Effect of Imposed Shear During Oval-Caliber Rolling on the Properties of Mn–Si Low-Alloy Steel

Abstract

1. Introduction

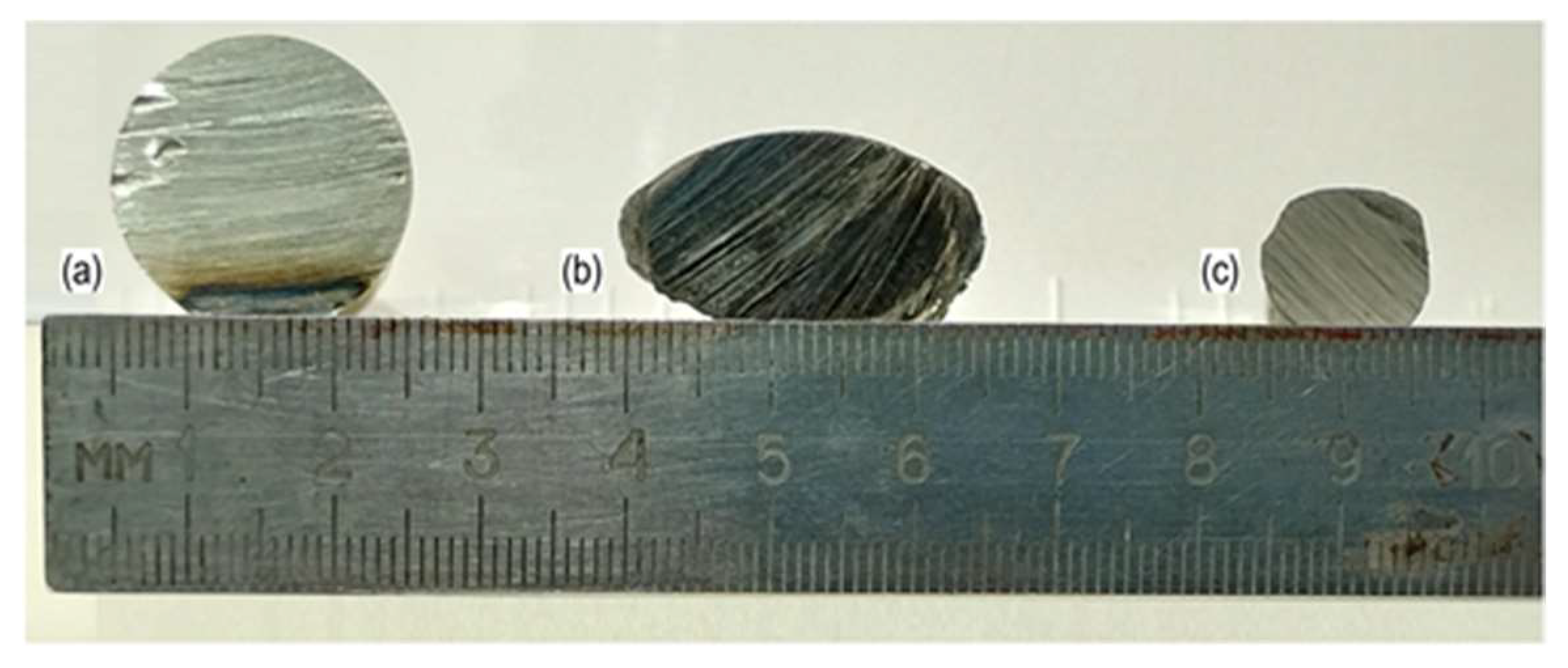

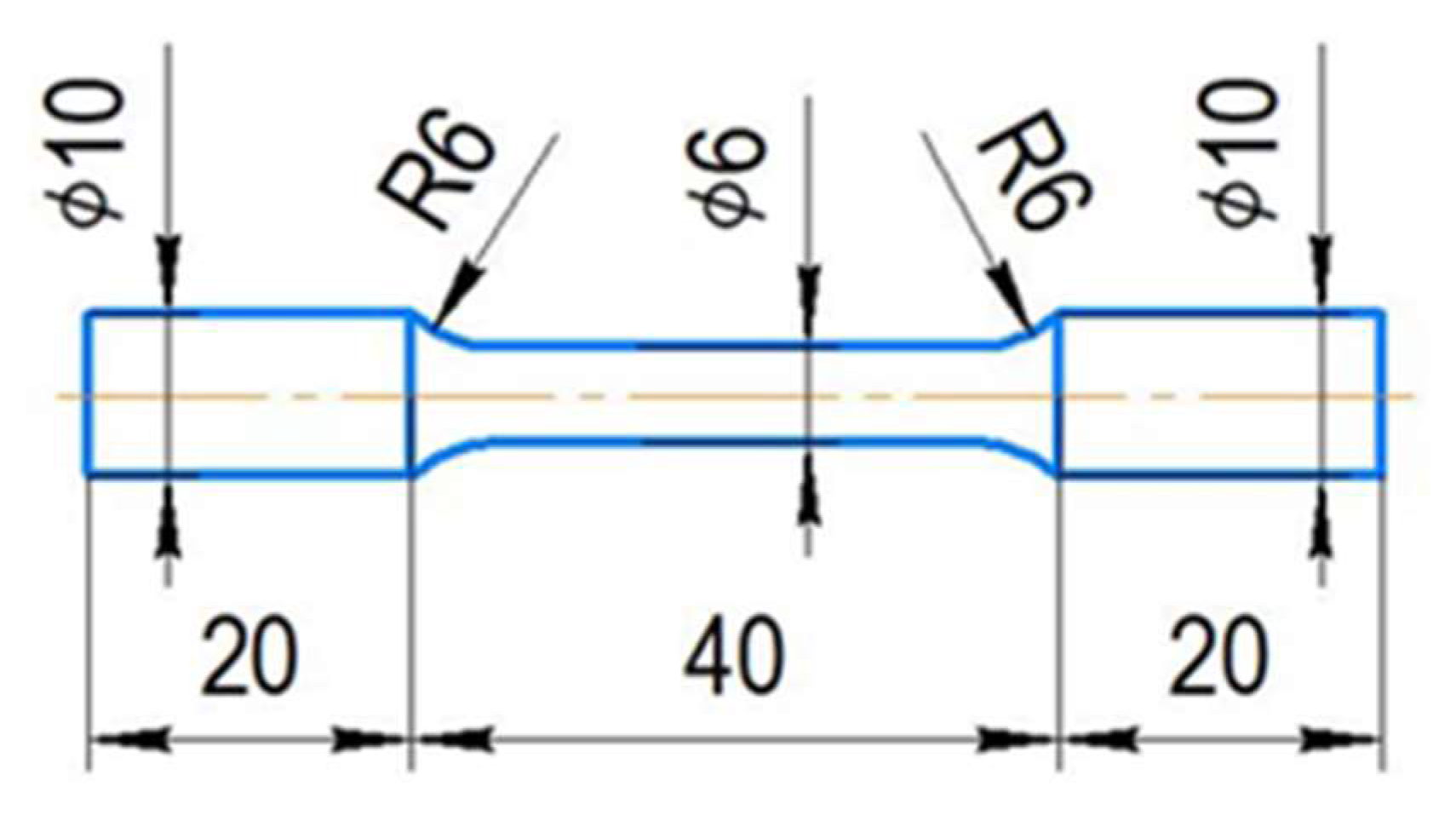

2. Materials and Methods

- Classic scheme: traditional oval followed by round calibers.

