Numerical and Experimental Analyses of Flue Gas Emissions, from Biomass Pellet Combustion in a Domestic Boiler

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Experimental Setup

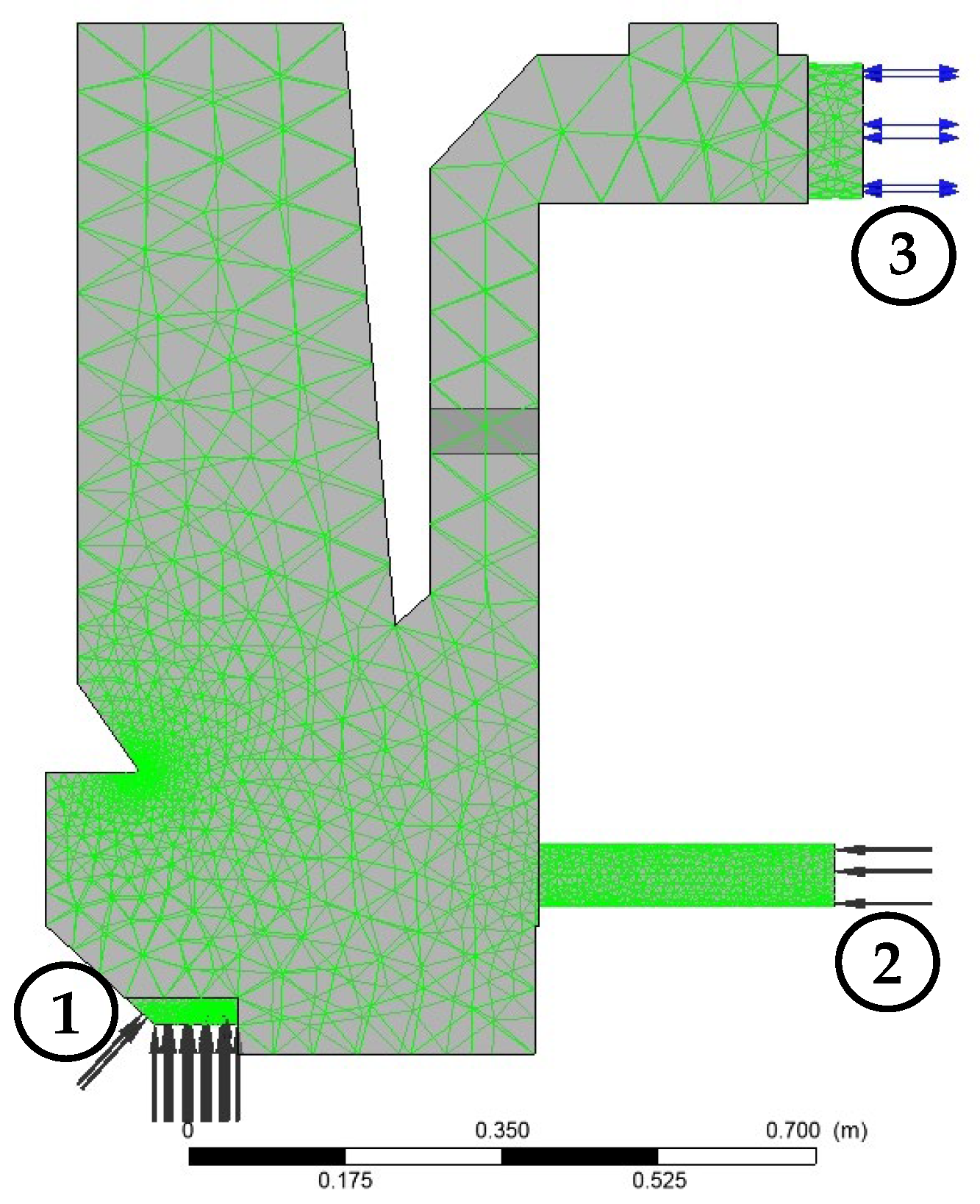

2.2.2. Modelling of the Combustion Process

2.2.3. Numerical Simulation Approach

