Abstract

This research investigates the influence of incorporating perlite aggregate and silica fume on the properties of cement mortar, with a focus on compressive strength, flexural strength, density, water absorption, and thermal conductivity. The results show that increasing the percentage of perlite (Pe) in the mixes causes a marked reduction in the compressive strength, reflecting the lightweight nature and low density of perlite. For mixes with Pe-20% through Pe-100%, the compressive strength decreased by up to 78% compared to the reference mix. However, the addition of silica fume (SF) in mixes with SF-20% to SF-100% partially offset this effect, limiting the strength losses to 18–71%, which indicates that silica fume contributes to strength enhancement over time. The flexural strength followed a similar trend, decreasing with a higher perlite content: reductions of up to 40% were observed for Pe mixtures, while SF mixes showed slightly smaller decreases, reaching 36%. The density also declined consistently with increasing perlite replacement, with a maximum reduction of 57% in mix Pe-100% due to the inherent porosity of perlite. The water absorption increased substantially in the same mix (Pe-100%), by 327% compared to the reference one, whereas the addition of silica fume (SF-100%) limited the increase to 181%, confirming its role in refining the pore structure. The thermal conductivity decreased with a higher perlite content, attributed to the formation of voids in the matrix. The lowest value was observed for Pe-100%, with an 82% reduction, while silica fume mixes also showed reductions of 37–81% relative to the reference mix. Based on a comprehensive evaluation of strength, density, water absorption, and thermal performance, mix SF-60% was identified as the optimal mixture, offering a balanced profile with a compressive strength of 4.4 MPa, thermal conductivity of 0.28 W/(m·K), and density of 1089 kg/m3. These performance levels make the developed mortars particularly suitable for non-load-bearing masonry units, lightweight blocks, and insulation panels, where reduced weight and enhanced thermal efficiency are essential. The study therefore provides practical guidance for the design of sustainable, lightweight mortars for energy-efficient construction applications.

1. Introduction

The utilization of lightweight aggregates is a well-established approach for producing lightweight concrete and mortar, where part or all of the natural coarse or fine aggregate is replaced with a lightweight aggregate [1,2,3,4,5]. Among these alternatives, perlite aggregate is noteworthy for its very low density and wide availability worldwide, with the largest reserves located in Türkiye [6]. Lightweight concrete is particularly valuable for thermal insulation in building walls, as it can significantly reduce heating and cooling demands [7]. In addition, lightweight concrete can be produced using recycled lightweight aggregates when this option is economically feasible [8]. For example, lightweight concrete is commonly applied in wall panels due to its superior insulation properties, with reported thermal conductivity values of approximately 0.147 W/m·K [9].

Perlite is a naturally occurring volcanic glass that expands when rapidly heated to approximately 870 °C, producing a lightweight aggregate with a specific gravity of about 0.356 and a water absorption capacity of up to 71%. The heating process generates a large number of internal voids, which substantially reduces the material’s density [10]. Concrete produced with perlite aggregate can achieve very low unit weights, with typical mixes having a water-to-cement ratio near 2.5, cement contents below 280 kg/m3, compressive strengths below 1.1 MPa, densities under 150 kg/m3, thermal conductivity values below 0.04 W/m·K, and a water absorption rate ranging from 117% to 235%. Such a mix design, characterized by a high water content and reduced cement dosage, is intentionally adopted to increase internal voids, thereby lowering the density and enhancing the thermal insulation performance [11]. Perlite can also be blended with natural rounded aggregates to produce lightweight mortar with adequate compressive strength, thereby minimizing waste and preserving natural resources [12].

Sengul et al. [13] investigated lightweight concrete by replacing natural sand with a perlite aggregate at substitution levels of 20%, 40%, 60%, 80%, and 100% by weight. Their results indicated that increasing the perlite content led to reductions in compressive strength and a modulus of elasticity, accompanied by a significant rise in water absorption. At the same time, the thermal conductivity decreased as the proportion of perlite increased. Because aggregates make up the largest fraction of concrete, their characteristics, such as type, density, texture, and porosity, play a crucial role in determining the mechanical behavior of the composite material [14]. The use of lightweight, porous aggregates like expanded perlite is therefore an effective strategy for producing lightweight concrete [15].

Lightweight aggregates with a high water absorption capacity can act as sources of internal curing after hardening, thereby enhancing cement hydration and mitigating shrinkage [16,17]. In addition, finely ground perlite has been shown to function as a pozzolanic additive in concrete [18]. Thermal conductivity (k) is a critical parameter for assessing the heat transfer characteristics of construction materials [19]. Owing to its inherently low k value, lightweight concrete is particularly suitable for cladding and insulation applications, where reduced heat transfer is required [20]. The incorporation of perlite aggregate in lightweight concrete production offers advantages such as lower density and improved energy dissipation, although it can also lead to decreases in the compressive strength and modulus of elasticity [3].

When the proportion of perlite aggregate exceeds 20%, it can help limit thermal expansion, improve thermal insulation, and enhance sound insulation [21]. Lightweight concrete may also be produced with different kinds of lightweight aggregates, such as pumice in combination with perlite, to achieve a more suitable balance between weight and strength [22]. Perlite powder has additionally been used to manufacture reactive powder lightweight concrete, demonstrating both pozzolanic reactivity and a good freeze–thaw resistance [23]. The incorporation of fibers into perlite-based lightweight concrete improves compressive strength and durability; however, this benefit is accompanied by a reduced workability, requiring the use of superplasticizers. Furthermore, the density of such mixes increases as fibers fill voids within the matrix [24].

