1. Introduction

In microgrids (MGs), which typically include distributed photovoltaics, distributed wind power, and small hydropower, these renewable energies can sometimes operate independently [

1,

2,

3]. However, renewable energy generation often has significant uncertainty and variability. Compared to large integrated energy systems, microgrids exhibit poorer flexibility and stability, with their stable operation relying on energy storage systems [

4]. In MGs, energy storage methods such as electrochemical storage, pumped storage, and hydrogen storage can be used to participate in renewable energy peak shaving. Among these, electrochemical storage is cost-effective but faces issues like lifespan degradation. To address this challenge, scholars have developed hybrid energy storage systems (HESS) that combine electrochemical storage with other forms of storage to alleviate lifespan degradation. However, in small-scale microgrids such as village-level microgrids (VMGs), research on the scheduling of hybrid storage systems and their role in mitigating battery lifespan degradation is still insufficient.

Chen et al. [

5] proposed an adaptive droop control method that adjusts inertia based on the frequency disturbance process, considering active frequency support. To enhance the active support capability of microgrids using energy storage devices, Hasan et al. [

6] proposed a BESS-based controller to simulate virtual inertia and improve frequency stability through active power control. However, frequent use of BESS can accelerate their lifespan degradation. To mitigate this issue, Wang et al. [

7] integrated supercapacitors (SC) into the DC link of wind turbines and proposed a “dual-droop” frequency support control scheme. Building on this, Jain et al. [

8] introduced a hybrid energy storage system (HESS) that combines BESS and SC for frequency support. They also developed a performance assessment model to reduce HESS investment costs and quantify the hidden contribution of BESS to inertia.

For wind–solar–storage systems in microgrids (MGs), Zhu et al. [

9] introduced the addition of mobile energy storage systems (MESS) and demonstrated that MESS can enhance emergency response capabilities. MGs are small, controllable power systems that can operate independently of traditional large-scale grids within a local area or be connected to external grids. This results in two operational states: islanded and grid-connected. In both states, energy storage devices play a crucial role in maintaining stability. Further, Battery Energy Storage Systems (BESS) play a vital role in mitigating grid fluctuations and enabling peak shaving and valley filling on the user side. However, conventional control strategies often neglect the impact of charge-discharge cycle numbers, leading to accelerated battery degradation and reduced economic benefits. The flat OCV–SOC (Open Circuit Voltage–SOC) plateau characteristic of LiFePO

4 batteries further complicates consistency evaluation. A promising solution involves employing a Dynamic Reconfigurable Battery System (DRBS) to achieve fast online OCV estimation, while using the coefficient of variation in OCV as an indicator to quantitatively assess consistency. Luo et al. [

10] quantified the V2G power supply capacity of EV aggregates through a reliability evaluation model based on the composite Poisson process, which provided a basis for the pre-bidding strategy, and established a microgrid optimization operation model considering V2G reliability to realize the collaborative scheduling of photovoltaic and electric vehicle aggregates. Zahraoui et al. [

11] established a multi-objective optimization model with the goal of minimizing daily operating costs and carbon emission reduction, effectively coordinating the volatility of distributed renewable energy, load demand changes, and the cooperation between multiple energy storages, demonstrating the key support of optimization technology for achieving low-carbon operation of microgrid economy. Regarding HESS, Tong et al. [

12] explored a complementary storage model in microgrids that combined gravity storage and super capacitors. It established corresponding control strategies and demonstrated that hybrid energy storage systems (HESS) significantly enhance efficiency compared to single storage technologies. To mitigate renewable energy grid fluctuations, Zhang et al. [

13] utilized HESS along with an adaptive power optimization distribution strategy. However, Zhang et al. [

13] and Yim et al. [

14] focused on using HESS to address microgrid stability issues without delving into its potential to mitigate electrochemical storage lifespan degradation. In summary, HESSs that combine supercapacitors and electrochemical storage are quite common. Therefore, it is necessary to explore HESS capacity configuration in village-level microgrids, the extension of lithium battery lifespan through supercapacitors, and the impact on energy scheduling. Liu et al. [

15] proposed a coordinated configuration method for electrical–hydrogen hybrid systems, leveraging the power and capacity complementarity between electrical storage and generalized hydrogen storage to balance energy imbalances. However, Tong et al. [

12] and Liu et al. [

15] focused excessively on the control and optimal configuration of HESS, without further exploring its scheduling role in microgrids or systems. To address supply forecast errors, Yim et al. [

14] considered HESS with supercapacitors and batteries in microgrids and designed a reference power modulation strategy to balance HESS power. power.