2.2.4. Model Validation Approach

3. Results

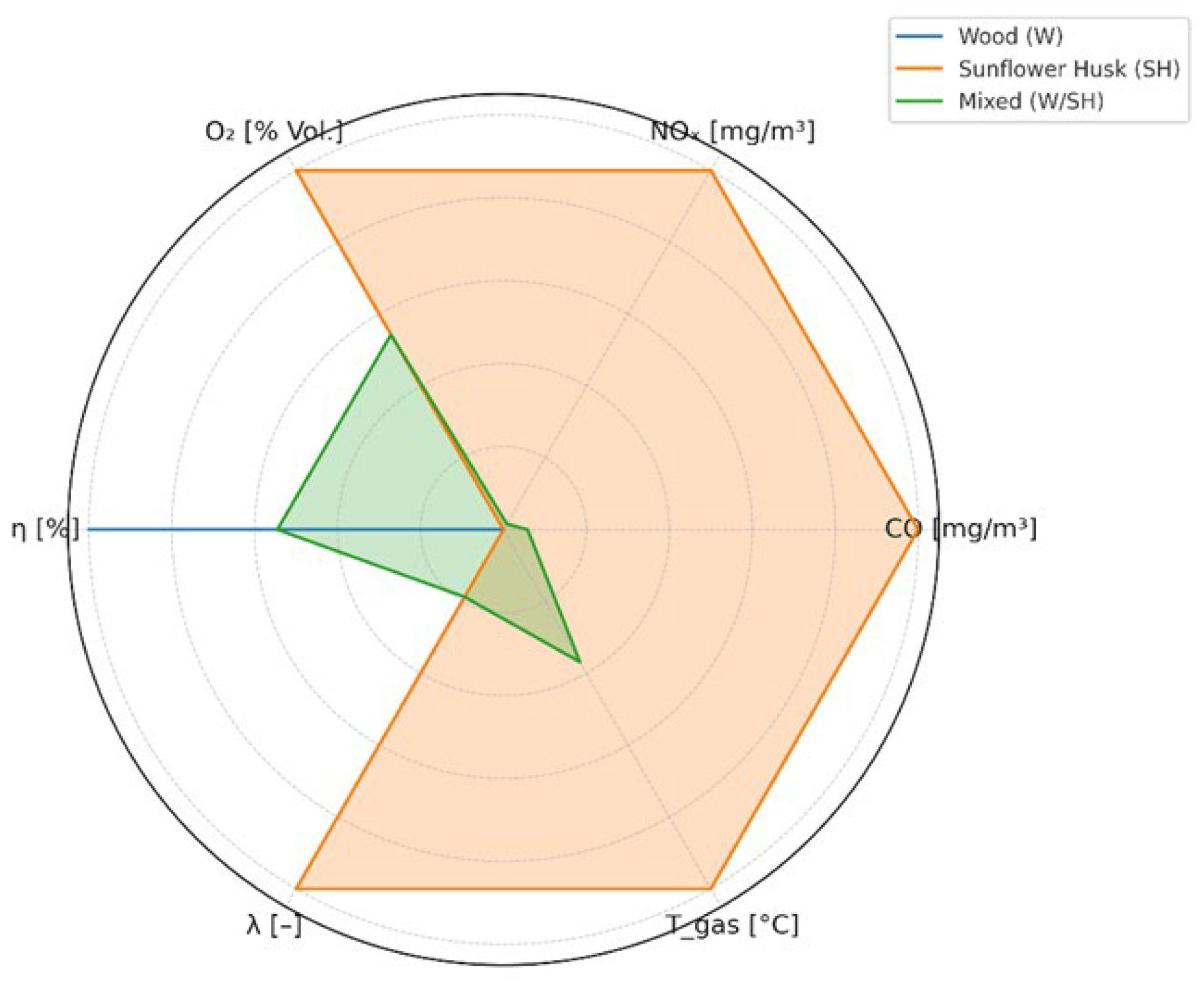

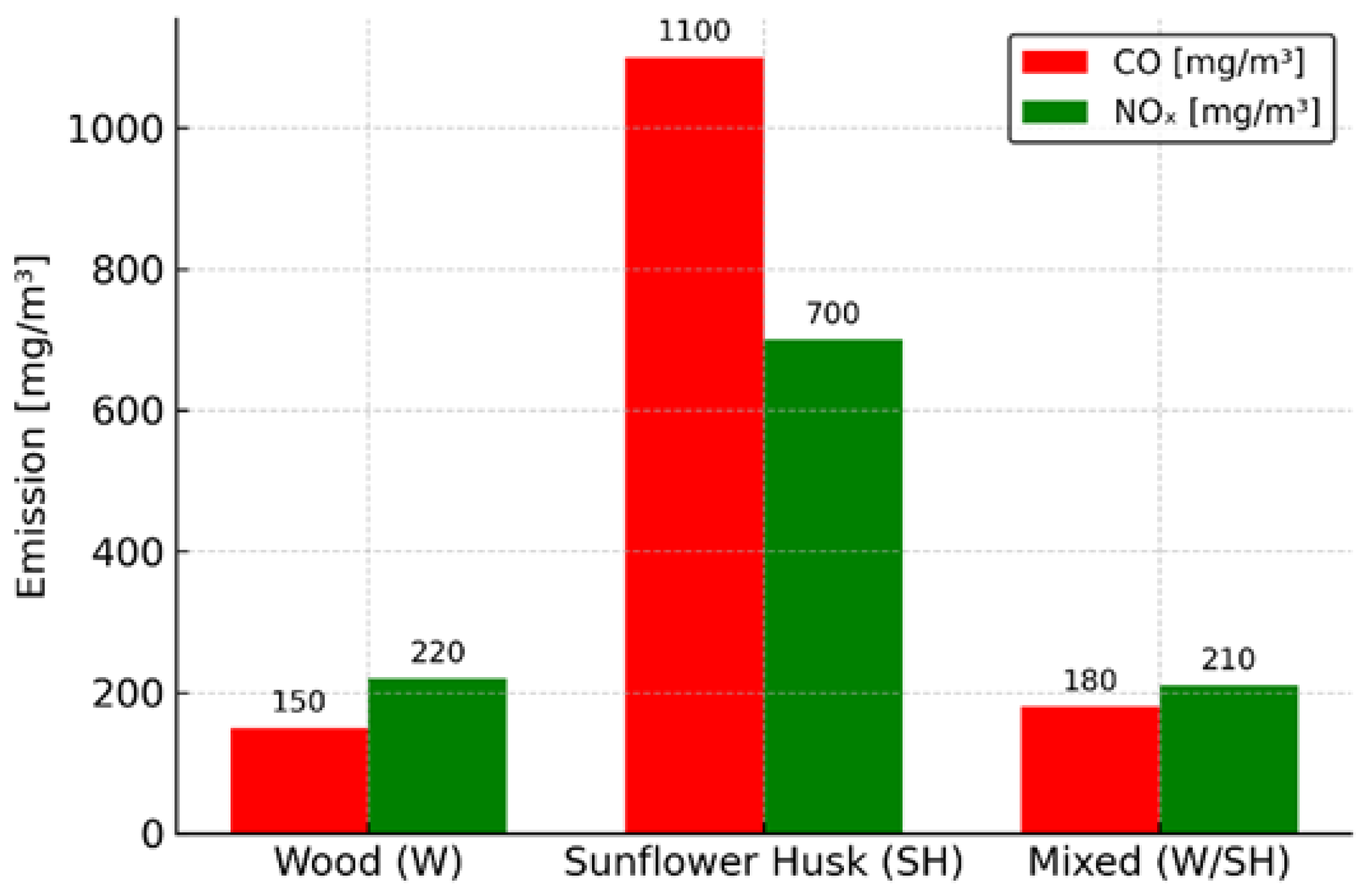

3.1. Experimental Determination of Flue Gas Parameters

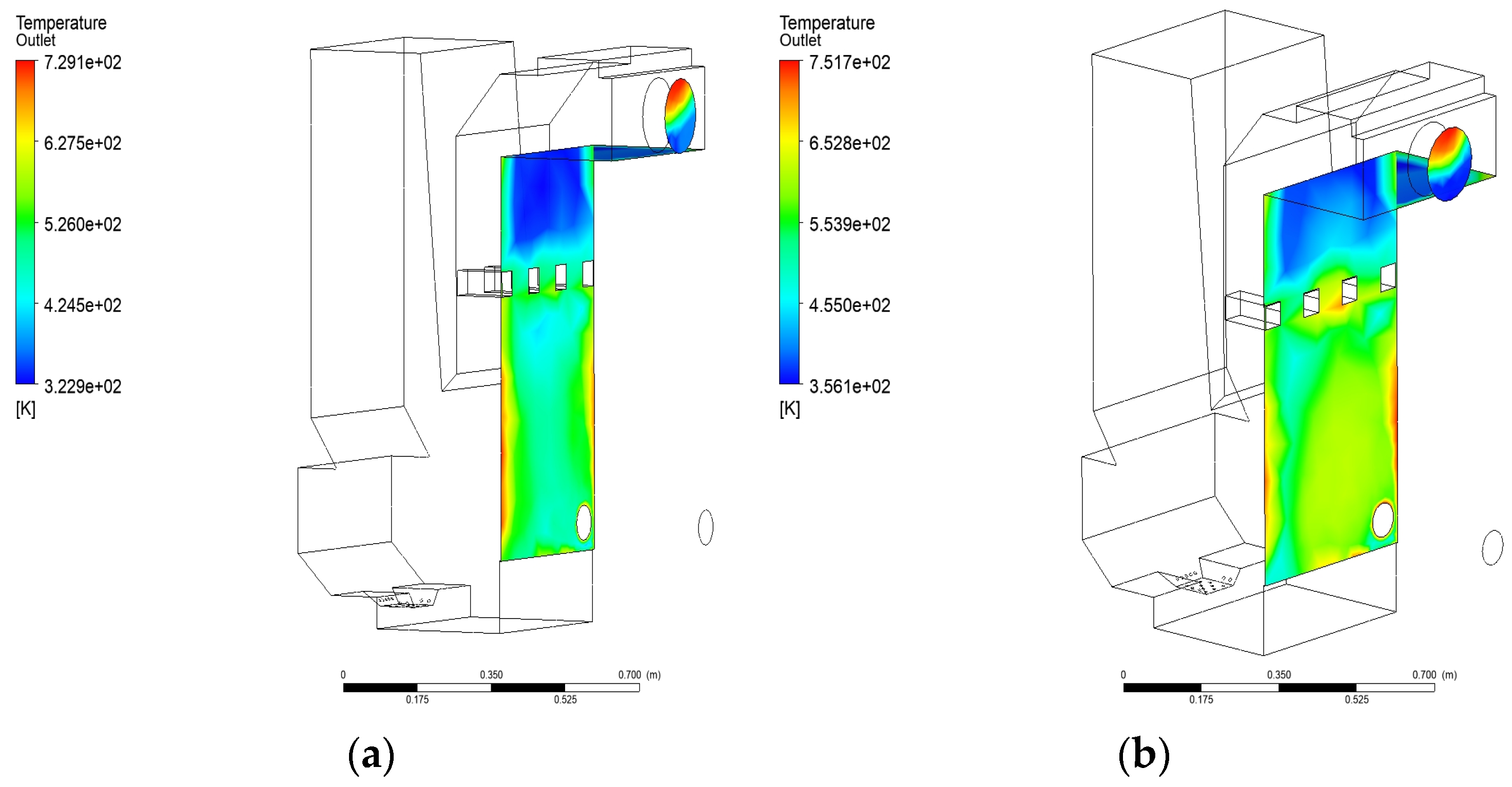

3.2. Combustion Process Modelling Results

3.3. Model Validation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scott, C.; Desamsetty, T.M.; Rahmanian, N. Unlocking Power: Impact of Physical and Mechanical Properties of Biomass Wood Pellets on Energy Release and Carbon Emissions in Power Sector. Waste Biomass Valorization 2025, 16, 441–458. [Google Scholar] [CrossRef]

