Plasticity, Flow Liquefaction, and Cyclic Mobility in Liquefiable Soils with Low to Moderate Plasticity

Abstract

1. Introduction

1.1. Background

1.1.1. Previous Studies on the Effect of Soil Plasticity on Liquefaction Resistance

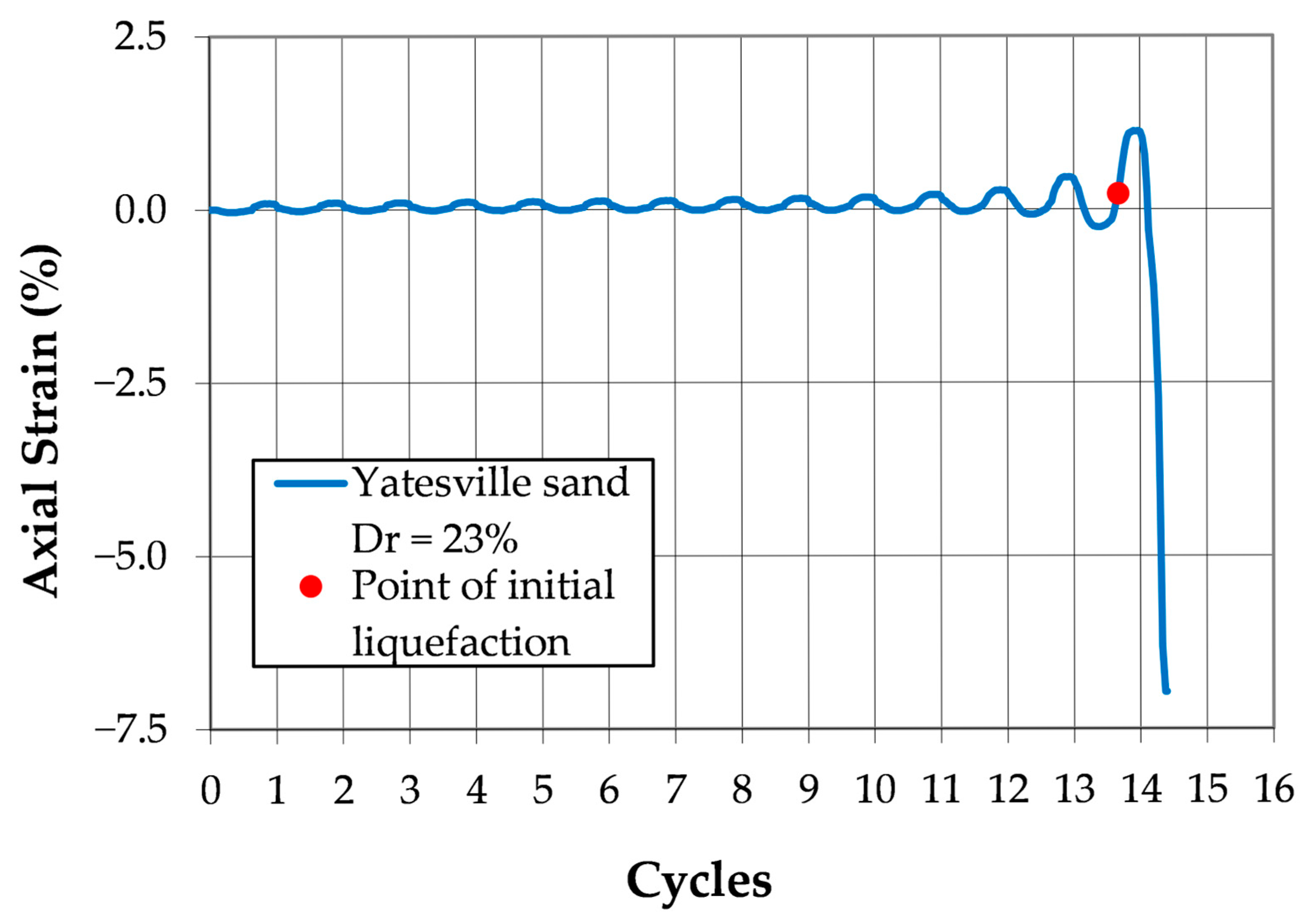

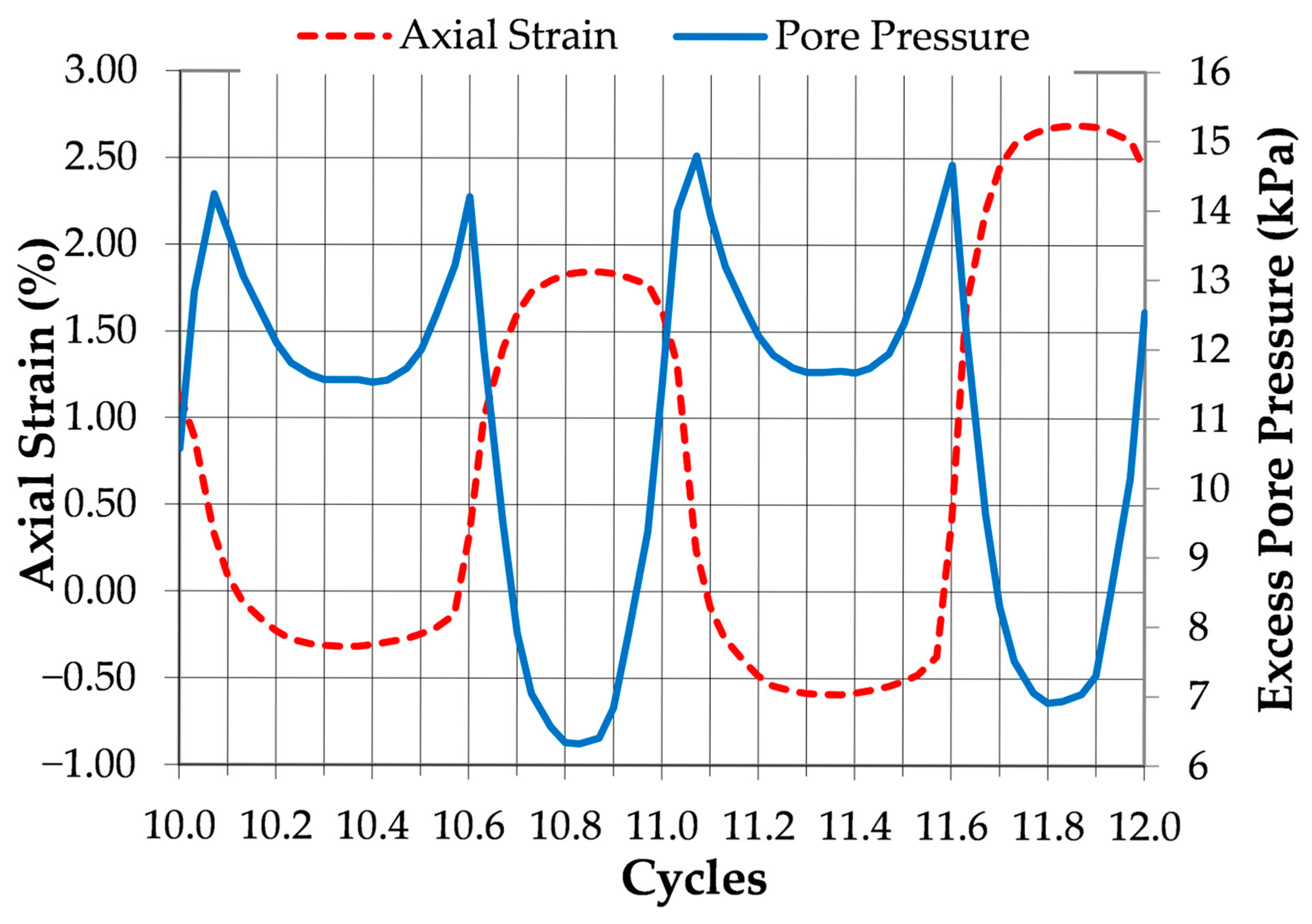

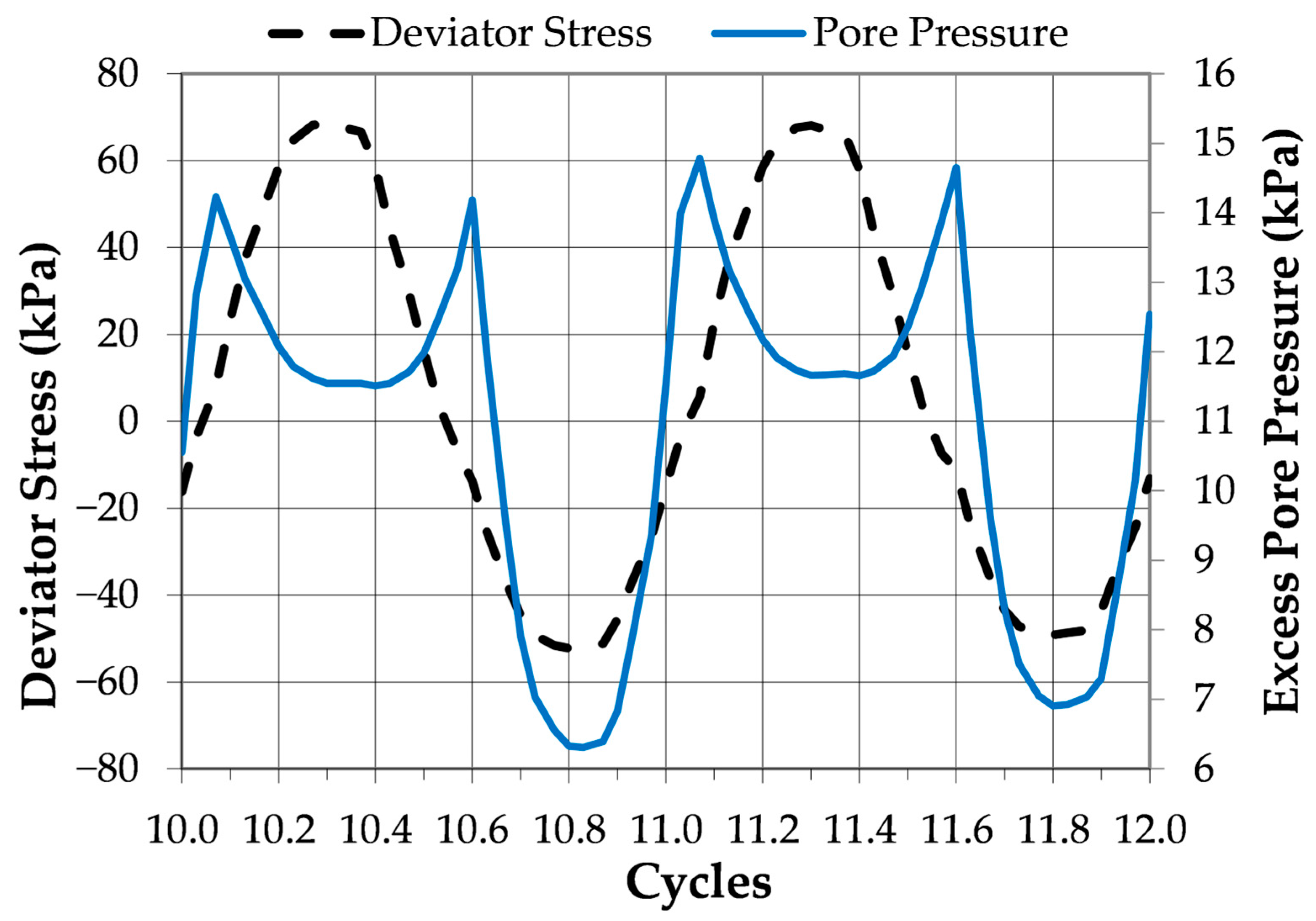

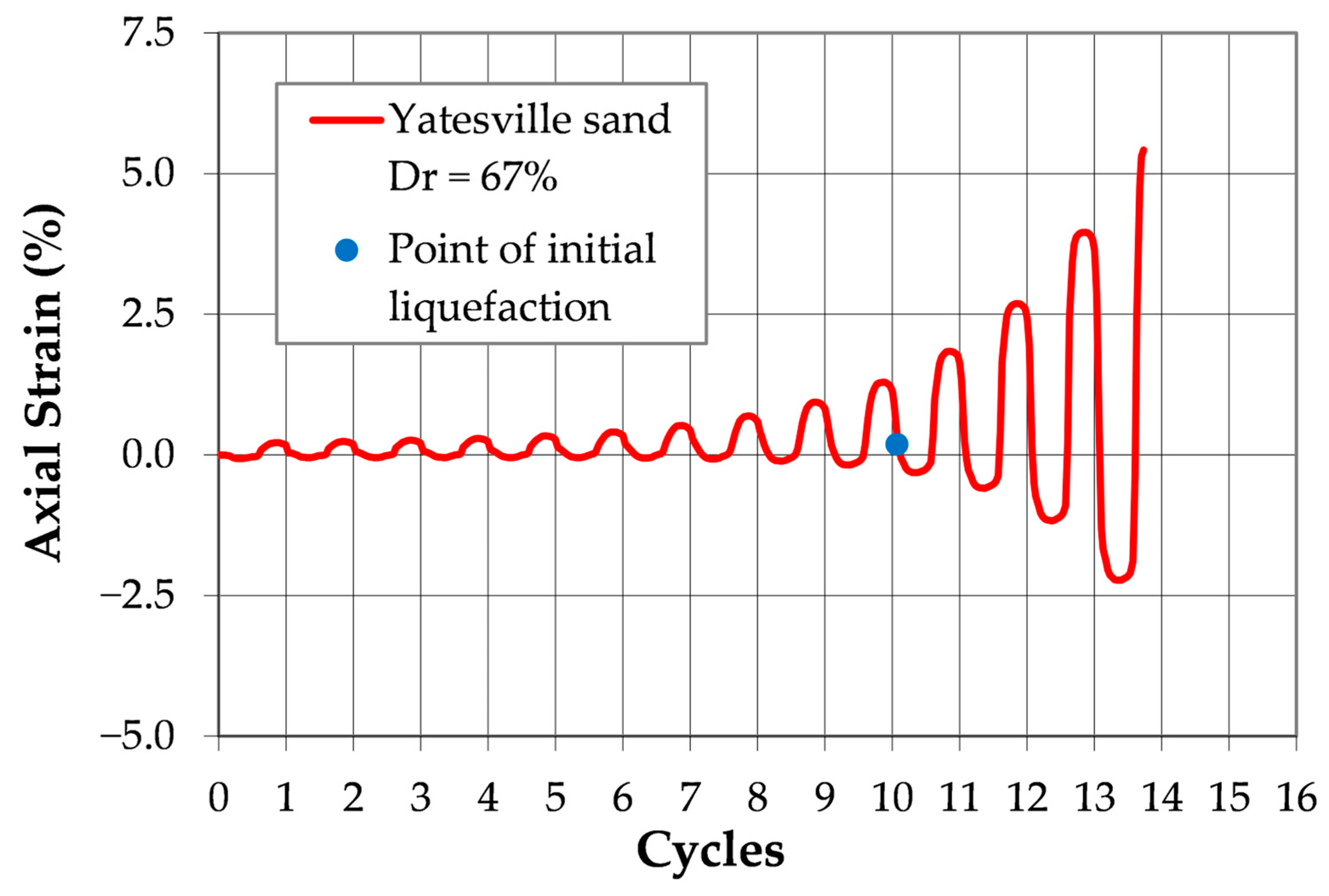

1.1.2. Liquefaction Failures: Flow Liquefaction and Cyclic Mobility

1.1.3. History of Plasticity-Based Liquefaction Susceptibility Criteria

2. Laboratory Testing Program

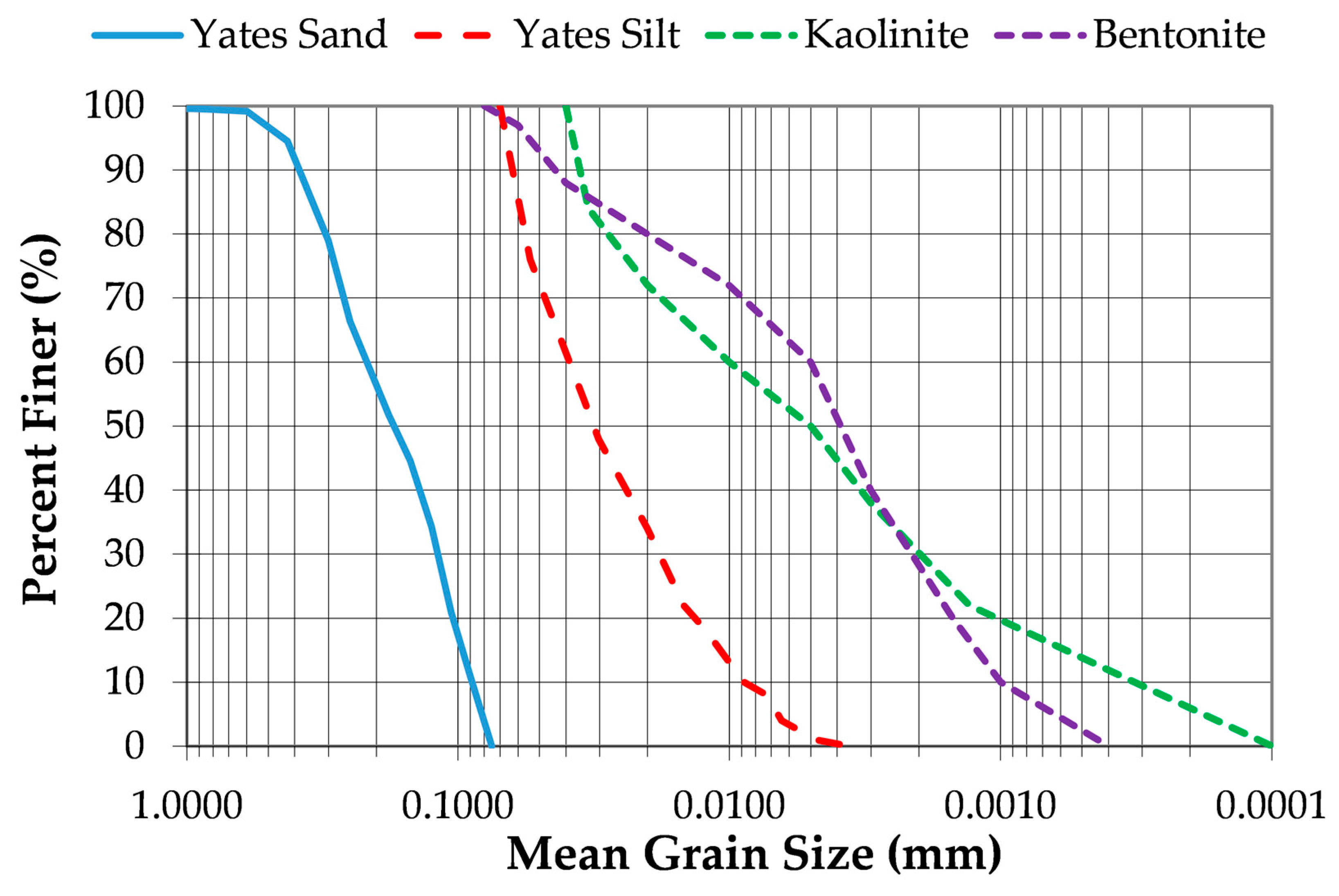

2.1. Soils Tested

2.2. Soil Mixtures

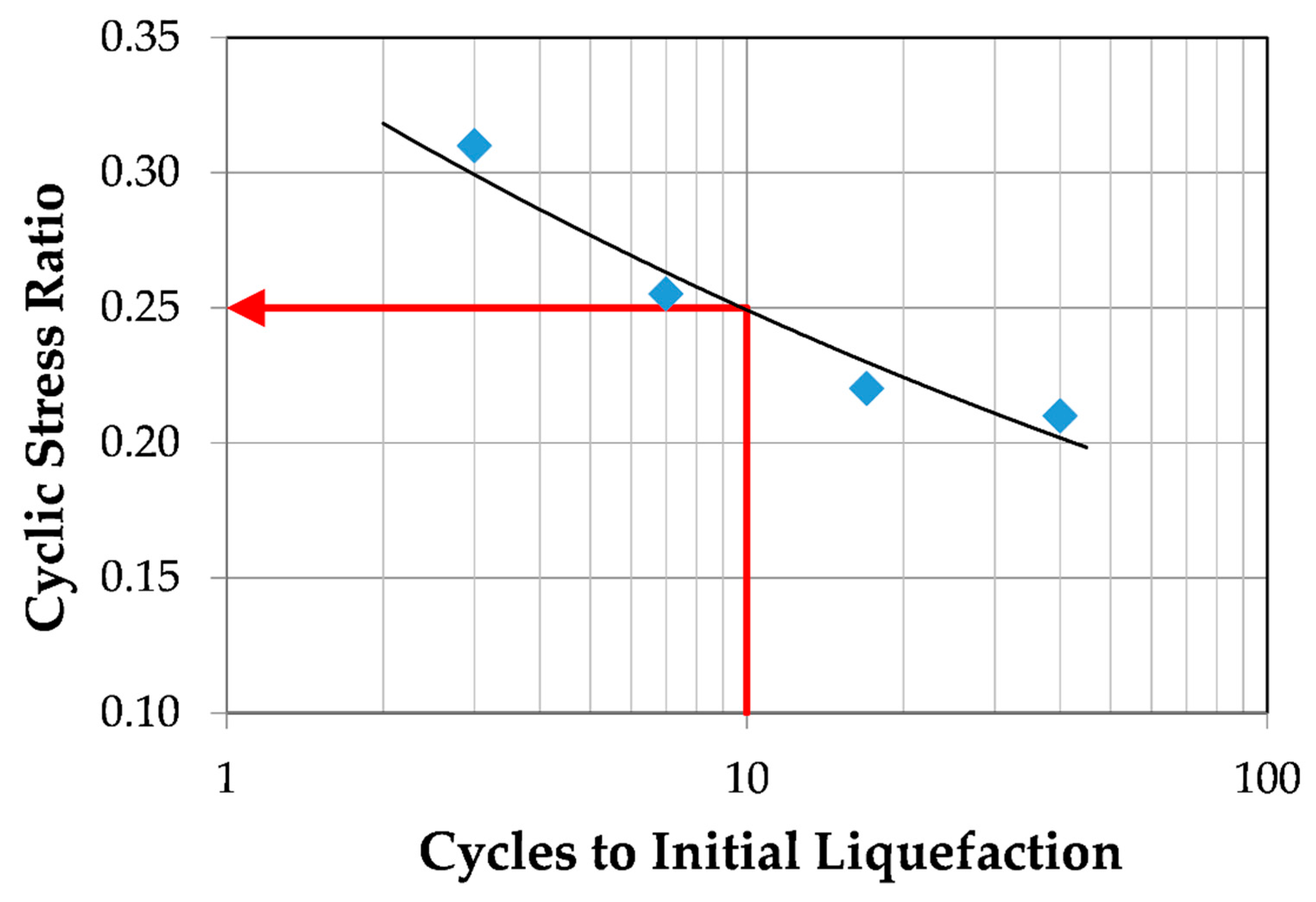

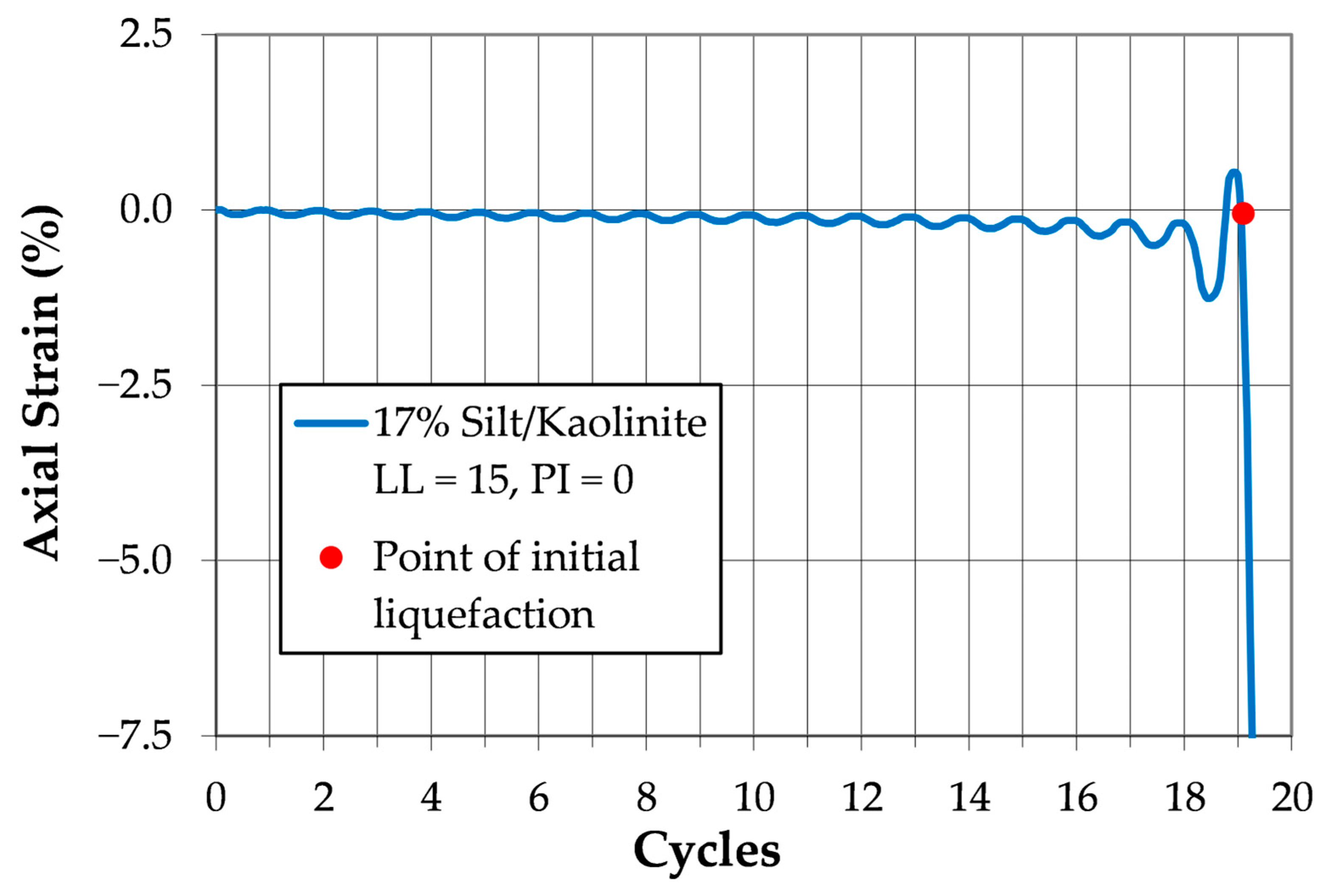

2.3. Cyclic Triaxial Testing

