Influence of Ventilation Openings on the Energy Efficiency of Metal Frame Modular Constructions in Brazil Using BIM

Abstract

1. Introduction

2. Literature Review

2.1. Modular Construction Design

2.2. Impact of Ventilation Openings on Energy Efficiency in Buildings

2.3. The Bioclimatic Zones of Brazil

3. Materials and Methods

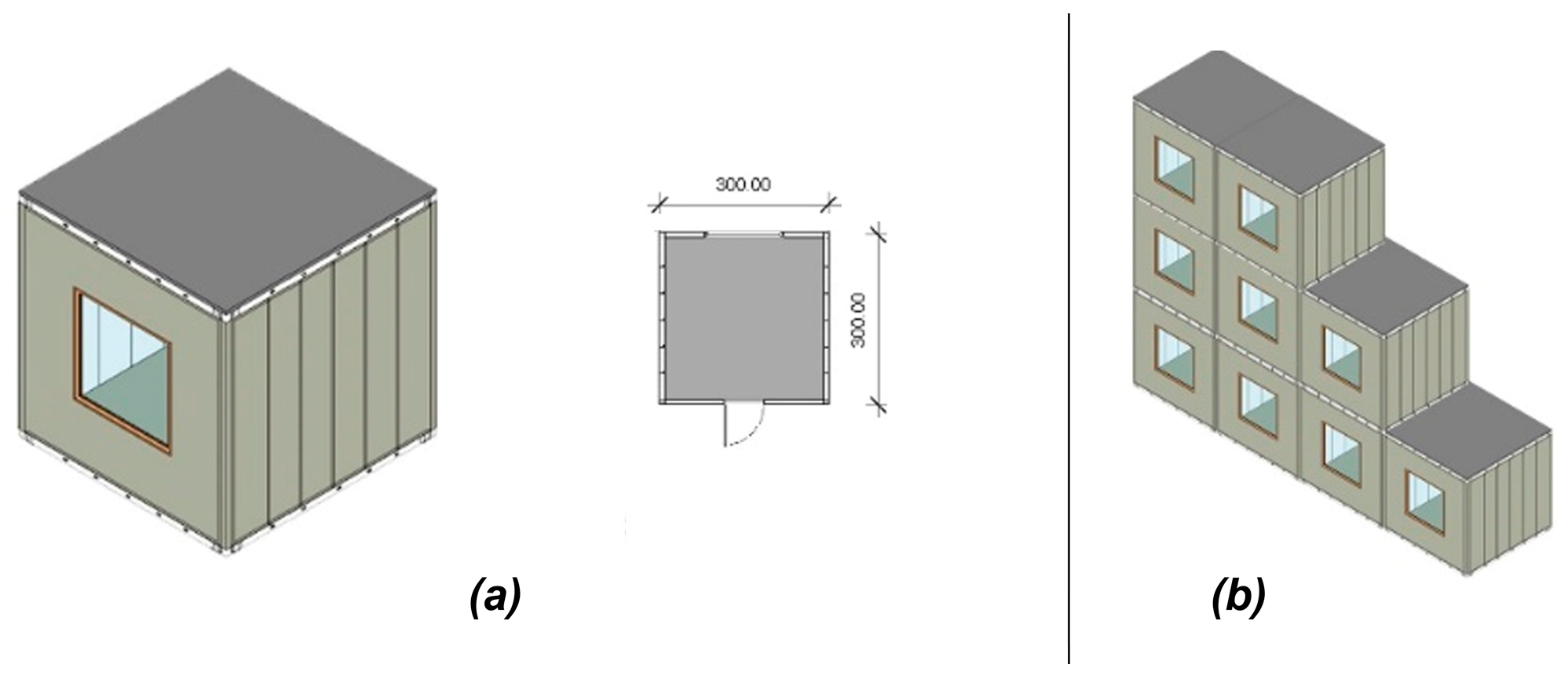

3.1. Metal Frame Modular Construction Design

- (a)

- Medium ventilation openings: a range of dimensions between 15% and 25% of the total floor area of the built environment. These dimensions are recommended in the cities located in the first, second, third, fourth, fifth, and sixth bioclimatic zones.

- (b)

- Small ventilation openings: a range of dimensions between 10% and 15% of the total floor area of the built environment. These dimensions are recommended in the cities located in the seventh bioclimatic zone.

- (c)

- Large ventilation openings: a recommended dimension equal to or above 40% of the total floor area of the built environment. These dimensions are recommended in the cities located in the eighth bioclimatic zone.

