Application of Radar for Diagnosis of Defects in Concrete Structures: A Structured Image-Based Approach

Abstract

1. Introduction

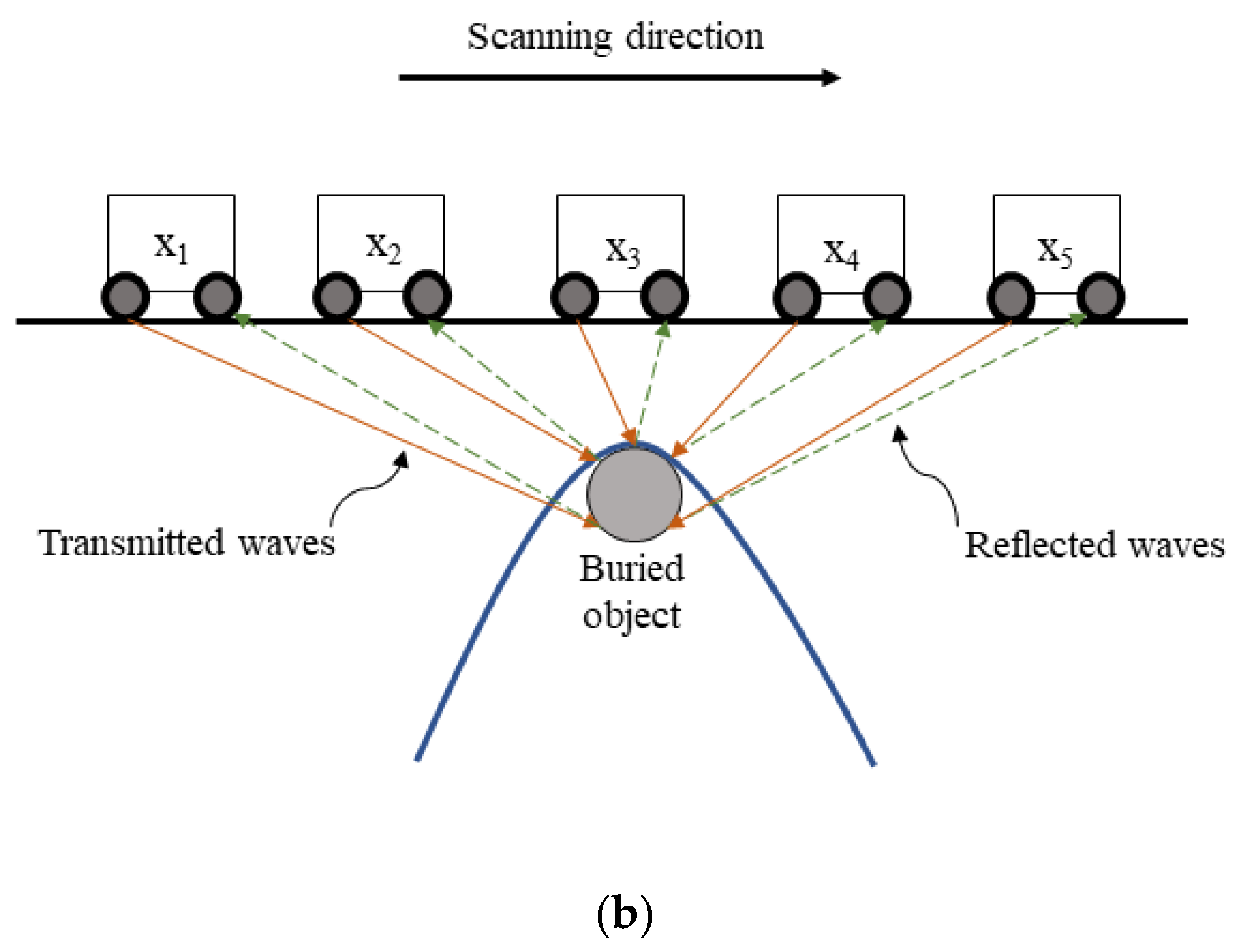

1.1. Principles of GPR

1.2. Concrete Investigation with GPR

1.2.1. Detection of Rebar

1.2.2. Rebar Corrosion and Deterioration

- Rebar is located by a distinct hyperbolic shape on the radargram.

- A strong reflection from the rebar indicates sound concrete, whereas a weak reflection shows signs of deterioration.

- A distorted/blurry hyperbolic shape may represent rebar corrosion and deterioration of concrete.

