1. Introduction

Currently, access to electricity is seen as a key indicator of a country’s sustainable economic development and the well-being of its inhabitants. It is essential for any nation aspiring to progress and prosper to ensure its citizens have access to electricity. In recent years, the rapid growth of the population, combined with technological advancements, has created a significant energy demand, particularly electricity [

1]. Conversely, many rural and remote areas, especially in developing countries, still lack access to electricity. To address this challenge, solutions such as extending existing electrical grids or deploying standalone or off-grid energy generation systems can be considered [

2]. However, a significant portion of the world’s electricity, approximately 75%, is still generated using fossil fuels [

3]. The problems associated with heavy reliance on these fuels, such as environmental degradation and climate change due to CO

2 emissions, have driven the growth of renewable energies. Energy sources like wind, solar, and geothermal are becoming increasingly popular and are seen as viable alternatives to mitigate these negative effects [

4]. Nevertheless, using renewable energy systems that operate independently of the grid to meet local energy demands presents various challenges, primarily due to the high initial investment costs and the low reliability resulting from the inherent unpredictability of renewable sources [

5].

The hybrid renewable energy system (HRES) concept has been developed to tackle these challenges. The HRES combines conventional and renewable energy sources and is designed to generate and store electricity autonomously or off the grid, catering to specific demand points. These systems are particularly effective in bringing electricity to remote and hard-to-reach rural areas [

6,

7].

These systems are designed to maximize efficiency, reliability, and sustainability in energy generation. HRESs offer certain advantages over single-source generation methods, including reducing dependency on a single energy source, thereby achieving greater reliability and stability in supply. They also optimize space usage by combining different technologies to better utilize the available land. Additionally, they allow for diversification and complementarity by leveraging the strengths of each generation source and providing greater resilience to climatic and resource variations. However, challenges include implementation costs, operational complexity, and integrating different energy sources. Therefore, the system choice depends on local resource availability, energy needs, budget, and environmental objectives [

7].

Several studies have explored hybrid renewable energy systems (HRESs). A statistical analysis was conducted to determine the key criteria for optimizing hybrid systems and the tools employed in their development [

8]. An updated review on the optimal multi-objective design of hybrid energy systems offers pertinent and current information on this subject [

9]. This review emphasizes four fundamental categories of HRES: sizing, optimization, control, and energy management [

10]. Various modeling techniques and computer simulation tools have been developed and advanced over time [

11]. One study focused on detailed modeling of hybrid energy resources, standby power systems, power conditioning units, and techniques for managing energy flow [

12]. A comprehensive review was conducted on different types of energy storage systems (ESSs), including their structures, classifications, advantages, and disadvantages in microgrid applications [

13]. Another detailed analysis provided fundamental reasons and advantages driving the adoption of HRES [

14]. A review examined the tools and limitations for optimizing HRES systems, along with an analysis of available types of storage and backup systems [

15]. Additionally, recent classifications, evaluation indicators, and sizing methodologies for hybrid renewable energy systems were reviewed [

16].

Additionally, several articles analyze case studies on the implementation of hybrid renewable energy systems (HRESs) in rural residential communities. For example, one study [

17] explores an HRES designed for a rural residential community, integrating photovoltaic panels (PVs), a wind energy conversion system (WECS), a battery energy storage system (BESS), and a diesel generator (DG) with a total capacity of 32 kW to meet the energy demands of 20 households. Another case study [

18] highlights a similar system with a total installed capacity of 56 kW, designed to cater to the energy needs of over 50 homes and six stores. A third case study [

19] focuses on an HRES deployed in a rural residential area, integrating PVs, WECS, BESS, and DG, with an installed capacity of 44.1 kW to meet the energy needs of 10 homes. Further research [

20] evaluates various energy sources deployed in a rural residential area with an installed capacity ranging between 50 and 60 kW and servicing 41 homes, and includes an assessment of different energy generation technologies such as solar PVs, WECSs, diesel generators, and BESSs. Another study [

21] summarizes the installation of a PV-PEMFC hybrid system in a rural residential area, focusing on its capacity and the benefits of combining solar and fuel cell technologies to meet energy demands sustainably. These systems are designed to integrate multiple renewable energy sources and storage technologies to optimize energy production, storage, and management in a rural residential setting [

22]. Each configuration varies slightly in installed capacity and the combination of renewable energy and storage components, aiming to provide sustainable and reliable electricity while reducing dependence on traditional fossil fuels.

