1. Introduction

Earthquakes are among the most destructive natural catastrophes, capable of causing significant loss of life and property. Nepal, located in South Asia, which is about 900 km in the east-west (EW) direction and 200 km long in the north-south (NS) direction, bordered by China and India, is prone to seismic activity caused by plate movement along the Himalayan region, resulting in numerous faults throughout the nation. The Himalayan series is one of the world’s most seismically active regions because of the faulting between the subducting Indian plate and the overriding Eurasian plate to the north. The convergence of the Indian plate occurs at a rate of 45 mm/year towards the Eurasian plate [

1]. As a result of this tectonic movement, Nepal is one of the most seismically active regions in the world, assessed as two-thirds portion of the Himalayas has the potential to produce mega earthquakes [

2]. Globally ranked among the eleven most earthquake-vulnerable countries [

3], Nepal faces substantial seismic risk due to the concentration of its settlements along the Himalayan megathrust fault. Numerous seismic disasters, including the devastating 1934 Nepal-Bihar earthquake (Mw 8.2), caused significant damage and casualties in the eastern part of Nepal as well as in the Kathmandu valley [

4]. Furthermore, the 25th April 2015 earthquake (Mw 7.8) along the Himalayan front was caused by a low angle thrust faulting mechanism at 8.2 km focal depth, resulting in significant devastation, particularly in the Kathmandu valley and neighboring districts, with a human loss of over 9000 lives, and severe infrastructure damage [

1,

5,

6]. These recurring catastrophes emphasized the urgent necessity of developing and enforcing updated seismic design codes, leading to the initiation of the Nepal National Building Code (NBC) project in 1994.

Following the 2015 earthquake, Nepal revised its seismic design provisions, updating the Nepal National Building Code [

7], in the year 2020. The updated version of the Nepal National Building Code [

8] is currently being utilized by several municipalities. However, there are still a significant number of municipalities that continue to allow the use of the previous building code (NBC 105:1994) [

9]. Furthermore, for up to three-storey reinforced concrete frame buildings with brick masonry infill that are frequently constructed in Nepal, the Mandatory Rules of Thumb (MRT-NBC 205:1994) on the prescriptive design of the Nepal building code recommends certain dimensions and details regarding the structural and nonstructural elements [

10]. These MRT provisions, while accessible for owner–builder practices, lacked alignment with modern seismic detailing standards, underscoring the ongoing challenge of ensuring consistent and reliable seismic safety across Nepal’s diverse building stock.

Meanwhile, on 3 November 2023, another strong earthquake struck Jajarkot, Rukum, and the surrounding 11 districts in the western part of Nepal, followed by many aftershocks that had a devastating effect on the lives and livelihoods of the people in one of the most impoverished areas of Nepal. A total of 153 persons have died, and 35,321 households have had their houses damaged, which are not livable now [

11]. After this earthquake, the Nepalese government expedited the updating of the guidelines, which had been commenced in 1994, revised as a draft in 2012, and again updated in 2024 [

12]. The purpose of this update is to mitigate the risk of future earthquake-induced losses by promoting safer construction practices and reducing structural collapse and casualties. Achieving this goal requires not only the implementation of revised provisions in new construction but also the systematic evaluation of the seismic performance of both new and existing buildings.

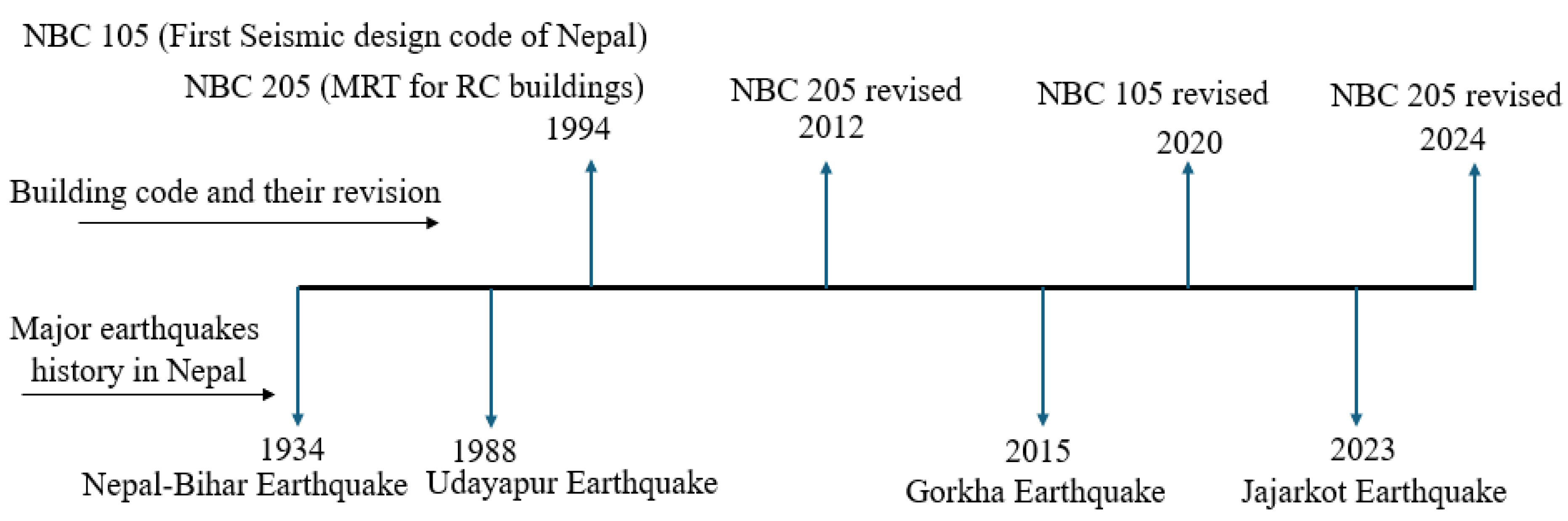

The evolution of earthquake disasters, seismic design codes, and mandatory rule-of-thumb (MRT) guidelines in Nepal is illustrated in

Figure 1. Following the 1988 Udayapur earthquake, the Government of Nepal enacted NBC 105 and NBC 205 in 1994. NBC 105 became Nepal’s first formal seismic design code, while NBC 205 provided simplified “rules of thumb” for reinforced concrete buildings, prescribing element dimensions and reinforcement details for footings, beams, columns, and slabs. NBC 205 underwent a draft revision in 2012, which introduced minor improvements, including upgraded detailing provisions and an increase in the standard concrete grade from 15 MPa to 20 MPa. More recently, both NBC 105 and NBC 205 were substantially revised in 2020 and 2024, respectively, drawing lessons from the 2015 Gorkha and 2023 Jajarkot earthquakes.

The latest version, NBC 205:2024, was developed in alignment with NBC 105:2020 and provides a more comprehensive framework for structural detailing. It enhances member dimensions and reinforcement specifications, with explicit consideration of seismic zones and soil conditions to improve building safety. Nevertheless, NBC 205:2024 retains its role as a simplified “Ready-to-Use” guideline, designed primarily for owner–builder projects in contexts where professional engineers are not available. It focuses on standardised, repeatable building configurations and incorporates simplified modelling assumptions, such as neglecting masonry infill stiffness. While this approach avoids modelling complications (e.g., frame stiffening, soft-storey or short-column effects, altered inter-storey drift, and irregular seismic behaviour), it still provides practical and replicable guidance for low-rise reinforced concrete construction. As this paper focuses on the RUD guidelines, the effect of masonry infills has been intentionally excluded. However, different micro- and macro-modelling techniques [

13,

14]—such as diagonal compression-only truss elements—are available in the literature to explicitly capture the effects of masonry infills.

Numerous studies were conducted to evaluate the seismic performance of existing structures [

14,

15,

16,

17,

18,

19] in which nonlinear pushover analysis and time history analysis were done to evaluate the global responses as well as the performance of the structures. Further, the study of Poudel [

20] focused on performance evaluation and retrofit of MRT-based structures. Three different consecutive models based on NBC 205:1994 and 2012 (MRT guidelines) and NBC 105:2020 were developed and analyzed in PERFORM 3D V8.0.0 software. The load-carrying capacity and beam-column moment capacity ratio were assessed. The analysis result indicated that the buildings constructed in accordance with MRT guidelines have inadequate moment carrying capacity, and the authors recommended retrofitting techniques to enhance seismic resilience. Similarly, Bento et al. [

21] performed nonlinear static procedures, evaluated and compared the response of two typologies of reinforced concrete buildings with the utilization of method as prescribed by ATC-40 [

22] and FEMA 273 [

23]. According to their findings, nonlinear static analysis is more appropriate for low-rise and high frequency structures i.e., for the structures that vibrate primarily in the fundamental mode. Moreover, Bhalkikar et al. [

24] proposed a novel technique using the pattern of hinge formation in the structure subjected to monotonic loading to quantify the damage of RC structures. Regression analysis was utilized in their study to examine the relationship between the damage and the hinge pattern using an energy-based damage index model, with the number of hinges formed in each damage state serving as an independent variable and the damage index as a dependent variable.

