1. Introduction

The optimal design of hybrid renewable–hydrogen energy systems is of paramount importance for ensuring the efficient use of intermittent renewable sources with hydrogen energy storage prior to embarking into their high investment costs. A well-designed hybrid renewable–hydrogen energy system not only could enhance the efficiency and sustainability of energy generation but also, on the broader context, could indirectly support future energy trading opportunities by monetizing surplus renewable energy in wholesale electricity markets, or among peer-to-peer energy trading platforms and multi-energy microgrids [

1]. While the optimal design of hybrid renewable–hydrogen energy systems opens potential endeavours for energy efficiency, sustainability and future energy trading, the ability to reduce the levelized cost of energy (LCOE) of such systems represents an immediate and major concern. Within this context, project managers and decision makers need accurate, effective and reliable computational modelling tools that enable them to assess the costs of the optimal design options of hybrid renewable–hydrogen energy systems suited for integration within their buildings while visualising the simulation of their associated dynamic energy management prior investment. Access to such tools will enable the comparison of different hybrid system configurations and to further assess their feasibility in terms of their technical, economic or environmental metrics. Numerous software tools have been reported in the literature [

2,

3] for modelling hybrid renewable–hydrogen energy systems. Among these, Hybrid Optimization of Multiple Energy Resources (HOMER) represents the most predominantly used software in academia and industry for optimizing the sizing of stand-alone or grid-connected hybrid renewable–hydrogen energy systems from an economic prospect [

4,

5,

6,

7,

8]. HOMER, which is developed by the National Renewable Energy Laboratory (NREL) [

9], enables the simulation of modern technologies such as PV panels, wind turbines, battery banks, electrolysers, hydrogen storage systems and fuel cells, and it is possible to assess the feasibility of different hybrid system sizing configurations [

2]. Despite its explicit optimal sizing capabilities, HOMER disregards the electrochemical dynamic behaviour of electrolysers and fuel cell stacks when operating at variable power levels. In HOMER, the models used for simulating electrolysers and fuel cell stacks rely on an average assumed efficiency [

9], without investigating the impact of transient load variations on their output. This, therefore, introduces a shortcoming in quantifying the exact rate of hydrogen production by electrolysers together with the hydrogen fuel consumption by the fuel cell and its output power generation. In common with HOMER, there exist few software tools that can be used for sizing hybrid renewable–hydrogen energy systems. These include Improved Hybrid Optimization by Genetic Algorithms (iHOGA), Transient System Simulation (TRNSYS) and Renewable Energy and Energy Efficiency Technology Screen (RETScreen). iHOGA allows mono or multi-objective optimization of stand-alone or grid-connected hybrid renewable–hydrogen energy systems [

10]; however, the professional version (Pro+) has an upper load limit of 5 MW, and the educational free version (EDU) is limited to a daily load of 7 kWh [

11]. Thus the software is more suitable for small to medium-sized hybrid renewable energy systems. TRNSYS is a simulation software that was initially designed for simulating thermal hybrid energy systems [

12]. While the software is primarily used for transient system simulations, it can help with the sizing of hybrid systems using deterministic approaches as studied in [

12], although without optimization [

10]. RETScreen is an excel-based decision-support tool that enables assessment of the financial feasibility of renewable energy and co-generation projects. RETScreen is an effective tool for pre-feasibility studies, although it has rarely been used in literature research and only a few literature insights [

13] have investigated its usage for the optimal sizing of renewable energy resources within buildings. Moreover, it has limited support for hydrogen technologies as it does not offer specific built-in models for electrolysers, hydrogen storage and fuel cells. Instead, users can indirectly simulate hydrogen-related projects through the combined heat and power model; however, this is not as detailed as those models available for the renewable energy technologies.

On the other hand, Artificial Intelligence (AI) algorithms can be seen evolving in this field and have demonstrated promising abilities in optimizing the sizing of hybrid renewable–hydrogen energy systems. To this end, several researchers have developed mathematical models for addressing the optimal sizing of hybrid renewable–hydrogen energy systems using AI algorithms including Genetic Algorithm (GA) [

14,

15], Particle Swarm Optimization (PSO) [

16], Crow Search Algorithm (CSA) [

17] and hybrid techniques [

18,

19,

20,

21]. While a considerable research effort has been conducted in terms of optimizing the sizing of hybrid renewable–hydrogen energy systems using AI algorithms, it is worth stating that research in this direction has often relied on simplistic system modelling that lacks consideration of the electrochemical dynamic behaviour of electrolysers and fuel cell systems in response to the intermittent renewables’ output and the dynamic load changes. A research gap exists in integrating AI optimization algorithms within accurate hybrid renewable–hydrogen energy system models to enable optimization of the hybrid system sizing while considering the real-world dynamic behaviour of the individual hybrid system components. Moreover, none of the aforementioned studies have conducted a benchmarking comparison between their developed AI-based hybrid system optimal sizing models and the commercially available software tools to allow a means of validation of the performance of such stand-alone AI-based models. Discrepancies could also lead to valuable insights into the strengths and weaknesses of each approach in several contexts, including scalability, flexibility and adaptability to more complex energy systems.

