1. Introduction

Researchers and scientists worldwide are actively engaged in the development of novel approaches and the enhancement of existing methods aimed at ensuring the structural resilience of buildings subjected to dynamic loading. Among the most critical types of dynamic actions are seismic loads, which appear to be increasing in both frequency and intensity in recent years. In response to these trends, numerous recent studies have focused on enhancing the seismic resilience of structural systems. Xu et al. [

1] recently published a comprehensive review of various techniques currently employed to improve the seismic performance of building structures. Mata et al. [

2], for example, conducted an in-depth analysis of the seismic behavior of composite moment-resisting frames incorporating slender built-up columns.

In the context of reinforced concrete structures subjected to dynamic (seismic) loading, the bond between the embedded reinforcement and the surrounding concrete also plays a crucial role, alongside the intrinsic quality of the constituent materials. The integrity of this bond directly influences the energy dissipation capacity, ductility, and overall seismic resilience of the building structures. Often, failure of reinforced concrete structures occurs through the weakening of the bond property [

3]. Accordingly, current standards, especially those concerning seismic design, require the exclusive use of ribbed reinforcement bars in concrete.

As reported by several authors, e.g., [

3,

4,

5,

6], the bond between the reinforcement and surrounding concrete is ensured through three primary mechanisms: adhesion, friction between the reinforcement bar and the concrete, and mechanical interlocking of the ribs with the surrounding concrete. Adhesion, which mainly develops during the early stages of cement hydration through the binding of hydrating cement particles to the steel surface, is the dominant mechanism at low load levels. As the load increases, adhesion fails, and the bond is maintained primarily by friction and mechanical interlocking [

3,

5]. Naaman [

7] determined that, at higher load levels, mechanical interlocking of the reinforcement ribs with the surrounding concrete becomes the predominant mechanism for ensuring the bond strength between the embedded reinforcement and concrete.

Due to the above-mentioned importance of a high-quality bond between the surrounding concrete and the embedded reinforcement in terms of the load-bearing capacity, stability, and durability of reinforced concrete structures, many researchers frequently investigate the influence of various concrete and reinforcement parameters on the quality of the bond between the reinforcement and concrete. The magnitude of the pull-out force

Fpull and/or the bond stress

τ between the embedded reinforcement and the surrounding concrete is generally measured for this purpose. The bond stress

τ is usually determined using Equation (1), where

Φ and

le stand for the nominal diameter of the reinforcement bar and the embedment length (i.e., the length over which the reinforcement is in direct contact with the surrounding concrete), respectively. The maximum bond stress

τmax stands for the peak bond stress occurring at the maximum pull-out force

Fmax, as defined by Equation (2).

A comprehensive review was recently conducted by Vembu et al. [

3] on the influence of individual concrete and reinforcement parameters on the quality of the bond between reinforcement and the surrounding concrete matrix.

Saje and Lopatič [

5] analyzed the influence of conventional ribbed steel reinforcement and various types of basalt reinforcement on the maximum bond strength

τmax between embedded reinforcement and both normal-strength and high-strength concrete. They reported that, for specimens with both steel and basalt reinforcement with a 12 mm diameter, the compressive strength of the concrete significantly affected the bond strength between the concrete and reinforcement. In both cases, the values of

τmax were approximately 70–80% higher when high-strength concrete was used than when normal-strength concrete was used. Specimens with embedded basalt reinforcement achieved approximately 30% lower

τmax values than those with ribbed steel reinforcement bars.

Gangolu et al. [

8] investigated the influence of rib geometry on bond strength

τmax in high-strength concrete. They found that the

τmax value for smooth (plain) bars was about 40–50% lower than that for bars with spiral ribs. Furthermore, a spiral rib orientation yielded higher

τmax values than ribs oriented transversely (i.e., perpendicular to the longitudinal axis of the bar). The effect of the reinforcement bar diameter on

τmax was found to be minimal, whereas increasing the embedment length

le resulted in a decrease in

τmax.

Similar findings were reported by Bashir et al. [

9], who examined the effects of

Φ and

le, as well as various rib geometries, on the value of

τmax. They found that, although the pull-out force

Fmax generally increased with larger bar diameters and longer embedment lengths, the bond strength

τmax tended to decrease with increasing bar diameter and embedment length, regardless of the rib type or orientation. Comprehensive research on the bonding properties between rebar and recycled concrete under different degrees of corrosion was recently performed by Su [

10], which showed that increasing the degree of steel corrosion initially improves the bond performance of recycled concrete, but this effect does not continue as the corrosion degree further increases. A negative impact of corrosion on the bond between reinforcement and concrete was also reported by Bidari et al. [

11]. As concluded by Tao et al. [

12], the bond strength between shaped steel and concrete increases as the concrete strength, cover thickness, steel fiber volume ratio, and stirrup ratio increase. The bond–slip behavior between steel reinforcement and epoxy resin concrete was investigated by Chen et al. [

13]. Their studies indicated that, when compared to ordinary concrete, the bond strength was higher in the case of epoxy resin concrete. Stochino et al. [

14] analyzed the influence of the presence of recycled aggregate in concrete on the mechanical behavior of composite ribbed slabs. Although the inclusion of recycled aggregate slightly reduced the basic mechanical properties of the concrete itself, it resulted in an improvement in the bond between the embedded steel sheet and the surrounding concrete, thereby enhancing the overall mechanical performance of these structural elements.

Despite numerous studies and findings recently reported in the literature, the influence of individual parameters of embedded reinforcement bars and surrounding concrete on the bond behavior between reinforcement and different types of concrete still remains under-researched. Moreover, the results from different studies are often contradictory, mainly due to the very limited number of test specimens used, which does not allow for a robust or advanced statistical analysis of the obtained results. For example, several studies indicate that an increase in the bar diameter results in a lower bond strength, while many researchers have reported contradictory results [

3]. Similar contradictions in findings are also observed, for instance, in the case of the influence of steel fibers in concrete on the bond between reinforcement and concrete [

3]. According to Wang et al. [

15], the bond strength increases from 46.57 MPa to 56.92 MPa when the steel fiber content increases from 0% to 2%.

Addressing the outlined issue necessitates comprehensive experimental research involving a substantial sample size. The resulting dataset will facilitate an in-depth analysis of the influence of various parameters through the application of advanced statistical methodologies.