To enhance the search capability and convergence speed of these algorithms, Xu et al. [

16] introduced an energy random mutation strategy into the satin bowerbird algorithm. Liu et al. [

17] improved the Slime mold-artificial bee colony algorithm to enhance the flexibility of comprehensive energy system solutions. These improvements aim to balance the local and global solving capabilities of the algorithms. Nevertheless, the generalizability of the algorithms proposed in Xu et al. [

16] and Liu et al. [

17] needs further improvement to enhance their ability to solve complex nonlinear scheduling problems. The snow goose algorithm proposed in this study effectively addresses the above challenges by integrating adaptive group behavior and external archiving mechanism. Different from single-agent optimization algorithms such as SPSA, smoothing function algorithm, and safety experimental dynamics algorithm, this type of algorithm has problems such as easy to fall into local optimization, slow convergence speed, and poor adaptability to high-dimensional uncertainty due to the single-point iteration characteristics. By simulating the group cooperation behavior of snow geese, SGA significantly improves the global search ability and convergence efficiency. This group-based optimization method not only reduces the dependence on local information and improves the robustness of optimization, but also provides a more efficient solution for the village-level microgrid scheduling problem with high dimension, strong uncertainty, multiple constraints and multiple objectives.

Based on the literature review, the current village-level microgrids face the following challenges:

Degradation of life cycle due to frequent use of electrochemical storage devices: village-level microgrids operating with either single electrochemical storage or hybrid energy storage systems (HESS) based on supercapacitors have insufficiently addressed the degradation of life cycle of electrochemical storage devices and the corresponding mitigation strategies.

Decline in active support and inertia: As renewable energy sources with weak damping and inertia continue to be integrated, there is a noticeable decline in the active support and inertia of village-level microgrids, which can adversely affect power quality.

Development of high-performance intelligent optimization algorithms: The scheduling of village-level microgrids, which includes capacity configuration, various strategies, and optimization objectives, presents significant complexity. Developing universally applicable and quantifiable performance algorithms remains a challenge.

To address these issues, this study constructs a hybrid energy storage system for village-level microgrids, leveraging supercapacitors to mitigate lithium battery life degradation and provide active support to the microgrid. The innovations and contributions of this study are summarized as follows:

Innovative HESS configuration for VMGs: This study proposes a novel hybrid energy storage system (HESS) that integrates supercapacitors and lithium batteries for village-level microgrids (VMGs). This HESS leverages the rapid charge/discharge capabilities of supercapacitors to mitigate the lifespan degradation of lithium batteries, enhancing VMG stability. A new supercapacitor capacity configuration model is also developed to optimize capacity allocation and maximize economic benefits.

Supercapacitor dynamics for grid support: This research develops virtual inertia time constant expressions for supercapacitors, utilizing their rapid charge/discharge characteristics to swiftly respond to power fluctuations in VMGs. This enhances active support, improves power quality, and increases resilience against disturbances, representing a significant advancement in microgrid support.

Enhanced optimization algorithm for scheduling: Improvements are made to the single-objective snow geese algorithm (SGA) to enhance its convergence and robustness. An external repository mechanism is introduced to construct a multi-objective SGA (MSGAR), enabling effective handling of multiple objectives like minimizing costs and losses while maximizing support capability. MSGAR demonstrates superior performance in solution quality, diversity, and convergence speed.

The remainder of this paper is organized as follows:

Section 2 details the modeling process of the village-level microgrid;

Section 3 introduces the SGAR and MSGAR algorithms;

Section 4 validates the proposed strategies and algorithms; and

Section 5 discusses the main findings, contributions, and limitations of this study.

3. Multi-Objective Snow Geese Algorithm-Based Solution

To address the limitations of the snow geese algorithm (SGA), SGA based on reinforced population adaptive behavior (SGAR) is proposed. In addition, based on SGAR, by introducing an external repository mechanism, a multi-objective SGAR is constructed to solve multi-objective optimization problems.

3.1. Snow Geese Algorithm Based on Reinforced Population Adaptive Behavior

The SGA simulates the migration behavior of snow geese to solve optimization problems [

19]. The specific modeling process is as follows:

(1) The chevron formation model

During the exploration phase of the algorithm, snow geese are categorized into different health conditions:

where

and

represent the positions of the

ith snow goose and the best snow goose, respectively;

and

represent the center position of the population and the position of the lowest-ranked snow goose after sorting the population;

B,

D, and

E are the weight coefficients for the corresponding components, and

is the velocity of the

ith snow goose.

