Water Hyacinth Geotextiles as a Nature-Based Solution for Riverbank Protection in the Vietnamese Mekong Delta

Abstract

1. Introduction

2. Materials and Methods

2.1. Measuring the Sediment Retention Capacity of the Geotextile

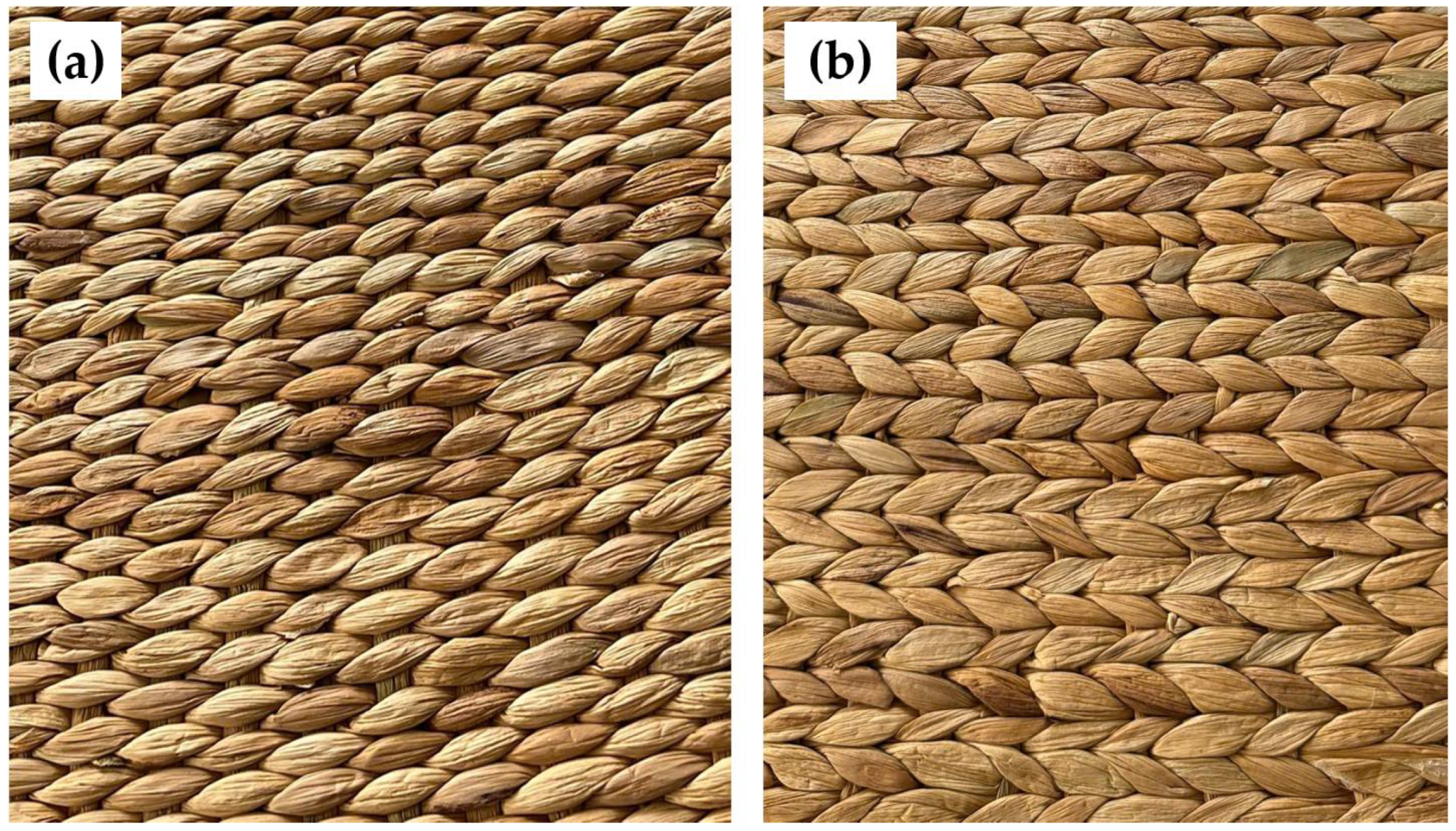

2.1.1. Preparation of WH Geotextile

2.1.2. Experimental Setup and Procedure

2.2. Calculating Significant Wave Height for Assessing Wave Height Reduction

2.3. Testing the Mechanical Durability Under Wet–Dry Cycles Due to Tidal Fluctuations

2.3.1. Preparing the Test Sample

- With Callux® CL 326 adhesive coating.