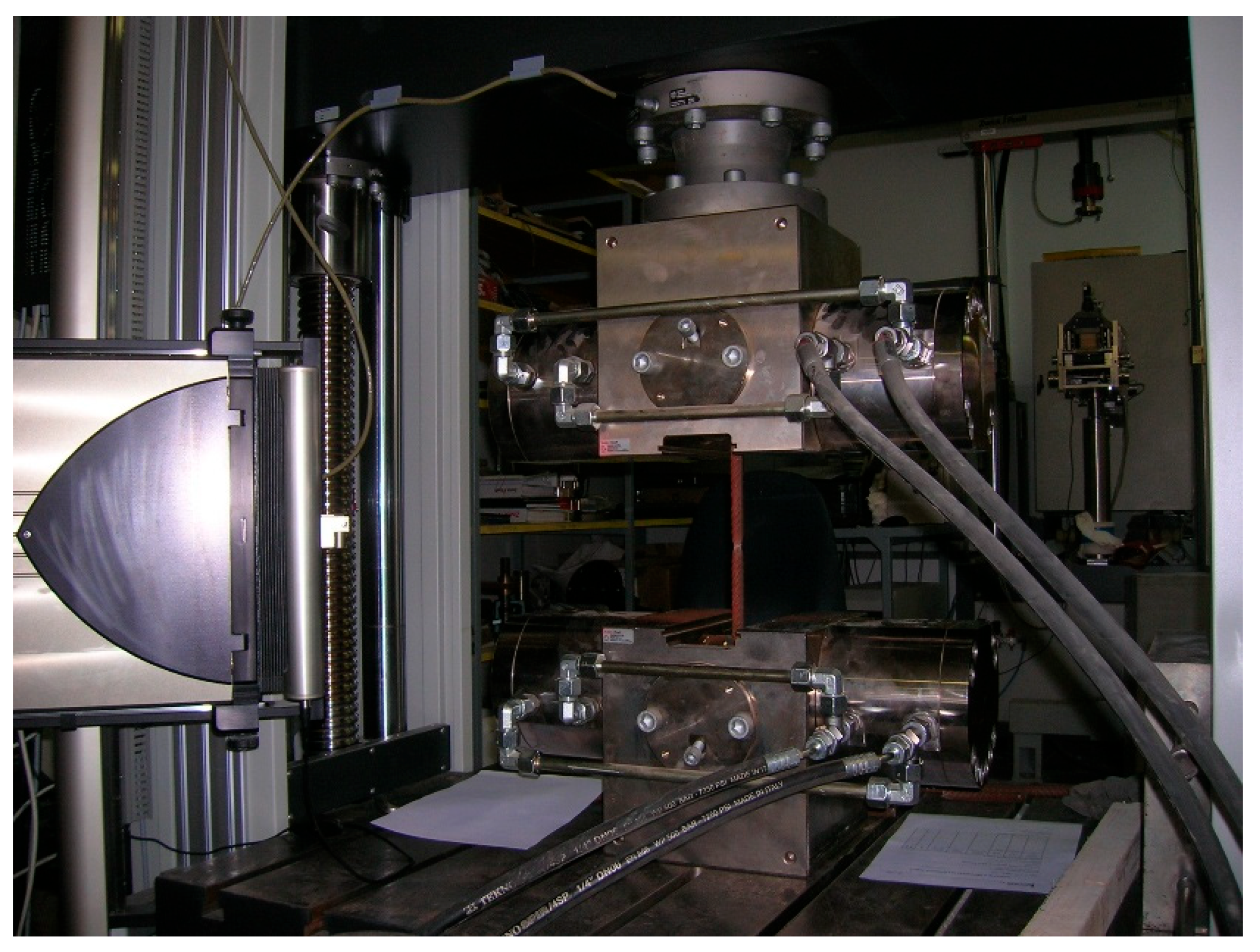

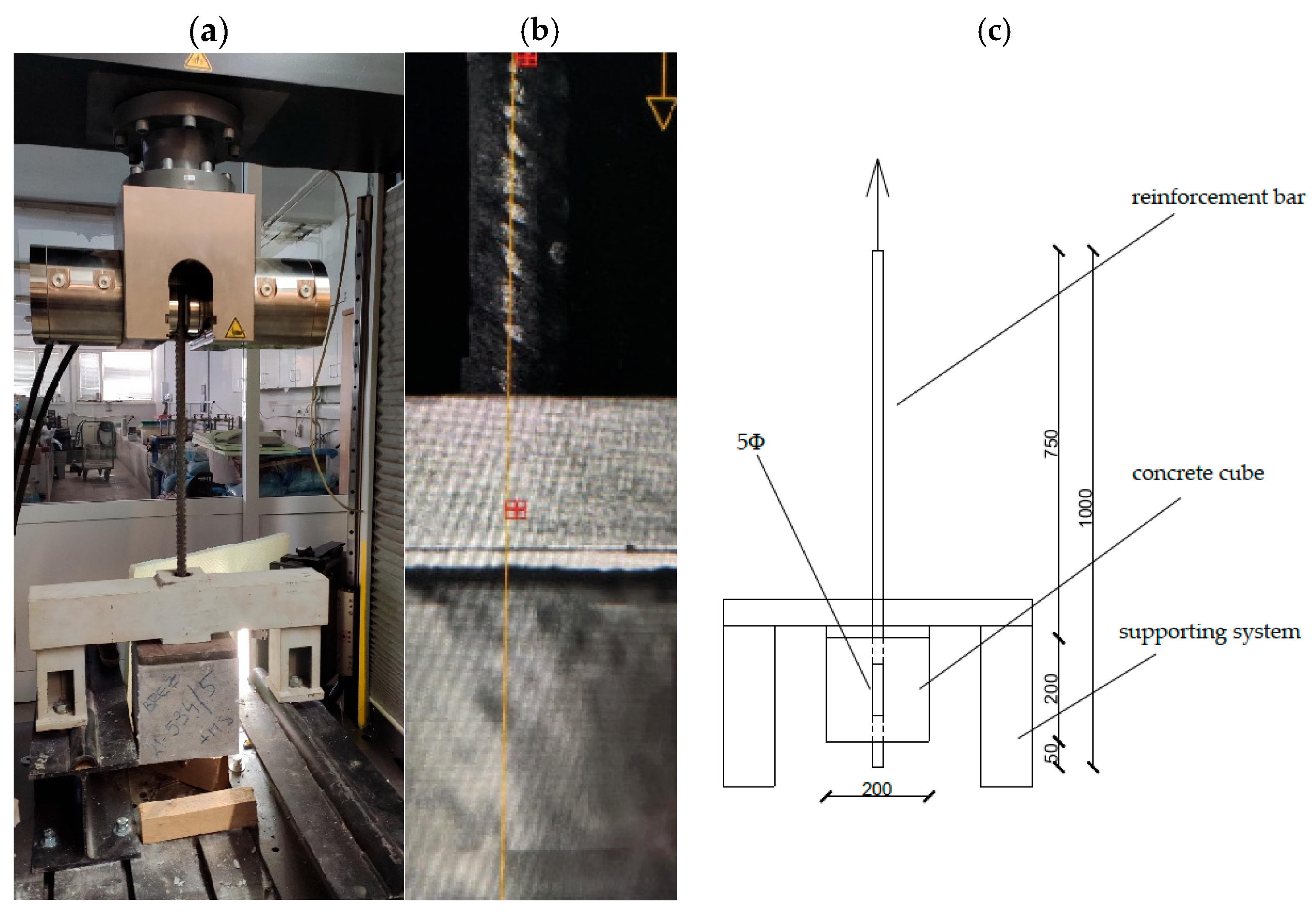

This paper presents the results of a comprehensive experimental study performed in the concrete laboratories of Igmat and Irma, Slovenia. Due to the large number of test specimens, an advanced statistical method—analysis of variance (ANOVA)—was used to analyze the experimental results, with the aim of determining the potential statistically significant influence of various reinforcement and concrete parameters on the bond behavior between embedded reinforcement and the surrounding concrete. Specifically, the influence of the reinforcement bar diameter, concrete age (and thus its compressive strength), and steel fiber content in the concrete matrix was analyzed in detail. A specific type of concrete, namely, tremie concrete, was studied, which is used for underwater foundations, piles, diaphragm walls, caissons, etc., ensuring proper placements without segregation or washout. Consequently, the effect of a bentonite coating on the reinforcement bars on the bond between the reinforcement and tremie concrete was also analyzed. The properties of all materials used were determined