- Accurately locating corroded rebar relies heavily on the condition of the surrounding concrete.

1.2.3. Detection of Voids

- Voids can be detected in reinforced and unreinforced concrete structures.

- Detecting voids surrounding other subsurface objects may be challenging, especially with metallic objects.

- Voids present themselves on B-scans as a recognizable change in contrast/color when compared to the surrounding image.

- Voids are typically seen as a local reflection.

2. Methodology

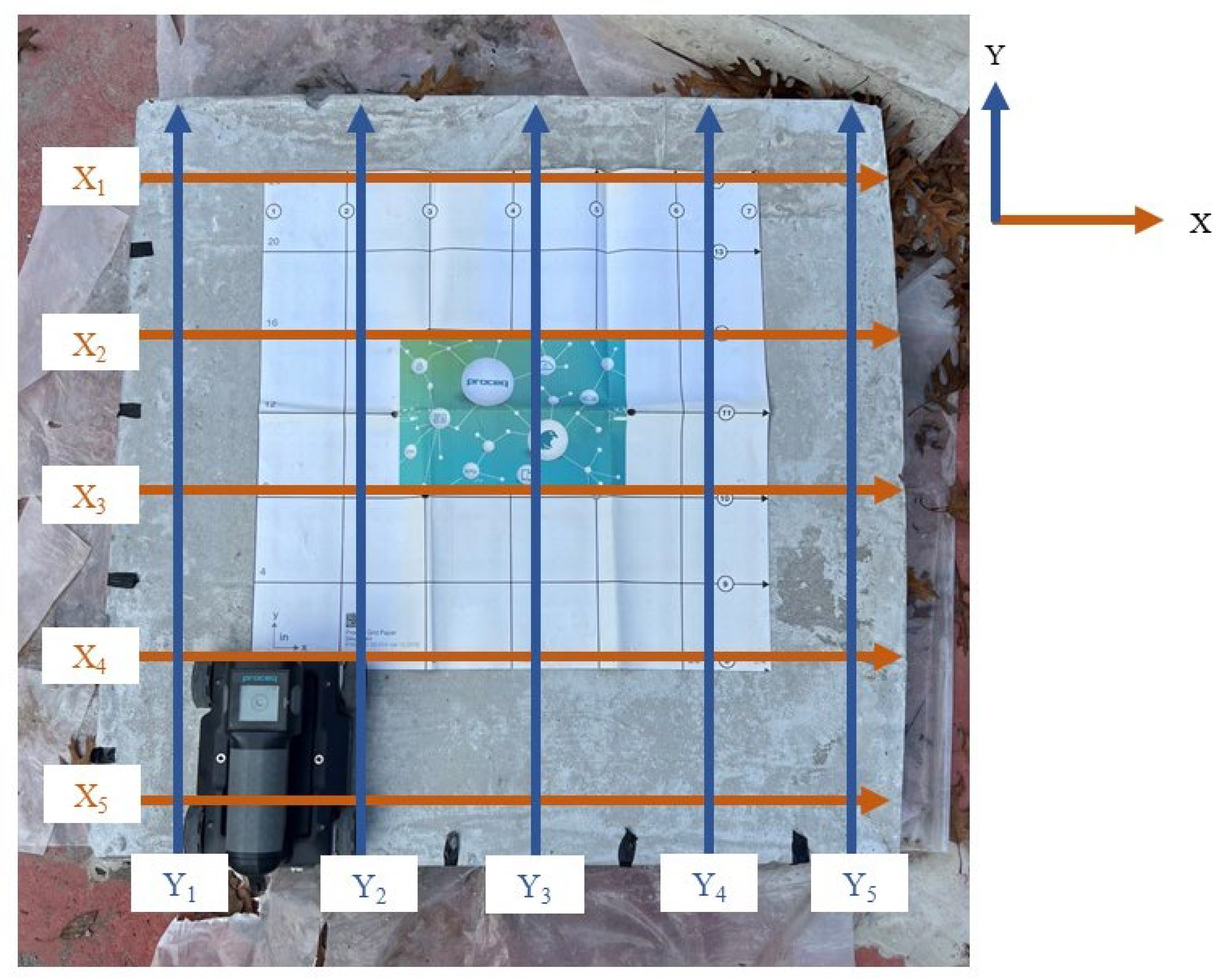

Evaluation Technique for Concrete with GPR

3. Laboratory Experiment

4. Results and Discussion

4.1. Slab with Corroded Rebar

4.2. Slabs with Voids and Delamination

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GPR | Ground Penetrating Radar |

