Influence of Physical and Mechanical Parameters on Cavitation Erosion and Antifouling Behaviour of Multilayer Silica-Based Hybrid Sol–Gel Coatings on Aluminium Alloys

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate Preparation

2.2. Sol–Gel Synthesis

3. Characterisation

3.1. Thickness Measurements

3.2. Water Contact Angle

3.3. Scratch Resistance

3.4. Cross-Cut Adhesion

3.5. Surface Roughness Measurements

3.6. Nanoindentation Measurements

3.7. Antifouling Activity

3.8. Preparation of Algal Culturing Medium

3.8.1. Preparation of Synthetic Sea Water

3.8.2. Preculturing of the Algae

3.8.3. Preparation of Concentrated Algal Inoculum

3.9. Transfer of the Substrate to the Test Vials

3.10. Scoring of the Results

3.11. Statistical Analysis of the Data

4. Results and Discussions

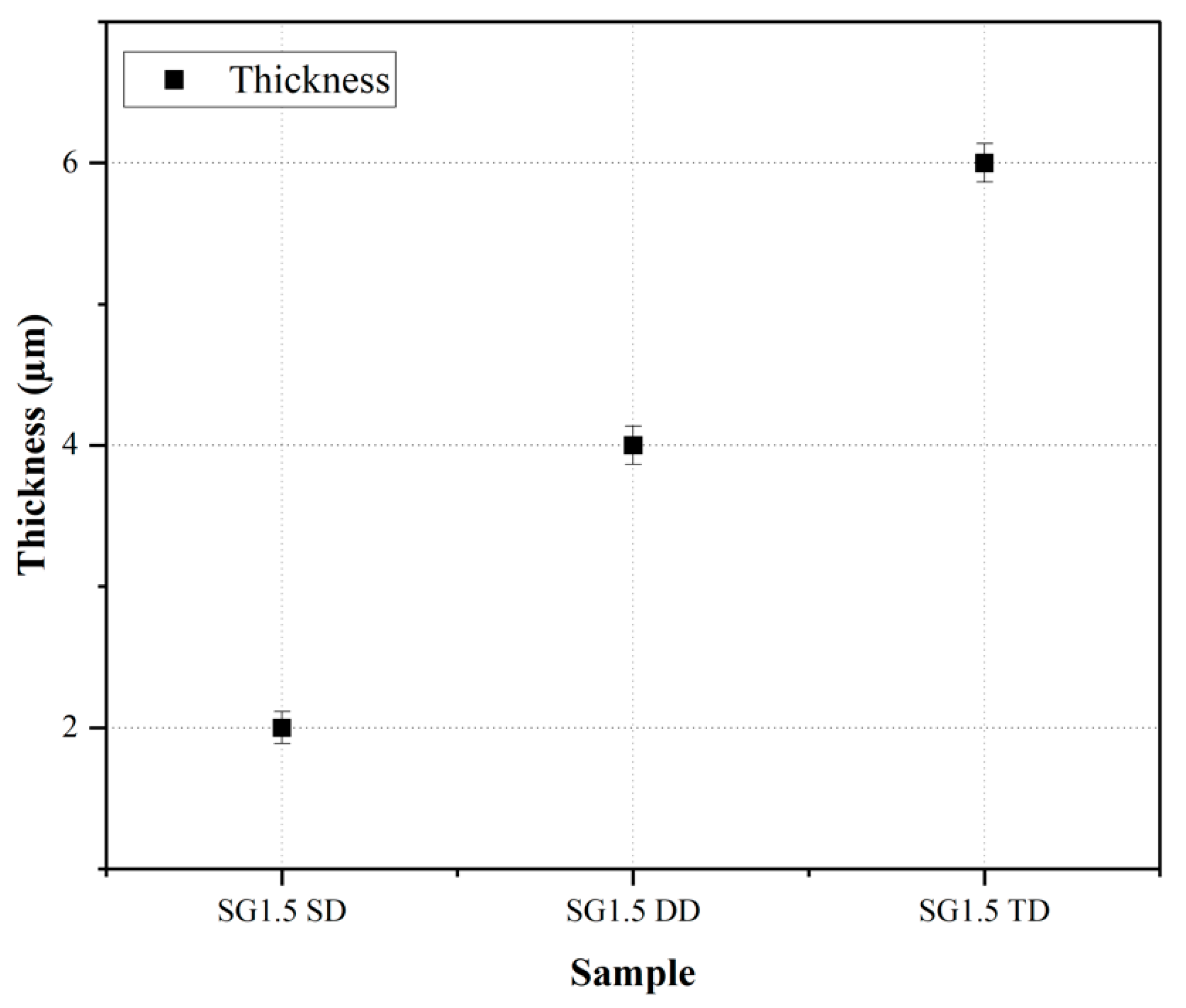

4.1. Thickness Measurements

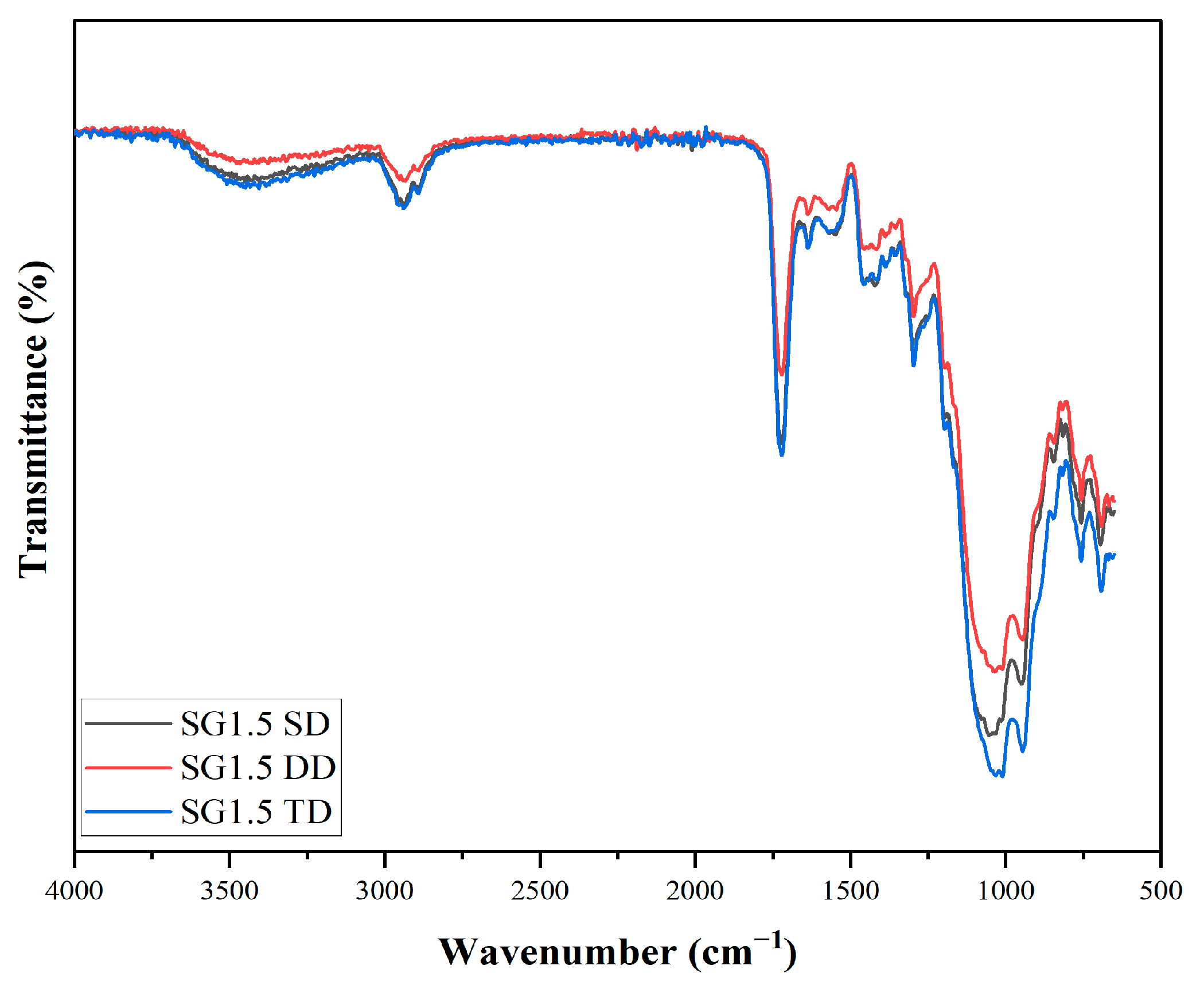

4.2. Attenuated Total Reflection-Fourier Transform Infrared Spectroscopy (ATR-FTIR)

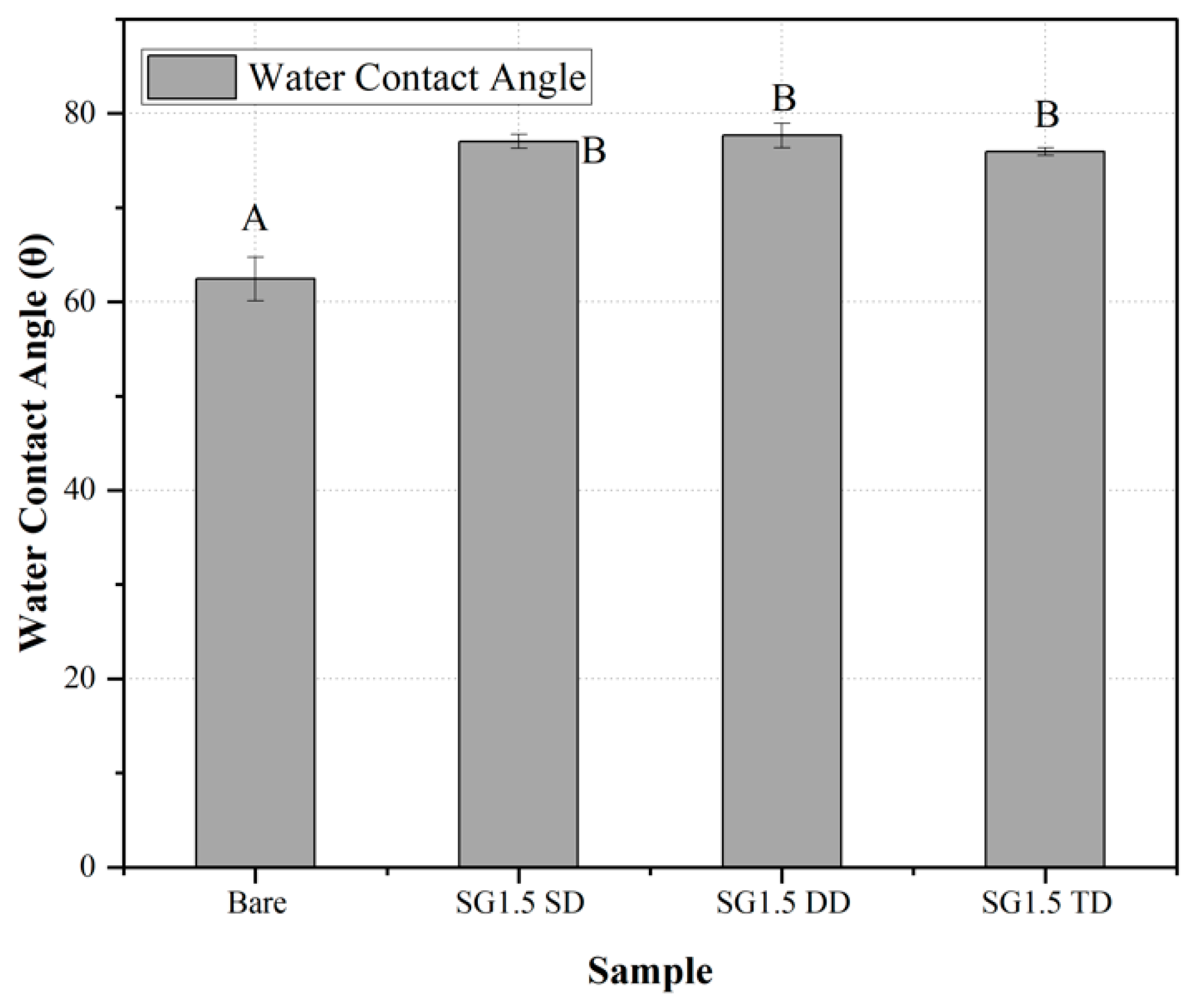