Lightweight concrete with a high strength performance can also be produced by adding fly ash together with microperlite. For example, a compressive strength of 40.8 MPa, a flexural strength of 6.3 MPa, and a density of 1406 kg/m3 have been reported. The use of 100% microperlite has been shown to reduce thermal conductivity by 82.4% [25]. Perlite powder may also help reduce shrinkage in lightweight concrete when used as a partial cement replacement, although it can simultaneously increase susceptibility to chloride penetration [26]. Another study investigated the effect of perlite density on the compressive strength of lightweight concrete, and values of 63, 102, 134, and 233 kg/m3 were examined [27]. The results indicated that lower-density perlite (e.g., 63 kg/m3) tends to produce smaller internal voids, whereas the higher-density perlite generates larger voids and consequently reduces compressive strength.

Perlite aggregate waste can serve as a replacement for quartz sand in autoclaved aerated concrete, enhancing its performance [28]. Likewise, lightweight concrete blocks have been manufactured using crushed marble fines combined with a perlite aggregate, where natural sand was substituted with perlite. The resulting mix achieved a thermal conductivity of 0.44 W/m·K and a flexural strength of 2.21 kN [29]. In addition, numerous studies have investigated the effects of perlite sand blended with cementitious materials on the physical and mechanical properties of cement mortars.

Leyton-Vergara et al. [30] conducted an experimental study on the influence of perlite aggregate grading on the thermal and mechanical properties of cement mortars. Mortars were prepared with fine perlite aggregates having a fineness modulus ranging from 2.2 to 3.5, and their compressive strength, thermal conductivity, water absorption, and density were evaluated. The results indicated that both the thermal conductivity and compressive strength increased with a higher fineness modulus. Alexa-Stratulat et al. [31] examined the partial replacement of fine aggregate with perlite aggregate (up to 30% by volume) in cement mortars and observed that the mechanical properties tended to decline as the perlite content increased.

Tie et al. [32] investigated lightweight cement mortars incorporating both perlite and supplementary cementitious materials. Cement was replaced with 35–70% slag and 25–50% fly ash, while fine aggregate was substituted with 50–100% perlite by volume. Their findings indicated that density reductions of up to 60% could be achieved, although higher replacement levels had a negative impact on mechanical performance. Jssem and Fawzi [33] evaluated the combined effects of perlite aggregate and silica fume on lightweight concrete by preparing 15 different mix designs and measuring their compressive strengths and densities. They reported dry densities between 440 kg/m3 and 1440 kg/m3 and compressive strengths ranging from approximately 10 MPa to 15 MPa at 28 days.

Sai et al. [34] examined the use of both perlite aggregate and perlite powder in lightweight concrete. They found that density decreased by 25–50%, slump increased by 33.3% at 30% replacement, and water absorption rose with a higher perlite content. Similarly, Sharma et al. [35] produced lightweight concrete by substituting natural sand with perlite aggregate at replacement levels of 0%, 25%, 50%, and 100%, and also by combining perlite and pumice in the same proportions. For the perlite-only mixes, the density remained below 2200 kg/m3, while the addition of pumice caused a slight increase. Mechanical properties decreased as the proportion of lightweight aggregate increased, with compressive strength reductions of 41.24% for 100% perlite and 37.69% for the perlite–pumice mixes.

Kadela et al. [36] investigated steel fiber-reinforced lightweight concrete containing a perlite aggregate and found that incorporating 1.3–2.6% steel fibers by weight enhanced the compressive strength by 18–48%, tensile strength by 25–52%, and flexural strength by 26–41%, while simultaneously increasing density by 10–18% compared to the reference mix. In another study, Naeem and Awad [37] explored the partial replacement of coarse aggregate with perlite in self-compacting concrete. They reported that the fresh properties deteriorated as the perlite content increased, owing to its high absorption capacity, and that the mechanical strength also decreased at higher replacement levels.

Perlite-based mortars and concretes are already used in several practical applications, which highlights their potential as sustainable construction materials. For example, perlite mortars are applied as fire protection coatings for steel columns, providing a resistance of up to 4 h when applied in layered systems. They are also commonly used with gypsum and cement in interior walls and ceilings not exposed to moisture, as well as in lightweight concretes with densities ranging from 400 to 1200 kg/m3 for thermal insulation. In addition, perlite can serve as a substitute for sand in the manufacture of lightweight tiles [38]. In this research, sand was replaced with perlite aggregates to develop mortars that combine thermal insulation with lightweight properties, while also incorporating silica fume to enhance mechanical performance.

Although numerous studies have examined the effects of perlite aggregates, silica fume, and other cementitious materials on the properties of mortars and concretes, most have investigated these additives in isolation. Only limited research has addressed their simultaneous incorporation in lightweight mortars or provided guidance on optimizing the balance between mechanical performance and thermal efficiency when both materials are used together. This gap is particularly important because perlite enhances thermal insulation but reduces strength, while silica fume refines the pore structure and improves strength. A systematic evaluation of their combined action is therefore needed to support the development of mortars that are both thermally efficient and mechanically adequate.

In this study, cement mortar mixes were prepared with varying proportions of perlite fine aggregate and silica fume, and their compressive strength, flexural strength, density, water absorption, and thermal conductivity were systematically assessed. By analyzing these performance metrics together, the study identifies an optimal balance between lightweight characteristics, thermal insulation, and mechanical adequacy. The findings provide new insights into the combined effect of perlite and silica fume, offering a pathway toward the design of sustainable, lightweight mortars suitable for non-load-bearing masonry units, insulation panels, and other energy-efficient building applications.

