1. Introduction

Since the early days of the oil industry, human ingenuity has been at work to overcome various challenges. Among these challenges, real-time and precise determination of the tops of the formation and its lithology whereas drilling is of utmost importance to guarantee efficient and safe drilling operations [

1]. Accurate information about the formation tops is essential when designing a casing program, as it is necessary to select the right depths for placing the casing to ensure efficient zonal separation, and to correctly design the correct mud weight in order to keep the wellbore conditions in check [

2,

3,

4].

Drilling engineers in oil fields use four distinct methods to identify different reservoir zones or formation tops: rate of penetration (ROP) charts, gamma-ray (GR) logs, formation cuttings, and mud logging [

5,

6,

7]. These techniques are helpful for drillers to delineate the formation tops, but each one has drawbacks such as high costs, lower accuracy, and substantial labor. Moreover, the majority of these measurements encounter temporal or depth-related delays, which restrict the ability to instantly estimate the formation tops. These limitations pose challenges to the feasibility and efficacy of current techniques employed for formation top determination.

Although lithology significantly impacts the ROP, other drilling parameters also exert considerable influence on ROP fluctuations [

8]. Consequently, relying solely on ROP for estimating lithology changes or formation tops is inadequate, particularly when other drilling parameters experience significant variability. Furthermore, as the wellbore depth increases, there is a noticeable time lag in obtaining geophysical logs or drilled cuttings, which delays the prediction of the currently drilled formation [

6]. Employing techniques such as GR, measurement, or logging while drilling, or mud logging in each section is also economically impractical and does not offer prompt and essential information.

On the other hand, to address these challenges, researchers from the realm of the oil and gas industry have harnessed the power of ML to transform key aspects of this industry. In drilling optimization, Berrehal et al. (2022) [

9] proposed an ML-based approach for a real-time mechanical earth model, enhancing wellbore stability in the Volve field. Similarly, Al-Sudani et al. (2017) [

10] introduced a control engineering system for real-time monitoring of drilling mechanical energy and bit wear, optimizing drilling performance. Meanwhile, for fracturing, Erofeev et al. (2021) [

11] predicted post-hydraulic fracturing oil and liquid production with 80% accuracy, enabling real-time HF candidate selection. In the domain of oil recovery, Ouadi et al. (2023) [

12] introduced high-accuracy models for predicting gas well productivity using Fishbone drilling, demonstrating its potential to enhance hydrocarbon recovery and reduce environmental impact. Although Ahmed et al. (2017) [

13] showcased the potential of AI techniques in estimating oil recovery factors in early-time reservoirs, surpassing existing correlations. Additionally, Hamadi et al. (2023) [

14] presented a robust machine-learning framework to predict key parameters in CO

2 -enhanced oil recovery, delivering superior accuracy and insights for efficient CO

2-EOR design. Furthermore, Mouedden et al. (2022) [

15] proposed FIScreT, a decision-making tool based on fuzzy logic for automating candidate well selection in stimulation processes.

In this paper, we propose an ML-based approach for real-time lithology prediction from drilling data. The results show a remarkable accuracy of 95% in identifying the claystone, marl, and sandstone. Leveraging multiple drilling parameters and the open Volve dataset, our methodology enables real-time lithofacies classification without time lags, significantly advancing geosteering capabilities.

2. Literature Review

Lithology prediction using machine learning has rapidly evolved from early foundational models to an array of sophisticated techniques, integrating real-time data and achieving high accuracy. The initial explorations into the field of lithology prediction were laid by Rogers et al. (1992) [

16], Benaouda et al. (1999) [

17], and Wang and Zhang (2008) [

18]. Utilizing well-log data, these pioneers developed predictive models; however, they faced challenges in predicting thin formations and dealing with missing density logs. As the field progressed, Qi and Carr (2006) [

19] and Al-Anazi and Gates (2010) [

20] contributed to the development of machine-learning models for lithofacies and permeability prediction, using refined artificial neural network (ANN) and support vector machine (SVM) techniques. Moazzeni and Haffar (2015) [

21] highlighted the impact of external factors on drilling parameters, revealing the need for further refinement of these machine-learning techniques. Addressing this need, Raeesi et al. (2012) [

22], Wang and Carr (2012) [

23], and Al-Mudhafar (2017) [

24] introduced the use of Artificial Neural Networks (ANNs) and comprehensive integrated workflows, which significantly improved lithofacies classification.

The challenge of real-time lithology prediction during drilling operations was addressed by Mohamed et al. (2019) [

25] and Nanjo and Tanaka (2019, 2020) [

26], utilizing machine-learning models and image analysis methods. Elkatatny et al. (2019) [

27] took a significant step towards real-time prediction, using ANN models to determine formation tops based on drilling parameters. Gupta et al. (2020) [

28] designed a real-time machine-learning workflow for lithology prediction during drilling, marking a milestone in the field.

In their research, Zhang and Baines (2021) [

29] explored machine-learning models such as ANN, SVM, and CNN, which yielded promising results, especially the 2D CNN combined with PCA feature extraction. Similarly, Wei Zhoucheng et al. (2019) [

30] proposed a multi-well lithology identification method that involved feature engineering, machine-learning model training, and optimal model selection. Additionally, Aniyom et al. (2022) [

31] demonstrated the potential of ensemble methods to improve lithology prediction performance through the development of a voting classifier machine-learning model.

Several studies have integrated additional features or methods into their models to improve classification performance. Xi Chen et al. (2020) [

32] combined the Reducing Error Correcting Output Code algorithm with the Kernel Fisher Discriminant Analysis, outperforming conventional methods. Jiang et al. (2021) [

33] introduced a stratigraphic unit as an additional feature, significantly improving lithology classification. Zerui Li et al. (2020) [

34] proposed a semi-supervised lithology identification workflow using a Laplacian support vector machine, enhancing classification performance by utilizing feature and depth similarities.

Mou et al. (2016) [

35] employed support vector machine models to estimate volcanic lithology in the Liaohe Basin, China, achieving high accuracy. In another study, Moazzeni et al. (2015) [

21] accurately predicted formation and lithology in the South Pars gas field, Iran, using artificial neural networks. Similarly, Wang De-ping et al. (2007) [

36] attained a 96% correctness rate in predicting lithology in the Bayantala oil field by utilizing an SVM model. These studies focused on specific geological contexts and demonstrated impressive accuracy levels.

Flexible and adaptive models have been explored for lithology prediction. Jia et al. (2012) [

37] demonstrated the efficacy of an adaptive neuro-fuzzy inference system for lithology identification from well-log data. Cheng et al. (2010) [

38] combined a particle swarm optimization (PSO) algorithm with the least squares support vector machines (LSSVM) for higher precision lithology identification.

Sebtosheikh and Salehi (2015) [

39] employed support vector machines (SVMs) with various kernel functions for accurate lithology prediction in a multilayered carbonate reservoir in Iran. Building on this, Avanzini et al. (2016) [

40] presented a workflow using cluster analysis to identify productive sweet spots in unconventional reservoirs, focusing on the Barnett Shale Formation. In a different approach, Gu et al. (2019) [

41] achieved high (>75%) lithology prediction accuracies by integrating CRBMs and PSO into PNNs. Additionally, Imamverdiyev and Sukhostat (2019) [

42] introduced a deep learning 1D CNN model that outperformed other methods in geological facies classification.

Moazzeni et al. (2019) [

43] made significant advancements through their research about real-time prediction models by developing an ANN model optimized with a genetic algorithm and Taguchi experimental design for lithology and formation prediction. In a related study, Zhang and Baines (2021) [

29] demonstrated the potential of real-time models with their 2D CNN model, achieving over 90% accuracy in identifying four lithology classes. These notable developments have contributed to the progress of real-time prediction techniques.

Finally, recent studies have demonstrated the feasibility of rapid, automated lithology prediction. Popescu et al. (2020) [

44] created a supervised machine-learning pipeline that enabled rapid, scalable, and confident lithology prediction. Ao et al. (2019) [

45] combined mean–shift feature extraction and random forest classification to improve prediction accuracy. Zhang et al. (2017) [

46] used a convolutional neural network for accurate lithology identification from borehole images with a success rate of about 95%.

3. Exploratory Data Analysis

Effective supervised machine learning depends on high-quality data. Meticulous data collection is vital, aiming for near-error-free and pertinent information. Rigorous statistical analysis precedes model development to assess data distribution, remove outliers, and validate parameter relationships. This data-driven approach establishes a strong foundation for accurate and reliable predictive models.