3.2. Data Inventory

3.3. Evaluation Process

4. Case Study and Simulation Analysis

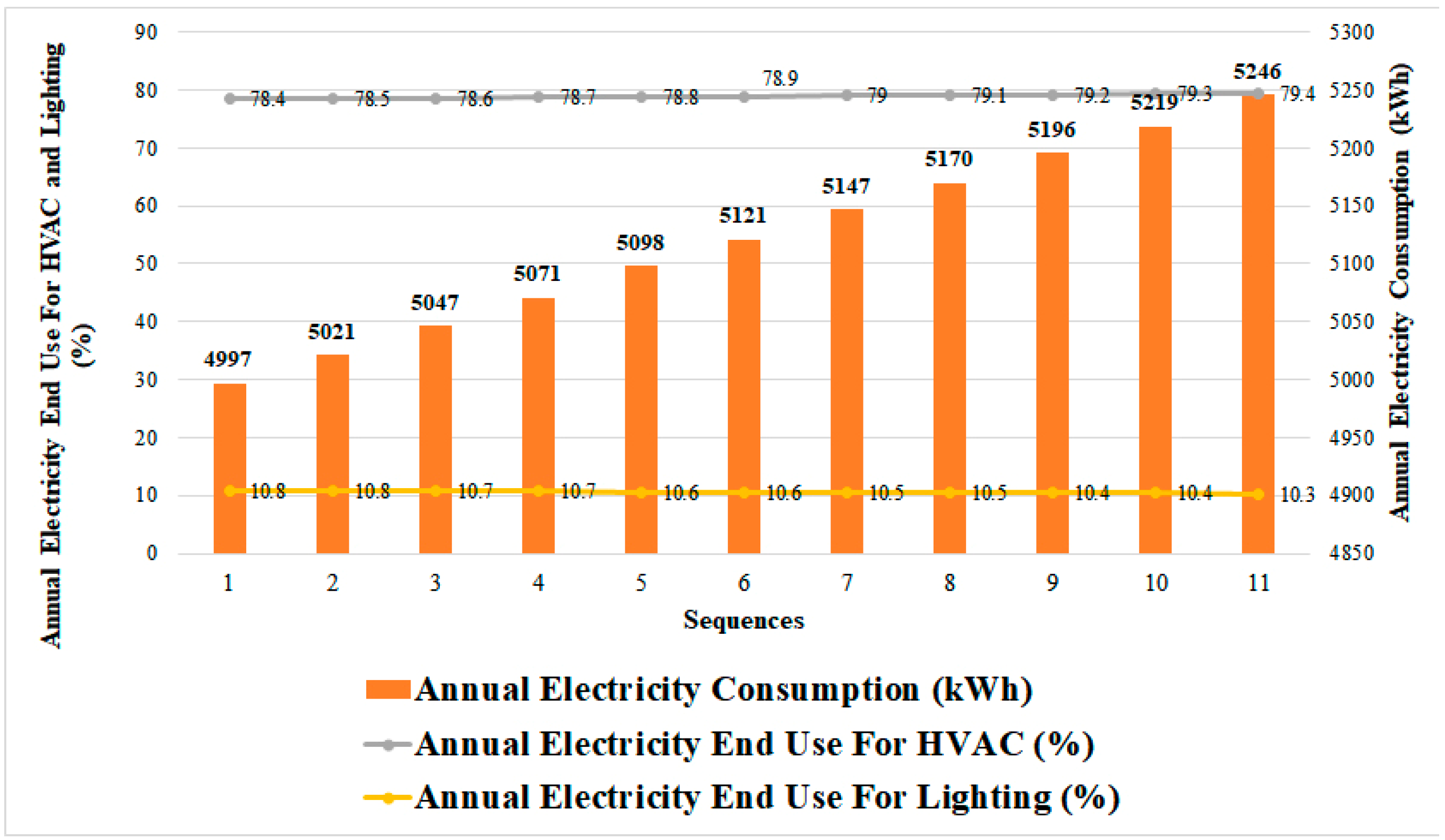

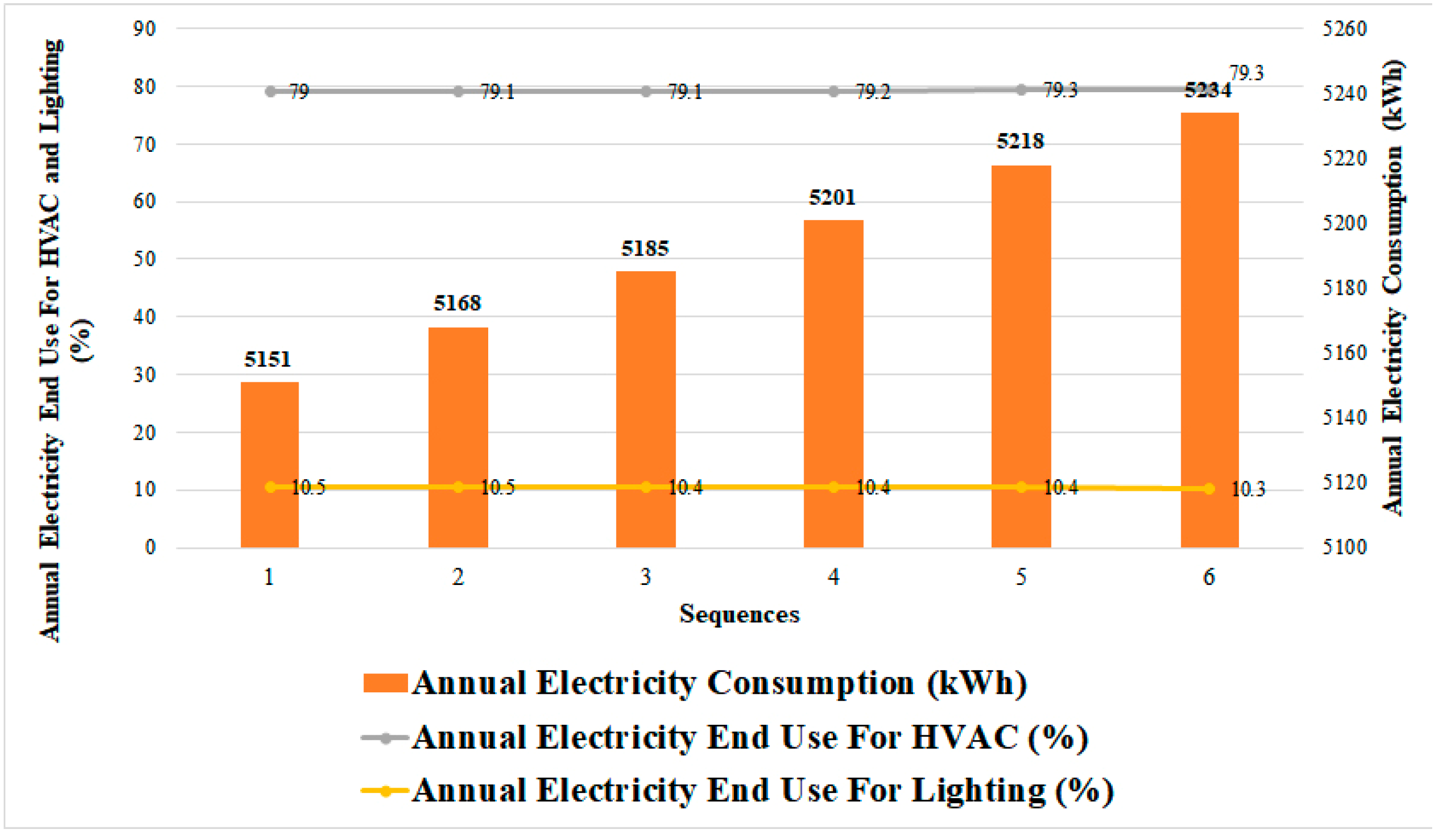

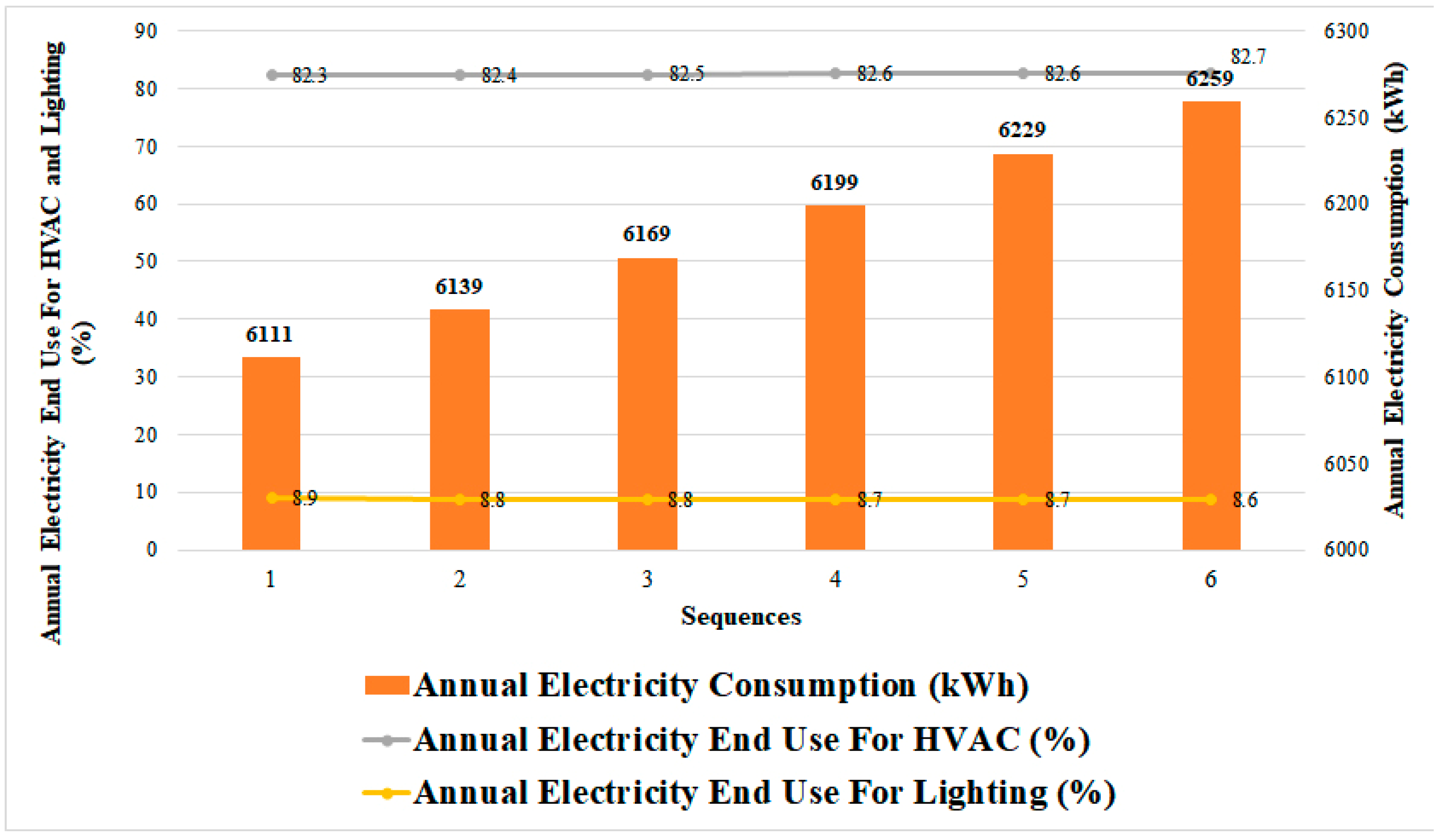

5. Results and Discussion

6. Conclusions

- The energy consumption of the same building varies between the examined cities based on their bioclimatic classification zone.

- Using the lowest values of ventilation openings as indicated in ABNT NBR 15220 for the different bioclimatic zones would increase energy efficiency in buildings.

- The bioclimatic zone of the location of the construction project could influence energy consumption, affecting the energy efficiency of buildings.

- Dedicating the application of the proposed framework to examining the energy efficiency of ventilation openings in Brazilian cities only.

- Taking into consideration only the minimum and maximum values of ventilation openings, as indicated in ABNT NBR 15220 for the small, medium, and large openings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ben-Alon, L.; Loftness, V.; Harries, K.A.; Cochran Hameen, E. Life cycle assessment (LCA) of natural vs conventional building assemblies. Renew. Sustain. Energy Rev. 2021, 144, 110951. [Google Scholar] [CrossRef]

- Najjar, M.K.; Tam, V.W.Y.; Di Gregorio, L.T.; Evangelista, A.C.J.; Hammad, A.W.A.; Haddad, A. Integrating Parametric Analysis with Building Information Modeling to Improve Energy Performance of Construction Projects. Energies 2019, 12, 1515. [Google Scholar] [CrossRef]

- Shi, D.; Gao, Y.; Zeng, P.; Li, B.; Shen, P.; Zhuang, C. Climate adaptive optimization of green roofs and natural night ventilation for lifespan energy performance improvement in office buildings. Build. Environ. 2022, 223, 109505. [Google Scholar] [CrossRef]

- Yayla, A.; Kayakutlu, G.; Kayalica, M.O. Life Cycle Assessment with BIM Towards Sustainable Energy Policy-Making: The Case of Urban Transformation in Istanbul. Int. J. Sustain. Constr. Eng. Technol. 2021, 12, 142–154. [Google Scholar] [CrossRef]