2. Materials and Methodology

2.1. Materials

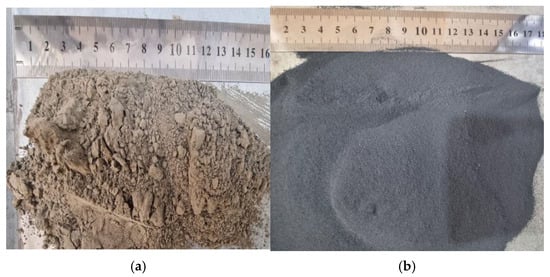

In the experimental program, sulphate-resistant Portland cement (SRPC), classified as ASTM Type V, was utilized in accordance with the Iraqi specification I.Q.S-No. 5 [39]. This cement was used in all mortar mixes. Table 1 summarizes its chemical and physical properties. Natural river sand, with a maximum particle size of 4.75 mm, was used as fine aggregate and complied with the requirements of Iraqi Standard I.Q.S-No. 45 [40]. Lightweight Turkish perlite aggregate was also incorporated, with a maximum particle size of 3 mm, a bulk density of 80 kg/m3, and a water absorption capacity of 136%. The results of the sieve analysis for both the perlite aggregate and natural sand are given in Table 2. The silica fume used in this study contained 93% SiO2 and 4.2% CaO, and it was added at 15% by weight of cement. Figure 1 illustrates the materials used in the experimental program.

Table 1.

Chemical and physical properties of sulfate-resistant Portland cement.

Table 2.

Sieve analysis for lightweight perlite aggregate and natural river sand.

Figure 1.

Materials used in the study: (a) sulphate-resistant Portland cement, (b) silica fume, (c) lightweight perlite aggregate.

2.2. Concrete Mix Proportion

In this study, twelve cement mortar mixes were prepared. Each mix contained 400 kg/m3 of cement, and the water-to-binder ratio was maintained as a constant at 0.42. In the initial six mixtures, natural sand was partially replaced with perlite aggregate at levels of 0%, 20%, 40%, 60%, 80%, and 100%, while, in the remaining six mixtures, silica fume was also incorporated. Previous research on lightweight concrete has shown that incorporating silica fume in the range of 10–20% of cement weight generally produces the greatest improvement in compressive strength. Accordingly, in this study, silica fume was added at 15% by weight of cement [41,42], as summarized in Table 3. In the mix nomenclature, ‘Pe’ refers to the percentage of sand replaced with perlite aggregate, whereas ‘SF’ denotes the same perlite replacement combined with 15% silica fume (by cement weight).

Table 3.

Mix proportion (kg/m3).

2.3. Sampling and Testing of Mortar

In this study, mortar samples were prepared and tested to assess the influence of perlite aggregate and silica fume on the mechanical and physical properties of lightweight cement mortars.

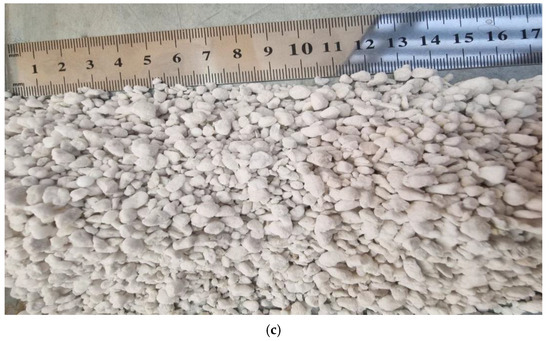

The perlite aggregate was first pre-soaked in water for 24 h to achieve a saturated surface-dry (SSD) condition before mixing. Subsequently, natural sand was replaced with perlite aggregate using the volumetric method, and the mixes were prepared using an electric mixer. After casting, the samples were stored in a water tank for 24 h and then cured until the designated testing ages. Fresh mortar properties were evaluated immediately after mixing, while tests on the hardened mortar were carried out at later stages, following the procedure summarized in Figure 2.

Figure 2.

Flowchart illustrating the experimental methodology.

To control the effect of the high absorption capacity of perlite (136%), the aggregate was presoaked in water for 24 h and used in a saturated surface-dry (SSD) condition before mixing. A constant water-to-binder ratio of 0.42 was maintained across all mixes to allow for direct comparison between different replacement levels. While this approach minimizes variability in mixing conditions, it may not completely eliminate the influence of perlite’s internal absorption on the effective w/b ratio. This represents a limitation of the present experimental program, but also reflects a practical scenario in which lightweight mortars are often produced with SSD lightweight aggregates and a fixed design w/b ratio.

3. Experimental Results and Discussion

3.1. Flowability

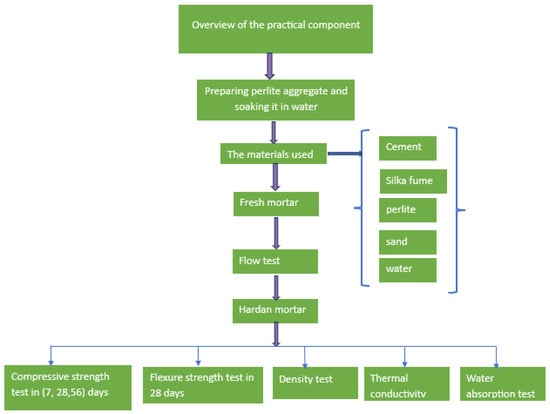

Flow testing was carried out to evaluate the workability of the cement mortar according to ASTM C1437-20 [43]. The results showed that the flow value of the mortar increased with the addition of perlite. This behavior is attributed to the pre-soaking of the perlite aggregate for 24 h before mixing and its high absorption capacity, which contributed to the enhanced workability. In contrast, mixes containing silica fume exhibited a significant reduction in flowability [44]. This reduction can be explained by the large specific surface area of silica fume, which increases water demand and decreases workability [45]. Overall, a higher proportion of lightweight aggregate relative to cement produced a greater flow, whereas higher silica fume contents resulted in lower flow values. The results are presented in Figure 3.

Figure 3.

Flow test results for all mixes.