- Voumik, L.C.; Islam, M.A.; Ray, S.; Mohamed Yusop, N.Y.; Ridzuan, A.R. CO2 Emissions from Renewable and Non-Renewable Electricity Generation Sources in the G7 Countries: Static and Dynamic Panel Assessment. Energies 2023, 16, 1044. [Google Scholar] [CrossRef]

- He, B.; Yuan, X.; Qian, S.; Li, B. Carbon Neutrality: A Review. J. Comput. Inf. Sci. Eng. 2023, 23, 061101. [Google Scholar] [CrossRef]

- Zapata, S.; Gómez, M.; Bartolomé, C.; Canalís, P.; Royo, J. Ash Behaviour during Combustion of Agropellets Produced by an Agro-Industry—Part 1: Blends Design and Experimental Tests Results. Energies 2022, 15, 1479. [Google Scholar] [CrossRef]

- Üçok, S. Properties of Bio-Pellets Obtained from Walnut and Peanut Shells: Energy Density, Emissions and Durability. Int. J. Agric. Biol. Eng. 2024, 17, 281–285. [Google Scholar]

- Deng, Y.; Ran, X.; Elshareef, H.; Dong, R.; Zhou, Y. Emergy, Environmental and Economic (3E) Assessment of Biomass Pellets from Agricultural Waste. Agriculture 2025, 15, 664. [Google Scholar] [CrossRef]

- Borges, R.J.; Iturralde Carrera, L.A.; Bastida, E.J.L.; García-Martínez, J.R.; Carrillo-Serrano, R.V.; Rodríguez-Reséndiz, J. Energy Sustainability Indicators for the Use of Biomass as Fuel for the Sugar Industry. Technologies 2024, 12, 36. [Google Scholar] [CrossRef]

- Ter-Mikaelian, M.T.; Chen, J.; Desjardins, S.M.; Colombo, S.J. Can Wood Pellets from Canada’s Boreal Forest Reduce Net Greenhouse Gas Emissions from Energy Generation in the UK? Forests 2023, 14, 1090. [Google Scholar] [CrossRef]

- Nocoń, A.; Jachimowski, A.; Koniuch, W.; Pełka, G.; Luboń, W.; Kubarek, P.; Jach-Nocoń, M.; Dawiec, D. Analysis of the Energy and Emission Performance of an Automatic Biomass Boiler in the Context of Efficient Heat Management. Energies 2024, 17, 5885. [Google Scholar] [CrossRef]

- Echi, S.; Bouabidi, A.; Driss, Z.; Abid, M.S. CFD Simulation and Optimization of Industrial Boiler. Energy 2019, 169, 105–114. [Google Scholar] [CrossRef]

- Gallant, R.; Farooque, A.A.; He, S.; Kang, K.; Hu, Y. A Mini-Review: Biowaste-Derived Fuel Pellet by Hydrothermal Carbonization Followed by Pelletizing. Sustainability 2022, 14, 12530. [Google Scholar] [CrossRef]

- Zheng, Z.; Yang, W.; Yu, P.; Cai, Y.; Zhou, H.; Boon, S.K.; Subbaiah, P. Numerical Study on Combustion Characteristics of Biomass in a Cyclone Furnace under Air-Staged Conditions. Fuel 2020, 259, 116083. [Google Scholar] [CrossRef]

- Sperandio, G.; Suardi, A.; Acampora, A.; Civitarese, V. Eco-Efficiency of Pellet Production from Dedicated Poplar Plantations. Energies 2024, 17, 3137. [Google Scholar] [CrossRef]

- Yang, Y.; Song, L.; Li, Y.; Shen, Y.; Yang, M.; Wang, Y.; Zheng, H.; Qi, W.; Lei, T. Effects of Different Biomass Types on Pellet Qualities and Processing Energy Consumption. Agriculture 2025, 15, 316. [Google Scholar] [CrossRef]

- Moraveji, A.; Toghraie, D. Computational Fluid Dynamics Simulation of Heat Transfer and Fluid Flow Characteristics in a Vortex Tube by Considering the Various Parameters. Int. J. Heat Mass Transf. 2017, 113, 432–443. [Google Scholar] [CrossRef]

- Murugan, P.C.; Sekhar, S.J. Application of Computer-Based Models in Agricultural Systems: A Case Study. Comput. Electron. Agric. 2017, 139, 33–40. [Google Scholar] [CrossRef]

- Safarian, S. Climate Impact Comparison of Biomass Combustion and Pyrolysis with Different Applications for Biochar Based on LCA. Energies 2023, 16, 5541. [Google Scholar] [CrossRef]

- Jha, S.; Nanda, S.; Acharya, B.; Dalai, A.K. A Review of Thermochemical Conversion of Waste Biomass to Biofuels. Energies 2022, 15, 6352. [Google Scholar] [CrossRef]

- Elsebaie, A.; Zhu, M.; Al-Abdeli, Y.M. Operational and Design Factors in Air Staging and Their Effects on Fouling from Biomass Combustion. Sustainability 2024, 16, 8584. [Google Scholar] [CrossRef]

- Kamperidou, V. Quality Analysis of Commercially Available Wood Pellets and Correlations between Pellets Characteristics. Energies 2022, 15, 2865. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Olba-Zięty, E. Properties of Pellets from Forest and Agricultural Biomass and Their Mixtures. Energies 2025, 18, 3137. [Google Scholar] [CrossRef]