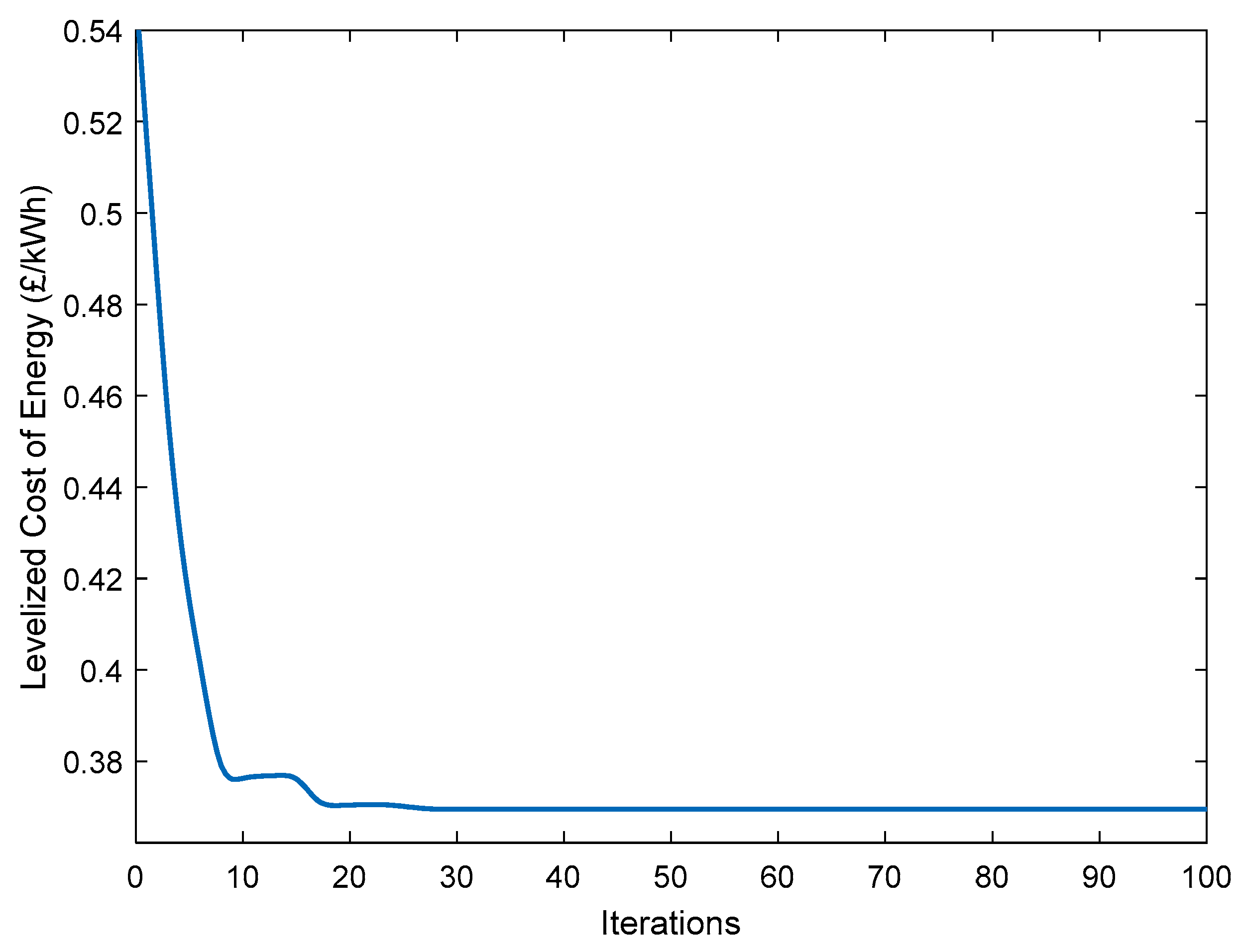

This paper aims to address these gaps by firstly developing a novel AI-based dynamic system model, in which a PSO optimization algorithm is integrated with a precise dynamic model that is developed for simulating the real-world dynamic behaviour of hybrid PV-H

2 energy systems to allow optimization of the hybrid system sizing while considering its dynamic behaviour. The selection of PSO as the AI algorithm to be implemented in the developed model is based on a comparative analysis as shown in

Table 1. PSO offers several outstanding features including simplicity, faster convergence and less computational burden. Unlike GA, which requires complex evolutionary operations including selection, crossover and mutation per iteration [

22], PSO requires fewer parameters to tune and employs a straightforward updating mechanism per iteration resulting in faster convergence with less computational burden [

23]. Compared to other widely used swarm intelligence algorithms such as the Artificial Bee Colony (ABC), PSO simultaneously updates all the dimensions of the search space, whereas ABC only updates one dimension value at a time [

24], making it slower and less efficient for high-dimensional optimization tasks. Additionally, PSO directly optimizes solutions with no larger datasets unlike learning-based approaches such as the Artificial Neural Networks (ANNs), which require extensive datasets for training and predictive tasks [