To achieve Net Zero-Energy Buildings (NZEBs), it is essential to minimize energy consumption through efficient design and fulfill the remaining energy needs with renewable energy sources. Hybrid renewable energy systems (HRESs) integrate multiple renewable sources, such as solar, wind, and biomass, and are often paired with storage solutions to ensure a dependable energy supply. Reaching NZEBs through the optimization of HRESs involves a comprehensive approach that combines advanced energy efficiency strategies, the strategic integration of various renewable energy sources, and intelligent control and management systems. Focusing on these areas allows buildings to reduce their energy demand and rely on clean, renewable energy, moving closer to the goal of zero-energy consumption [

23].

2. Materials and Methods

2.1. Study Area

In this case study, the Yucatan Peninsula region in Mexico, which has excellent natural resources for electricity generation, was analyzed. In addition, government databases were searched for localities without access to electricity. The selected locality was in the state of Campeche, municipality of Carmen, El Arca.

El Arca is located 101.8 km from Ciudad del Carmen, Campeche, the most populated locality of the municipality, in a westerly direction. As of 2020, it is known that there are 48 inhabited dwellings in the village, of which more than 50% do not have electricity services, with an equivalent of twenty-five dwellings without electricity.

Figure 1 shows the maps of Mexico and the state of Campeche, where the study locality is located.

