Abstract

South Africa is endowed with a wealth of coal-fired power stations that can produce extremely high volumes of fly ash per year exceeding 34 million tonnes. The use of high-volume fly ash (HVFA) binders in the construction sector has the capacity to significantly reduce greenhouse gas emissions associated with traditional cement production and offset the carbon footprint of Eskom. The excessive production of fly ash by Eskom warrants the need for developing ultra-high-volume fly ash binders (UHVFA, fly ash/binder > 60 wt%). Nonetheless, fly ash (FA) replacement of cement is still largely limited to 35% regardless of more ambitious research indicating the potential to surpass 60%. In view of the urgent need for South Africa to offset and reduce its carbon footprint, this work reviews and summarises the literature on the performance of HVFA binders with a focus on two specific areas: (i) strength and (ii) durability. On HVFA binder strength, the focus is drawn on work that analysed the compressive strength, flexural strength, and split tensile strength. This review focuses on the extant literature analysing the durability of HVFA binders using various tests, including sorptivity, resistivity, permeability, tortuosity, rapid chloride penetration tests, resistance to sulphate attack, and microstructural analysis. As the FA content increases towards optima, i.e., 50–80%, the most indicative composite characteristics of the strength and durability properties are UCS (30–90 MPa) and permeability (low). This review reveals the leading methodologies, instrumentation, findings, challenges, and contradictions.

1. Introduction

High-volume fly ash (HVFA) binders involve the replacement of Portland cement (Pc) with fly ash (FA), often exceeding 50% by weight [1]. Mehta (2017) [1] defines HVFA as containing a minimum of 50% FA, low water content (<130 kg/m3), and cement content less than 200 kg/m3 for concretes [2]. Ultra-high-volume fly ash (UHVFA) binders may contain FA exceeding 60% by weight [3,4,5,6]. Fly ash is a pozzolana; therefore, by itself, it possesses little to no cementitious value and cannot react with water alone [7,8,9]. Generally, it has been reported that Pc replacement with HVFA improves binder workability and durability and reduces drying shrinkage and matrix toughness [5]. Its contribution to strength is mixed.

Fly ash, the fine, powdery residue derived predominantly from coal combustion, has long been an intrinsic byproduct of the global energy landscape. Nowhere is this more evident than in South Africa, a nation endowed with a wealth of coal-fired power stations that produce 34 million tonnes of fly ash per year. While fly ash has often been perceived as a residual environmental challenge, it also presents an unparalleled opportunity. Harnessing the potential of fly ash, particularly in the realm of construction materials, not only aligns with the principles of sustainability but is increasingly vital in the context of a world that must ardently strive to limit global temperature increases. Geopolymer binders are getting traction as an eco-friendly alternative to Portland cement binders for applications in the construction industry [10]. Geopolymer binders are made from rich silica and alumina source materials such as fly ash, calcined kaolin, and blast furnace slag.

Fly ash binders offer reduced CO2 emissions of up to 80% relative to Portland cement binders. Further, FA binders are primarily based on the use of other industrial wastes or clays, granulated ground blast furnace slag (GGBFS), and metakaolin [10]. The urgency of addressing climate change and the imperative to ensure that global temperatures remain within a safe threshold of 2 degrees Celsius above pre-industrial levels (and an even more ambitious target of keeping it below 1.5 degrees Celsius) have been unequivocally underscored by the international scientific community. In this regard, South Africa’s unique position as both a coal-dependent nation and a signatory to international climate agreements warrants special attention. The vast quantities of fly ash produced by its coal power stations are not only emblematic of the nation’s energy landscape but also a resource with transformative potential for the construction sector. High-volume fly ash binders, when used effectively, have the capacity to significantly reduce greenhouse gas emissions associated with traditional cement production and offset the carbon footprint of Eskom.

Given correct mix design and formulation development, geopolymer binders derived from fly ash can exhibit superior chemical and mechanical properties compared with ordinary Portland cement [10]. Apart from their potential to surpass Portland cement-based binders, fly ash binders can be highly cost-effective. However, the performance of FA binders depends on the composition, fineness, mineralogy, and particle morphology of the precursor materials selected. The properties and performance of the FA binders can vary significantly depending on the mix ratios [11]. Durability is a paramount consideration in the context of construction materials, and it is particularly salient when it comes to fly ash-based binders. The durability of these binders can significantly influence the performance of the structures they support [12].

This systematic review aims to rigorously investigate the existing corpus of the literature on ultra-high and high-volume fly ash binders with a specific focus on their performance and durability. The research seeks to answer the following questions: (i) How does the addition of FA > 50% (wt) in HVFA and UHVFA binders affect their mechanical properties (compressive, flexural, and tensile strength)? (ii) How do the HVFA and UHVFA binders’ durability properties (sorptivity, tortuosity, absorption, Cl− resistance, resistance to chemical attack, etc.) change as the FA content approaches optima? (iii) What are major research trends on additives and measures incorporated in developing mechanically high-performing and durable HVFA/UHVFA binders? By consolidating the available knowledge and insights, the research aims to elucidate the current state of understanding and highlight areas for further research and development. The implications extend beyond the realm of construction in South Africa; they resonate with the global imperative to transform a once problematic byproduct into an indispensable solution, all the while advancing the cause of climate action and the pursuit of durable, sustainable infrastructure. In doing so, we strive to underscore the crucial role that high-volume fly ash binders can play in offsetting coal-fired power stations’ carbon footprint, particularly in South Africa.

2. Materials, Methods, and Content Analysis

Although there is a vast literature on fly ash binders, this review was limited to the literature specifically investigating the strength and durability of high-volume fly ash binders exceeding 50% FA content by weight. This review uses Elsevier’s Scopus, Web of Science (WoS), and Google Scholar-the leading scientific databases of citations and summaries of peer-reviewed literary work. For instance, the search prompt below was used to extract 223 articles from Scopus.

Title-abs-key ((“high volume fly ash*”) AND (“binder” *) OR (“cement” *) OR (“mortar”*) AND (“strength”*) OR (“performance”*) AND (“durability”*)) and (limit-to (subjarea, “engi”) or limit-to (subjarea, “mate”) or limit-to (subjarea, “envi”) or limit-to (subjarea, “ener”) or limit-to (subjarea, “eart”)).