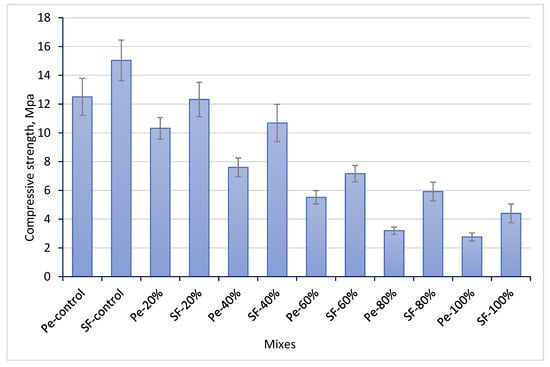

3.2. Compressive Strength

Mortar cubes with dimensions of 5 × 5 × 5 cm were cast in accordance with BSEN12390–4 [46] and tested for compressive strength at 7, 28, and 56 days, as shown in Figure 4. The results at 56 days for the mixes ranging from Pe-control to Pe-100% demonstrated that increasing the perlite content was associated with a decrease in the compressive strength, which is consistent with the previous findings [47]. The reference mix achieved the highest compressive strength of 12.5 MPa, while the lowest value of 2.76 MPa was recorded for the Pe-100% mixture, reflecting the low density of perlite aggregate [48]. In contrast, mixes SF-control to SF-100%, which incorporated 15% silica fume by weight of cement, showed improved compressive strength due to the ability of silica fume to fill the pores [49]. The lightweight mortars produced in this study can therefore be considered suitable for non-load-bearing applications where the required compressive strength exceeds 3.5 MPa, in line with RILEM/CEB recommendations [50].

Figure 4.

Compressive strength test.

Lightweight mortars with compressive strengths in the range of 4–7 MPa are not intended for structural load-bearing applications, but they are suitable for use in non-load-bearing walls, insulation panels, and lightweight blocks. According to RILEM/CEB recommendations, mortars with compressive strengths above 3.5–4 MPa can be applied in non-load-bearing masonry units [51]. The results of this study show that the incorporation of silica fume improves the performance even in mixes with the highest perlite content, as seen in mix SF-100%, which achieved a 59% higher strength than mix Pe-100%. This improvement is attributed to the pore-filling and pozzolanic activity of silica fume, which reduces porosity and enhances the microstructure. By balancing strength with low density and thermal insulation properties, such mortars provide a viable option for sustainable, thermally efficient construction applications.

Table 4 presents the development of compressive strength with age, while Figure 4 illustrates the compressive strength testing procedure. The results of compressive strength at 56 days for all mixes are shown in Figure 5.

Table 4.

Compressive strength (MPa) at different ages for all mixes.

Figure 5.

Compressive strength at 56 days for all mixes.

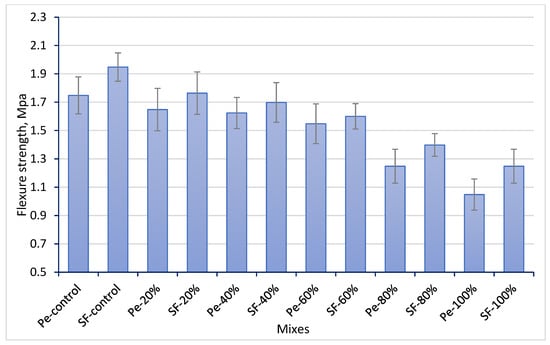

3.3. Flexural Strength

Flexural testing was performed in accordance with ASTM C78-18 [52]. The samples were tested at 28 days, and the results showed that flexural strength decreased progressively as the perlite content increased, reflecting the low density of perlite. The Pe-100% mixture, which contained the highest proportion of perlite, exhibited the lowest flexural strength at 1.048 MPa, whereas the reference mix achieved the highest value. Mortars incorporating silica fume displayed a modest increase in flexural strength, as illustrated in Figure 6.

Figure 6.

Flexural strength at 28 days for all mixes.

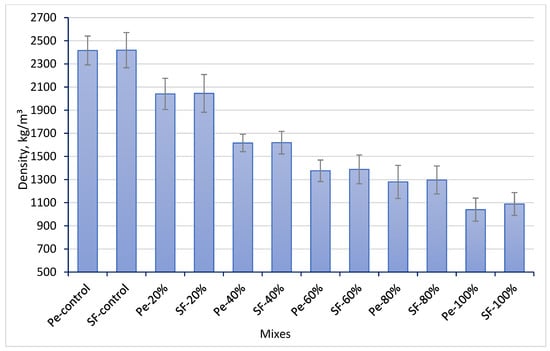

3.4. Density

Density testing was conducted in accordance with ASTM C642-13 [53]. The results for the mixes from Pe-control to Pe-100% showed a clear reduction in density as the perlite content increased, which can be attributed to the very low density of the perlite aggregate [54]. The reference mix exhibited the highest density of 2400 kg/m3, whereas the Pe-100% mix had the lowest value of 1040 kg/m3, due to its full replacement with the perlite aggregate. For the mixes SF-control to SF-100%, density also decreased with higher perlite contents. However, a slight increase was noted in the first six SF mixtures, reflecting the ability of silica fume to fill pore spaces and densify the matrix. The density results for all mixes are illustrated in Figure 7.

Figure 7.

Density for all mixes.

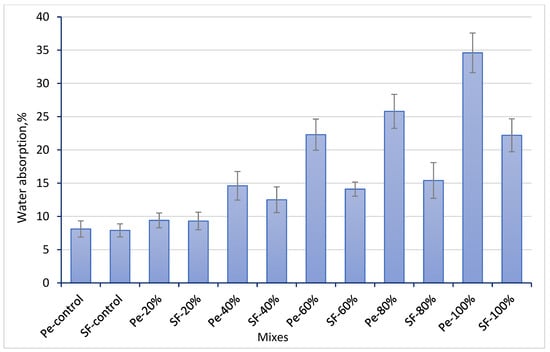

3.5. Water Absorption

Water absorption testing was carried out in accordance with ASTM C642 [53]. As expected, absorption increased with the proportion of lightweight aggregate, since perlite absorbs significantly more water than natural sand; however, this rise in water absorption does not necessarily compromise durability [55]. For the mixes ranging from Pe-control to Pe-100%, absorption values increased consistently with higher perlite contents, reaching a maximum of 34.6% in the Pe-100% mixture. This behavior is explained by the high absorption capacity of the perlite aggregate itself, measured at 136%, which leads to a greater water uptake in the mortar. The mixes from SF-control to SF-100% also showed a higher absorption with increasing perlite replacement, although their values were lower than those of the corresponding Pe mixtures, owing to the pore-refining action of silica fume. The absorption results for all mixes are presented in Figure 8.