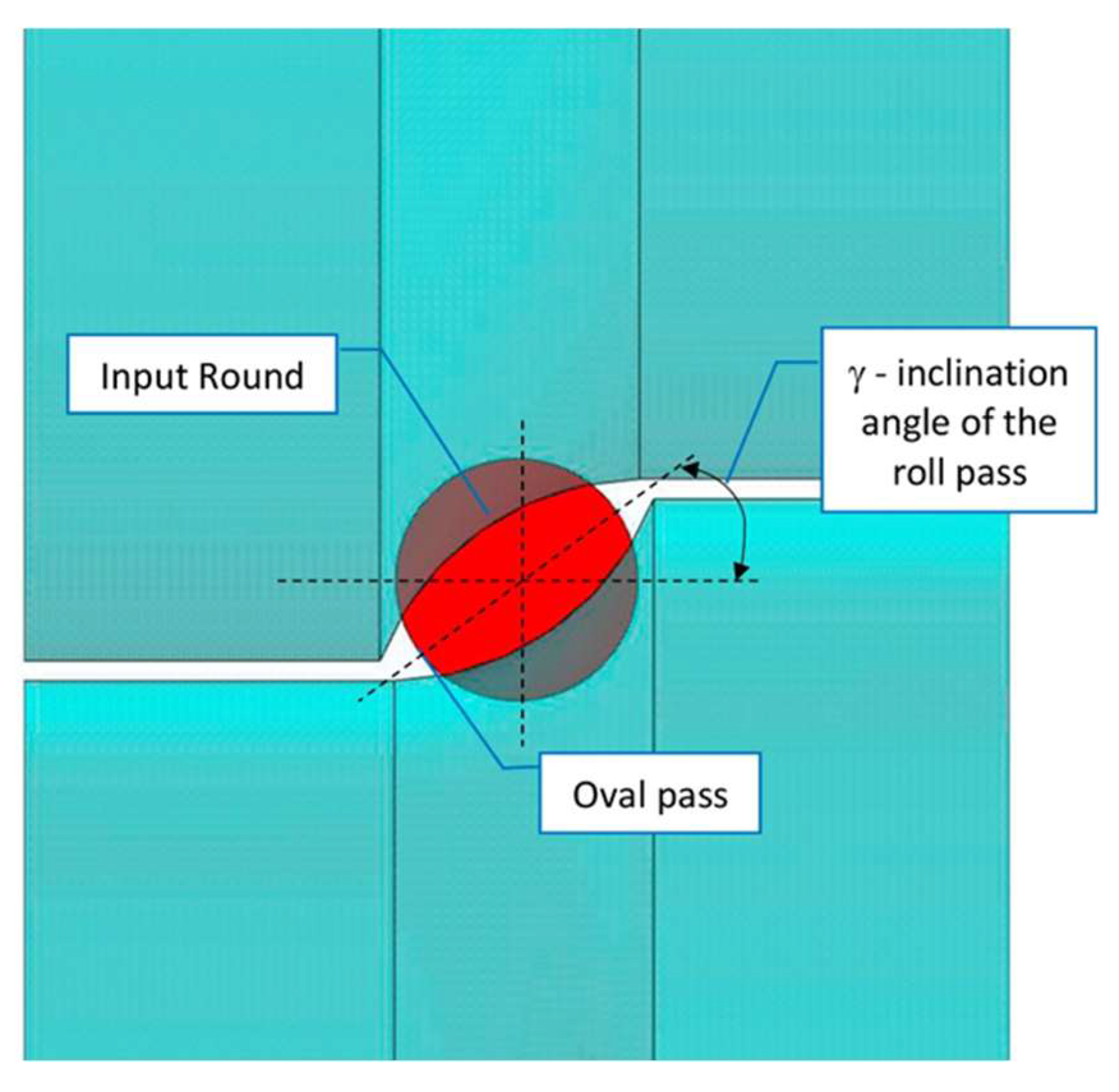

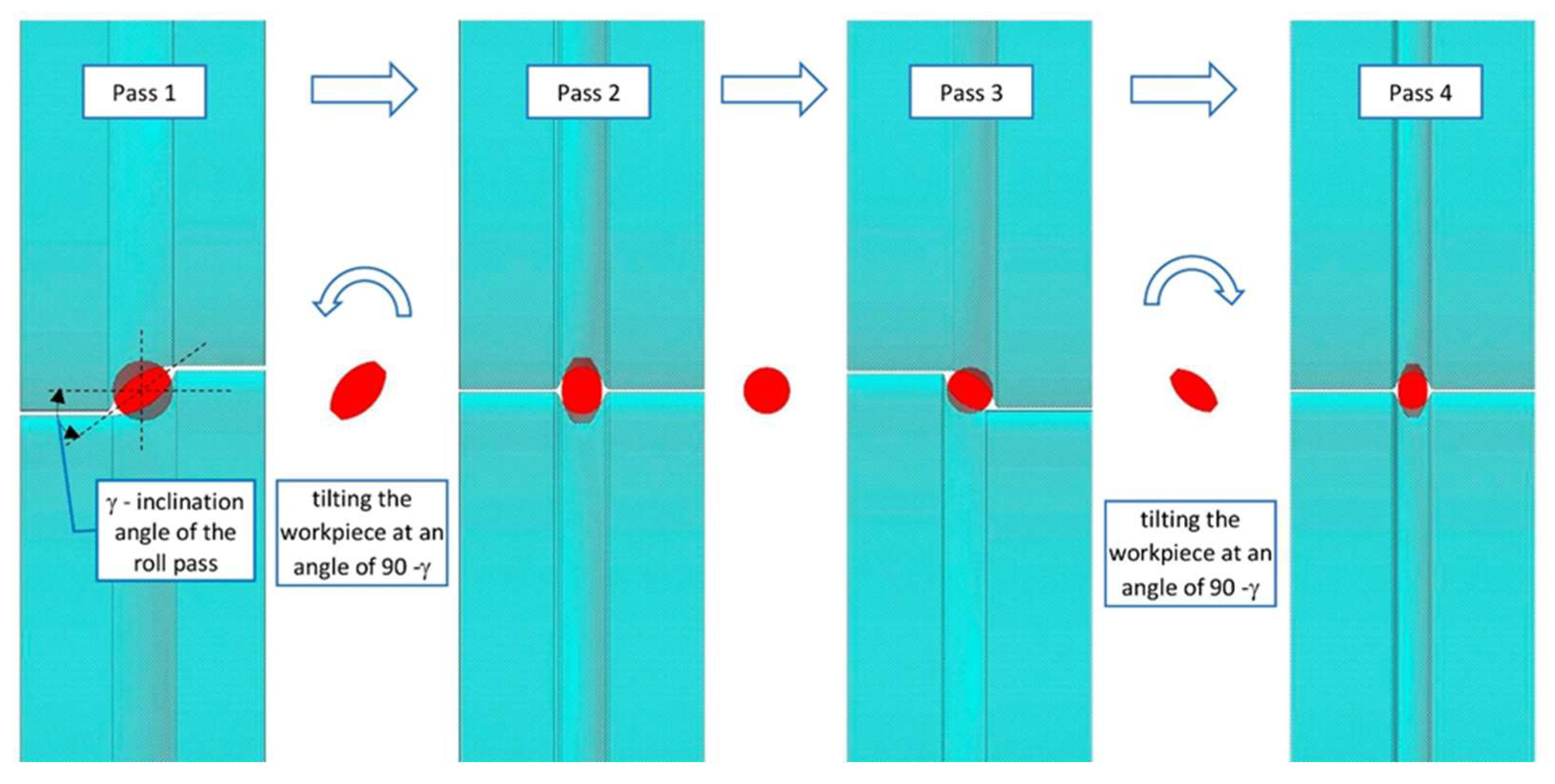

- Modified scheme: inclined oval calibers followed by round calibers, as illustrated in Figure 2.

