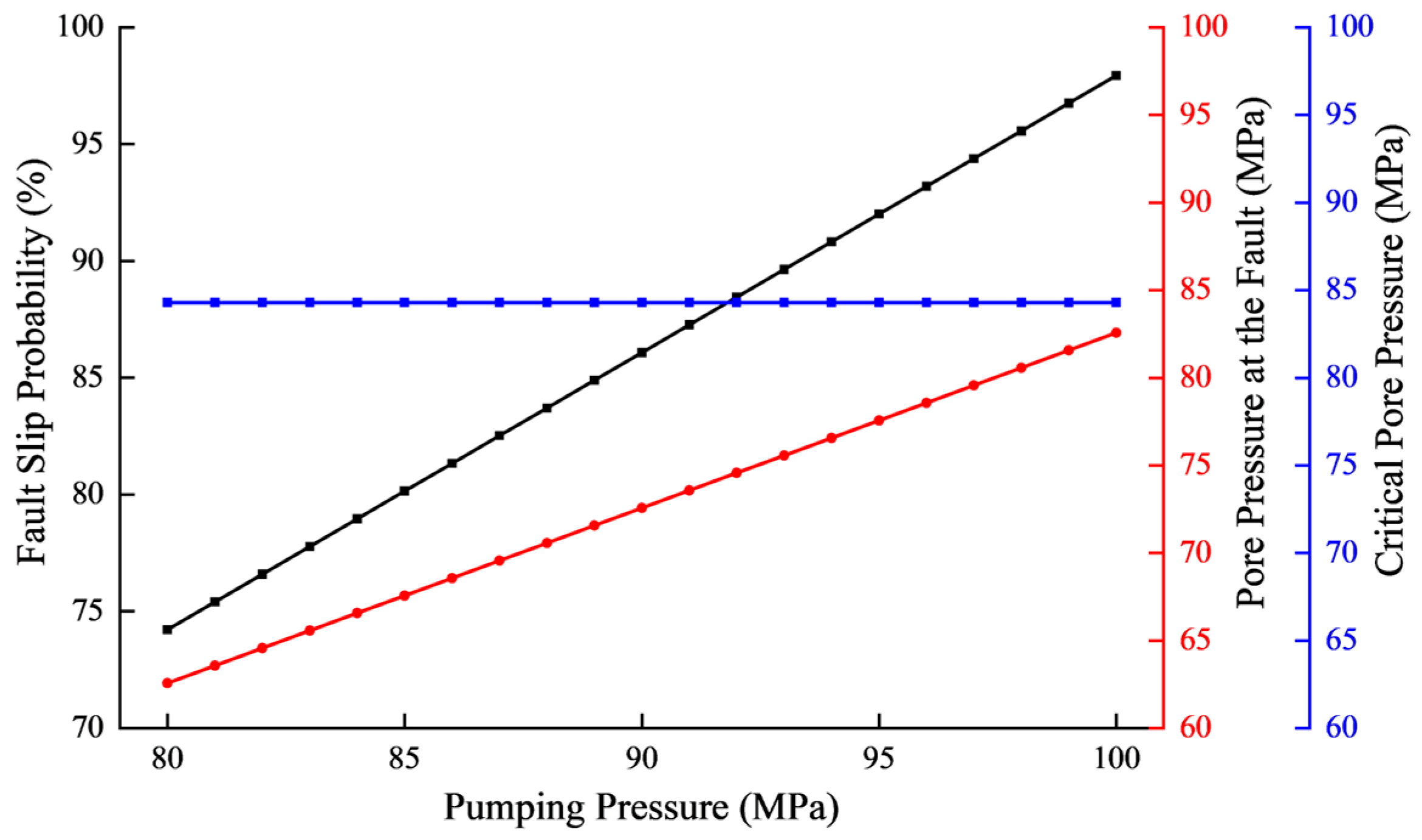

4.1.1. Pumping Pressure

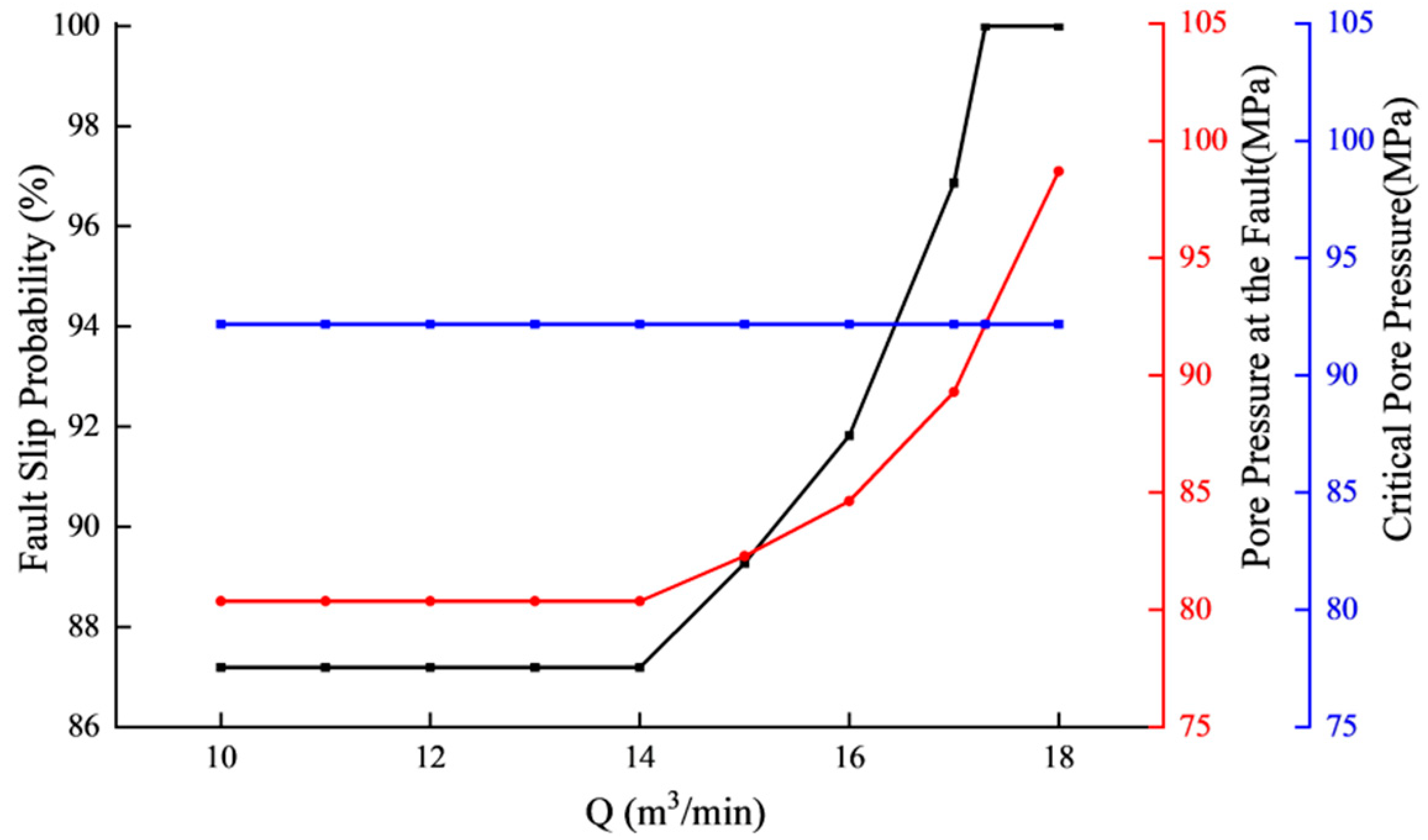

4.1.2. Pumping Rate

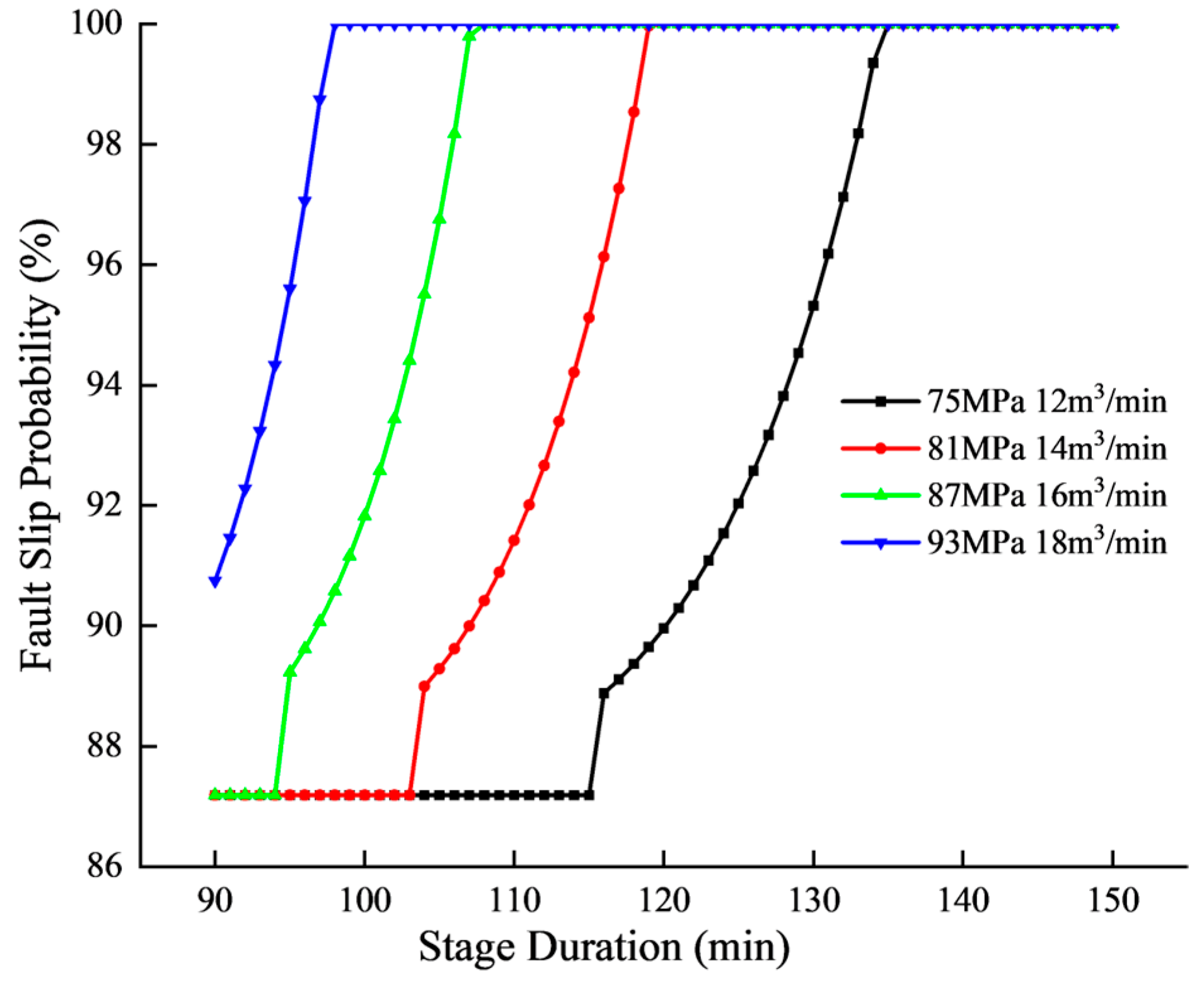

4.1.3. Stage Duration

4.2. Geological Factors