2.2. Estimation of Electricity Consumption

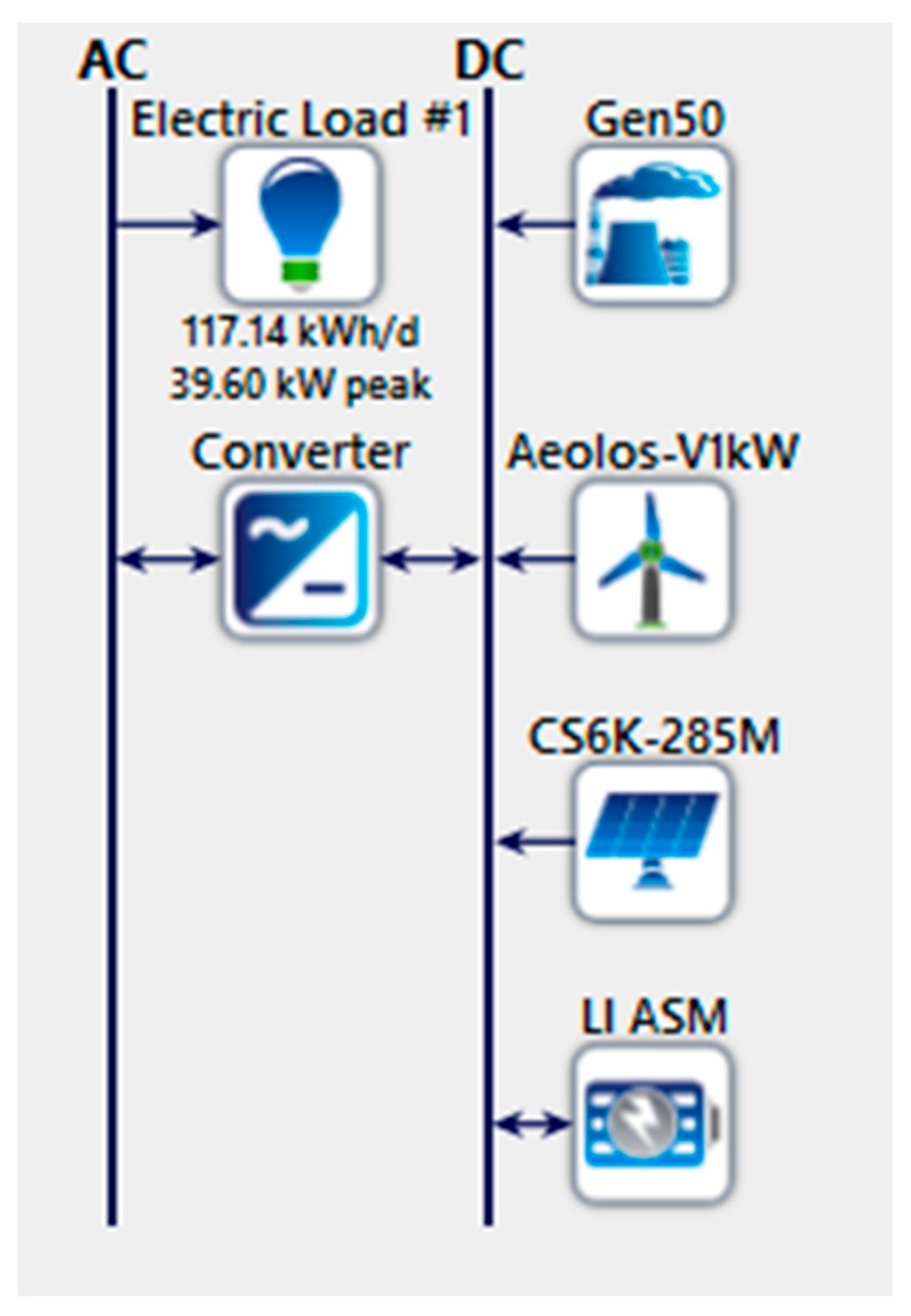

The off-grid hybrid system has been meticulously designed to provide a reliable source of electricity for the town of Arca, located in Ciudad del Carmen, Campeche. The village has both solar and wind potential. This community consists of several houses and is mainly focused on agricultural activities. The energy demand consists of 25 households that require a supply of lights and appliances.

Specific details of the energy consumption reveal that the total demand for one dwelling is 4.88 kW with an energy consumption of 177.14 kWh/day and a load factor of 0.123. By incorporating a random variable of 52.184% from hour to hour and 11.082% from day to day, variability is introduced into the load data throughout the year.