3. Results and Discussion

4. Conclusions

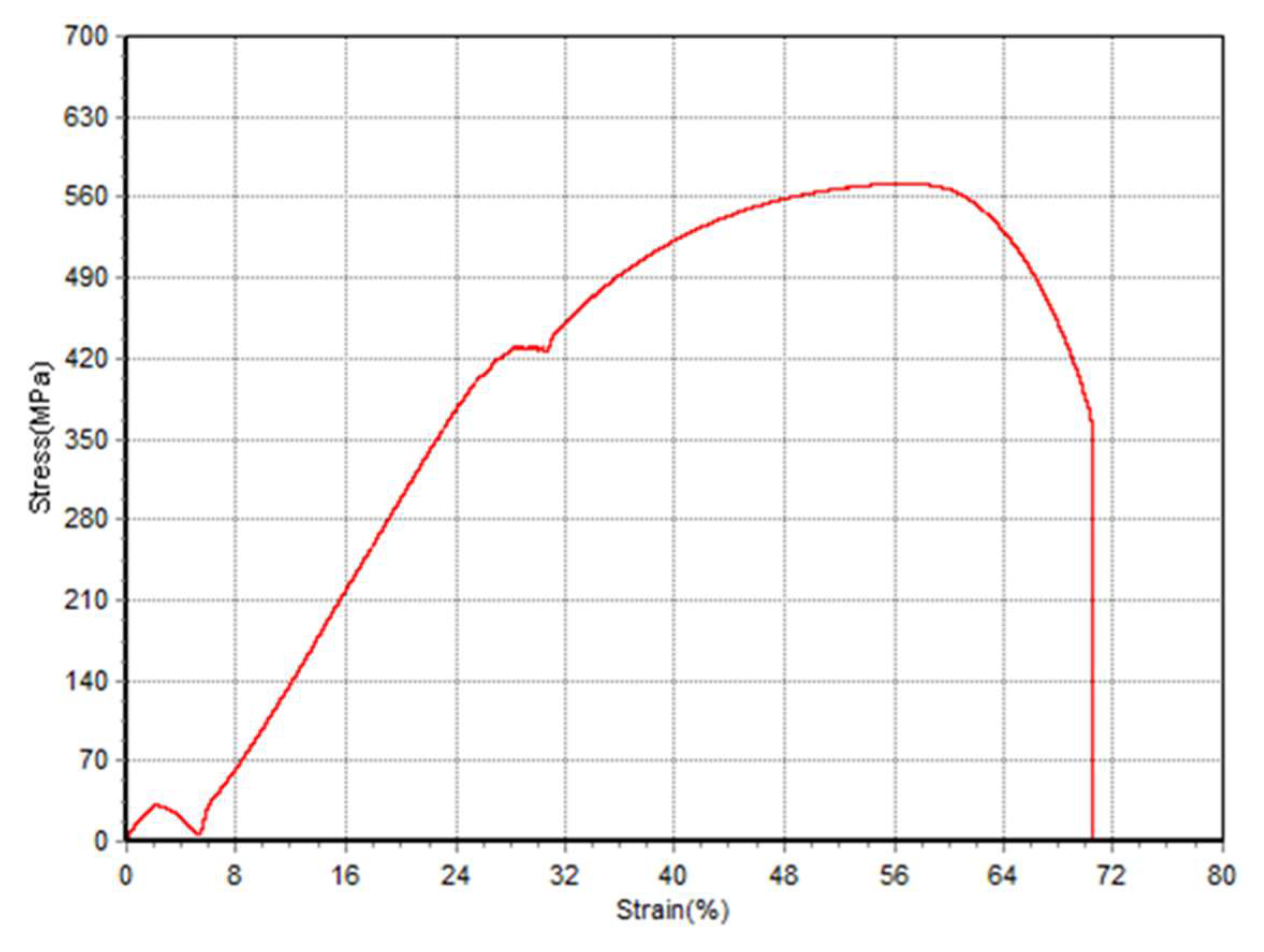

- Strength–ductility balance: Classical oval–round rolling enhanced the strength of 25G2S steel by raising σ0.2 to ~444 MPa and σᵥ to ~584 MPa, while the modified (inclined) scheme retained comparable strength (~433 and ~572 MPa, respectively). At the same time, the modified route provided superior ductility, with elongation exceeding 26% and reduction in area approaching 69%, highlighting its advantage in achieving a more favorable mechanical balance.