| NDT | Non-destructive Testing |

| RC | Reinforced Concrete |

| EM | Electromagnetic |

| PVC | Polyvinyl Chloride |

| FRP | Fiber-Reinforced Polymer |

| AI | Artificial Intelligence |

| SP | Self-Potential |

| MHz | Megahertz |

| SFCW | Stepped Frequency Continuous Wave |

| ASTM | American Society for Testing and Materials |

References

- Lai, W.W.-L.; Chang, R.K.W.; Sham, J.F.C. Detection and imaging of city’s underground void by GPR. In Proceedings of the 2017 9th International Workshop on Advanced Ground Penetrating Radar (IWAGPR), Edinburgh, UK, 28–30 June 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Fornasari, G.; Capozzoli, L.; Rizzo, E. Combined GPR and Self-Potential Techniques for Monitoring Steel Rebar Corrosion in Reinforced Concrete Structures: A Laboratory Study. Remote Sens. 2023, 15, 2206. [Google Scholar] [CrossRef]

- Malla, P.; Khedmatgozar Dolati, S.S.; Ortiz, J.D.; Mehrabi, A.B.; Nanni, A.; Ding, J. Damage Detection in FRP-Reinforced Concrete Elements. Materials 2024, 17, 1171. [Google Scholar] [CrossRef] [PubMed]

- Zatar, W.; Nghiem, H.; Nguyen, H. Detecting Reinforced Concrete Rebars Using Ground Penetrating Radars. Appl. Sci. 2024, 14, 5808. [Google Scholar] [CrossRef]

- Malla, P.; Khedmatgozar Dolati, S.S.; Ortiz, J.D.; Mehrabi, A.B.; Nanni, A.; Dinh, K. Feasibility of Conventional Non-Destructive Testing Methods in Detecting Embedded FRP Reinforcements. Appl. Sci. 2023, 13, 4399. [Google Scholar] [CrossRef]

- Varnavia, A.V.; Khamzin, A.K.; Torgashov, E.V.; Sneed, L.H.; Goodwin, B.T.; Anderson, N.L. Data acquisition and processing parameters for concrete bridge deck condition assessment using ground-coupled ground penetrating radar: Some considerations. J. Appl. Geophys. 2015, 114, 123–133. [Google Scholar] [CrossRef]

- ASTM D4748; Standard Test Method for Determining the Thickness of Bound Pavement Layers Using Short-Pulse Radar. ASTM: West Conshohocken, PA, USA, 2020.

- Hasan, M.I.; Yazdani, N. An experimental and numerical study on embedded rebar diameter in concrete using ground penetrating radar. Chin. J. Eng. 2016. [Google Scholar] [CrossRef]

- Ristic, A.V.; Petrovacki, D.; Govedarica, M. A new method to simultaneously estimate the radius of a cylindrical object and the wave propagation velocity from GPR data. Comput. Geosci. 2009, 35, 1620–1630. [Google Scholar] [CrossRef]

- Tešić, K.; Baričević, A.; Serdar, M. Non-destructive corrosion inspection of reinforced concrete using ground-penetrating radar: A review. Materials 2021, 14, 975. [Google Scholar] [CrossRef]

- Wong, T.W.P.; Poon, C.S.; Lai, W.L.W. Laboratory validation of corrosion-induced delamination in concrete by ground penetrating radar. In Proceedings of the 2018 17th International Conference on Ground Penetrating Radar (GPR), Rapperswil, Switzerland, 18–21 June 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Eisenmann, D.; Margetan, F.J.; Ellis, S. On the use of ground penetrating radar to detect rebar corrosion in concrete structures. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; Volume 1949. [Google Scholar] [CrossRef]

- Dinh, K.; Gucunkski, N.; Kim, J.; Duong, T.H. Method for attenuation assessment of GPR data from concrete bridge decks. NDT E Int. 2017, 92, 50–58. [Google Scholar] [CrossRef]

- Abouhamad, M.; Dawood, T.; Jabri, A.; Alsharqawi, M.; Zayed, T. Corrosiveness mapping of bridge decks using image-based analysis of GPR data. Autom. Constr. 2017, 80, 104–117. [Google Scholar] [CrossRef]

- Alani, A.M.; Aboutalebi, M.; Kilic, G. Applications of ground penetrating radar (GPR) in bridge deck monitoring and assessment. J. Appl. Geophys. 2013, 97, 45–54. [Google Scholar] [CrossRef]