3.1. Data Collection and Description

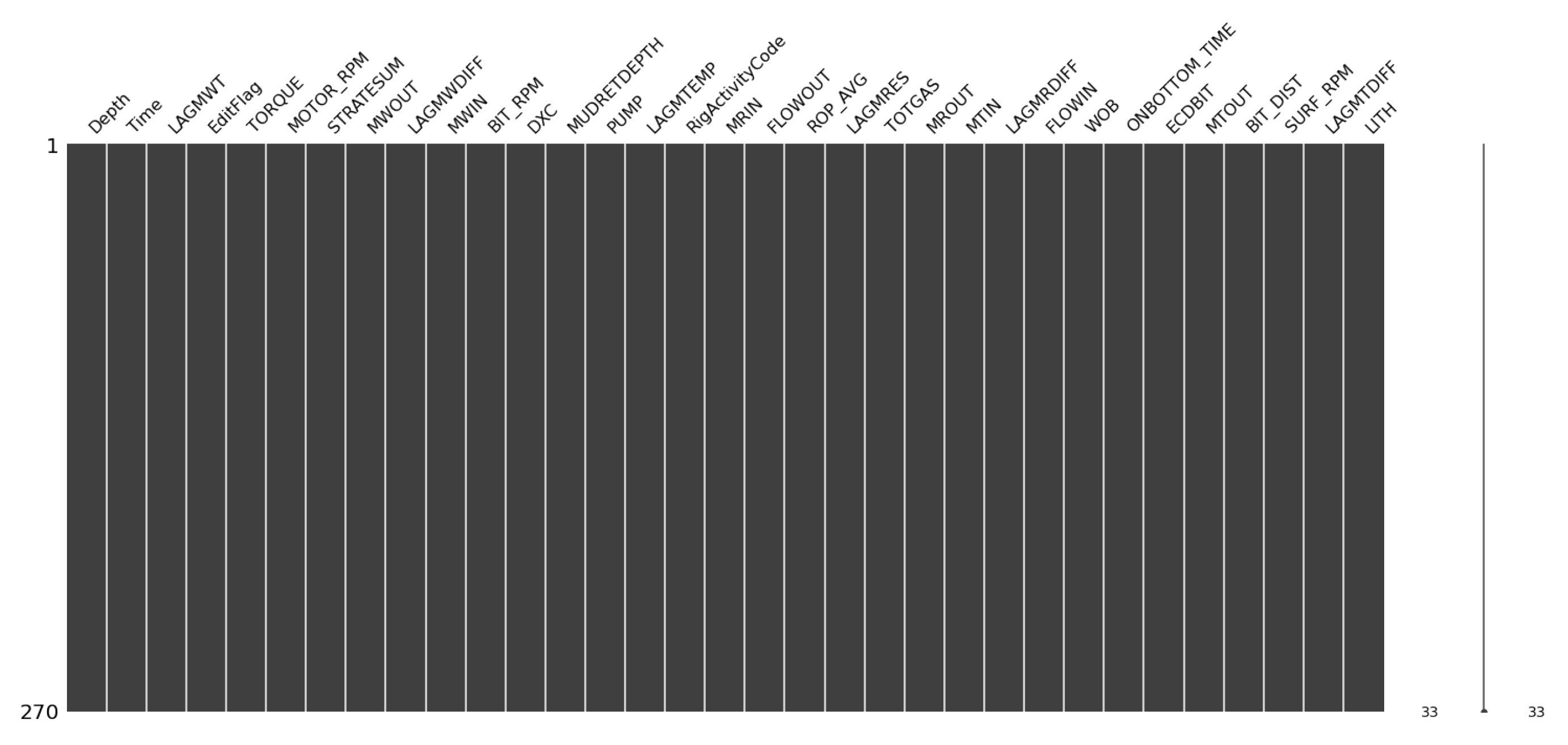

Our analysis revolves around data from two wells originating from Equinor’s open database, more precisely the Volve field in the North Sea. Each well’s dataset comprises 33 columns; 2 columns (Depth and Time) are called the identifiers as we obtain the measurements at each depth in real time, 30 columns are the measured magnitudes obtained from the drilling data with more than 440 observations. Guided by our objective of real-time lithology prediction, we prioritize instantaneous drilling parameters to capture the subsurface formation’s immediate response. Consequently, features like LAGMRES, LAGMRDIFF, and others, which represent lagged or derived measures, were excluded to prevent redundancy and potential multicollinearity. Operational indicators such as EditFlag and RigActivityCode were also omitted due to their lack of direct relevance to formation characteristics. Aggregate measures, like MOTOR_RPM and MTOUT, were discarded to ensure the model’s sensitivity to real-time changes. This targeted selection facilitates efficient and precise modeling, in line with our core objective of immediate formation insight. The last column, abbreviated as LITH, is the lithology label sourced from mud logging data, and as demonstrated in

Figure 1, each column consists of 270 rows without any missing values.

Within the dataset, the 30 columns represent.

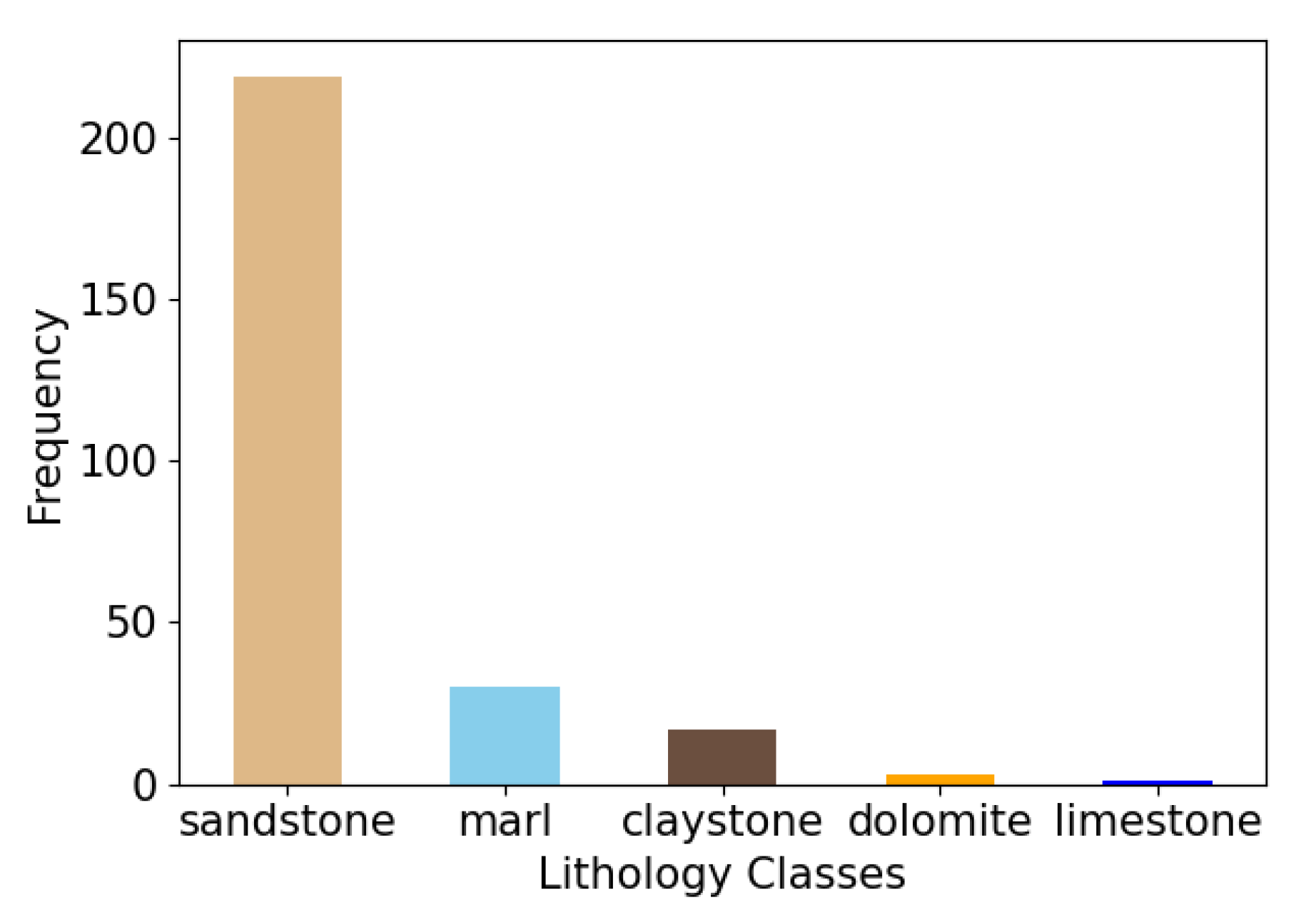

During the investigation of the LITH column, we encountered a diverse array of lithologies, categorized into five distinct classes: sandstone, marl, claystone (shale), dolomite, and limestone (see

Figure 2). Given the limited observations for limestone and dolomite, our analysis primarily focused on sandstone, marl, and claystone for classification purposes.

3.2. Oversampling of the Imbalanced Class

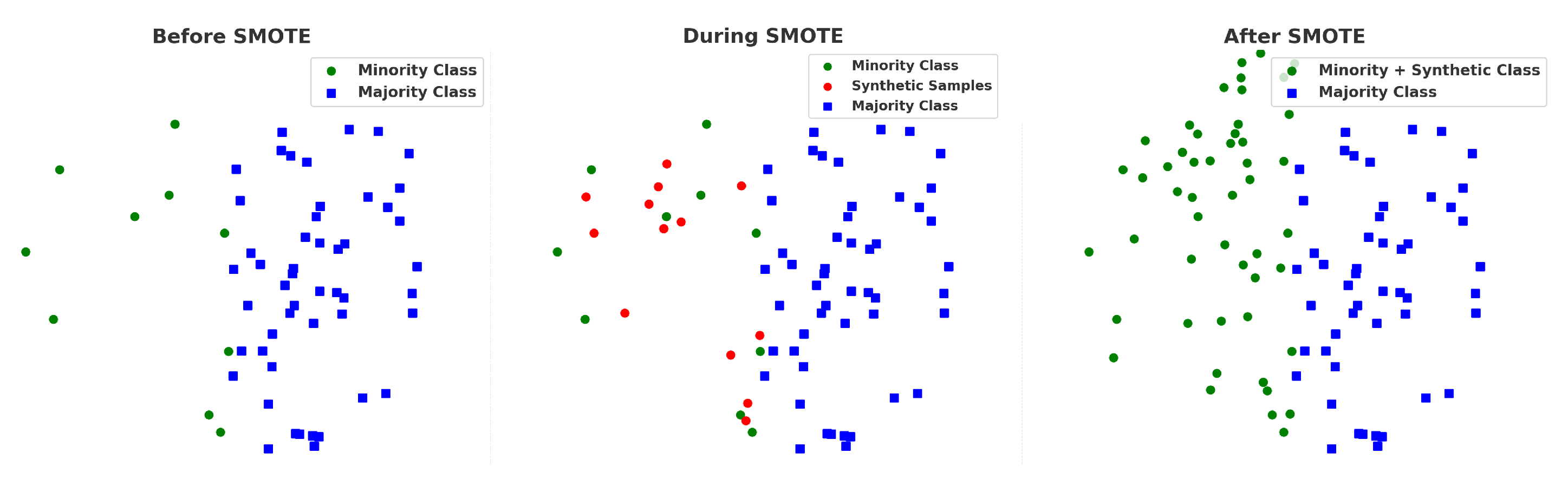

To address the class imbalance in the dataset, we applied the SMOTE technique, which creates synthetic samples for the under-represented classes. Moreover, Insights about this technique from R. Blagus et al. (2013) [