Table 1 shows the equipment to be considered for the profile estimation [

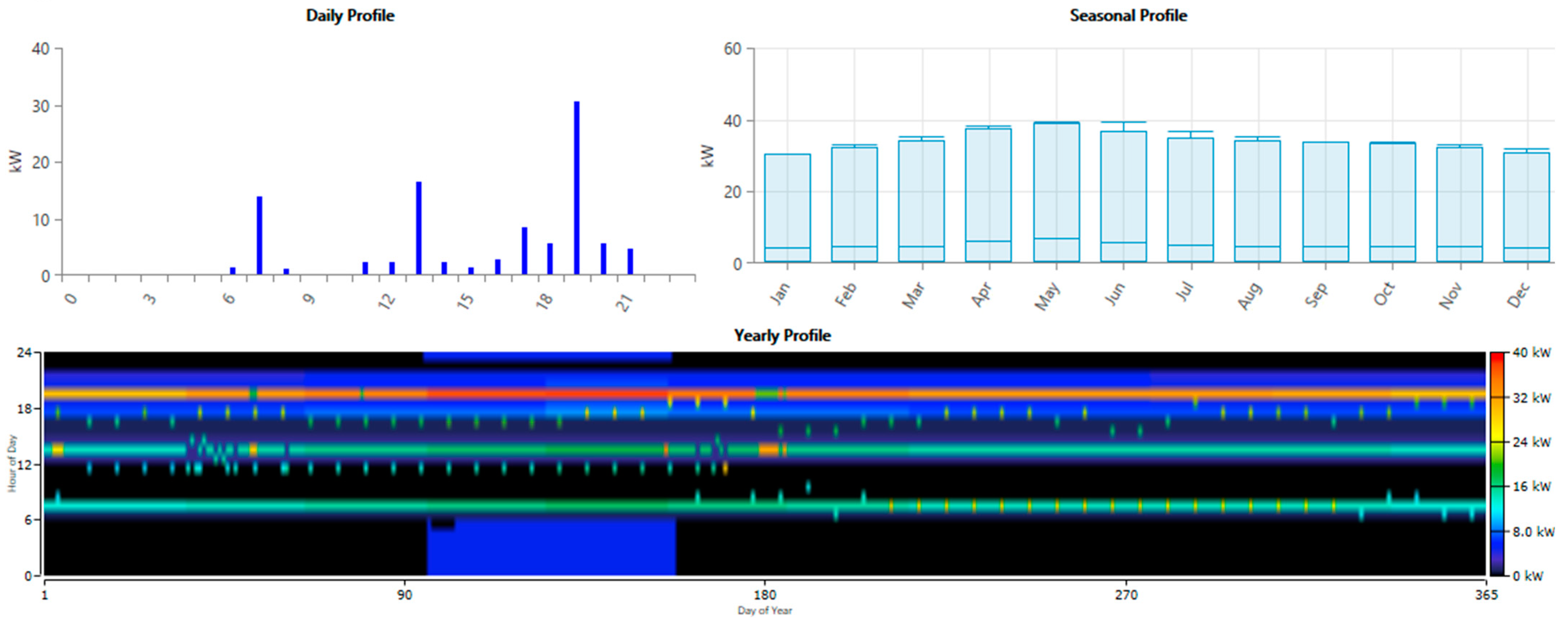

24]. These load data are entered into the HOMER Pro Version 3.14.5 software, which allows graphical representations of hourly and monthly load profiles, as shown in

Figure 2.

Figure 2 shows the estimated load behavior in hours, days, months, and within a year. In the day behavior, there are three hours when the demand is high, mainly due to the use of food-cooking equipment.

Specific energy consumption details reveal that the total demand for a home is 4.8 kW, with an energy consumption of 177.14 kWh/day and a load factor of 0.123. By incorporating a random variable of 52.184% from hour to hour and 11.082% from day to day, variability is introduced into the load data throughout the year.

2.3. Solar Panel

The power output of a solar panel is a crucial measure that determines its ability to generate electricity from solar energy. HOMER calculates the power output using the equation below [

17,

25,

26].

where:

: The nominal capacity of the PV generator, i.e., its power output under standard test conditions [kW].

: The photovoltaic derating factor [%].

: Incident solar radiation on the photovoltaic field at the current time step [kW/m2].

: Incident radiation under standard test conditions [1 kW/m2].

: The power temperature coefficient [%/°C].

: The temperature of the photovoltaic cell at the current time step [°C].

: The temperature of the photovoltaic cell under standard test conditions [25 °C].

2.4. Wind Turbine

First, HOMER estimates the wind speed at the hub height of the wind turbine. This calculation involves adjusting the measured wind speed at a specific height (typically ground level) to the hub height, considering how wind speed changes with elevation. Then, HOMER uses the previously calculated wind speed to estimate the amount of energy generated by the turbine at that speed, assuming standard air density. This estimation is derived from the turbine’s power curve, which illustrates how wind speed correlates with electrical power production. Lastly, HOMER adjusts the generated energy value to account for the actual air density at the turbine’s location. Air density varies with altitude, temperature, and atmospheric pressure, influencing the turbine’s efficiency and power generation. This adjustment ensures the energy estimation accurately reflects the specific environmental conditions surrounding the turbine [

2,

26].

2.4.1. Calculation of Hub Height Wind Speed

At each time interval, HOMER determines the wind speed at the turbine’s hub height by utilizing the inputs provided on the Wind Resource page along with the Wind Shear setting you specify. If the logarithmic law is applied, HOMER calculates the wind speed at hub height using the following equation:

where:

: Wind speed at the wind turbine hub height [m/s].