Figure 8.

Water absorption for all mixes.

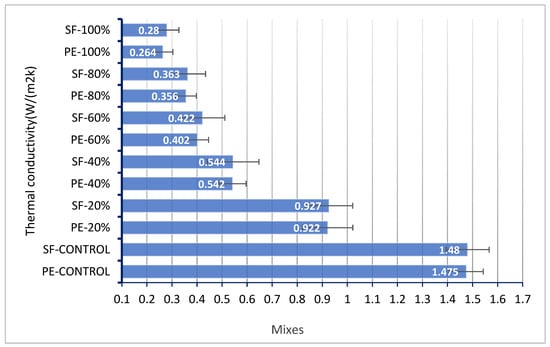

3.6. Thermal Conductivity

In 1980, Valore [56] proposed an equation correlating density with thermal conductivity, which was adopted in the present research to estimate thermal conductivity values. For the mixes Pe-control to Pe-100%, the highest thermal conductivity was recorded for the reference mix (1.475 W/m·K), while the lowest was obtained for Pe-100% (0.264 W/m·K). These results demonstrate that increasing the proportion of perlite aggregate reduces thermal conductivity, as the very low density of perlite decreases the overall weight of the mortar and thereby limits heat transfer. For the mixtures SF-control to SF-100%, the highest conductivity was measured in SF-control, which contained no perlite aggregate, whereas the lowest value occurred in SF-100%, corresponding to the maximum perlite replacement. Compared with the Pe series, the SF mixtures showed slightly higher conductivity values, attributable to the pore-filling effect of silica fume, which increases density. The thermal conductivity results for all mixtures are presented in Figure 9.

Figure 9.

Thermal conductivity for all mixes.

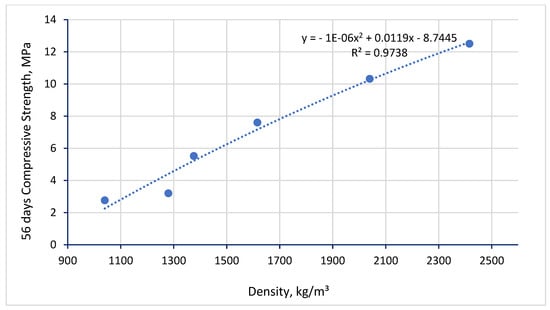

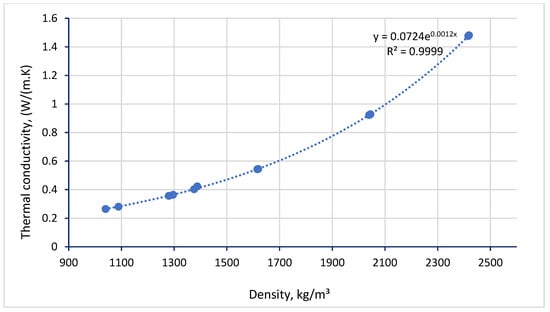

3.7. Relationship Between Thermal Conductivity, Density, and Compressive Strength

The relationship between the compressive strength and density for the Pe-control to Pe-100% mixtures was found to be approximately linear: in general, a higher density corresponded to a higher compressive strength. The results indicated that Pe-100% exhibited the lowest compressive strength (2.76 MPa at 56 days) and also the lowest density (1040 kg/m3). In contrast, the reference mix (Pe-control), which contained no perlite aggregate, achieved the highest values for both properties. This trend can be explained by the low-density nature of perlite aggregate, which reduces the overall density of the mortar and consequently lowers its compressive strength, as lightweight aggregates are less capable of sustaining applied loads compared with natural aggregates.

For the mixtures from SF-control to SF-100%, an increase in density was accompanied by an increase in compressive strength, and vice versa. At 56 days, the compressive strengths of these mixes were generally higher than those of the corresponding Pe series, primarily due to the incorporation of silica fume. A clear relationship was also observed between the thermal conductivity of mortar and its density, with higher densities associated with higher conductivity values. As shown in Figure 9, the lowest thermal conductivity recorded in this study was for Pe-100%, which contained 100% perlite, with a value of 0.246 W/m·K. This result is in agreement with previous studies [57]. The relationship between compressive strength and density is illustrated in Figure 10, while the relationship between density and thermal conductivity is presented in Figure 11.

Figure 10.

Relationship between density and compressive strength.

Figure 11.

Relationship between density and thermal conductivity.

4. Conclusions

This study examined the influence of incorporating perlite aggregate and silica fume on the properties of cement mortar. From the experimental results, the following main conclusions were derived:

- At 56 days, the compressive strength of mixes Pe-20% to Pe-100% showed average reductions of 17%, 39%, 56%, 74%, and 78%, respectively, compared with the reference mix. This decrease reflects the lower density of the perlite aggregate, where higher replacement levels lead to reduced strength. In contrast, mixes containing silica fume (SF-20% to SF-100%) exhibited smaller reductions of 18%, 29%, 52%, 61%, and 71%, demonstrating that silica fume helped mitigate strength loss and contributed to improved performances at later stages.

- In the flexural strength tests, mixes Pe-20% to Pe-100% showed reductions of 6%, 6%, 11%, 29%, and 40%, respectively, relative to the reference mix, with strength decreasing as perlite content increased. A similar trend was observed in the silica fume mixes (SF-20% to SF-100%), which exhibited reductions of 9%, 13%, 28%, and 36% with higher perlite replacement.