47] further guided our approach, as illustrated in

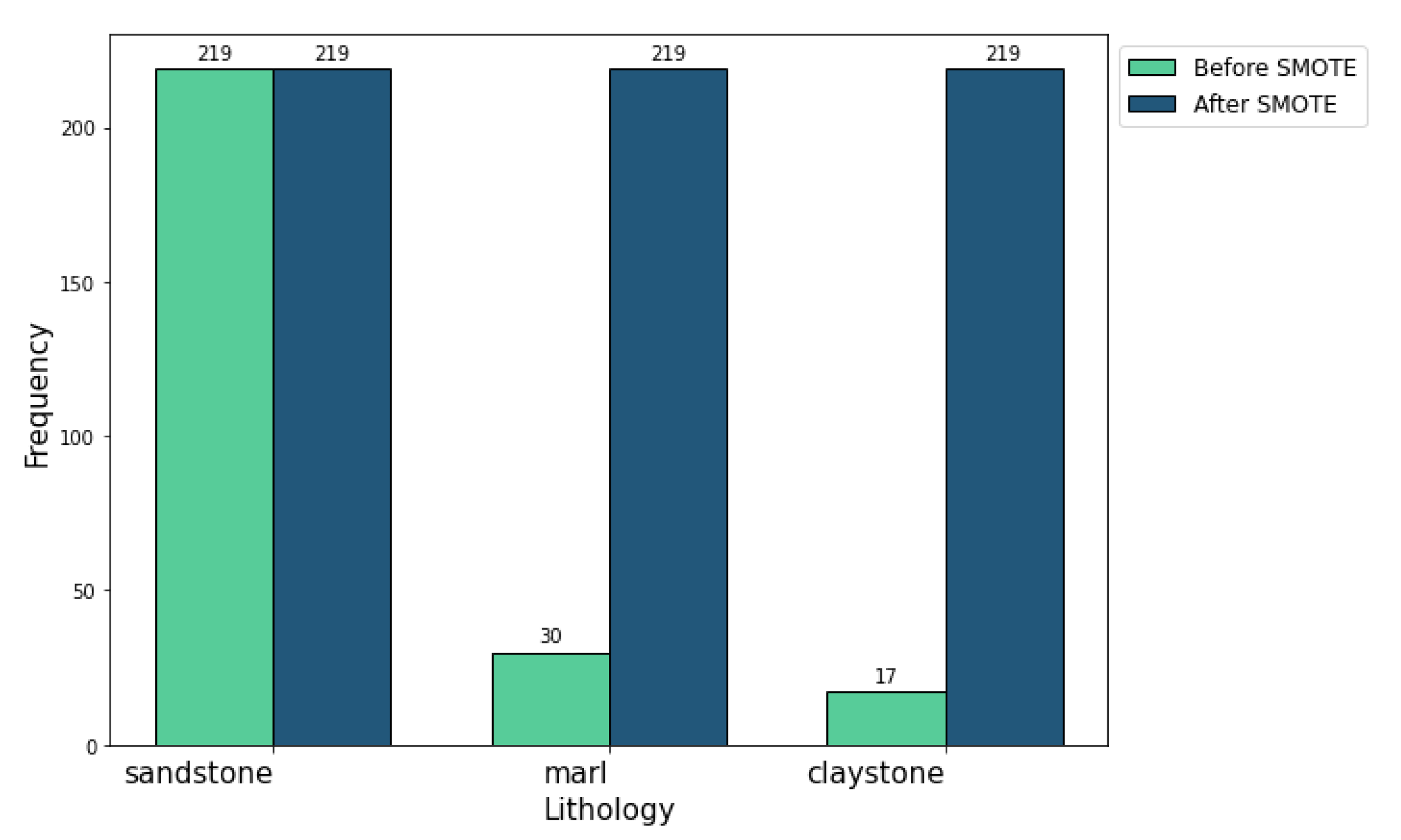

Figure 3. Originally, we had 219, 30, and 17 samples for sandstone, claystone, and marl, respectively. After using SMOTE technique, each class was balanced, resulting in 219 samples for each class, as depicted in

Figure 4.

The balanced dataset will be later partitioned for modeling after feature selection, with feature variables (X) and the target variable (Y) split in a 70:30 ratio. Consequently, our testing set encompassed 195 samples, with 65 from each class, whereas the training set held the residual 70%. Further details on this process and its outcomes are elaborated in the random forest classifier implementation section.

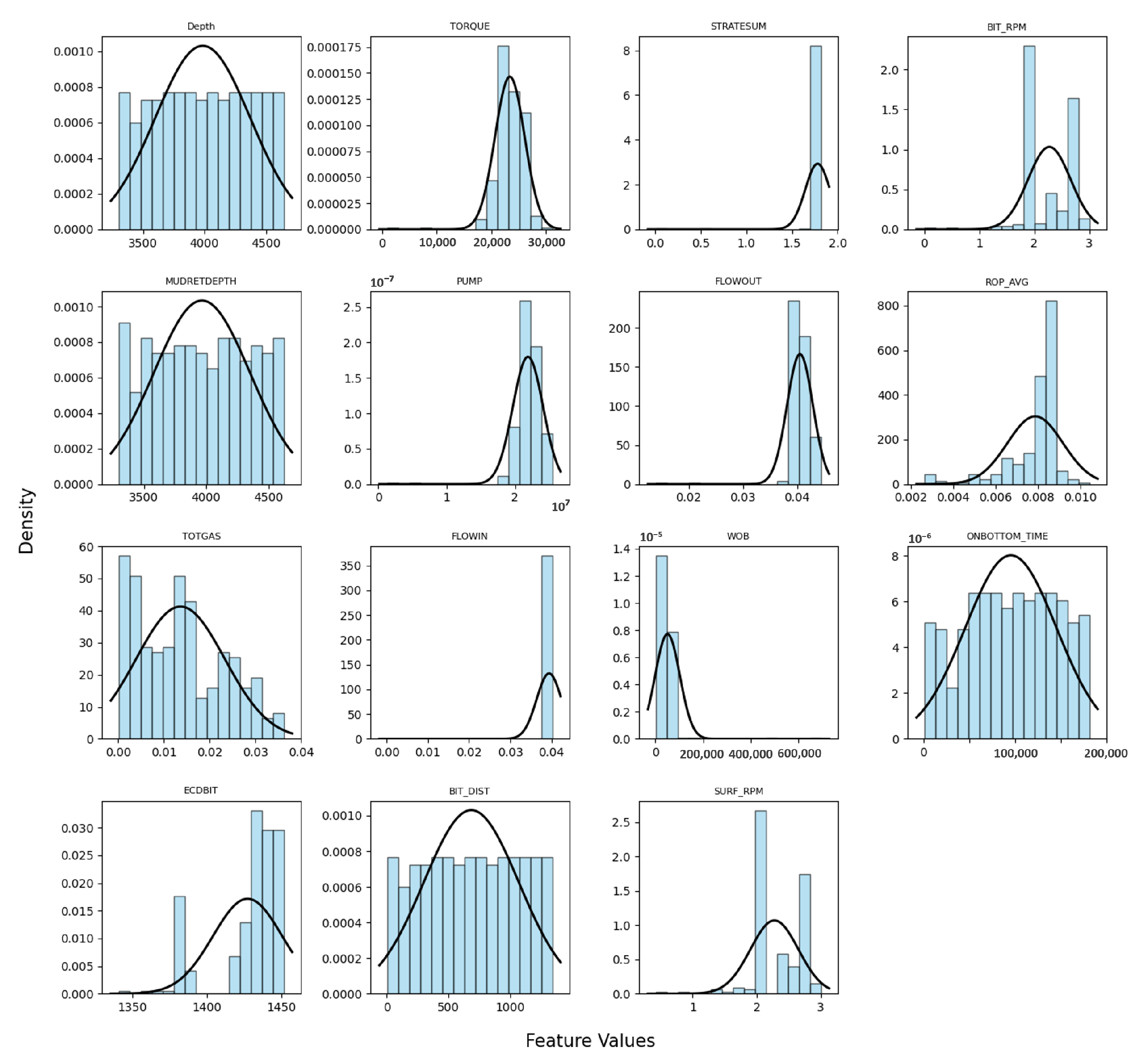

Figure 5 showcases raw data distribution histograms, highlighting the initial step in our approach to predicting underground lithology through drilling data, complemented by a normal distribution curve illustrating a bell-shaped pattern commonly seen in various natural phenomena and statistical processes [

49]. These histograms provide a direct visual insight into the distribution patterns. The horizontal coordinates (X-axis) illustrate the feature value range. An example is the “Depth” feature, where the x-axis delineates depths from the dataset’s minimum to maximum values. The vertical coordinates (Y-axis) depict data point frequency within a range. In histograms, the y-axis quantifies the occurrences of specific value ranges in the dataset. This comprehensive visualization of data patterns serves as the foundation for our machine-learning model’s training. By understanding the nuances and variations in parameters like rate of penetration (ROP) and others, we can better tailor our prediction algorithms. Moreover, these distributions shed light on the potential outliers or anomalies that might skew the model’s performance. The raw data distribution graphs, therefore, serve as an initial checkpoint, ensuring that the data we feed into our webb app are not only representative of real-world drilling scenarios but are also devoid of biases that could undermine the model’s predictive capabilities.