Among the recent review papers published on fly ash research, Herath et al. (2023) [13] investigated the durability of HVFA binders with 65% and 80% FA blended with nano silica and hydrated lime, exposed to aggressive solutions for 2 years. Sugandhini et al., 2023 [14] studied the effect of blending 20% Pc with 80% FA and polypropylene fibres of between 0.6 and 1.0% in corrosive environments. Yu et al. [7] investigated the hydration and physical characteristics of HVFA binder systems with low water/binder (w/b) ratios and a widespread range of FA replacement from as low as 20% FA to almost 100% FA by weight. Provis et al., 2009 [4,15] investigated the durability of alkali-activated binders using X-ray microtomography (μCT) for the first time to provide direct insight into the FA binder’s 3D pore structure and microstructure using a synchrotron beamline instrument to analyse metasilicate-activated fly ash blends. Donatello et al. (2013) [16] investigated the resistance of UHVFA binders activated by Na2SO4 and ASTM-compliant seawater after 90 days of immersion. Hemalatha and Ramaswamy (2017) [17] reviewed the characteristics of fly ash for use in sustainable concrete. In their review, they focus on concrete and the characteristics of FA [17]. Swathi and Asadi (2022) [18,19] experimentally investigated the mechanical strength and durability of HVFA (70%wt) to understand the performance, and microstructure characteristics using the rapid chloride penetration, water absorption, and sorptivity tests. Other reviews are brief in nature, summarizing, and do not necessarily focus on HVFA. The development of HVFH (>50% FA by weight) and UHVFA presents a unique opportunity for coal-rich countries like South Africa, which is endowed with large FA dumps to offset its carbon footprint from its use of over 100 million tonnes of coal per annum. Therefore, this review aims to provide a single exhaustive research study summarizing the durability and strength findings related to HVFA to serve as a ready reference and guide for researchers working on HVFA and UHVFA binders. The literature collected for this review is used to reveal the leading methodologies, instrumentation, findings, challenges, and contradictions.

3. Results

3.1. High-Volume Fly Ash Binder Strength

3.1.1. The Split Tensile Strength

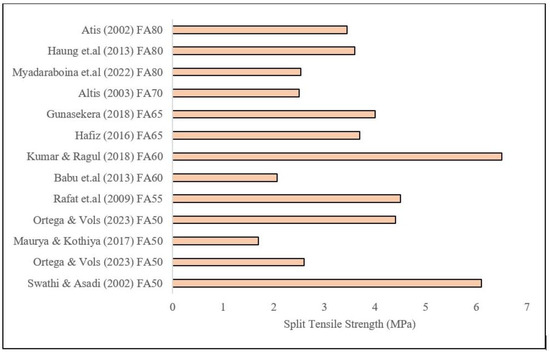

Split tensile strength is tested based on the IS: 5816-1999 standard procedure or in accordance with ASTM C496-11 [20]. Cylindrical specimens are water-treated for hydration, and specimen dimensions and weight are measured before tests. Specimens are subjected to a gradual load at a rate of 0.6 to 1.5 MPa/m until they reach the breaking point. The split tensile strength of HVFA samples is tested under constant load under a split tensile machine. Figure 1 summarizes research findings on the HVFA binder’s split tensile strength. It is clear from Figure 1 that there have been major strides to increase FA dosage in HVFA binders towards optimum. However, the drop in split tensile strength with an increase in FA dosages remains problematic as seen in Figure 1. Further, most studies are limited to dosages between 50–60% with very few seldom exceeding 80% FA dosages.

Figure 1.

Research findings on HVFA binder’s split tensile strength [18,19,20,21,22,23,24,25,26,27].

Swathi and Asadi (2020) [19] observed that the optimum split tensile strength is obtained when 50% FA is used in HVFA binders (see Figure 1 above). It was reported that at 90 days, 50% yielded a split tensile strength of 6.23 MPa and started decrement thereafter [24,25]. Babu et al. [25] investigated the tensile strength behaviour of HVFA binders blended with quarry dust (0.14%) and reported that the 28-day tensile strength of Pc binders was lower than that of HVFA binders (FA at 50%) blended with quarry dust at 2.1 MPa and 2.2 MPa, respectively, while at FA content of 60%, the HVFA tensile strength was reported to be 2.07 MPa.

Maurya and Kothiya (2023) [27] reported consistent observations on the drop of tensile strength with increased content of FA without additives. At 50% dosage of FA, they reported that HVFA binders’ tensile strength was about 1.7 MPa lower than that of Pc at 28 days of age. However, they also reported that graphite oxide as an additive significantly increased the tensile strength for dosages between 0.005 and 0.02 by weight % of binder beyond which the tensile strength dropped [27]. A dosage of 0.02% graphite oxide achieved tensile strength of about 5 MPa, which was slightly above that of Pc binders at 90 days of age. This was attributed to the formation of the chemical bond between the graphene oxides containing oxygen functional groups and the CSH/CH hydration product. Maurya and Kothiya (2023) [27] reported that a drop in compressive strength of HVFA binders FA can be eliminated by blending with graphite oxide at 0.02% by weight.

3.1.2. Flexural Strength Test

The flexural strength test is often performed using the two-point constant loading based on the ASTM C78 standard. Table 1 provides a summary of research findings on the HVFA binder’s FA/Pc ratio and flexural strength. Swathi and Asadi (2022) [18] reported that the maximum flexural strength is observed at 50% FA at 8.58 MPa after 90 days [20]. While most authors seem to argue that optimum strength is achieved between 50–60% FA, it is clear from Table 1 that recent research indicates the possibility of almost similar results for FA dosages within the range of 70–80% FA [7,28].

Table 1.

Literature review of HVFA binders FA/Pc ratio and flexural strength [7,17,18,21,23,24,25,26,27,28,29,30,31,32,33,34].