25]. These advantages have positioned PSO as a well-suited choice for integration within the developed model. The developed model brings major advantages over the ones existing in the literature by accounting for the variations in the electrolyser’s parasitic current losses in response to fluctuations in PV input generation, thus quantifying the real amount of hydrogen produced by the electrolyser. In addition, it accounts for the variations in the fuel cell’s electrochemical losses in response to the variations in the level of hydrogen stored in the tank, thus quantifying the real amount of hydrogen consumed by the fuel cell. This real-world identification of hydrogen production and consumption levels ensures the exact sizing of the hydrogen storage tank, which contributes to cost savings and less space requirement [

26]. This paper then benchmarks the developed AI-based precise dynamic system model versus the commercially available HOMER Pro 3.16 software to identify correlation and discrepancies between both approaches, thus contributing to the conclusion of the best practices in the design and optimal sizing of a hybrid PV-H

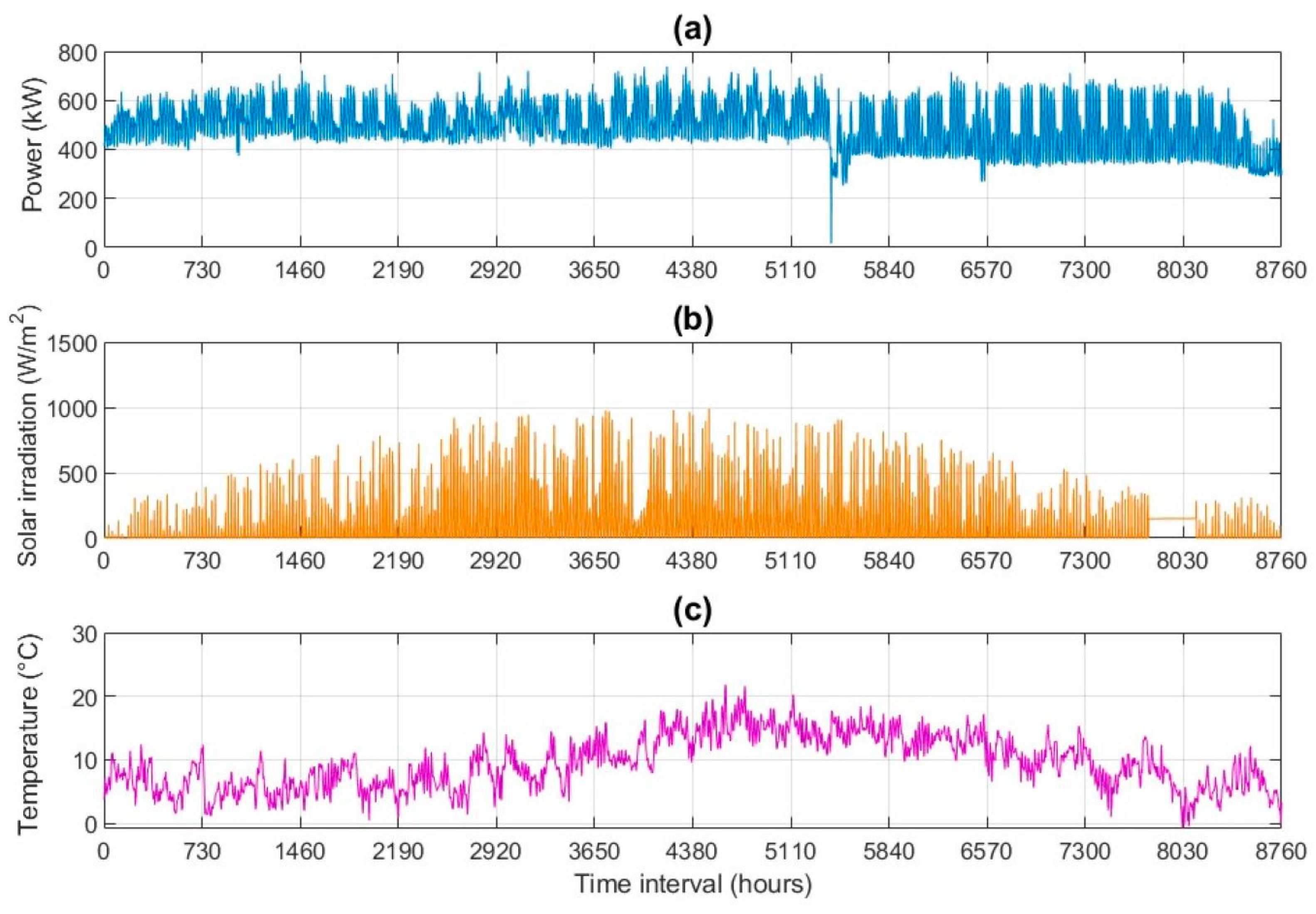

2 energy system for decarbonising grid-connected buildings. HOMER, given its optimization capabilities and suitability for this scale of implementation, best suits this benchmarking and allows fair comparison with the developed novel PSO-based dynamic system sizing model. For benchmarking, the developed novel PSO dynamic system sizing model was applied on a case-study grid-connected building in Aberdeen, Scotland. The yearly energy consumption of the case-study building and its location atmospheric data were used in both the developed novel model and in HOMER. The results from the developed model were then benchmarked with those obtained from the commercially available HOMER software, revealing the potential of the developed model.