4.3. Contact Angle Measurements

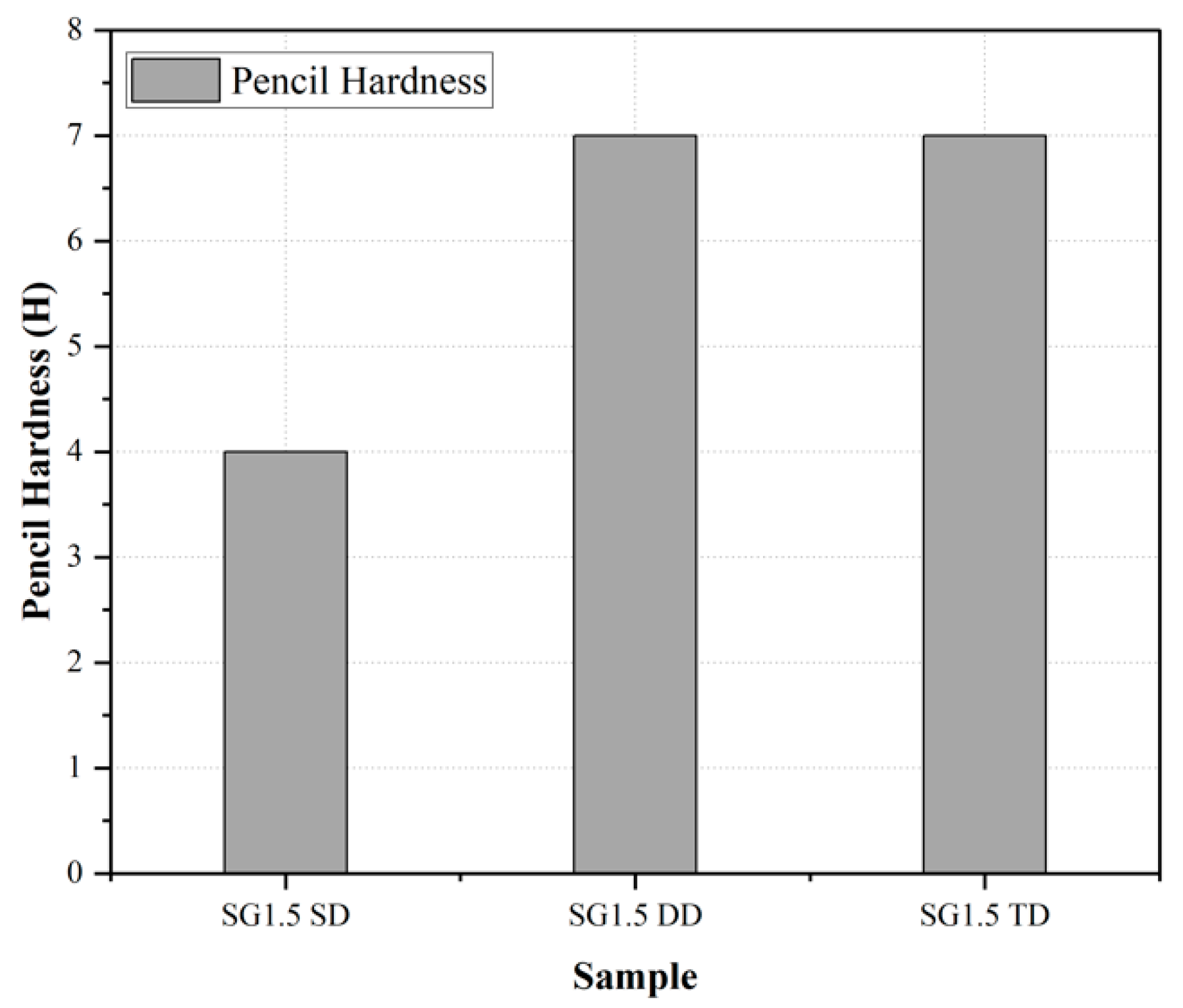

4.4. Pencil Hardness Test

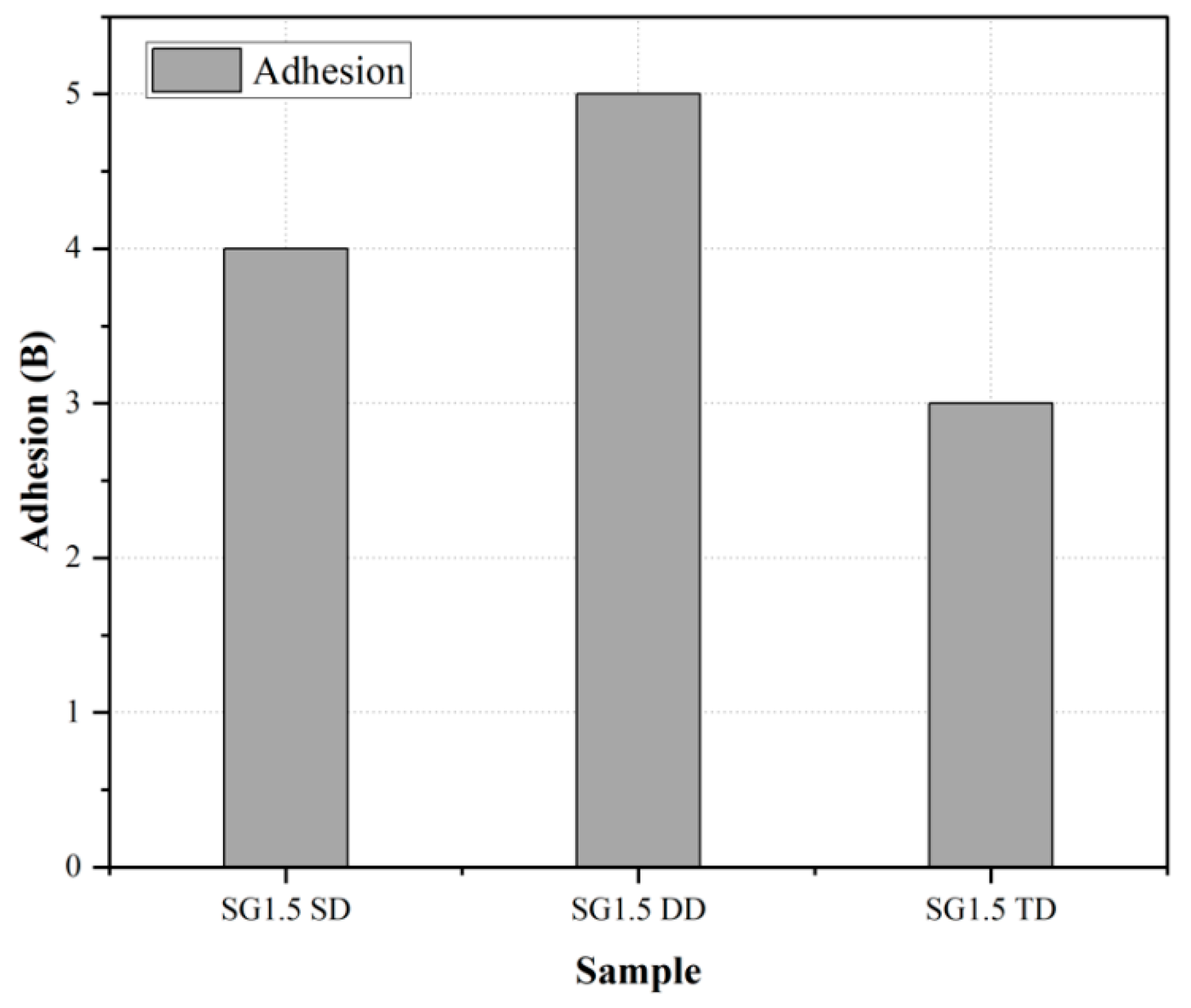

4.5. Cross-Cut Adhesion Test

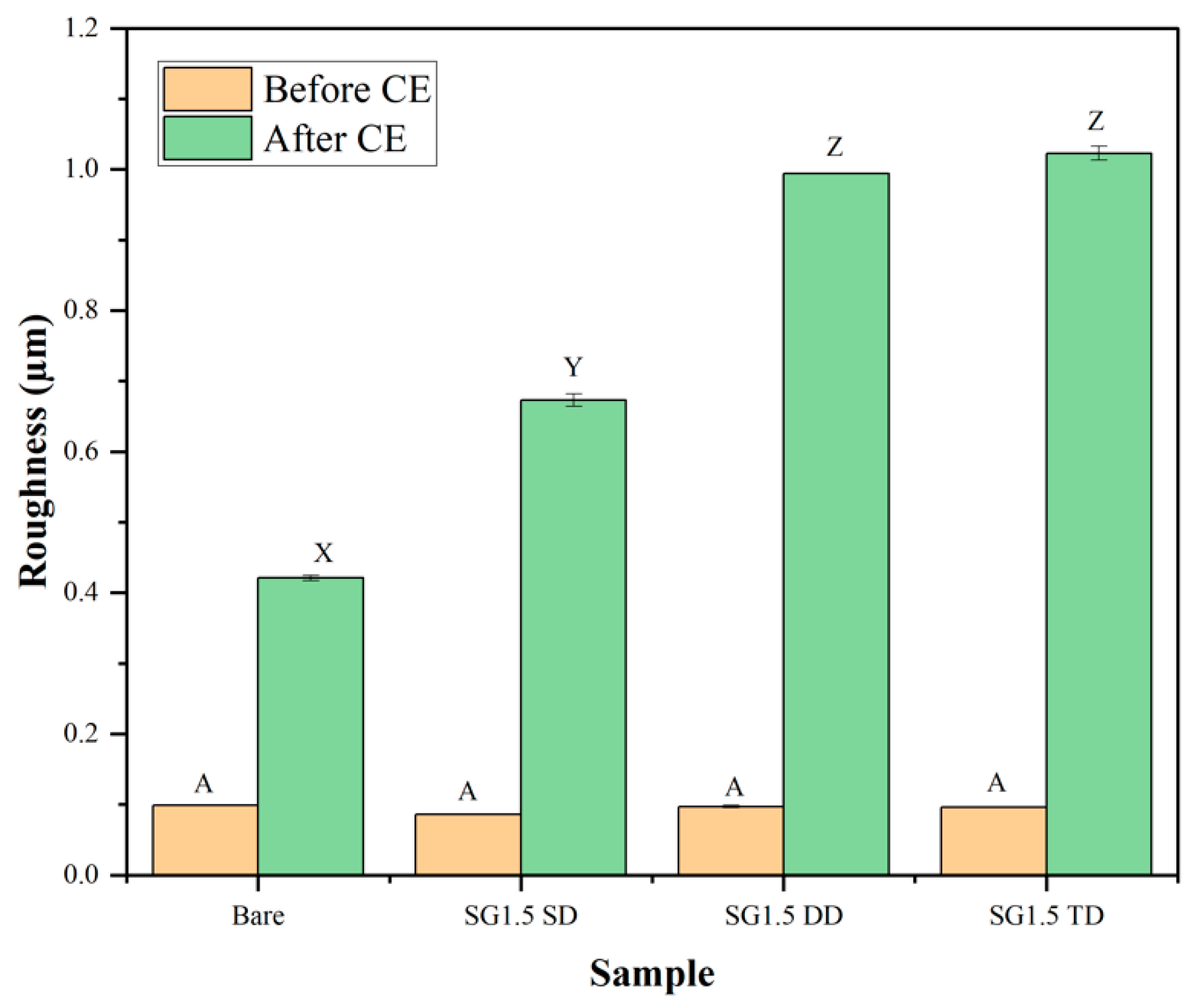

4.6. Surface Roughness Measurements

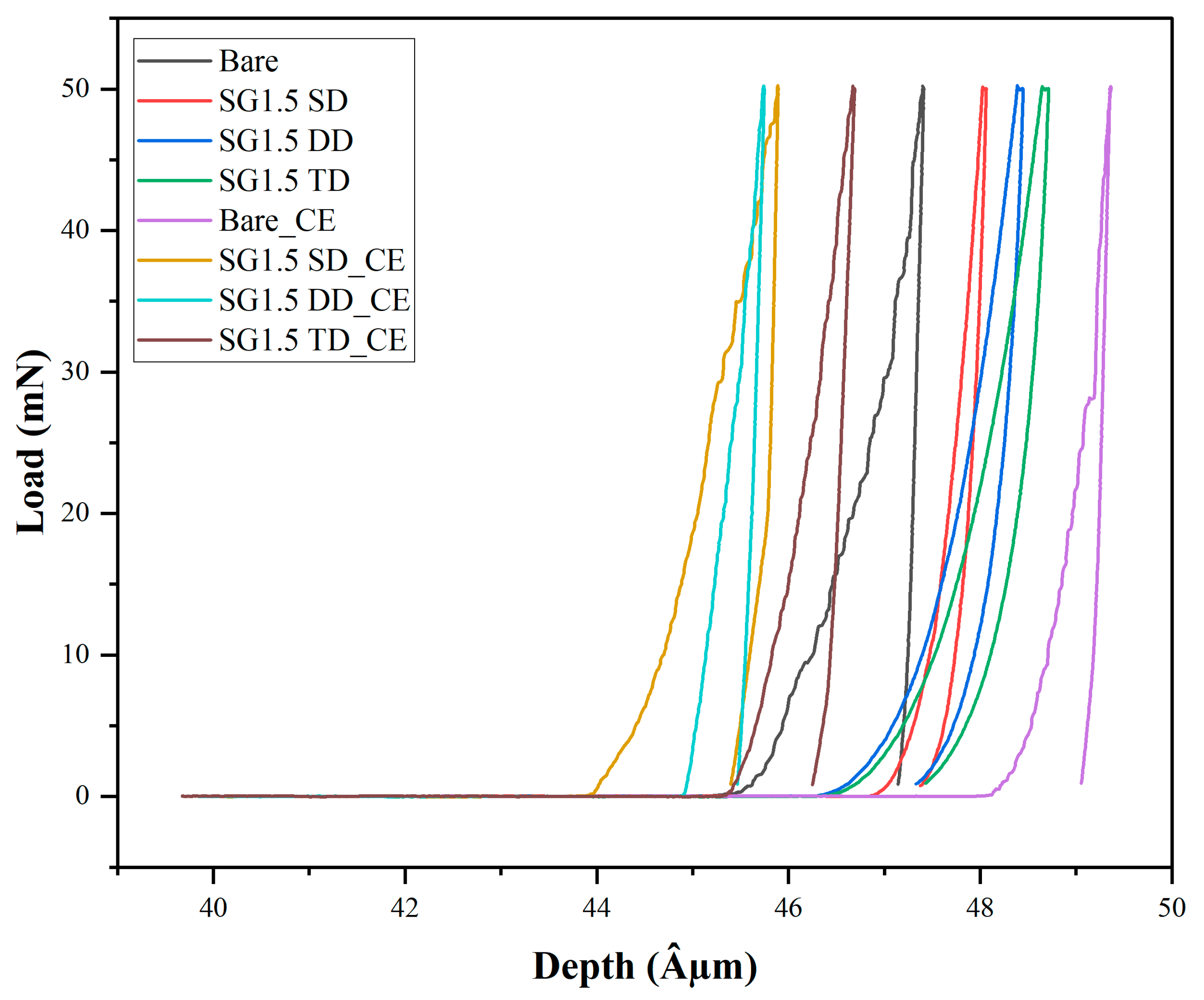

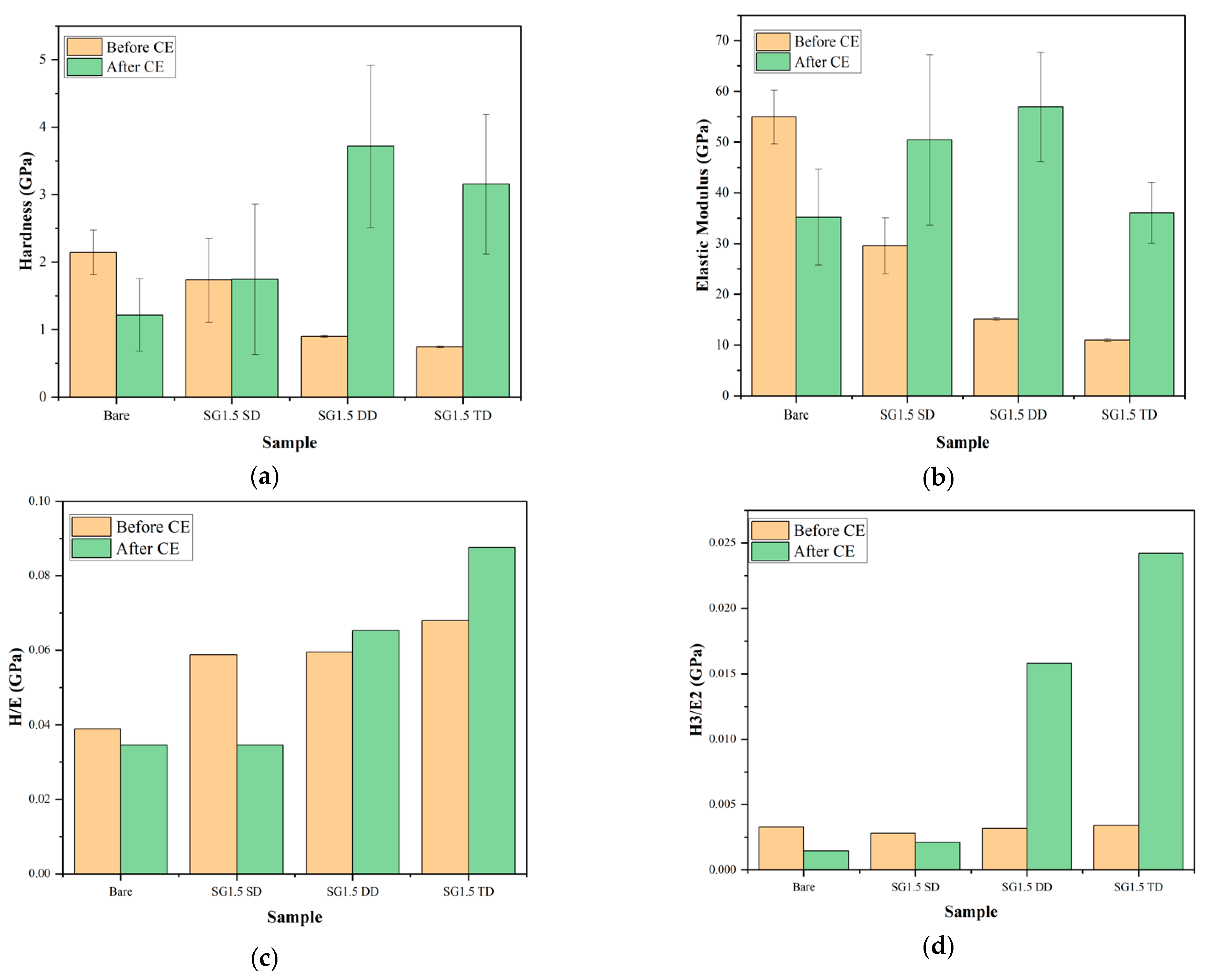

4.7. Nanoindentation Measurements

Effect of Cavitation Erosion on Nanoindentation Results

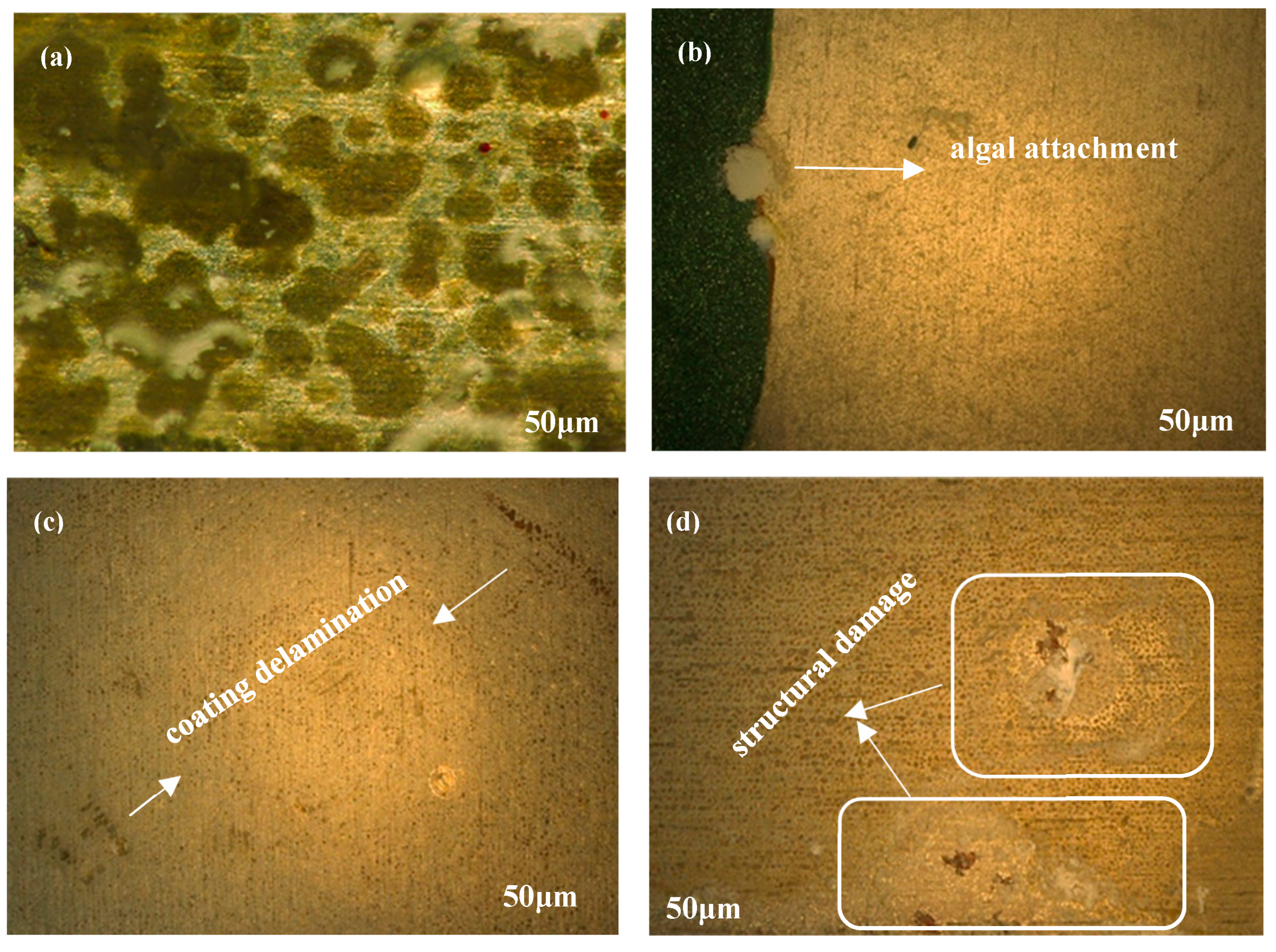

4.8. Antifouling Activity

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, H.; Guo, X.; Chen, R.; Liu, Q.; Liu, J.; Yu, J.; Lin, C.; Wang, J.; Zhang, M. Enhanced anti-biofouling ability of polyurethane anti-cavitation coating with ZIF-8: A comparative study of various sizes of ZIF-8 on coating. Eur. Polym. J. 2021, 144, 110212. [Google Scholar] [CrossRef]

- Liang, L.; Pang, Y.; Tang, Y.; Zhang, H.; Liu, H.; Liu, Y. Combined wear of slurry erosion, cavitation erosion, and corrosion on the simulated ship surface. Adv. Mech. Eng. 2019, 11, 1687814019834450. [Google Scholar] [CrossRef]

