Evaluation of the Technological Properties of Soil–Cement Bricks with Incorporation of Coconut Fiber Powder

Abstract

:1. Introduction

2. Materials and Methods

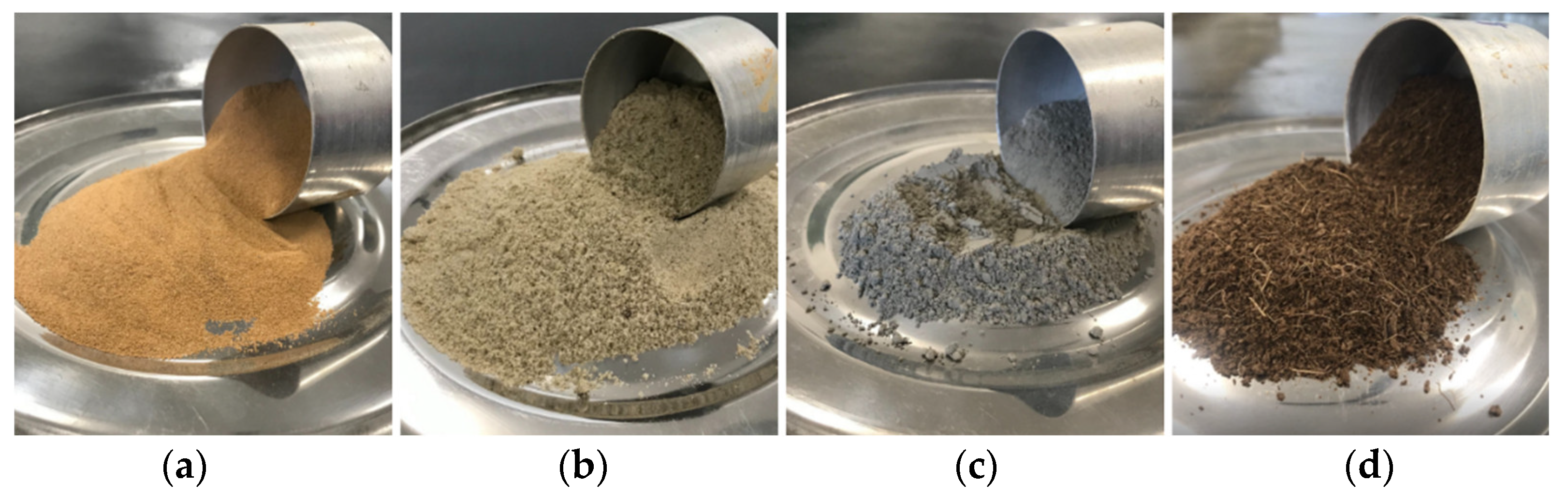

2.1. Materials

2.2. Sample Preparation and Characterization