- Kumar, R.; Chakraborty, S.; Elangovan, D.; Padmanaban, S. Concept of net zero energy buildings (NZEB)—A literature review. Clean. Eng. Technol. 2022, 11, 100582. [Google Scholar] [CrossRef]

- Najjar, M.K. Optimizing the Sustainable Decision-Making Process towards Improving Energy Performance over the Entire Life Cycle of Buildings. Ph.D. Thesis, Universidade Federal do Rio de Janeiro, Rio de Janeiro, Brazil, 2019. Available online: https://monografias.poli.ufrj.br/rep-download.php?farquivo=tesepoli10033681.pdf&fcodigo=5148 (accessed on 1 June 2023).

- U.S. Department of Energy. Chapter 5: Increasing Efficiency of Building Systems and Technologies. In Quadrennial Technology Review, An Assessment of Energy Technologies and Research Opportunities; U.S. Department of Energy: Washington, DC, USA, 2015; pp. 143–181. Available online: https://www.energy.gov/sites/prod/files/2017/03/f34/qtr-2015-chapter5.pdf (accessed on 1 June 2023).

- Nur, W.; Wan, H.; Hamimi, A.; Tharim, A.; Ahmad, A.C. Determination of Design Solutions to Overcome the Daylighting Design Failure Observed in Existing Educational Building. Int. J. Sustain. Constr. Eng. Technol. 2022, 2, 153–167. [Google Scholar]

- Dussault, J.M.; Gosselin, L.; Galstian, T. Integration of smart windows into building design for reduction of yearly overall energy consumption and peak loads. Sol. Energy 2012, 86, 3405–3416. [Google Scholar] [CrossRef]

- Fritsche, Y.; Pinheiro, M.V.M.; Guerra, M.P. Light quality and natural ventilation have different effects on protocorm development and plantlet growth stages of the in vitro propagation of Epidendrum fulgens (Orchidaceae). S. Afr. J. Bot. 2022, 146, 864–874. [Google Scholar] [CrossRef]

- Suzuki, E.H.; Lofrano, F.C.; Kurokawa, F.A.; Prado, R.T.A.; Leite, B.C.C. Decision-making process for thermal comfort and energy efficiency optimization coupling smart-window and natural ventilation in the warm and hot climates. Energy Build. 2022, 266, 112110. [Google Scholar] [CrossRef]