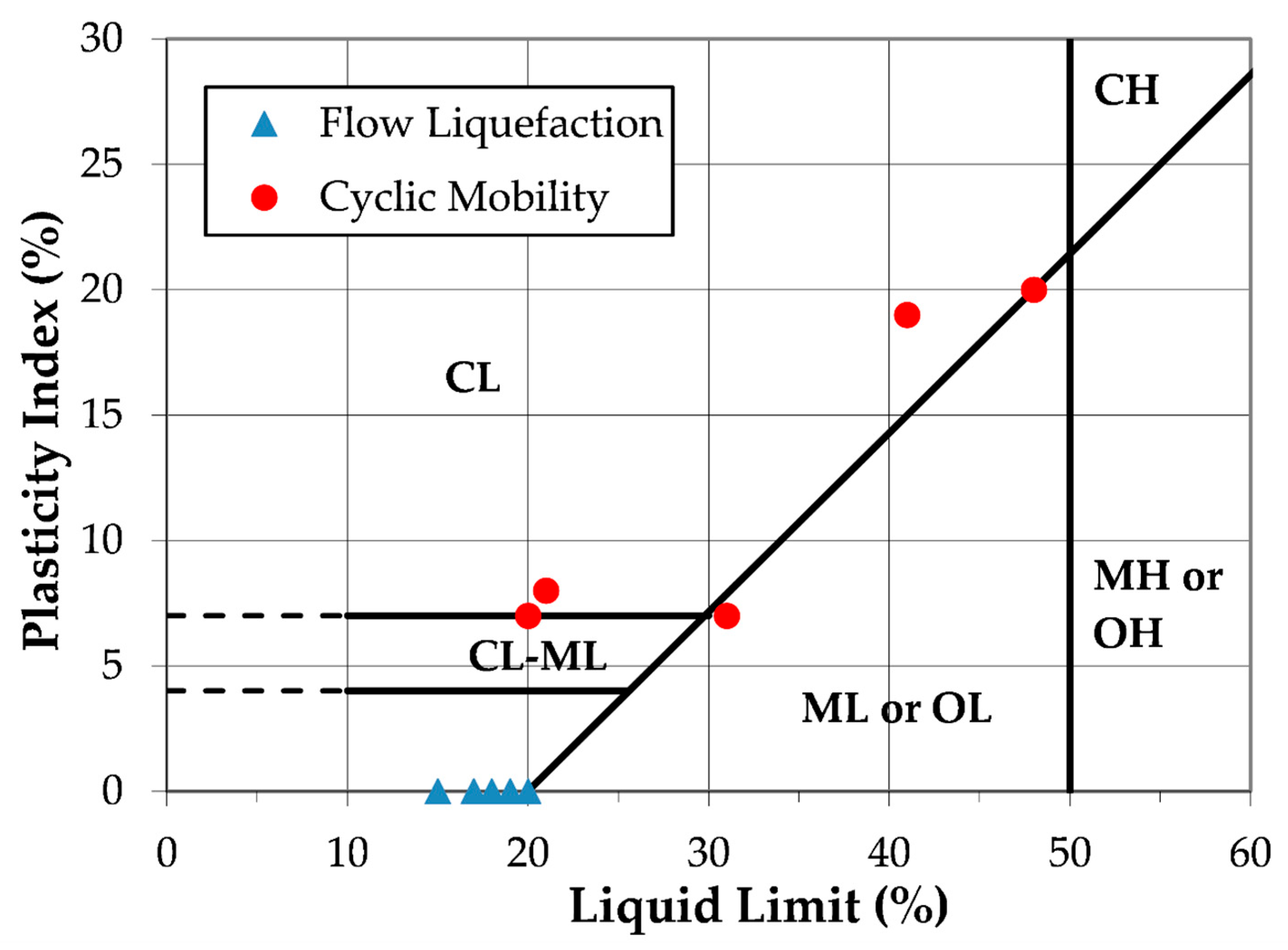

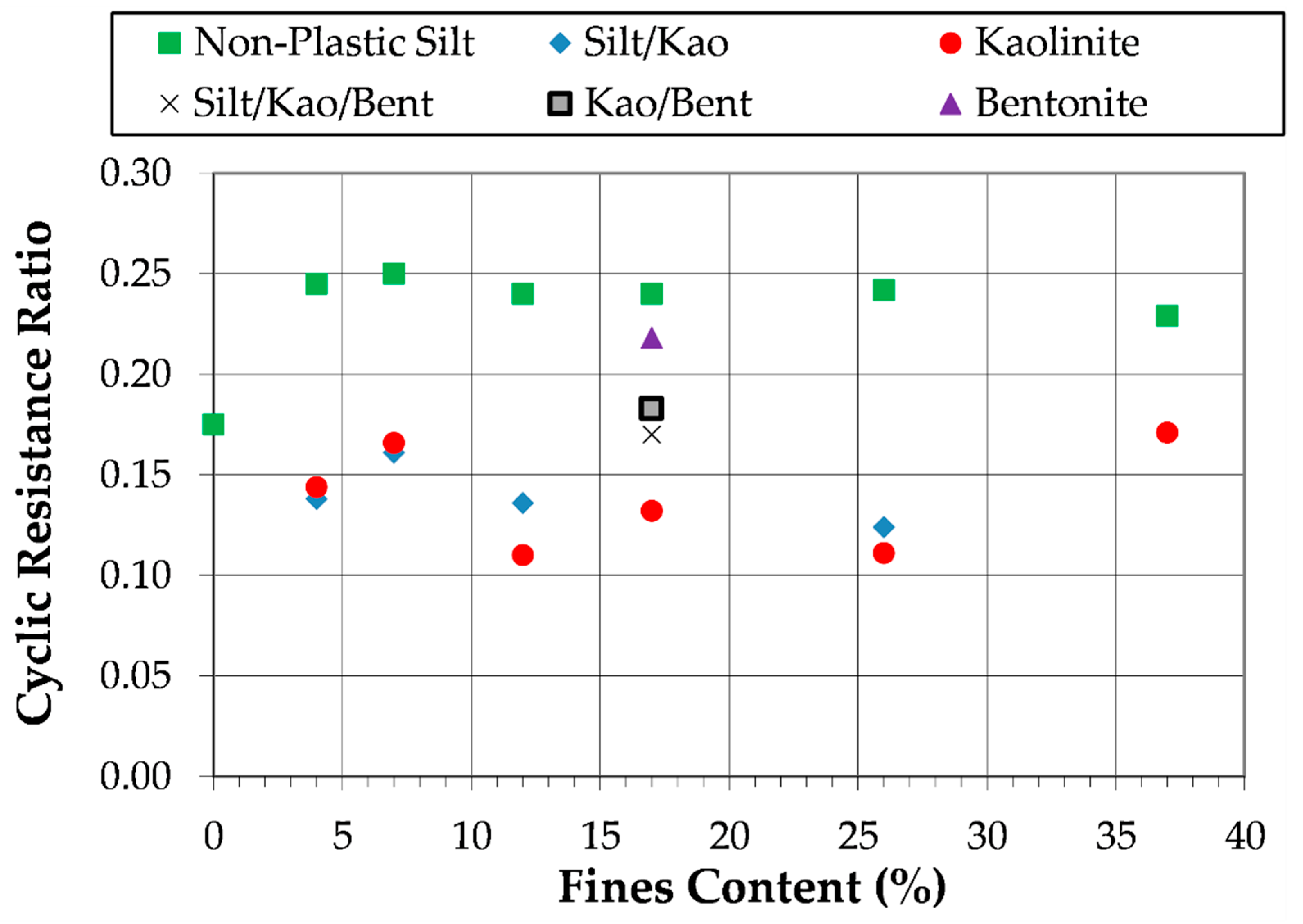

3. Results

4. Discussion of Results

4.1. Liquefaction of Clayey Sands with Low Plasticity

4.2. Plasticity-Based Liquefaction Susceptibility Criteria

4.3. Resolution of the Paradox of the Lab and the Field

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mogami, T.; Kubo, K. The Behaviour of Soil during Vibration. In Proceedings of the Third International Conference on Soil Mechanics and Foundation Engineering, Zurich, Switzerland, 16–27 August 1953; Volume 1, pp. 152–153. [Google Scholar]

- Seed, H.B.; Lee, K.L. Liquefaction of Saturated Sands during Cyclic Loading. J. Soil Mech. Found. Div. 1966, 92, 105–134. [Google Scholar] [CrossRef]