- Without Callux® CL 326 adhesive coating.

2.3.2. Tensile Strength Testing

3. Results

3.1. Sediment Retention

3.2. Wave Energy Reduction

3.3. Mechanical Durability Under Wet–Dry Cycles

3.3.1. Maximum Tensile Strength of the Geotextiles

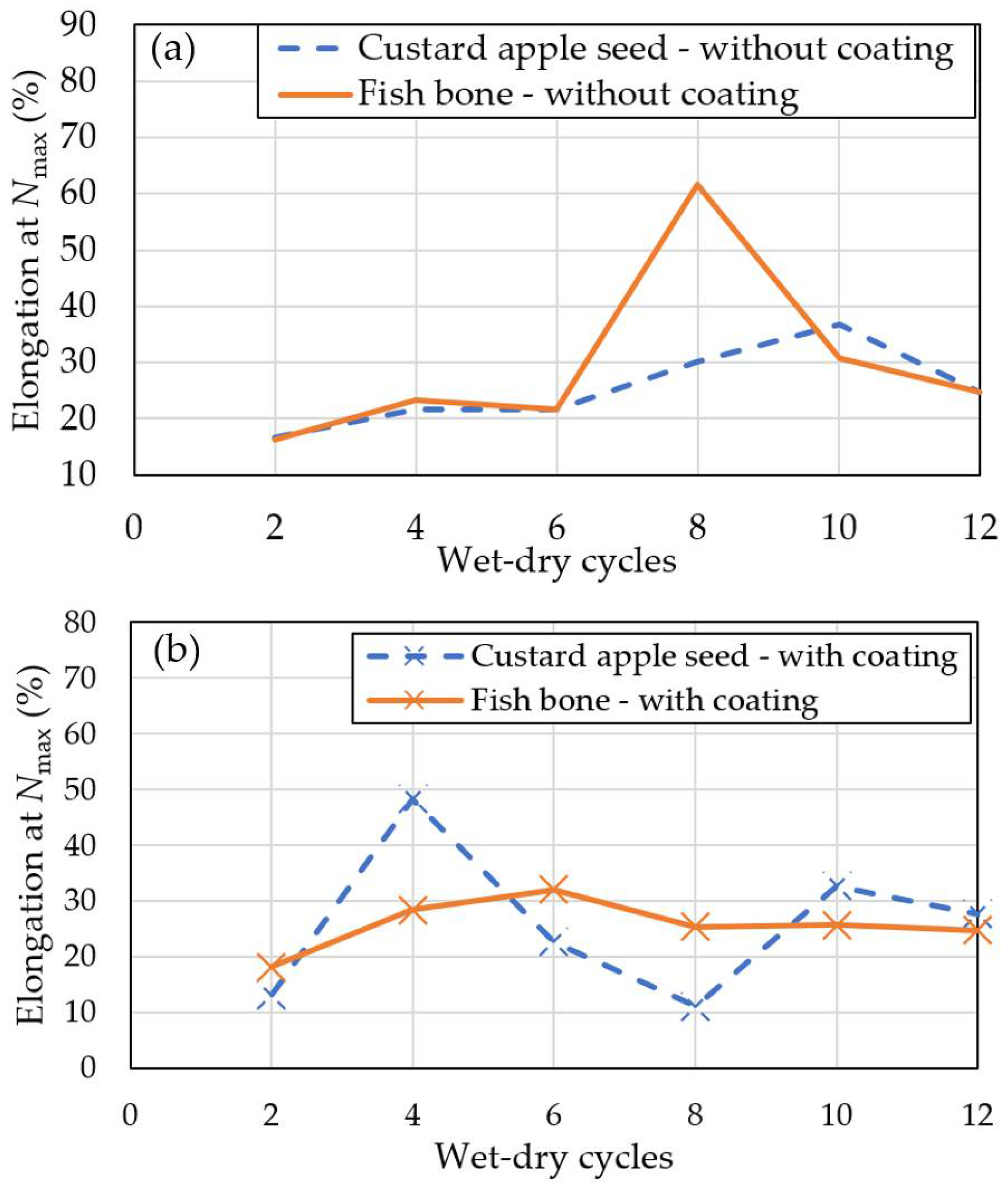

3.3.2. Elongation of the Geotextiles at Maximum Tensile Strength

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FTU | Formazin Turbidity Unit |

| VMD | Vietnamese Mekong Delta |

| WH | Water hyacinth |

References

- Gao, Y.; Hang, L.; He, J.; Zhang, F.; Van Paassen, L. Pullout behavior of geosynthetic reinforcement in biocemented soils. Geotext. Geomembr. 2021, 49, 646–656. [Google Scholar] [CrossRef]