- Begić, H.; Krstić, H. Possibilities of Using Prefabricated Modular Panels for Building NZEB Buildings in Earthquake-Affected Areas in Croatia—Case Study. Int. J. Sustain. Constr. Eng. Technol. 2022, 1, 137–148. [Google Scholar] [CrossRef]

- Zulkefli, N.S.; Mohd-Rahim, F.A.; Zainon, N. Integrating building information modelling (Bim) and sustainability to greening existing building: Potentials in malaysian construction industry. Int. J. Sustain. Constr. Eng. Technol. 2020, 11, 76–83. [Google Scholar] [CrossRef]

- Moreno, A.C.R.; De Morais, I.S.; Souza, R.G. De Thermal Performance of Social Housing-A Study Based on Brazilian Regulations. Energy Procedia 2017, 111, 111–120. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Silvestre, J.D.; Pyl, L. Integration of LCA and LCC analysis within a BIM-based environment. Autom. Constr. 2019, 103, 127–149. [Google Scholar] [CrossRef]

- González, J.; Soares, C.A.P.; Najjar, M.; Haddad, A.N. BIM and BEM Methodologies Integration in Energy-Efficient Buildings Using Experimental Design. Buildings 2021, 11, 491. [Google Scholar] [CrossRef]

- Tan, T.; Mills, G.; Papadonikolaki, E.; Liu, Z. Combining multi-criteria decision making (MCDM) methods with building information modelling (BIM): A review. Autom. Constr. 2021, 121, 103451. [Google Scholar] [CrossRef]

- Bapat, H.; Sarkar, D.; Gujar, R. A Sustainable approach to reduce Embodied and Operational Cooling Energy for an Elevated Metro Rail Station of Ahmedabad, India, using Building Information Modelling (BIM) and Factor Comparison Method. J. Inst. Eng. Ser. A 2022, 103, 115–128. [Google Scholar] [CrossRef]

- Motalebi, M.; Rashidi, A.; Nasiri, M.M. Optimization and BIM-based lifecycle assessment integration for energy efficiency retrofit of buildings. J. Build. Eng. 2022, 49, 104022. [Google Scholar] [CrossRef]

- Tokazhanov, G.; Galiyev, O.; Lukyanenko, A.; Nauyryzbay, A.; Ismagulov, R.; Durdyev, S.; Turkyilmaz, A.; Karaca, F. Circularity assessment tool development for construction projects in emerging economies. J. Clean. Prod. 2022, 362, 132293. [Google Scholar] [CrossRef]

- Pervez, H.; Ali, Y.; Petrillo, A. A quantitative assessment of greenhouse gas (GHG) emissions from conventional and modular construction: A case of developing country. J. Clean. Prod. 2021, 294, 126210. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Lim, Y.; Ling, P.C.H.; Siang, C.; Chong, H. Automation in Construction Planning and coordination of modular construction. Autom. Constr. 2022, 141, 104455. [Google Scholar] [CrossRef]

- Dan-Adrian, C.; Tsavdaridis, K.D. A comprehensive review and classification of inter-module connections for hot-rolled steel modular building systems. J. Build. Eng. 2022, 50, 104006. [Google Scholar] [CrossRef]

- Shamaeva, T.V.; Zinkevich, E.S. Architecture of medium- And multistoried residential buildings with steel framework. IOP Conf. Ser. Mater. Sci. Eng. 2020, 944, 012033. [Google Scholar] [CrossRef]

- Sorgato, M.J.; Melo, A.P.; Lamberts, R. The effect of window opening ventilation control on residential building energy consumption. Energy Build. 2016, 133, 1–13. [Google Scholar] [CrossRef]

- Xie, X.; Luo, Z.; Grimmond, S.; Blunn, L. Use of wind pressure coefficients to simulate natural ventilation and building energy for isolated and surrounded buildings. Build. Environ. 2023, 230, 109951. [Google Scholar] [CrossRef]

- Tien, P.W.; Wei, S.; Liu, T.; Calautit, J.; Darkwa, J.; Wood, C. A deep learning approach towards the detection and recognition of opening of windows for effective management of building ventilation heat losses and reducing space heating demand. Renew. Energy 2021, 177, 603–625. [Google Scholar] [CrossRef]

- Zoure, A.N.; Genovese, P.V. Implementing natural ventilation and daylighting strategies for thermal comfort and energy efficiency in office buildings in Burkina Faso. Energy Rep. 2023, 9, 3319–3342. [Google Scholar] [CrossRef]

- Li, X.X.; Huang, K.L.; Feng, G.H.; Li, W.Y.; Wei, J.X. Night ventilation scheme optimization for an Ultra-low energy consumption building in Shenyang, China. Energy Rep. 2022, 8, 8426–8436. [Google Scholar] [CrossRef]

- Modular Building Institue What is Modular Construction? Available online: https://www.modular.org/HtmlPage.aspx?name=why_modular (accessed on 29 December 2021).

- Olawumi, T.O.; Chan, D.W.M.; Ojo, S.; Yam, M.C.H. Automating the modular construction process: A review of digital technologies and future directions with blockchain technology. J. Build. Eng. 2021, 46, 103720. [Google Scholar] [CrossRef]

- Zhang, J.; Long, Y.; Lv, S.; Xiang, Y. BIM-enabled Modular and Industrialized Construction in China. Procedia Eng. 2016, 145, 1456–1461. [Google Scholar] [CrossRef]

- Lee, M.; Lee, D.; Kim, T.; Lee, U.K. Practical analysis of BIM tasks for modular construction projects in South Korea. Sustainability 2020, 12, 6900. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Tam, V.W.Y. Critical factors in effective construction waste minimization at the design stage: A Shenzhen case study, China. Resour. Conserv. Recycl. 2014, 82, 1–7. [Google Scholar] [CrossRef]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Anderson, N.; Wedawatta, G.; Rathnayake, I.; Domingo, N.; Azizi, Z. Embodied Energy Consumption in the Residential Sector: A Case Study of Affordable Housing. Sustainability 2022, 14, 5051. [Google Scholar] [CrossRef]

- Hammad, A.W.A.; Akbarnezhad, A.; Wu, P.; Wang, X.; Haddad, A. Building information modelling-based framework to contrast conventional and modular construction methods through selected sustainability factors. J. Clean. Prod. 2019, 228, 1264–1281. [Google Scholar] [CrossRef]

- Tavares, V.; Freire, F. Life cycle assessment of a prefabricated house for seven locations in different climates. J. Build. Eng. 2022, 53, 104504. [Google Scholar] [CrossRef]

- Liew, J.Y.R.; Chua, Y.S.; Dai, Z. Steel concrete composite systems for modular construction of high-rise buildings. Structures 2019, 21, 135–149. [Google Scholar] [CrossRef]

- Chang, S.J.; Kang, Y.; Yun, B.Y.; Yang, S.; Kim, S. Assessment of effect of climate change on hygrothermal performance of cross-laminated timber building envelope with modular construction. Case Stud. Therm. Eng. 2021, 28, 101703. [Google Scholar] [CrossRef]