- Increasing the perlite content in the mortar resulted in a progressive reduction in density. The greatest decrease was observed in Pe-100%, with a 57% reduction, reflecting the inherently low density of the perlite aggregate. The average density reductions for mixes Pe-20% to Pe-100% were 16%, 33%, 43%, 47%, and 57%, respectively. For the silica fume mixes (SF-control to SF-100%), the corresponding reductions were 15%, 33%, 43%, 46%, and 55%.

- Water absorption increased with a higher perlite content, reflecting the very high absorption capacity of the perlite aggregate. The maximum increase was observed in Pe-100%, which recorded a 327% rise compared to the reference mix. In contrast, SF-100% showed a lower increase of 181%, as silica fume contributed to reducing absorption. The absorption increments for mixes Pe-20% to Pe-100% were 16%, 80%, 175%, 219%, and 327%, respectively, while those for mixes SF-20% to SF-100% were 18%, 58%, 78%, 94%, and 181%, respectively.

- Thermal conductivity decreased as the amount of perlite aggregate increased, due to the formation of additional voids in the mortar. The greatest reduction was observed in Pe-100%, which showed an 82% decrease compared with the reference mix. The average reductions for mixes Pe-20% to Pe-100% were 37%, 63%, 72%, and 82%, respectively. Similarly, the silica fume mixes (SF-20% to SF-100%) also exhibited progressively lower conductivity with increasing perlite content, with reductions of 37%, 63%, 71%, 75%, and 81%, respectively, relative to the reference.

- MixSF-60% can be regarded as a suitable optimal balance under the present study conditions, as it combines a compressive strength of 4.4 MPa with a low density of 1089 kg/m3 and a reduced thermal conductivity of 0.28 W/(m·K). Although other mixtures, such as SF-40%, also showed good performance, SF-60% offered the most favorable compromise between mechanical strength and thermal insulation. Ultimately, the choice of mix may be adjusted in practice depending on the specific performance requirements of a given application.

While the present study provides comprehensive insights into the simultaneous effects of perlite fine aggregate and silica fume on the engineering properties of lightweight mortars, certain limitations remain. In particular, detailed microstructural investigations such as pore size distribution analysis, XRD quantitative phase analysis, and SEM–EDS characterization were beyond the scope of this work. Future studies incorporating these techniques would be highly valuable for deepening the understanding of the microstructural mechanisms that govern the observed macroscopic behaviors. Moreover, as thermal conductivity was estimated using [56] correlation, future work should include direct experimental measurements to validate and complement these estimates, especially for very low-density mixes. In addition, although this study focused on Portland cement-based mortars, extending the proposed approach to geopolymer binders could offer further opportunities for developing sustainable, lightweight, and thermally efficient materials.

Author Contributions

M.S.W.: investigation, conceptualization, visualization, validation, formal analysis, writing—review and editing. M.S.R.: conceptualization, formal analysis, validation, data curation, writing—review and editing. A.D.: project administration, conceptualization, review and editing, supervision, and funding acquisition. L.F.A.B.: visualization, resources, writing—review and editing. T.P.R.: formal analysis, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The authors declare that the data supporting the findings of this study are available within the paper.

Acknowledgments

The authors express sincere gratitude for the support received from the University of Kerbala in Iraq.

Conflicts of Interest

Tiago Pinto Ribeiro is an employee of Paterson & Cooke (UK), Ltd. The other authors declare no conflicts of interest.

References

- Mahmmod, L.M.R.; Dulaimi, A.; Bernardo, L.F.A.; Andrade, J.M.d.A. Characteristics of Lightweight Concrete Fabricated with Different Types of Strengthened Lightweight Aggregates. J. Compos. Sci. 2024, 8, 144. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Beskopylny, A.N.; Mailyan, A.L.; Shcherban’, N.; Chernil’nik, A.; Elshaeva, D. Composition and Properties of Lightweight Concrete of Variotropic Structure Based on Combined Aggregate and Microsilica. Buildings 2025, 15, 346. [Google Scholar] [CrossRef]

- Bakhshi, M.; Dalalbashi, A.; Soheili, H. Energy dissipation capacity of an optimized structural lightweight perlite concrete. Constr. Build. Mater. 2023, 389, 131765. [Google Scholar] [CrossRef]

- Kumar, P.; Pasla, D.; Saravanan, T.J. Self-compacting lightweight aggregate concrete and its properties: A review. Constr. Build. Mater. 2023, 375, 130861. [Google Scholar] [CrossRef]

- Agrawal, Y.; Gupta, T.; Sharma, R.; Panwar, N.L.; Siddique, S. A comprehensive review on the performance of structural lightweight aggregate concrete for sustainable construction. Constr. Mater. 2021, 1, 39–62. [Google Scholar] [CrossRef]

- Erdem, T.K.; Meral, Ç.; Tokyay, M.; Erdoğan, T. Use of perlite as a pozzolanic addition in producing blended cements. Cem. Concr. Compos. 2007, 29, 13–21. [Google Scholar] [CrossRef]

- Lam, T.V.; Vu, D.T.; Dien, V.K.; Bulgakov, B.; Anatolyevna, K.E. Properties and thermal insulation performance of light-weight concrete. Mag. Civ. Eng. 2018, 8, 173–191. [Google Scholar]

- Smoczkiewicz-Wojciechowska, A.; Sybis, M.; Mądrawski, J.; Kostrzewski, W. The study on possible applications of lightweight concrete based on waste aggregate in terms of compressive strength and thermal insulation properties. Pol. J. Environ. Stud. 2022, 31, 833–841. [Google Scholar] [CrossRef]

- Ding, X.; Yu, J.; Lin, J.; Chen, Z.; Li, J. Experimental investigations of prefabricated lightweight self-insulating foamed concrete wall panels. Structures 2024, 61, 106001. [Google Scholar] [CrossRef]

- Ibrahim, M.; Ahmad, A.; Barry, M.S.; Alhems, L.M.; Mohamed Suhoothi, A. Durability of structural lightweight concrete containing expanded perlite aggregate. Int. J. Concr. Struct. Mater. 2020, 14, 50. [Google Scholar] [CrossRef]