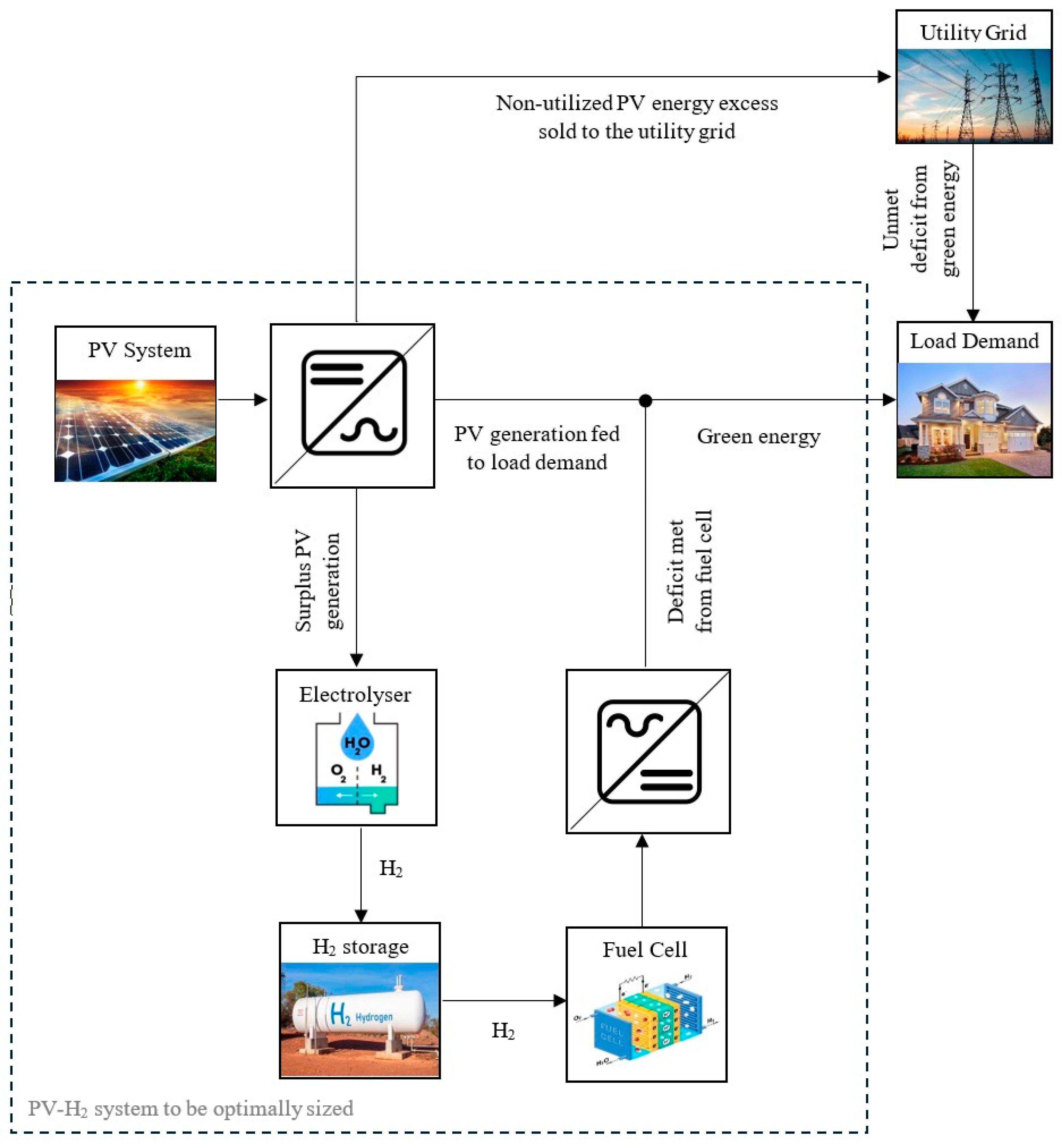

3. The Developed Precise Dynamic Hybrid PV-H2 System Model

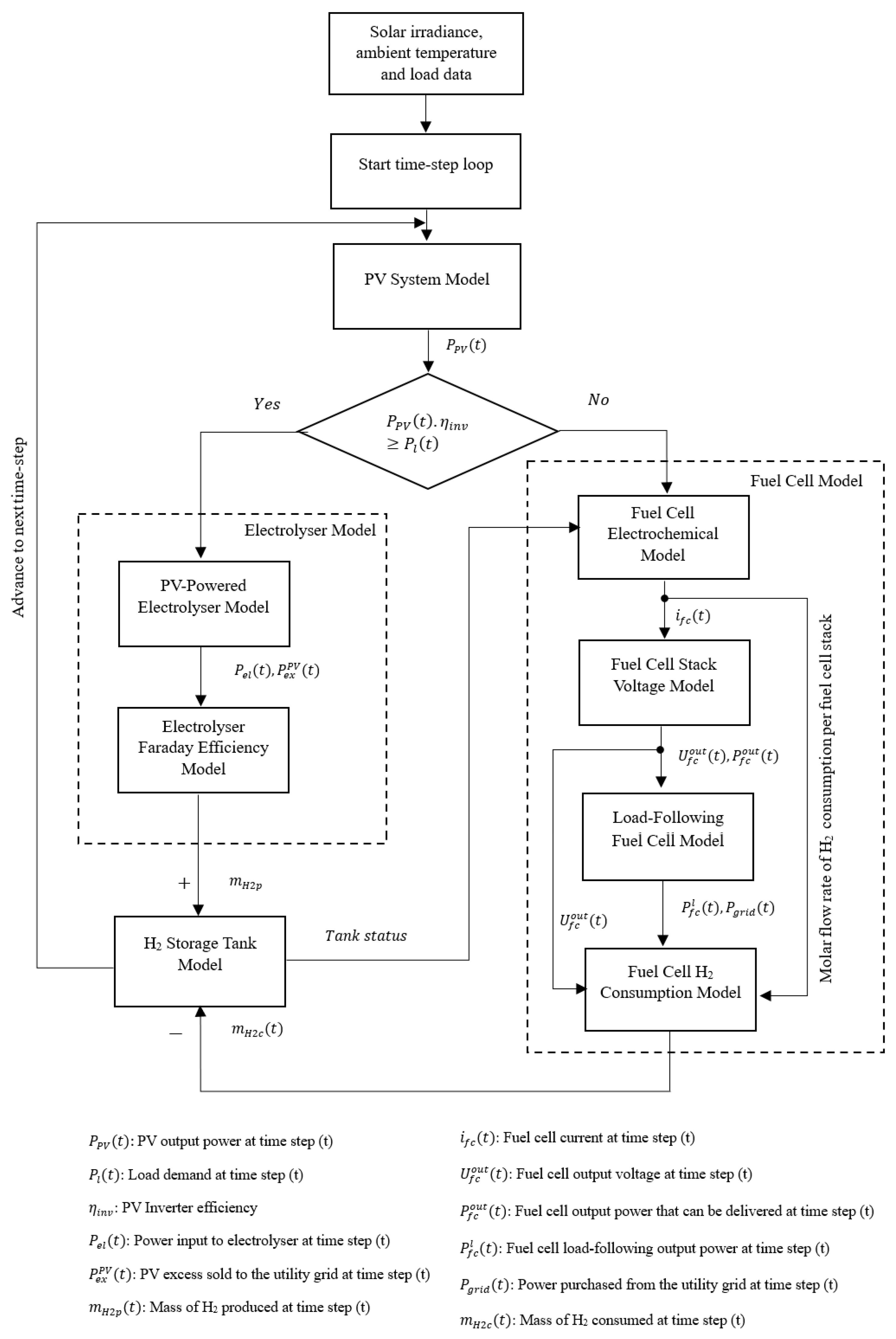

Figure 2 demonstrates the structure of the developed precise dynamic hybrid system model with the implemented energy management strategy. The developed model integrates distinct interconnected smaller models, each modelling a specific component of the hybrid system. This section presents the functioning of the developed model, and the energy management strategy implemented across the hybrid system components and the grid. Further details of the developed mathematical model can be found in our earlier research publication [

26]. A comparison between the developed precise dynamic hybrid system model versus the generic models used in the literature can be seen in

Table 2.

In the developed model, the time dependence is taken into consideration by accounting for the hourly variations in load demand and PV generation throughout the day over a one-year timescale. The sizes of all system components are considered as continuous variables which are iteratively updated by the PSO algorithm as will be discussed later in

Section 5. The operational conditions of inverters are considered fixed; thus, the inputs/outputs from inverters are related by means of constant efficiencies. The developed model runs on an hourly basis loop over a one-year time interval. For each time step, the PV system model firstly runs to determine the PV output power (

) while considering the variations in solar irradiance and ambient temperature. The net AC hourly output power from the PV system is then compared to the hourly load demand to identify the surplus power. When the PV power is higher than the load demand, the electrolyser model runs to simulate the H

2 generation from the available surplus PV power. The developed precise dynamic electrolyser model integrates two sub-models: the PV surplus-powered electrolyser model and the Faraday efficiency model. The PV surplus-powered electrolyser model allows powering the electrolyser by the PV surplus power while limiting this to the rated power of the electrolyser and allocating any extra PV excess (

) for sale to the utility grid. The Faraday efficiency model then accounts for the variations in parasitic current losses taking place in the electrolytic cell stacks due to gas crossover. In this sub-model, the hydrogen output from the electrolyser (

) is quantified while considering the variations in the parasitic current losses in response to the varying power input to the electrolyser (

). The hydrogen output from the electrolyser is then cumulatively added to the hydrogen storage tank model and the hourly tank status is updated accordingly.