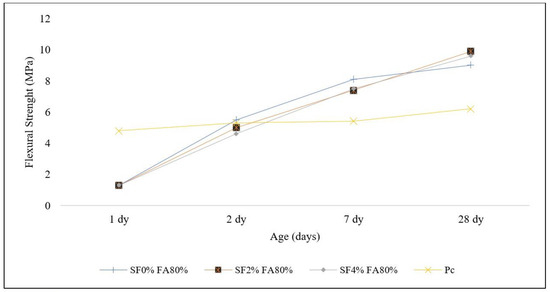

However, the review noted that the drop in flexural strength due to an increase in FA content is still a concern in HFVA binders regardless of the promising findings illustrated in Table 1. For instance, Babalu et al. (2023) [35] reported results indicating an increase in flexural strength with FA content but only up to 30 wt% FA, beyond which they noted a drop. Kumar et al. (2005) [36], whose results were consistent with the finding of Babalu et al. (2023) [35] and other studies that reported a 3.75% and 7.30% flexural strength drop for mixes containing 50% and 60% FA, respectively [7,37]. In Babalu et al. (2023) [35], a 90-day drop in flexural strength at 50% and 60% FA was reported as 4.5% and 11.93%, respectively, while in Siddique (2003) [1,38], a 43.63% drop in flexural strength was reported. The consistent drop in flexural strength from various findings has been attributed to the high-quality and dense C–S–H gel produced by blending FA of 30%. However, in pastes containing FA content above 30%, it is alleged that there is a significant lack of CH, which reduces the overall strength of the binder [35]. Yu et al. (2017) [7] reported that when FA is blended with silica fume, the flexural strengths of UHVFA exhibit significant improvement with an increase in curing time. As seen in Figure 2, the use of silica fume in UHVFA binders with FA dosages as high as 80% was reported to achieve a flexural strength higher than that of Pc binders [7]. It is clear from Figure 2, that while the flexural strength of Pc binders tends to be high from the onset and constant throughout the period, HVFA binders achieve significantly low flexural strength at 1 day old. Interestingly, the flexural strength of silica fume containing HVFA binders rises to match that of Pc binders within 2 days and almost doubles that of Pc binders at 28 days of age (see Figure 2).

Figure 2.

The flexural strength of silica fume containing UHVFA binders is almost double that of Pc binders at 80% FA; SF0.00, SF0.02, SF0.04 at 0; 0.02; 0.04% Silica fume respectively (Modified from Yu et al., 2017) [7].

3.1.3. Compressive Strength

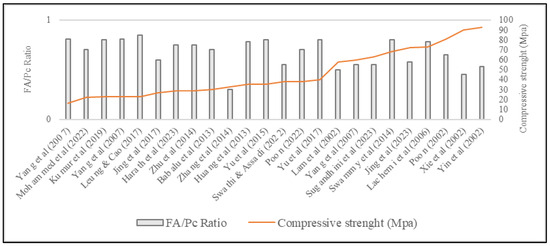

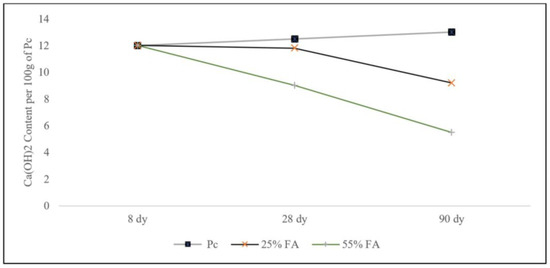

The compressive strength of HVFA binders is determined using the ASTM C39 2012 standard test method [20] for compressive strength of cylindrical specimens. Tests are performed on cylindrical specimens at specified ages of the binder, which are days 3, 7, 28, 56, 91, up to day 210 [37]. The pozzolanic nature of FA compromises the strength of HVFA binders in the early stages due to the slow reaction of HVFA. Several studies have examined the pozzolanic rate of reaction of HVFA binders by measuring the Ca(OH)2 content within the binder from day 1 to 91 days of age. Figure 3 provides an overview of the literature review on the compressive strength of HVFA binders. It can be deduced from Figure 3 that HVFA binders’ optimum compressive strength in extant studies has been limited to FA dosages between 50 and 60%. Figure 4 provides a comparative illustration of Ca(OH)2 content between Pc and HVFA binders over time. The late-age precipitation of Ca(OH)2 at the edge of FA particles strengthens the contacts between FA, cement, and other particles leading to a denser matrix. Ultimately, this results in the late-age compressive strength of HVFA binders, which is illustrated in Figure 5 [39]. In HFVA systems with 45% to 55% FA by weight, more than 80% of the FA will be unreacted after 90 days of curing. Although FA starts reacting with Ca(OH)2 between 3 and 7 days, high amounts of Ca(OH)2 and FA will still be unreacted at 90 days of curing [7]. In infrastructure developments that do not require early-age strength of binders, such as dams, the low compressive strength of HVFA systems may not be a concern [4,6].

Figure 3.

Literature review of compressive strength HVFA-based binders indicating that optimum compressive strength in extant studies has been limited to FA dosages between 50 and 60% [7,13,14,17,18,35,40,41,42,43,44,45,46,47,48,49].

Figure 4.

Rate of reaction of FA in HVFA binders over 90 days of curing (Modified from Lam et al., 2000) [50].

Figure 5.

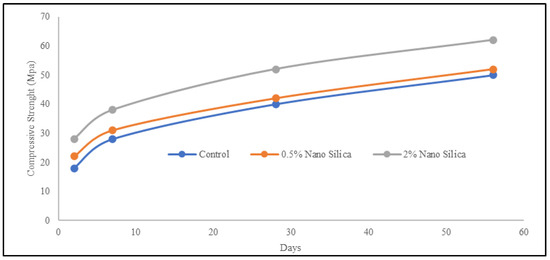

Effect of nano silica particles on the compressive strength of HVFA binders (Modified from Palla et al., 2017 [51]).