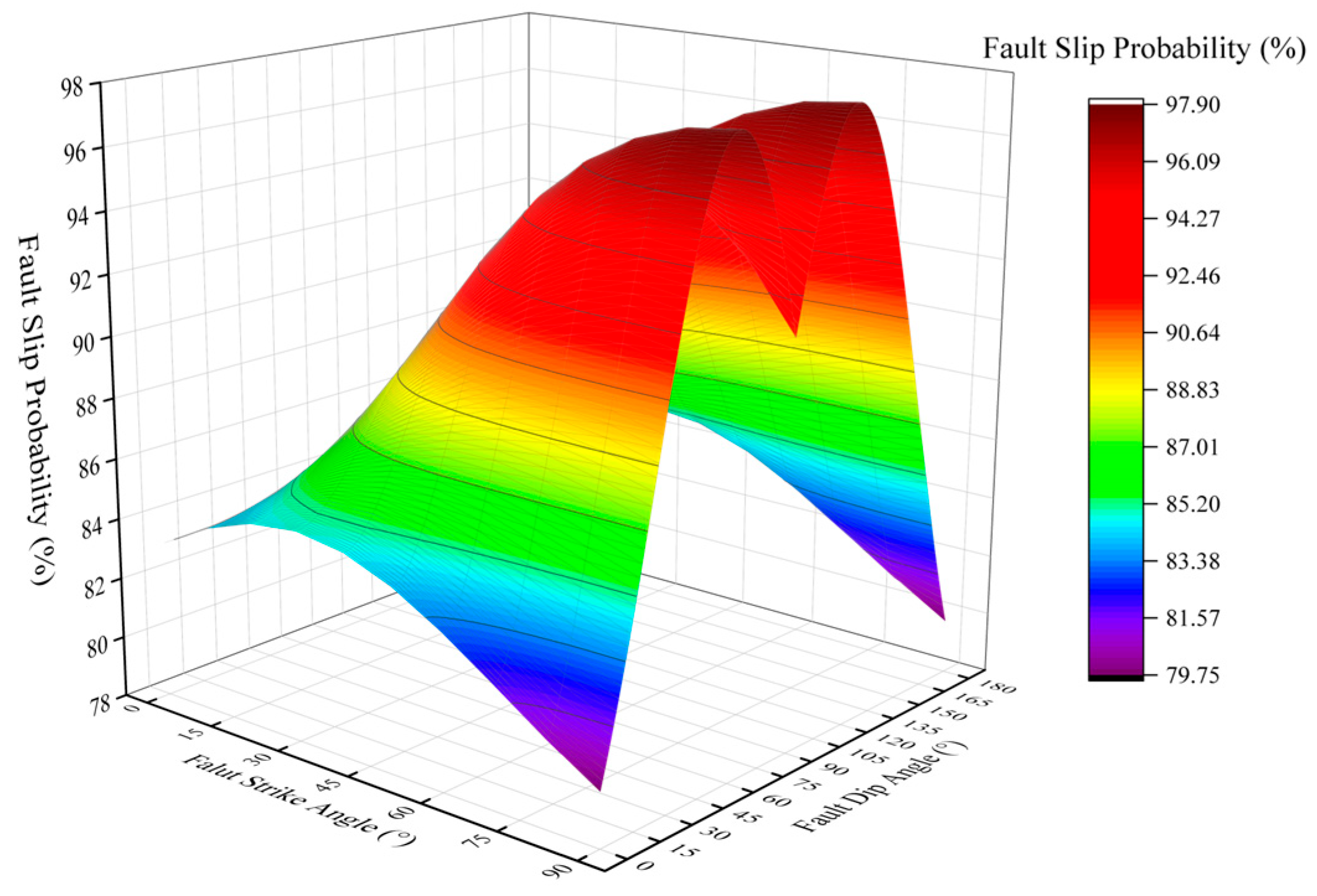

4.2.1. Fault Dip and Strike

4.2.2. Fault Friction Coefficient

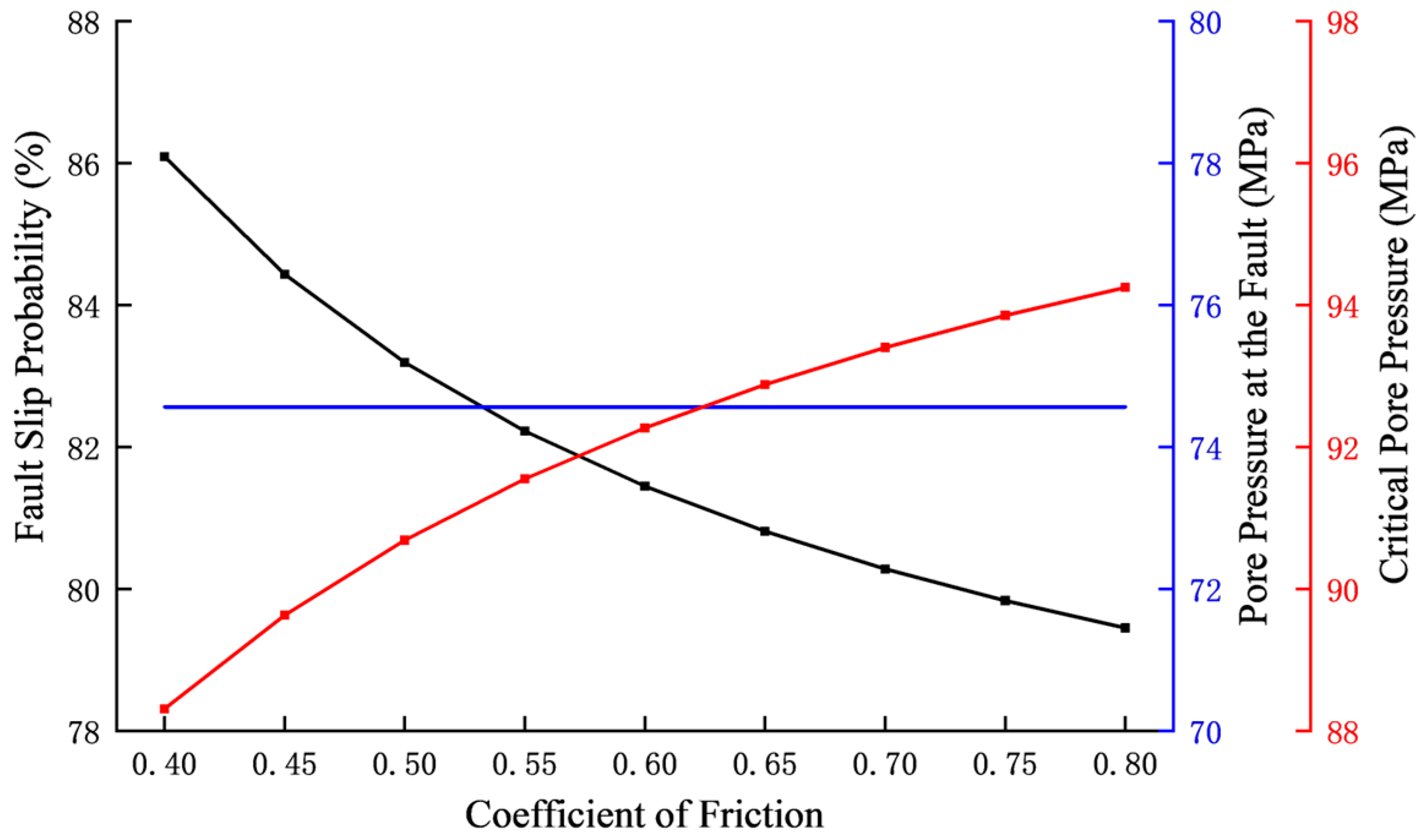

4.2.3. Horizontal Stress Anisotropy

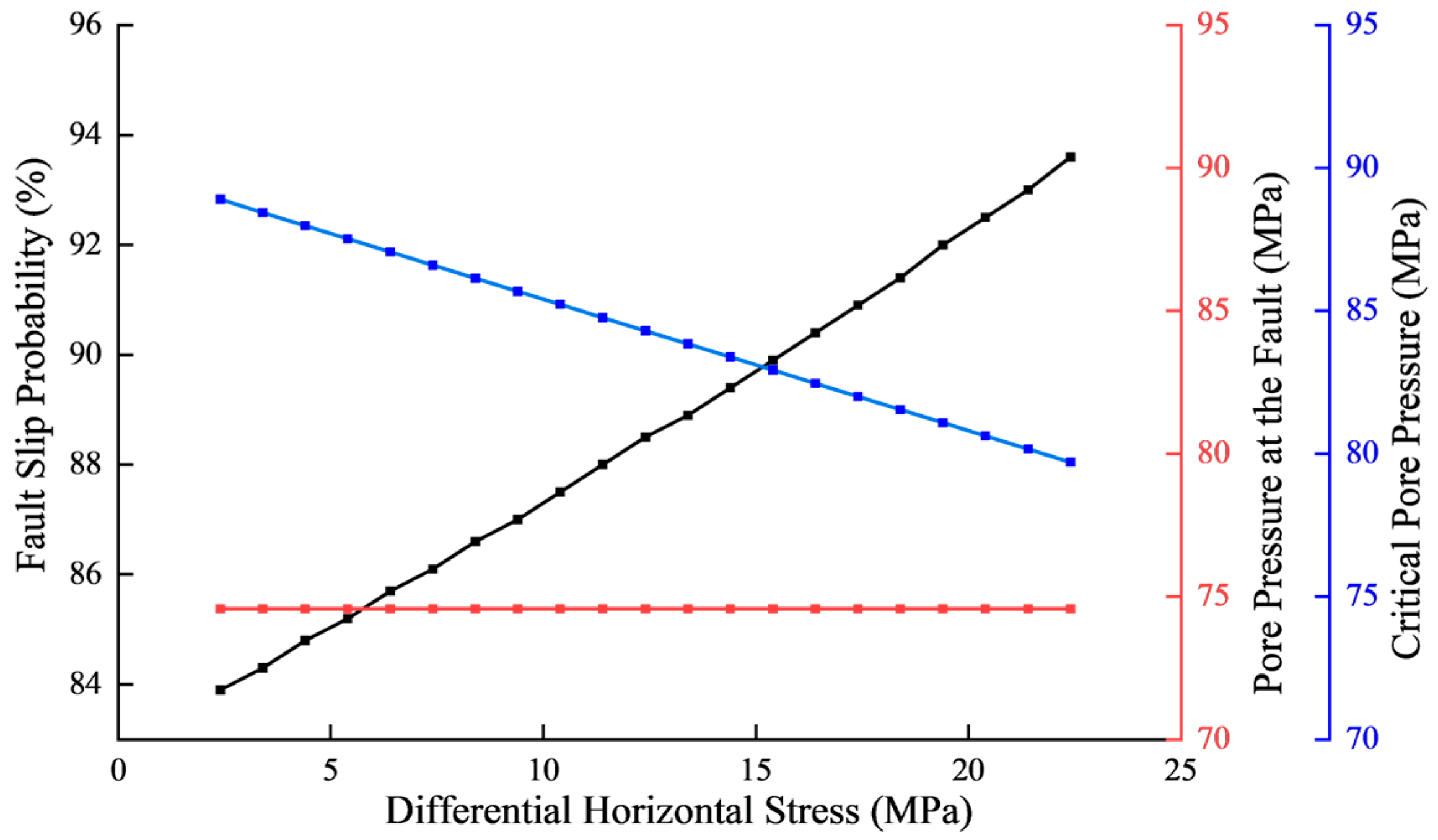

5. Conclusions

- (1)

- This study establishes a fault slip probability model based on porosity-coupled pressure evolution, which is quantitatively validated using operational parameters from 10 casing deformation wells in the Luzhou Block. Six wells exhibited slip probabilities exceeding 92%, confirming model reliability for risk quantification. The key findings are outlined below.

- (2)

- Engineering parameters significantly influence slip risks. Wellhead pressures tween 80 and 100 MPa increase slip probability by 32%, while elevated pumping rates substantially accelerate slip potential. High-pressure/high-rate combinations and extended stage durations exhibit positive correlations with slip hazards.