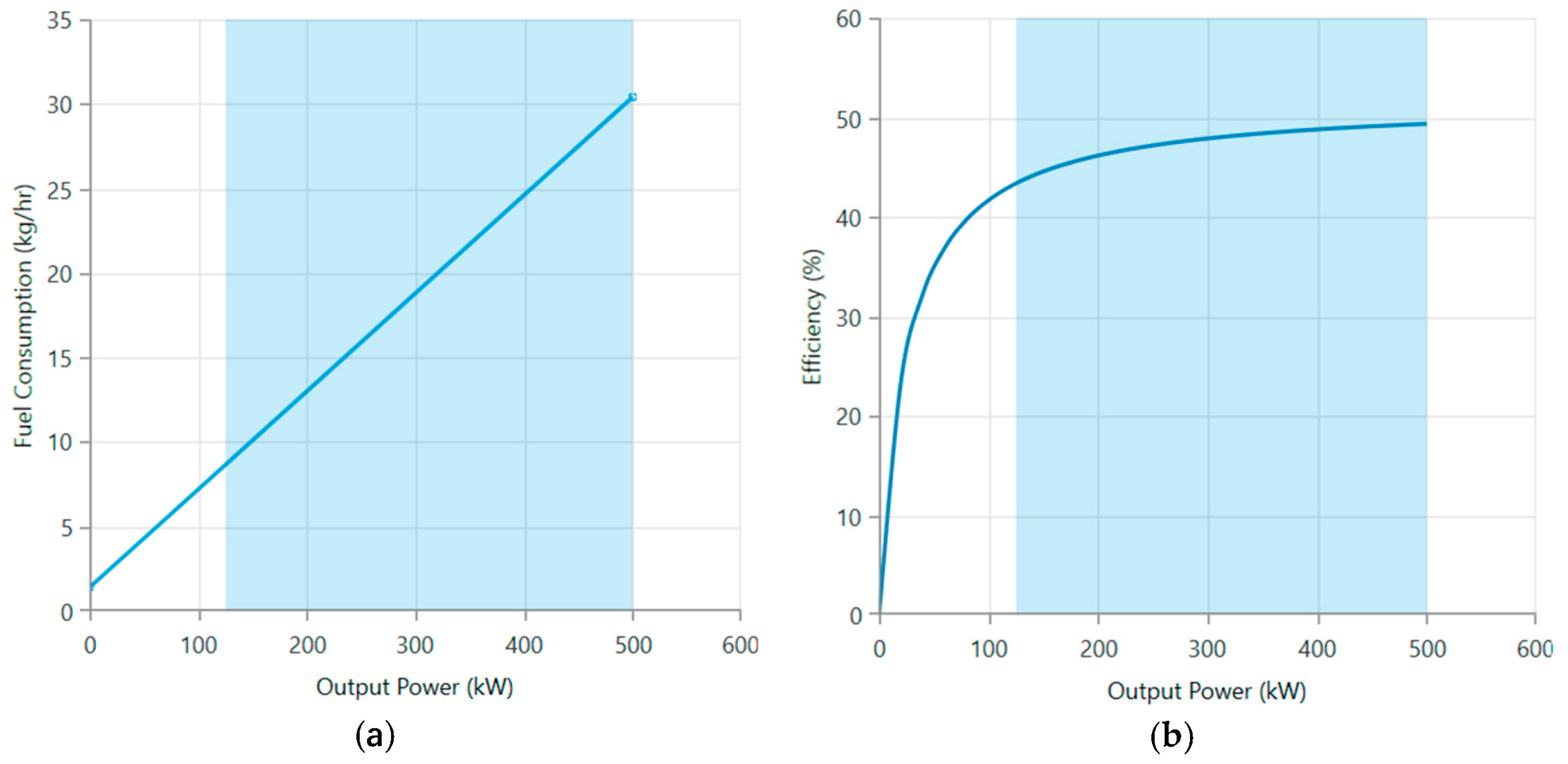

If the net AC output power from the PV system is lower than the load demand, then the fuel cell model is allowed to run. The developed precise dynamic fuel cell model integrates a fuel cell electrochemical model, a stack voltage model, a load-following fuel cell model and a fuel cell hydrogen consumption model. The electrochemical model first allows determining the molar flow rate of the hydrogen consumption per single fuel cell stack based on the status of the hydrogen in the storage tank, then computes the fuel cell current (

) from the electrochemical reaction of a single fuel cell using the total charge carried by the electrons transferred per each mole of hydrogen. The fuel cell stack voltage model is then applied to model the voltage–current characteristics of the fuel cell where the variations in the polarization losses with the change in current at each time step are captured and the corresponding influences on the fuel cell output voltage (

) are calculated, thus allowing the real-world simulation of the fuel cells’ behaviour. The stack voltage model also yields the fuel cell output power (

), which is then used as a threshold value for the load-following fuel cell model. In the load-following model, the fuel cell is allowed to produce power that is only enough to meet the unmet load demand by the PV system. If this unmet load demand exceeds the threshold value of the fuel cell output power, then the fuel cell produces its maximum power, while the remainder of the unmet load demand has to be purchased from the utility grid. Finally, the fuel cell hydrogen consumption model allows determination of the amount of hydrogen that has to be consumed (

) to deliver the fuel cell output power in the load-following mode and then subtract this from the hydrogen storage tank level to update the tank level accordingly. The mathematical formulas used in formulating each model are fully described in [

26]. The hourly power balancing equation underlining the energy management strategy set out is given by Equation (1):

where

is the PV output power at time step (

t),

is the PV inverter efficiency,

is the fuel cell load-following output power at time step (

t),

is the power purchased from the utility grid at time step (

t),

is the power consumed by the load demand at time step (

t),

is the power consumed by the electrolyser at time step (

t) and

is the non-utilised PV excess sold to the utility grid at time step (

t). It should be noted that there are specific times that the value of one term or more from the power balancing equation can dynamically be zero depending on the operating conditions.