- Lee, K.L.; Seed, H.B. Cyclic Stress Conditions Causing Liquefaction of Sand. J. Soil Mech. Found. Div. 1967, 93, 47–70. [Google Scholar] [CrossRef]

- Seed, H.B. Soil Liquefaction and Cyclic Mobility Evaluation for Level Ground during Earthquakes. J. Geotech. Eng. Div. 1979, 105, 201–255. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Shokooh, A. A Unified Approach to Densification and Liquefaction of Cohesionless Sand in Cyclic Shearing. Can. Geotech. J. 1979, 16, 659–678. [Google Scholar] [CrossRef]

- Polito, C.; Sibley, E. Threshold Fines Content and the Behavior of Sands with Non-Plastic Silts. Can. Geotech. J. 2020, 57, 462–465. [Google Scholar] [CrossRef]

- Thevanayagam, S. Effect of Fines and Confining Stress on Undrained Shear Strength of Silty Sands. J. Geotech. Geoenviron. Eng. 1998, 124, 479–491. [Google Scholar] [CrossRef]

- Hazirbaba, K. Pore Pressure Generation Characteristics of Sands and Silty Sands: A Strain Approach. Ph.D. Thesis, University of Texas at Austin, Austin, TX, USA, 2005. [Google Scholar]

- Kokusho, T. Liquefaction Strengths of Poorly-Graded and Well-Graded Granular Soils Investigated by Lab Tests. In Earthquake Geotechnical Engineering, Proceedings of the 4th International Conference on Earthquake Geotechnical Engineering–Invited Lectures, Thessaloniki, Greece, 25–28 June 2006; Pitilakis, K., Ed.; Springer: Dordrecht, The Netherlands, 2006; Volume 6, pp. 159–184. [Google Scholar]

- Tao, M.; Figueroa, J.L.; Saada, A.S. Influence of Nonplastic Fines Content on the Liquefaction Resistance of Soils in Terms of the Unit Energy. In Cyclic Behaviour of Soils and Liquefaction Phenomena, Proceedings of the International Conference, Bochum, Germany, 31 March–2 April 2004; Triantafyllidis, T., Ed.; CRC Press: London, UK, 2004; pp. 223–231. [Google Scholar]

- Seed, H.B.; Idriss, I.M.; Arango, I. Evaluation of Liquefaction Potential Using Field Performance Data. J. Geotech. Eng. 1983, 109, 458–482. [Google Scholar] [CrossRef]

- Bray, J.D.; Sancio, R.B. Assessment of the Liquefaction Susceptibility of Fine-Grained Soil. J. Geotech. Geoenviron Eng. 2006, 132, 1165–1177. [Google Scholar] [CrossRef]

- Polito, C.; Martin, J.R. The Effects of Non-Plastic Fines on the Liquefaction Resistance of Sands. J. Geotech. Geoenviron. Eng. 2001, 127, 408–415. [Google Scholar] [CrossRef]