(2) The linear matrix model

When the angle

θ between the snow geese in the cross-shaped matrix exceeds π, they enter the second phase of flight, which is the exploitation phase:

where

rand1 is a random number between 0 and 1, indicating whether the snow goose is in a local optimal solution,

Brownian(

dim) represents standard Brownian motion (

dim is the variable dimension), and ⊕ represents element-wise multiplication.

Although the SGA maintains population diversity by changing migration states, it still suffers from slow convergence and the problem of easily falling into local optimal solutions in the later iterations. To address this issue, this study proposes the SGA based on reinforced population adaptive behavior (SGAR). The specific principle of reinforced population adaptive behavior is as follows:

When the snow geese in the cross-shaped matrix deviate too much (entering the exploitation phase), they return to the normal matrix controlled by the parameter

θ, which has high randomness. This study introduces an asymptotic development and exploration control factor

cycle, to replace the original parameter

θ:

where

Tmax represents the maximum number of iterations,

C is the number of cycles, and

rand2 is a random number between 0 and 1.

Under the influence of the cycle, the probability of entering the exploration phase decreases with increasing iteration count, while the probability of entering the development phase increases. This process is repeated C times, balancing the intensity of global search and local development.

(2) To better align the behaviors of the two populations during the reinforced exploration and exploitation phases with the divided population, in the exploration phase, the third part of Equation (20) is improved as follows for the last 1/5 of the population (weaker snow geese):

where

Fpro is the protection coefficient for following the high-quality population.

As indicated by Equation (23), by simulating the migration behavior of weaker snow geese, different speeds are exhibited as they fly towards the center position of the population, enhancing the overall flight efficiency of the population.

During the exploitation phase, the concept of a radius for the high-quality population is introduced to guide the population and dynamically simulate the flight speed of the snow geese. Equation (21) is improved as follows:

where

is the radius of the high-quality population, and

N represents the coefficient of physical fitness decline caused by long-duration flight of the snow geese.

In the linear matrix, the coefficient of physical fitness decline N is introduced, which decreases as the algorithm iteration count increases. This aims to simulate the decrease in speed caused by the decline in physical fitness of the snow geese in the later stages of migration. Additionally, the radius of the high-quality population is introduced to enhance the ability of the snow geese to follow the high-quality population, significantly improving the algorithm’s local development capability.

3.2. Multi-Objective SGAR

To solve the multi-objective microgrid scheduling model developed in this study, based on SGAR, a multi-objective SGAR (MSGAR) is constructed by introducing an external repository mechanism.

The external repository mechanism involves several processes: selection of non-dominated solutions after iteration, storing non-dominated solutions in the external repository, and updating and maintaining the external repository. When solution

S1 dominates solution

S2, it is denoted as

S1 ≺

S2, and the dominance relationship can be determined by the following equation [

20]:

where

i,

j = 1, 2, 3, …,

NO;

NO is the number of objective functions.

As the non-dominated solutions are continuously stored, the quantity may exceed the capacity of the external repository. In such cases, non-dominated solutions need to be removed from the crowded regions of the solution space based on crowding distance to prevent the repository from exceeding its capacity limit. The crowding distance

crdi of the

ith non-dominated solution is calculated as follows [

21]:

where

represents the normalized fitness of the

ith solution under the

mth objective function.

MSGAR first generates an initial population and an empty external archive. Then, it calculates all objective function values for each individual in the population and stores the non-dominated solutions from the initial population into the archive. The main loop begins and continues until the maximum number of iterations is reached. The external archive is updated by merging the new population with the current archive. Fast non-dominated sorting is applied to the combined set to obtain the first non-dominated front. If the number of solutions in the first front exceeds the archive capacity, the crowding distance of each solution in this front is calculated, and the top NO solutions with the largest crowding distance are retained. Finally, after the loop terminates, the solutions in the external archive serve as the obtained approximate Pareto-optimal set.

The solution process of MSGAR is presented in

Figure 2.

At each iteration, each individual needs to calculate the fitness function with the time complexity of O(Np·Tif), where Np is the population size, Tif is the fitness function to calculate the time. The time complexity of population sorting, position updating and speed updating is O(Np·dim), where dim is the problem dimension. The overall time complexity is O(Tmax· (Np·Tif + Np·dim)),where Tmax is the maximum number of iterations. Non-dominated sorting is added to MSGAR with a time complexity of O(Np2·No), where No is the number of objective functions. The time complexity of external archive maintenance is O(Np·log Np), and the overall time complexity is O(Tmax· (Np·Tif + Np2·No + Np·log Np)).

3.3. Multi-Objective Snow Geese Algorithm-Based Solution Method Process

The solution process of the VMG scheduling model is shown in

Figure 3.

