Abstract

The joining of two chemically dissimilar metals is a challenge due to the formation of hard and brittle intermetallic compounds (IMCs) in the diffusion layer. The joining of steel/Fe with aluminum (Al) and zirconium (Zr) alloy is particularly important for the automobile and nuclear industries, respectively. The Al–steel and Zr–steel joints produced by conventional fusion welding exhibit IMCs. The IMCs can enhance brittleness and cause catastrophic failure. This concept paper presents a novel idea of suppressing IMCs in welded joints using a high-entropy interlayer (HEI). It also discusses the potential candidates for HEIs and inspires research to exploit this new and promising research area.

1. Background and Purpose

1.1. High-Entropy Alloys

High-entropy alloys (HEAs) comprise of multiple principle elements mixed in equiatomic or near-equiatomic concentrations. Configurational entropy of a multi-component system increases with an increasing number of elements, as shown in Equation (1).

where ΔS, ci, and R denote configurational entropy, molar content of the ith component, and gas constant, respectively. Enhanced configurational entropy of multiple principle element alloys suppresses intermetallic compounds and stabilizes the solid solution phase in HEAs [1].

The HEA is a versatile material. In addition to structural, high temperature, and irradiation resistant applications [2,3], its utilization as a filler material [4] and diffusion barrier [5] is also being explored. Hao et al. used (CoCrFeNi)100-xCux high-entropy alloy as a filler metal between 304 stainless steel and TC4 titanium alloy and produced a reliable joint with 158–161 MPa tensile strength and 803 HV hardness [4]. The Cu- and Ti- rich phases were observed in the microstructures of transition zones [4]. Tsai et al. explored the applications of AlMoNbSiTaTiVZr HEA as a diffusion barrier by depositing layers of Cu and AlMoNbSiTaTiVZr using magnetron sputtering [5]. The AlMoNbSiTaTiVZr exhibited amorphous structure and successfully prevented copper-silicide formation [5]. This versatility of HEAs has provoked researchers to exploit their new and less explored applications.

1.2. Intermetallic Compounds in Dissimiar Metals Welded Joints

Conventional welding of dissimilar (metallurgically incompatible) metals results in intermetallic compounds (IMCs) in the diffusion layer, which degrades the properties of welded joints.

Aluminum and steel are extensively utilized in automobile structures. The bonding of Al and steel forms hard and brittle IMCs, such as FeAl3, Fe2Al5, and Fe3Al14 [6,7]. These IMCs deteriorate the mechanical properties of joints. Hence, it is crucial to develop Al–steel joints free from IMCs. Research on suppressing IMCs by using a thin interlayer between Al and steel (Figure 1) is in progress [8].

Figure 1.

Schematic of joining of dissimilar metal using interlayer.

Al–steel joint having an interlayer of Co has been developed using friction melt bonded welding. However, Co2Al, Fe4Al13, CoAl3, and Fe2Al5 IMC were observed [8]. The Cr interlayer will also result in Al–Cr (such as Al7Cr, Al11Cr2, Al4Cr, Al9Cr4, Al8Cr5, AlCr2) and Fe–Cr–Al IMC [9]. The Ni interlayer cannot be used as well due to the formation of, Al3Ni2, Al3Ni2, Al3Ni5, AlNi3, and FeNi3 IMCs, as evident from phase diagrams of Al–Ni and Fe–Ni alloys. The following section presents a new concept of high-entropy interlayer to solve this problem in Al–steel joints.

2. High-Entropy Interlayer (HEI)—An Unorthodox Approach

NiCoCr alloy forms a single-phase solid solution without any IMC [10]. Moreover, when a high-entropy alloy is developed by combining Al and Fe with Ni, Co, and Cr, a solid solution phase without any IMC is observed. Several studies on AlNiCoCrFe HEA have shown only BCC (ordered and disordered) solid solution in AlNiCoCrFe HEA, as shown in Table 1.

Table 1.

Various studies reporting no intermetallic phase in AlNiCoCrFe high-entropy alloys (HEAs).

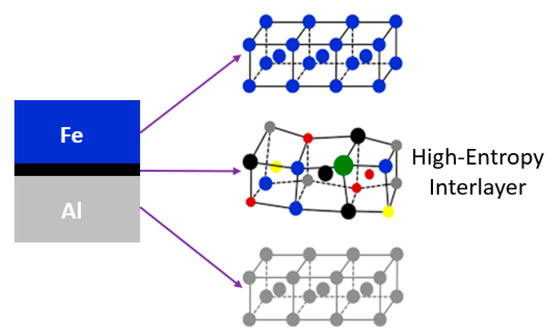

Moreover, FeNiCoCr [10] and AlNiCoCr [15] (four component alloys, often termed as medium entropy alloys) do not show IMCs as well. No presence of intermetallic compounds in NiCoCr, FeNiCoCr, AlNiCoCr, and FeNiCoCrAl suggests that high-entropy effect can be used to suppress the formation of IMC in Al–steel joints using interlayer of these alloys. The effects of various types of high-entropy interlayers (HEIs) on suppression of IMCs can be analyzed, as shown in Figure 2. If an interlayer made up of three or four component alloy is used, thermal diffusion during the joining process will lead to the formation of HEA between steel and Al.