Even after the revision of NBC 105 in 2020, NBC 205 has continued to be widely used in many municipalities of Nepal. Although NBC 205 was extensively adopted for residential buildings, particularly those up to three storeys, it did not fully comply with the provisions of NBC 105:2020 [

8], thereby necessitating an update to strengthen seismic safety. This update was released in 2024 and is now being gradually implemented across municipalities. Nevertheless, a notable research gap remains, as very few studies have evaluated the seismic performance of buildings designed in accordance with the latest Ready-to-Use Detailing (RUD) guidelines (NBC 205:2024). The lack of empirical and analytical evidence leaves uncertainty regarding the effectiveness of the updated provisions in improving structural safety under seismic loading. To address this gap, this study evaluates the seismic performance of structures designed following NBC 205:2024. Nonlinear static analysis was performed on models without infill masonry, as recommended by the guidelines, using ETABS Version 20 [

25]. The pushover capacity was assessed in terms of base shear and roof displacement, while overall seismic performance was evaluated using the ATC-40 [

22] capacity spectrum method, with the performance point employed to establish the relationship between seismic demand and structural capacity.

The remainder of this paper is structured as follows:

Section 2 provides an overview of the recently updated NBC 205:2024 guidelines.

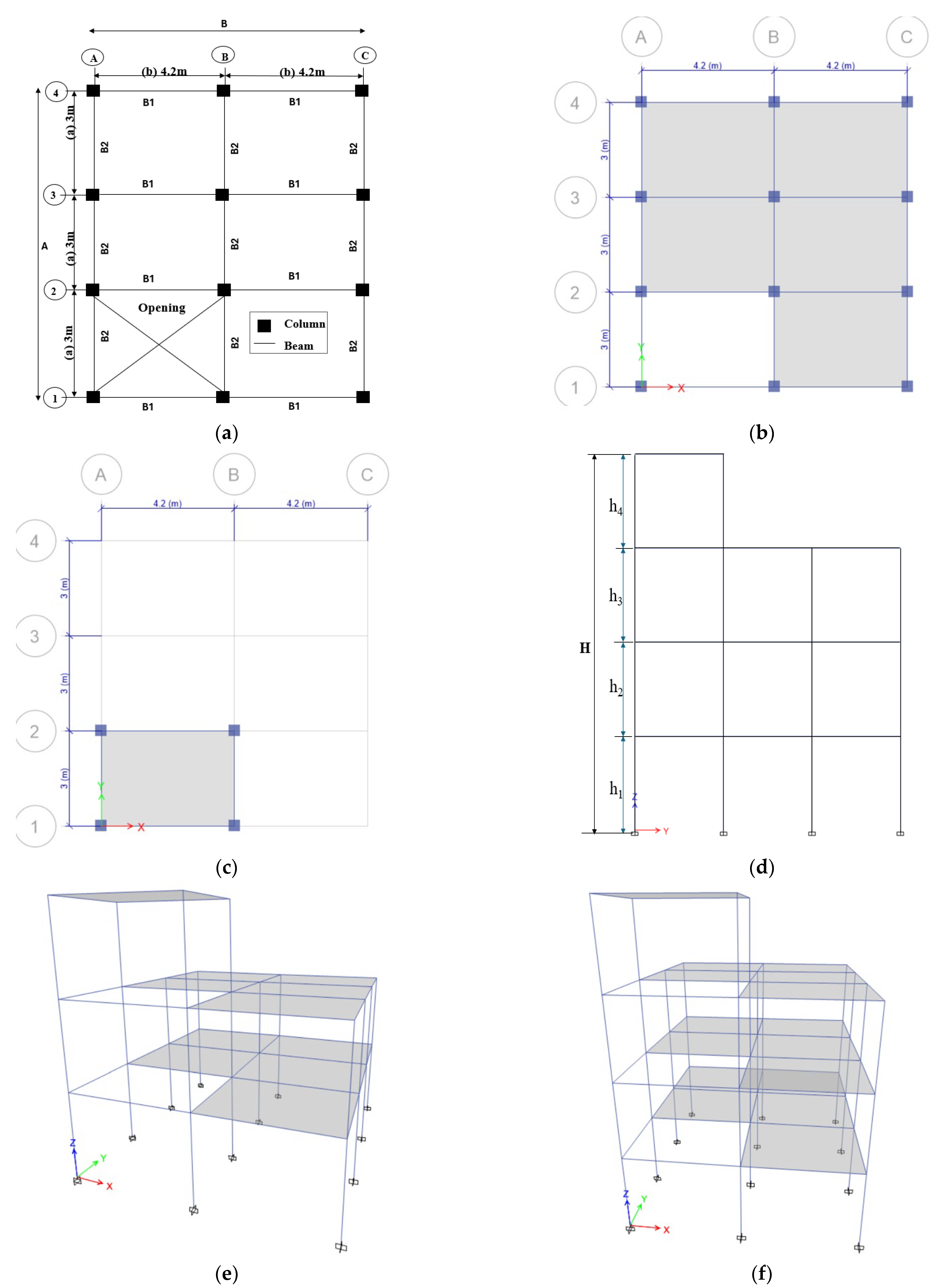

Section 3 describes the selected case study buildings that comply with these provisions.

Section 4 outlines the reinforcement details and structural member sizes.

Section 5 and

Section 6 present the nonlinear modelling and analysis procedure. Finally,

Section 7 and

Section 8 discuss the results, conclusions, and potential directions for future research.

2. Overview of NBC 205:2024

Over the past three decades, there has been a significant proliferation of reinforced concrete (RC) frame buildings in the urban and semi-urban areas of Nepal. Many of these buildings have been constructed under the guidance of mid-level technicians and masons, often with minimal professional structural design input, making them highly vulnerable to earthquakes with a credible likelihood of occurrence in Nepal. Despite the use of modern materials, these buildings could pose a major risk to life in future seismic events. To address this issue, and following the update of NBC 105 in 2020, the guideline previously titled Mandatory Rules of Thumb for Reinforced Concrete Buildings Without Masonry Walls (NBC 205:1994), which was first revised in 2012, has been further revised and published in 2024 as the Ready-To-Use Detailing (RUD) Guideline for Low-Rise Reinforced Concrete Buildings without masonry infill.

This latest version supersedes all earlier editions and aligns with the updated seismic design provisions in NBC 105:2020 to ensure consistency with current standards. The guideline aims to improve the structural quality of new RC buildings by providing standardised structural detailing for low-rise reinforced concrete (RC) buildings without masonry infill, particularly in areas where professional engineering services are limited. It applies to buildings classified under Category C of the Building Act 2055 [

26]. This category typically includes buildings with a plinth area of less than 92.93 m

2, up to three storeys plus a staircase cover (total height not exceeding 12 m), and a structural span of up to 4.5 m. Its primary purpose is to regulate construction in municipalities and rural municipalities where professional engineers and senior technicians are not readily available, ensuring that buildings constructed under the supervision of mid-level technicians (sub-engineers) meet minimum seismic safety standards to reduce potential loss of life due to structural failure. To this end, the guideline offers ready-to-use dimensions and detailing for both structural and non-structural elements of ordinary residential RC frame buildings, which are commonly constructed by owner–builders in Nepal. It further specifies the sizes of structural members and reinforcement requirements for soil types C and D, as defined in NBC 105:2020, covering seismic demands ranging from 0.25 g to 0.40 g. In addition, site selection and investigation can be carried out using the simple Dropping Weight Method to estimate allowable soil bearing capacity. In this method, the 1.5 m depth pit is excavated, a stacked unit of four full-size standard bricks on top of each other, tied by strings, is dropped from a height of 1.5 m at three different locations, and the depression in the pit is measured by using a ruler. The soil bearing capacity is evaluated based on the depression as illustrated in NBC 205:2024.