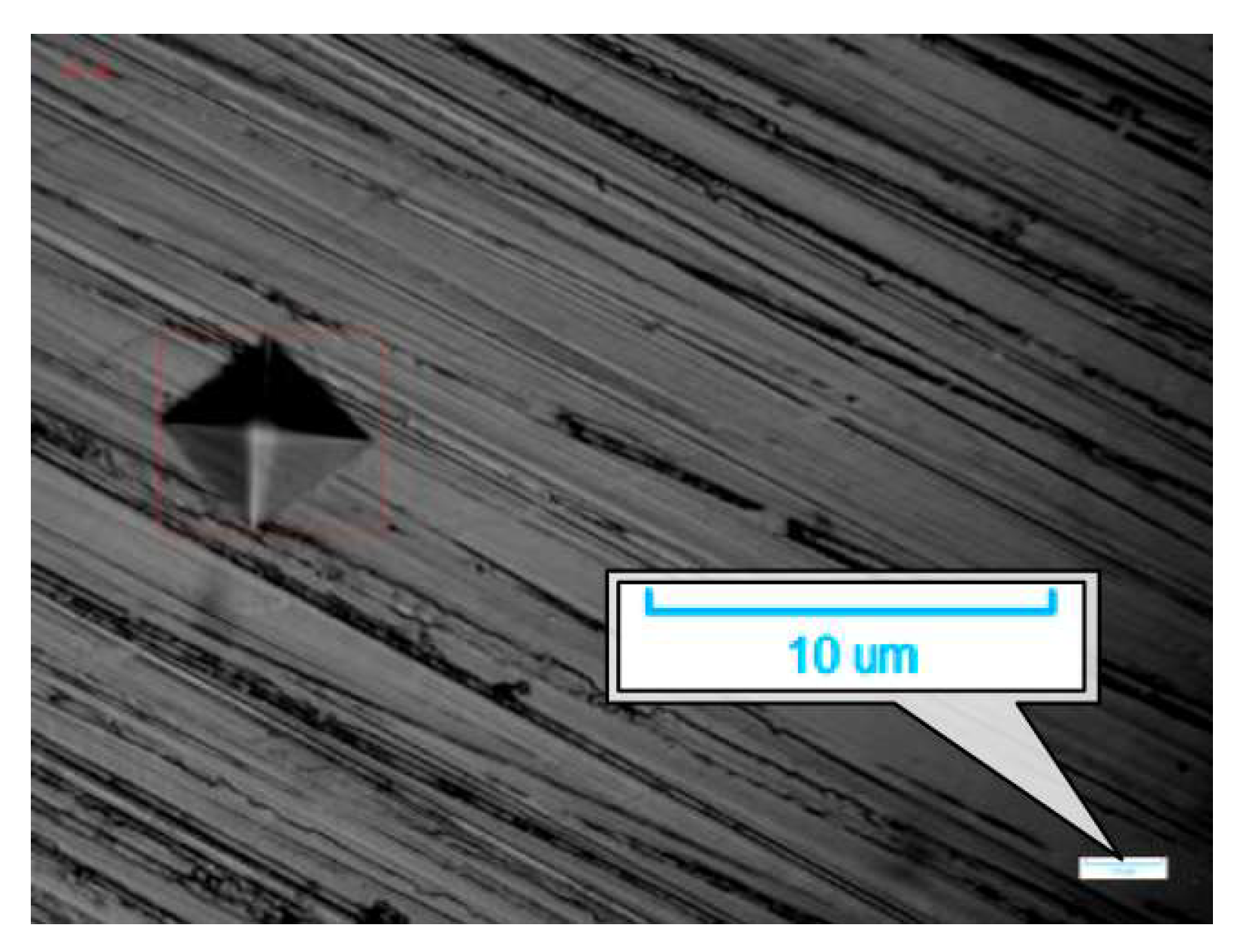

- Hardness evolution and uniformity: Both rolling schemes reduced Vickers hardness relative to the as-received state (244 HV → 213 HV for classical, 184 HV for modified). Notably, the modified path minimized scatter (±4.8 HV), which signifies improved structural uniformity and reproducibility of properties across the section.

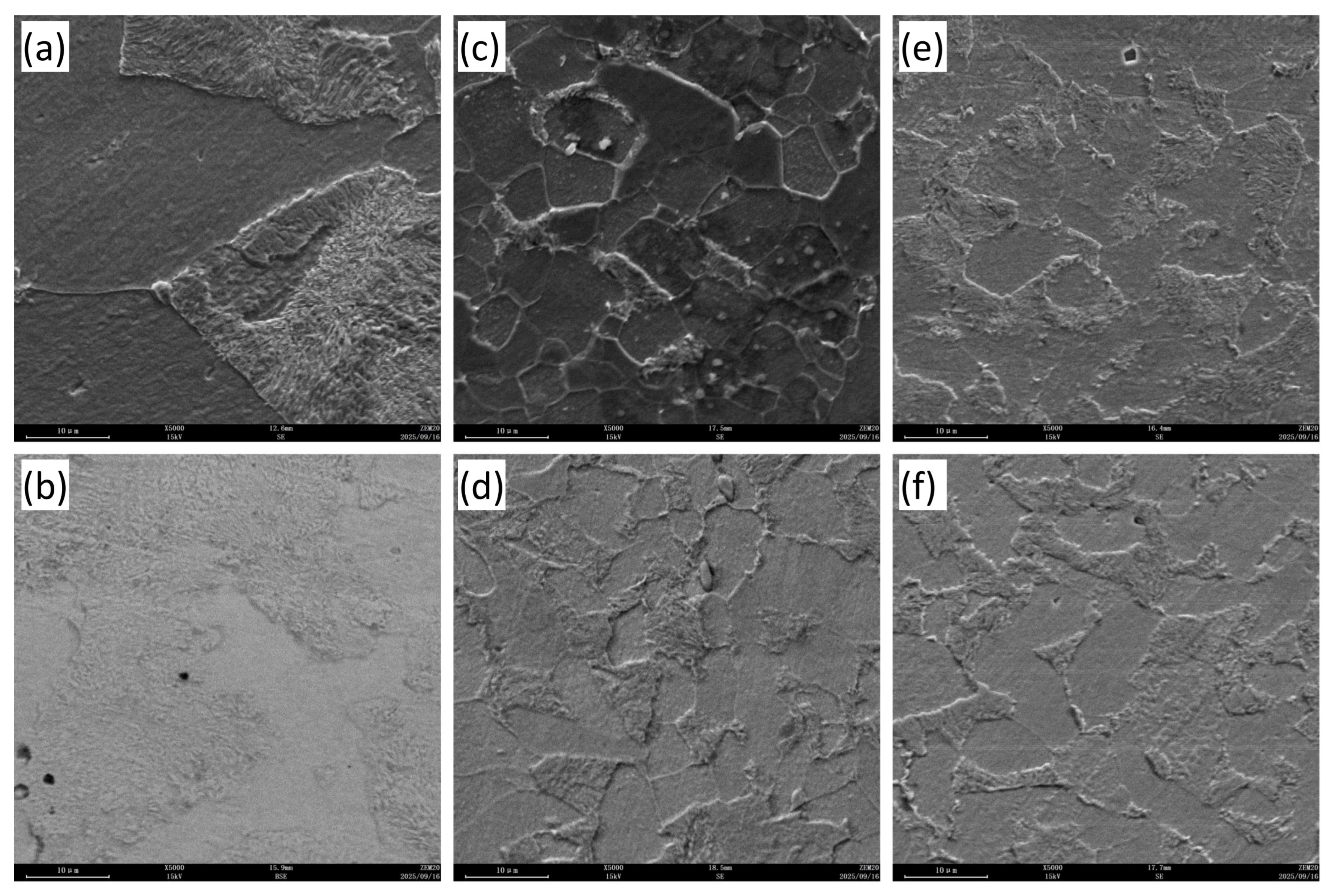

- Microstructural refinement: SEM micrographs confirmed significant grain refinement in all rolled states. In particular, the modified scheme led to equiaxed ferrite grains of 3–5 µm and suppressed banding in the longitudinal section, indicative of enhanced isotropy. Such morphological features are consistent with active dynamic and metadynamic recrystallization triggered by shear-assisted deformation.