- (3)

- Geological factors demonstrate critical control: higher friction coefficients reduce slip vulnerability. Low-dip faults exhibit maximum risk when strikes align with the maximum horizontal stress, whereas high-dip faults show a bimodal risk distribution at 60–120° strikes with amplified strike-direction sensitivity. Horizontal stress anisotropy directly correlates with slip probability elevation.

- (4)

- Optimizing fracturing parameters, controlling operational duration, and avoiding high-risk fault orientations can effectively mitigate slip risks. These insights inform technical strategies for controlling casing deformation during multistage hydraulic fracturing processes in shale gas reservoirs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, G.; Shi, X.; Liu, Y.; Wu, W.; Yang, Y.; Zhu, Y.; Chen, L.; Xu, L.; Zhong, K.; Yin, Y. New Insights into Enrichment Controlling Factors of Deep Shale Gas in Wufeng-Longmaxi Formations, Southern Sichuan Basin. Nat. Gas Ind. 2024, 44, 58–71. [Google Scholar]

- Wang, H.; Zhou, S.; Zhao, Q.; Shi, Z.; Liu, D.; Jiao, P. Enrichment Characteristics, Exploration and Development Progress of Deep Shale Gas in Southern Sichuan Basin, China. Oil Gas Geol. 2023, 44, 1430–1441. [Google Scholar]

- Guo, T.; Xiong, L.; Lei, W.; Zhao, Y.; Pang, Q. Progress, Challenges and Countermeasures in Deep Shale Gas Exploration and Development in Weirong and Yongchuan Areas, Southern Sichuan Basin. Nat. Gas Ind. 2022, 42, 45–59. [Google Scholar]

- Deng, N.; Xu, H.; Deng, H.; He, J.; Liu, S.; Li, K.; Zheng, Z.; Sheng, L.; Song, W. Fault System Impacts on Present-Day In-Situ Stress Disturbances: Case Study of Deep Shale Gas in Northern Luzhou Block, Sichuan Basin. Geol. China 2025, 52, 95–110. [Google Scholar]

- Zheng, S.; Xie, X.; Luo, L.; Jing, Y.; Tang, M.; Yang, R.; Zhong, G.; Wang, J.; Chen, Z. Optimized Drilling Technology for Deep Shale Gas Horizontal Wells in Sichuan Basin: A Case Study of Well Lu 203. Nat. Gas Ind. 2019, 39, 88–93. [Google Scholar]

- Han, L.; Li, X.; Liu, Z.; Duan, G.; Wan, Y.; Guo, X.; Guo, W.; Cui, Y. Controlling Factors and Prevention Strategies for Casing Deformation in Deep Shale Gas Wells, Luzhou Area, Southern Sichuan Basin. Petrol. Explor. Dev. 2023, 50, 853–861. [Google Scholar] [CrossRef]

- Yan, J.; Lai, S.; Guo, W.; Shi, X.; Liao, M.; Tang, H.; Hu, Q.; Huang, Y. Research Progress on Geomechanical Casing Deformation Types and Influencing Factors in Shale Gas Wells. Lithol. Reserv. 2024, 36, 1–14. [Google Scholar]

- Meng, H.; Shen, Y.; Zhu, W.; Li, X.; Lei, D.; Ge, H. External Load Analysis of Casing During Hydraulic Fracturing in Zhaotong Shale Gas Hor-izontal Wells, Sichuan Basin. Spec. Oil Gas Reserv. 2023, 30, 166–174. [Google Scholar]

- Yin, A.; Li, J.; Lian, W.; Zhang, H. Research Advances in Casing Deformation Mechanisms and Control Methods for Shale Gas Hor-izontal Wells. Xinjiang Oil Gas 2025, 21, 50–60. [Google Scholar]

- Yong, R.; Wu, J.; Zeng, B.; Huang, H.; Cui, S.; Gou, Q.; Xu, E.; Zhao, S. Geological-Engineering Integration Technology for Casing Deformation Prevention in Luzhou Shale Gas Block. Drill. Prod. Technol. 2024, 47, 83–92. [Google Scholar]

- Kroll, K.A.; Cochran, E.S.; Murray, K.E. Poroelastic Properties of the Arbuckle Group in Oklahoma Derived from Well Fluid Level Response to the 3 September 2016 Mw 5.8 Pawnee and 7 November 2016 Mw 5.0 Cushing Earthquakes. Seismol. Res. Lett. 2017, 88, 963–970. [Google Scholar] [CrossRef]

- Skoumal, R.J.; Barbour, A.J.; Brudzinski, M.R.; Langenkamp, T.; Kaven, J.O. Induced Seismicity in the Delaware Basin, Texas. J. Geophys. Res. Solid Earth 2020, 125, e2019JB018558. [Google Scholar] [CrossRef]