For construction materials, all structural concrete should achieve a compressive strength of 20 N/mm2 (M20) with a nominal mix ratio of 1:1.5:3, and reinforcement bars should have a yield strength of 500 N/mm2 (preferably Fe500D) for both longitudinal and transverse reinforcement. The RUD Guideline provides standardized designs and detailing for all structural components, ensuring consistency with NBC 105:2020 for buildings located in seismic zones with site subsoil categories C and D. Although such buildings can also be designed using conventional engineering design standards, they must still comply with NBC 105:2020. Overall, the simplified design procedures aim to save design time and enable owner-builders to adopt appropriate detailing practices, thereby enhancing the seismic resilience of low-rise RC buildings in Nepal.

5. Nonlinear Modelling Approach

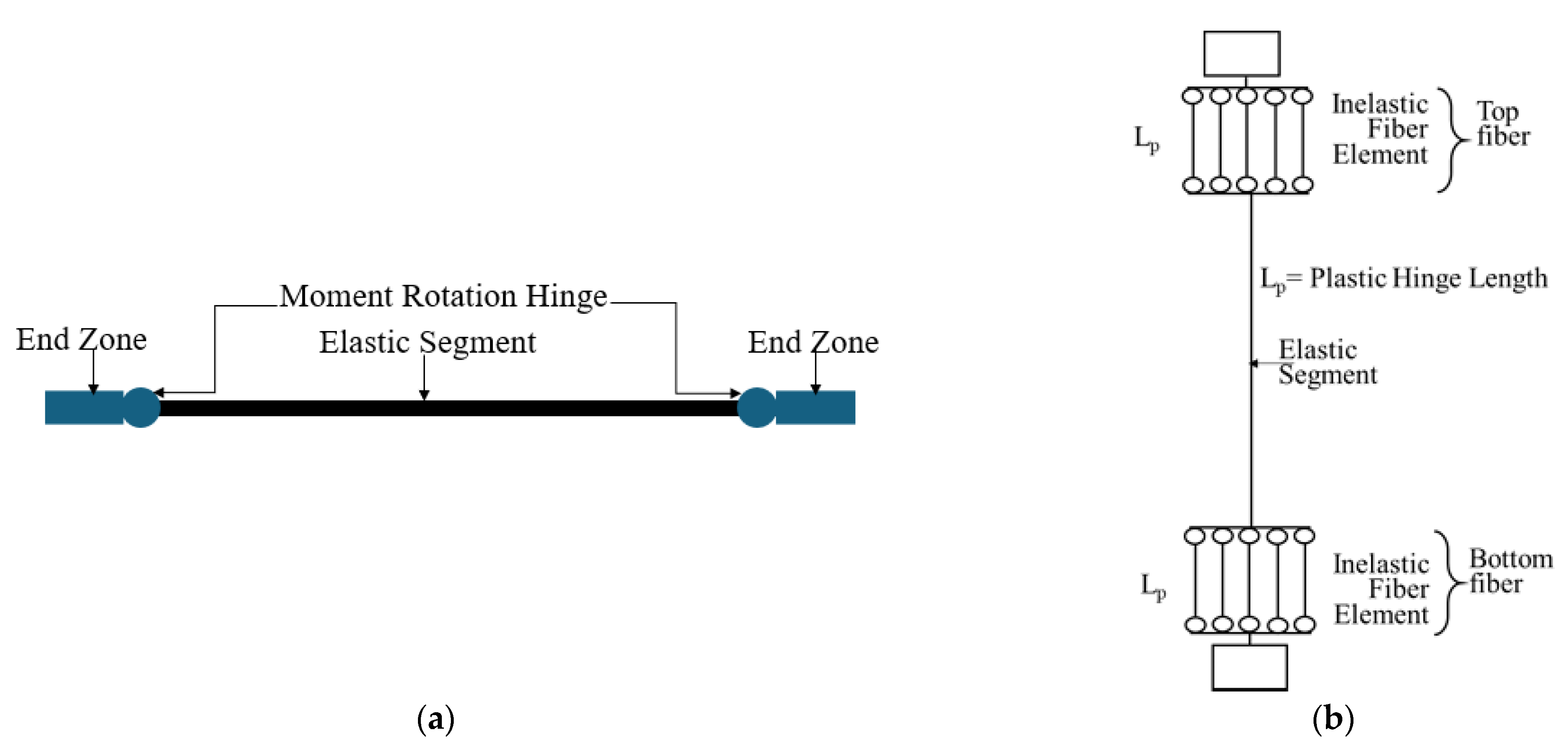

The nonlinear behavior of beams and columns, particularly those located in the plastic hinge zone, was the primary focus of the analysis. To represent this behavior, plastic hinges were positioned at the ends of beams and columns. This assignment was based on the moment–curvature and shear deformation responses of the cross sections. The remaining lengths of the beams and columns were modeled as linear elastic components with uncracked flexural stiffness in addition to the hinges allocated to each end.

Figure 3a,b depict the location of hinges assigned to the beam and column elements. Beams usually have relatively low axial forces and are bent in only one plane, about the cross-section’s strong axis. Hence, it is not necessary to account for P-M interaction, biaxial bending, and biaxial shear. For the beams, the plastic hinge was modeled using a moment rotation hinge since the beams are horizontal line elements that primarily fail in the flexural moment (

M3). The longitudinal and transverse reinforcement presented in

Table A3 and

Table A4 was used to determine the moment capacity for the beams, and the American Society of Civil Engineers (ASCE) [

27] is utilized for the calculation of moment hinge rotation. While for columns, the P-M interaction was taken into consideration because of the high axial forces. Additionally, as columns typically bend in both directions, biaxial shear and bending was also considered. Therefore, the column section in the plastic zone was modeled with separate fibers of confined, unconfined concrete and steel fibers to capture the P-M

2-M

3 interaction. As indicated in

Figure 3, moment–rotation hinges were assigned to the beam elements, while inelastic fibre hinges were assigned to the column members at both ends, with the hinge length determined accordingly. Numerous studies have shown that the length of fiber hinges can be determined based on the cross-sectional geometry, size, and yield strength of the reinforcement bars. In this study, the equation proposed by Paulay and Priestley [

28] is used for the evaluation of plastic hinge length and is given in Equation (1), which has been shown to be accurate for beams and columns in low-rise buildings [

28].

where

Lp is plastic hinge length in mm,

L is the length of the member in mm,

db is the size of the reinforcement bar in mm, and

fy is the steel yield stress in MPa.