- Shchukin, D.G.; Skorb, E.; Belova, V.; Möhwald, H. Ultrasonic cavitation at solid surfaces. Adv. Mater. 2011, 23, 1922–1934. [Google Scholar] [CrossRef] [PubMed]

- Plesset, M.S.; Chapman, R.B. Collapse of an initially spherical vapour cavity in the neighbourhood of a solid boundary. J. Fluid Mech. 1971, 47, 283–290. [Google Scholar] [CrossRef]

- Krefting, D.; Mettin, R.; Lauterborn, W. High-speed observation of acoustic cavitation erosion in multibubble systems. Ultrason. Sonochemistry 2004, 11, 119–123. [Google Scholar] [CrossRef] [PubMed]

- Dang, H.; Lovell, C.R. Microbial surface colonization and biofilm development in marine environments. Microbiol. Mol. Biol. Rev. 2016, 80, 91–138. [Google Scholar] [CrossRef]

- Francolini, I.; Vuotto, C.; Piozzi, A.; Donelli, G. Antifouling and antimicrobial biomaterials: An overview. Apmis 2017, 125, 392–417. [Google Scholar] [CrossRef]

- Mooss, V.A.; Hamza, F.; Zinjarde, S.S.; Athawale, A.A. Polyurethane films modified with polyaniline-zinc oxide nanocomposites for biofouling mitigation. Chem. Eng. 2019, 359, 1400–1410. [Google Scholar] [CrossRef]

- Banerjee, I.; Pangule, R.C.; Kane, R.S. Antifouling coatings: Recent developments in the design of surfaces that prevent fouling by proteins, bacteria, and marine organisms. Adv. Mater. 2011, 23, 690–718. [Google Scholar] [CrossRef]

- Xie, Q.; Pan, J.; Ma, C.; Zhang, G. Dynamic surface antifouling: Mechanism and systems. Soft Matter 2019, 15, 1087–1107. [Google Scholar] [CrossRef]

- Magin, C.M.; Cooper, S.P.; Brennan, A.B. Non-toxic antifouling strategies. Mater. Today 2010, 13, 36–44. [Google Scholar] [CrossRef]

- Lu, Y.; Yin, Y.; Mayers, B.T.; Xia, Y. Modifying the surface properties of superparamagnetic iron oxide nanoparticles through a sol−gel approach. Nano Lett. 2002, 2, 183–186. [Google Scholar] [CrossRef]

- Ni, M.; Leung, M.K.; Leung, D.Y.; Sumathy, K.J.R. A review and recent developments in photocatalytic water-splitting using TiO2 for hydrogen production. Renew. Sustain. Energy Rev. 2007, 11, 401–425. [Google Scholar] [CrossRef]