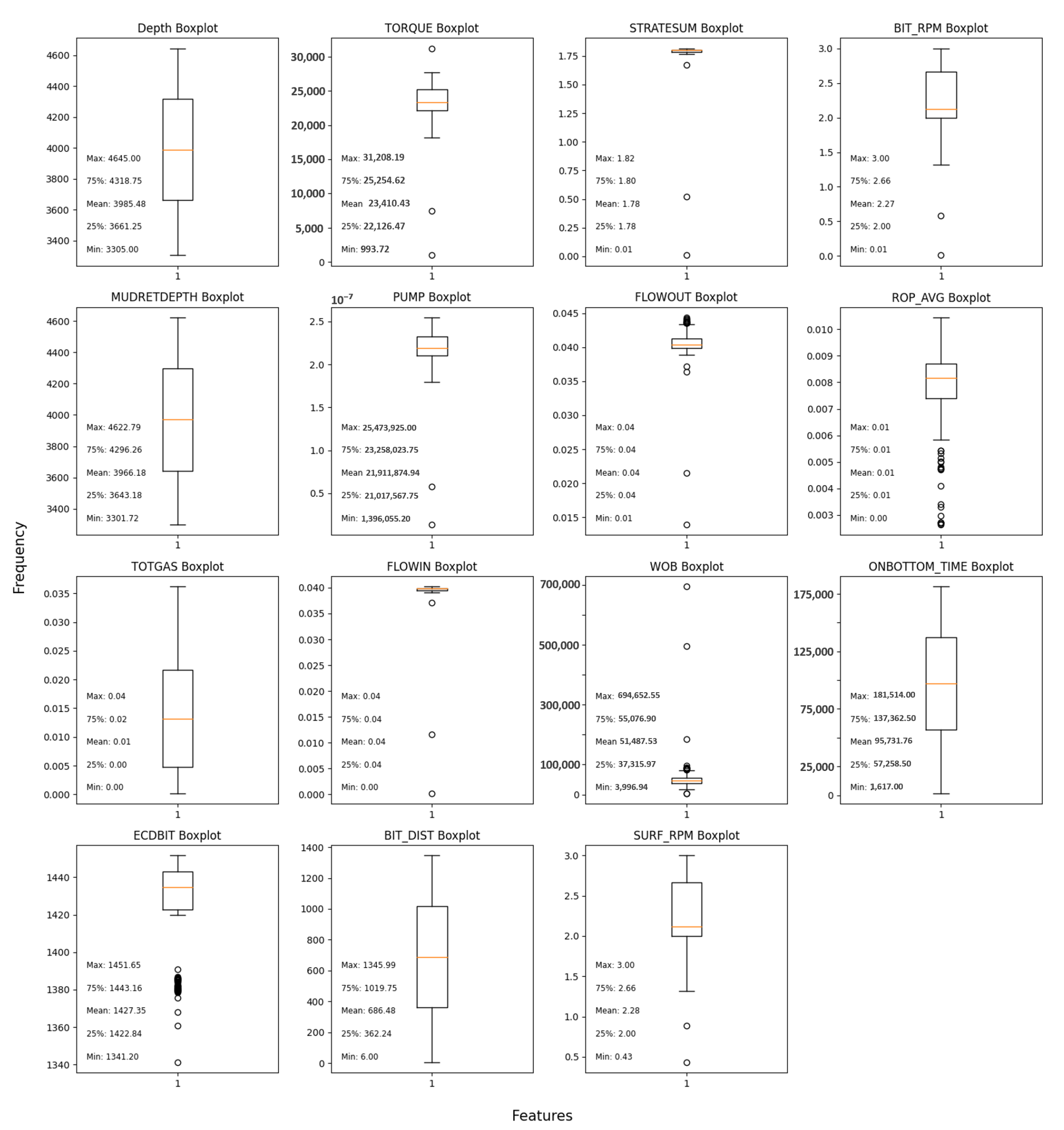

Figure 6 presents box plots before automated outlier removal, showing central tendency and dispersion. Boxes represent the interquartile range (middle 50% of data), with lines indicating medians. Whiskers extend to the minimum and maximum data points (excluding outliers), and relevant statistics are displayed at the top left of each plot.

To ensure the integrity and accuracy of our analysis, it is essential to identify and handle outliers, which are extreme data points that deviate significantly from the majority of the data. Outliers can arise due to various factors such as measurement errors, data entry mistakes, or rare occurrences. If left untreated, outliers can distort statistical analyses, leading to misleading conclusions and unreliable predictions.

To address this issue, we employed the Interquartile Range (IQR) method for outlier detection and removal. For each column, we calculated the first quartile (Q1) and third quartile (Q3) values. The Interquartile Range (IQR) was then determined as the difference between Q3 and Q1. Any data point that fell below (Q1 − 1.5 × IQR) or above (Q3 + 1.5 × IQR) was considered an outlier and subsequently removed from the dataset [

50].

By applying the IQR method, we effectively identified and eliminated outliers while preserving the majority of the data that represent the underlying distribution. This approach ensures the robustness and reliability of our analysis, allowing us to draw meaningful insights from the data.

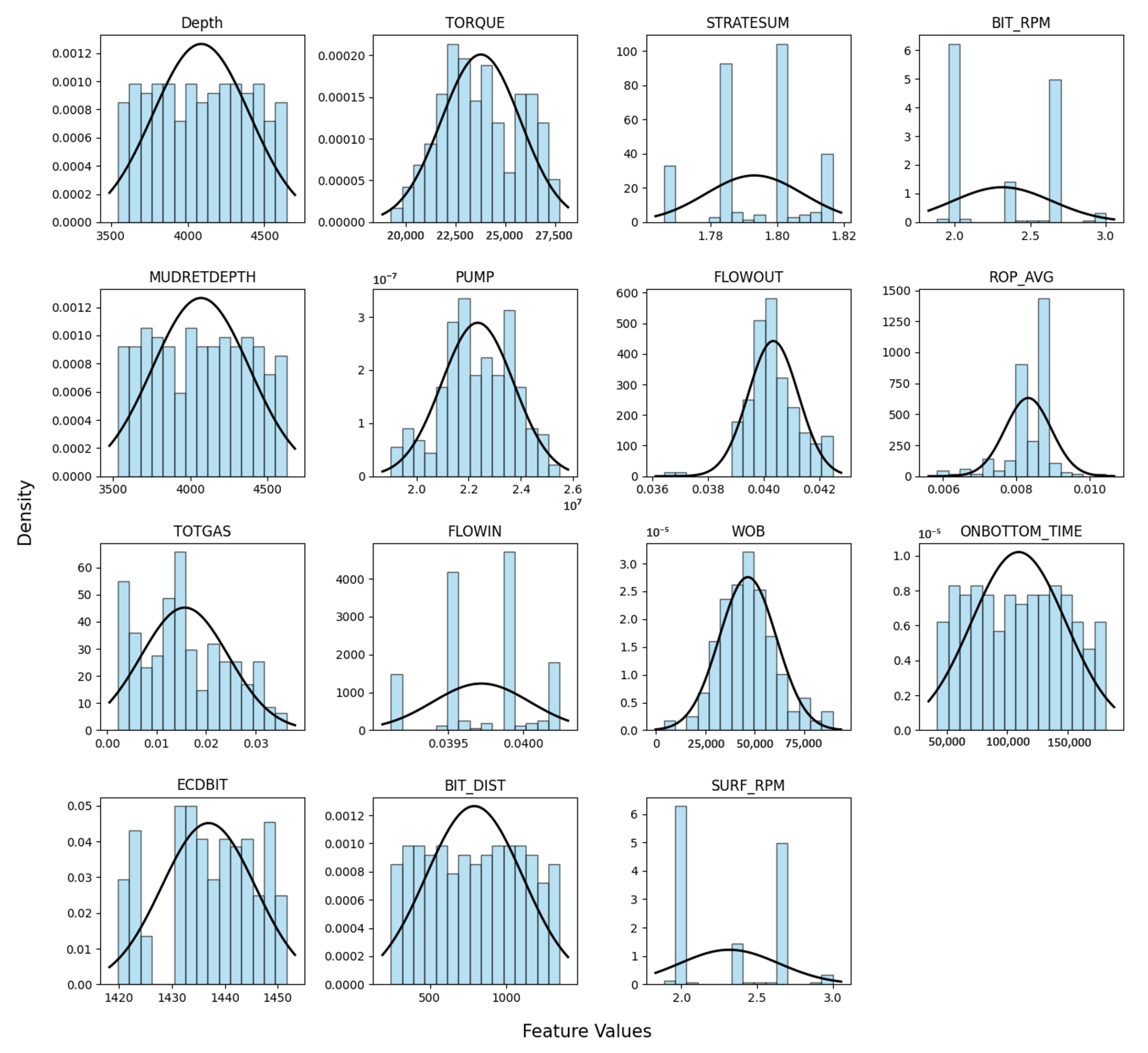

After outlier removal, the distribution may exhibit a more refined and meaningful pattern, which can be observed in the subsequent histograms (

Figure 7).

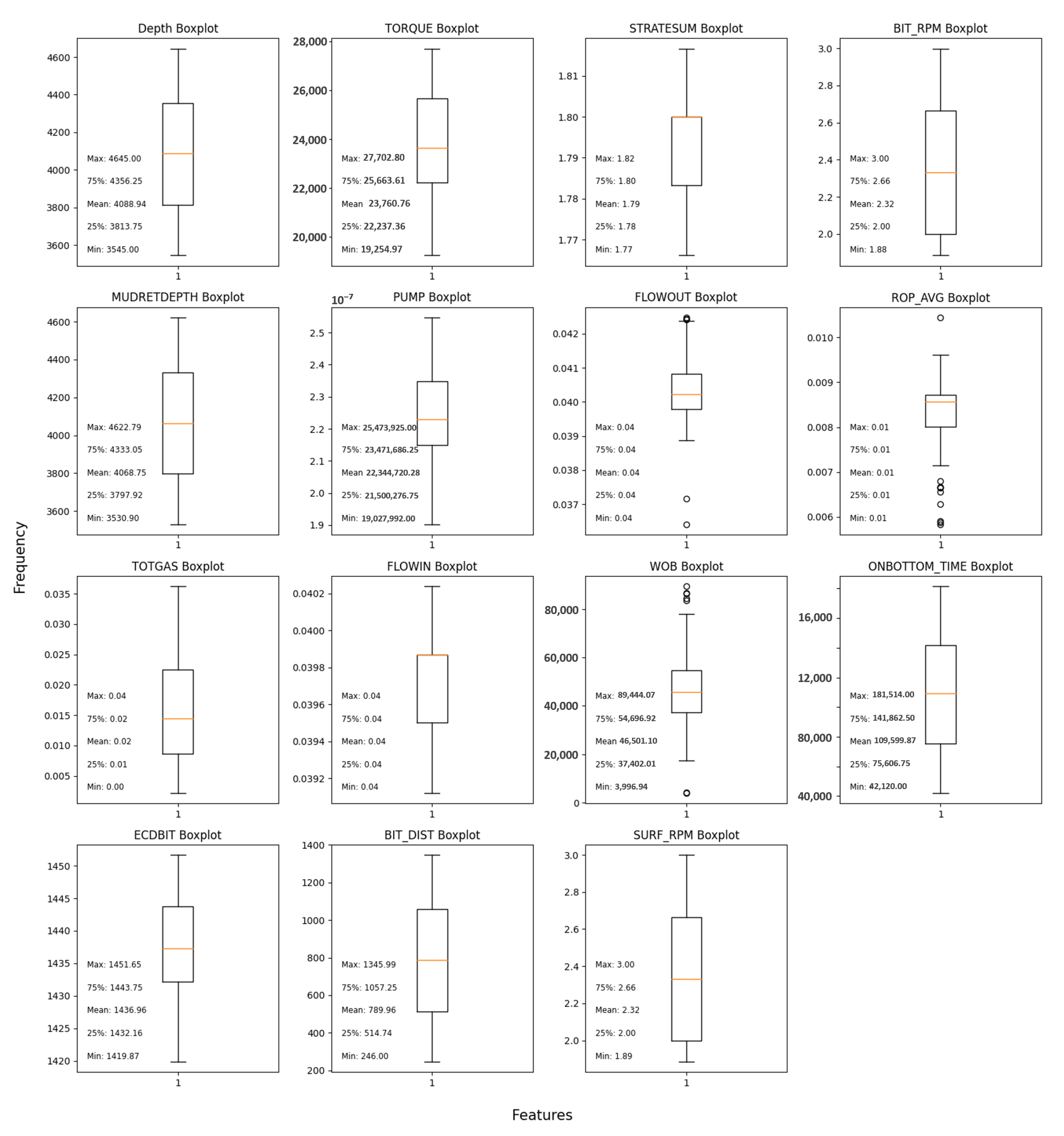

After deploying the Interquartile Range (IQR) method to treat outliers, the boxplots in

Figure 8 vividly underscore the dataset’s transformation. Specifically, attributes such as ECDBIT and ROP_AVG now exhibit a tighter and more precise data distribution, clearly indicating the effective removal of extreme values. For instance, the constricted range of ECDBIT suggests a consistent enhancement in drilling efficiency across the dataset. Similarly, the ROP_AVG attribute’s spread has been significantly tightened, reflecting a more uniform average rate of penetration. Moreover, this meticulous data refinement process also rectified anomalies like the physically implausible negative values in the WOB feature. Such diligent data preprocessing not only illuminates central tendency and dispersion more clearly but also sets a robust and reliable foundation for the subsequent predictive modeling stages of our analysis.