- Im, S.N.; Hurlebaus, S. Non-destructive testing methods to identify voids in external post-tensioned tendons. KSCE J. Civ. Eng. 2012, 16, 338–397. [Google Scholar] [CrossRef]

- Bonduà, S.; Monteiro Klen, A.; Pilone, M.; Asimopolos, L.; Asimopolos, N.-S. A Set of Ground Penetrating Radar Measures from Quarries. Data 2024, 9, 42. [Google Scholar] [CrossRef]

- Thitimakorn, T.; Kampananon, N.; Jongjaiwanichkit, N.; Kupongsak, S. Subsurface void detection under road surface using ground penetrating radar (GPR), a case study in Bangkok metropolitan area, Thailand. Int. J. Eng. 2016, 7, 2. [Google Scholar] [CrossRef]

- Xie, X.; Qin, H.; Yu, C.; Liu, L. An automatic recognition algorithm for GPR images of RC structure voids. J. Appl. Geophys. 2013, 99, 125–134. [Google Scholar] [CrossRef]

- Cassidy, N.J.; Eddies, R.; Dods, S. Void detection beneath reinforced concrete sections: The practical application of ground-penetrating radar and ultrasonic techniques. J. Appl. Geophys. 2011, 74, 263–276. [Google Scholar] [CrossRef]

- Sham, J.F.C.; Lai, W.L.W. Diagnosis of reinforced concrete structures by ground penetrating radar survey-case study. In Proceedings of the 2017 9th International Workshop on Advanced Ground Penetrating Radar (IWAGPR), Edinburgh, UK, 28–30 June 2017. [Google Scholar] [CrossRef]

- Ni, S.-H.; Huang, Y.-H.; Lo, K.-F.; Lin, D.-C. Buried pipe detection by ground penetrating radar using the discrete wavelet transform. Comput. Geotech. 2010, 37, 440–448. [Google Scholar] [CrossRef]

- Rathod, H.; Gupta, R. Sub-surface simulated damage detection using non-destructive testing techniques in reinforced-concrete slabs. Constr. Build. Mater. 2019, 215, 754–764. [Google Scholar] [CrossRef]

- Kozlov, R.; Gavrilov, K.; Shevgunov, T.; Kirdyashkin, V. Stepped-frequency continuous-wave signal processing method for human detection using radars for sensing rooms through the wall. Inventions 2022, 7, 79. [Google Scholar] [CrossRef]

- Travassos, X.L.; Avila, S.L.; Adriano, R.L.S.; Ida, N. A review of ground penetrating radar antenna design and optimization. J. Microw. Optoelectron. Electromagn. Appl. 2018, 17, 385–402. [Google Scholar] [CrossRef]

- Lai, W.W.-L.; Dérobert, X.; Annan, P. A review of ground penetrating radar application in civil engineering: A 30-year journey from locating and testing to imaging and diagnosis. NDT E Int. 2018, 96, 58–78. [Google Scholar] [CrossRef]

| Study | Year | GPR Antenna Frequency | Purpose/ Experiment | Main Findings |

|---|---|---|---|---|

| Fornasari et al. [2] | 2023 | 2 GHz | Combined GPR with self-potential methods to monitor corrosion in RC specimens under controlled lab conditions. | The integration of GPR and electrochemical techniques improved corrosion localization and provided complementary insights into structural deterioration. |

| Malla et al. [3] | 2024 | Not specified | Used image-based methods to evaluate damage in FRP-reinforced concrete with support from GPR data. | GPR signal patterns helped identify internal deterioration; imaging tools improved flaw recognition. |

| Malla et al. [5] | 2023 | Not specified | Assessed the feasibility of using conventional NDT tools, including GPR, for detecting embedded FRP bars. | GPR was effective for general positioning but limited by weak dielectric contrast of FRP; image processing aided interpretation. |

| Zatar et al. [4] | 2024 | 1.5–2.6 GHz | Studied the use of GPR for detection and localization of steel rebars in RC members. | Clear hyperbolic reflections were used to identify depth and spacing of embedded rebar, validated against known placements. |

| Wong et al. [11] | 2018 | 2 GHz | Evaluated concrete delamination by accelerated rebar corrosion in a laboratory setting. Part of the slab was immersed in 4% saline solution and the other was exposed to freshwater. | Noticeable changes in the amplitudes of the rebar reflections were observed in the saline and freshwater sections of the slab when compared to the control. There was an increase in amplitude in both sections due to the accelerated corrosion. |