2.2.1. Soil

2.2.2. Coconut Fiber

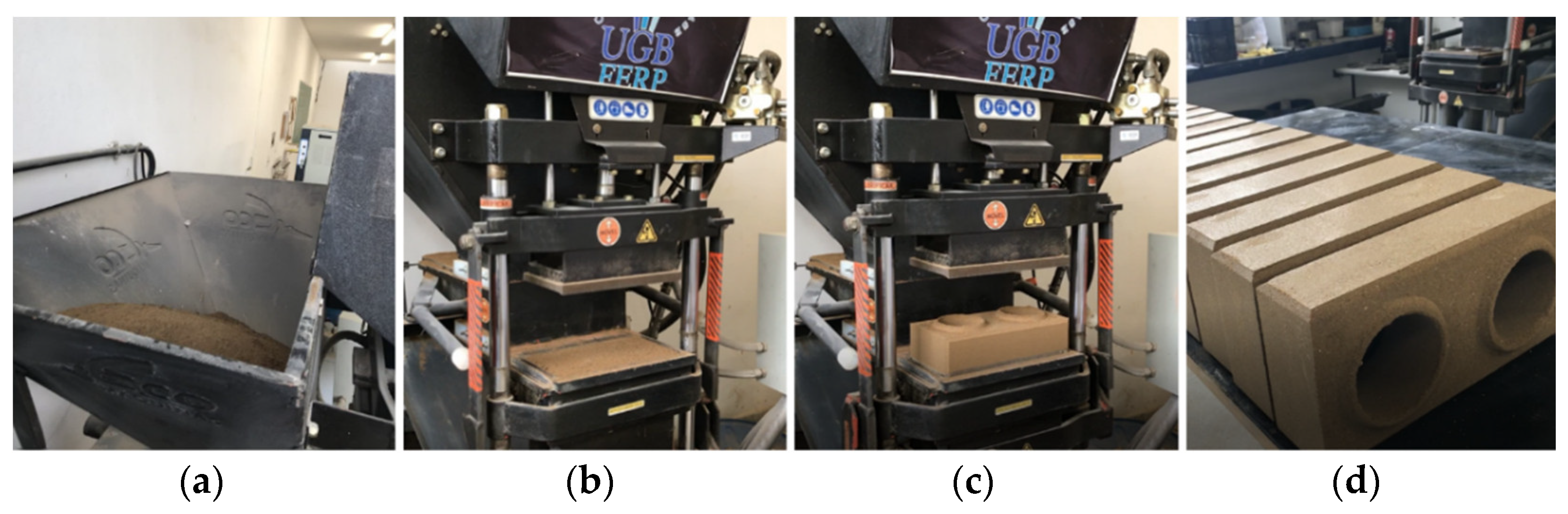

2.3. Manufacturing of the Bricks

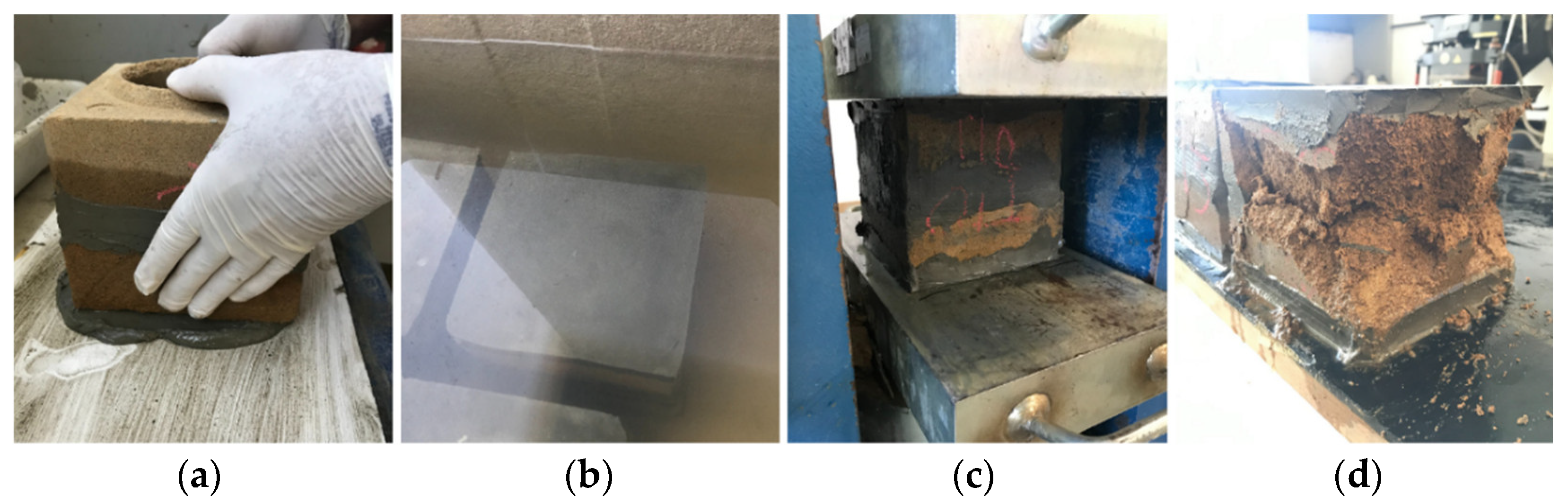

2.4. Curing the Bricks

2.5. Technological Tests

2.5.1. Compressive Strength

2.5.2. Water Absorption

2.6. Statistical Analysis