through experimental methods specifically suited for this type of concrete, in compliance with relevant standards under controlled laboratory conditions. The bond between the concrete and reinforcement was evaluated using the standardized pull-off test, which is widely recognized as a reliable method for assessing the quality of the concrete–reinforcement interface [

3].

3. Results

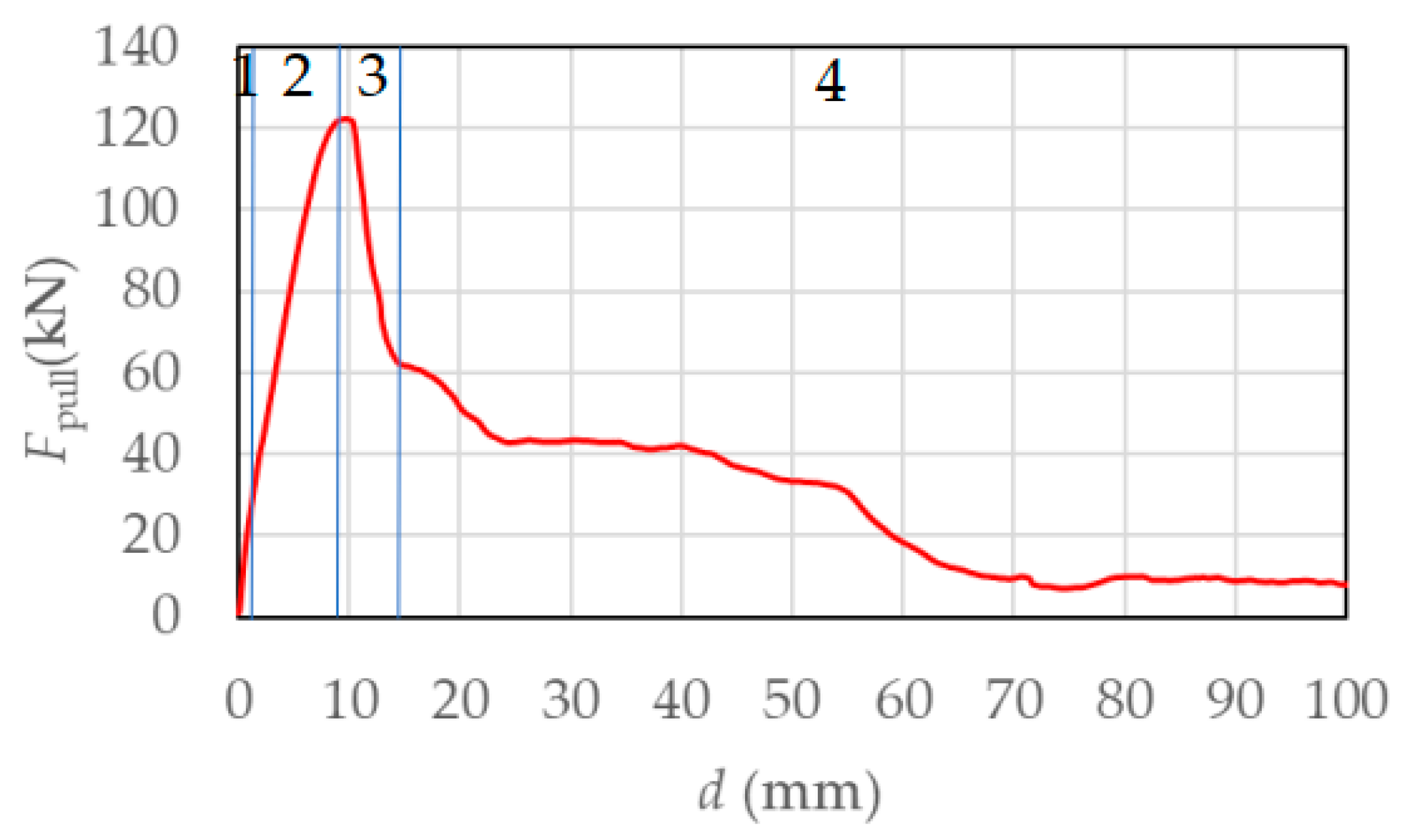

3.1. General Presentation of d–Fpull (d–τ) Diagram

A typical diagram of the development of the pull-out force

Fpull (or bond stress

τ) as a function of slip

d between the embedded reinforcement bar and the surrounding concrete is presented in

Figure 6. The maximum pull-out force

Fmax (and the maximum bond stress

τmax) corresponds to the peak point on the curve shown in the figure.

As can be seen in

Figure 6, the

d–

Fpull (or

d–

τ) diagram can be logically divided into four characteristic phases, clearly indicated in

Figure 6:

Phase 1: An initial increase in the pull-out force Fpull (or bond stress τ), during which the full bond is maintained between the reinforcement and the concrete (i.e., the relative slip d = 0).