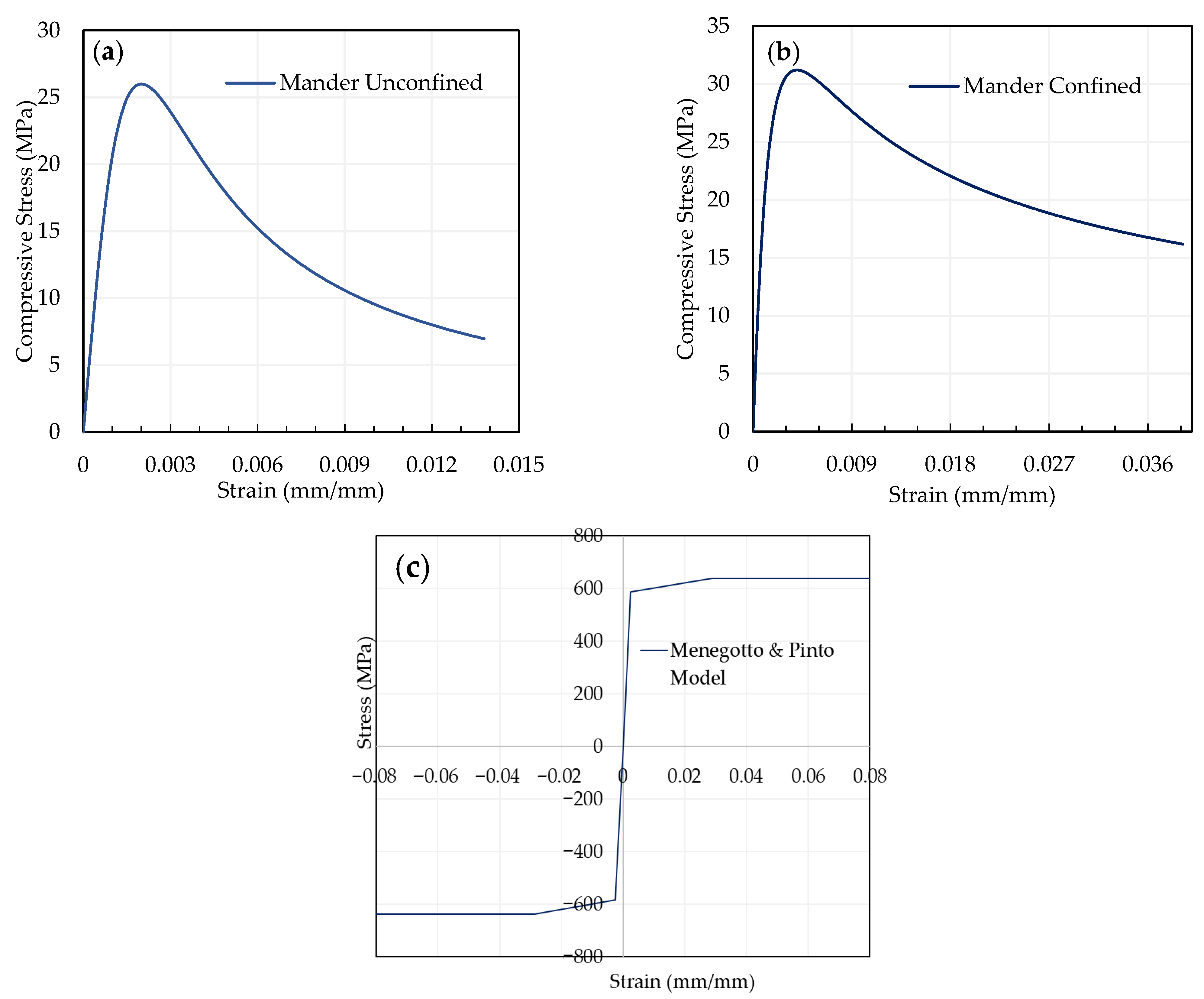

The Mander concrete stress–strain models for confined and unconfined concrete [

29] were adopted to capture the nonlinear behaviour of concrete, while the Menegotto–Pinto model [

30] was used to represent the stress–strain response of steel reinforcement. To simulate the steel fiber, a non-degrading type hysteretic model with strain hardening and without strength loss was used. Post-yield stiffness in this investigation is defined as 1.2% of the elastic stiffness. Similar values were also adopted by [

31,

32] in their study to evaluate the hysteretic energy. The consecutive material models for steel and concrete adopted in this study are shown in

Figure 4.

The overall modeling approach is summarized in

Table 2 and the nonlinear modeling and the pushover analysis were performed by using the CSI application: ETABS.

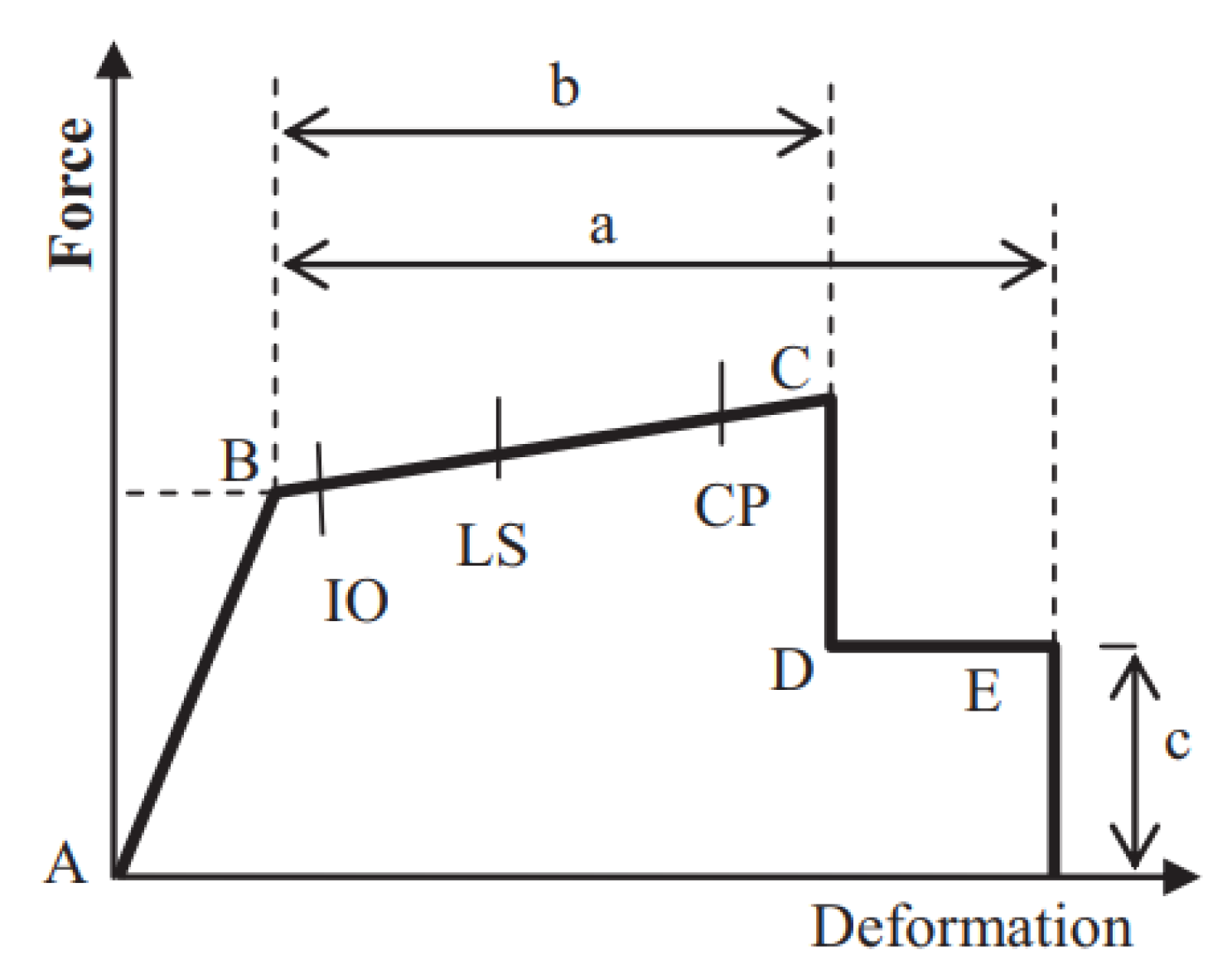

The force-displacement curve for plastic hinge is shown in

Figure 5. Point A is the condition of the unloaded state, Point A to B is the linear slope implying elastic structural behavior, Point B indicates the starting of the yielding of the member and Point C represents the ultimate value and strength degradation occurs, Point D corresponds to the residual strength and is limited to 20% of the yield strength and the eventual collapse of the structure is beyond the point E. The behavior from point B to point C is inelastic and can be categorized under these performance levels. The acceptance criteria for plastic rotation of beams according to ASCE 41-17 [