3. Results and Discussion

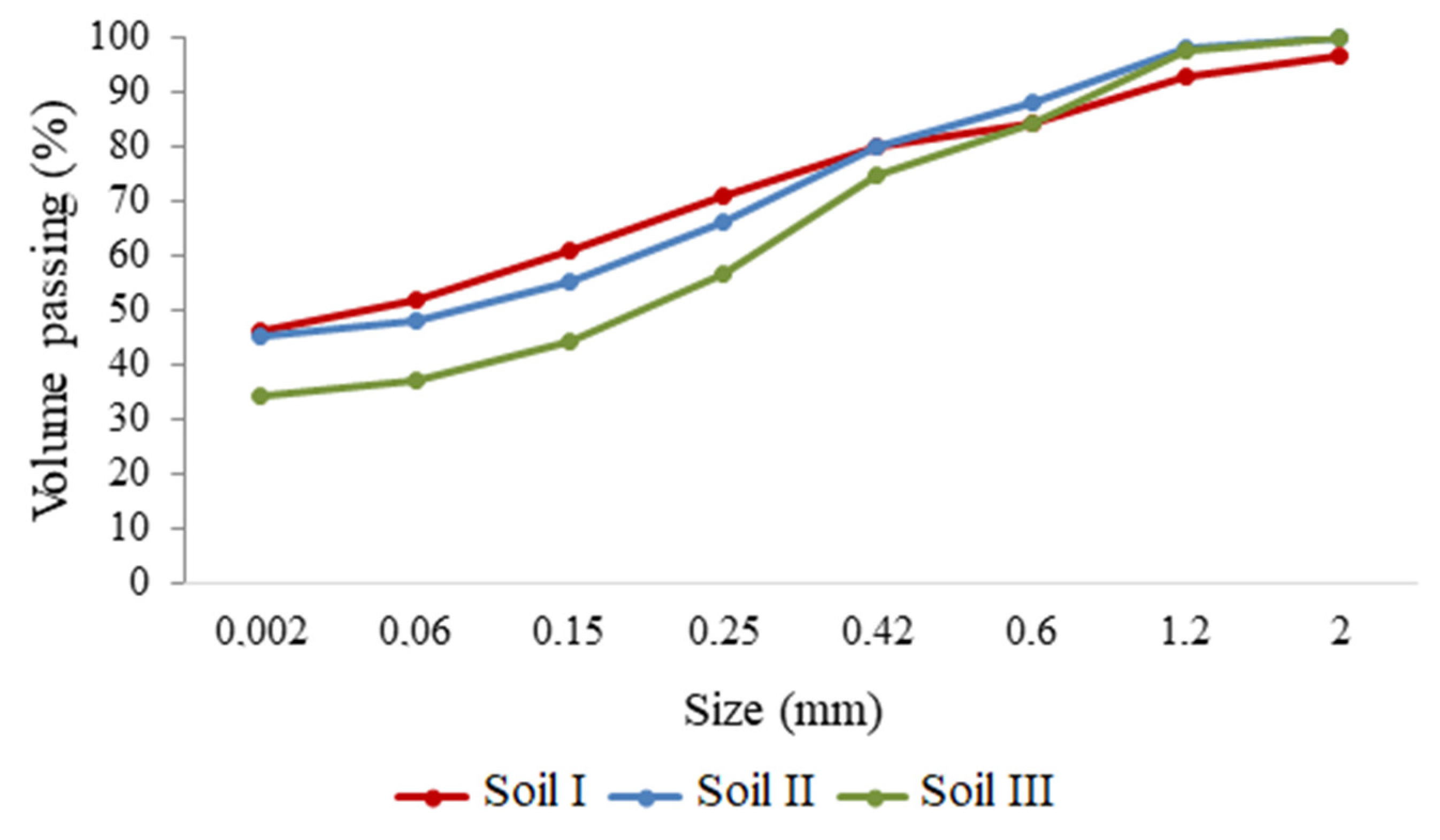

3.1. Particle Size Analysis (Soil and Coconut Fiber)

3.2. Atterberg Limits

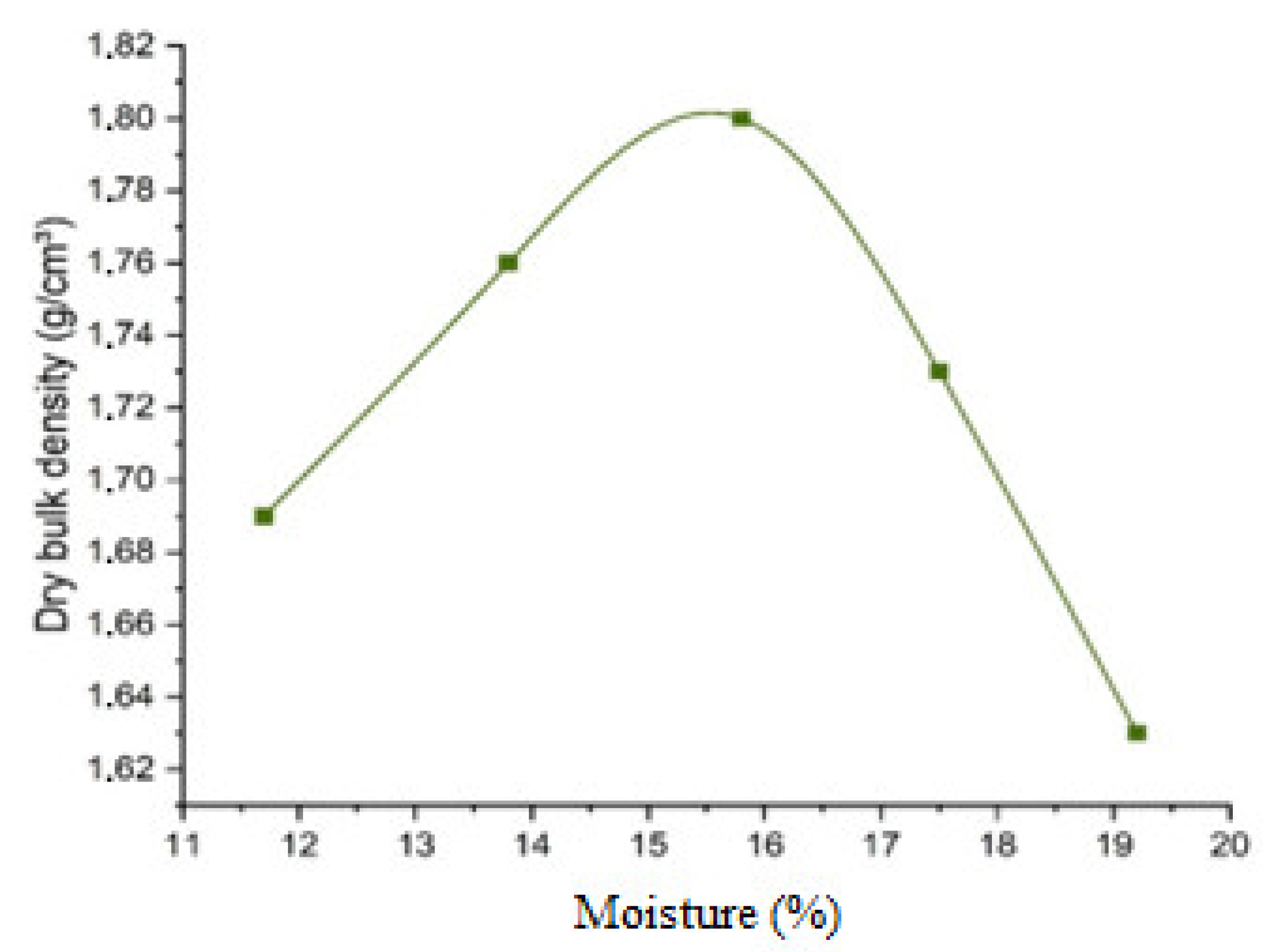

3.3. Moisture Content and Compaction Energy

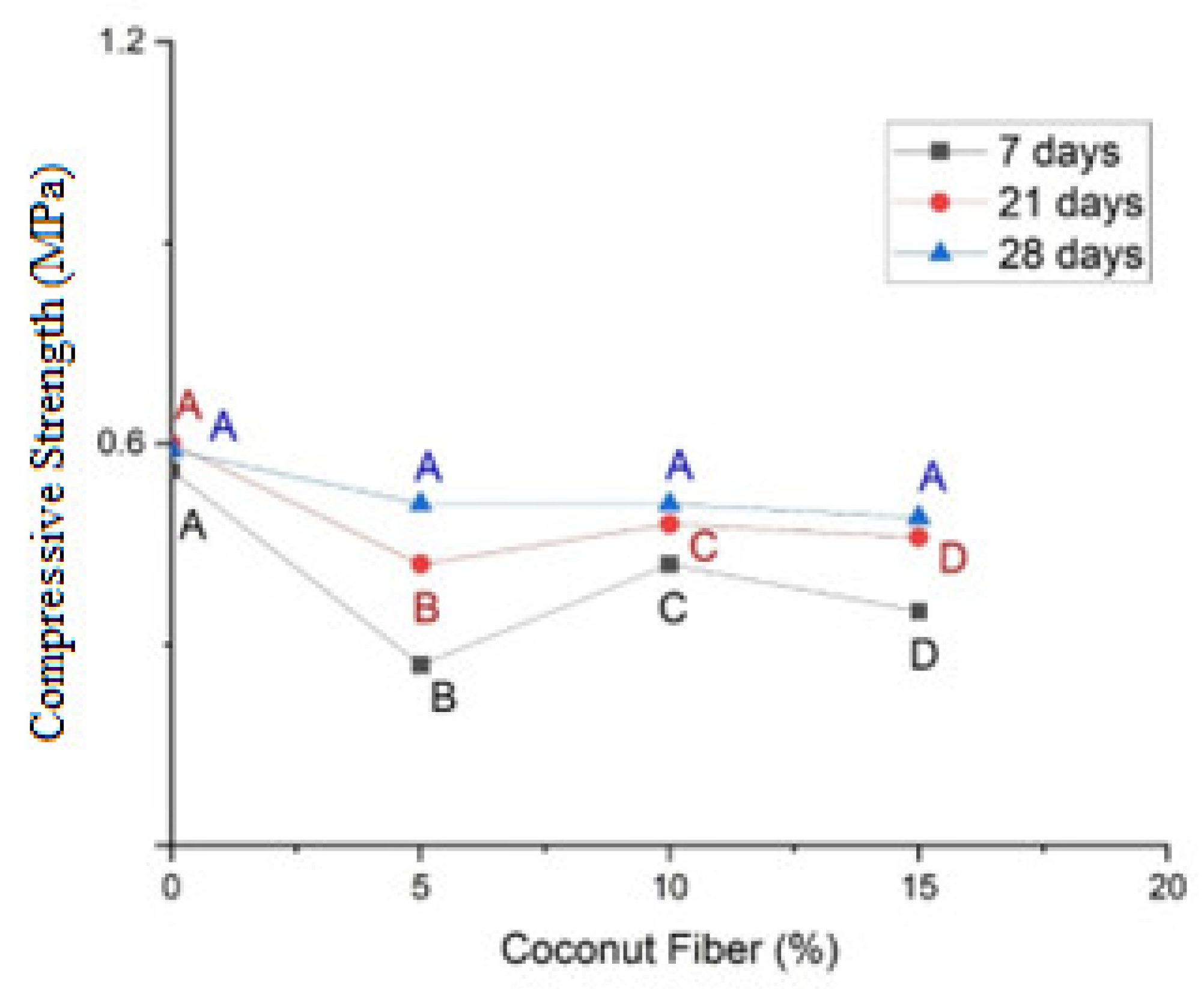