Phase 2: A linear increase in slip d with increasing pull-out force Fpull (or bond stress τ) up to the maximum values Fmax (or τmax).

Phase 3: A nearly linear decrease in Fpull (or τ) with a further increase in d.

Phase 4: A pronounced increase in d, with a less steep decline in Fpull (or τ).

It is estimated that, during Phase 1, the bond between the reinforcement and concrete is primarily governed by adhesion; in Phases 2 and 3, the dominant mechanisms are friction between the bar and the concrete, and mechanical interlock of the ribs into the concrete. During Phase 4, bonding is mainly ensured by mechanical interlock alone.

3.2. Influence of Different Parameters on Fmax and τmax Values

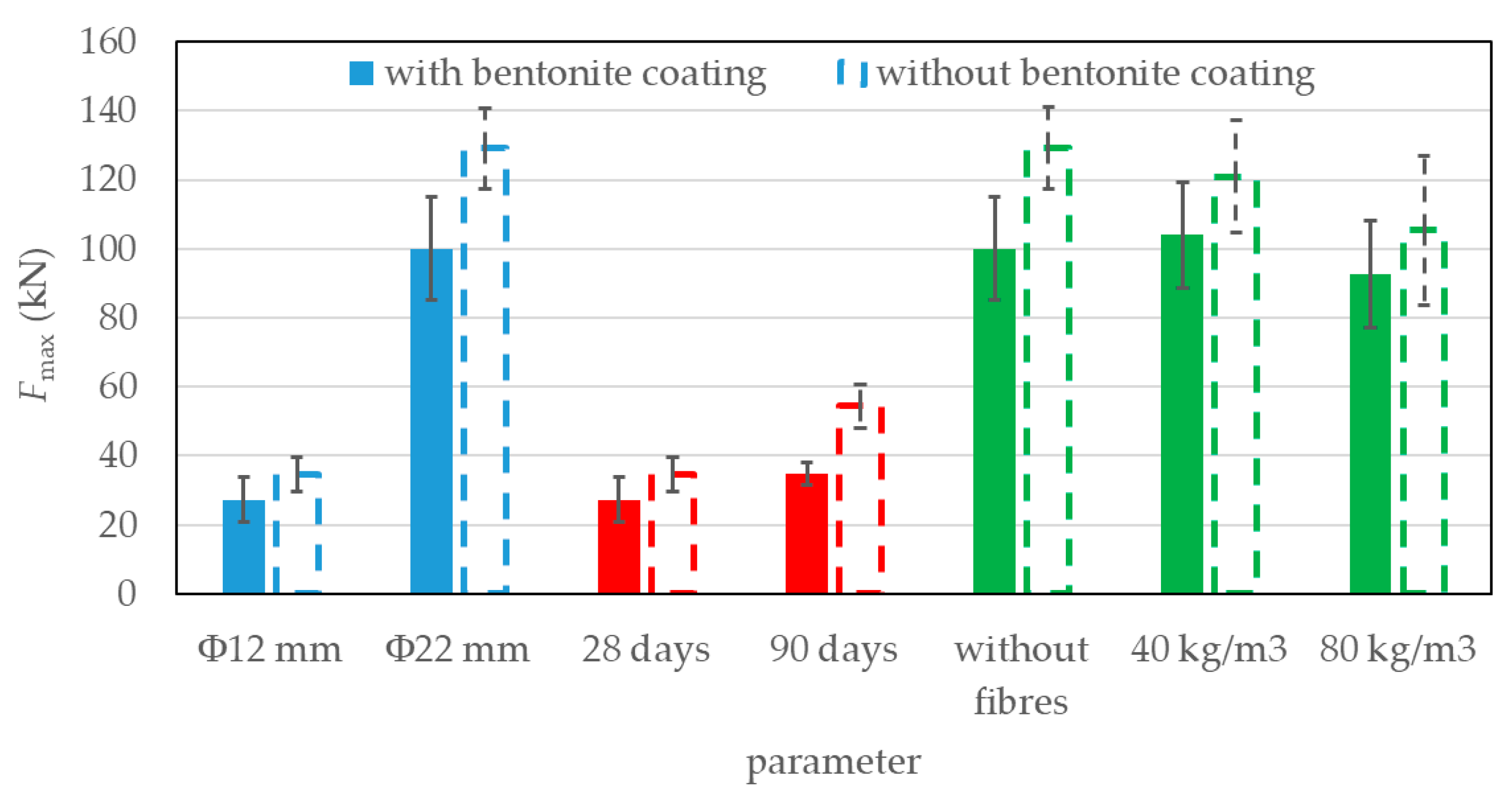

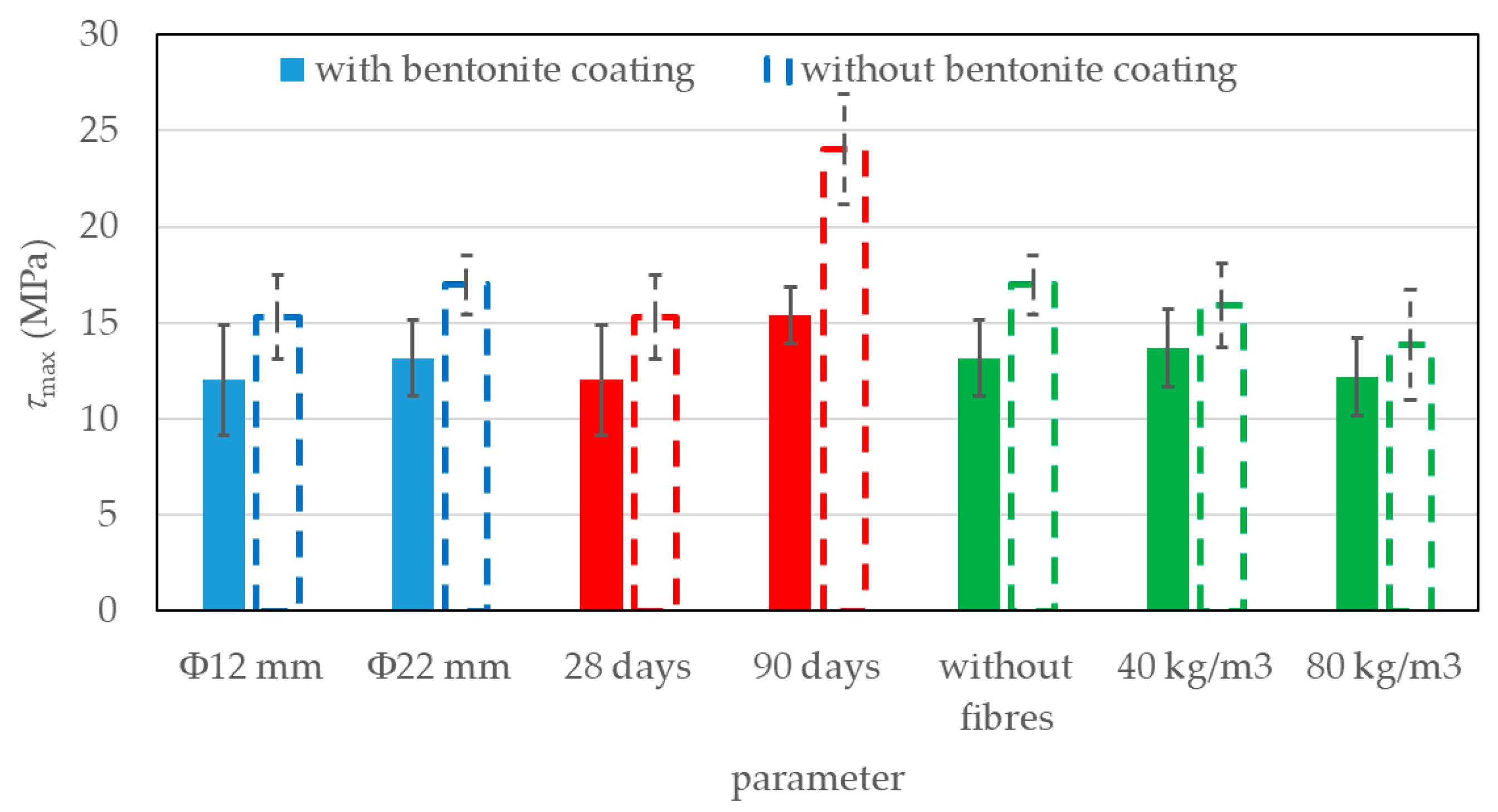

Figure 7 and

Figure 8 show the influence of the reinforcement bar diameter

Φ, concrete age, and amount of fibers on the

Fmax and

τmax values, respectively. The graphs present the average values of four results (for specimens without a coating) and five results (for specimens with a bentonite coating), along with the standard deviations from these averages.

As expected, increasing the diameter of the reinforcement bar resulted in a significantly higher maximum pull-out force Fmax, both for bars without the bentonite coating and for those with the coating. For specimens without the coating, increasing the bar diameter from 12 mm to 22 mm led to an average increase in Fmax of 273%. For specimens with the bentonite coating, this increase was very similar and reached 268%. In contrast, the increase in bond stress τmax with increasing bar diameter was significantly lower, i.e., 11% without the coating and 9% with the bentonite coating. It is noticeable that, in both diameter groups, the presence of a bentonite coating resulted in somewhat lower values of Fmax and τmax. For the 12 mm bars, Fmax and τmax were on average 21% lower with the bentonite coating, while for the 22 mm bars, they were 22% lower.

The next group of results, presented in

Figure 7 and

Figure 8, demonstrates the effect of concrete age—and thus its compressive strength—on the maximum pull-out force