- Ishihara, K. Liquefaction and Flow Failure during Earthquakes. Géotechnique 1993, 43, 351–415. [Google Scholar] [CrossRef]

- Goudarzy, M.; Sarkar, D.; Wichtmann, T. Influence of Plastic Fines Content on the Liquefaction Susceptibility of Sands: Monotonic Loading. Acta Geotech. 2021, 16, 1283–1295. [Google Scholar] [CrossRef]

- Akhila, M.; Rangaswamy, K.; Sankar, N. Liquefaction Susceptibility of Silty Sands and Low Plastic Clay Soils. Int. J. Geotech. Earthq. Eng. 2019, 10, 17–31. [Google Scholar] [CrossRef]

- Monkul, M.M.; Ozden, G. Effects of Plastic Fines on the Instability of Sand. Soils Found. 2009, 49, 581–591. [Google Scholar]

- Park, S.-S.; Kim, Y.-S. Liquefaction Resistance of Sands Containing Plastic Fines with Different Plasticity. J. Geotech. Geoenviron. Eng. 2013, 139, 825–830. [Google Scholar] [CrossRef]

- Varghese, V. An Experimental Study on Effect of Plastic Fines Content on Liquefaction Properties of Sand. Int. J. Eng. Res. Appl. 2015, 5, 102–106. [Google Scholar]

- Eseller-Bayat, E.E.; Monkul, M.M.; Akin, O.; Yenigun, S. Evaluation of the Effect of Relative Density on Liquefaction Assessment of Sands with Plastic and Non-Plastic Fines. In Liquefaction Triggering, Consequences and Mitigation; ASCE: Reston, VA, USA, 2018; pp. 244–253. [Google Scholar] [CrossRef]

- Akhila, M.; Ranga Swamy, K.; Sankar, N. Effects of Fines Content and Plasticity on Liquefaction Resistance of Sands. Proc. Inst. Civ. Eng. Geotech. Eng. 2020, 173, 483–495. [Google Scholar] [CrossRef]

- Hsiao, D.-H.; Lin, C.-C. Effects of the Properties of Fines on the Pore Water Pressure Generation Characteristics of Sand–Silt–Clay Mixtures during Cyclic Loading. Appl. Sci. 2023, 13, 8126. [Google Scholar] [CrossRef]

- Dang, Q.-H.; Reiffsteck, P.; Vu, M.-N.; Nguyen-Sy, T.; Pham, V.-H. Effect of Plastic Fine Content on the Static Liquefaction Potential of Sandy Soil. Appl. Sci. 2024, 14, 5881. [Google Scholar] [CrossRef]

- Jradi, L. Study of the Influence of Fine Particles on the Properties of Liquefaction of Sands. Ph.D. Thesis, Université Paris-Est, Créteil, France, 2018. [Google Scholar]

- Qi, W.; Guoxing, C.; Hongmei, G.; Dandan, J. Effect of Plastic Fines on Liquefaction Characteristics of Gravelly Soil. In Proceedings of the 6th International Conference on Earthquake Geotechnical Engineering, Christchurch, New Zealand, 1–4 November 2015; Available online: https://www.issmge.org/uploads/publications/59/60/748.00_Qi.pdf (accessed on 5 May 2025).

- Ganiyu, M.O.; Kennedy, C. Effect of Content and Plasticity of Fines on Liquefaction Behaviour of Soils. Q. J. Eng. Geol. Hydrogeol. 2020, 53, 343–350. [Google Scholar]

- Belkhatir, M.; Arab, A.; Belkhatir, M. Fines Content and Cyclic Preloading Effect on Liquefaction Potential of Silty Sands. Acta Polytech. Hung. 2012, 9, 185–200. [Google Scholar]

- Bouferra, R.; Shahrour, I. Liquefaction Susceptibility Study of Sandy Soils: Effect of Low Plastic Fines. Arab. J. Geosci. 2013, 6, 4083–4091. [Google Scholar] [CrossRef]

- Thevanayagam, S.; Shenthan, T.; Mohan, S.; Liang, J. Undrained Fragility of Clean Sands, Silty Sands, and Sandy Silts. J. Geotech. Geoenviron. Eng. 2002, 128, 849–859. [Google Scholar] [CrossRef]

- Rao, S.E.; Varghese, V.; Patel, S. An Experimental Study on Effect of Plastic Fines Content on Liquefaction Properties of Sand. In Proceedings of the 50th Indian Geotechnical Conference, Pune, India, 17–19 December 2015. [Google Scholar]

- Goudarzy, M.; Sarkar, D.; Lieske, W.; Wichtmann, T. Influence of Plastic Fines Content on the Liquefaction Susceptibility of Sands: Cyclic Loading. Acta Geotech. 2022, 17, 4977–4988. [Google Scholar] [CrossRef]

- Vaid, Y.P.; Sivathayalan, S. Fundamental Factors Affecting Liquefaction Susceptibility of Sands. Can. Geotech. J. 2000, 37, 592–606. [Google Scholar] [CrossRef]

- Yang, J.; Sato, T.; Koseki, J. Undrained Cyclic Behavior of Sand under Anisotropic Consolidation and Its Application to Liquefaction Analysis. Soils Found. 2006, 46, 135–147. [Google Scholar]

- Mesri, G.; Stark, T.D.; Chen, C.S.; Choi, Y.L. The Chicago-O’Hare Test Embankment: Prediction and Performance. Géotechnique 1990, 40, 231–244. [Google Scholar]

- Yamaguchi, A.; Mori, T.; Kazama, M.; Yoshida, N. Liquefaction in Tohoku District during the 2011 off the Pacific Coast of Tohoku Earthquake. Soils Found. 2012, 52, 811–829. [Google Scholar] [CrossRef]

- Casagrande, A. Liquefaction and Cyclic Mobility of Sands: A Critical Review. In Proceedings of the 5th Pan American Conference on Soil Mechanics and Foundation Engineering, Buenos Aires, Argentina, 17–22 November 1975; Volume 5, pp. 80–133. [Google Scholar]

- Polito, C.P. The Effects of Non-Plastic and Plastic Fines on the Liquefaction of Sandy Soils. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 1999; p. 289. [Google Scholar]

- Wang, W. Some Findings in Soil Liquefaction; Report; Water Conservancy and Hydro-Electric Power Scientific Research Institute: Beijing, China, 1979; pp. 1–17. [Google Scholar]

- Jennings, P.C. Earthquake Engineering and Hazards Reduction in China; CSCPRC Report No. 8; National Academy of Sciences: Washington, DC, USA, 1980. [Google Scholar]

- Seed, H.B.; Lee, K.L.; Idriss, I.M.; Makdisi, F. Analysis of the Slides in the San Fernando Dams During the Earthquake of February 9, 1971; Report No. UCB/EERC 73-2; Earthquake Engineering Research Center, University of California: Berkeley, CA, USA, 1973. [Google Scholar]

- Marcuson, W.F.; Hynes, M.E.; Franklin, A.G. Evaluation and Use of Residual Strength in Seismic Safety Analysis of Embankments. Earthq. Spectra 1990, 6, 529–572. [Google Scholar] [CrossRef]

- Finn, W.L.; Ledbetter, R.H.; Wu, G. Liquefaction in Silty Soils: Design and Analysis. In Ground Failures Under Seismic Conditions; Geotechnical Special Publication No. 44; ASCE: Reston, VA, USA, 1994; pp. 51–76. [Google Scholar]

- Koester, J.P. The Influence of Fine Type and Content on Cyclic Strength. In Ground Failures Under Seismic Conditions; Geotechnical Special Publication No. 44; ASCE: Reston, VA, USA, 1994; pp. 17–33. [Google Scholar]

- Andrews, D.C.A.; Martin, G.R. Criteria for Liquefaction of Silty Soils. In Proceedings of the 12th World Conference on Earthquake Engineering, Auckland, New Zealand, 30 January–4 February 2000. [Google Scholar]