3.4. Compression Strength

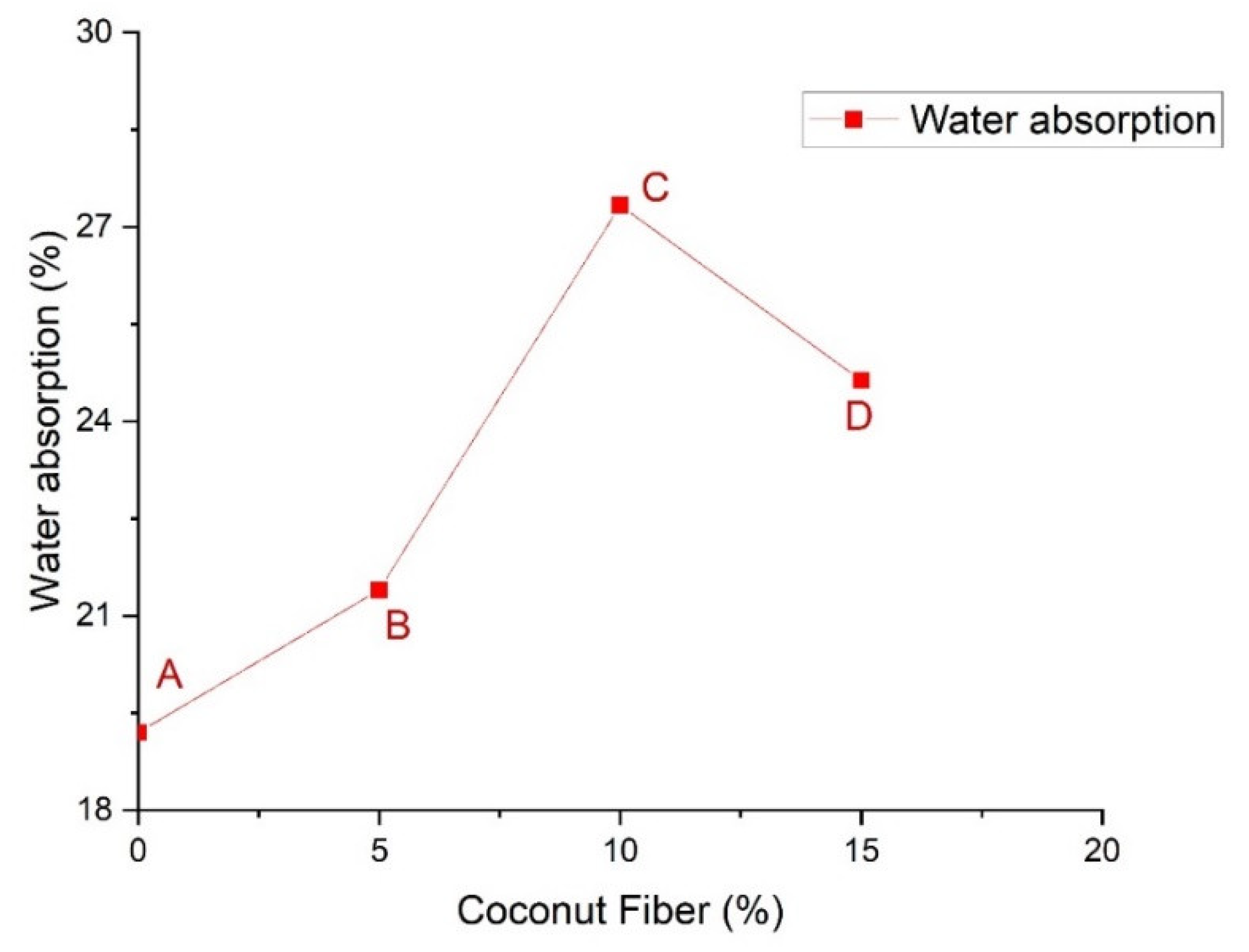

3.5. Water Absorption

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Da Silva, T.R.; de Azevedo, A.R.G.; Cecchin, D.; Marvila, M.T.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M.; Klyuev, S.; Szelag, M. Application of Plastic Wastes in Construction Materials: A Review Using the Concept of Life-Cycle Assessment in the Context of Recent Research for Future Perspectives. Materials 2021, 14, 3549. [Google Scholar] [CrossRef] [PubMed]