- Amoruso, F.M.; Schuetze, T. Hybrid timber-based systems for low-carbon, deep renovation of aged buildings: Three exemplary buildings in the Republic of Korea. Build. Environ. 2022, 214, 108889. [Google Scholar] [CrossRef]

- Domljan, D.; Janković, L. Design of Sustainable Modular Wooden Booths Inspired by Revitalization of Croatian Traditional Construction and New User Needs Due to COVID-19 Pandemic. Sustainability 2022, 14, 720. [Google Scholar] [CrossRef]

- Shan, S.; Pan, W. Structural design of high-rise buildings using steel-framed modules: A case study in Hong Kong. Struct. Des. Tall Spec. Build. 2020, 29, e1788. [Google Scholar] [CrossRef]

- Rahman, S.; John, K.; Kafle, B.; Al-Ameri, R. Structural Performance of Modular Sandwich Composite Floor Slabs Containing Basalt FRP-Reinforced Self-Compacting Geopolymer Concrete. Appl. Sci. 2022, 12, 4246. [Google Scholar] [CrossRef]

- Tembhurkar, S.; Ralegaonkar, R.; Azevedo, A.; Madurwar, M. Low cost geopolymer modular toilet unit for ODF India—A case study. Case Stud. Constr. Mater. 2022, 16, e00937. [Google Scholar] [CrossRef]

- Zhong, H.Y.; Lin, C.; Shang, J.; Sun, Y.; Kikumoto, H.; Ooka, R.; Qian, F.P.; Zhao, F.Y. Wind tunnel experiments on pumping ventilation through a three-story reduce-scaled building with two openings affected by upwind and downwind buildings. Build. Environ. 2022, 219, 109188. [Google Scholar] [CrossRef]

- Jiang, Z.; Kobayashi, T.; Sandberg, M.; Yamanaka, T.; Kobayashi, N. Analysis of single-sided ventilation flows of a generic isolated building using particle tracking method in LES simulation. Build. Environ. 2023, 235, 110230. [Google Scholar] [CrossRef]

- Salcido, J.C.; Raheem, A.A.; Issa, R.R.A. From simulation to monitoring: Evaluating the potential of mixed-mode ventilation (MMV) systems for integrating natural ventilation in office buildings through a comprehensive literature review. Energy Build. 2016, 127, 1008–1018. [Google Scholar] [CrossRef]

- Lotfabadi, P.; Hançer, P. Optimization of visual comfort: Building openings. J. Build. Eng. 2023, 72, 106598. [Google Scholar] [CrossRef]

- Matour, S.; Garcia-Hansen, V.; Omrani, S.; Hassanli, S.; Drogemuller, R. Wind-driven ventilation of Double Skin Façades with vertical openings: Effects of opening configurations. Build. Environ. 2021, 196, 107804. [Google Scholar] [CrossRef]

- Bauer, A.; Möller, S.; Gill, B.; Schröder, F. When energy efficiency goes out the window: How highly insulated buildings contribute to energy-intensive ventilation practices in Germany. Energy Res. Soc. Sci. 2021, 72, 101888. [Google Scholar] [CrossRef]

- Fabi, V.; Andersen, R.V.; Corgnati, S.; Olesen, B.W. Occupants’ window opening behaviour: A literature review of factors influencing occupant behaviour and models. Build. Environ. 2012, 58, 188–198. [Google Scholar] [CrossRef]

- Kim, S.; Zadeh, P.A.; Staub-french, S.; Froese, T.; Terim, B. Assessment of the Impact of Window Size, Position and Orientation on Building Energy Load Using BIM. Procedia Eng. 2016, 145, 1424–1431. [Google Scholar] [CrossRef]

- Gan, V.J.L.; Deng, M.; Tan, Y.; Chen, W.; Cheng, J.C.P. BIM-based framework to analyze the effect of natural ventilation on thermal comfort and energy performance in buildings. Energy Procedia 2019, 158, 3319–3324. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, X.; Khan, A.M.; Houda, M.; Kashif Ur Rehman, S.; Jameel, M.; Javed, M.F.; Alrowais, R. BIM-based architectural analysis and optimization for construction 4.0 concept (a comparison). Ain Shams Eng. J. 2023, 14, 102110. [Google Scholar] [CrossRef]

- Maglad, A.M.; Houda, M.; Alrowais, R.; Khan, A.M.; Jameel, M.; Rehman, S.K.U.; Khan, H.; Javed, M.F.; Rehman, M.F. Bim-based energy analysis and optimization using insight 360 (case study). Case Stud. Constr. Mater. 2023, 18, e01755. [Google Scholar] [CrossRef]

- Desempenho Térmico de Edificações NBR 15220; Parte 3: Zoneamento Bioclimático Brasileiro e Diretrizes Construtivas Para Habitações Unifamiliares de Interesse Social. ABNT—Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2005.

- Edificações Habitacionais—Desempenho NBR 15575; Parte 1: Base-Padrão de Arquivos Climáticos Para a Avaliação do Desempenho Térmico por Meio do Procedimento de Simulação Computacional. ABNT—Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2021.

- Rabbi, I.M.; Nico, E.A. Econômica Em His Thermal Comfort, Energy Efficiency and Economic Feasibility in Social Introdução e Fundamentação Teórica Visando à redução da carência habitacional brasileira, o Programa Minha Casa Minha. PARC Pesqui. Arquitetura Construção 2022, 13, e022020. [Google Scholar]

- Krüger, E.L.; Mori, F. Análise da eficiência energética da envoltória de um projeto padrão de uma agência bancária em diferentes zonas bioclimáticas brasileiras. Ambient. Construído 2012, 12, 89–106. [Google Scholar] [CrossRef]

- Luziani, S.; Paramita, B. Autodesk Green Building Studio an Energy Simulation Analysis in the Design Process. KnE Soc. Sci. 2019, 2019, 735–749. [Google Scholar] [CrossRef]