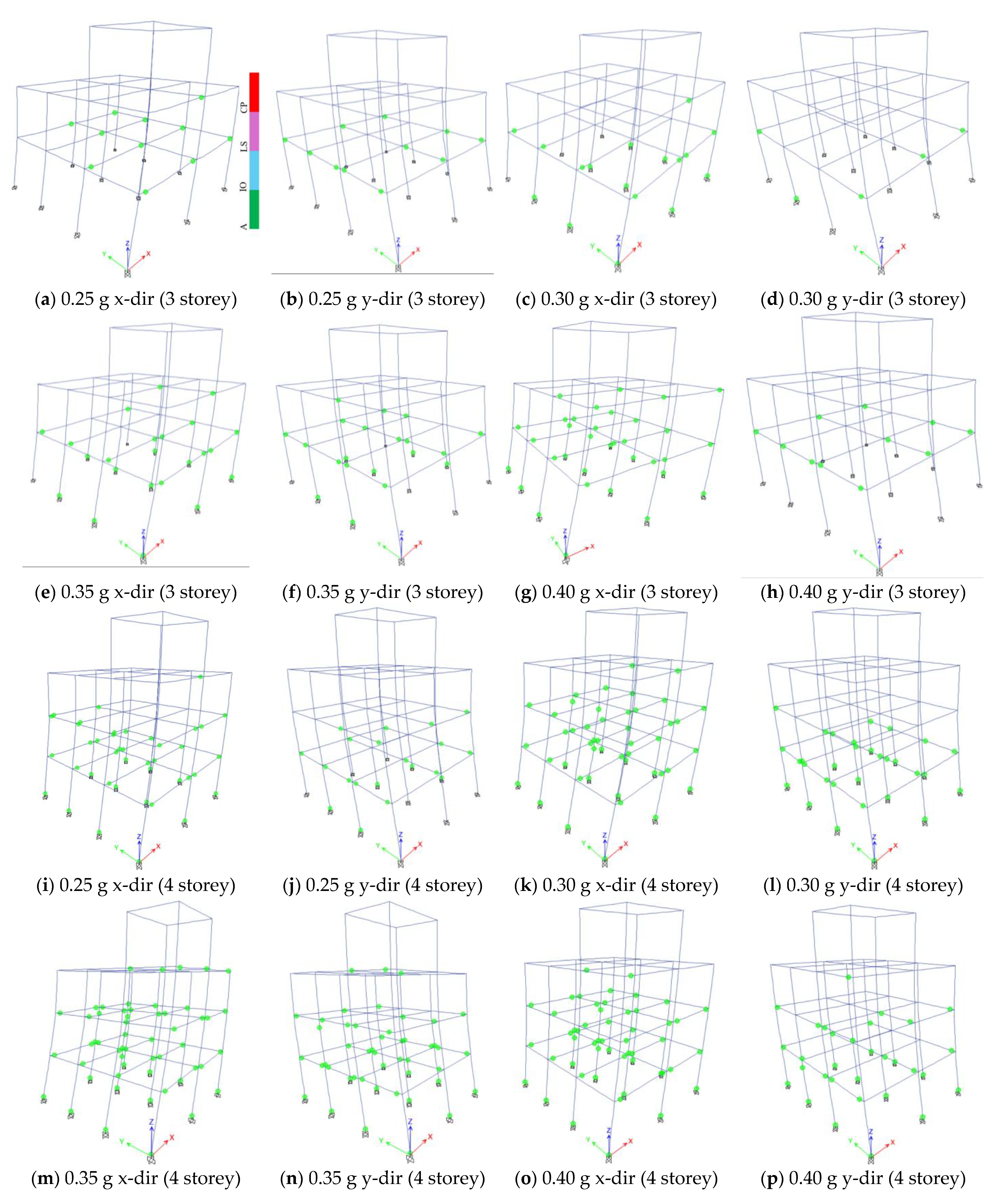

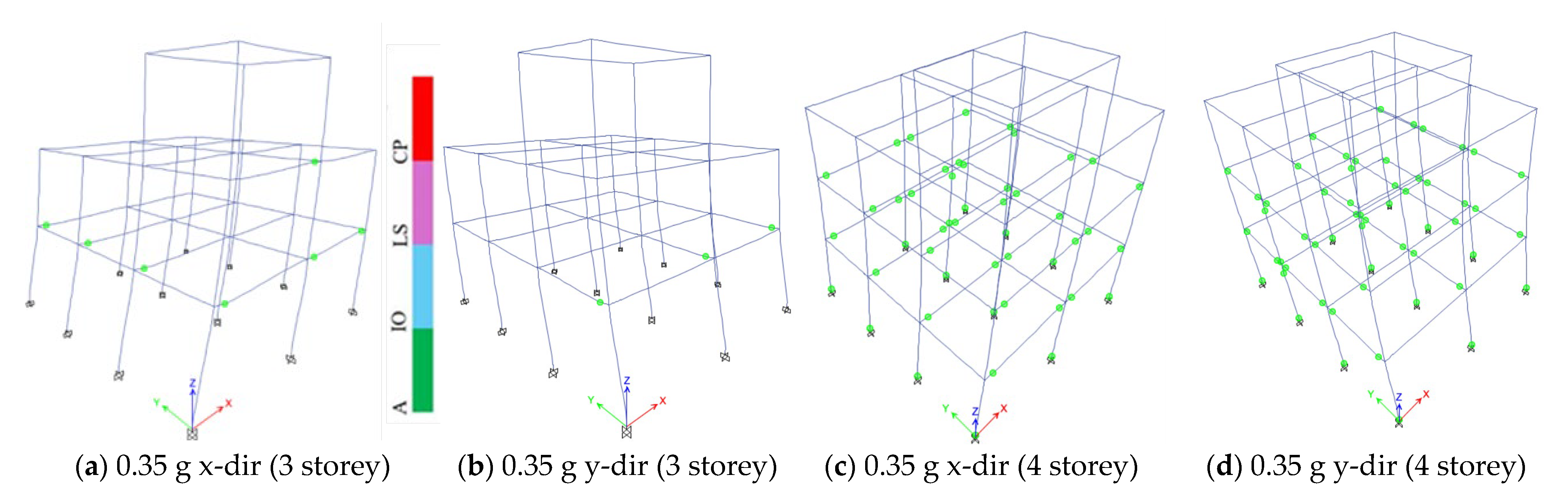

27] are 0.005 radians for the immediate occupancy (IO) level, 0.02 radians for the life safety (LS) level, and 0.04 radians for the collapse prevention (CP) level. Similarly, for the columns, the plastic rotation is 0.003 radians, 0.01 radians, and 0.035 radians for IO, LS, and CP, respectively.