- Tapan, M.; Engin, C. Effect of expanded perlite aggregate size on physical and mechanical properties of ultra lightweight concrete produced with expanded perlite aggregate. Period. Polytech. Civ. Eng. 2019, 63, 845–855. [Google Scholar] [CrossRef]

- Hasana, A.S.M.; Nora, N.M.; Jamaludina, A.H.; Ruslana, A.K.; Osmana, N.M.; Sooriab, S.Z.; Saliaha, S.N.M.; Fauzia, M.A. Control Strength Lightweight Mortar made by Recycled Concrete Aggregate and Expanded Perlite. J. Kejuruter. 2024, 36, 2287–2299. [Google Scholar] [CrossRef]

- Sengul, O.; Azizi, S.; Karaosmanoglu, F.; Tasdemir, M.A. Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build. 2011, 43, 671–676. [Google Scholar] [CrossRef]

- Sengul, O.; Tasdemir, C.; Tasdemir, M.A. Influence of aggregate type on mechanical behavior of normal-and high-strength concretes. Mater. J. 2002, 99, 528–533. [Google Scholar]

- ASTM C 332; Standard Specification for Lightweight Aggregates for Insulating Concrete. ASTM International: West Conshohocken, PA, USA, 2009.

- Lura, P.; Bentz, D.P.; Lange, D.A.; Kovler, K.; Bentur, A. Pumice aggregates for internal water curing. In Proceedings of the International RILEM Symposium on Concrete Science and Engineering: A Tribute to Arnon Bentur, Evanston, IL, USA, 21–24 March 2004; pp. 22–24. [Google Scholar]

- Whwah, M.S.; Mahmmod, L.M.R.; Abdoulhaleem, H.H.; Dulaimi, A. Internal Curing Utilising Recycled Concrete Aggregate: A Sustainable Approach for Improving High-Strength Concrete’s Performance. Arab. J. Sci. Eng. 2024, 50, 8061–8076. [Google Scholar] [CrossRef]

- Yu, L.-H.; Ou, H.; Lee, L.-L. Investigation on pozzolanic effect of perlite powder in concrete. Cem. Concr. Res. 2003, 33, 73–76. [Google Scholar] [CrossRef]

- ACI Committee 122. Guide to Thermal Properties of Concrete and Masonry Systems; ACI Committee: Farmington Hills, MI, USA, 2002. [Google Scholar]

- Asadi, I.; Shafigh, P.; Hassan, Z.F.B.A.; Mahyuddin, N.B. Thermal conductivity of concrete–A review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Benjeddou, O.; Ravindran, G.; Abdelzaher, M.A. Thermal and acoustic features of lightweight concrete based on marble wastes and expanded perlite aggregate. Buildings 2023, 13, 992. [Google Scholar] [CrossRef]

- Stratoura, M.C.; Lazari, G.-E.D.; Badogiannis, E.G.; Papadakis, V.G. Perlite and rice husk ash Re-use as fine aggregates in lightweight aggregate structural concrete—Durability assessment. Sustainability 2023, 15, 4217. [Google Scholar] [CrossRef]

- Yan, G.; Al-Mulali, M.Z.; Madadi, A.; Albaijan, I.; Ali, H.E.; Algarni, H.; Le, B.N.; Assilzadeh, H. Effect of perlite powder on properties of structural lightweight concrete with perlite aggregate. Struct. Eng. Mech. 2022, 84, 393–411. [Google Scholar]

- Al-Daraji, M.; Aljalawi, N. The effect of kevlar fibers on the mechanical properties of lightweight Perlite Concrete. Eng. Technol. Appl. Sci. Res. 2024, 14, 12906–12910. [Google Scholar] [CrossRef]

- Leong, G.W.; Mo, K.H.; Ibrahim, Z.; Radwan, M.K.; Ling, T.-C.; Sinoh, S.S. Lightweight cementitious composites incorporating fly ash cenospheres and perlite microspheres. Constr. Build. Mater. 2023, 404, 133226. [Google Scholar] [CrossRef]

- Saikiran, M.; Rajeshwari, C. The Effects of Natural Perlite Aggregate and Perlite Powder on the Properties of Structural Light-Weight Concrete. Innovations 2023, 74, 72–81. [Google Scholar]

- Panagiotopoulou, C.; Angelopoulos, P.; Kosmidi, D.; Angelou, I.; Sakellariou, L.; Taxiarchou, M. Study of the influence of the addition of closed-structure expanded perlite microspheres on the density and compressive strength of cement pastes. Mater. Today Proc. 2022, 54, 118–124. [Google Scholar] [CrossRef]

- Różycka, A.; Pichór, W. Effect of perlite waste addition on the properties of autoclaved aerated concrete. Constr. Build. Mater. 2016, 120, 65–71. [Google Scholar] [CrossRef]

- Alyousef, R.; Benjeddou, O.; Soussi, C.; Khadimallah, M.A.; Jedidi, M. Experimental study of new insulation lightweight concrete block floor based on perlite aggregate, natural sand, and sand obtained from marble waste. Adv. Mater. Sci. Eng. 2019, 2019, 8160461. [Google Scholar] [CrossRef]

- Leyton-Vergara, M.; Pérez-Fargallo, A.; Pulido-Arcas, J.; Cárdenas-Triviño, G.; Piggot-Navarrete, J. Influence of granulometry on thermal and mechanical properties of cement mortars containing expanded perlite as a lightweight aggregate. Materials 2019, 12, 4013. [Google Scholar] [CrossRef]

- Alexa-Stratulat, S.-M.; Taranu, G.; Toma, A.-M.; Olteanu, I.; Pastia, C.; Bunea, G.; Toma, I.-O. Effect of expanded perlite aggregates and temperature on the strength and dynamic elastic properties of cement mortar. Constr. Build. Mater. 2024, 438, 137229. [Google Scholar] [CrossRef]