Figure 2.

High-entropy interlayer (HEI) for suppressing intermetallic compounds in welded joints.

This approach can be useful in the field of nuclear materials as well. Zirconium (Zr) alloys and stainless steels (SS) are widely used in in-core and out-core components of nuclear reactors, respectively. The joining of these two materials using conventional fusion welding results in IMCs in diffusion layer, which reduces the mechanical properties of the joint [16]. Solid solution phase (with no IMCs) has been reported in Zr and Fe containing HEAs, such as ZrFeCrNiTi [17] and ZrTiHfCuNiFe [18]. By using interlayers of these HEAs, the formation of IMC in Zr–SS joints can be suppressed. The study of Wen et al. [19] on joining of Cu with 304 stainless steel using CoCrFeMnNi high-entropy alloy as an interlayer, in which well bonded interface and no intermetallic were observed, gives confidence on the success of this concept.

3. Conclusions

Yes, the literature survey suggests that the high-entropy interlayers (HEI) can develop intermetallic-free welded joints of dissimilar metals.

4. Experimental Validation

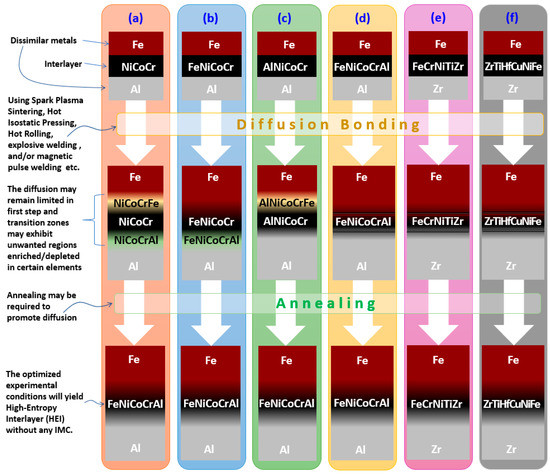

Although the literature provides a strong basis to trust this new concept, its validation by experiments is crucial, which can be carried out by following different schemes shown in Figure 3.

Figure 3.

Experimental schemes for carrying out diffusion bonding of Al and Fe without forming intermetallic compounds using (a) NiCoCr, (b) FeNiCoCr, (c) AlNiCoCr, and (d) FeNiCoCrAl interlayers, and for joining Fe and Zr using (e) FeCrNiTiZr, and (f) ZrTiHfCuNiFe interlayers.

The dissimilar metal joints can be developed using spark plasma sintering (SPS), hot isostatic pressing (HIP), hot rolling, explosive welding (EXW) [20], and/or magnetic pulse welding (MPW) [21]. The transition zones may exhibit regions enriched/depleted in certain elements [4]; hence, the successful development of dissimilar metal joint using HEI without IMCs will require optimization of experimental conditions (compressive load/pressure, temperature, interlayer’s initial thickness, holding time, surface roughness, etc.). After getting preliminary results, fine tuning of chemical compositions may also be required. The presence of contamination and desorbed oxygen on the surface of metal blocks and thin foils can hinder the diffusion; therefore, cleaning of the surfaces prior to diffusion bonding will be required.

5. Impact of HEI Concept

The HEI concept could have a significant impact on the welding technology used in automobile and nuclear industries, as it can help develop IMC-free Al–steel and steel–Zr welded joints. High brittleness of welded joints due to the presence of IMCs can cause catastrophic failure of the critical components of automobiles and nuclear power plants, which can put human lives at risk. The HEI concept could help avoid the brittleness by suppressing IMCs in welded joints.

Author Contributions

Conceptualization, O.A.W.; writing—original draft preparation, O.A.W.; writing—review and editing, O.A.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research has not received any specific grants from funding agencies in the public, commercial, or not-for-profit sectors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Anand, G.; Goodall, R.; Freeman, C.L. Role of configurational entropy in body-centred cubic or face-centred cubic phase formation in high entropy alloys. Scr. Mater. 2016, 124, 90–94. [Google Scholar] [CrossRef]

- Egami, T.; Guo, W.; Rack, P.D.; Nagase, T. Irradiation resistance of multicomponent alloys. Metall. Mater. Trans. A 2014, 45, 180–183. [Google Scholar] [CrossRef]

- Nagase, T.; Rack, P.D.; Noh, J.H.; Egami, T. In-situ TEM observation of structural changes in nano-crystalline CoCrCuFeNi multicomponent high-entropy alloy (HEA) under fast electron irradiation by high voltage electron microscopy (HVEM). Intermetallics 2015, 59, 32–42. [Google Scholar] [CrossRef]