4. Formulating the Cost-Optimization Objective Function and Constraints for the Optimal Sizing of Hybrid PV-H2 Energy System

A frequently adopted economic metric used for assessing the economic feasibility of hybrid renewable energy systems is the system’s LCOE, which reflects the cost per unit energy [

27]. Thus, in formulating the cost-optimization function for the proposed hybrid PV-H

2 energy system, the objective function is set to minimize the system’s LCOE as shown in Equation (2). The optimization variables are set as the sizes of the system components (i.e., the PV system, electrolyser, hydrogen storage tank and fuel cell system). The aim is to find the optimal sizing of the hybrid system components (optimization variables) that minimize the system’s LCOE.

The system’s LCOE, given by Equation (3) [

16,

17], considers the Net Present Cost (NPC) of the hybrid system components over the project lifetime, the cost of grid imports and the earned revenue from selling unutilized PV energy excess to the utility grid.

where

is the objective function for the optimal sizing of the proposed hybrid PV-H

2 energy system,

is the system’s levelized cost of energy (GBP/kWh),

,

,

,

,

and

are, respectively, the net present costs of the PV system, electrolyser, fuel cell system, hydrogen storage tank, PV inverter and fuel cell inverter in (GBP),

is the cost of grid imports (GBP),

is the earned revenue from selling unutilized PV energy excess to the utility grid (GBP),

is the hourly building load demand,

is the capital recovery factor [

16,

17,

18],

is the real interest rate and

is the project lifetime.

The net present cost of each of the hybrid system components is calculated considering the capital cost of the component, the operation and maintenance cost that is incurred over the project lifetime, the replacement cost in case the lifetime of the system component is less than the project lifetime and the salvage value of the system component, which defines the earned revenue from the remaining life of the system component at the end of the project lifetime [

20]. An illustrative example for calculating the net present cost of the PV system is given in Equation (5) [

20].

where

and

are the capital cost and the operation and maintenance cost of the PV system per unit rating (GBP/kW), respectively,

is the rating of the PV system (kW),

is the total replacement cost of the PV system (GBP) and

is the salvage value of the PV system (GBP).

The total replacement cost of the PV system is given by Equations (6) and (7) [

20], where when the PV system lifetime is more than the project lifetime, then no replacement is needed for the PV system over the project lifetime, while when the PV system lifetime is less than the project lifetime, then the PV system will need replacement over the project lifetime.

where

is the replacement cost of the PV system per unit rating (GBP/kW),

is the PV system lifetime (year) and

is the number of PV system replacements over the project lifetime rounded down to the nearest integer.

The salvage value of the PV system is given by Equations (8)–(10) [

20].

where

is the remaining lifetime of the PV system at the end of the project lifetime (year) and

is the duration of the PV system replacement (year).

The net present costs of the PV inverter and the hydrogen storage tank (

) are also calculated in the same way as the net present cost of the PV system is calculated given that these three components (PV system, PV inverter and hydrogen storage tank) are continuously operating over the year and will, accordingly, need replacement if their predefined lifetime is less than the project lifetime.

To calculate the NPC of the electrolyser, fuel cell system and fuel cell inverter, which are partly operated over the year, an illustrative example is given for the electrolyser in Equations (11) and (12). To find the total replacement cost of the electrolyser (Equation (12)), the exact number of operating hours of the electrolyser is first computed over the project lifetime; if this is found to be less than the electrolyser lifetime in hours, then no replacement is needed for the electrolyser over the project lifetime. If the electrolyser’s operating hours are more than the electrolyser lifetime, then the electrolyser will need replacement over the project lifetime as depicted in Equation (12) [

20].

where

and

are, respectively, the capital cost and operation and maintenance cost of the electrolyser per unit rating (GBP/kW),

is the size of the electrolyser (kW),

is the total replacement cost of the electrolyser (£),

is the salvage value of the electrolyser (GBP) and is calculated in the same way that the PV system is calculated,

is the replacement cost of the electrolyser per unit rating (GBP/kW),

is the electrolyser lifetime in (year),

is the exact number of the electrolyser operating hours over the project lifetime (h) and

is the electrolyser lifetime in (h).

is the number of electrolyser replacements rounded down to the nearest integer, which is calculated in the same way that the PV system is calculated

The same applies to the net present costs of the fuel cell system and fuel cell inverter (

) given that they are also partially operated over the year.

The cost of grid imports and the earned revenue from selling unutilized PV energy excess to the utility grid are calculated using Equations (13) and (14) [

17,

18].

where

(

t) is the grid electricity purchase hourly tariff rate considering day/night tariff schemes,

is the grid feed-in tariff rate,

is the power imported from the utility grid at time step (

t) and

is the unutilised PV power excess at time step (

t).

The objective function

is subject to the inequality constraints given by Equations (15)–(18). These constraints represent the boundary limitations of the optimization variables from which the range of feasible solutions is encountered [

16,

17,

18,

20].

where

and

are, respectively, the minimum and maximum boundaries of the PV system’s size,

and

are, respectively, the minimum and maximum boundaries of the electrolyser’s size,

and

are, respectively, the minimum and maximum boundaries of the hydrogen storage tank’s size, and

and

are, respectively, the minimum and maximum boundaries of the fuel cell system.