- Tie, T.S.; Mo, K.H.; Alengaram, U.J.; Kaliyavaradhan, S.K.; Ling, T.-C. Study on the use of lightweight expanded perlite and vermiculite aggregates in blended cement mortars. Eur. J. Environ. Civ. Eng. 2022, 26, 3612–3631. [Google Scholar] [CrossRef]

- Jssem, M.; Fawzi, N.M. Effect of expanded perlite aggregate and silica fume on some properties of lightweight concrete. J. Eng. 2024, 30, 172–185. [Google Scholar] [CrossRef]

- Sai, K.; Srikanth, K.; Chaitra, K. Effect of natural perlite aggregate and its powder on properties of light weight concrete. Int. J. Adv. Agric. Sci. Technol. 2025, 12, 124–129. [Google Scholar]

- Sharma, B.; Sharma, R.; Bansal, P.P. Effect of fine aggregate replacement with expanded perlite and pumice on the development of lightweight concrete. Aust. J. Civ. Eng. 2022, 20, 115–129. [Google Scholar] [CrossRef]

- Kadela, M.; Małek, M.; Jackowski, M.; Kunikowski, M.; Klimek, A.; Dudek, D.; Rośkowicz, M. Recycling of tire-derived fiber: The contribution of steel cord on the properties of lightweight concrete based on perlite aggregate. Materials 2023, 16, 2124. [Google Scholar] [CrossRef]

- Naeem, B.Q.; Awad, H.K. Effect of Perlite Aggregate Replacement of Coarse Aggregate on the Behavior of SCC Exposed to Fire Flame by Using Different Cooling Methods. J. Eng. 2025, 31, 54–72. [Google Scholar] [CrossRef]

- Singh, M.; Garg, M. Perlite-based building materials—A review of current applications. Constr. Build. Mater. 1991, 5, 75–81. [Google Scholar] [CrossRef]

- IQS. Portland cement. In No. 5. Central Organization for Standardization and Quality Control, Iraq-Baghdad (2019); IQS: Bagdad, Iraq, 2019. [Google Scholar]

- IQS. Aggregate from natural sources for concrete and building construction. In No. 45. Central Organization for Standardization and Quality Control, Iraq-Baghdad (1984); IQS: Bagdad, Iraq, 1984. [Google Scholar]

- Tanyildizi, H.; Coskun, A. Performance of lightweight concrete with silica fume after high temperature. Constr. Build. Mater. 2008, 22, 2124–2129. [Google Scholar] [CrossRef]

- Suryanita, R.; Maizir, H.; Zulapriansyah, R.; Subagiono, Y.; Arshad, M.F. The effect of silica fume admixture on the compressive strength of the cellular lightweight concrete. Results Eng. 2022, 14, 100445. [Google Scholar] [CrossRef]

- ASTM C1437-20; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2020.

- Koksal, F.; Gencel, O.; Kaya, M. Combined effect of silica fume and expanded vermiculite on properties of lightweight mortars at ambient and elevated temperatures. Constr. Build. Mater. 2015, 88, 175–187. [Google Scholar] [CrossRef]

- Mazloom, M.; Ramezanianpour, A.A.; Brooks, J.J. Effect of silica fume on mechanical properties of high-strength concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- BSI. Testing hardened concrete, part 4: Compressive strength—Specification for testing machines. In BSI Standards Publication; The British Standards Institution Limited: London, UK, 2019. [Google Scholar]

- Sriwattanapong, M.; Sinsiri, T.; Pantawee, S.; Chindaprasirt, P. A study of lightweight concrete admixed with perlite. Suranaree J. Sci. Technol 2013, 20, 227–234. [Google Scholar]

- Whwah, M.S.; Al-Hussainy, H.A.; Dulaimi, A.; Bernardo, L.F.A.; Ribeiro, T.P. Investigation of the Effects of Water-to-Cement Ratios on Concrete with Varying Fine Expanded Perlite Aggregate Content. J. Compos. Sci. 2025, 9, 390. [Google Scholar] [CrossRef]

- Demir, İ.; Başpınar, M.S.; Doğan, C. Investigation of the Effects of Fly Ash, Fine Sand and Expanded Perlite on the Properties on Foam Concrete. Afyon Kocatepe Üniversitesi Fen Ve Mühendislik Bilim. Derg. 2022, 22, 1425–1433. [Google Scholar] [CrossRef]

- RILEM. Functional Classification of Lightweight Concretes: Recommendation LC2, 2nd ed.; RILEM: Paris, France, 1978. [Google Scholar]

- Ariyaratne, I.E.; Ariyanayagam, A.; Mahendran, M. Bushfire-resistant lightweight masonry blocks with expanded perlite aggregate. Fire 2022, 5, 132. [Google Scholar] [CrossRef]

- Al-Hdabi, A.; Al Nageim, H.; Seton, L. Performance of gap graded cold asphalt containing cement treated filler. Constr. Build. Mater. 2014, 69, 362–369. [Google Scholar] [CrossRef]

- Fang, X.; Garcia, A.; Winnefeld, F.; Partl, M.N.; Lura, P. Impact of rapid-hardening cements on mechanical properties of cement bitumen emulsion asphalt. Mater. Struct. 2016, 49, 487–498. [Google Scholar] [CrossRef]

- Aminpour, N.; Memari, A. Development of EPS light-weight concrete for 3D printing. Struct. Concr. 2025. [Google Scholar] [CrossRef]

- Newman, J.; Choo, B.S.X. Advanced Concrete Technology Set; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Valore, R.C. Calculations of U-values of hollow concrete masonry. Concr. Int. 1980, 2, 40–63. [Google Scholar]

- Drozdzol, K. Thermal and mechanical studies of perlite concrete casing for chimneys in residential buildings. Materials 2021, 14, 2011. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).