There have been significant research efforts to improve HVFA systems both in their early stages and in old age. It has been proved that HVFA systems may surpass the compressive strength of purely Pc systems. This has been achieved by enhancing the hydration of HVFA systems by lowering the water-to-binder ratio (w/b) [52]; introducing an appropriate amount of a silica fume [53]; substituting ordinary Portland cement with high early strength Pc [7]; replacing part of the FA with rice husk ash, which is more reactive; chemical activation [54]; incorporating nanomaterials such as nano-SiO2 [55]; accelerated curing and autoclaving; and grinding. However, accelerated curing and mechanical treatment are energy-consuming and, therefore, counterproductive in ensuring the ecological sustainability of HVFA binders. Furthermore, chemical activation and use of nanomaterials are not economically sustainable. Thus, altering the w/b ratio, introducing an appropriate amount of a silica fume or rice husk ash, and substituting ordinary Portland cement with high early strength Pc remain the feasible options [7]. Samhitha et al., 2019 [56] developed a high-strength HVFA concrete of M70 grade. After various trials, they reported that 30%Pc + 70% FA as total powder achieves 70 MPa when blended with 10% silica fume, 30% lime by weight, and a w/b ratio of 0.3. They also reported that the high-strength HVFA had a significant drop in water absorption and porosity of 85% and 34%, respectively.

3.1.4. Effect of w/b Ratio on Strength

Lowering the w/b ratio can lower the expected drop in HVFA binders’ compressive strength [39,55]. Although replacing Pc with FA is known to lower the early strength within and up to the first 28 days of age, Lam (2000) [50] observed that at w/b ratios at 0.55 FA/Pc ratio of w/b ratio of 0.5, the compressive strength fell by 38% at day 28, but at w/b ratio of 0.3, it fell by 28% only [50]. The pozzolanic reactivity of FA is significantly altered by varying w/b. Table 2 provides a summary of the literature review on various studies that analysed the effect of the w/b ratio on compressive strength. It can be deduced from Table 2 that w/b ratios around 0.2 result in optimum HVFA compressive strength. This observation is in sync with the findings of Yu et al. (2017) [7], who reported that UHVFA binders of 80% FA content resulted in adequate compressive strength (40 MPa at 7 days and 60 MPa at 28 days) by lowering the w/b ratio to 0.2 and properly combining raw materials. The low w/b ratio in HVFA binders results in lower heat of hydration and chloride ingress compared with pure Pc binders [4,7]. The unreacted Pc and FA particles after 90 days of curing serve as microaggregates contributing to the strength of the binder [17]. Furthermore, low w/b ratios equally curb HVFA binders’ weaknesses of delayed setting and low early-age strength [57]. Although lowering the w/b ratio increases the strength of HVFA binders, it is also reported to cause cracking in early-age HVFA binders; therefore, it should be applied carefully [17]. It has been reported that the compressive strength of HVFA contributes to the compressive strength of concretes more than that of pastes. It has been reported that while most research has reduced the w/b ratio to a value close to 0.25 as shown in the table below, the early-age compressive strength results remain significantly low for most studies and are limited to HVFA binder applications with low early strength demands, such as waterproofing.

Table 2.

Literature review of the effect of w/b ratio on HVFA compressive strength [7,8,18,33,35,40,44,46,56,57,58,59,60].

3.1.5. Effect of Blending FA with More Reactive Pozzolans on Strength

Fly ash is a known pozzolana that possesses little or no cementitious value and cannot react with water alone. The inability to lower w/b ratios to achieve desirable compressive strength for applications that require higher early compressive strength necessitates the incorporation of other more reactive pozzolans, such as rice husk ash. More reactive pozzolan nanoparticles can be used to accelerate the pozzolanic reaction of HVFA binders and aid their compressive strength [61]. Rice husk ash has also been studied for its use as a reactive filler in HVFA binders without heat treatment by replacing inert quartz filler and increasing amorphous silica content while maintaining the physical role of the micron-sized quartz filler [61,62]. Due to the high porosity of rice husk ash, internal curing is highly effective as it promotes the hydration reaction [63]. It has been reported that an outstanding compressive strength of 200 MPa at 91 days of natural curing is possible by blending HVFA with rice husk ash. This was possible due to the promotion of pozzolanic reaction by adding water and amorphous silica provided by the porous (i.e., internal curing effect) and reactive filler, respectively; hence, the volume of capillary pores was reduced [64].

Blending HVFA with nanoparticles tightly bonds hydration products, which accelerate the pozzolanic reaction [27,65]. Yu (2017) [7] studied the compressive strength and tensile characteristics of fibre-reinforced HVFA systems by reducing the w/b ratio and adding a small amount of silica fume. The addition of silica fume has been reported to improve the early-age compressive strength of HVFA binders, modify the interfacial transition zone, and reduce the sorptivity, permeability, and porosity of HVFA binders [66]. Yu (2017) [7] established that the compressive strength of HVFA binders of 80% FA, 2% silica fume, 2% PVC fibre, and 0.2 w/b ratio reaches 47.3 MPa, while HVFA at 0.175 w/b reaches 52.9 MPa at 28 days.

Nano silica is leading among reactive pozzolans used to blend HVFA [51,67]. Supit and Shaikh (2015) [65] reported that the addition of nano silica to HVFA binders increases the compressive strength in early ages between 1 to 3 days. Incorporating 2% nano silica in HVFA significantly improved the early compressive strength, while no significant late strength was gained. Supit and Shaikh (2015) [65] reported that the reactivity of nano silica is higher in HVFA systems containing 38% FA than those containing 58%. Nano silica particles tend to agglomerate when used in high content forming weak zones that prevent the formation of homogenous hydrate microstructures [65,68]. Nano silica and silica fume are considered the best fillers due to their fineness because they increase the packing density [29]. Similarly, it has been reported that incorporating 2% silica nanoparticles HVFA into cement mortar at 40% FA and w/b ratio 0.25 accelerated the hydration process by shortening the dormant period. Solikin et al. [69] experimentally investigated the influence of incorporating ultra-fine FA in HVFA binders and reported that the 28-day and 56-day strength improved by almost 6% and 4%. Similarly, Fu et al (2021) [70] reported a 32, 52, and 40% higher compressive strength at 7, 28, and 56 days, respectively, and a 61 and 42% higher flexural strength at 28 and 56 days. The findings were also in sync with what Shaikh et al. reported on the influence of ultra-fine FA on HVFA binder strength [65]. Similarly, nano silica particles have experimentally proved to enhance HVFA binder strength as shown in Table 3 below and Figure 5. Notably, both Figure 5 and Table 3 illustrate the gradual increase in compressive strength of HVFA binders owing to the late-age precipitation of Ca(OH)2.

Table 3.