- Yu, C.; Xiong, W.; Ma, H.; Zhou, J.; Si, F.; Jiang, X.; Fang, X. Numerical Investigation of Combustion Optimization in a Tangential Firing Boiler Considering Steam Tube Overheating. Appl. Therm. Eng. 2019, 154, 87–101. [Google Scholar] [CrossRef]

- Rahmanta, M.A.; Aprilana, A.; Ruly; Cahyo, N.; Hapsari, T.W.D.; Supriyanto, E. Techno-Economic and Environmental Impact of Biomass Co-Firing with Carbon Capture and Storage in Indonesian Power Plants. Sustainability 2024, 16, 3423. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, M.; Xiao, F.; Wang, H.; Jin, Y.; Hu, N.; Yang, H. Optimization of the Air Distribution in a Biomass Grate-Fired Furnace. Energies 2023, 16, 7634. [Google Scholar] [CrossRef]

- Lavergne, S.; Larsson, S.H.; Da Silva Perez, D.; Marchand, M.; Campargue, M.; Dupont, C. Effect of Process Parameters and Biomass Composition on Flat-Die Pellet Production from Underexploited Forest and Agricultural Biomass. Fuel 2021, 302, 121076. [Google Scholar] [CrossRef]

- Bianco, V.; Szubel, M.; Matras, B.; Filipowicz, M.; Papis, K.; Podlasek, S. CFD Analysis and Design Optimization of an Air Manifold for a Biomass Boiler. Renew. Energy 2021, 163, 2018–2028. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, L. CFD Studies on Biomass Thermochemical Conversion. Int. J. Mol. Sci. 2008, 9, 1108–1130. [Google Scholar] [CrossRef]

- Čajová Kantová, N.; Čaja, A.; Patsch, M.; Holubčík, M.; Ďurčanský, P. Dependence of the Flue Gas Flow on the Setting of the Separation Baffle in the Flue Gas Tract. Appl. Sci. 2021, 11, 2961. [Google Scholar] [CrossRef]

- Liu, B.; Bao, B.; Wang, Y.; Xu, H. Numerical Simulation of Flow, Combustion and NO Emission of a Fuel-Staged Industrial Gas Burner. J. Energy Inst. 2017, 90, 441–451. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, S.; Mu, L.; Jamshidnia, H.; Zhao, X. Investigation of the Forced-Convection Heat-Transfer in the Boiler Flue-Gas Heat Recovery Units Employing the Real-Time Measured Database. Energy 2022, 238, 121715. [Google Scholar] [CrossRef]

- Tognoli, M.; Najafi, B.; Rinaldi, F. Dynamic Modelling and Optimal Sizing of Industrial Fire-Tube Boilers for Various Demand Profiles. Appl. Therm. Eng. 2018, 132, 341–351. [Google Scholar] [CrossRef]

- Alhijazi, A.A.K.; Almasri, R.A.; Alloush, A.F. A Hybrid Renewable Energy (Solar/Wind/Biomass) and Multi-Use System Principles, Types, and Applications: A Review. Sustainability 2023, 15, 16803. [Google Scholar] [CrossRef]

- ANSYS, Inc. ANSYS CFX-Solver Theory Guide; Release 2025 R1; ANSYS, Inc.: Canonsburg, PA, USA, 2025. [Google Scholar]

- Obernberger, I.; Thek, G. Physical Characterisation and Chemical Composition of Densified Biomass Fuels with Regard to Their Combustion Behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical Characteristics of Biomass Ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef]

- Nath, B.; Chen, G.; Bowtell, L.; Mahmood, R.A. CFDs Modeling and Simulation of Wheat Straw Pellet Combustion in a 10 kW Fixed-Bed Downdraft Reactor. Processes 2024, 12, 863. [Google Scholar] [CrossRef]

- Wardach-Święcicka, I.; Polesek-Karczewska, S.; Kardaś, D. Biomass Combustion in the Helically Coiled Domestic Boiler Combined with the Equilibrium/Chemical Kinetics CFD Approach. Appl. Mech. 2023, 4, 779–802. [Google Scholar] [CrossRef]

- Xu, C.; Ju, F.; Zheng, X.; Liu, Y.; Huang, J.; Li, G.; Li, Y.; Zhu, L.; Ye, L.; Pan, H. Computational Fluid Dynamics Modelling of Fixed-Bed Reactors Using Particle-Resolved Approach. Processes 2025, 13, 1820. [Google Scholar] [CrossRef]

- Kaczyński, K.; Pełka, P. Combustion Analysis of Mixed Secondary Fuel Produced from Agro-Biomass and RDF in a Fluidized Bed. Energies 2024, 17, 2343. [Google Scholar] [CrossRef]

- Obidziński, S.; Joka Yildiz, M.; Dąbrowski, S.; Jasiński, J.; Czekała, W. Application of Post-Flotation Dairy Sludge in the Production of Wood Pellets: Pelletization and Combustion Analysis. Energies 2022, 15, 9427. [Google Scholar] [CrossRef]

- Gunnarsson, A.; Andersson, K.; Adams, B.R.; Fredriksson, C. Discrete-Ordinates Modelling of the Radiative Heat Transfer in a Pilot-Scale Rotary Kiln. Energies 2020, 13, 2192. [Google Scholar] [CrossRef]

- Pafcuga, M.; Holubcik, M.; Durcansky, P.; Kapjor, A.; Malcho, M. Small Heat Source Used for Combustion of Wheat-Straw Pellets. Appl. Sci. 2021, 11, 5239. [Google Scholar] [CrossRef]