- Polito, C.P. Plasticity Based Liquefaction Criteria. In Proceedings of the 4th International Conference on Recent Advances in Geotechnical Earthquake Engineering and Soil Dynamics, San Diego, CA, USA, 29 March 2001; University of Missouri-Rolla: Rolla, MO, USA, 2001. [Google Scholar]

- Seed, R.B.; Cetin, K.O.; Moss, R.E.S.; Kammerer, A.M.; Wu, J.; Pestana, J.M.; Riemer, M.F.; Sancio, R.B.; Bray, J.D.; Kayen, R.E.; et al. Recent Advances in Soil Liquefaction Engineering: A Unified and Consistent Framework. In Proceedings of the 26th Annual ASCE Los Angeles Geotechnical Spring Seminar, Long Beach, CA, USA, 30 April 2003. [Google Scholar]

- Boulanger, R.W.; Idriss, I.M. Liquefaction Susceptibility Criteria for Silts and Clays. J. Geotech. Geoenviron. Eng. 2006, 132, 1413–1426. [Google Scholar] [CrossRef]

- Prakash, S.; Puri, V.K. Recent Advances in Liquefaction of Fine-Grained Soils. In Proceedings of the International Conferences on Recent Advances in Geotechnical Earthquake Engineering and Soil Dynamics, San Diego, CA, USA, 24 May 2010. [Google Scholar]

- Uprety, S.; Puri, V. Effect of Plasticity on Liquefaction of a Selected Fine-Grained Soil. In Geo-Congress 2019: Earthquake Engineering and Soil Dynamics (GSP 308); ASCE: Reston, VA, USA, 2019. [Google Scholar] [CrossRef]

- Ghani, S.; Kumari, S. Liquefaction Study of Fine-Grained Soil Using Computational Model. Innov. Infrastruct. Solut. 2021, 6, 58. [Google Scholar] [CrossRef]

- ASTM D4318-17e1; Standard Test Method for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017; Volume 4.08[1].

- ASTM D5311/D5311M-13; Standard Test Method for Load-Controlled Cyclic Triaxial Strength of Soil. ASTM International: West Conshohocken, PA, USA, 2013; Volume 4.08[1].

- Ladd, R.S. Preparing Test Specimens Using Undercompaction. Geotech. Test. J. 1978, 1, 16–23. [Google Scholar] [CrossRef]

- ASTM D2487-17; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2020; Volume 4.08[1].

| Condition | Threshold |

|---|---|

| Maximum epicentral distance (km) | Log Dmax = 0.87 M − 4.5 |

| Minimum intensity | 6 |

| Mean grain size, D50 (mm) | D50 < 0.02 mm or D50 > 1.0 mm |

| Clay content (% <0.005 μm) | Clay content > 10% |

| Coefficient of uniformity, Cu | Cu > 10 |

| Relative density (%) | Dr > 75% |

| Void ratio, e | E < 0.8 |

| Plasticity index, PI | PI> 10% |

| Depth to water table (m) | Depth > 5 m |

| Depth to sand layer (m) | Depth > 20 m |

| Authors | Liquefiable? | LL (%) | PI (%) | w/LL | % Finer | Ref. |

|---|---|---|---|---|---|---|

| Andrews and Martin [44] | Yes | <32% | -- | -- | 2μ < 10 | [27] |

| Polito [45] | Yes | ≤25% | PI < 7 | -- | -- | [28] |

| Potentially | 25 ≤ LL ≤ 35 | 7 < PI < 10 | -- | -- | ||

| Seed et al. [46] | Yes | <37 | PI < 12 | >0.8 | -- | [29] |

| Potentially | 37 < LL < 47 | 12 < PI < 20 | >0.85 | -- | ||

| Bray and Sancio [12] | Yes | -- | PI < 12 12 < PI < 18 | >0.85 >0.8 | -- | [30] |