Literature review on the influence of nano silica, ultra-fine fly ash, silica fume, slag, and hydrated lime on HVFA binder strength [17,65,69,70,71,72,73,74,75,76,77].

3.1.6. Chemical Activation of HVFA Binders to Enhance Strength

Chemical activation of HVFA binders can be achieved through alkali or sulphate activation. Researchers have investigated the effect of chemical activators such as NaCl and Na2SO4. Shi and Day (1995) [78] reported an increase in compressive strength from 22 MPa at 0% Na2SO4 to 37 MPa at 4% Na2SO4 on day 98 and from 3% to 17% after 1 day [41]. This indicates that the inclusion of Na2SO4 as an activator result in significant improvement of compressive strength, particularly at an early age. On the contrary, as Shi and Day (1995) [78] reported, the use of NaCl2 as an activator in smaller dosages (1–2%) lowered the compressive strength of HVFA binders while a dosage above 3% resulted in improved compressive strength. Small dosages of Na2SO4 and CaC12 can increase the pozzolanic reactivity of HVFA binders. Na2SO4 significantly improves compressive strength at an early age; however, its effect at a late age depends on the dosage and type of FA. CaCl2 has a varying effect on HVFA binders’ compressive strength at both early and intermediate ages but significantly improves the late age strength for dosages exceeding 3% [79]. Similarly, CaSO4, NaOH, and sodium silicate activation of HVFA using accelerated curing, including direct electric curing, was reported to yield a large amount of ettringite and early-age strength [24,53].

Alkali activation breaks the glass phases of FA to increase the pozzolanic reaction while sulphate activation reacts the SO4 with Al2O3 in the FA glass phase to produce ettringite. FA alkali activation is a physicochemical process that gives HVFA substantial cementitious and bonding properties. The extent of alkali activation is governed by vitreous phase content, particle size distribution, and the proportion of reactive silica in the FA, which will react with alumina and alkalis [80]. For optimum alkali activation, the following specifications should be considered:

- The content of unburnt material in the HVFA must not exceed 5%.

- Fe2O3 content must not exceed 10%.

- Reactive silica content should be above 40% and below 50%.

- Percentage passing of FA particles below 45 micro metres should exceed 80% [53,80].

3.2. Durability of High-Volume Fly Ash Binders

Durability refers to the capability of HVFA to resist weathering, chemical attacks, and abrasion while maintaining its properties. It has been investigated using various methods that are discussed in this section, including permeability, sorptivity, tortuosity, chloride penetration resistance, resistance to sulphate attacks, etc. To understand the durability characteristic of HVFA binders, this section further reviews the literature pertaining to the durability of HVFA binders in corrosive environments.

3.2.1. Water Absorption, Permeability, and Sorptivity

The sorptivity test is a measure of the binder’s capillary suction when in direct contact with water. Sorptivity is evaluated using the ASTM C 1585 standard [20] after passing 90, 180, and 270 days of water curing followed by drying until reaching constant mass. Sorptivity was fully modelled by Hall (1989) using a square-root-time relationship. HVFA binders are placed in contact with water on one surface (<5 mm deep) while the other is sealed to allow for uniaxial water absorption only, and the mass gain is measured at definite intervals for the first six hours. The rate of sorption is the gradient of the line of best fit drawn on the plot of absorption against the square root of the period [81,82]. The values of sorptivity can be computed using the following equation.

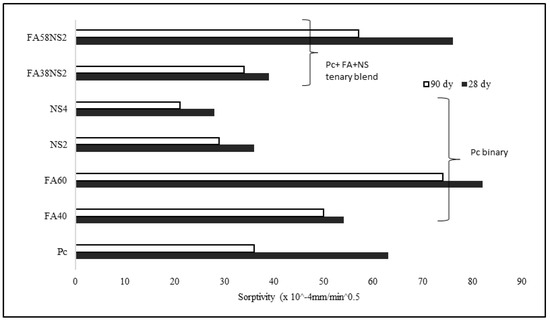

where S is the coefficient of sorptivity in mm/min1/2), , A is the surface exposed to water in mm2, t is the time in minutes, ∇w is a change in weight, and d is the density of water in g/mm3 (Swathi and Asadi 2022) [18]. Figure 6 illustrates that the sorptivity of binary mixes of HVFA binders without additives is significantly higher at both early age and late stages compared with Pc systems. At 60% FA dosages, the sorptivity is almost twice that of Pc binders. Although nano silica mix designs may significantly lower the sorptivity of ternary blends of FA and Pc, the drop at FA dosages above 50% is insignificant as seen in Figure 6. However, at lower FA dosages below 40%, nano silica particles of 2% dosage have a significant effect [65,68].

Figure 6.

A comparative analysis of behaviour of sorptivity in Pc, HVFA, and nano silica containing HVFA binder systems (Modified from Supit and Shaikh 2021) [83].