- Voulvoulis, N.; Scrimshaw, M.D.; Lester, J.N. Comparative environmental assessment of biocides used in antifouling paints. Chemosphere 2002, 47, 789–795. [Google Scholar] [CrossRef] [PubMed]

- Zheludkevich, M.; Serra, R.; Montemor, M.; Salvado, I.M.; Ferreira, M.J.S. Corrosion protective properties of nanostructured sol–gel hybrid coatings to AA2024-T3. Surf. Coat. 2006, 200, 3084–3094. [Google Scholar] [CrossRef]

- ANNEX. TO REACH—Conditions of Restriction. 1907. 2006. Available online: https://osha.europa.eu/en/legislation/directives/regulation-ec-no-1907-2006-of-the-european-parliament-and-of-the-council (accessed on 26 March 2023).

- Chambers, L.D.; Stokes, K.R.; Walsh, F.C.; Wood, R. Modern approaches to marine antifouling coatings. Surf. Coat. 2006, 201, 3642–3652. [Google Scholar] [CrossRef]

- Fahim, J.; Hadavi, S.; Ghayour, H.; Tabrizi, S.H. Cavitation erosion behavior of super-hydrophobic coatings on Al5083 marine aluminum alloy. Wear 2019, 424, 122–132. [Google Scholar] [CrossRef]

- Fang, Z.; Cao, J.; Guan, Y. Corrosion Control Technologies for Aluminum Alloy Vessel; Springer: Singapore, 2020. [Google Scholar]

- Osborne, J. Observations on chromate conversion coatings from a sol–gel perspective. Prog. Org. Coat. 2001, 41, 280–286. [Google Scholar] [CrossRef]

- Wang, H.; Akid, R. A room temperature cured sol–gel anticorrosion pre-treatment for Al 2024-T3 alloys. Corros. Sci. 2007, 49, 4491–4503. [Google Scholar] [CrossRef]

- Sanchez, C.; Ribot, F.; Lebeau, B. Molecular design of hybrid organic-inorganic nanocomposites synthesized via sol-gel chemistry. J. Mater. Chem. 1999, 9, 35–44. [Google Scholar] [CrossRef]

- Sharp, K. Inorganic/organic hybrid materials. Adv. Mater. 1998, 10, 1243–1248. [Google Scholar] [CrossRef]

- Ashrafi-Shahri, S.; Ravari, F.; Seifzadeh, D. Smart organic/inorganic sol-gel nanocomposite containing functionalized mesoporous silica for corrosion protection. Prog. Org. Coat. 2019, 133, 44–54. [Google Scholar] [CrossRef]