- Kaza, S.; Yao, L.; Bhada-Tata Woerden, P.F.V. What a Waste 2.0—A Global Snapshot of Solid Waste Management to 2050; World Bank Group: Washington, DC, USA, 2018; ISBN 978-1-4648-1329-0. [Google Scholar]

- Das, S.; Lee, S.-H.; Kumar, P.; Kim, K.-H.; Lee, S.S.; Bhattacharya, S.S. Solid waste management: Scope and the challenge of sustainability. J. Clean. Prod. 2019, 228, 658–678. [Google Scholar] [CrossRef]

- Kochova, K.; Gauvin, F.; Schollbach, K.; Brouwers, H. Using alternative waste coir fibres as a reinforcement in cement-fibre composites. Constr. Build. Mater. 2019, 231, 117121. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Suntijitto, A. Properties of natural fiber cement materials containing coconut coir and oil palm fibers for residential building applications. Constr. Build. Mater. 2015, 94, 664–669. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO STATS). Production Quatity. Coconuts (2020). Available online: https://www.fao.org/faostat/en/#home (accessed on 10 March 2022).

- Ferreira, G.M.G.; Cecchin, D.; De Azevedo, A.R.G.; Valadão, I.C.R.P.; Costa, K.A.; Silva, T.R.; Ferreira, F.; Amaral, P.I.S.; Huther, C.M.; Sousa, F.A.; et al. Bibliometric analysis on the use of natural fibers in construction materials. Agron. Res. 2021, 19, 1–12. [Google Scholar]

- Adeniyi, A.G.; Onifade, D.V.; Ighalo, J.O.; Adeoye, A.S. A review of coir fiber reinforced polymer composites. Compos. Part B Eng. 2019, 176, 107305. [Google Scholar] [CrossRef]

- Ganguly, A.; Shankar, S.; Das, A.; Shukla, M.; Swaroop, C.; Bhardwaj, T. Natural fibre reinforced composites: A review based on additive manufacturing routes and biodegradability perspective. Mater. Today Proc. 2022, 62, 131–135. [Google Scholar] [CrossRef]

- Walte, A.B.; Bhole, K.; Gholave, J. Mechanical Characterization of Coir Fiber Reinforced Composite. Mater. Today Proc. 2020, 24, 557–566. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Vilela, A.P.; Carvalho, T.M.; De Oliveira, E.F.F.; Mendes, J.F.; Ribeiro, A.G.C.; de S. Brandão Vaz, L.E.V.; Mendes, R.F. Technological properties of soil–cement bricks produced with iron ore mining waste. Constr. Build. Mater. 2020, 262, 120883. [Google Scholar] [CrossRef]

- Krishna, R.; Mishra, J.; Meher, S.; Das, S.K.; Mustakim, S.; Singh, S.K. Industrial solid waste management through sustainable green technology: Case study insights from steel and mining industry in Keonjhar, India. Mater. Today Proc. 2020, 33, 5243–5249. [Google Scholar] [CrossRef]

- Danso, H.; Manu, D. Influence of coconut fibres and lime on the properties of soil–cement mortar. Case Stud. Constr. Mater. 2019, 12, e00316. [Google Scholar] [CrossRef]

- Salih, M.M.; Osofero, A.I.; Imbabi, M.S. Constitutive models for fibre reinforced soil bricks. Constr. Build. Mater. 2019, 240, 117806. [Google Scholar] [CrossRef]

- Raj, S.; Mohammad, S.; Das, R.; Saha, S. Coconut fibre-reinforced cement-stabilized rammed earth blocks. World J. Eng. 2017, 14, 208–216. [Google Scholar] [CrossRef]

- De Lima, T.E.S.; de Azevedo, A.R.G.; Marvila, M.T.; Candido, V.S.; Fediuk, R.; Monteiro, S.N. Potential of Using Amazon Natural Fibers to Reinforce Cementitious Composites: A Review. Polymers 2022, 14, 647. [Google Scholar] [CrossRef]

- Parlato, M.; Cuomo, M.; Porto, S. Natural fibers reinforcement for earthen building components: Mechanical performances of a low quality sheep wool (“Valle del Belice” sheep). Constr. Build. Mater. 2022, 326, 126855. [Google Scholar] [CrossRef]