- Hao, X.; Dong, H.; Xia, Y.; Li, P. Microstructure and mechanical properties of laser welded TC4 titanium alloy/304 stainless steel joint with (CoCrFeNi)100-xCux high-entropy alloy interlayer. J. Alloys Compd. 2019, 803, 649–657. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yeh, J.W.; Gan, J.Y. Diffusion barrier properties of AlMoNbSiTaTiVZr high-entropy alloy layer between copper and silicon. Thin Solid Film. 2008, 516, 5527–5530. [Google Scholar] [CrossRef]

- Singh, J.; Arora, K.S.; Shukla, D.K. Dissimilar MIG-CMT weld-brazing of aluminium to steel: A review. J. Alloys Compd. 2019, 783, 753–764. [Google Scholar] [CrossRef]

- Kobayashi, S.; Yakou, T. Control of intermetallic compound layers at interface between steel and aluminum by diffusion-treatment. Mater. Sci. Eng. A 2002, 338, 44–53. [Google Scholar] [CrossRef]

- Jimenez-Mena, N.; Jacques, P.J.; Ding, L.; Gauquelin, N.; Schryvers, D.; Idrissi, H.; Delannay, F.; Simar, A. Enhancement of toughness of Al-to-steel Friction Melt Bonded welds via metallic interlayers. Mater. Sci. Eng. A 2019, 740, 274–284. [Google Scholar] [CrossRef]

- Leshchinsky, E.; Sobiesiak, A.; Maev, R. Intermetallic Al-, Fe-, Co- and Ni-Based thermal barrier coatings prepared by cold spray for applications on low heat rejection diesel engines. J. Spray Technol. 2018, 27, 456–470. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Otto, F.; Pharr, G.M.; George, E.P. Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys. Intermetallics 2014, 46, 131–140. [Google Scholar] [CrossRef]

- Linden, Y.; Pinkas, M.; Munitz, A.; Meshi, L. Long-period antiphase domains and short-range order in a B2 matrix of the AlCoCrFeNi high-entropy alloy. Scr. Mater. 2017, 139, 49–52. [Google Scholar] [CrossRef]

- Lim, K.R.; Lee, K.S.; Lee, J.S.; Kim, J.Y.; Chang, H.J.; Na, Y.S. Dual-phase high-entropy alloys for high-temperature structural applications. J. Alloys Compd. 2017, 728, 1235–1238. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Liaw, P.K. Alloy design and properties optimization of high-entropy alloys. Jom 2012, 64, 830–838. [Google Scholar] [CrossRef]

- Ji, W.; Fu, Z.; Wang, W.; Wang, H.; Zhang, J.; Wang, Y.; Zhang, F. Mechanical alloying synthesis and spark plasma sintering consolidation of CoCrFeNiAl high-entropy alloy. J. Alloys Compd. 2014, 589, 61–66. [Google Scholar] [CrossRef]

- Jumaev, E.; Hong, S.H.; Kim, J.T.; Park, H.J.; Kim, Y.S.; Mun, S.C.; Park, J.Y.; Song, G.; Lee, J.K.; Min, B.H.; et al. Chemical evolution-induced strengthening on AlCoCrNi dual-phase high-entropy alloy with high specific strength. J. Alloys Compd. 2019, 777, 828–834. [Google Scholar] [CrossRef]

- Pan, H.; Liu, B.; Guo, Y.; Liu, Y.; Quan, G. An investigation on diffusion bonding of Zircaloy-4 and 304L stainless steel with Ti and Ag multiple interlayers. Mater. Lett. 2019, 240, 185–188. [Google Scholar] [CrossRef]

- Eremin, E.N.; Yurov, V.M.; Laurinas, V.C.; Guchenko, S.A. Structure and properties of corrosion-resistant coatings of the Zr-Fe-Cr-Ni-Ti system. Nanosci. Nanotechnol. NANO SciTech. 2019, 2151. [Google Scholar] [CrossRef]

- Meng, Y.H.; Duan, F.H.; Pan, J.; Li, Y. Phase stability of B2-ordered ZrTiHfCuNiFe high entropy alloy. Intermetallics 2019, 111. [Google Scholar] [CrossRef]

- Ding, W.; Wang, X.; Liu, N.; Qin, L. Diffusion bonding of copper and 304 stainless steel with an interlayer of CoCrFeMnNi High-Entropy alloy. Acta Metall. Sin. 2020, 56, 1084–1090. [Google Scholar] [CrossRef]

- Becker, N.; Gauthier, D.; Vidal, E.E. Fatigue properties of steel to aluminum transition joints produced by explosion welding. Int. J. Fatigue 2020, 139, 105736. [Google Scholar] [CrossRef]

- Bellmann, J.; Schettler, S.; Dittrich, S.; Lueg-Althoff, J.; Schulze, S.; Hahn, M.; Beyer, E.; Tekkaya, A.E. Experimental study on the magnetic pulse welding process of large aluminum tubes on steel rods. IOP Conf. Ser. Mater. Sci. Eng. 2019, 480, 012033. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).