- Shear-driven mechanism: The introduction of tilted oval calibers modifies the strain path, superimposing shear on the deformation field. This raises the effective strain and accelerates subgrain boundary formation, thereby promoting DRX kinetics. The observed microstructural changes directly support this mechanistic interpretation.

- Technological significance: The modified oval–round rolling scheme provides an efficient pathway to tailor mechanical response via controlled microstructural refinement. The method offers practical potential for industrial-scale rolling operations, where improved ductility, structural homogeneity, and reliable strength are critical performance targets.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Valiev, R.Z.; Islamgaliev, R.K. Enhanced Superplasticity of Ultrafine-Grained Alloys Processed by Severe Plastic Deformation. Mater. Sci. Forum 1999, 304, 39–46. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using High-Pressure Torsion for Metal Processing: Fundamentals and Applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Segal, V.M. Review: Modes and Processes of Severe Plastic Deformation (SPD). Materials 2018, 11, 1175. [Google Scholar] [CrossRef]

- Ji, Y.H.; Park, J.J. Development of Severe Plastic Deformation by Various Asymmetric Rolling Processes. Mater. Sci. Eng. A 2009, 499, 14–17. [Google Scholar] [CrossRef]

- Dhinwal, S.S.; Toth, L.S.; Hodgson, P.D.; Haldar, A. Effects of Processing Conditions on Texture and Microstructure Evolution in Extra-Low Carbon Steel during Multi-Pass Asymmetric Rolling. Materials 2018, 11, 1327. [Google Scholar] [CrossRef] [PubMed]

- Naizabekov, A.B.; Bykhin, M.B.; Nogaev, K.A.; Bykhin, B.B. Study of the Process of Realization of High-Rate Plastic Deformation in Lengthwise Rolling. In Proceedings of the 19th International Conference on Metallurgy and Materials (METAL 2010), Brno, Czech Republic, 19–21 May 2010; pp. 192–202. Available online: https://www.confer.cz/metal/2010 (accessed on 2 September 2025).

- Vincze, G.; Simões, F.J.P.; Butuc, M.C. Asymmetrical Rolling of Aluminum Alloys and Steels: A Review. Metals 2020, 10, 1126. [Google Scholar] [CrossRef]

- Ren, X.; Huang, Y.; Zhang, X.; Li, H.; Zhao, Y. Influence of Shear Deformation during Asymmetric Rolling on the Microstructure, Texture, and Mechanical Properties of the AZ31B Magnesium Alloy Sheet. Mater. Sci. Eng. A 2021, 800, 140306. [Google Scholar] [CrossRef]

- Godec, M.; Kralj, D.; Kosec, B.; Kolar, M.; Kosec, M. Influence of Symmetric and Asymmetric Rolling on Texture and Deep Drawing Properties of Aluminum Alloys. Trans. Nonferrous Met. Soc. China 2025, 35, 473–483. [Google Scholar] [CrossRef]

- Ghalehbandi, S.M.; Malaki, M.; Gupta, M. Accumulative Roll Bonding–A Review. Appl. Sci. 2019, 9, 3627. [Google Scholar] [CrossRef]

- Ghaderi, O.; Zare, M.; Sadabadi, H.; Toroghinejad, M.R.; Najafizadeh, A.; Church, B.C.; Rohatgi, P.K. Structural and Mechanical Properties of Cu-SiCp Nanocomposites Fabricated by Accumulative Roll Bonding (ARB). Front. Mater 2024, 11, 1362746. [Google Scholar] [CrossRef]

- Roy, S.; Singh, S.D.; Suwas, S.; Kumar, S.; Chattopadhyay, K. Evolution of Texture and Microstructure during Accumulative Roll Bonding of Aluminum AA5086 Alloy. Mater. Sci. Eng. A 2011, 528, 8469–8474. [Google Scholar] [CrossRef]

- Ebrahimi, M. Accumulative Roll-Bonding of Aluminum Alloys and Composites: A Review. J. Mater. Res. Technol. 2022, 18, 348–369. [Google Scholar] [CrossRef]

- Sivakumar, K.; Ramesh, K.; Suresh, S.; Rajendran, I.; Ramesh, R. Review on Accumulative Roll Bonding (ARB) Techniques for Improving the Mechanical Properties of Multi-Layered Materials. J. Mater. Sci. Technol. 2020, 56, 1–15. [Google Scholar] [CrossRef]

- Abishkenov, M.; Ashkeyev, Z.; Nogaev, K. Investigation of the Shape Rolling Process Implementing Intense Shear Strains in Special Diamond Passes. Materialia 2022, 26, 101573. [Google Scholar] [CrossRef]

- Ashkeyev, Z.; Abishkenov, M.; Nogaev, K.; Bestembek, Y.; Azimbayev, K.; Tavshanov, I. Stress State of Workpieces during Upsetting with Additional Shear. Eng. Solid Mech. 2023, 11, 253–262. [Google Scholar] [CrossRef]

- Nogayev, K.; Abishkenov, M.; Tavshanov, I.; Ashkeyev, Z.; Kunaev, V.; Akhmetova, G.; Kamarov, A. Enhanced Shear De-formation in Rod Rolling with Inclined Oval Pass Modification. Acta Metall. Slovaca 2025, 31, 186–193. [Google Scholar] [CrossRef]

- Nogayev, K.; Kamarov, A.; Abishkenov, M.; Ashkeyev, Z.; Sembayev, N.; Kydyrbayeva, S. Finite Element-Based Multi-Objective Optimization of a New Inclined Oval Rolling Pass Geometry. Modelling 2025, 6, 110. [Google Scholar] [CrossRef]

- Steel-Grades. GOST 25G2S—Chemical Composition and Mechanical Properties of Steel Grade 25G2S. Available online: https://www.steel-grades.com/metals/85/211097/GOST-25G2S.html (accessed on 6 September 2025).