For comprehensive details about the features and their corresponding representations, please consult

Table A1 in

Appendix B.

3.3. Feature Selection

During the analysis of drilling data, a substantial number of abbreviated measurements were obtained. To streamline the dataset for further analysis and facilitate faster model training, we conducted feature selection by eliminating erroneous and redundant features, ensuring the integrity of our predictive model.

3.3.1. Erroneous Features

Erroneous features refer to those in the dataset that offer limited or redundant information when classifying the target variable. These features may consist of constant or uniform values, reducing their usefulness in predictive modeling. It is crucial to identify and address such features to optimize the dataset and enhance the efficiency of the predictive model. Descriptive statistics play a pivotal role in detecting erroneous features. Through a thorough examination of the summarized data (see

Table 1), we can identify features that may necessitate removal or further investigation, ensuring the integrity and accuracy of our analysis.

Several features in the drilling data exhibit constant values, as evident from their identical mean, minimum, maximum, and percentiles. RigActivityCode and DXC fall into this category, rendering them erroneous and unsuitable for meaningful analysis. RigActivityCode appears to be a mere annotation without any informative value, whereas DXC lacks variability, diminishing its relevance in our predictive model. Similarly, MWIN and LAGMTDIFF reveal uniform percentiles along with the maximum and minimum, further confirming their erroneous nature.

Moreover, another approach to identifying erroneous features involves assessing the percentage of data containing zeros. In

Table 2, we have calculated the percentages for each feature. Notably, LAGMWDIFF contains a substantial 81% of zero values, solidifying the rationale for eliminating this feature from our dataset.

3.3.2. Redundant Features

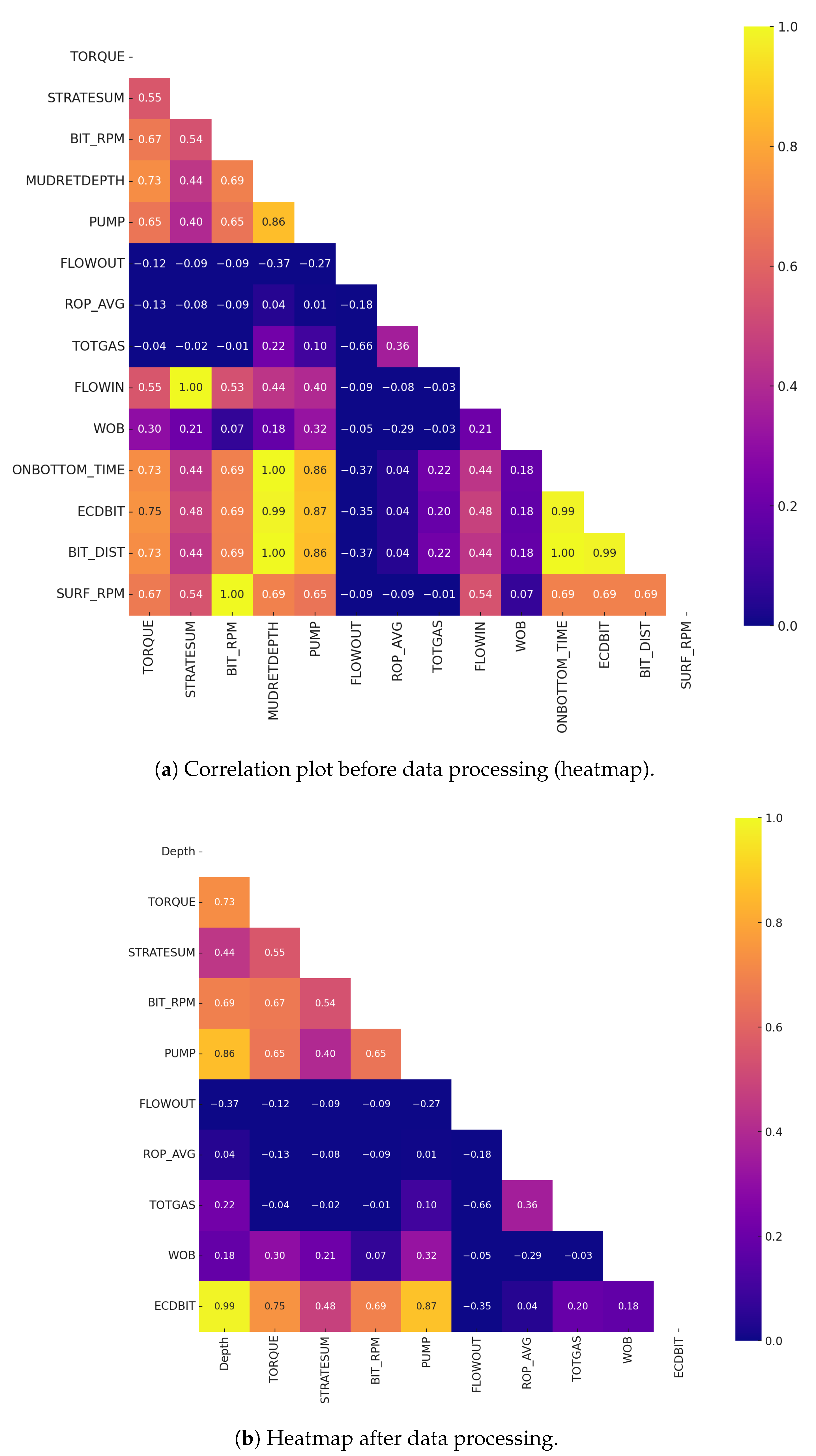

Redundant features have high correlations among them. To quantitatively assess these correlations, a heatmap is plotted using the Spearman correlation method (see

Figure 9a), which is a non-parametric measure, is employed to assess monotonic relationships between variables. Its advantage lies in its ability to capture correlations in non-linear datasets, making it suitable for comprehensive analyses in cases where linear relationships might not hold [

51].

Upon identifying highly correlated features using

Figure 9a, a careful selection process is undertaken to remove redundant variables, supported by domain knowledge. For instance, SURF_RPM (rotation per minute on the surface) is correlated with BIT_RPM (rotation per minute at drill bit) due to the inherent relationship between the rotation measured at the surface and the bit. Consequently, SURF_RPM is excluded from the dataset. Similarly, MUDRETDEPTH, BIT_DIST, and ONBOTTOM_TIME, exhibiting correlations, are removed.

Regarding FLOWIN (incoming mud flow), its association with STRATESUM (total stroke rate) is attributed to the pump measurement received when mud flows in. Thus, FLOWIN is selected for removal. In contrast, FLOWOUT (outgoing mud flow) is found to have no significant correlation with STRATESUM, as the outflow is not determined by the inflow. Consequently, both FLOWOUT and STRATESUM are retained in the dataset for further analysis. To explore the remaining features, refer to

Figure 9b for the heatmap after removing redundant features.

3.3.3. Selected Characteristics

After a careful review, we successfully streamlined the initial set of 33 features to a refined selection of 9 key characteristics. The chosen features are as follows:

TORQUE: Average surface torque (N.m);

STRATESUM: Total pump strokes rate (spm);

BIT_RPM: Rotation per minute at drill bit (c/s);

PUMP: Pump pressure (Pa);

FLOWOUT: Outgoing mud flow (m3/s);

ROP_AVG: Average rate of penetration (m/s);

TOTGAS: Total gas content (ppm);

WOB: Weight on bit (N);

ECDBIT: Effective circulation density on bit (kg/m3).

The log-style plot provides valuable insights into the behavior of selected characteristics in relation to changes in lithology types at different depths. Notably, as we drill through the marl formation (represented by the light blue color), we observe an increase in BIT_RPM and WOB. This can be attributed to the nature of marl, which tends to be more compact and challenging to penetrate. As a result, higher rotational speeds and increased weight on the bit are necessary to maintain drilling efficiency and progress through this lithology.

Conversely, during drilling through sandstone (depicted in Beige), we notice an increase in ROP (rate of penetration) and TOTGAS. Sandstone formations often exhibit more porous and permeable characteristics, allowing for smoother drilling operations and higher penetration rates. Additionally, the increase in TOTGAS could indicate the presence of gas-bearing zones within the sandstone, potentially impacting drilling performance (see

Figure 10).

Our exploratory data analysis employs the pair plot that visualizes pairwise relationships between different variables in the dataset, segmented by the type of lithology. Each plot shows a different pairing of variables, with histograms along the diagonal representing the distribution of a single variable for each lithology (see

Figure 11). It is evident that each lithology type exhibits distinct patterns and relationships between variables, reflecting the unique physical properties of each rock type. However, due to the high dimensionality of the data, further specific analysis is needed to tease out more detailed interpretations of the relationships between variables.