- AlShuhail, K.; Aldawoud, A.; Syarif, J.; Abu Abdoun, I. Enhancing the performance of compressed soil bricks with natural additives: Wood chips and date palm fibers. Constr. Build. Mater. 2021, 295, 123611. [Google Scholar] [CrossRef]

- Tran, K.; Satomi, T.; Takahashi, H. Improvement of mechanical behavior of cemented soil reinforced with waste cornsilk fibers. Constr. Build. Mater. 2018, 178, 204–210. [Google Scholar] [CrossRef]

- Souza, P.C.; Nascimento, E.S.S.; Melo, L.; Oliveira, H.A.; Almeida, V.G.O.; Melo, F.M.C. Study for the incorporation of wood ash in soil–cement brick. Cerâmica 2022, 68, 38–45. [Google Scholar] [CrossRef]

- Danso, H.; Martinson, B.; Ali, M.; Williams, J. Effect of fibre aspect ratio on mechanical properties of soil building blocks. Constr. Build. Mater. 2015, 83, 314–319. [Google Scholar] [CrossRef] [Green Version]

- Associação Brasileira de Normas Técnicas. Amostra de Solo—Preparação para Ensaios de Compactação e Ensaios de Caracterização; NBR 6457; ABNT: Rio de Janeiro, Brazil, 2016; 8p. [Google Scholar]

- Associação Brasileira de Normas Técnicas. Solo—Análise Granulométrica; NBR 7181; ABNT: Rio de Janeiro, Brazil, 2016; 12p. [Google Scholar]

- Associação Brasileira de Normas Técnicas. Solo—Determinação do Limite de Liquidez; NBR 6459; ABNT: Rio de Janeiro, Brazil, 2016; 5p. [Google Scholar]

- Associação Brasileira de Normas Técnicas. Solo—Determinação do Limite de Plasticidade; NBR 7180; ABNT: Rio de Janeiro, Brazil, 2016; 3p. [Google Scholar]

- Associação Brasileira de Normas Técnicas. Fabricação de Tijolo e Bloco de Solo-Cimento com Utilização de Prensa Manual ou Hidráulica—Procedimento; NBR 10833; ABNT: Rio de Janeiro, Brazil, 2012; 3p. [Google Scholar]

- Associação Brasileira de Normas Técnicas. Solo—Ensaio de Compactação; NBR 7182; ABNT: Rio de Janeiro, Brazil, 2016; 9p. [Google Scholar]

- Associação Brasileira de Normas Técnicas. Agregados—Determinação da Composição Granulométrica; NBR NM 248; ABNT: Rio de Janeiro, Brazil, 2003; 6p. [Google Scholar]

- Associação Brasileira de Normas Técnicas. Tijolo de Solo-Cimento—Análise Dimensional, Determinação da Resistência à Compressão e da Absorção de Água—Método de Ensaio; NBR 8492; ABNT: Rio de Janeiro, Brazil, 2012; 4p. [Google Scholar]

- Associação Brasileira de Normas Técnicas. Tijolo de Solo-Cimento—Requisitos; NBR 8491; ABNT: Rio de Janeiro, Brazil, 2012; 5p. [Google Scholar]

- Associação Brasileira de Cimento Portland (ABCP). Fabricação de Tijolos de Solo-Cimento com a Utilização de Prensas Manuais, 3rd ed.; ABCP: São Paulo, Brazil, 2000; 16p, ISBN 85-87024-28-0. [Google Scholar]

- Elahi, T.E.; Shahriar, A.R.; Islam, M.S. Engineering characteristics of compressed earth blocks stabilized with cement and fly ash. Constr. Build. Mater. 2021, 277, 122367. [Google Scholar] [CrossRef]

- Jose, A.; Kasthurba, A. Laterite soil–cement blocks modified using natural rubber latex: Assessment of its properties and performance. Constr. Build. Mater. 2021, 273, 121991. [Google Scholar] [CrossRef]

- Da Silva, T.R. Avaliação da Incorporação de Poliotereftalato de Etileno em Tijolos de Solo-Cimento. Ph.D. Thesis, Universidade Federal Fluminense, Niterói, Brazil, 2020; 76p. [Google Scholar]

- Da Silva, T.R.; Cecchin, D.; de Azevedo, A.R.G.; Valadão, I.; Alexandre, J.; da Silva, F.C.; Marvila, M.T.; Gunasekaran, M.; Filho, F.G.; Monteiro, S.N. Technological Characterization of PET—Polyethylene Terephthalate—Added Soil-Cement Bricks. Materials 2021, 14, 5035. [Google Scholar] [CrossRef] [PubMed]

- De Albuquerque, L.Q.C.; Biscaro, G.A.; Negro, S.R.L.; De Oliveira, A.C.; De Carvalho, L.A.; Leal, S.T. Resistance the compression of manufactured cement bricks ground with the wooded hill of termite Cornitermes cumulans (Kollar, 1832). Ciência E Agrotecnologia 2008, 32, 553–560. [Google Scholar]