- Zhao, X.; Chen, L.; He, K.; Wu, N.; Zeng, J. Effect of Contact Heat Transfer on Hot Rolling of Aluminum Alloy. Procedia Manuf. 2019, 37, 91–96. [Google Scholar] [CrossRef]

- Speicher, K.; Steinboeck, A.; Wild, D.; Kiefer, T.; Kugi, A. An Integrated Thermal Model of Hot Rolling. Math. Comput. Model. Dyn. Syst. 2014, 20, 66–86. [Google Scholar] [CrossRef]

- Baciu, F.; Rusu-Casandra, A.; Pastramă, Ş.-D. Low Strain Rate Testing of Tensile Properties of Steel. Mater. Today: Proc. 2020, 32, 128–132. [Google Scholar] [CrossRef]

- ISO 6507-1:2023; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. ISO: Geneva, Switzerland, 2023.

- Derazkola, H.A.; García Gil, E.; Murillo-Marrodán, A.; Méresse, D. Review on Dynamic Recrystallization of Martensitic Stainless Steels during Hot Deformation: Part I—Experimental Study. Metals 2021, 11, 572. [Google Scholar] [CrossRef]

- Montheillet, F. Dynamic Recrystallization Behaviours in Metals and Alloys. Materials 2023, 16, 976. [Google Scholar] [CrossRef] [PubMed]

- Varela-Castro, G.; Cabrera, J.-M.; Prado, J.-M. Critical Strain for Dynamic Recrystallisation. The Particular Case of Steels. Metals 2020, 10, 135. [Google Scholar] [CrossRef]

- Hwang, J.-K. Hardening and Softening Behavior of Caliber-Rolled Wire. Materials 2022, 15, 2939. [Google Scholar] [CrossRef]

- Zhang, T.; Li, L.; Lu, S.-H.; Gong, H.; Wu, Y.-X. Comparisons of Different Models on Dynamic Recrystallization of Plate during Asymmetrical Shear Rolling. Materials 2018, 11, 151. [Google Scholar] [CrossRef]