Fmax and maximum bond stress

τmax. In this case, the diameter of the reinforcing bars

Φ was 12 mm. The presented values represent the mean results of four tests in the uncoated condition and five tests in the coated condition, including the corresponding standard deviations. As shown in

Table 2, the average compressive strength of the concrete was 68.4 MPa at 28 days and 79.3 MPa at 90 days. With increasing concrete age from 28 to 90 days, both

Fmax and

τmax increased in specimens with and without the bentonite coating. On average, the increase in

Fmax and

τmax was 28% for the coated bars and 57% for the uncoated bars. At both testing ages, the application of the bentonite coating to the reinforcement resulted in somewhat lower

Fmax and

τmax values. Specifically, at 28 days, the coated bars exhibited a 27% reduction in both the maximum pull-out force and bond stress compared to the uncoated bars. At 90 days, this reduction increased to 56%.

The last group of results demonstrates the influence of the steel fiber content in the concrete on the Fmax and τmax values. In this case, the diameter of the reinforcing bars was 22 mm. The results represent the mean values of four tests (without prior coating) and five tests (with prior coating), along with the corresponding standard deviations from the mean. In the case of the bentonite coating, a slight increase (approx. 4%) in both Fmax and τmax was observed when 40 kg/m3 of steel fibers was added compared to the fiber-free specimens. However, in the uncoated condition, a reduction of around 6% in both Fmax and τmax was recorded with the same fiber content. Interestingly, with a further increase in the fiber content from 40 kg/m3 to 80 kg/m3, a decrease in both Fmax and τmax was observed. Specifically, in the case with the coating, the reduction amounted to approximately 11%, while in the uncoated condition, the reduction was about 13%.

In all cases, the presence of a bentonite coating on the reinforcing bars led to a reduction in both Fmax and τmax. In the fiber-free concrete, this reduction averaged 29%, whereas in the fiber-reinforced concrete, the average reduction was approximately 15%.