- Chou, T.; Chandrasekaran, C.; Cao, G. Sol-gel-derived hybrid coatings for corrosion protection. J. Sol-Gel Sci. Technol. 2003, 26, 321–327. [Google Scholar] [CrossRef]

- Mackenzie, J.; Bescher, E. Some factors governing the coating of organic polymers by sol-gel derived hybrid materials. J. Sol-Gel Sci. Technol. 2003, 27, 7–14. [Google Scholar] [CrossRef]

- Hwang, J.M.; Yeo, C.S.; Kim, Y. Preparation and Characterization of Sol-Gel Derived SiO2-TiO2-PDMS Composite Films. Bull. Korean Chem. Soc. 2001, 22, 1366–1370. [Google Scholar]

- Du, Y.J.; Damron, M.; Tang, G.; Zheng, H.; Chu, C.-J.; Osborne, J.H. Inorganic/organic hybrid coatings for aircraft aluminum alloy substrates. Prog. Org. Coat. 2001, 41, 226–232. [Google Scholar]

- Hofacker, S.; Mechtel, M.; Mager, M.; Kraus, H. Sol–gel: A new tool for coatings chemistry. Prog. Org. Coat. 2002, 45, 159–164. [Google Scholar] [CrossRef]

- Suárez-Vega, A.; Agustín-Sáenz, C.; O’Dell, L.A.; Brusciotti, F.; Somers, A.; Forsyth, M. Properties of hybrid sol-gel coatings with the incorporation of lanthanum 4-hydroxy cinnamate as corrosion inhibitor on carbon steel with different surface finishes. Appl. Surf. Sci. 2021, 561, 149881. [Google Scholar] [CrossRef]

- Mozammel, M.; Khajeh, M.; Ilkhechi, N.N. Effect of surface roughness of 316 L stainless steel substrate on the morphological and super-hydrophobic property of TiO2 thin films coatings. Silicon 2018, 10, 2603–2607. [Google Scholar] [CrossRef]

- Cullen, M.; O’Sullivan, M.; Kumar, A.M.; Sorour, A.A.; Duffy, B.; Oubaha, M. The role of the hydrolysis and zirconium concentration on the structure and anticorrosion performances of a hybrid silicate sol-gel coating. J. Sol-Gel Sci. Technol. 2018, 86, 553–567. [Google Scholar] [CrossRef]

- MacHugh, E.; Cullen, M.; Kaworek, A.; Duffy, B.; Oubaha, M. The effect of curing and zirconium content on the wettability and structure of a silicate hybrid sol-gel material. J. Non-Cryst. Solids 2019, 525, 119658. [Google Scholar] [CrossRef]

- Schubert, U. Organofunctional metal oxide clusters as building blocks for inorganic-organic hybrid materials. J. Sol-Gel Sci. Technol. 2004, 31, 19–24. [Google Scholar] [CrossRef]

- Wang, T.; Wang, X.; Zhang, Y.; Liu, L.; Xu, L.; Liu, Y.; Zhang, L.; Luo, Z.; Cen, K. Effect of zirconium (IV) propoxide concentration on the thermophysical properties of hybrid organic-inorganic films. J. Appl. Phys. 2008, 104, 013528. [Google Scholar] [CrossRef]

- Del Monte, F.; Cheben, P.; Grover, C.; Mackenzie, J. Preparation and optical characterization of thick-film zirconia and titania ormosils. J. Sol-Gel Sci. Technol. 1999, 15, 73–85. [Google Scholar] [CrossRef]

- Fedel, M.; Deflorian, F. Influence of a boiling water treatment on the electrochemical properties of a sol–gel film on AA1050. Trans. IMF 2015, 93, 313–320. [Google Scholar] [CrossRef]

- Fedel, M. Effect of sol–gel layers obtained from GLYMO/MTES mixtures on the delamination of a cataphoretic paint on AA1050. J. Coat. Technol. Res. 2017, 14, 425–435. [Google Scholar] [CrossRef]

- Naderi, R.; Fedel, M.; Urios, T.; Poelman, M.; Olivier, M.G.; Deflorian, F. Optimization of silane sol–gel coatings for the protection of aluminium components of heat exchangers. Surf. Interface Anal. 2013, 45, 1457–1466. [Google Scholar] [CrossRef]

- Tiringer, U.; Van Dam, J.; Abrahami, S.; Terryn, H.; Kovač, J.; Milošev, I.; Mol, J. Scrutinizing the importance of surface chemistry versus surface roughness for aluminium/sol-gel film adhesion. Surf. Interfaces 2021, 26, 101417. [Google Scholar] [CrossRef]

- Lebeau, B.; Innocenzi, P. Hybrid materials for optics and photonics. Chem. Soc. Rev. 2011, 40, 886–906. [Google Scholar] [CrossRef]

- Ferreira, R.; André, P.; Carlos, L. Organic–inorganic hybrid materials towards passive and active architectures for the next generation of optical networks. Opt. Mater. 2010, 32, 1397–1409. [Google Scholar] [CrossRef]

- Elmaghrum, S.; Gorin, A.; Kribich, R.K.; Corcoran, B.; Copperwhite, R.; McDonagh, C.; Oubaha, M. Development of a sol–gel photonic sensor platform for the detection of biofilm formation. Sens. Actuators B 2013, 177, 357–363. [Google Scholar] [CrossRef]

- Oubaha, M.; Kavanagh, A.; Gorin, A.; Bickauskaite, G.; Byrne, R.; Farsari, M.; Winfield, R.; Diamond, D.; McDonagh, C.; Copperwhite, R. Graphene-doped photo-patternable ionogels: Tuning of conductivity and mechanical stability of 3D microstructures. J. Mater. Chem. 2012, 22, 10552–10559. [Google Scholar] [CrossRef]

- Ghosh, G.; Sidpara, A.; Bandyopadhyay, P. Understanding the role of surface roughness on the tribological performance and corrosion resistance of WC-Co coating. Surf. Coat. 2019, 378, 125080. [Google Scholar] [CrossRef]

- Wang, A.; Rack, H. Dry sliding wear in 2124 Al-SiCw/17-4 PH stainless steel systems. Wear 1991, 147, 355–374. [Google Scholar] [CrossRef]

- Bayer, R.; Sirico, J. The influence of surface roughness on wear. Wear 1975, 35, 251–260. [Google Scholar] [CrossRef]

- Walter, R.; Kannan, M. Influence of surface roughness on the corrosion behaviour of magnesium alloy. Mater. Des. 2011, 32, 2350–2354. [Google Scholar] [CrossRef]

- Hong, T.; Nagumo, M. Effect of surface roughness on early stages of pitting corrosion of type 301 stainless steel. Corros. Sci. 1997, 39, 1665–1672. [Google Scholar] [CrossRef]