: Wind speed at the height of the anemometer [m/s].

: Wind turbine hub height [m].

: The height of the anemometer [m].

: The length of the surface roughness [m].

2.4.2. Calculation of Turbine Power Output with Standard Air Density

Once HOMER calculates the wind speed at the hub height, it refers to the wind turbine’s power curve to estimate the power output at that specific wind speed under standard temperature and pressure conditions. In

Figure 3, the red dotted line shows the wind speed at the hub height, while the blue dotted line represents the power output predicted by the power curve for that wind speed. If the wind speed at the hub height falls outside the range specified by the power curve, the turbine does not generate power, based on the assumption that wind turbines do not operate at speeds below the minimum or above the maximum cut-off thresholds [

26].

2.4.3. Applying Density Correction

Once HOMER determines the wind speed at hub height, it queries the wind turbine power curve to calculate the expected power output of the wind turbine at that wind speed under standard temperature and pressure conditions.

Power curves typically outline the performance of wind turbines under standard temperature and pressure conditions. To align these predictions with real-world conditions, HOMER adjusts the power value indicated by the power curve by multiplying it by the air density ratio. This adjustment is made according to the following equation [

1,

2,

26]:

where:

: The power of the wind turbine [kW].

: The wind turbine power at standard temperature and pressure [kW].

: The actual density of the air [kg/m3].

: The density of air at standard temperature and pressure (1225 kg/m3).

2.5. Inverter

AC and DC power supplies require conversion between the two since the load demand is AC. A power inverter is needed to convert the DC generated by the PV module and batteries to AC for the load to consume. The inverter selected is the MEAN WELL TS 3000-148 (MEAN WELL USA Inc., Fremont, CA, USA), with a power rating of 3 kW and a capital cost of

$1600. The lifetime of the inverter is estimated at ten years, and its efficiency is 91% [

1,

27].

2.6. Diesel Generator

In this study, it is assumed that a diesel generator serves as a backup power source to provide extra electricity when the supply from renewable sources is not enough to meet the demand. Most calculations in this section are based on the fuel curve, which shows how much fuel the generator consumes to produce electricity. For simplicity, it is assumed that the fuel curve is linear. Consequently, the fuel consumption of the generator is expressed with the following equation [

17]:

In this context,

represents the interpolated coefficient of the fuel curve, while

is the slope of the fuel curve.

denotes the rated power capacity of the generator, and

is the actual power output of the generator. The efficiency of the generator is defined as the ratio of the electrical power output it produces to the total power consumed during the combustion process.

In this equation,

LHVfuel refers to the lower heating value of the fuel. To find the optimal capacity for the diesel generator, this parameter was varied incrementally from 0 to 100 kW in steps of 10 kW [

17,

26].

2.7. Battery

HOMER determines the maximum power that the storage bank can absorb at each time step. This maximum absorbable power is crucial for HOMER to decide whether the storage bank can take in all the excess renewable energy or how much extra power a cyclic load generator should produce. The maximum load power that the storage bank can handle changes at each time step based on its current state of charge and its recent charging and discharging patterns.

HOMER applies three distinct constraints on the maximum load power that the storage bank can accept. The first of these limitations is derived from the kinetic storage model and it is represented by the following equation:

where:

: The available energy [kWh] in the accumulator at the beginning of the time step.

: The total energy [kWh] stored at the beginning of the time step.

: The storage capacity coefficient.

: The storage rate constant.

: The time step length [h].

The second limitation refers to the maximum loading rate of the Al-storage Component. The storage charge power corresponding to this maximum charge rate is given by the following equation:

where:

: The maximum charge rate of the accumulator [A/Ah].

: The total capacity of the storage bank [kWh].

The third limitation refers to the maximum load current of the storage component. The maximum load power of the storage bank corresponding to this maximum load current is given by the following equation:

where:

= number of storage bank batteries.

= maximum battery charging current [A].

= nominal voltage of the accumulator [V].

HOMER sets the maximum storage load power equal to the lowest of these three values, assuming that each is applied after load losses, therefore:

where

is the storage load efficiency.