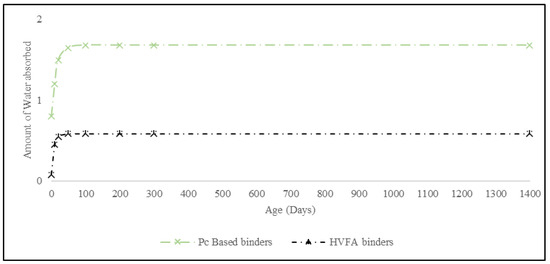

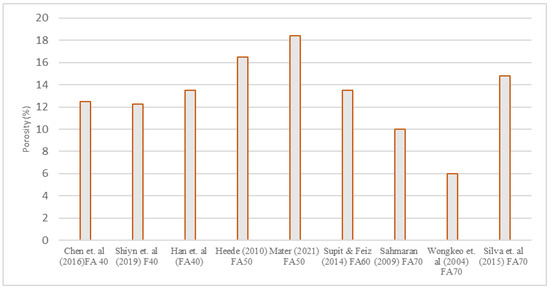

Swathi and Asadi (2022) [18] reported results indicating that HVFA binders absorbed around 30% of the total water absorbed by Pc binders (see Figure 7). Figure 8 shows porosity findings by various authors and, also, illustrates a trend indicating a significant drop in the porosity of HVFA binders with an increase in FA dosages. Yu et al. (2017) [7] also noted that compared with Pc binders, HVFA binders containing 80% FA have low initial rates of water absorption and high late-stage water absorption [7]. This was attributed to early-age low w/b ratio and high FA content in late age. Similarly, Palla et al. [51] reported that at 7 days, adding HVFA binders with very little (0.05%) or no nanoparticles resulted in higher water absorption and permeable pores due to the insignificant presence of hydration products, which renders the matrix porous and less dense. Palla et al. (2017) [51] reported that the incorporation of 2% of nano silica particles in HVFA binders reduced the permeable pores at 7 days and 28 days by 19% and 28%, respectively. Resultantly, the binders exhibited a drop in water absorption of 24% and 44%, respectively. Yu et al. [7] reported similar results after blending HVFA with 2% silica fume and concluded that blending HVFA with silica fume significantly reduced sorptivity. Yu et al. [7] reported a decline in water absorption and sorptivity of silica nanoparticle (2%)-blended HVFA binders of 20% and 46%, respectively. Palla et al. (2017) [51] reported that silica nanoparticles reduced porosity, sorptivity, and water absorption up to 25–40% and densified the interfacial transition zone. The drop in water absorption was attributed to the reduced number of capillary voids and a denser microstructure of HVFA blended with nano silica. Higher sorptivity in the absence of nano silica was attributed to a higher pore density in the matrix, while in the case of 2% nano silica-blended matrix, the sorptivity drop was due to a denser microstructure and a resultant drop in interconnected capillary voids. The void drop was influenced by the early pozzolanic activity of nano silica particles and the late age pozzolanic activity of FA, which resulted in a dense microstructure [7,65].

Figure 7.

Comparison of high-strength Pc binder and high-strength HVFA binder water absorption (Modified from Swathi and Asadi 2022) [18].

Figure 8.

Literature review of HVFA binders’ porosity at age 28 days indicating a general gradual increase in porosity from 40–50% FA dosages and a decline in porosity for dosages above 50% [81,84,85,86,87,88,89].

These findings are consistent with observations made by (i) Li et al. [90], indicating a drop in absorption by 26.8% at the incorporation of 2% nano silica [41]; (ii) Shirgir et al. (2011) [91], indicating a drop in absorption by 23% at the incorporation of 5% of micro silica; (iii) Li, indicating a drop in water absorption by 84.4%, 82.1%, 75.3%, and 74.3% with 0.25%, 0.30%, 0.35%, and 0.40%, respectively, by simultaneously incorporating 10% micro silica and 2% micro silica; (iv) Rahmat et.al, indicating a drop in absorption by 60%, 57%, and 41% after the incorporation of 3% nanoparticles of CuO, SiO2, and Fe2O3, respectively [84]; and (v) Jalal et al. [92] indicating a drop in water absorption of 46% and 50% at the incorporation of 2% nano silica and 10% silica fume simultaneously [92]. This has been attributed to the nanoparticles’ size gradient, which enables them to occupy micro/nano-sized voids and enhance the structure and density of binders.

Permeability is the ability of water and other aggressive ions, such as Cl and SO4, to penetrate concrete and corrode HFVA binders. Low permeability slows acidic ions’ penetration into the HVFA matrix, thus improving resistance to chemical attacks. Resistance to chemical attack highly depends on matrix porosity, permeability, and CH content. Assi et al. (2016) [30] investigated the effect of geopolymers containing an FA/Pc ratio of 85/15 and concluded that HVFA systems blended with silica fume can competitively replace Pc. Assi et al. (2016) [30] reported that there was a 7.03% drop in the void ratio and an 18.9% drop in absorption after the immersion when Pc content in the geopolymer was reduced from 15% Pc to 0%. Hossain et al. (2020) [47] studied the water absorption and sorptivity of alkali-activated binders by blending rice husk ash, fly ash, and slag activated with 2.5 M NaOH solution. It was reported that water absorption and sorptivity of the early-age alkali-activated FA binders were significantly higher than those of Pc [41,47].

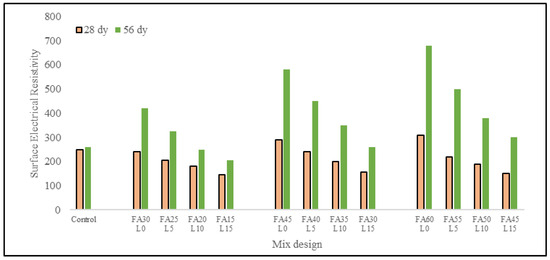

3.2.2. Resistivity

Resistivity is directly related to the HVFA matrix microstructure [7]. Surface electrical resistivity is an indirect measure of the porosity, diffusivity, microstructure, and chloride ion penetration [93]. An increase in the matrix porosity ultimately yields increased pore water and reduced resistivity. Surface resistivity can be conducted using the AASHTO TP 95 standard procedure. Du et al. studied the resistivity of HVFA mortars of 84, 75, and 60% FA by weight, and all the HVFA binders exhibited a high surface resistivity from 40.7 and 138.6 kΩcm, which falls under the very low chloride permeability group of the AASHTOT59 standard [71]. Other HVFA studies of chloride penetration has shown that it drops with an increase in FA dosage [94]. It has been reported that HVFA binders in early stages between 1 to 3 days and up to 14 days depict higher resistivity at 2% nano silica-blended matrixes compared with binders without nano silica. At 0 to 0.5%, nano silica-blended HVFA specimens exhibit lower resistivity due to reduced hydration and a porous matrix. Higher resistivity at 2% nano silica blending of HVFA is attributed to the combined pozzolanic reactivity of nano silica and FA in both early and late stages, resulting in dense, less porous matrices [7].

Maurya and Kothiyal (2023) [27] investigated the effect of incorporating graphite oxide (0.005 to 0.04%) on HVFA binder electrical resistivity [27]. They reported that the matrix resistivity gradually increases with an increase in graphite oxide dosage throughout the life of the mortar. The optimum resistivity increment was reported as 0.04% graphite oxide content at 90 days. Duran-Herrera et al. (2019) [93] investigated the effect of replacing Pc with FA of up to 60% by weight and concluded that electrical resistivity drops with an increase in FA dosage in early ages (see Figure 9) [93]. Late-stage electrical resistivity of HVFA binders was reported to rise significantly above Pc due to the late pozzolanic reaction of FA, which densifies binder matrixes [57,93]. Current flow through the hydrated binder is caused by the electrolytic flow of ions present in the pore solution. Pc replacement with FA reduces the concentration of alkali ions (Na+; K+), leading to a lower ionic conductivity and a higher electrical resistivity [93].