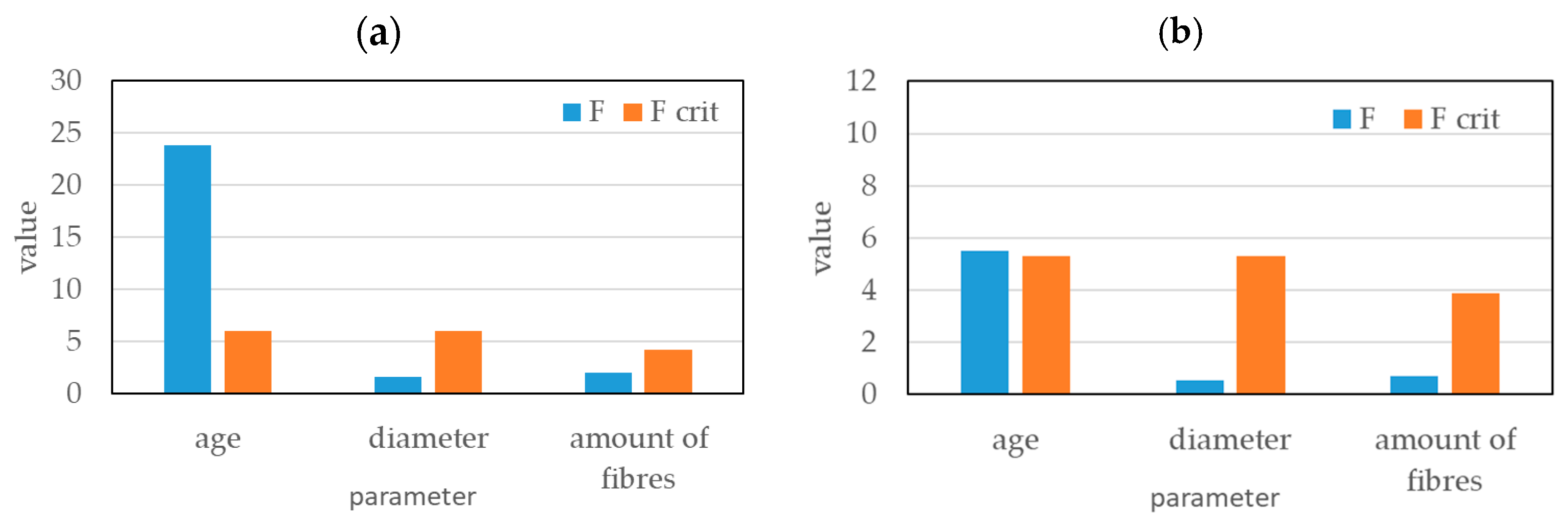

3.3. Statistical Analysis of Influence of Different Parameters on Fmax and τmax Values

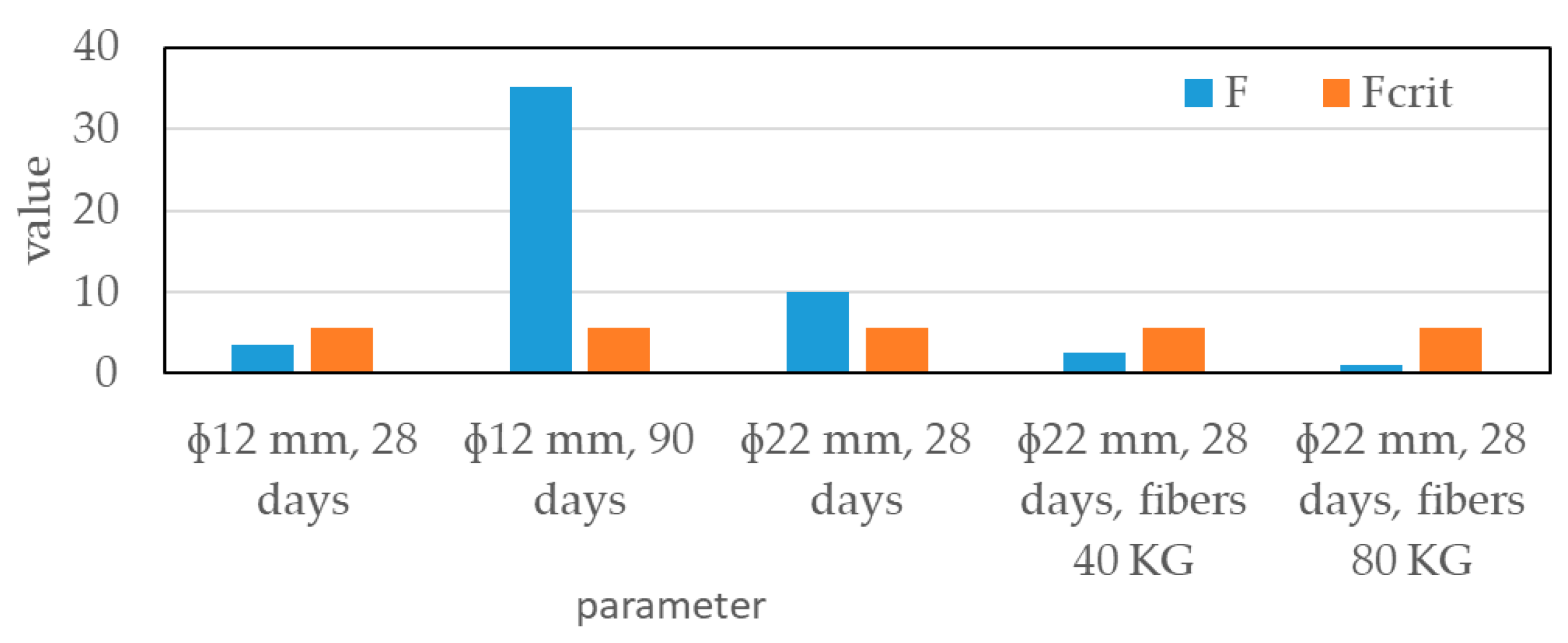

The following section presents the results of a statistical analysis evaluating the influence of the prior coating of the reinforcing bars on the values of Fmax and τmax, conducted using the analysis of variance (ANOVA) technique. A statistically significant effect of the coating is considered to be present when the critical F-value (Fcrit) exceeds the calculated F-statistic.

As shown in

Figure 9, the prior coating of the reinforcing bars had a statistically significant effect on the reduction in

Fmax and

τmax only in two specific cases: (i) specimens aged 90 days with a bar diameter of 12 mm and (ii) specimens aged 28 days with a bar diameter of 22 mm. In all other cases, the effect of the coating on

Fmax and

τmax was not statistically significant.