- Ren, F.; Huang, Q.; Chen, J. Centrifuge modeling of geosynthetic-reinforced soil retaining walls subjected to the combined effect of earthquakes and rainfall. Geotext. Geomembr. 2022, 50, 470–479. [Google Scholar] [CrossRef]

- Tri, V.P.D.; Yarina, L.; Nguyen, H.Q.; Downes, N.K. Progress toward resilient and sustainable water management in the Vietnamese Mekong Delta. WIREs Water 2023, 10, e1670. [Google Scholar] [CrossRef]

- Duy, D.V.; Ty, T.V.; Phat, L.T.; Minh, H.V.T.; Thanh, N.T.; Downes, N.K. Assessing River Corridor Stability and Erosion Dynamics in the Mekong Delta: Implications for Sustainable Management. Earth 2025, 6, 34. [Google Scholar] [CrossRef]

- Wiewel, B.V.; Lamoree, M. Geotextile composition, application and ecotoxicology—A review. J. Hazard. Mater. 2016, 317, 640–655. [Google Scholar] [CrossRef] [PubMed]

- Prambauer, M.; Wendeler, C.; Weitzenböck, J.; Burgstaller, C. Biodegradable geotextiles—An overview of existing and potential materials. Geotext. Geomembr. 2019, 47, 48–59. [Google Scholar] [CrossRef]

- Umar, T. Key factors influencing the implementation of three-dimensional printing in construction. Proc. Inst. Civ. Eng.—Manag. Procure. Law 2021, 174, 104–117. [Google Scholar] [CrossRef]

- Van Der Weert, R.; Kamerling, G. Evapotranspiration of water hyacinth (Eichhornia crassipes). J. Hydrol. 1974, 22, 201–212. [Google Scholar] [CrossRef]

- Methacanon, P.; Weerawatsophon, U.; Sumransin, N.; Prahsarn, C.; Bergado, D. Properties and potential application of the selected natural fibers as limited life geotextiles. Carbohydr. Polym. 2010, 82, 1090–1096. [Google Scholar] [CrossRef]

- Tanchaisawat, T.; Bergado, D.T.; Artidteang, S. Large-scale soil erosion performance test of water hyacinth limited life geosynthetics combined with Ruzi grasses. Int. J. Geotech. Eng. 2014, 8, 315–327. [Google Scholar] [CrossRef]

- Artidteang, S.; Tanchaisawat, T.; Bergado, D.; Chaiyaput, S. Natural fibers in reinforcement and erosion control applications with limited life geosynthetics. Ground Improvement Case Histories: Compaction. In Ground Improvement Case Histories. Compaction, Grouting, and Geosynthetics; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; pp. 717–740. [Google Scholar]

- Abral, H.; Kadriadi, D.; Rodianus, A.; Mastariyanto, P.; Ilhamdi; Arief, S.; Sapuan, S.; Ishak, M. Mechanical properties of water hyacinth fibers—Polyester composites before and after immersion in water. Mater. Des. 2014, 58, 125–129. [Google Scholar] [CrossRef]

- Prongmanee, N.; Noulmanee, A.; Dulyasucharit, R.; Horpibulsuk, S.; Chai, J.-C. Durability against Wetting and Drying Cycles and Installation Damage of Water Hyacinth Geotextiles Coated with Natural Rubber Latex. J. Mater. Civ. Eng. 2023, 35, 04023408. [Google Scholar] [CrossRef]

- Gupta, A.K.S. Geotextiles: Opportunities for natural-fibre products. Int. Trade Forum 1991, 27, 10–15. [Google Scholar]

- Suddeepong, A.; Hoy, M.; Nuntasena, C.; Horpibulsuk, S.; Kantatham, K.; Arulrajah, A. Evaluation of Interface Shear Strength of Natural Kenaf Geogrid and Recycled Concrete Aggregate for Sustainable Pavement Applications. J. Nat. Fibers 2022, 19, 6165–6181. [Google Scholar] [CrossRef]