The maximum discharge power

) of the battery banks is calculated according to Equations (6)–(8).

where:

: The storage discharge efficiency.

2.8. Economic Assessment

HOMER defines the levelized cost of energy (COE) as the average expense incurred for each kWh of useful electrical energy generated by the system. To determine the COE, HOMER calculates it by dividing the annualized cost of electricity production (which is the total annualized cost minus the expenses associated with serving the thermal load) by the total electrical load that has been met. This calculation is performed using the following equation:

where:

Cann,tot = total annualized system cost [$/year].

Cboiler = marginal boiler cost [$/kWh].

Hserved = total thermal load served [kWh/year].

Eserved = total electrical load served [kWh/year].

The second term in the numerator represents the part of the annualized cost attributed to serving the thermal load. In systems like wind or photovoltaic systems, which do not provide a thermal load, this second term is zero (

Hthermal = 0). Thus, it does not contribute to the annualized cost.

The levelized cost of energy (COE) is a useful metric for comparing different energy systems, but HOMER does not use it to rank these systems. Instead, HOMER ranks systems based on their total Net Present Cost (NPC). The NPC represents the present value of all costs incurred over the system’s lifetime, subtracted by the present value of all the revenues it generates.

Costs in the NPC calculation include capital expenditures, replacement costs, operational and maintenance expenses, fuel costs, emission penalties, and the cost of purchasing power from the grid. Revenues include the residual value at the end of the project and income from selling electricity back to the grid.

To calculate the total NPC, HOMER sums the discounted cash flows for each year over the project’s lifetime. This total NPC is HOMER’s primary economic output and the criterion by which it ranks all system configurations in the optimization results. It also serves as the foundation for calculating the total annualized cost and the levelized cost of energy. The NPC is calculated using the following equations:

where:

CRF: This capital recovery factor is calculated using the following equation.

where

i is the real interest rate,

N is the estimated lifetime for the system, and

i is calculated as shown in the following equation, where

is the nominal interest rate 0.

2.9. Renewable Fraction (RF)

The renewable portion refers to the share of overall electric power generated from renewable sources. It is calculated as the ratio between the total power generated by renewable energy sources and the total power produced by the system as a whole. This calculation is performed as follows:

where

is the power output of the diesel generator and

is the power output of renewable sources (wind and solar) of the considered system [

17].

2.10. Emission

HOMER calculates the emissions of the following six pollutants.

- •

Carbon dioxide (CO2)

- •

Carbon monoxide (CO)

- •

Unburned hydrocarbons (UHC)

- •

Particulate matter (PM)

- •

Sulfur dioxide (SO2)

- •

Nitrogen oxides (NOX)

HOMER calculates emissions of various pollutants from electricity generation, thermal energy production, and grid electricity consumption. Before simulating the power system, HOMER determines the emissions factor for each pollutant (expressed in kilograms emitted per unit of fuel consumed). Following the simulation, annual pollutant emissions are computed by multiplying these factors by the total annual fuel consumption.

Emission factors are directly provided for carbon monoxide, unburned hydrocarbons, particulate matter, and nitrogen oxides. For carbon dioxide and sulfur dioxide, HOMER calculates emissions factors based on the carbon and sulfur content of the fuel. This process relies on three primary assumptions [

26]:

- •

All carbon present in the fuel that is not emitted as carbon monoxide or unburned hydrocarbons is emitted as carbon dioxide.

- •

The fraction of carbon in the emissions from unburned hydrocarbons is identical to the fraction of carbon present in the fuel itself.

- •

All sulfur in the burned fuel that is not emitted as particulate matter is emitted as sulfur dioxide.

2.11. Dispatch Strategy

A dispatch strategy refers to a defined set of rules governing how generators and battery banks operate within a system. HOMER offers modeling for two primary dispatch strategies: cyclic load and load following. The optimal strategy depends on various factors such as generator and battery bank sizes, fuel prices, operational and maintenance costs, the proportion of renewable energy in the system, and the characteristics of renewable resources. When both strategies are modeled, HOMER simulates each system using both approaches, allowing users to determine which strategy is most optimal based on the simulation results.