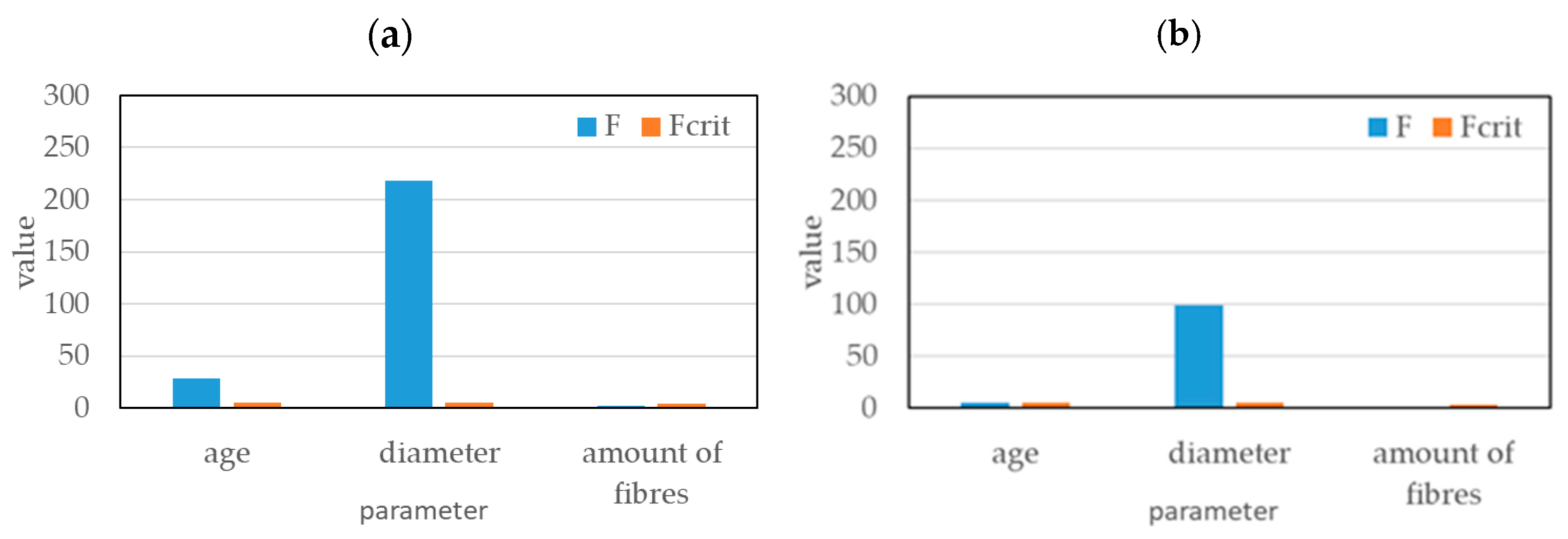

It can be clearly realized from

Figure 10 that, both in the case without the prior coating of the reinforcing bars (

Figure 10a) and with the bentonite-coated bars (

Figure 10b), increasing the concrete age from 28 to 90 days and increasing the bar diameter from 12 mm to 22 mm had a statistically significant effect on the increase in the maximum pull-out force

Fmax.

Similarly, the increase in concrete age from 28 to 90 days had a statistically significant effect on the increase in the maximum bond stress

τmax in both the coated and uncoated conditions. In contrast, unlike its effect on

Fmax, the influence of the bar diameter on

τmax was not statistically significant, regardless of the presence of the coating (

Figure 11).

The addition of steel fibers to the concrete did not have a statistically significant effect on either the maximum pull-out force

Fmax (

Figure 10) or the maximum bond stress

τmax (

Figure 11) in any of the tested cases. This is consistent with the findings of some other authors [

3], while other studies reported an increase in the bond strength with a higher content of steel fibers in the concrete [

15].

4. Discussion

An adequate bond between reinforcement and the surrounding concrete is of critical importance in most structural applications. Accordingly, numerous authors have investigated the influence of various parameters on the bond quality between reinforcement and different types of concrete [

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

29,

30]. However, mainly due to the typically limited number of test specimens, the findings of different studies are often contradictory. Additionally, the influence of individual factors in the case of tremie concrete—particularly the effect of a preliminary bentonite coating on reinforcing bars—on the bond between concrete and reinforcement remains relatively poorly investigated.

To enable a more comprehensive analysis of the influence of concrete and reinforcement parameters on bond behavior, an extensive experimental campaign was conducted using a large number of specimens, and the results of this study are presented in this article. This approach allowed for the application of an advanced statistical method to assess the impact (i.e., statistically significant influence) of individual parameters on the bond strength between tremie concrete and reinforcement. The use of a novel, advanced measurement system based on laser-based, non-contact slip monitoring between concrete and reinforcement further enhances the relevance and accuracy of the reported results.

The results presented in the previous sections show that the bond stress values between the embedded ribbed reinforcement and the surrounding tremie concrete generally fall within the range of 10–17 MPa, which corresponds well with the results reported in the literature [

3].

The application of the bentonite coating to the reinforcing bars resulted in a reduction in both the maximum pull-out force Fmax and the bond stress τmax in all analyzed cases. This reduction ranged, on average, between 15% and 56%. However, further detailed statistical analysis of the results revealed that statistically significant reductions in Fmax and τmax due to the coating were observed only in two cases: 90-day-old specimens with 12 mm diameter bars and 28-day-old specimens with 22 mm diameter bars. In all other cases, the presence of the bentonite coating did not result in statistically significant differences, likely due to the relatively high variability (variance) within each set of test results, which was appropriately taken into account using the AnoVa technique. This is a very important and useful finding that suggests that, in general, the presence of a bentonite coating on reinforcement does not have an important impact on the bond between embedded reinforcement and the surrounding tremie concrete.

While the increase in the bar diameter from 12 mm to 22 mm resulted in a statistically significant increase in

Fmax in both the coated and uncoated conditions, the effect of the bar diameter on

τmax was not statistically significant. These findings are consistent with those reported by Gangolu et al. [

6], while Bashir et al. [

9], Eligehausen et al. [

29], and Tayeh et al. [

30] observed a slight decrease in the bond stress

τmax with increasing bar diameter.

The amount of steel fibers in the concrete had no statistically significant effect on either the pull-out force Fmax or the bond stress τmax. This indicates that the presence of fibers in tremie concrete does not influence the bond between the concrete and reinforcement. This result is expected, as the fiber content does not substantially affect the properties or quality of the interfacial transition zone between the reinforcement and the cementitious matrix, which plays a key role in bond performance.

In contrast, as concrete ages, its mechanical properties improve, which enhances the interfacial transition zone and, consequently, the bond strength between the reinforcement and the cement matrix. This is reflected in the statistically significant increase in both

Fmax and

τmax with concrete age, from 28 to 90 days. Similar finding were reported by Wang et al. [

15], who observed a positive correlation between compressive strength and bond strength in the case of ultra-high-performance manufactured sand concrete.

5. Conclusions

This paper presents the results of a comprehensive experimental study aiming to determine the influence of various parameters (including a prior bentonite coating on embedded reinforcement bars) related to tremie concrete and embedded ribbed reinforcement on the maximum pull-out force (

Fmax) and bond stress (

τmax) between the reinforcement and surrounding tremie concrete. Pull-out tests were conducted in accordance with Annex D of the standard EN 10080:2005 [

26], with the most significant modification being the use of an advanced optical measurement system for monitoring deformations and displacements during testing, allowing for the determination of deformation/displacement values accurately and precisely. Additionally, the use of an advanced statistical technique enabled a more detailed analysis of the influence of various parameters on the quality of the bond between the embedded reinforcement and the surrounding tremie concrete.