| Boulanger and Idriss [47] | Yes | -- | < 3 | -- | -- | [31] |

| Potentially | -- | 3 < PI < 7 | -- | -- |

| Yatesville Sand | Yatesville Silt | Kaolinite | Bentonite | |

|---|---|---|---|---|

| USCS classification | SP | ML | CH | CH |

| Specific gravity, Gs | 2.72 | 2.78 | 2.60 | 2.69 |

| Median grain size, D50 (mm) | 0.18 | 0.03 | 0.005 | 0.004 |

| Liquid limit, LL | Not tested | Not tested | 58 | 385 |

| Plastic limit, PL | Not tested | Not tested | 27 | 42 |

| Plasticity index, PI | Not tested | Not tested | 31 | 343 |

| Fines | Fines | Clay | ||||

|---|---|---|---|---|---|---|

| Content | Type | Content | LL | PL | PI | Activity |

| 0 | -- | 0 | -- | -- | -- | 0 |

| 4 | K | 4.0 | 17 | -- | -- | 0 |

| 4 | M/K | 2.0 | 20 | -- | -- | 0 |

| 4 | M | 0 | -- | -- | -- | 0 |

| 7 | K | 7.0 | 19 | -- | -- | 0 |

| 7 | M/K | 3.5 | 19 | -- | -- | 0 |

| 7 | M | 0 | -- | -- | -- | 0 |

| 12 | Bent | 12.0 | 48 | 28 | 20 | 1.67 |

| 12 | K | 12.0 | 17 | -- | -- | 0 |

| 12 | M/K | 6.0 | 17 | -- | -- | 0 |

| 12 | M | 0 | -- | -- | -- | 0 |

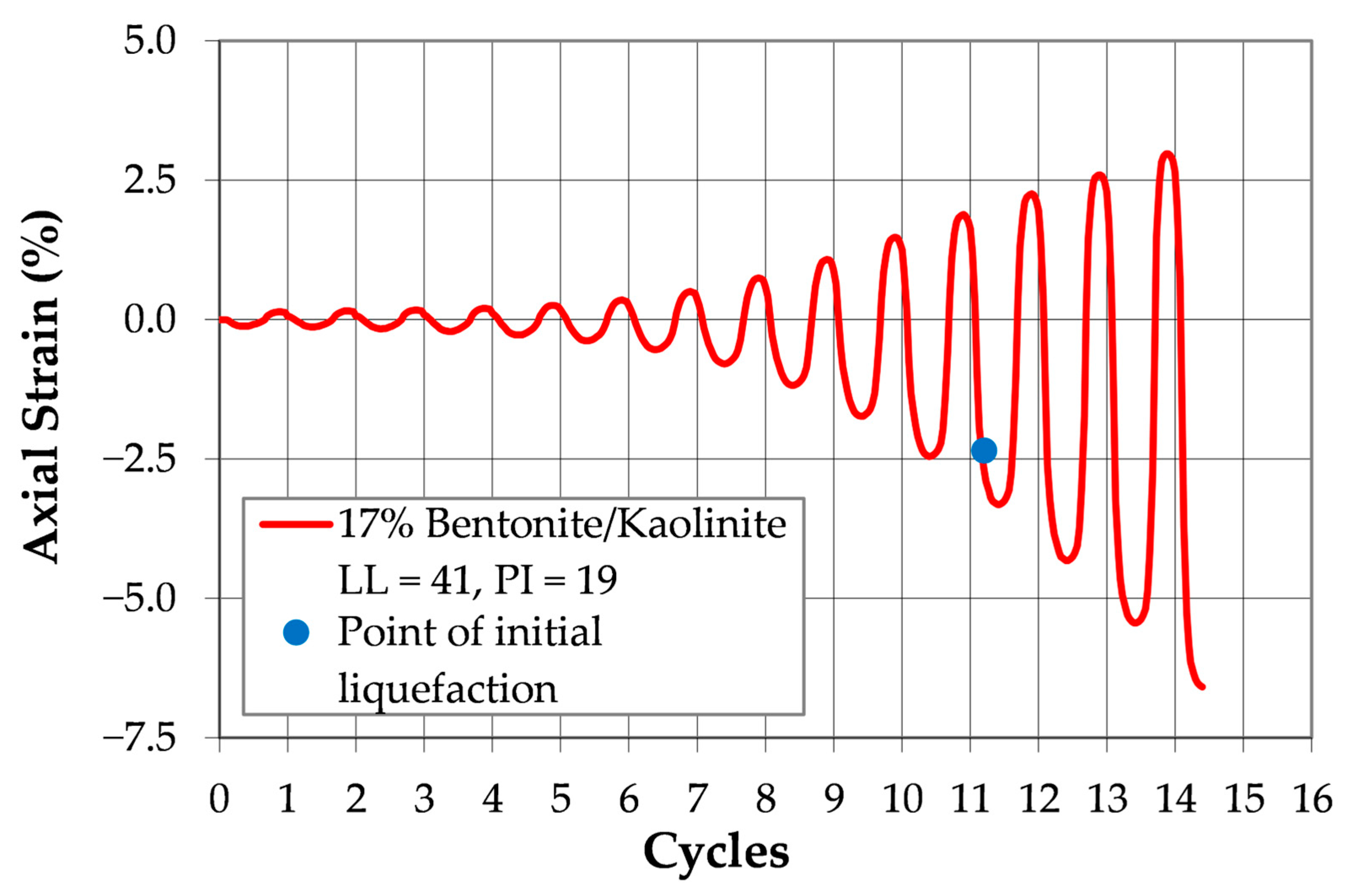

| 17 | K/B | 17.0 | 41 | 22 | 19 | 1.12 |

| 17 | K | 17.0 | 18 | -- | -- | 0 |

| 17 | M/K | 8.5 | 15 | -- | -- | 0 |

| 17 | M/K/B | 11.3 | 31 | 24 | 7 | 0.93 |

| 17 | M | 0 | -- | -- | -- | 0 |

| 26 | K | 26.0 | 20 | 13 | 7 | 0.27 |

| 26 | M/K | 13.0 | 15 | 14 | 1 | 0.15 |

| 26 | M | 0 | -- | -- | -- | 0 |

| 37 | K | 37.0 | 21 | 13 | 8 | 0.22 |

| 37 | M | 0 | -- | -- | -- | 0 |

| Cyclic | Cycles | Cyclic | |||||||

|---|---|---|---|---|---|---|---|---|---|

| File | Fines | Fines | Clay | Stress | to | Resistance | Failure | ||

| Name | Type | Content | Content | Ratio | Initial | LL | PI | Ratio | Mode |

| (%) | (%) | Liq’n | N10 | ||||||

| YMK4C15 | M/K | 4 | 2 | 0.121 | 28 | ||||

| YMK4C16 | M/K | 4 | 2 | 0.120 | 22 | 20 | -- | 0.140 | FL |

| YMK4C18 | M/K | 4 | 2 | 0.148 | 6 | ||||

| YMK7C18 | M/K | 7 | 3.5 | 0.147 | 20 | ||||

| YMK7C20 | M/K | 7 | 3.5 | 0.159 | 10 | 19 | -- | 0.164 | FL |

| YMK7C22 | M/K | 7 | 3.5 | 0.178 | 7 | ||||

| YMK12C15 | M/K | 12 | 6 | 0.114 | 24 | ||||

| YMK12C18 | M/K | 12 | 6 | 0.142 | 8 | 17 | -- | 0.136 | FL |

| YMK12C20 | M/K | 12 | 6 | 0.158 | 5 | ||||

| YMK17C14 | M/K | 17 | 8.5 | 0.105 | 20 | ||||

| YMK17C16 | M/K | 17 | 8.5 | 0.125 | 10 | 15 | -- | 0.132 | FL |

| YMK17C18 | M/K | 17 | 8.5 | 0.139 | 6 | ||||

| YMK26C14 | M/K | 26 | 13 | 0.110 | 25 | ||||

| YMK26C16 | M/K | 26 | 13 | 0.122 | 14 | 15 | -- | 0.124 | FL |

| YMK26C18 | M/K | 26 | 13 | 0.144 | 7 | ||||

| YK4C10 | K | 4 | 4 | 0.070 | 30 | ||||

| YK4C17 | K | 4 | 4 | 0.128 | 16 | 17 | -- | 0.142 | FL |

| YK4C20 | K | 4 | 4 | 0.151 | 8 | ||||

| YK7C17 | K | 7 | 7 | 0.133 | 13 | ||||

| YK7C20 | K | 7 | 7 | 0.148 | 12 | 19 | -- | 0.164 | FL |

| YK7C22 | K | 7 | 7 | 0.173 | 4 | ||||

| YK12C12 | K | 12 | 12 | 0.080 | 40 | ||||

| YK12C15 | K | 12 | 12 | 0.108 | 13 | 17 | -- | 0.11 | FL |

| YK12C20 | K | 12 | 12 | 0.139 | 3 | ||||

| YK17C12 | K | 17 | 17 | 0.084 | 46 | ||||

| YK17C15 | K | 17 | 17 | 0.111 | 10 | 18 | -- | 0.132 | FL |

| YK17C17 | K | 17 | 17 | 0.124 | 7 | ||||

| YK26C12 | K | 26 | 26 | 0.061 | 97 | ||||

| YK26C16 | K | 26 | 26 | 0.124 | 7 | 20 | 7 | 0.111 | CM |

| YK26C18 | K | 26 | 26 | 0.137 | 5 | ||||

| YK37C14 | K | 37 | 37 | 0.108 | 167 | ||||

| YK37C20 | K | 37 | 37 | 0.143 | 22 | 21 | 8 | 0.171 | CM |

| YK37C23 | K | 37 | 37 | 0.197 | 5 | ||||

| YMKB17C21 | M/K/B | 17 | 11.3 | 0.170 | 10 | ||||

| YMKB17C23 | M/K/B | 17 | 11.3 | 0.183 | 6 | 31 | 7 | 0.17 | CM |

| YMKB17C25 | M/K/B | 17 | 11.3 | 0.196 | 5 | ||||

| YKB17C19 | K/B | 17 | 17 | 0.148 | 49 | ||||

| YKB17C21 | K/B | 17 | 17 | 0.171 | 13 | 41 | 19 | 0.183 | CM |

| YKB17C23 | K/B | 17 | 17 | 0.195 | 8 | ||||

| YB12C20 | B | 12 | 12 | 0.166 | 23 | ||||

| YB12C22 | B | 12 | 12 | 0.188 | 14 | 48 | 20 | 0.218 | CM |

| YB12C24 | B | 12 | 12 | 0.201 | 14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Polito, C.P.; Martin, J.R. Plasticity, Flow Liquefaction, and Cyclic Mobility in Liquefiable Soils with Low to Moderate Plasticity. CivilEng 2025, 6, 31. https://doi.org/10.3390/civileng6020031

Polito CP, Martin JR. Plasticity, Flow Liquefaction, and Cyclic Mobility in Liquefiable Soils with Low to Moderate Plasticity. CivilEng. 2025; 6(2):31. https://doi.org/10.3390/civileng6020031

Chicago/Turabian StylePolito, Carmine P., and James R. Martin. 2025. "Plasticity, Flow Liquefaction, and Cyclic Mobility in Liquefiable Soils with Low to Moderate Plasticity" CivilEng 6, no. 2: 31. https://doi.org/10.3390/civileng6020031

APA StylePolito, C. P., & Martin, J. R. (2025). Plasticity, Flow Liquefaction, and Cyclic Mobility in Liquefiable Soils with Low to Moderate Plasticity. CivilEng, 6(2), 31. https://doi.org/10.3390/civileng6020031