7. Conclusions

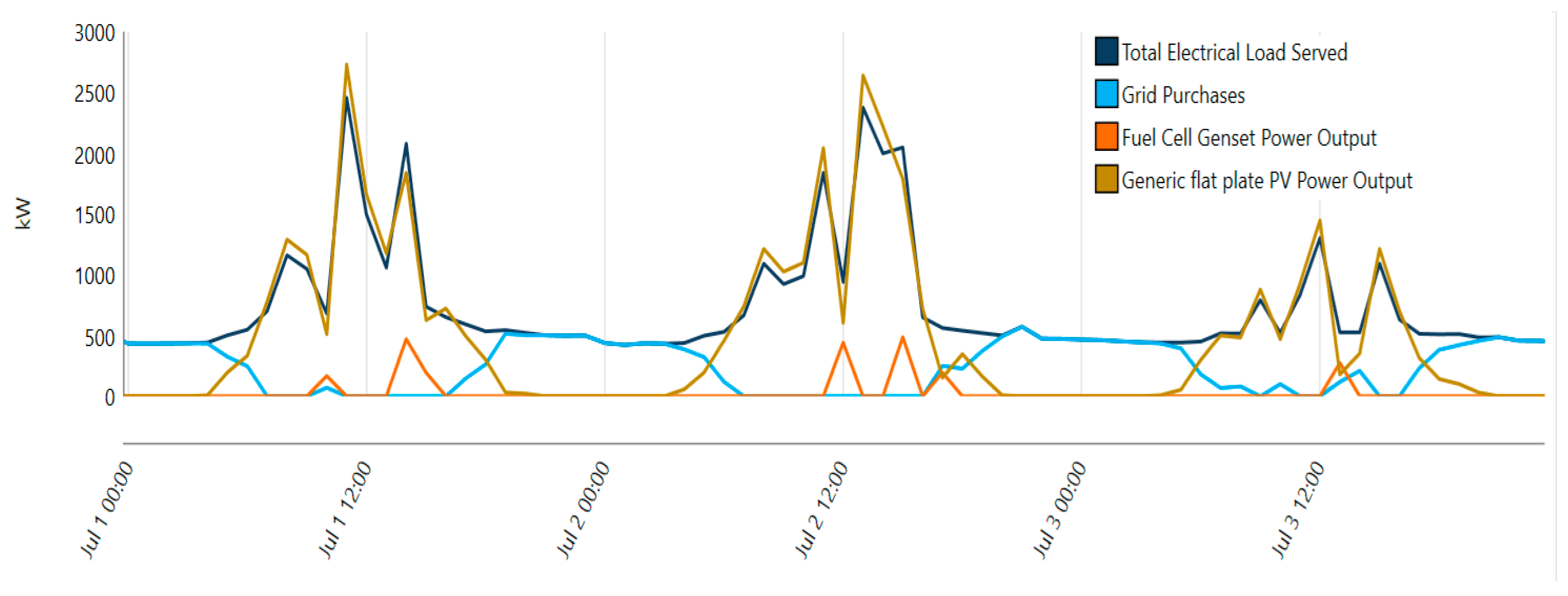

In this paper, a novel PSO dynamic hybrid PV-H2 energy system sizing model is developed to enable the optimal sizing of hybrid PV-H2 energy systems within grid-connected buildings and accurately simulate their real-world dynamic behaviour. This model is developed by integrating a PSO algorithm with a precise hybrid PV-H2 energy system model that allows simulation of the dynamic behaviour of the hybrid system components. The developed novel model allows optimization of the hybrid system components’ sizing from an economic perspective while considering the dynamic behaviour of the hybrid system components. The results obtained from the developed novel PSO dynamic model were verified against those obtained from the commercially available HOMER software showing a strong agreement in the optimal sizing results while achieving a lower LCOE than the one attained by the HOMER software. The benchmarking comparison also revealed the potential of the energy management strategy implemented in the developed model, which allows maximization of the green energy supply to the building, thus aligning with the future of the net-zero energy transition, while the one implemented in HOMER only looks to minimize the system’s net present cost regardless of the green energy supply to the building. The comparison further showed that the developed model provides more accurate dynamic simulation results for the electrolyser and the fuel cell outputs, which reflects their real-world dynamic behaviour because it implements with the optimization a precise dynamic model for the hybrid system.

The analysis of the developed model has pointed out some improvements that can be considered in future work. Firstly, the currently developed model only deals with the time-of-use electricity pricing, which is the most popular choice for many businesses in the UK for paying energy bills; however, in spot electricity markets, prices can fluctuate every hour depending on the market. Therefore, further research work should integrate a dynamic grid pricing mechanism with the developed optimal sizing dynamic hybrid system model to enhance its adaptability in dealing with volatile energy markets. Furthermore, the currently developed model is primarily focused on cost optimization; however, other aspects are not considered in the optimization process. Therefore, future work should aim for the development of a multi-objective optimization technique to allow sizing real-world hybrid PV-H2 energy systems within a grid-connected building while optimizing, along with cost, other aspects like environmental and technical aspects. Developing such an AI-based multi-objective optimal sizing dynamic hybrid system model, which allows addressing the HOMER gap of only considering single-objective cost optimization, will be the scope of our upcoming research paper.