- Ferrer, M.A. Modular Construction in Multi-Storey Buildings. Master’s Thesis, Università Degli Studi di Padova, Padova, Italy, 2019. [Google Scholar]

| BioZ | City | Ventilation Openings |

|---|---|---|

| 1 | Curitiba | Medium (15%, 16%, 17%, 18%, 19%, 20%, 21%, 22%, 23%, 24%, and 25%) |

| 2 | Rio Negro | Medium (15%, 16%, 17%, 18%, 19%, 20%, 21%, 22%, 23%, 24%, and 25%) |

| 3 | São Paulo | Medium (15%, 16%, 17%, 18%, 19%, 20%, 21%, 22%, 23%, 24%, and 25%) |

| 4 | Brasília | Medium (15%, 16%, 17%, 18%, 19%, 20%, 21%, 22%, 23%, 24%, and 25%) |

| 5 | Campos | Medium (15%, 16%, 17%, 18%, 19%, 20%, 21%, 22%, 23%, 24%, and 25%) |

| 6 | Paranaíba | Medium (15%, 16%, 17%, 18%, 19%, 20%, 21%, 22%, 23%, 24%, and 25%) |

| 7 | Goiás | Small (10%, 11%, 12%, 13%, 14%, and 15%) |

| 8 | Rio de Janeiro | Large (40%, 41%, 42%, 43%, 44%, and 45%) |

| Sequence | Size of the Ventilation Opening in the Façade (m2) | Dimension of the Opening (m) |

|---|---|---|

| Required sequences to be modeled in the cities of Curitiba, Rio Negro, São Paulo, Brasília, Campos, and Paranaíba | ||