The Cyclic Charging (CC) strategy operates such that whenever the diesel generator is running, it operates at its maximum capacity. Any surplus energy generated beyond immediate demand is directed towards charging the battery bank. This strategy is typically advantageous in systems where there is limited or no renewable energy available [

2,

17].

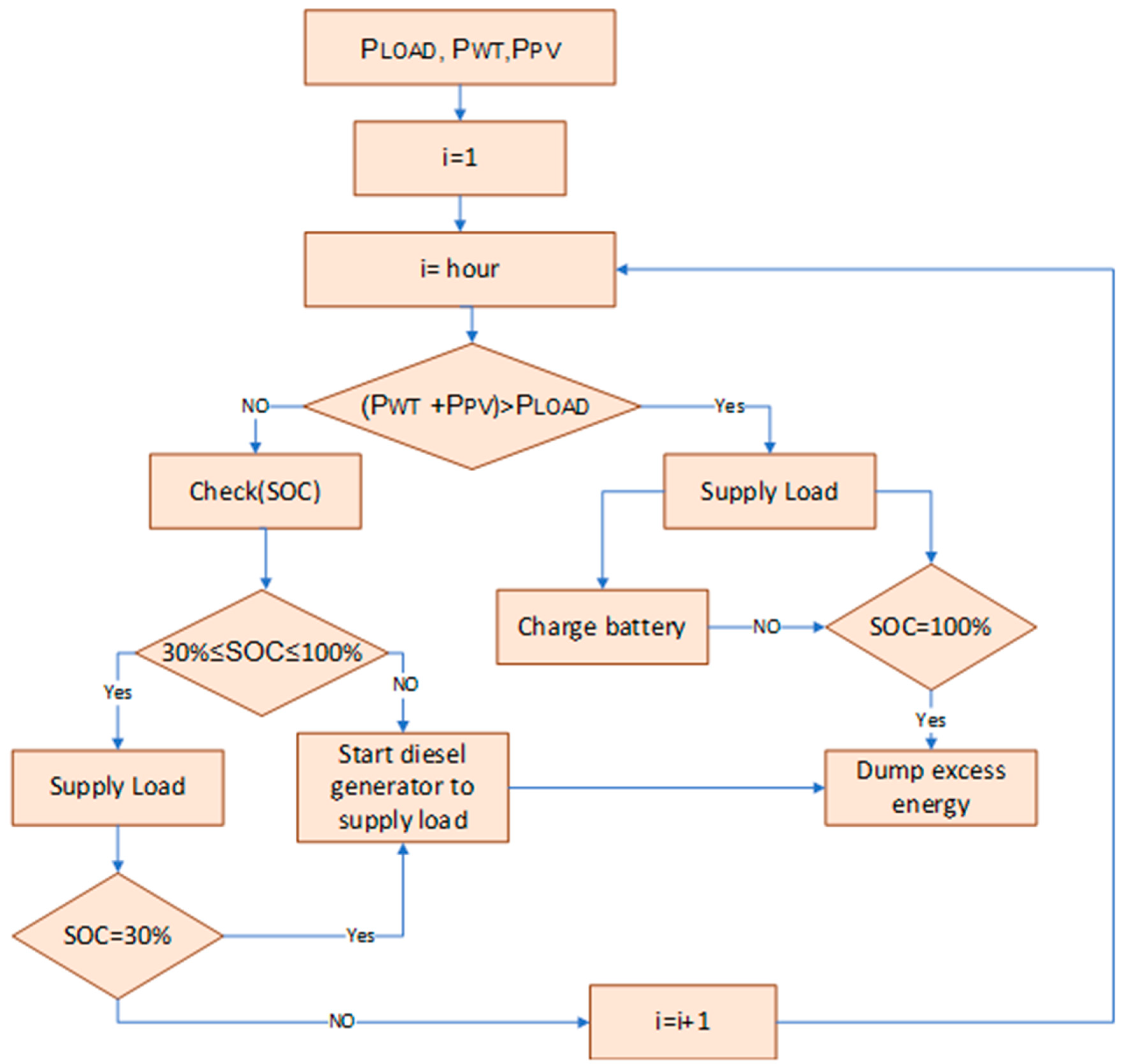

The Load-Following (LF) strategy involves the diesel generator producing enough power to meet current demand whenever it is required without running at full capacity unnecessarily.