- Royo, J.; Canalís, P.; Zapata, S.; Gómez, M.; Bartolomé, C. Ash Behaviour during Combustion of Agropellets Produced by an Agro-Industry—Part 2: Chemical Characterization of Sintering and Deposition. Energies 2022, 15, 1499. [Google Scholar] [CrossRef]

- Álvarez-Bermúdez, C.; Chapela, S.; Varela, L.G.; Gómez, M.Á. CFD Simulation of an Internally Cooled Biomass Fixed-Bed Combustion Plant. Resources 2021, 10, 77. [Google Scholar] [CrossRef]

- Motyl, P.; Król, D.; Poskrobko, S.; Juszczak, M. Numerical Modelling and Experimental Verification of the Low-Emission Biomass Combustion Process in a Domestic Boiler with Flue Gas Flow around the Combustion Chamber. Energies 2020, 13, 5837. [Google Scholar] [CrossRef]

- Ion, I.V.; Popescu, F.; Mahu, R.; Rusu, E. A Numerical Model of Biomass Combustion Physical and Chemical Processes. Energies 2021, 14, 1978. [Google Scholar] [CrossRef]

- Tańczuk, M.; Junga, R.; Werle, S.; Chabiński, M. Experimental analysis of the fixed bed gasification process of the mixtures of the chicken manure with biomass. Renew. Energy 2019, 136, 1055–1063. [Google Scholar] [CrossRef]

- Koido, K.; Konno, D.; Sato, M. Life Cycle CO2 Emissions and Techno-Economic Analysis of Wood Pellet Production and CHP with Different Plant Scales and Sawdust Drying Processes. Sustainability 2025, 17, 140. [Google Scholar] [CrossRef]

- Pełka, G.; Jach-Nocoń, M.; Paprocki, M.; Jachimowski, A.; Luboń, W.; Nocoń, A.; Wygoda, M.; Wyczesany, P.; Pachytel, P.; Mirowski, T. Co mparison of Emissions and Efficiency of Two Types of Burners When Burning Wood Pellets from Different Suppliers. Energies 2023, 16, 1695. [Google Scholar] [CrossRef]

- Lee, H.-H.; Kang, S.-B.; Choi, J.-J.; Youn, Y.-J.; Kim, K.-W.; Jeong, M.-S.; Byeon, J.-K. Co-Firing Combustion Characteristics of Woodchips and Spent Mushroom Substrates in a 400 kWth Stoker-Type Boiler. Energies 2022, 15, 9096. [Google Scholar] [CrossRef]

- Soltero, V.M.; Chacartegui, R.; Ortiz, C.; Quirosa, G. Techno-Economic Analysis of Rural 4th Generation Biomass District Heating. Energies 2018, 11, 3287. [Google Scholar] [CrossRef]

- Mameri, F.; Delacourt, E.; Morin, C.; Schiffler, J. 0D Dynamic Modeling and Experimental Characterization of a Biomass Boiler with Mass and Energy Balance. Entropy 2022, 24, 202. [Google Scholar] [CrossRef] [PubMed]

- Kulkarni, A.; Mishra, G.; Palla, S.; Ramesh, P.; Surya, D.V.; Basak, T. Advances in Computational Fluid Dynamics Modeling for Biomass Pyrolysis: A Review. Energies 2023, 16, 7839. [Google Scholar] [CrossRef]

- Silva, J.; Teixeira, S.; Teixeira, J. A Review of Biomass Thermal Analysis, Kinetics and Product Distribution for Combustion Modeling: From the Micro to Macro Perspective. Energies 2023, 16, 6705. [Google Scholar] [CrossRef]

- Cao, H.; Jin, Y.; Song, X.; Wang, Z.; Liu, B.; Wu, Y. Computational Fluid Dynamics Simulation of Combustion and Selective Non-Catalytic Reduction in a 750 t/d Waste Incinerator. Processes 2023, 11, 2790. [Google Scholar] [CrossRef]

- He, J.; Zhang, J.; Wang, L.; Hu, X.; Xue, J.; Zhao, Y.; Wang, X.; Dong, C. Optimizing the Controlling Parameters of a Biomass Boiler Based on Big Data. Energies 2023, 16, 7783. [Google Scholar] [CrossRef]

- Vincenti, B.; Gallucci, F.; Paris, E.; Carnevale, M.; Palma, A.; Salerno, M.; Cava, C.; Palone, O.; Agati, G.; Caputi, M.V.M.; et al. Syngas Quality in Fluidized Bed Gasification of Biomass: Comparison between Olivine and K-Feldspar as Bed Materials. Sustainability 2023, 15, 2600. [Google Scholar] [CrossRef]

- Zlateva, P.; Terziev, A.; Krumov, K.; Murzova, M.; Mileva, N. Research on the Combustion of Mixed Biomass Pellets in a Domestic Boiler. Fuels 2025, 6, 40. [Google Scholar] [CrossRef]

- Bala-Litwiniak, A.; Musiał, D. Computational and Experimental Studies of Selected Types of Biomass Combustion in a Domestic Boiler. Materials 2022, 15, 4826. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, Y.; Zhou, J.; Zhu, Z.; Zhang, Z.; Li, Y.; Wang, L.; Zhang, J. Polystyrene-Supported Novel Imidazolium Ionic Liquids: Highly Efficient Catalyst for the Fixation of Carbon Dioxide under Atmospheric Pressure. Fuel 2021, 305, 121495. [Google Scholar] [CrossRef]