- Kneafsey, T.; Dobson, P.; Blankenship, D.; Schwering, P.; White, M.; Morris, J.P.; Huang, L.; Johnson, T.; Burghardt, J.; Mattson, E.; et al. The EGS Collab Project: Outcomes and Lessons Learned from Hydraulic Fracture Stimulations in Crystalline Rock at 1.25 and 1.5 km Depth. Geothermics 2025, 126, 103178. [Google Scholar] [CrossRef]

- Chen, C.; Xiang, D.; Zhang, F.; Meng, A.; Yin, Z.; Jiang, Z. Fault Slip and Casing Deformation Mechanisms Induced by Hydraulic Fracturing in Changning-Weiyuan Blocks, Sichuan Basin: Prevention Strategies. Petrol. Sci. Bull. 2019, 4, 364–377. [Google Scholar]

- Wang, Z.; He, J.; Zheng, B.; Mao, T.; Li, S.; Li, X. Experimental Study on Friction Behavior During Fault Slip Under Fluid Injection. J. Eng. Geol. 2025, 33, 858–865. [Google Scholar]

- Zhang, Q.; Zhang, F.; Yi, X.; Liu, Y.; Wang, H.; Ma, J.; Chen, X. Analysis of Fault Activation Impacts on Casing During Fracturing Operations. China Petrol. Mach. 2023, 51, 74–79+89. [Google Scholar]

- Yan, W.; Wang, K.; Deng, J.; Tang, Q.; Bu, H.; Tan, C.; Yin, Q.; Qin, F. Characteristics of Fault-Slip Induced Casing Deformation: Case Study of Dagang Guandong Shale Oil. Petrol. Sci. Bull. 2022, 7, 543–554. [Google Scholar]

- Sun, R.; Huang, D.; Chen, D.; Zhao, J.H. Research on Casing Failure Mechanisms and Countermeasures in Hydraulic Fracture of Shale Reservoirs Considering Dynamic Evolution of Fault Slip. Eng. Fail. Anal. 2024, 161, 108301. [Google Scholar] [CrossRef]

- Xiong, T.S.; Wang, H.C.; Liu, H.; Yang, J.X.; Ma, B.; He, P.; Yang, Q.Y.; Guo, C.B.; Huang, X.N. Application of Key Factors Analysis and Measures Prevention of Casing Deformation—A Case Study from China. In Proceedings of the SPE Advances in Integrated Reservoir Modelling and Field Development Conference and Exhibition, Abu Dhabi, United Arab Emirates, 2–4 June 2025. [Google Scholar]

- Liu, H.; Fan, Z.; Liu, Y.; Lian, W.; Xi, Y.; Zhang, X. Calculation Method for Fault Slip Displacement Based on Focal Mechanisms. World Petrol. Ind. 2024, 31, 40–47. [Google Scholar]

- Wang, X.; Zhong, S.; Wu, Y.; Song, L.; Tuo, Y.; Lin, T. Shear Effects of Hydraulic Fracturing-Induced Fault Slip on Casing Integrity. Drill. Prod. Technol. 2023, 46, 7–14. [Google Scholar]

- Liu, P.; Li, J.; Xi, Y.; Lian, W.; Zhang, X.; Guo, X. Calculation Model and Influencing Factors of Shale Fault Slip Displacement. China Petrol. Mach. 2022, 50, 74–80. [Google Scholar]

- Liu, H.; Liu, H.; Liu, Y.; Cao, W.; Lian, W.; Li, J. Dynamic Slip Behaviors of Faults During Multistage Hydraulic Fracturing in Shale Gas Reservoirs. China Petrol. Mach. 2024, 52, 65–74. [Google Scholar]

- Zhang, W.; Li, J.; Zhang, H.; Wang, D.; Li, T.; Liu, H. Influence of Fault Slip on Casing Shear Deformation: Mitigation Strategies. Fault-Block Oil Gas Field 2023, 30, 734–742. [Google Scholar]

- Yan, X.; Yu, H.T.; Jing, H.W. Numerical Investigation of the Stress Regime Effect on Injection-Induced Fault Reactivation and Associated Seismicity. Comput. Geotech. 2024, 169, 106251. [Google Scholar] [CrossRef]

- He, Y.; Li, Y. FEM Simulation of Fault Reactivation Induced with Hydraulic Fracturing in the Shangluo Region of Sichuan Province. Energies 2024, 17, 1614. [Google Scholar] [CrossRef]

- Polun, S.G.; Bidgoli, T.S. Introducing PyFaultSlip: A Free and Open-Source Tool for the Assessment of Induced Fault Slip Hazards from Deep Fluid Injection. Comput. Geosci. 2024, 196, 105813. [Google Scholar] [CrossRef]

- Li, J.; Zhao, C.; Liu, G.; Zhang, H.; Zhang, X.; Ren, K. Fault Slip Behaviors and Influencing Factors Under Shale Gas Fracturing Conditions. J. China Univ. Petrol. (Nat. Sci. Ed.) 2021, 45, 63–70. [Google Scholar]