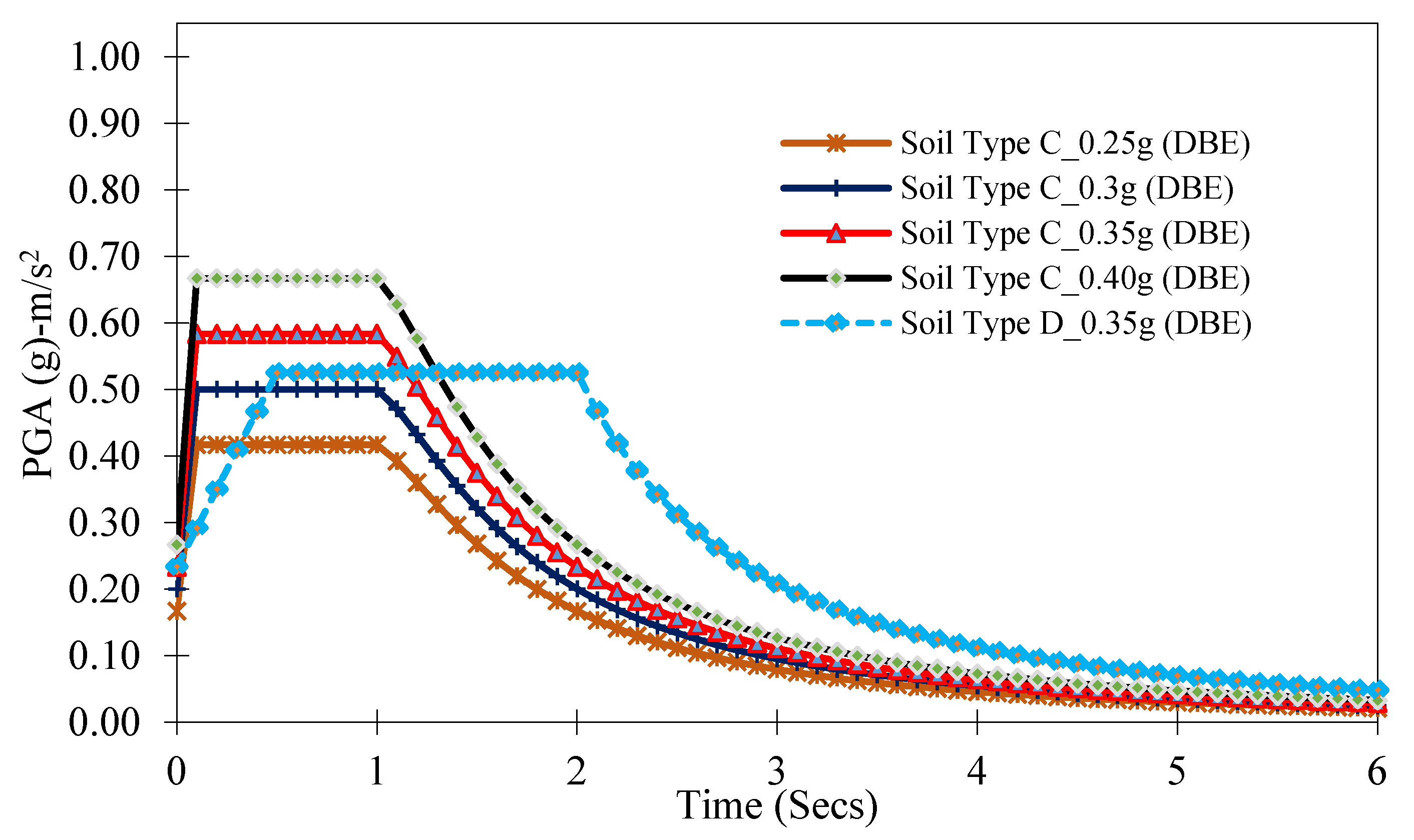

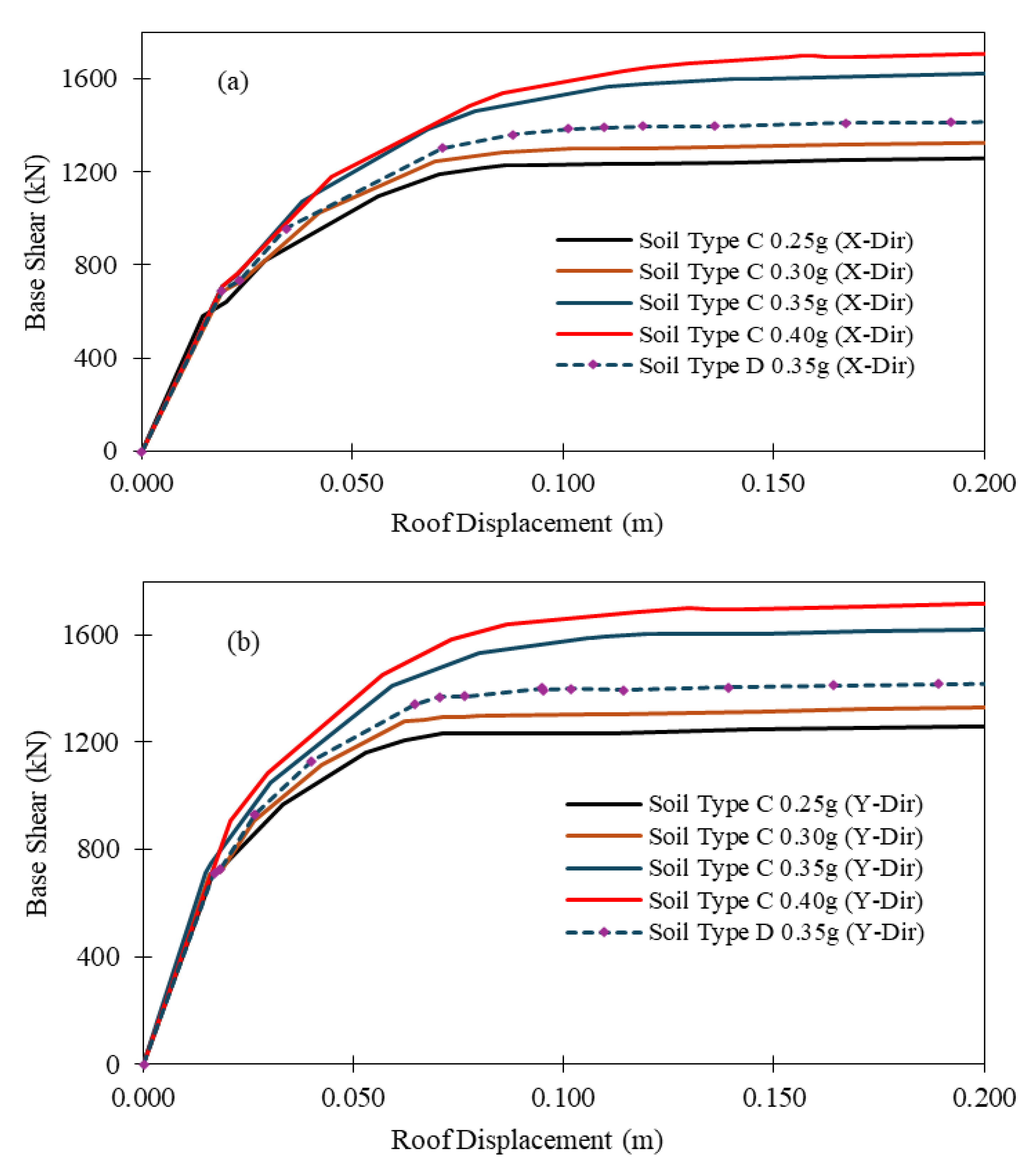

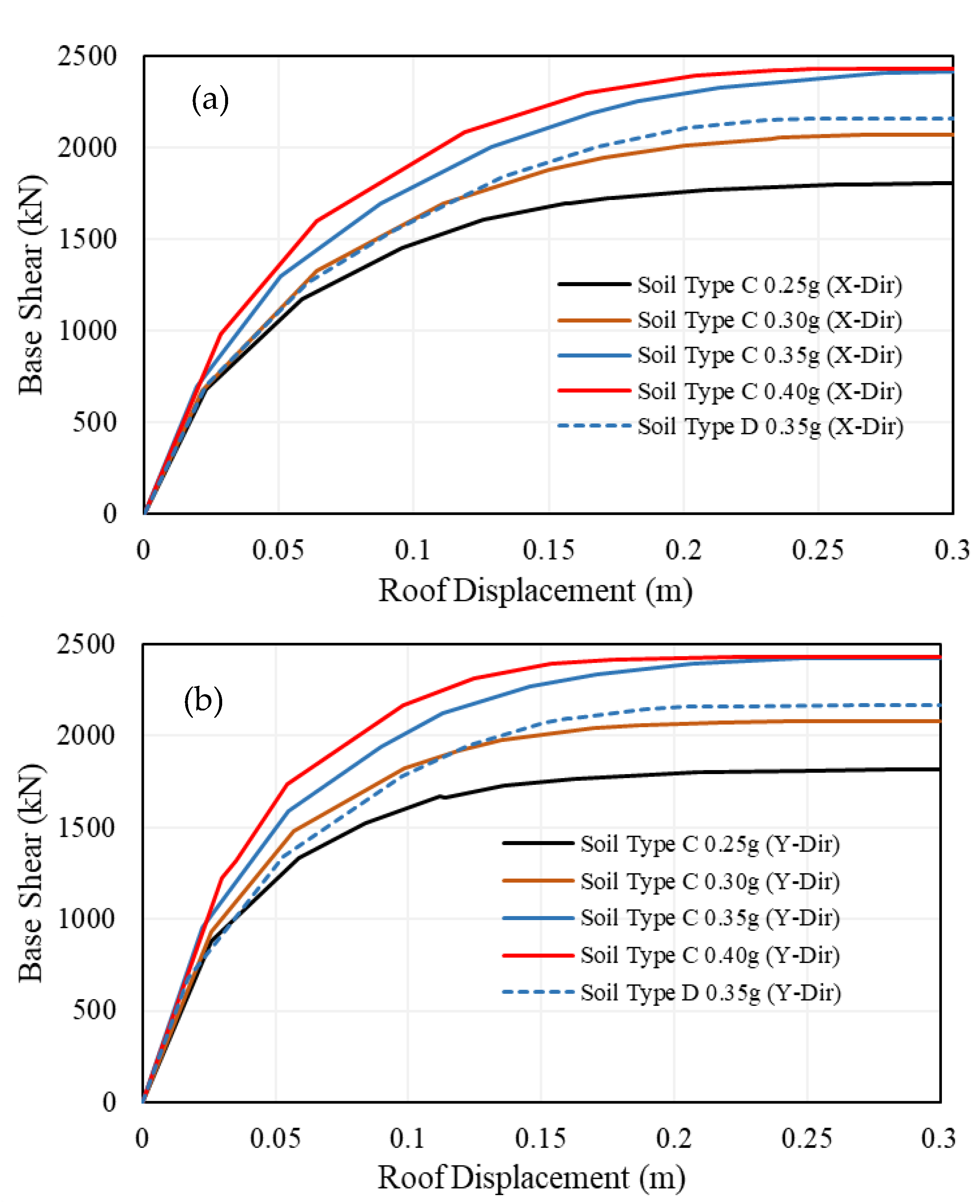

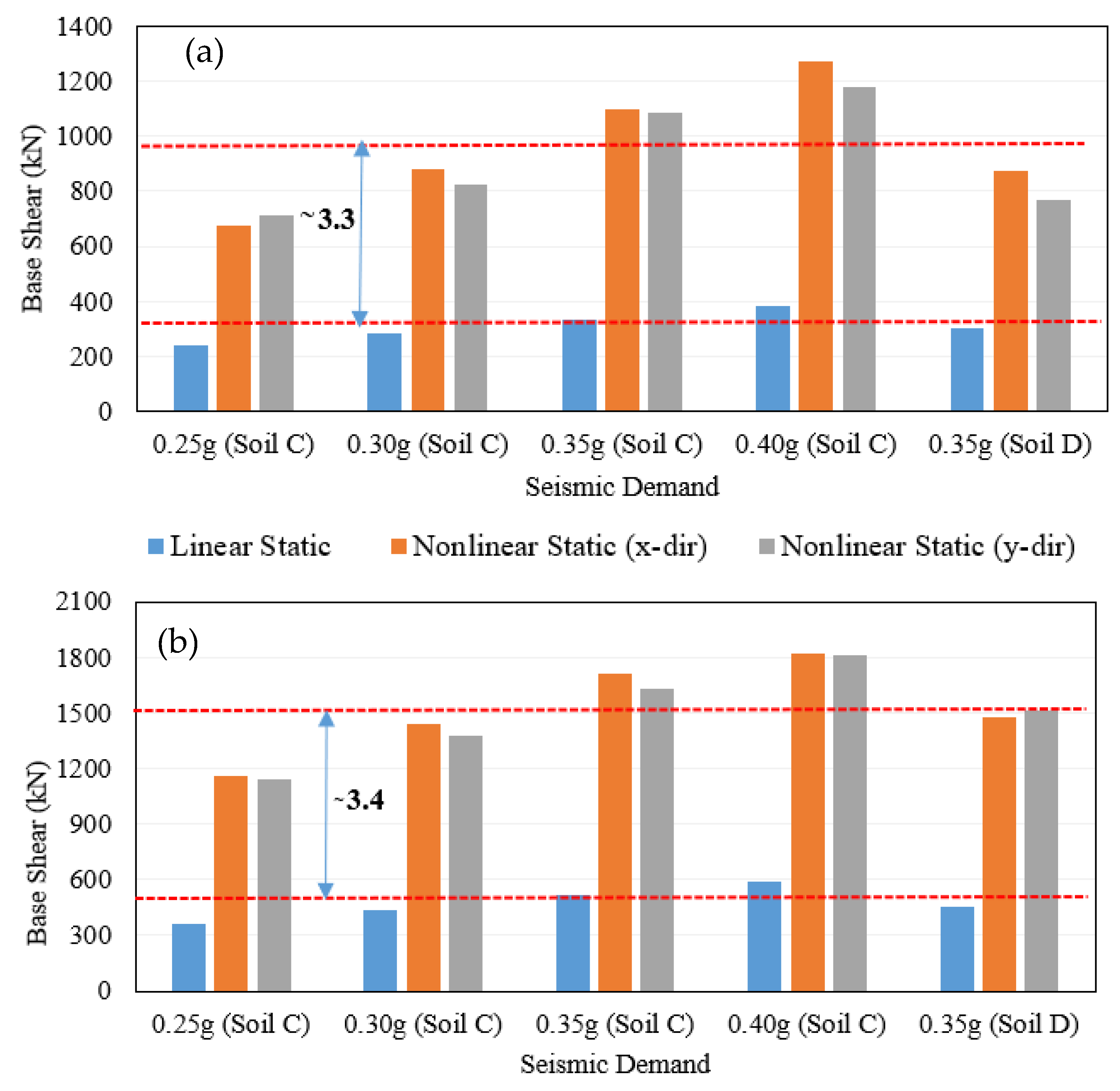

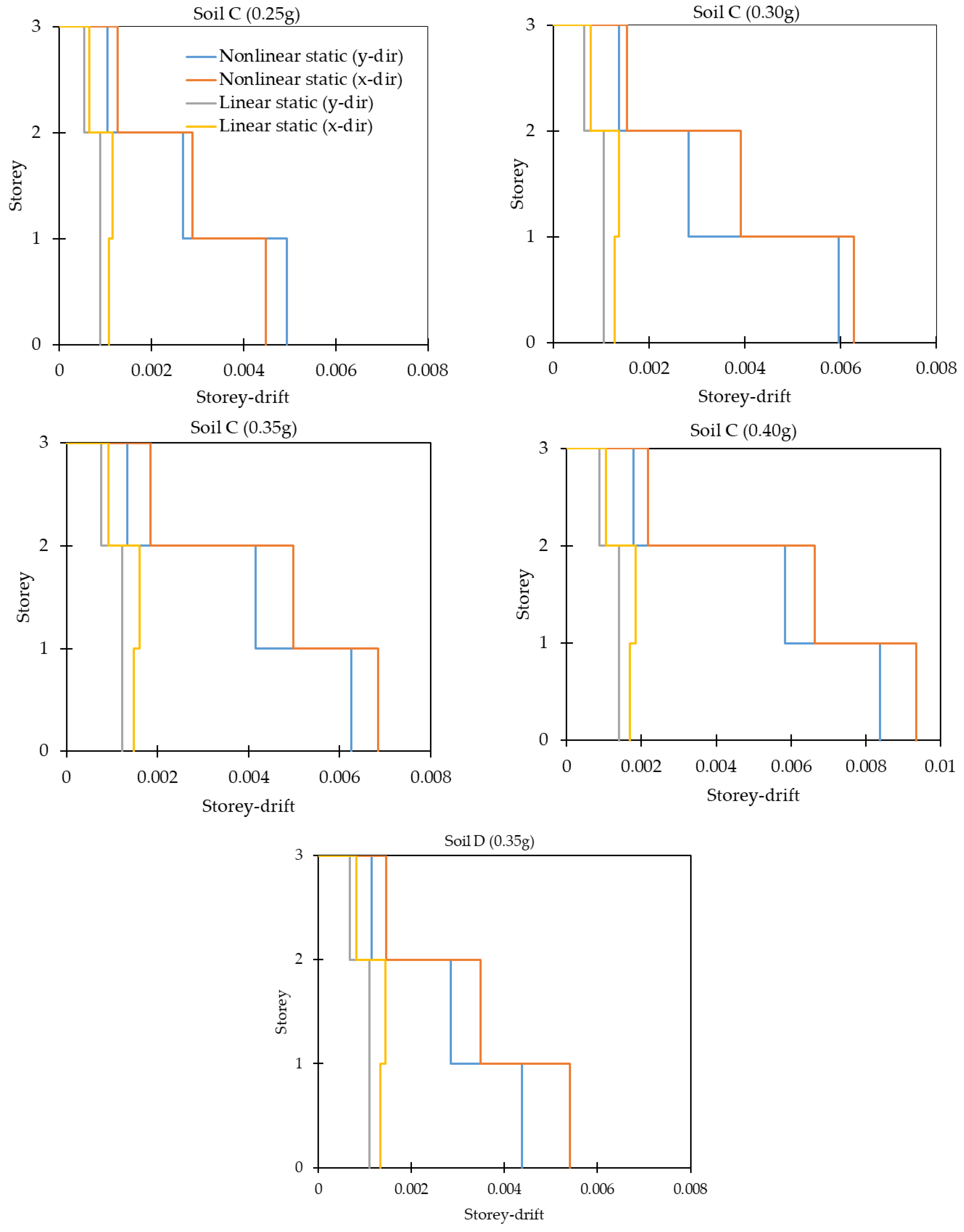

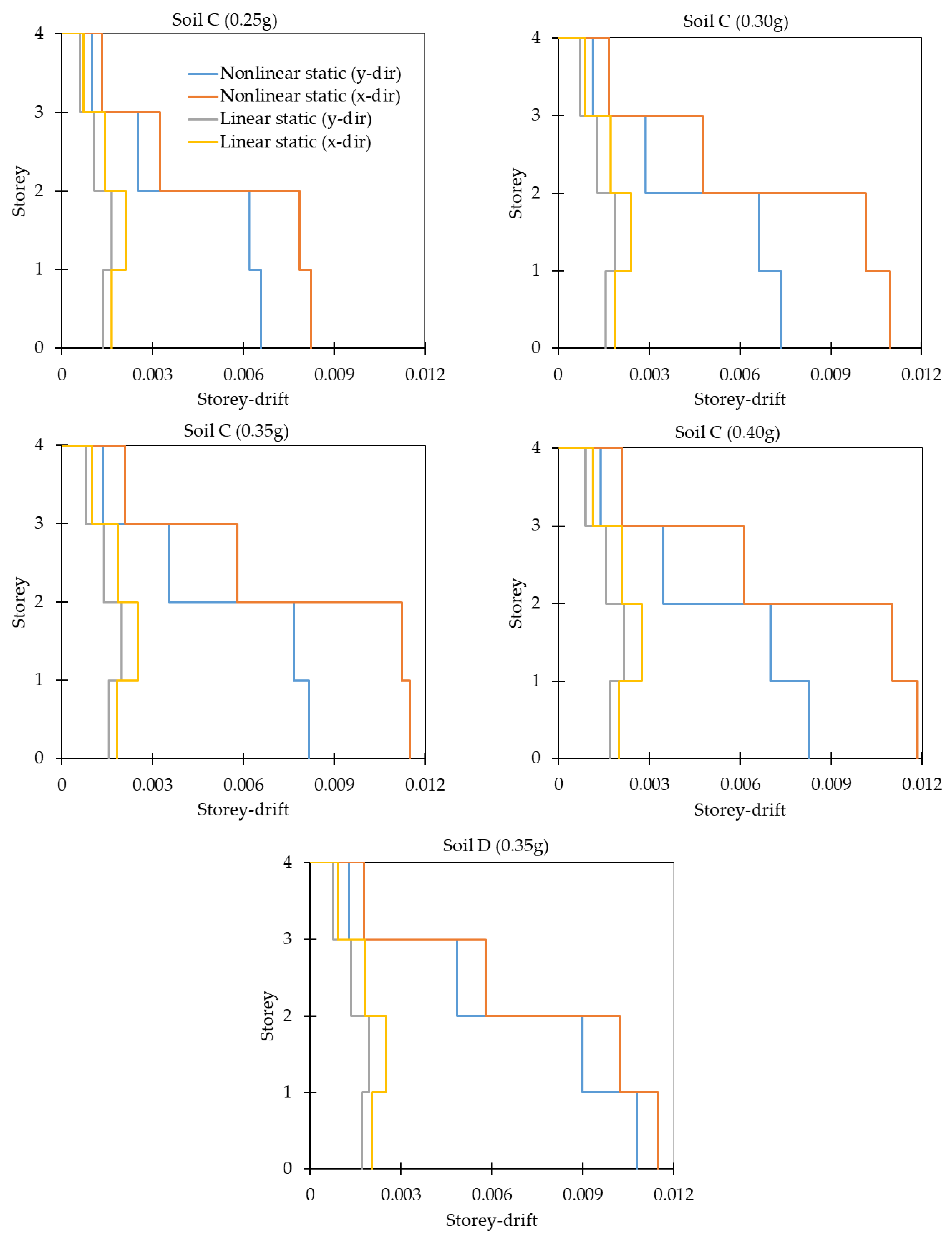

The seismic performance of the proposed study buildings was evaluated in terms of seismic capacity, base shear, and performance point. In this study, the seismic response of the bare frame is evaluated using design-level earthquakes, which means the structure is designed to withstand an earthquake having a 475-year return period, i.e.,10% probability of exceedance over 50 years.

6. Nonlinear Static Pushover Analysis

Although nonlinear dynamic analysis is generally regarded as the most accurate method for predicting seismic behaviour, its application is often limited by complexity, uncertainties in structural properties, difficulties in selecting appropriate ground motions, and significant computational demands. As a result, nonlinear static pushover analysis is widely adopted in practice due to its relative simplicity and lower computational requirements [

33]. This method allows progressive tracking of structural yielding under incremental lateral loading until the target displacement is achieved. Its effectiveness in estimating the seismic response of both new and existing buildings has been validated in numerous studies [