- Gómez, M.Á.; Martín, R.; Collazo, J.; Porteiro, J. CFD Steady Model Applied to a Biomass Boiler Operating in Air Enrichment Conditions. Energies 2018, 11, 2513. [Google Scholar] [CrossRef]

- Emmanouilidou, E.; Lazaridou, A.; Mitkidou, S.; Kokkinos, N.C. A Comparative Study on Biodiesel Production from Edible and Non-Edible Biomasses. J. Mol. Struct. 2024, 1306, 137870. [Google Scholar] [CrossRef]

- Najafi, H.; Woodbury, K.A.; Beck, J.V.; Keltner, N.R. Real-Time Heat Flux Measurement Using Directional Flame Thermometer. Appl. Therm. Eng. 2015, 86, 229–237. [Google Scholar] [CrossRef]

- Royo, J.; Canalís, P.; Quintana, D. Chemical study of fly ash deposition in combustion of pelletized residual agricultural biomass. Fuel 2020, 268, 117–228. [Google Scholar] [CrossRef]

- Rodriguez, J.L.; Álvarez, X.; Valero, E.; Ortiz, L.; de la Torre-Rodríguez, N.; Acuña-Alonso, C. Influence of ashes in the use of forest biomass as source energy. Fuel 2021, 283, 119256. [Google Scholar] [CrossRef]

- Royo, J.; Canalís, P.; Quintana, D.; Díaz-Ramírez, M.; Sin, A.; Rezeau, A. Experimental study on the ash behaviour in combustion of pelletized residual agricultural biomass. Fuel 2019, 239, 991–1000. [Google Scholar] [CrossRef]

- Turzyński, T.; Kluska, J.; Ochnio, M.; Kardaś, D. Comparative Analysis of Pelletized and Unpelletized Sunflower Husks Combustion Process in a Batch-Type Reactor. Materials 2021, 14, 2484. [Google Scholar] [CrossRef]

- Rzeźnik, W.; Rzeźnik, I.; Mielcarek-Bocheńska, P. Air Pollutants Emission during Co-Combustion of Animal Manure and Wood Pellets in a 15 kW Boiler. Energies 2023, 16, 6691. [Google Scholar] [CrossRef]

- Horvat, I.; Dovic, D.; Filipović, P. Numerical and Experimental Methods in Development of the Novel Biomass Combustion System Concept for Wood and Agro Pellets. Energy 2021, 231, 120929. [Google Scholar] [CrossRef]

- Mižáková, J.; Piteľ, J.; Hošovský, A.; Pavlenko, I.; Ochowiak, M.; Khovanskyi, S. Biomass Combustion Control in Small and Medium-Scale Boilers Based on Low Cost Sensing the Trend of Carbon Monoxide Emissions. Processes 2021, 9, 2030. [Google Scholar] [CrossRef]

- Channiwala, S.A.; Parikh, P.P. A Unified Correlation for Estimating HHV of Solid, Liquid and Gaseous Fuels. Fuel 2002, 81, 1051–1063. [Google Scholar] [CrossRef]

- Shan, Y.; Zhou, H.; Sheng, C. Ash Formation and Associated Interactions during Co-Combustion of Wheat Straw and Sewage Sludge. Energies 2024, 17, 1486. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Lim, C.J.; Bi, X.T.; Kuang, X.; Melin, S.; Yazdanpanah, F.; Sokhansanj, S. Analysis on Storage Off-Gas Emissions from Woody, Herbaceous, and Torrefied Biomass. Energies 2015, 8, 1745–1759. [Google Scholar] [CrossRef]

- Nyashina, G.S.; Dorokhov, V.V.; Shvedov, D.K.; Strizhak, P.A. Wood Pellets with Waste: Energy, Environmental and Mechanical Aspects. Renew. Energy 2025, 250, 123269. [Google Scholar] [CrossRef]

- Feldmeier, S.; Schwarz, M.; Wopienka, E.; Pfeifer, C. Categorization of Small-Scale Biomass Combustion Appliances by Characteristic Numbers. Renew. Energy 2021, 163, 2128–2136. [Google Scholar] [CrossRef]

- González, J.F.; Álvarez Murillo, A.; Díaz García, D.; Nogales-Delgado, S. The Determination of Combustion for Different Pellets Based on Ostwald Diagrams in a Domestic Stove under Experimental Conditions. Appl. Sci. 2023, 13, 12007. [Google Scholar] [CrossRef]

- Silva, J.P.; Teixeira, S.; Teixeira, J.C. Development of a CFD Model to Study the Fundamental Phenomena Associated with Biomass Combustion in a Grate-Fired Boiler. Processes 2025, 13, 2617. [Google Scholar] [CrossRef]