- Malik, A. Environmental challenge vis a vis opportunity: The case of water hyacinth. Environ. Int. 2007, 33, 122–138. [Google Scholar] [CrossRef] [PubMed]

- Munk, W.H. Proposed Uniform Procedure for Observing Waves and Interpreting Instrument Records: Scripps Institution of Oceanography; Wave Report; Scripps Institution of Oceanography: San Diego, CA, USA, 1944. [Google Scholar]

- Dean, R.G.; Dalrymple, R.A. Water Wave Mechanics for Engineers and Scientists; World Scientific Publishing Company: Singapore, 1991; Volume 2. [Google Scholar]

- ITST, TCVN 8871-1÷6:2011; Geotextiles—Parts 1–6: Standard Test Methods. Ministry of Science and Technology: Hanoi, Vietnam, 2011; p. 52.

- Dąbrowska, J.; Kiersnowska, A.; Zięba, Z.; Trach, Y. Sustainability of geosynthetics-based solutions. Environments 2023, 10, 64. [Google Scholar] [CrossRef]

- Hussain, M.A.; Shuai, Z.; Moawwez, M.A.; Umar, T.; Iqbal, M.R.; Kamran, M.; Muneer, M. A Review of Spatial Variations of Multiple Natural Hazards and Risk Management Strategies in Pakistan. Water 2023, 15, 407. [Google Scholar] [CrossRef]

- IUCN. Global Standard for Nature-Based Solutions. A User-Friendly Framework for the Verification, Design and Scaling up of NbS; IUCN: Gland, Switzerland, 2020.

- Le Gouvello, R.; Cohen-Shacham, E.; Herr, D.; Spadone, A.; Simard, F.; Brugere, C. The IUCN Global Standard for Nature-based Solutions™ as a tool for enhancing the sustainable development of marine aquaculture. Front. Mar. Sci. 2023, 10, 1146637. [Google Scholar] [CrossRef]

- Seddon, N.; Smith, A.; Smith, P.; Key, I.; Chausson, A.; Girardin, C.; House, J.; Srivastava, S.; Turner, B. Getting the message right on nature-based solutions to climate change. Glob. Change Biol 2021, 27, 1518–1546. [Google Scholar]

- Miszkowska, A.; Lenart, S.; Koda, E. Changes of permeability of nonwoven geotextiles due to clogging and cyclic water flow in laboratory conditions. Water 2017, 9, 660. [Google Scholar] [CrossRef]

- Markiewicz, A.; Koda, E.; Kawalec, J. Geosynthetics for filtration and stabilisation: A review. Polymers 2022, 14, 5492. [Google Scholar] [CrossRef]

- Chatrabhuj; Meshram, K. Use of geosynthetic materials as soil reinforcement: An alternative eco-friendly construction material. Discov. Civ. Eng. 2024, 1, 41. [Google Scholar] [CrossRef]

- Tanasă, F.; Nechifor, M.; Ignat, M.-E.; Teacă, C.-A. Geotextiles—A versatile tool for environmental sensitive applications in geotechnical engineering. Textiles 2022, 2, 189–208. [Google Scholar] [CrossRef]

| No | Date | Time | Status | Notes |

|---|---|---|---|---|

| 1 | 5 July 2025 | 05:00 | Wet | Submerge 24 geotextile samples in water |

| 2 | 11:00 | Dry | Remove 24 geotextile samples from water | |

| 3 | 17:00 | Wet | Submerge 24 geotextile samples in water | |

| 4 | 23:00 | Dry | Remove 24 geotextile samples from water | |

| 5 | 6 July 2025 | 05:00 | Wet | Submerge 20 geotextile samples in water; collect 4 samples (2 cycles) |

| 6 | 11:00 | Dry | Remove 20 geotextile samples from water | |

| 7 | 17:00 | Wet | Submerge 20 geotextile samples in water | |

| 8 | 23:00 | Dry | Remove 20 geotextile samples from water | |

| 9 | 7 July 2025 | 05:00 | Wet | Submerge 16 geotextile samples in water; collect 4 samples (4 cycles) |