| 1 | Medium ventilation openings of (15%) | 1.125 × 1.20 |

| 2 | Medium ventilation openings of (16%) | 1.20 × 1.20 |

| 3 | Medium ventilation openings of (17%) | 1.275 × 1.20 |

| 4 | Medium ventilation openings of (18%) | 1.35 × 1.20 |

| 5 | Medium ventilation openings of (19%) | 1.425 × 1.20 |

| 6 | Medium ventilation openings of (20%) | 1.50 × 1.20 |

| 7 | Medium ventilation openings of (21%) | 1.575 × 1.20 |

| 8 | Medium ventilation openings of (22%) | 1.65 × 1.20 |

| 9 | Medium ventilation openings of (23%) | 1.725 × 1.20 |

| 10 | Medium ventilation openings of (24%) | 1.80 × 1.20 |

| 11 | Medium ventilation openings of (25%) | 1.875 × 1.20 |

| Required sequences to be modeled in the city of Goiás | ||

| 1 | Small ventilation openings of (10%) | 0.90 × 1.00 |

| 2 | Small ventilation openings of (11%) | 0.99 × 1.00 |

| 3 | Small ventilation openings of (12%) | 1.08 × 1.00 |

| 4 | Small ventilation openings of (13%) | 1.17 × 1.00 |

| 5 | Small ventilation openings of (14%) | 1.26 × 1.00 |

| 6 | Small ventilation openings of (15%) | 1.35 × 1.00 |

| Required sequences to be modeled in the city of Rio de Janeiro | ||

| 1 | Large ventilation openings of (40%) | 2.40 × 1.50 |

| 2 | Large ventilation openings of (41%) | 2.46 × 1.50 |

| 3 | Large ventilation openings of (42%) | 2.52 × 1.50 |

| 4 | Large ventilation openings of (43%) | 2.58 × 1.50 |

| 5 | Large ventilation openings of (44%) | 2.64 × 1.50 |

| 6 | Large ventilation openings of (45%) | 2.70 × 1.50 |

| Analysis of Annual Electricity Consumption (kWh) | ||||||||

|---|---|---|---|---|---|---|---|---|

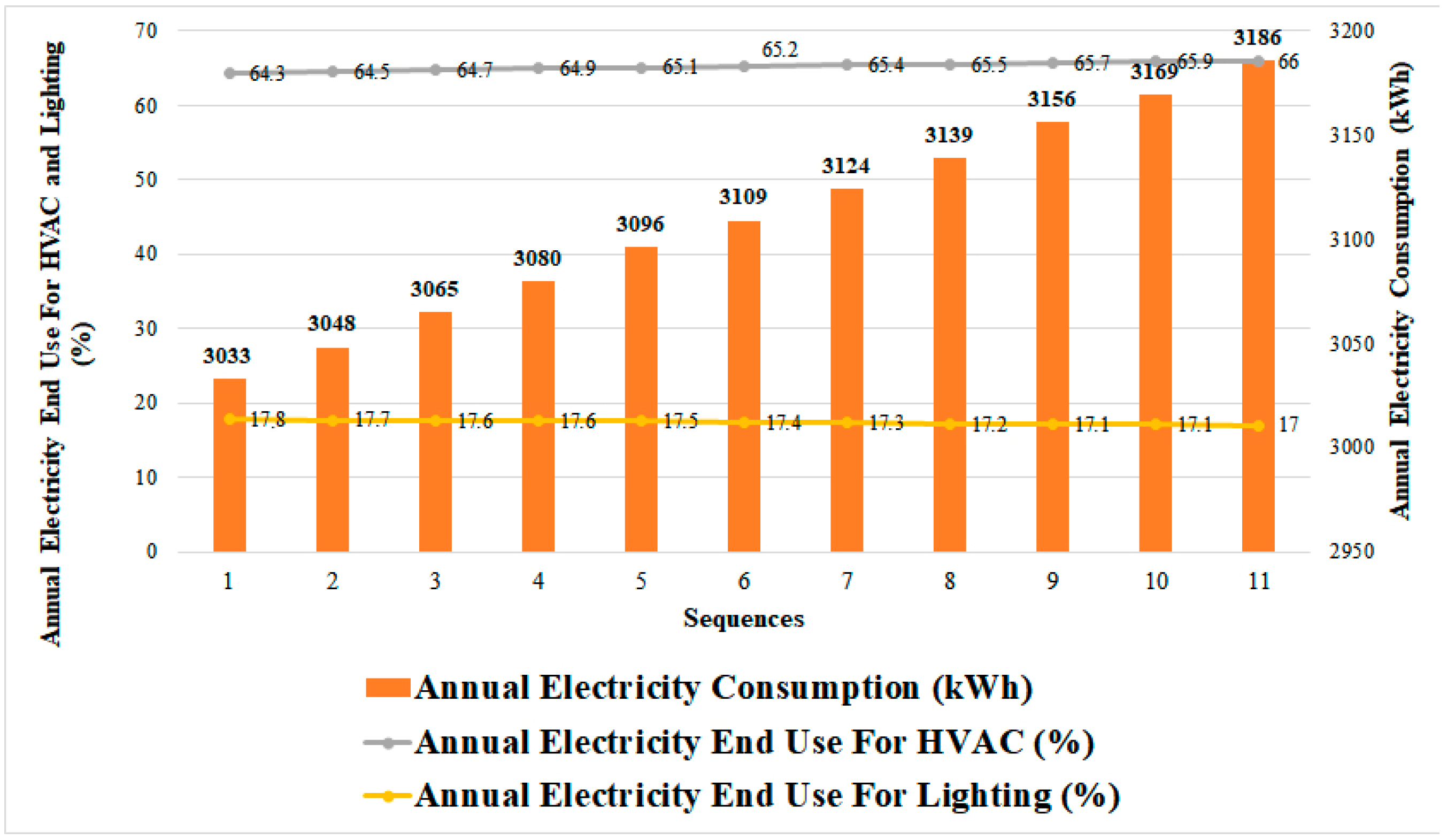

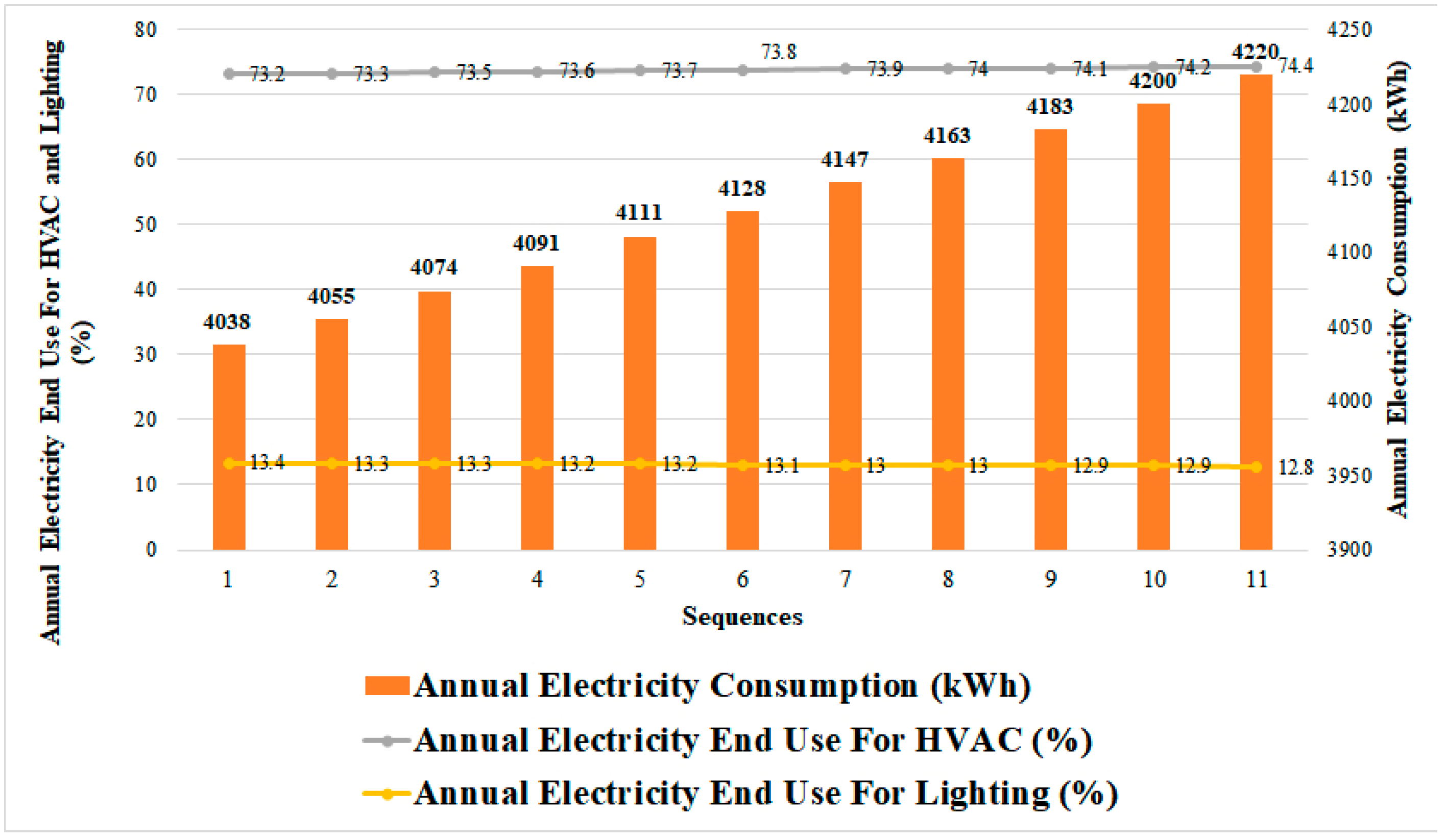

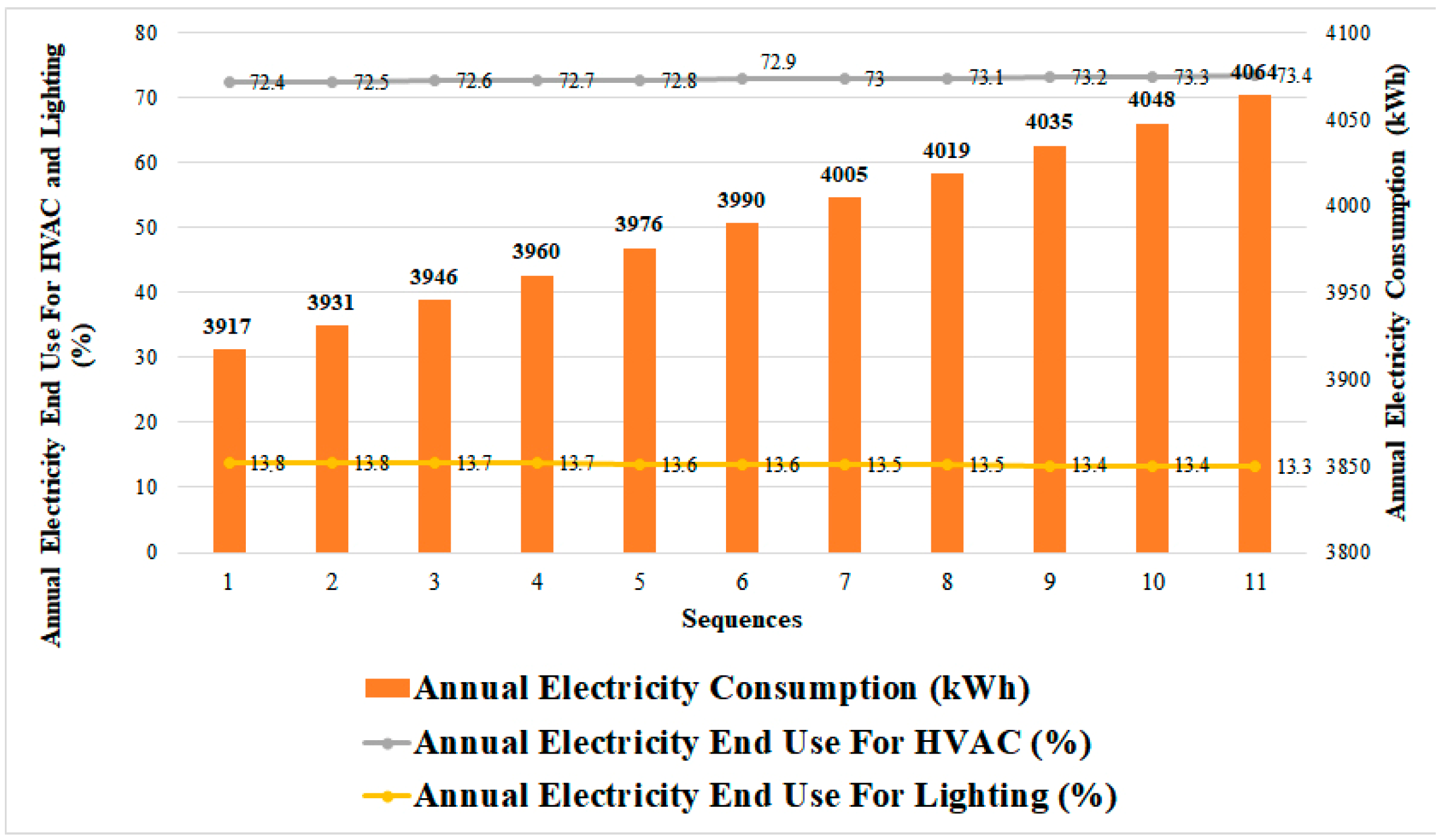

| Sequences | Curitiba | Rio Negro | São Paulo | Brasília | Campos | Paranaíba | Goiás | Rio de Janeiro |