Figure 9.

Literature review of the influence of lime (L) and FA content in HVFA binders on surface resistivity (Modified from Duran-Herrera et al., 2019) [93].

3.2.3. Durability of HVFA Binders in Corrosive Environments

The durability in acidic medium has been studied in detail by various authors [17,95]. Sulfuric acid has very little deteriorating effect on HVFA binders [1]. It has been reported that HVFA binders are more acid-resistant compared with Pc binders. Mehta et al. (2017) [1] reported that HVFA binders gain mass within the first month when exposed to 2% sulphuric acid and that HVFA binders experience mass loss proportional to the concentration of sulphuric acid. Mass gain within the first 28 days is attributed to the absorption of sulphuric acid in the pores within the HVFA binder. Hashimoto et al., 2017 [96] reported that HVFA pastes are highly resistant to the sulfuric acid solution at temperatures between 60 °C and 220 °C. Exposure of HVFA to sulfuric acid exceeding 4 days results in the formation of natroalunite crystals, which adds to the dense matrix of the binder and increases the compressive strength [79]. Similarly, Hashimoto et al. (2017) [96] concluded that 5% Na2SO4 has no deteriorating effect on HVFA binders whereas MgSO4 has an acute decalcification effect yielding gypsum as a product. HVFA binders are satisfactorily resistant to chloride attacks with short exposures characterised by no major change in compressive strength [55]. Donatello et al. (2013) [55] studied the durability of HVFA binders with an FA/Pc ratio of 80/20 in aggressive solutions activated by Na2SO4. Shane reported that the overall 90-day resistance of the HVFA binder was satisfactory in Na2SO4 solutions at 4.4% and in ASTM seawater. The HVFA binders exhibited significant initial resistance to an HCl (0.1 M) attack of a very aggressive concentration. However, prolonged exposure of 90 days reduced the compressive strength by 90%. On the contrary, 90-day exposure of HVFA binders to 4.4% Na2SO4 solution resulted in enhanced compressive strength by 25% [55].

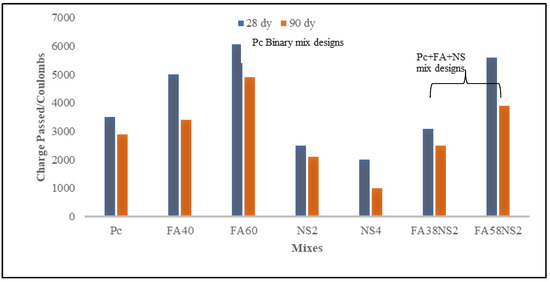

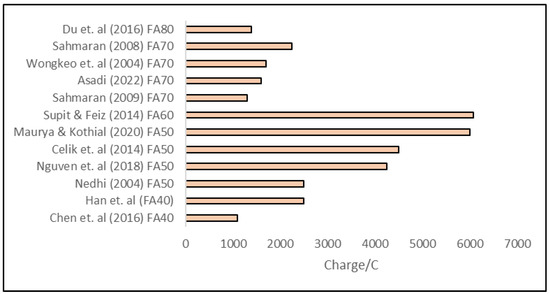

3.2.4. Chloride Permeability

Chloride permeability can be investigated using the ASTM C1202-07 standard procedure [20], the diffusion tank test. Chloride tests seek to establish the HVFA resistance to chloride diffusion or ingress. Water-saturated specimens are subjected to an electric current and the chloride penetration is expressed as the total charge passed during the test after 6 h. The results can be interpreted using Table 4. The smaller the charge, the lower the chloride penetration. Generally, any value lower than 2000 coulombs depicts high chloride resistance, a value of 2000 to 4000 coulombs indicates medium resistance, and a value higher than 4000 coulombs depicts lower resistance [37,65]. Swathi and Asadi (2020) [19] observed the passage of Cl− through mortar specimens of FA content ranging from 0% to 70% over 28 days of curing. They noted the least passage of Cl− in binder samples of 50% FA by weight at 1458 coulombs compared with binders containing 0, 25, and 70% FA. Overall, Swathi and Asadi (2022) [18] reported that Cl− penetration decreases with an increase in the FA dosage due to the formation of a denser microstructure and the release of C–S–H gel. Similar results were reported by Supit and Shaikh as illustrated in Figure 10 below, indicating that nano silica containing HVFA ternary mix designs could achieve Cl− penetration resistance almost similar to that of Pc systems at dosages close to 60% FA. This is consistent with the findings illustrated in Figure 11 from the analysis of various articles on charge passage through HVFA binders at 28 days. It is observed from Figure 11 that although most authors whose mix designs incorporated FA dosages above 60% indicate a fall within the high permeability zone, other authors reported results within low to medium permeability at FA dosages greater than 50% [24,97].

Table 4.

Interpretation of rapid chloride test charge penetration (Haque et al., 1998) [98].

Table 4.

Interpretation of rapid chloride test charge penetration (Haque et al., 1998) [98].

| Charge (Coulomb) | Permeability of Chloride Ion |

|---|---|

| >4000 | Permeability is High |

| 2000–4000 | Permeability is Moderate |

| 1000–2000 | Permeability is Low |

| 100–1000 | Permeability is Very Low |

| <100 | Negligible Permeability |

Figure 10.

Cl− Resistance of HFVA Binders; (Modified from Supit and Shaikh 2014) [73].

Figure 11.

Literature review of charge passage through HVFA binders at 28 days [18,64,73,88,99,100,101,102,103].