- Krawczyk, P.; Kurkus-Gruszecka, M.; Wilczyński, M.; Dzido, A. Numerical Analysis of Design and Operational Parameters of Low Power Pellet Burners. Renew. Energy 2025, 243, 122577. [Google Scholar] [CrossRef]

| Parameter | Unit | W | SH | W/SH |

|---|---|---|---|---|

| Carbon (C) | Wt.% | 45.6 | 48.2 | 49.6 |

| Hydrogen (H) | Wt.% | 6.1 | 5.7 | 5.6 |

| Sulfur (S) | Wt.% | 0.03 | 0.12 | 0.06 |

| Oxygen (O) | Wt.% | 47.87 | 45.28 | 44.37 |

| Nitrogen (N) | Wt.% | 0.4 | 0.7 | 0.37 |

| Ash (A) | Wt.% | 0.73 | 2.47 | 0.69 |

| Moisture (W) | Wt.% | 7.47 | 7.42 | 7.07 |

| Lower heating value (LHV) | kJ/kg | 16,770 | 18,200 | 16,710 |

| Parameter | Unit | W | SH | W/SH |

|---|---|---|---|---|

| O2 | Vol.% | 9.15 | 9.5 | 9.34 |

| CO2 | Vol.% | 8.3 | 7.9 | 8.1 |

| CO | mg/m3 | 90.3 | 1095.3 | 148.7 |

| NOx | mg/m3 | 194.1 | 679.3 | 201.8 |

| η | % | 91.4 | 90.3 | 90.9 |

| Temperature output | °C | 72.6 | 75.9 | 74.1 |

| Temperature Inlet | °C | 52.9 | 55.4 | 53.7 |

| Flue gas temperature | °C | 96.2 | 98.1 | 96.9 |

| Ambient temperature | °C | 20.9 | 21.7 | 21.4 |

| Engine power | kW | 12.5 | 10.9 | 11.8 |

| Air excess coefficient | λ | 1.41 | 1.57 | 1.44 |

| Fuel consumption | kg/h | 7.6 | 7.3 | 6.8 |

| Parameter | № | W | SH | W/SH |

|---|---|---|---|---|

| CH4 ** | 1 * | ~0 | ~0 | ~0 |

| 2 * | 0 | 0 | 0 | |

| CO ** | 1 * | ~0 | ~0 | ~0 |

| 2 * | 0 | 0 | 0 | |

| CO2 ** | 1 * | 25.7 × 10−2 | 28.3 × 10−2 | 25.4 × 10−2 |

| 2 * | 26.9 × 10−2 | 24.2 × 10−2 | 25.0 × 10−2 | |

| H2O ** | 1 * | 3.28 × 10−2 | 2.8 × 10−2 | 3.1 × 10−2 |

| 2 * | 2.3 × 10−2 | 1.9 × 10−2 | 2.2 × 10−2 | |

| N2 ** | 1 * | 66.5 × 10−2 | 62.5 × 10−2 | 66.7 × 10−2 |

| 2 * | 64.8 × 10−2 | 68.1 × 10−2 | 67.3 × 10−2 | |

| NO ** | 1 * | 4.5 × 10−3 | 6.1 × 10−3 | 4.7 × 10−3 |

| 2 * | 3.5 × 10−3 | 3.4 × 10−3 | 3.42 × 10−3 | |

| O2 ** | 1 * | 40.1 × 10−3 | 56.8 × 10−3 | 41.5 × 10−3 |

| 2 * | 56.2 × 10−3 | 54.8 × 10−3 | 51.6 × 10−3 | |

| Flue gas density, kg/m3 | 1 * | 77.4 × 10−2 | 85.1 × 10−2 | 77.5 × 10−2 |

| 2 * | 77.3 × 10−2 | 80.4 × 10−2 | 76.6 × 10−2 | |

| Flue gas temperature, °C | 1 * | 238 | 199 | 241 |

| 2 * | 250 | 217 | 248 | |

| Flue gas velocity, m/s | 1 * | 73.1 × 10−2 | 59.9 × 10−2 | 70.3 × 10−2 |

| 2 * | 68.4 × 10−2 | 61.4 × 10−2 | 69.1 × 10−2 | |

| Flue gas mass flowrate, kg/s | 1 * | −1.14 × 10−4 | −1.0 × 10−4 | −1.1 × 10−4 |

| 2 * | −1.15 × 10−4 | −1.0 × 10−4 | −1.11 × 10−4 |

| Pellets | Experimental Temperature, °C | Simulation Temperature, °C | Difference, °C | Deviation, % |

|---|---|---|---|---|

| W | 96.2 | 98.4 | +2.2 | +2.29 |

| SH | 98.1 | 101.3 | +3.2 | +3.26 |

| W/SH | 96.9 | 95.7 | −1.2 | −1.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mileva, N.; Zlateva, P.; Ivanov, M.; Krumov, K.; Terziev, A.; Comarla, A. Numerical and Experimental Analyses of Flue Gas Emissions, from Biomass Pellet Combustion in a Domestic Boiler. Eng 2025, 6, 257. https://doi.org/10.3390/eng6100257

Mileva N, Zlateva P, Ivanov M, Krumov K, Terziev A, Comarla A. Numerical and Experimental Analyses of Flue Gas Emissions, from Biomass Pellet Combustion in a Domestic Boiler. Eng. 2025; 6(10):257. https://doi.org/10.3390/eng6100257

Chicago/Turabian StyleMileva, Nevena, Penka Zlateva, Martin Ivanov, Kalin Krumov, Angel Terziev, and Adriana Comarla. 2025. "Numerical and Experimental Analyses of Flue Gas Emissions, from Biomass Pellet Combustion in a Domestic Boiler" Eng 6, no. 10: 257. https://doi.org/10.3390/eng6100257

APA StyleMileva, N., Zlateva, P., Ivanov, M., Krumov, K., Terziev, A., & Comarla, A. (2025). Numerical and Experimental Analyses of Flue Gas Emissions, from Biomass Pellet Combustion in a Domestic Boiler. Eng, 6(10), 257. https://doi.org/10.3390/eng6100257