| 1 | 3648 | 3033 | 4038 | 3917 | 4997 | 4913 | 5151 | 6111 |

| 2 | 3663 | 3048 | 4055 | 3931 | 5021 | 4933 | 5168 | 6139 |

| 3 | 3679 | 3065 | 4074 | 3946 | 5047 | 4957 | 5185 | 6169 |

| 4 | 3693 | 3080 | 4091 | 3960 | 5071 | 4977 | 5201 | 6199 |

| 5 | 3710 | 3096 | 4111 | 3976 | 5098 | 5000 | 5218 | 6229 |

| 6 | 3724 | 3109 | 4128 | 3990 | 5121 | 5020 | 5234 | 6259 |

| 7 | 3741 | 3124 | 4147 | 4005 | 5147 | 5043 | - | - |

| 8 | 3756 | 3139 | 4163 | 4019 | 5170 | 5063 | - | - |

| 9 | 3773 | 3156 | 4183 | 4035 | 5196 | 5085 | - | - |

| 10 | 3788 | 3169 | 4200 | 4048 | 5219 | 5105 | - | - |

| 11 | 3804 | 3186 | 4220 | 4064 | 5246 | 5128 | - | - |

| Annual Electricity End Use for Lighting (%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Sequences | Curitiba | Rio Negro | São Paulo | Brasília | Campos | Paranaíba | Goiás | Rio de Janeiro |

| 1 | 62.5 | 64.3 | 73.2 | 72.4 | 78.4 | 78 | 79 | 82.3 |

| 2 | 62.6 | 64.5 | 73.3 | 72.5 | 78.5 | 78.1 | 79.1 | 82.4 |

| 3 | 62.8 | 64.7 | 73.5 | 72.6 | 78.6 | 78.2 | 79.1 | 82.5 |

| 4 | 63 | 64.9 | 73.6 | 72.7 | 78.7 | 78.3 | 79.2 | 82.6 |

| 5 | 63.1 | 65.1 | 73.7 | 72.8 | 78.8 | 78.4 | 79.3 | 82.6 |

| 6 | 63.3 | 65.2 | 73.8 | 72.9 | 78.9 | 78.5 | 79.3 | 82.7 |

| 7 | 63.4 | 65.4 | 73.9 | 73 | 79 | 78.5 | - | - |

| 8 | 63.6 | 65.5 | 74 | 73.1 | 79.1 | 78.6 | - | - |

| 9 | 63.7 | 65.7 | 74.1 | 73.2 | 79.2 | 78.7 | - | - |

| 10 | 63.9 | 65.9 | 74.2 | 73.3 | 79.3 | 78.8 | - | - |

| 11 | 64 | 66 | 74.4 | 73.4 | 79.4 | 78.9 | - | - |

| Annual Electricity End Use for HVAC (%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Sequences | Curitiba | Rio Negro | São Paulo | Brasília | Campos | Paranaíba | Goiás | Rio de Janeiro |

| 1 | 16.3 | 17.8 | 13.4 | 13.8 | 10.8 | 11 | 10.5 | 8.9 |

| 2 | 16.2 | 17.7 | 13.3 | 13.8 | 10.8 | 11 | 10.5 | 8.8 |

| 3 | 16.2 | 17.6 | 13.3 | 13.7 | 10.7 | 10.9 | 10.4 | 8.8 |

| 4 | 16.1 | 17.6 | 13.2 | 13.7 | 10.7 | 10.9 | 10.4 | 8.7 |

| 5 | 16 | 17.5 | 13.2 | 13.6 | 10.6 | 10.8 | 10.4 | 8.7 |

| 6 | 16 | 17.4 | 13.1 | 13.6 | 10.6 | 10.8 | 10.3 | 8.6 |

| 7 | 15.9 | 17.3 | 13 | 13.5 | 10.5 | 10.7 | - | - |

| 8 | 15.8 | 17.2 | 13 | 13.5 | 10.5 | 10.7 | - | - |

| 9 | 15.8 | 17.1 | 12.9 | 13.4 | 10.4 | 10.6 | - | - |

| 10 | 15.7 | 17.1 | 12.9 | 13.4 | 10.4 | 10.6 | - | - |

| 11 | 15.6 | 17 | 12.8 | 13.3 | 10.3 | 10.5 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Najjar, M.K.; De Araujo, L.O.C.; Oladimeji, O.; Khalas, M.; Figueiredo, K.V.; Boer, D.; Soares, C.A.P.; Haddad, A. Influence of Ventilation Openings on the Energy Efficiency of Metal Frame Modular Constructions in Brazil Using BIM. Eng 2023, 4, 1635-1654. https://doi.org/10.3390/eng4020093

Najjar MK, De Araujo LOC, Oladimeji O, Khalas M, Figueiredo KV, Boer D, Soares CAP, Haddad A. Influence of Ventilation Openings on the Energy Efficiency of Metal Frame Modular Constructions in Brazil Using BIM. Eng. 2023; 4(2):1635-1654. https://doi.org/10.3390/eng4020093

Chicago/Turabian StyleNajjar, Mohammad K., Luis Otávio Cocito De Araujo, Olubimbola Oladimeji, Mohammad Khalas, Karoline V. Figueiredo, Dieter Boer, Carlos A. P. Soares, and Assed Haddad. 2023. "Influence of Ventilation Openings on the Energy Efficiency of Metal Frame Modular Constructions in Brazil Using BIM" Eng 4, no. 2: 1635-1654. https://doi.org/10.3390/eng4020093

APA StyleNajjar, M. K., De Araujo, L. O. C., Oladimeji, O., Khalas, M., Figueiredo, K. V., Boer, D., Soares, C. A. P., & Haddad, A. (2023). Influence of Ventilation Openings on the Energy Efficiency of Metal Frame Modular Constructions in Brazil Using BIM. Eng, 4(2), 1635-1654. https://doi.org/10.3390/eng4020093