- Cabrini, M.; Cigada, A.; Rondell, G.; Vicentini, B. Effect of different surface finishing and of hydroxyapatite coatings on passive and corrosion current of Ti6Al4V alloy in simulated physiological solution. Biomaterials 1997, 18, 783–787. [Google Scholar] [CrossRef]

- Li, W.; Li, D. Influence of surface morphology on corrosion and electronic behavior. Acta Mater. 2006, 54, 445–452. [Google Scholar] [CrossRef]

- Krzak-Roś, J.; Filipiak, J.; Pezowicz, C.; Baszczuk, A.; Miller, M.; Kowalski, M.; Będziński, R. The effect of substrate roughness on the surface structure of TiO2, SiO2, and doped thin films prepared by the sol-gel method. Acta Bioeng. Biomech. 2009, 11, 21–29. [Google Scholar]

- Zhao, H.; Yu, M.; Liu, J.; Li, S.; Xue, B.; Liang, M. Effect of surface roughness on corrosion resistance of sol-gel coatings on AA2024-T3 alloy. J. Electrochem. Soc. 2015, 162, C718. [Google Scholar] [CrossRef]

- Fernández-Hernán, J.; López, A.; Torres, B.; Rams, J. Influence of roughness and grinding direction on the thickness and adhesion of sol-gel coatings deposited by dip-coating on AZ31 magnesium substrates. A Landau–Levich equation revision. Surf. Coat. 2021, 408, 126798. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, X.; Lao, Y.; Lv, X.; Tao, Y.; Huang, B.; Wang, J.; Zhou, J.; Cai, Z. TiO2 nanoparticles in the marine environment: Physical effects responsible for the toxicity on algae Phaeodactylum tricornutum. Sci. Total Environ. 2016, 565, 818–826. [Google Scholar] [CrossRef]

- Liu, Z.; Tian, S.; Li, Q.; Wang, J.; Pu, J.; Wang, G.; Zhao, W.; Feng, F.; Qin, J.; Ren, L. Integrated dual-functional ORMOSIL coatings with AgNPs@ rGO nanocomposite for corrosion resistance and antifouling applications. ACS Sustain. Chem. Eng. 2020, 8, 6786–6797. [Google Scholar] [CrossRef]

- Hegde, M.; Kavanagh, Y.; Duffy, B.; Tobin, E.F. Abrasion and Cavitation Erosion Resistance of Multi-Layer Dip Coated Sol-Gel Coatings on AA2024-T3. Corros. Mater. Degrad. 2022, 3, 661–671. [Google Scholar] [CrossRef]

- ISO 15184:2020; Paints and Varnishes—Determination Of Film Hardness by Pencil Test. ISO: Geneva, Switzerland, 2020.

- ASTM D3359-09; Standard Test Methods for Measuring Adhesion by Tape Test. ASTM: West Conshohocken, PA, USA, 2023.

| Substrate | Coating Reference |

|---|---|

| MAPTMS + ZPO + 1.5% HMDI single dip | SG1.5 SD |

| MAPTMS + ZPO + 1.5% HMDI double dip | SG 1.5 DD |

| MAPTMS + ZPO + 1.5% HMDI triple dip | SG 1.5 TD |

| Salts | Concentration (Dissolved in 2 L of Deionized Water) |

|---|---|

| NaCl | 52.8 g |

| KCl | 1680 mg |

| CaCl2·2H2O | 3340 mg |

| MgCl2·6H2O | 9200 mg |

| MgSO4·7H2O | 11,160 mg |

| NaHCO3 | 340 mg |

| H3BO3 | 60 mg |

| Sample | Bare | SG1.5 SD | SG1.5 DD | SG1.5 TD |

|---|---|---|---|---|

| Time (min) | Average Cumulative Mass Loss (mg) | |||

| Start | 0 | 0 | 0 | 0 |

| 1 | 0.5 | 0 | 0 | 0 |

| 3 | 1.0 | 0.2 | 0.6 | 0.3 |

| 5 | 1.8 | 0.5 | 0.8 | 0.6 |

| 7 | 2.4 | 0.63 | 1.1 | 0.8 |

| 9 | 2.8 | 0.8 | 1.23 | 1.22 |

| 11 | 3.5 | 1.0 | 1.4 | 1.38 |

| Rank | Materials |

|---|---|

| 1 | SG1.5 DD |

| 2 | SG1.5 TD |

| 3 | SG1.5 SD |

| 4 | Bare |

| Parameter | Before Cavitation Test | After Cavitation Test | ||||||

|---|---|---|---|---|---|---|---|---|

| Bare | SG1.5 SD | SG1.5 DD | SG1.5 TD | Bare | SG1.5 SD | SG1.5 DD | SG1.5 TD | |

| H | 2.14 | 1.73 | 0.89 | 0.74 | 1.21 | 1.74 | 3.71 | 3.15 |

| E | 54.95 | 29.53 | 15.12 | 10.94 | 37.17 | 50.41 | 56.93 | 36.03 |

| H/E | 0.038 | 0.059 | 0.059 | 0.067 | 0.03 | 0.035 | 0.065 | 0.08 |

| H3/E2 | 3.2 × 10−3 | 5.9 × 10−3 | 3.1 × 10−3 | 3.4 × 10−3 | 1.3 × 10−3 | 2.0 × 10−3 | 9.8 × 10−3 | 0.024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hegde, M.; Mroczkowska, M.; Mohan, J.; Neves, A.C.; Kavanagh, Y.; Duffy, B.; Tobin, E.F. Influence of Physical and Mechanical Parameters on Cavitation Erosion and Antifouling Behaviour of Multilayer Silica-Based Hybrid Sol–Gel Coatings on Aluminium Alloys. Eng 2023, 4, 1393-1408. https://doi.org/10.3390/eng4020081

Hegde M, Mroczkowska M, Mohan J, Neves AC, Kavanagh Y, Duffy B, Tobin EF. Influence of Physical and Mechanical Parameters on Cavitation Erosion and Antifouling Behaviour of Multilayer Silica-Based Hybrid Sol–Gel Coatings on Aluminium Alloys. Eng. 2023; 4(2):1393-1408. https://doi.org/10.3390/eng4020081

Chicago/Turabian StyleHegde, Manasa, Marta Mroczkowska, Joseph Mohan, Adriana Cunha Neves, Yvonne Kavanagh, Brendan Duffy, and Edmond F. Tobin. 2023. "Influence of Physical and Mechanical Parameters on Cavitation Erosion and Antifouling Behaviour of Multilayer Silica-Based Hybrid Sol–Gel Coatings on Aluminium Alloys" Eng 4, no. 2: 1393-1408. https://doi.org/10.3390/eng4020081

APA StyleHegde, M., Mroczkowska, M., Mohan, J., Neves, A. C., Kavanagh, Y., Duffy, B., & Tobin, E. F. (2023). Influence of Physical and Mechanical Parameters on Cavitation Erosion and Antifouling Behaviour of Multilayer Silica-Based Hybrid Sol–Gel Coatings on Aluminium Alloys. Eng, 4(2), 1393-1408. https://doi.org/10.3390/eng4020081