- Peterie, S.L.; Miller, R.D.; Intfen, J.; Bidgoli, T.; Buchanan, R. A Geologically-Based Approach to Mitigate Potentially Induced Seismicity in Kansas. In SEG Technical Program Expanded Abstracts 2015; Society of Exploration Geophysicists: Houston, TX, USA, 2015; pp. 4871–4876. [Google Scholar]

- Huang, H.Y.; Xu, E.S.; Zhong, G.H.; Zhang, Z.; Yang, X.; Liu, C.X.; Yu, W. Analysis of Casing Deformation in Horizontal Wells of Deep Shale Gas Reservoirs: Causes and Mitigation Strategies. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 2–4 June 2025. [Google Scholar]

- Ye, T.; Chen, Z.; Dai, C. Data-Driven Analysis and Template Construction for Casing Deformation in Deep Shale Gas Basin. SPE J. 2025, 30, 2256–2268. [Google Scholar] [CrossRef]

- Nermoen, A.; Shchipanov, A.; Porzer, M.M.; Šancer, J.; Berenblyum, R. Evaluation of Safe Operating Envelope for CO2 Injection under Uncertain Rock Mechanical Parameters and Earth Stresses. Int. J. Greenh. Gas Control 2024, 136, 104189. [Google Scholar] [CrossRef]

- Li, D.; Jia, J.; Teng, F.; Zhu, G.; Wu, M. Calculation of Bottom-Hole Pressure During Fracturing Operations. Fault-Block Oil Gas Field 2013, 20, 384–387. [Google Scholar]

- Xu, F. Computational Analysis and Comparative Assessment of KGD, PKN, and Modified P3D Hydraulic Fracturing Design Models. Energy Environ. Prot. 2017, 39, 220–225. [Google Scholar]

- Miller, C.; Dyes, A.B.; Hutchinson, C.A., Jr. The Estimation of Permeability and Reservoir Pressure from Bottom Hole Pressure Build-Up Characteristics. J. Petrol. Technol. 1950, 2, 91–104. [Google Scholar] [CrossRef]

- Yokoyama, R.; Wang, K.; Suzuki, S.; Miwa, S.; Okamoto, K. Determination of Spearman’s Rank Correlation for Melt Spreading-Solidification Dynamics Through the Combination of Integrated Experiments and Monte Carlo Method. Int. J. Heat Mass Transf. 2025, 242, 126831. [Google Scholar] [CrossRef]

| Well No. | (MPa) | (m3/min) | t (h) | (MPa) | (MPa) | (MPa) | (°) | |

|---|---|---|---|---|---|---|---|---|

| Well 1 | 102 | 18.2 | 2.28 | 93.9 | 102.8 | 90.2 | 14 | 83.13% |

| Well 2 | 92 | 17.2 | 2.73 | 95.6 | 102.4 | 90 | 155 | 80.81% |

| Well 3 | 95 | 14 | 1.84 | 99.6 | 108 | 94.3 | 177 | 92.99% |

| Well 4 | 89 | 11.5 | 2.25 | 93.9 | 99.2 | 87.8 | 158 | 100% |

| Well 5 | 79 | 16.5 | 2.02 | 94.1 | 99.8 | 88.5 | 0 | 70.14% |

| Well 6 | 74 | 15 | 1.82 | 94.1 | 98.9 | 87.6 | 0 | 76.38% |

| Well 7 | 74 | 15 | 1.91 | 94.1 | 97.7 | 86 | 120 | 92.66% |

| Well 8 | 89 | 16 | 2.03 | 88.8 | 93.8 | 83.1 | 90 | 100% |

| Well 9 | 84 | 14 | 1.4 | 88.8 | 93.8 | 83.1 | 120 | 97.47% |

| Well 10 | 83 | 14 | 2.48 | 98 | 105.1 | 91 | 110 | 100% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Lian, W.; Li, J.; Wu, Y. Assessing Fault Slip Probability and Controlling Factors in Shale Gas Hydraulic Fracturing. Eng 2025, 6, 272. https://doi.org/10.3390/eng6100272

Wang K, Lian W, Li J, Wu Y. Assessing Fault Slip Probability and Controlling Factors in Shale Gas Hydraulic Fracturing. Eng. 2025; 6(10):272. https://doi.org/10.3390/eng6100272

Chicago/Turabian StyleWang, Kailong, Wei Lian, Jun Li, and Yanxian Wu. 2025. "Assessing Fault Slip Probability and Controlling Factors in Shale Gas Hydraulic Fracturing" Eng 6, no. 10: 272. https://doi.org/10.3390/eng6100272

APA StyleWang, K., Lian, W., Li, J., & Wu, Y. (2025). Assessing Fault Slip Probability and Controlling Factors in Shale Gas Hydraulic Fracturing. Eng, 6(10), 272. https://doi.org/10.3390/eng6100272