| C | Si | Mn | Ni (max) | S (max) | P (max) | Cr (max) | Cu (max) |

|---|---|---|---|---|---|---|---|

| 0.20–0.29 | 0.60–0.90 | 1.20–1.60 | ≤0.30 | ≤0.045 | ≤0.040 | ≤0.30 | ≤0.30 |

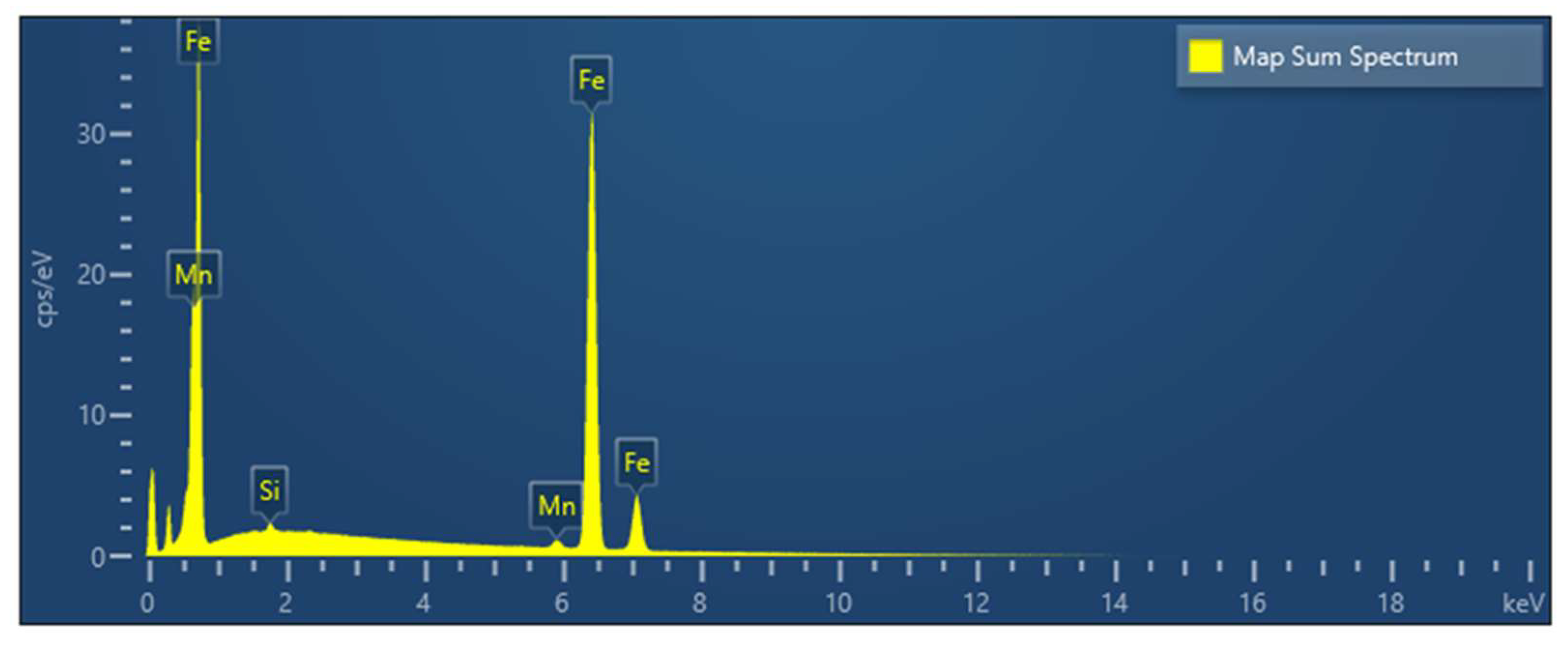

| Element | Concentration, wt % | Uncertainty, wt % | Atomic % |

|---|---|---|---|

| Si | 0.31 | 0.02 | 0.61 |

| Mn | 1.43 | 0.05 | 1.45 |

| Fe | 98.26 | 0.06 | 97.94 |

| Condition | Sample | Yield Strength, MPa | Ultimate Tensile Strength, MPa | Elongation at Break, % | Reduction in Area, % |

|---|---|---|---|---|---|

| Initial (unrolled) | 1 | 293.5 | 502 | 21.95 | 66.37 |

| 2 | 269 | 492 | 24.39 | 64.2 | |

| 3 | 272.5 | 504 | 21.95 | 61.15 | |

| 4 | 258.5 | 477 | 25 | 61.56 | |

| Classical rolling | 1 | 434 | 577 | 23.81 | 68.18 |

| 2 | 475.5 | 593 | 21.43 | 67.84 | |

| 3 | 441.5 | 590 | 21.43 | 63.73 | |

| 4 | 424.5 | 577 | 29.27 | 69.62 | |

| Modified rolling | 1 | 444 | 579 | 24.39 | 69.2 |

| 2 | 419.5 | 572 | 23.81 | 71.3 | |

| 3 | 435 | 589 | 24.39 | 67.61 | |

| 4 | 459.5 | 571 | 30.95 | 65.96 | |

| 5 | 448.5 | 583 | 26.83 | 68.61 | |

| 6 | 404.5 | 545 | 27 | 70.84 | |

| 7 | 402.5 | 574 | 25.55 | 70.58 |

| Condition | Yield Strength, MPa | Ultimate Tensile Strength, MPa | Elongation at Break, % | Reduction in Area, % |

|---|---|---|---|---|

| Initial (unrolled) | (268.6 ± 14.3) | (493.8 ± 12.6) | (23.32 ± 1.29) | (63.32 ± 2.15) |

| Classical rolling | (443.9 ± 22.3) | (584.3 ± 6.8) | (24.48 ± 3.14) | (67.84 ± 2.47) |

| Modified rolling | (433.0 ± 20.8) | (572.4 ± 15.7) | (26.81 ± 2.49) | (68.61 ± 1.85) |

| Indentation No. | Vickers Hardness | ||

|---|---|---|---|

| Initial (Unrolled) | Classical Rolling | Modified Rolling | |

| 1 | 262.7 | 211.1 | 174 |

| 2 | 230.8 | 227.3 | 185.4 |

| 3 | 224.8 | 206.6 | 184.1 |

| 4 | 223.9 | 211.1 | 184.8 |

| 5 | 223.9 | 202.2 | 179.2 |

| 6 | 244.5 | 212.7 | 182.9 |

| 7 | 252.3 | 208.8 | 186.7 |

| 8 | 268 | 229.9 | 185.4 |

| 9 | 263.7 | 214.2 | 187.9 |

| 10 | 245.5 | 211.1 | 179.2 |

| Mean ± SD | (244.0 ± 17.7) | (213.5 ± 9.1) | (183.6 ± 4.8) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nogayev, K.; Abishkenov, M.; Ashkeyev, Z.; Akhmetova, G.; Kydyrbayeva, S.; Tavshanov, I. Effect of Imposed Shear During Oval-Caliber Rolling on the Properties of Mn–Si Low-Alloy Steel. Eng 2025, 6, 265. https://doi.org/10.3390/eng6100265

Nogayev K, Abishkenov M, Ashkeyev Z, Akhmetova G, Kydyrbayeva S, Tavshanov I. Effect of Imposed Shear During Oval-Caliber Rolling on the Properties of Mn–Si Low-Alloy Steel. Eng. 2025; 6(10):265. https://doi.org/10.3390/eng6100265

Chicago/Turabian StyleNogayev, Kairosh, Maxat Abishkenov, Zhassulan Ashkeyev, Gulzhainat Akhmetova, Saltanat Kydyrbayeva, and Ilgar Tavshanov. 2025. "Effect of Imposed Shear During Oval-Caliber Rolling on the Properties of Mn–Si Low-Alloy Steel" Eng 6, no. 10: 265. https://doi.org/10.3390/eng6100265

APA StyleNogayev, K., Abishkenov, M., Ashkeyev, Z., Akhmetova, G., Kydyrbayeva, S., & Tavshanov, I. (2025). Effect of Imposed Shear During Oval-Caliber Rolling on the Properties of Mn–Si Low-Alloy Steel. Eng, 6(10), 265. https://doi.org/10.3390/eng6100265