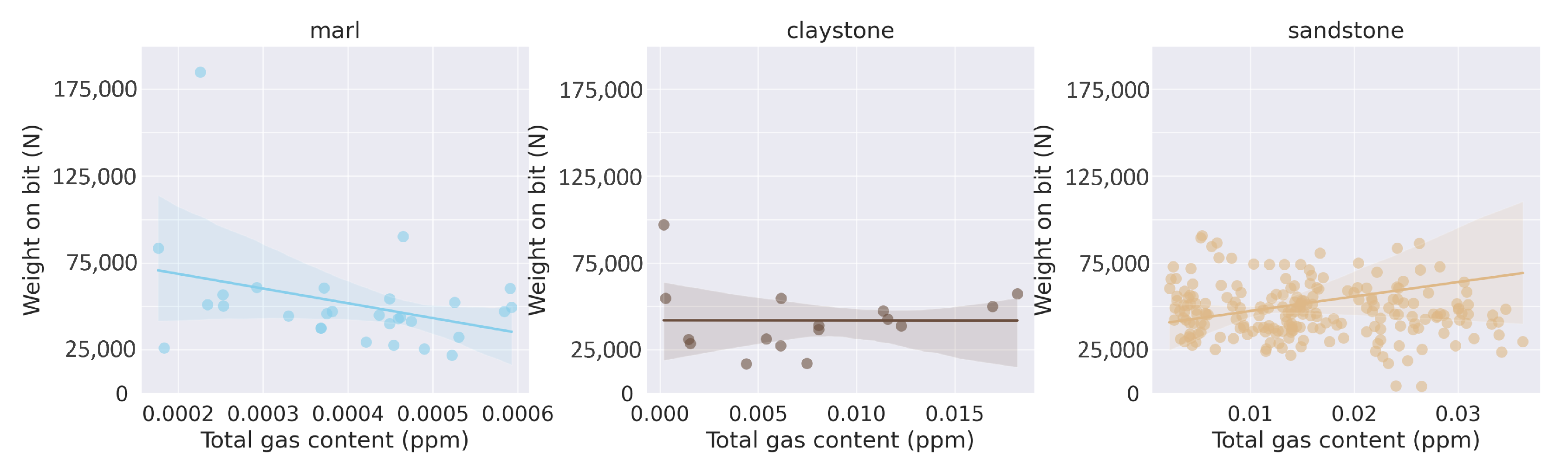

In the next phase of our exploration, we zoom into this expansive landscape and focus on two salient examples, shedding light on the correlations between total gas content and two pivotal drilling parameters, as showcased in

Figure 12 and

Figure 13.

The scatter plots (see

Figure 12) demonstrate varying degrees of positive correlation between the total gas content (TOTGAS) and the weight on bit (WOB) across different lithologies. Marl shows a slight positive correlation, claystone exhibits a stronger positive correlation as indicated by the steeper upward-sloping trend line where the points are more closely clustered around the trend line, and sandstone reveals a weak positive correlation due to the wide spread of points. This suggests that the physical characteristics of the lithology, such as porosity, permeability, and gas capacity, could influence the relationship between gas content and weight on the bit. For instance, claystone, which is typically less permeable, might require a higher weight on the bit to achieve efficient drilling, especially in gas-rich sections. Conversely, sandstone, known for its higher porosity and permeability, might allow more efficient gas flow, leading to a less pronounced increase in weight on the bit with higher gas content. However, these are preliminary observations and would require further, more detailed analysis to ascertain the exact nature and significance of the relationships observed.

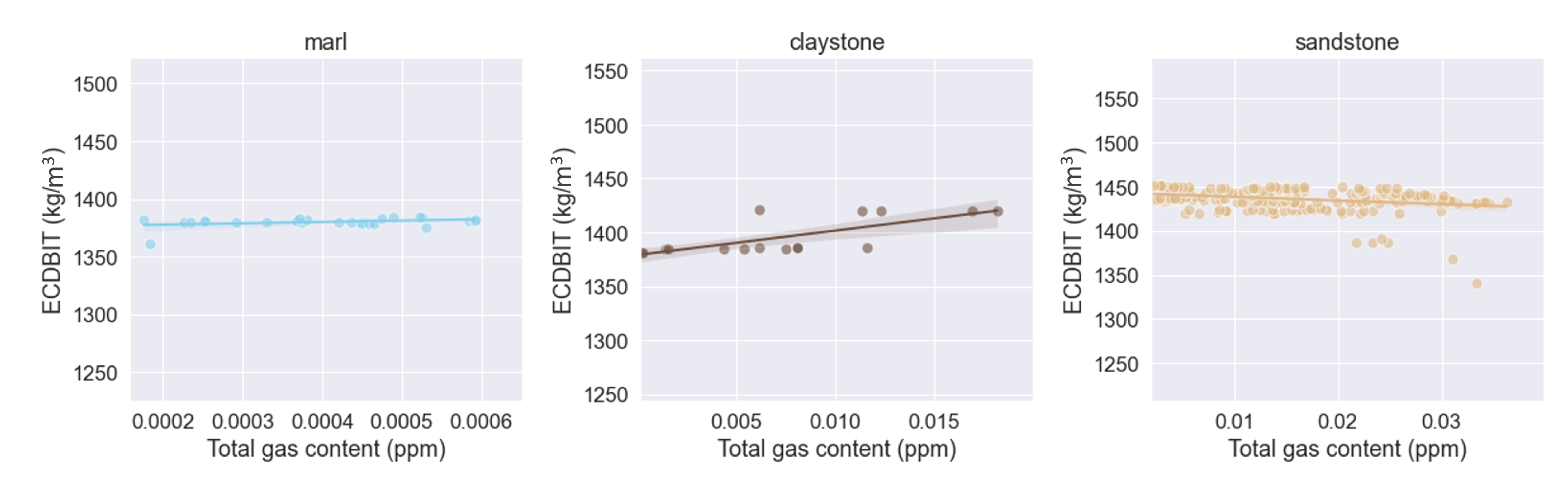

Our attention then shifts to

Figure 13, which illustrates the relationship between total gas content (TOTGAS) and effective circulation density on the bit (ECDBIT) across different lithologies: marl, claystone, and sandstone via scatter plots. The ECDBIT represents the pressure exerted by the drilling fluid at the bit, which can affect drilling efficiency. The plots reveal varying patterns across lithologies. In the case of marl, a weak negative correlation is observed, suggesting that as gas content increases, the pressure exerted by the drilling fluid decreases. This could be attributed to the high clay content in marl, which swells in the presence of water and may restrict fluid flow. For claystone, a slight positive correlation is observed, which could indicate that the denser and less permeable nature of this lithology requires increased drilling fluid pressure to extract gas. Lastly, for sandstone, the correlation appears to be quite weak, possibly due to its high porosity and permeability allowing gas to flow more freely without significantly affecting the pressure of the drilling fluid. However, further detailed analysis would be required to confirm these interpretations and understand the underlying mechanisms.

5. Results Summary

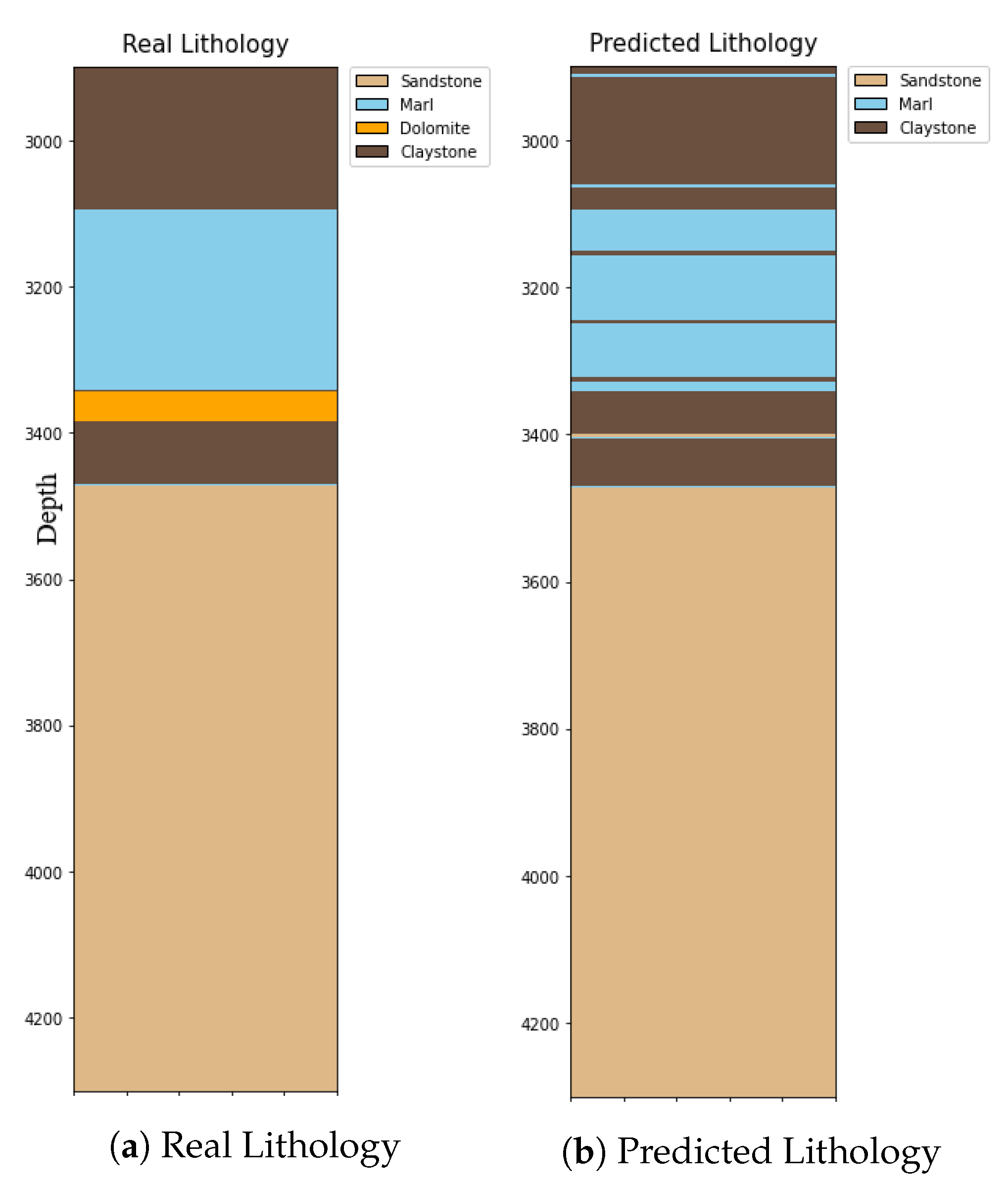

After building our model with well 1 data as the foundation, we meticulously evaluated its performance within this same dataset. The assessment involved comparing predicted and actual lithology results, revealing the model’s impressive accuracy in capturing lithological patterns (see

Figure 17). The model demonstrated success rates of 100% for sandstone, 88% for claystone, and 96% for marl, yielding an overall success rate of 99%. These results reflect the model’s capability to learn meaningful relationships from the provided drilling parameters and effectively predict the majority of lithologies present in well 1.