34].

For pushover analysis, the nonlinear material properties of all structural components must first be rigorously defined. Following the development of the nonlinear model, the analysis can be executed using either user-defined hinge properties calibrated to the specific structural system or the default hinge libraries provided in widely used finite element software such as SAP2000, ETABS, and comparable platforms. These hinge definitions are typically based on established guidelines, including FEMA-440 [

35], ASCE 41-17 [

27], and ATC-40 guidelines [

22], which employ the capacity spectrum approach originally proposed by Freeman and collaborators [

36]. In this study, both moment and fiber hinge have their hinge properties manually evaluated and assigned in the models.

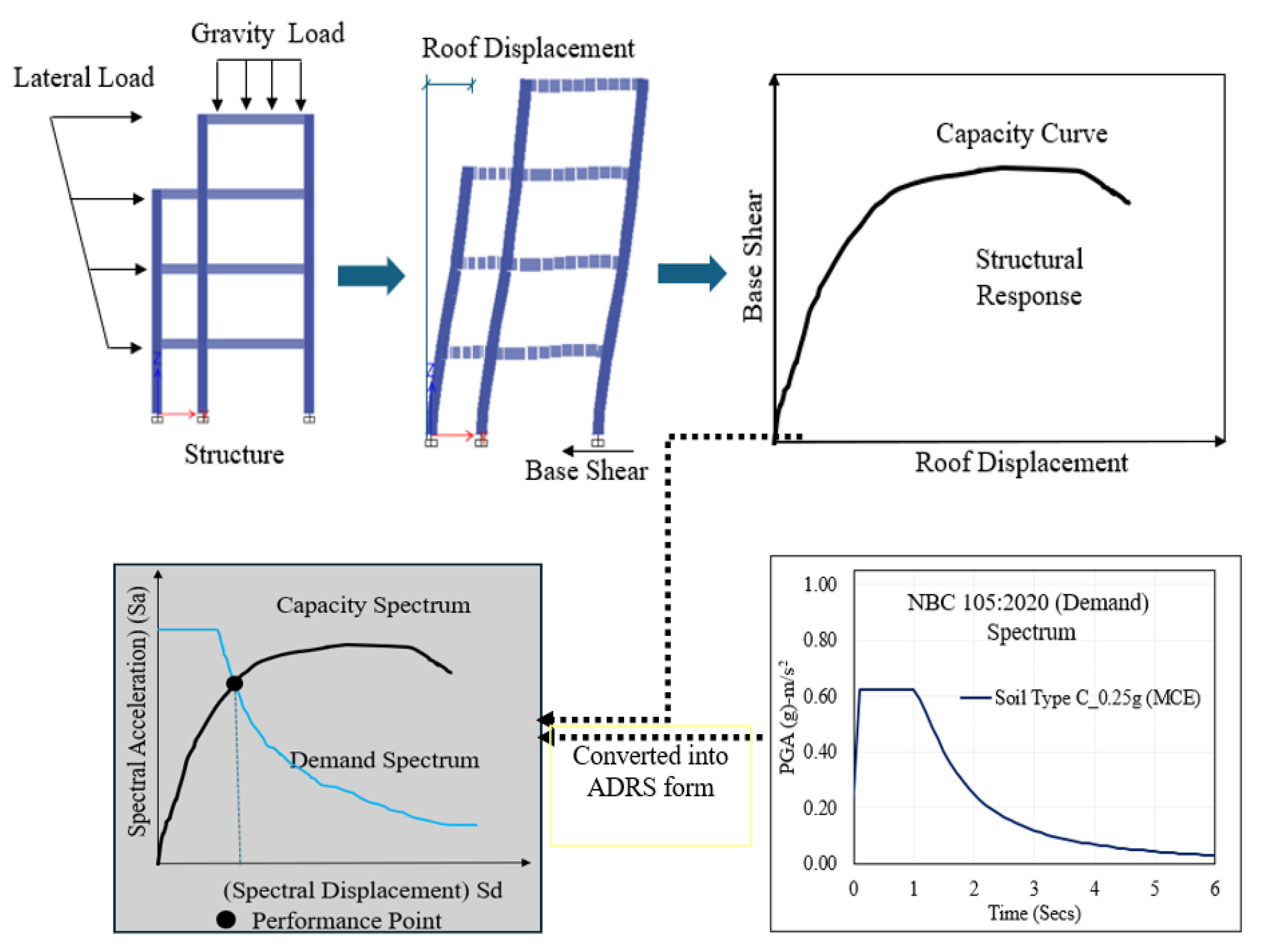

Figure 6 shows the general process for predicting the structure’s performance point by using nonlinear static analysis. The pushover curve is converted into a capacity spectrum after it has been obtained. A demand spectrum can then be created from the general response spectrum in the form of an acceleration displacement response spectrum (ADRS) format [

37]. The structure’s performance point, as depicted in

Figure 6, is where capacity and the demand spectrum intersect. The overall capacity depends on the deformation and strength capacities of individual components in the structure, and this pushover capacity approximates how the structure responds when its elastic limits are exceeded. The performance levels can be established as per ATC-40 (1996) [

22], FEMA 440 [

35], and FEMA 356 [

38], and to demonstrate the realistic seismic performance of the structures that adhere to the structure’s inelastic deformation.

Although pushover analysis is a widely used tool for evaluating seismic performance, its reliability decreases for certain building types. A single load pattern may not be sufficient to describe, in particular, irregular structures or vertical discontinuities and torsionally sensitive buildings with asymmetric stiffness or mass distribution. Higher mode effects and coupled torsional responses may be crucial in these situations, and non-linear time history analysis is typically more suitable. While this study does not focus on those structural configurations, it is crucial to understand that conclusions from pushover analysis should be applied cautiously to structures that are extremely irregular or sensitive to torsion.