| 10 | 11:00 | Dry | Remove 16 geotextile samples from water | |

| 11 | 17:00 | Wet | Submerge 16 geotextile samples in water | |

| 12 | 23:00 | Dry | Remove 16 geotextile samples from water | |

| 13 | 8 July 2025 | 05:00 | Wet | Submerge 12 geotextile samples in water; collect 4 samples (6 cycles) |

| 14 | 11:00 | Dry | Remove 12 geotextile samples from water | |

| 15 | 17:00 | Wet | Submerge 12 geotextile samples in water | |

| 16 | 23:00 | Dry | Remove 12 geotextile samples from water | |

| 17 | 9 July 2025 | 05:00 | Wet | Submerge 8 geotextile samples in water; collect 4 samples (8 cycles) |

| 18 | 11:00 | Dry | Remove 8 geotextile samples from water | |

| 19 | 17:00 | Wet | Submerge 8 geotextile samples in water | |

| 20 | 23:00 | Dry | Remove 8 geotextile samples from water | |

| 21 | 10 July 2025 | 05:00 | Wet | Submerge 4 geotextile samples in water; collect 4 samples (10 cycles) |

| 22 | 11:00 | Dry | Remove 4 geotextile samples from water | |

| 23 | 17:00 | Wet | Submerge 4 geotextile samples in water | |

| 24 | 23:00 | Dry | Remove 4 geotextile samples from water (12 cycles) |

| Days | Wet–Dry Cycles | Maximum Tensile Strength—N (kN/m) | |||

|---|---|---|---|---|---|

| Without Adhesive Coating | With Adhesive Coating | ||||

| Custard Apple Seed | Fish Bone | Custard Apple Seed | Fish Bone | ||

| 1 | 2 | 10.44 | 13.65 | 14.21 | 21.89 |

| 2 | 4 | 3.8 | 4.95 | 5.82 | 3.86 |

| 3 | 6 | 6.9 | 6.06 | 3.61 | 2.09 |

| 4 | 8 | 4.02 | 5.65 | 5.62 | 6.15 |

| 5 | 10 | 2.26 | 4.38 | 5.43 | 7.61 |

| 6 | 12 | 5.66 | 5.82 | 5.53 | 8.36 |

| Days | Wet–Dry Cycles | Elongation at Nmax (%) | |||

|---|---|---|---|---|---|

| Without Adhesive Coating | With Adhesive Coating | ||||

| Custard Apple Seed | Fish Bone | Custard Apple Seed | Fish Bone | ||

| 1 | 2 | 16.67 | 16.34 | 13.1 | 18.1 |

| 2 | 4 | 21.67 | 23.34 | 48.34 | 28.34 |

| 3 | 6 | 21.67 | 21.67 | 22.67 | 32.01 |

| 4 | 8 | 30.1 | 61.67 | 11.01 | 25.34 |

| 5 | 10 | 36.67 | 30.67 | 32.67 | 25.67 |

| 6 | 12 | 24.67 | 24.67 | 27.67 | 24.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bang, N.Q.; Duy, D.V.; Ty, T.V.; Thang, C.N.; Downes, N.K.; Tanaka, H. Water Hyacinth Geotextiles as a Nature-Based Solution for Riverbank Protection in the Vietnamese Mekong Delta. CivilEng 2025, 6, 55. https://doi.org/10.3390/civileng6040055

Bang NQ, Duy DV, Ty TV, Thang CN, Downes NK, Tanaka H. Water Hyacinth Geotextiles as a Nature-Based Solution for Riverbank Protection in the Vietnamese Mekong Delta. CivilEng. 2025; 6(4):55. https://doi.org/10.3390/civileng6040055

Chicago/Turabian StyleBang, Nguyen Quoc, Dinh Van Duy, Tran Van Ty, Cu Ngoc Thang, Nigel K. Downes, and Hitoshi Tanaka. 2025. "Water Hyacinth Geotextiles as a Nature-Based Solution for Riverbank Protection in the Vietnamese Mekong Delta" CivilEng 6, no. 4: 55. https://doi.org/10.3390/civileng6040055

APA StyleBang, N. Q., Duy, D. V., Ty, T. V., Thang, C. N., Downes, N. K., & Tanaka, H. (2025). Water Hyacinth Geotextiles as a Nature-Based Solution for Riverbank Protection in the Vietnamese Mekong Delta. CivilEng, 6(4), 55. https://doi.org/10.3390/civileng6040055