The solution process shown in

Figure 3 can be divided into the following steps:

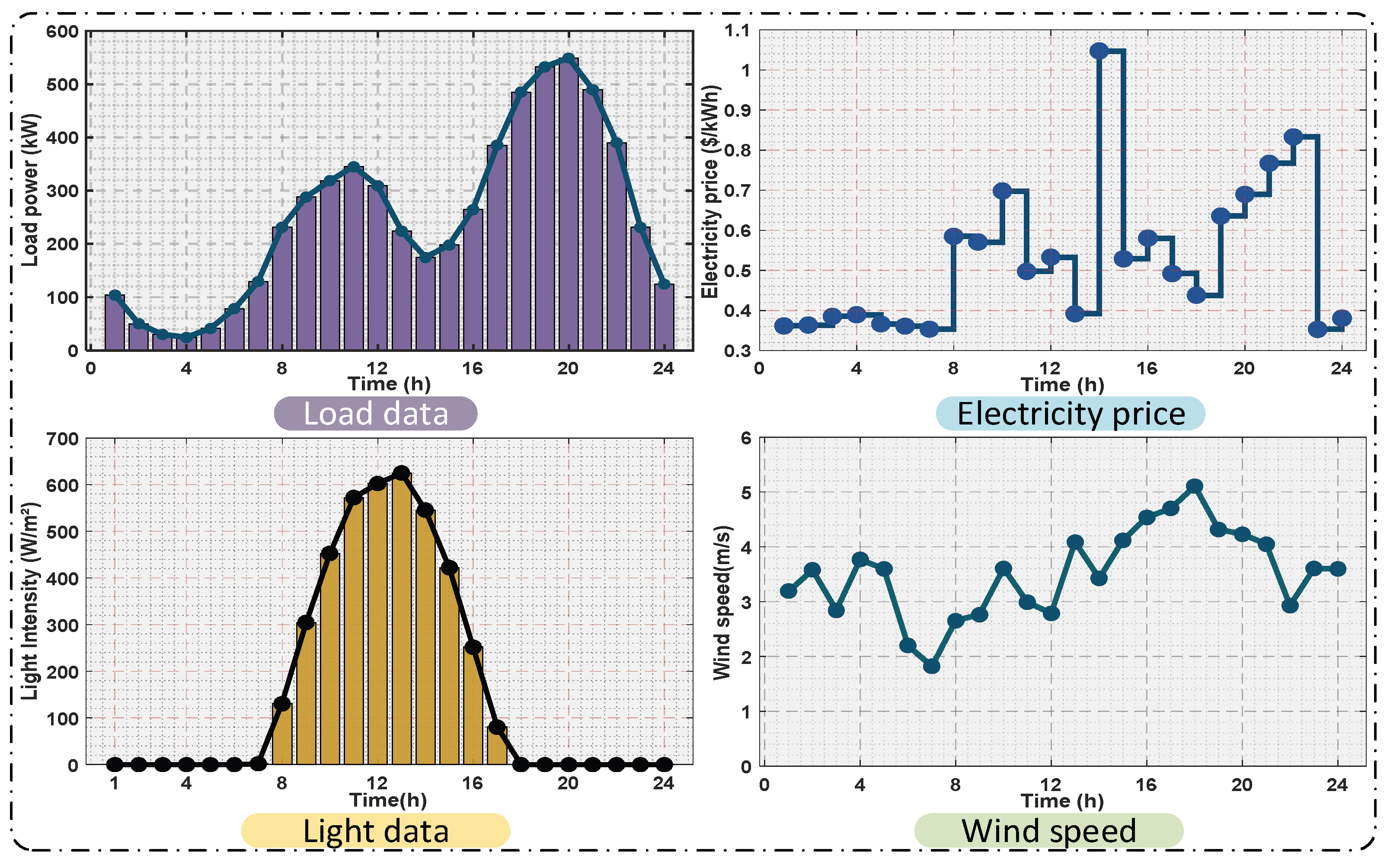

(1) Initialization: Set the device parameters, algorithm parameters, and load and weather data, ensuring they align with the operational characteristics of the village-level microgrid. Then generate a set of initial output values for the devices to prepare for evaluating the objective functions relevant to the VMG.

(2) Scheduling and objective function evaluation: Utilize the MSGAR algorithm to optimize the device outputs. The objective functions here directly correspond to the VMG’s optimization goals, such as minimizing economic costs and reducing carbon emissions. Run the VMG scheduling simulation model, calculate the power balance, and rigorously verify all operational constraints. Calculate the values of these objective functions based on the device outputs and pass them to the MSGAR algorithm to guide the optimization process.