| Eisenmann et al. [12] | 2018 | 1.6 GHz and 2.6 GHz | Evaluation on-site of a bridge and a laboratory experiment to analyze rebar corrosion and the effect on GPR signals. | The areas with low amplitudes represented the thinning of rebar due to corrosion. The 2.6 GHz antenna system was preferred over the 1.6 GHz for concrete. |

| Dinh et al. [13] | 2017 | 1.5 GHz | Utilized MATLAB to create contour maps of bridge decks. The authors studied the characteristics from A-scan and B-scan data from a bridge deck as their model motivation. | Concrete in good condition displayed a strong reflection from the rebar, whereas a corrosive concrete environment exhibited weak reflections. These weaker reflections made the hyperbolic shapes on the B-scan image appear faded or blurry. |

| Abouhamad et al. [14] | 2017 | 1.5 GHz | Created contour maps for bridge decks from both numerical-based (amplitude values) and image-based (radargram data) analyses. | Numerical-based results: Lower amplitude values corresponded to deterioration. Image-based results: Strong rebar reflection with clear hyperbola shape indicated good condition. Strong attenuation and distorted hyperbola shape represented signs of severe corrosion. The image-based analysis proved to be more accurate. |

| Alani et al. [15] | 2013 | 2 GHz | Investigation on bridge decks for determining rebar location and spacing, as well as locating areas of moisture penetration and delamination. | Sound concrete was represented in the radargram as clearer signals and strong returns from the rebar. Deteriorated areas were shown to have signal attenuation due to moisture. |

| Study | Year | GPR Antenna Frequency | Purpose/Experiment | Main Findings |

|---|---|---|---|---|

| Bonduà et al. [17] | 2024 | 250–2000 MHz | Used multi-frequency GPR scans in quarry environments to detect material changes, voids, and stratification. | Higher-frequency antennas improved detection of shallow voids and air gaps, offering insights for structural and material diagnostics. |

| Lai et al. [1] | 2017 | 400 and 900 MHz | Excavated air-filled voids in a soil tank in a laboratory experiment and analyzed asphalt pavement in the field for detection of voids. | The overlaid or surface material can affect the feasibility of detecting the voids. Detecting voids in plain concrete with non-metallic utilities is comparatively easy. Voids will display as local reflectors while utilities will show as continuous reflections. |

| Thitimakorn et al. [18] | 2016 | 400 MHz | Surveyed a road for subsurface void detection and drilled cores to confirm results. | The GPR successfully found the location of the void as the results were validated with the core sample, but GPR should be used along with another testing method. |

| Xie et al. [19] | 2013 | 900 MHz | Utilized an automatic recognition algorithm for detecting voids in RC structures through a simulation with synthetic images. | The algorithm was able to locate the three individual voids in each simulation model, which included one without any rebar. The models with steel bars were observed to be a disadvantage for locating voids. |

| Cassidy et al. [20] | 2011 | 450 and 900 MHz | Scanned an RC slab with a buried void and compared results to ultrasonic-pulse echo technique. | The 900 MHz antenna provided more desirable results for this situation. Ultrasonic techniques have the ability to overcome some of the challenges of GPR. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hedjazi, S.; Spears, M.; Kabir, E.; Taheri, H. Application of Radar for Diagnosis of Defects in Concrete Structures: A Structured Image-Based Approach. CivilEng 2025, 6, 45. https://doi.org/10.3390/civileng6030045

Hedjazi S, Spears M, Kabir E, Taheri H. Application of Radar for Diagnosis of Defects in Concrete Structures: A Structured Image-Based Approach. CivilEng. 2025; 6(3):45. https://doi.org/10.3390/civileng6030045

Chicago/Turabian StyleHedjazi, Saman, Macy Spears, Ehsanul Kabir, and Hossein Taheri. 2025. "Application of Radar for Diagnosis of Defects in Concrete Structures: A Structured Image-Based Approach" CivilEng 6, no. 3: 45. https://doi.org/10.3390/civileng6030045

APA StyleHedjazi, S., Spears, M., Kabir, E., & Taheri, H. (2025). Application of Radar for Diagnosis of Defects in Concrete Structures: A Structured Image-Based Approach. CivilEng, 6(3), 45. https://doi.org/10.3390/civileng6030045