- Oliveira, J.; Amaral, A.; Schneider, R. Incorporação de Resíduos Sólidos de Tornearias Mecânicas na Fabricação de Tijolos Solo-Cimento. Nativa 2014, 2, 53–57. [Google Scholar] [CrossRef] [Green Version]

- Adesina, A.; Das, S. Performance of engineered cementitious composites incorporating crumb rubber as aggregate. Constr. Build. Mater. 2020, 274, 122033. [Google Scholar] [CrossRef]

- De Azevedo, A.R.; Marvila, M.T.; Tayeh, B.A.; Cecchin, D.; Pereira, A.C.; Monteiro, S.N. Technological performance of açaí natural fibre reinforced cement-based mortars. J. Build. Eng. 2020, 33, 101675. [Google Scholar] [CrossRef]

- Hernández-Olivares, F.; Medina-Alvarado, R.E.; Burneo-Valdivieso, X.E.; Zúñiga-Suárez, A.R. Short sugarcane bagasse fibers cementitious composites for building construction. Constr. Build. Mater. 2020, 247, 118451. [Google Scholar] [CrossRef]

- Hablot, E.; Dewasthale, S.; Zhao, Y.; Zhiguan, Y.; Shi, X.; Graiver, D.; Narayan, R. Reactive extrusion of glycerylated starch and starch–polyester graft copolymers. Eur. Polym. J. 2013, 49, 873–881. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

| Coconut Fiber (%) | Cement:Soil:Waste (Volume) |

|---|---|

| 0 | 1:10:0 |

| 5 | 1: 9.5:0.5 |

| 10 | 1: 9:1 |

| 15 | 1: 8.5:1.5 |

| Particle Size Composition | Soil I (%) | Soil II (%) | Soil III (%) |

|---|---|---|---|

| Coarse sand | 12.71 | 11.68 | 15.50 |

| Medium sand | 13.58 | 22.10 | 28.00 |

| Fine sand | 20.09 | 18.07 | 19.30 |

| Silt | 5.58 | 2.95 | 2.90 |

| Clay | 48.04 | 45.20 | 34.30 |

| Fiber % | CP 01 (MPa) | CP 02 (MPa) | CP 03 (MPa) | CP 04 (MPa) | CP 05 (MPa) | CP 06 (MPa) | CP 07 (MPa) | Average (MPa) | St. Dev. (MPa) |

|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.760 | 0.620 | 0.610 | 0.540 | 0.540 | 0.540 | 0.500 | 0.587 | 0.087 |

| 5 | 0.648 | 0.519 | 0.355 | 0.579 | 0.325 | 0.587 | 0.567 | 0.511 | 0.123 |

| 10 | 0.441 | 0.450 | 0.491 | 0.544 | 0.476 | 0.618 | 0.569 | 0.513 | 0.066 |

| 15 | 0.445 | 0.438 | 0.517 | 0.495 | 0.382 | 0.703 | 0.483 | 0.495 | 0.102 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira, G.M.G.; Cecchin, D.; Valadão, I.C.R.P.; da Silva, T.R.; do Carmo, D.d.F.; Moll Hüther, C.; Ferreira, F.; de Azevedo, A.R.G. Evaluation of the Technological Properties of Soil–Cement Bricks with Incorporation of Coconut Fiber Powder. Eng 2022, 3, 311-324. https://doi.org/10.3390/eng3030023

Ferreira GMG, Cecchin D, Valadão ICRP, da Silva TR, do Carmo DdF, Moll Hüther C, Ferreira F, de Azevedo ARG. Evaluation of the Technological Properties of Soil–Cement Bricks with Incorporation of Coconut Fiber Powder. Eng. 2022; 3(3):311-324. https://doi.org/10.3390/eng3030023

Chicago/Turabian StyleFerreira, Gabriela Machado Guimarães, Daiane Cecchin, Izabella Christynne Ribeiro Pinto Valadão, Tulane Rodrigues da Silva, Dirlane de Fátima do Carmo, Cristina Moll Hüther, Flávio Ferreira, and Afonso Rangel Garcez de Azevedo. 2022. "Evaluation of the Technological Properties of Soil–Cement Bricks with Incorporation of Coconut Fiber Powder" Eng 3, no. 3: 311-324. https://doi.org/10.3390/eng3030023

APA StyleFerreira, G. M. G., Cecchin, D., Valadão, I. C. R. P., da Silva, T. R., do Carmo, D. d. F., Moll Hüther, C., Ferreira, F., & de Azevedo, A. R. G. (2022). Evaluation of the Technological Properties of Soil–Cement Bricks with Incorporation of Coconut Fiber Powder. Eng, 3(3), 311-324. https://doi.org/10.3390/eng3030023