(3) Evaluation and iteration: After evaluating the objective function values, update the population within the MSGAR framework. First, perform fast non-dominated sorting to update the external archive. Subsequently, based on this external archive, guide the population evolution to generate a new population. This new population will be used for the next iteration. If the maximum number of iterations has not been reached, the updated population is fed back into the scheduling process to refine the solutions further. This iterative process ensures that the scheduling outcomes progressively align with the VMG’s optimization objectives. If the maximum number of iterations is reached, proceed to the final step.

(4) Output of optimal results: Once the iterations are complete, output the optimal population position determined by MSGAR. Based on this position, calculate the operational status of each device within the VMG, reflecting the optimal scheduling outcomes that balance the VMG’s economic, environmental, and operational objectives. Finally, output the comprehensive scheduling results for the VMG.

5. Conclusions

Energy storage technologies can effectively mitigate the intermittency and volatility of renewable energy generation in microgrids, thereby enhancing the stability and reliability of the microgrid system. However, the frequent use of traditional chemical energy storage devices accelerates their lifespan degradation. To address this issue, this study proposes a hybrid energy storage system in VMG. Capacity allocation and scheduling strategies are designed for the SC to reduce the degradation of lithium batteries and fully utilize the fast charging and discharging characteristics of the SC. A virtual inertia time constant model for the SC is constructed to enhance its active support capability to the VMG. The findings of this research are as follows:

Compared to existing evolutionary algorithms, the improved SGAR and MSGAR algorithms proposed in this paper demonstrate stronger convergence performance on both single-objective and multi-objective benchmark test functions. For the F1 function in the CEC-2022 test set, SGAR achieves a variance of 6.9118, while SGA achieves a variance of 477.2542, significantly improving the convergence effect. For the UF8 function in the CEC-2009 test set, MSGAR achieves a mean and standard deviation of SP of only 0.1025 and 0.0624, demonstrating greater competitiveness.

With the introduction of the hybrid energy storage system (HESS), the loss rate of electrochemical energy storage decreases from the original 1.0394 to 0.4356, resulting in a 58.09% reduction in losses. Although the total cost increases due to the high installation cost of the SC, the carbon emissions of the VMG decrease by 45.56%.

After optimizing the active support of the microgrid, the loss rate of electrochemical energy storage decreases by 40.49% compared to when HESS is not used, and the VMG carbon emissions decrease by 59.47%. The scheduling results focus on the coordination and cooperation among various components within the microgrid, ensuring the efficient operation of the entire system. Ultimately, the SC achieves a virtual inertia time constant of 0.1931 s, representing an 8.73% improvement compared to not using active support optimization.

Although the model and strategies proposed in this study have shown positive effects in reducing energy storage device losses and enhancing VMG’s active support capability, there are still limitations. First, the currently employed metaheuristic algorithms have room for optimization in terms of convergence performance. Second, the universality of the proposed strategies needs further improvement. Future research will focus on addressing these challenges. In view of the above limitations, the research can be refined from two aspects in the future: at the algorithm level, the convergence efficiency in high-dimensional problems can be improved by integrating adaptive parameter adjustment and multi-operator collaboration. At the policy level, a multi-scenario database is constructed, based on transfer learning, adaptation rules are refined, and a demand response mechanism is incorporated to enhance the versatility of the strategy in various scenarios.

Although the design, scheduling strategy and optimization algorithm of hybrid energy storage system proposed for village-level microgrids focus on small-scale rural power systems, its core technical framework has the potential to be extended to city-level microgrids or regional power systems. For urban systems, on the basis of the existing “supercapacitor lithium battery” hybrid energy storage structure, large-scale energy storage technologies such as pumped storage can be introduced to build a multi-level collaborative energy storage architecture to cope with more complex “source–load” fluctuations, and the scheduling strategy can be upgraded to a hierarchical collaborative mode, which expands the objective function to cover network loss and power supply reliability at the total scheduling layer, and coordinates the dynamic coupling relationship within the partition with the help of the improved MSGAR algorithm at the partition layer, while retaining the priority response mechanism of the supercapacitor. In terms of active support, a “virtual inertial pool” can be formed by aggregating distributed supercapacitors, and combined with virtual synchronous machine technology to realize dynamic adaptive adjustment of inertial support capacity. At the algorithm level, parallel computing and population division strategies are introduced to improve the efficiency of solving high-dimensional decision variables, so as to provide a transferable technical path for the low-carbon transformation of urban energy systems.