Figure 4 shows the Load-Following strategy diagram. LF is usually preferred in systems with various renewable energy sources, where fluctuations in renewable energy production can sometimes exceed the immediate load requirements. For this study, the LF strategy will be employed [

26,

28].

5. Conclusions

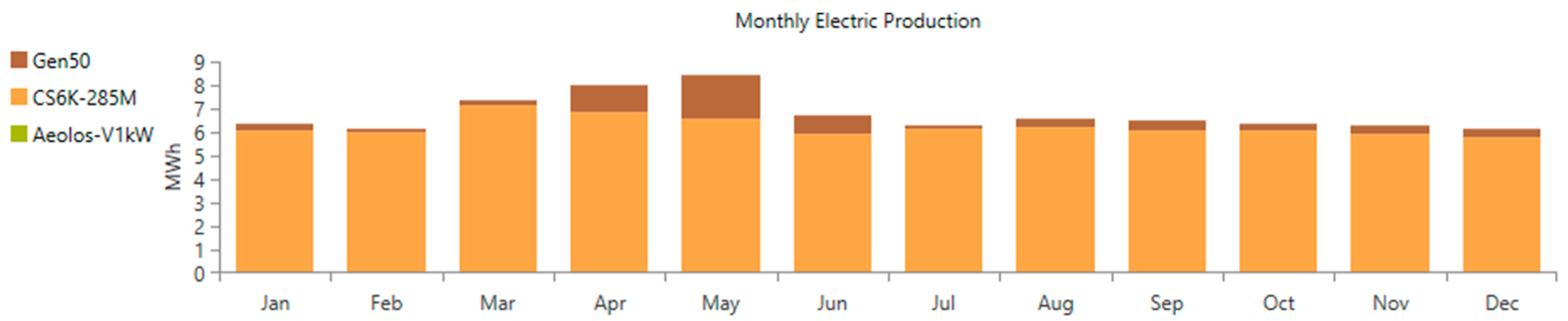

Management strategies employed in hybrid renewable energy systems are chosen based on specific study objectives. Many researchers prioritize techno-economic goals, examining both technical factors like duration, demand fulfillment, and system performance, as well as economic factors such as minimizing costs, maximizing savings, and reducing energy expenses.

To achieve these objectives, researchers utilize various algorithms, including fuzzy logic, particle swarm optimization, neural networks, and specialized software such as HOMER. These tools facilitate monitoring and optimization of components within hybrid renewable energy systems, enabling efficient evaluation of system performance and economic viability. From the scenarios analyzed above, it is concluded that the most appropriate scenario for this location is composed of photovoltaic panel systems, battery systems, and a diesel generator (PV-BESS-DG). Focusing on the PV-BESS-DG scenario shows a combination that stands out for its economic feasibility and operational balance. The PV-BESS-DG scenario demonstrates solid economic feasibility with the lowest NPC of $308,911 and a levelized COE of $0.480/kWh, efficiently integrating PV with BESS and DG. The absence of WT suggests a storage strategy prioritizing efficiency and cost control. Combining PV and BESS allows continuous generation and greater operational autonomy, optimizing available solar resources. Including the DG as strategic support guarantees the reliability of the supply, especially in situations of low solar generation or adverse weather conditions. On the other hand, scenario III, composed of photovoltaic energy and battery storage, is the least profitable of those analyzed despite having the best return on investment. Their high initial capital and replacement costs make the proposed hybrid systems more attractive when making an investment estimated in 25 years.