Expanding on the promising results achieved, the model’s adaptability was then put to the test through a comprehensive blind assessment. Well 2 was chosen as an entirely novel dataset, unassociated with the model’s training. This strategic selection aimed to evaluate the model’s generalization capacity. The model achieved success rates of 100% for sandstone, 87% for claystone, and 94% for marl in well 2. However, when considering Dolomite, which the model was not trained on, its prediction success was 0%. Notably, if well 2 did not encompass the Dolomite lithology, the overall success rate would have stood at 93%. Given its presence, the overall success rate was adjusted to 70% (refer to

Figure 18).

The success rate for each lithology is computed as:

where

n represents the number of lithologies.

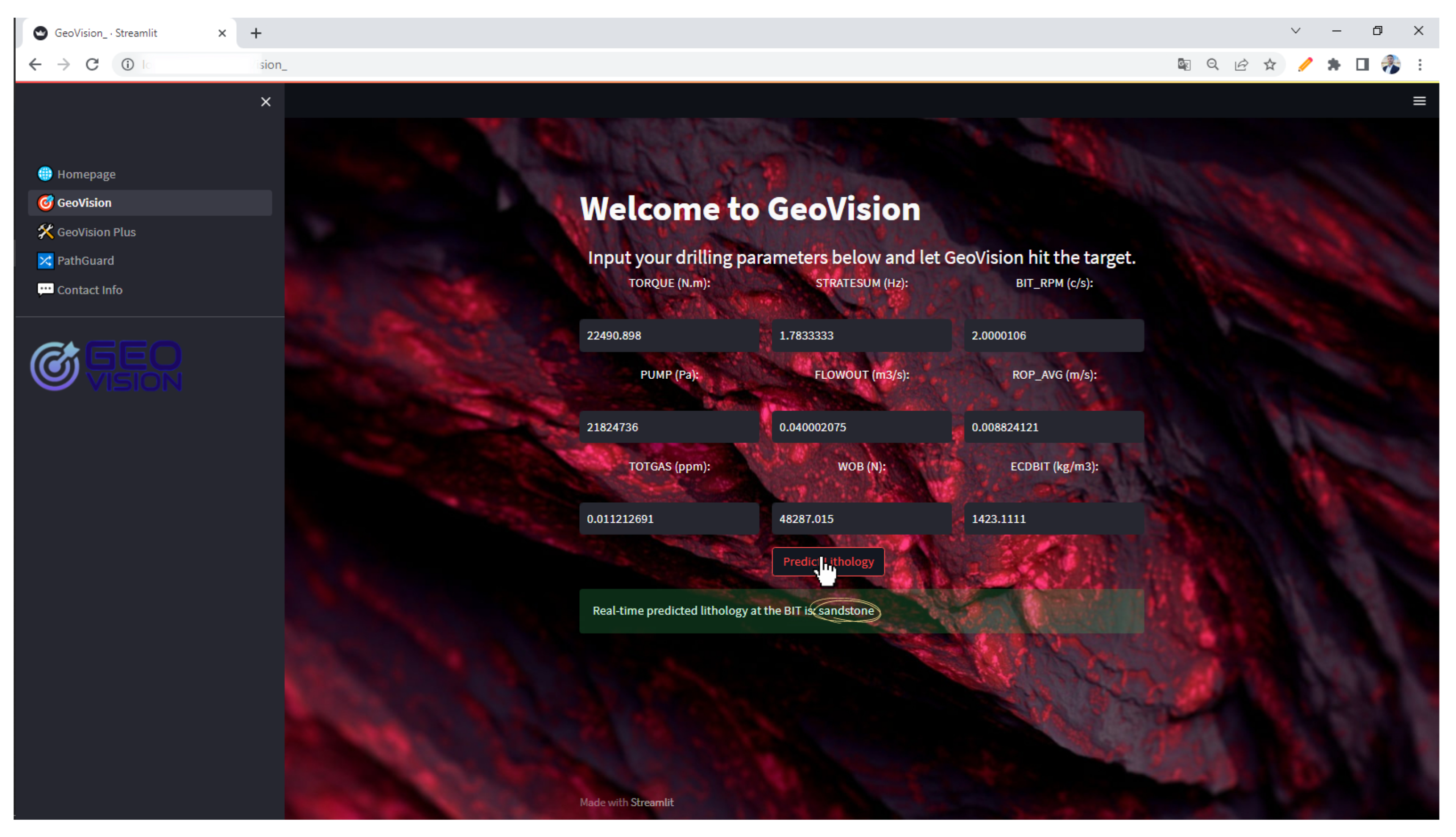

Model Deployment

Once the model was trained and evaluated, the next crucial step was deploying it for practical use. The primary objective was to predict lithology types using nine drilling parameters as inputs and make them accessible through a user-friendly website or mobile application.Ensuring consistent performance and accuracy over time required a well-planned monitoring and maintenance strategy.

The deployment process involved the following steps:

Model Serialization: the trained model was serialized using the pickle library in Python, saving it as a binary file.

Web Framework: the Flask web framework in Python was employed to create a responsive web application capable of handling HTTP requests and responses (see

Figure 19).

Model Loading: during the application’s initialization, the serialized model was loaded into the web application’s memory for efficient usage.

Prediction Endpoint: an endpoint was set up in the web application to receive input data in JSON format and return predictions in the same format.

Deployment: the web application was successfully deployed on Sttreamlit web server, making it accessible for users.

The GeoVision web app showcases a user-friendly interface with its intuitive design where users can easily input drilling parameters and promptly receive accurate lithology predictions as

Figure 19 exemplifies its successful real-time lithology prediction, precisely identifying sandstone at the drill bit. These figures demonstrate the app’s ease of use and its potential as a tool for geological analysis and decision-making processes.

6. Discussion

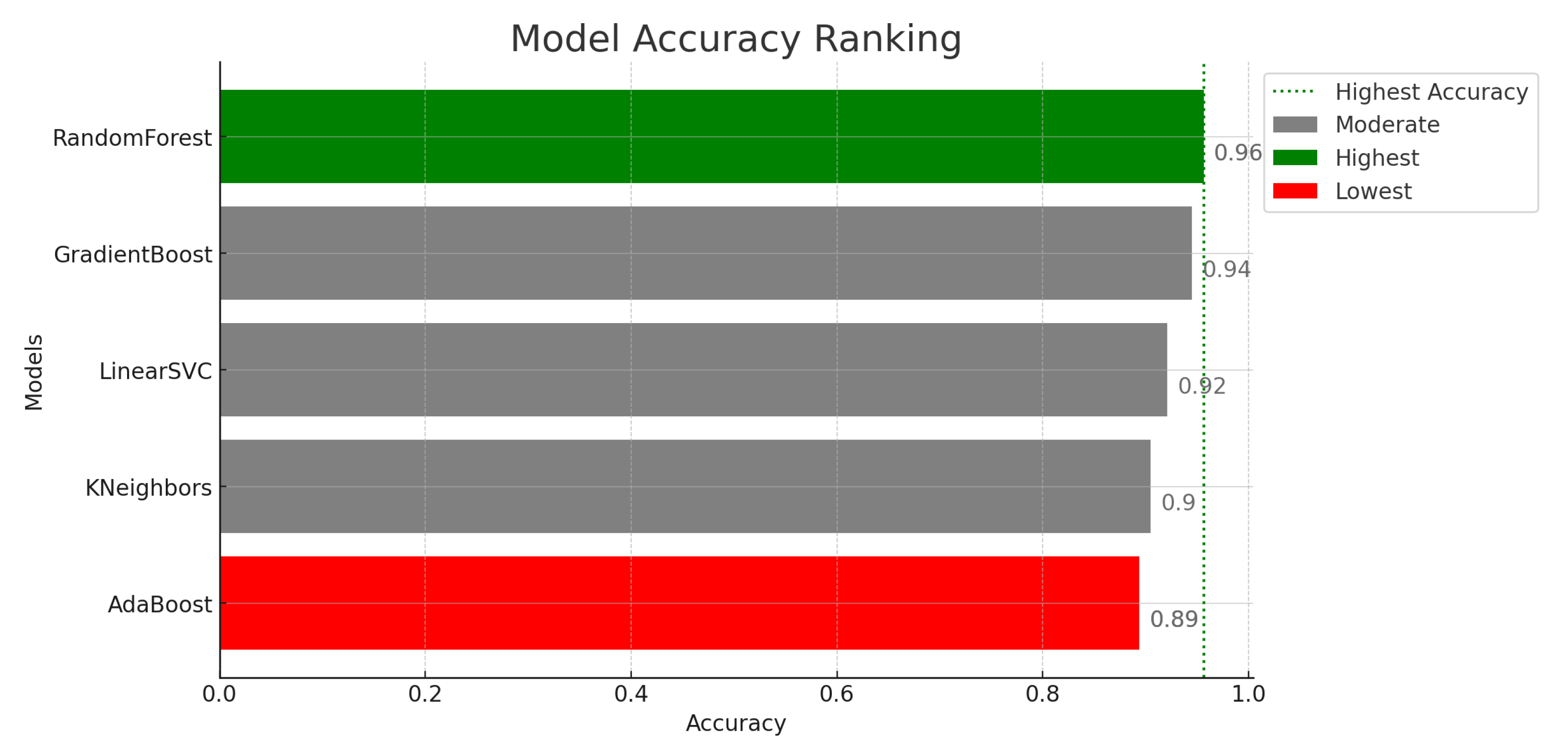

Our investigation into lithology prediction using machine-learning classifiers yielded valuable insights into the performance and practicality of different models. Among the classifiers tested, the random forest model emerged as the most accurate, boasting an impressive 96% accuracy rate. This high level of accuracy can be attributed to the ensemble approach of the random forest algorithm, which unifies multiple decision trees to make predictions.

This ensemble strategy enables it to grasp intricate relationships and interactions between drilling parameters and lithology types, making it well-suited for our prediction task. Notably, the work of Sun et al. (2019) and the conclusions drawn by Fernandez Delgado et al. (2014) also highlight the efficacy of the random forest classifier, reinforcing its suitability for lithology identification tasks [

54,

55].