Based on the presented results, the following key conclusions and findings can be drawn:

The prior bentonite coating of reinforcement bars had a statistically significant effect on the reduction in both Fmax and τmax only in two cases: 90-day-old specimens with 12 mm diameter reinforcement and 28-day-old specimens with 22 mm diameter reinforcement. In all other cases, the coating did not result in a statistically significant reduction in Fmax or τmax.

In the uncoated condition, increasing the reinforcement bar diameter from 12 mm to 22 mm led to an average increase in Fmax of 273% and in τmax of 11%. In the coated condition, the same increase in the bar diameter resulted in an average increase in Fmax of 268% and in τmax of 9%. While the increase in the bar diameter had a statistically significant effect on Fmax in both the coated and uncoated conditions, its influence on τmax was not statistically significant.

In the uncoated condition, increasing the concrete age from 28 to 90 days resulted in a 57% increase in both Fmax and τmax. In the coated condition, this increase averaged 28%. In both cases, the increase in concrete age had a statistically significant positive effect on Fmax and τmax.

The addition of fibers to the concrete generally led to a slight decrease in Fmax and τmax. However, this effect was not statistically significant in either the coated or uncoated condition.

The results presented in this study are derived exclusively from the standardized pull-out test methodology. While this approach enables a controlled evaluation of bond strength, it provides a limited representation of the complex mechanisms governing the interaction at the steel–concrete interface, especially in the case with a bentonite coating on the surface of the embedded reinforcement. To achieve a more in-depth understanding of bond behavior and associated failure modes, the implementation of advanced experimental techniques such as scanning electron microscopy (SEM), ultrasonic testing methods, or digital image correlation (DIC) is recommended.

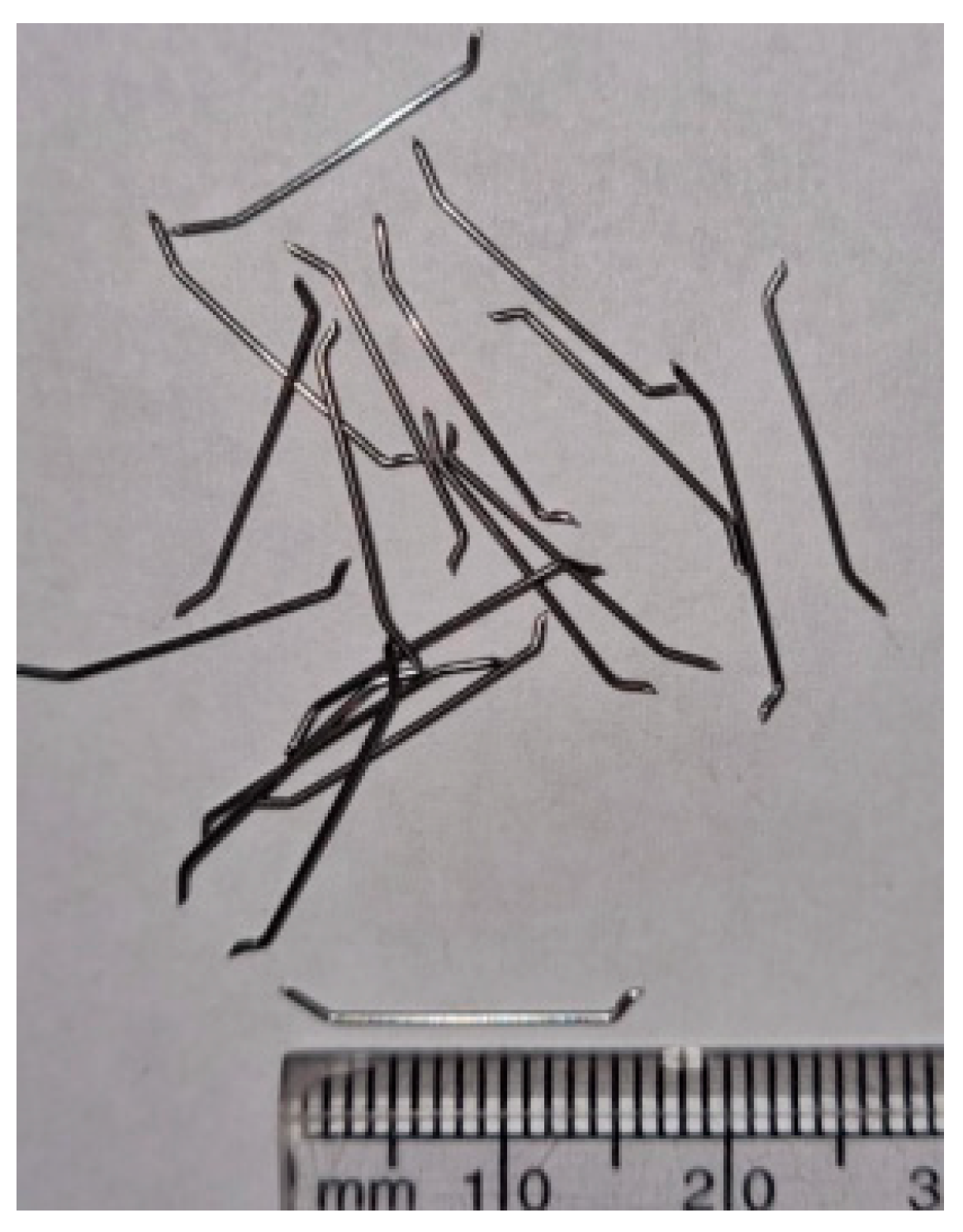

Furthermore, the present investigation considers only a single type of steel fiber and a specific type of reinforcing bar that lacks any visible signs of corrosion. The inclusion of a broader range of fiber types, particularly with varying aspect ratios (length to diameter), as well as different rib geometries of the reinforcing bars and varying degrees of corrosion damage, would significantly enhance the scientific rigor and practical relevance of the study. Such parameters are known to substantially influence bond performance and should be systematically evaluated in future research. Moreover, other concrete types should be considered, in addition to the tremie concrete used in this study.

However, the results of this study reveal that it would be pertinent to further investigate the influence of additional parameters on the bond quality between concrete and reinforcement using advanced statistical analysis techniques. Moreover, other concrete types can also be considered (in addition to tremie concrete). This approach, which is based on a relatively large number of test specimens and advanced statistical analysis, would significantly contribute to enhancing the quality, durability, and, most importantly, load-bearing capacity of (dynamically loaded) reinforced concrete structures and improve insights into the effects of different parameters on the bond behavior between reinforcement and various concrete types.