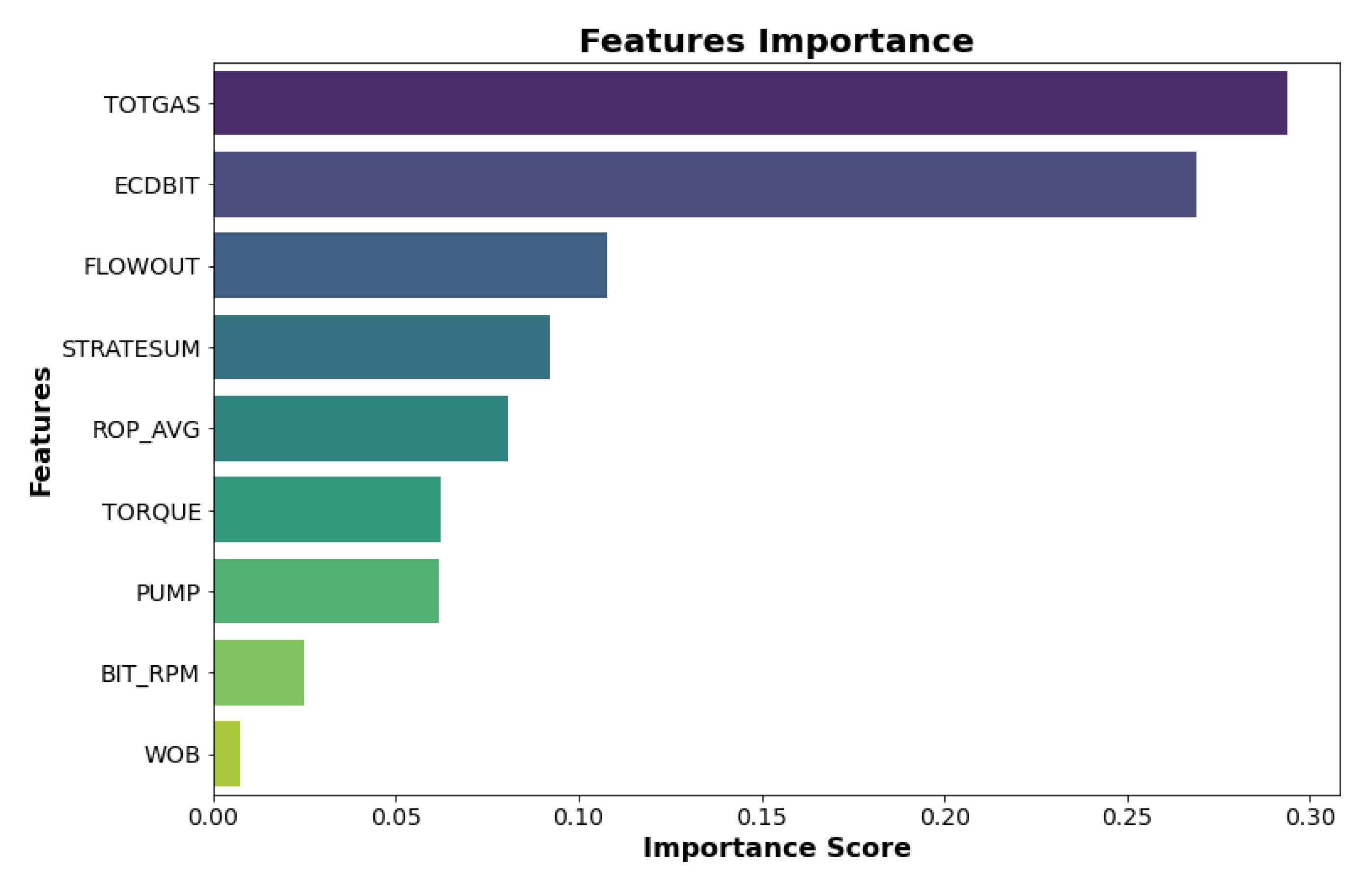

An essential element of our data analysis is the feature importance bar plot, which sheds light on the factors significantly influencing the lithology prediction model. These importance values are data-driven, yet they hold physical significance. Notably, the parameter representing total gas content (‘TOTGAS’) ranks as the most crucial feature, as variations in gas concentrations often serve as key indicators of different rock types and geological formations. Another influential factor is ‘ECDBIT’, characterizing effective circulation density on the bit, impacting drilling performance and efficiency, making it vital for distinguishing between lithologies. Additionally, the ‘FLOWOUT’ parameter, reflecting outgoing mud flow, holds significant importance in conveying information about subsurface formations, aiding in identifying lithological characteristics. Moreover, the ‘ROP’ (rate of penetration) parameter, representing average drilling speed, becomes essential in recognizing lithological transitions due to variations in drilling resistance. Understanding the physical significance of these influential parameters enhances our lithology prediction model and offers valuable insights for geological investigations and resource exploration.

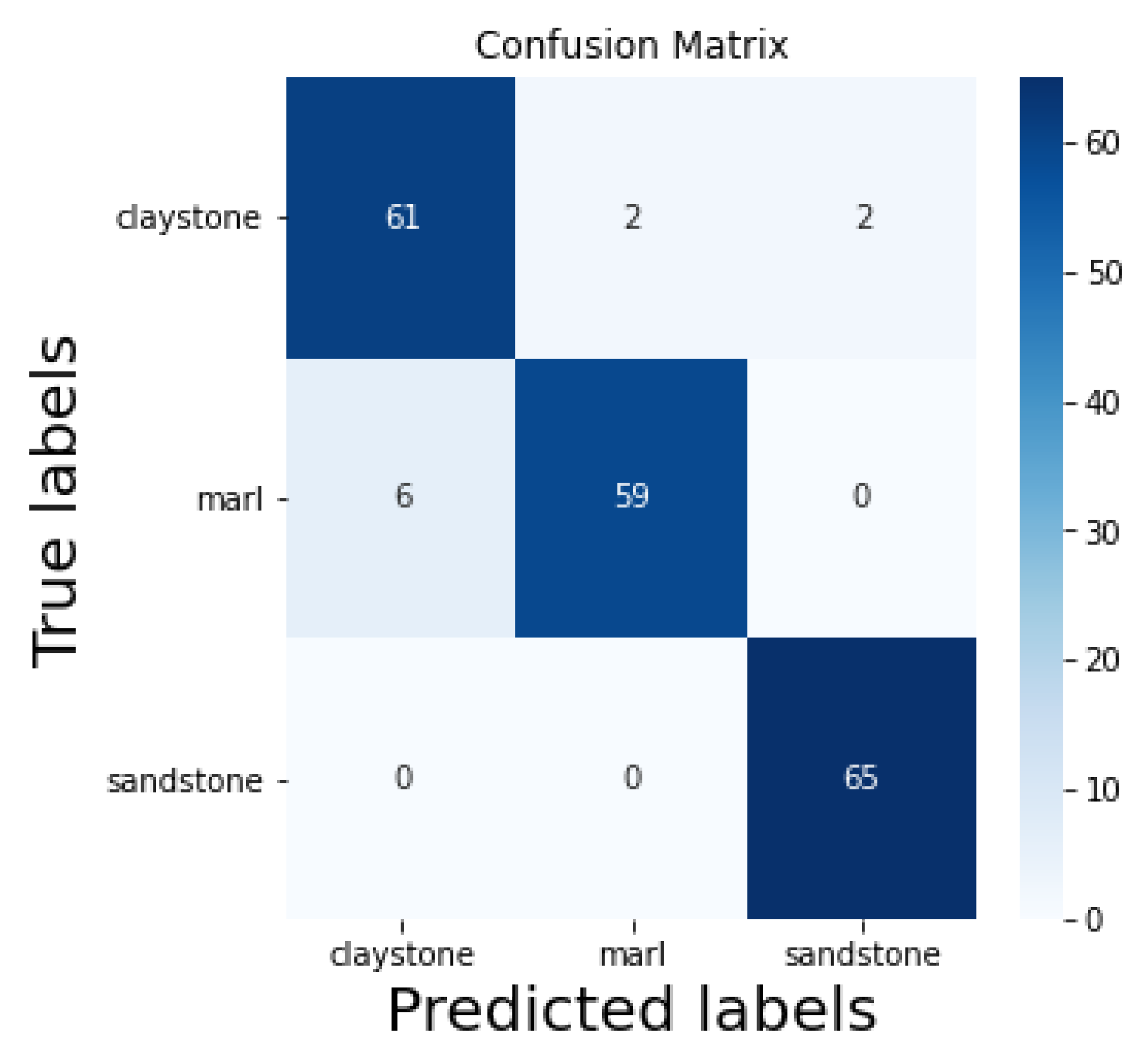

The random forest classifier demonstrated impressive performance in predicting lithology types, showcasing its ability to learn and generalize from the training data. With an accuracy of 95%, the model correctly classified the majority of lithologies, indicating the efficacy of the chosen features and the robustness of the random forest algorithm in capturing complex relationships. High precision values of 91% for claystone and 97% for both marl and sandstone highlight the model’s proficiency in accurately identifying instances of each lithology class. The 100% recall for sandstone suggests that the model successfully identified all samples of this class, whereas the slightly lower recall values for claystone (94%) and marl (91%) indicate some misclassifications. The confusion matrix further supports the model’s performance, showing successful predictions of 61 claystone, 59 marl, and 65 sandstone samples out of a total of 65 for each class.

Moreover, the random forest model exhibited robust generalization capabilities, performing well on well 1 data, which were used for model training, as well as on well 2 data, which it had never encountered before. This ability to generalize indicates that the model effectively learned meaningful patterns and features from the training data and applied this knowledge to accurately predict lithology in new wells. However, the model faced challenges in identifying dolomites in well 2, which can be attributed to the limited representation of dolomite samples in the training data. To overcome this limitation, future research can focus on collecting more data for rare lithologies to improve the model’s performance on such classes.

7. Conclusions

In this research, we present a machine learning-based approach to real-time lithology prediction using drilling data. The proposed methodology uses a random forest classifier to effectively differentiate claystone, marl, and sandstone, achieving a remarkable accuracy of 96%. Instead of relying solely on the traditional metric of rate of penetration (ROP) for lithology prediction, our model exploits the intricate relationships between a wider range of drilling data features, notably rate of penetration, total gas content, and torque.

Despite acknowledging some challenges in identifying rare lithologies, our research marks significant progress in immediate subsurface analysis. Crucially, this methodology, through real-time lithology insights during drilling operations, has the potential to significantly enhance geosteering capabilities, a vital aspect for maintaining the optimal well trajectory within the pay zone. The robustness of our results, underscored by consistent precision and recall values around 95%, validates the efficacy of our approach.

In conclusion, as we persist in refining our models and gathering data, we foresee major advancements in subsurface analysis. For example, this research paves the way for the development of ‘looking ahead of the bit’ projects which, by utilizing extensive datasets, could predict lithology ahead of the bit and extend the reach of our real-time insights. Furthermore, enhancements to our Geovision web application, like incorporating a dedicated section for streamlined, diverse data visualization features could make the app more user-friendly and insightful.