Nath and Sarker (2011) [104] reported that FA binders proved to have better resistance at both early and late ages. They observed that Cl− resistance increased with an increase in FA content. FA-based binders depicted high and moderate resistance to Cl− penetration at 28 and 180 days of age, respectively. Nath and Sarker (2011) [104] concluded that FA resulted in up to 45% drop in Cl− permeability at 28 days and up to 70% drop at 180 days [33]. The findings are consistent with Jalal et al.’s observations that even binders containing FA content of 15% result in a 24% increase in Cl− resistance. Jalal et al. [92] investigated the effect of nanoparticles on Cl− penetration and established that nano silica (10%) and silica (2%) fumes improved the Cl− resistance of FA-based binders. Wongkeo et al. (2013) [99] also established that at an equal w/b ratio, Pc binders exhibited lower resistance to chloride penetration compared with HVFA. However, Yu et al. (2017) [7] reported that a Pc binder containing nanoparticles exhibited higher Cl− resistance compared with HVFA binders without nanoparticles. Furthermore, Yu et al. [7] observed that early-age and late-stage HVFA Cl− penetration increased compared with Pc binders.

Nonetheless, Yu et al. [7] concluded that when blended with nanoparticles, the Cl− resistance of HVFA surpasses even that of Pc binders with the same proportion of nanoparticles. Results from Yu et al. [7] exhibited that at 2% nano silica blending, the Cl− permeability dropped by 38%. Yu reported that HVFA binders of 58% FA and 2% NS achieve high Cl− permeability, indicating a more connected pore structure. Yu et al. [7] argues that it is possible to attain medium resistance to Cl− penetration in HVFA systems if proper nano silica content is used to replace Pc [7]. This is consistent with several reports indicating that silica fume incorporation reduces Cl− penetration and porosity, thus improving the durability of HVFA by modifying the interfacial transition zone [9,65]. The incorporation of FA and micro silica in binders is one of the best ways to achieve a superior resistance to ion penetration. Cl− penetration can also be determined by exposure to powdered samples of the binder at a specific depth and by measuring the total chloride content using Volhard titration. Specimens are coated on all five sides except the one through which the chloride ingress is allowed. The procedure is outlined in the NT Build 443 (1996) for bulk diffusion as a transport mechanism to determine resistance to chloride penetration. After exposure to a corrosive environment, the specimens are drilled to a specific depth to determine the total chloride content using Volhard titration.

3.2.5. Microstructural Analysis

The mineralogical and microstructural characteristics of materials and samples of the HVFA binders can be analysed using various methods, including the scanning electron microscope (SEM), backscattered electron imaging (BSE), X-ray diffraction analysis (XRD), and mercury intrusion porosimetry (MIP). Observed presence or absence of a dense microstructure of HVFA binders can be used to confirm and explain observations made in sorptivity, permeability, and Cl− penetration tests. It is possible to investigate the hydration products in HVFA binders formed at various stages. To identify the morphology and chemical composition of formed hydrated products, SEM images and energy dispersive spectrum (EDS) can be used [10,105].

Supit and Shaihk (2015) [65] reported that the reaction between nanoparticles and CH crystals in HVFA binders containing nanoparticles generated a dense microstructure that reduced capillary pores, water permeability, and CL penetration based on SEM analysis. SEM analysis has been used to explain the early-age lower compressive strength of HVFA, which is attributed to the porous microstructure [65]. BSE analysis is used to identify constituent phases in pastes based on their brightness. The diverse hydration products are identified from the varying brightness of unhydrated cement particles, calcium hydroxide, other hydration products, CSH, and voids [10]. White sections show the unhydrated cement particles, black sections show voids or cracks, and grey sections show CH, other hydration products, and CSH.

Mercury intrusion porosimetry (MIP) was used by Supit and Shaihk (2015) [65] to investigate the durability of HVFA binders containing nano-silica after 28 days. The MIP analysis examined pores whose diameter ranged between 0.01 and 100 micrometres. The pores are broadly classified as large capillary, medium capillary, and gel pores based on their diameters of 0.05–10, 0.01–0.05, and <0.01 micrometres. Gel pores are micropores with no impact on permeability or strength, and they form a part of CSH. Capillary pores influence strength and durability; however, they decrease with hydration. MIP analysis of HVFA binders indicates more capillary pores than in Pc, which is attributed to slow hydration and generation of CSH due to the pozzolanic reaction of FA. Small amounts of nanoparticles create a larger surface area and more CSH is generated, thus lowering the concentration of capillary pores. Supit and Shaihk (2015) [65] reported that 2% nano silica HVFA can achieve a 25% lower cumulative pore volume than Pc. At 60% FA content, nano silica lowered the cumulative pore volume by 56%, respectively.

Swathi and Asadi (2022) [18] performed microstructural analysis through X-ray diffraction and (SEM) using the Rigaku mini flex 600 equipment of 40 kV, 15 mA, and a scanning range of (2θ) from 30° to 90° at 100 degrees per min [24]. They reported that at lower FA content, the samples (ranging from 0% to 70% FA) exhibited a significant frequency of microcracks and pores. Maurya and Kothial (2023) [27] reported that analysis of HVFA mortar using SEM shows a higher content of unreacted FA particles and that a microstructure density increases with FA until 50%, beyond which a loose matrix is observed [35]. They reported the presence of unhydrated FA spheres weakly attached to the hydrated cement products and, later, a decrement of FA particles with time and the production of CSH at 90 days [35].

Supit et al. (2014) [103] onducted an SEM microstructural analysis of 28-day-old HVFA pastes containing ultra-fine fly ash. They observed several white and black areas in the SEM images showing unhydrated products and voids, respectively, in HVFA pastes at 40–60% FA dosage. They also reported that very few black areas and white sections were noticed in pastes where there was an 8% dosage of ultra-fine ash replacement. Using BSE image analysis, Supit et al. (2014) [103] observed that the incorporation of UFFA, as a partial cement replacement in HVFA pastes, densified the microstructure, which led to the improvement of compressive strength. It is suggested that the particle packing effect of UFFA plays an important role in reducing the volume of pores and, ultimately, an improvement in the early-age compressive strength. They concluded that the strength development of mortars is largely influenced by the dosage of ultra-fine fly ash, which has finer particle sizes compared with the coarser class F fly ash.

Maurya and Kothial (2023) [27] investigated the microstructure of carbon-optimised HVFA binders using SEM. Functionalised carbon (0.005%) was blended with high-volume fly ash-based cement mortar at 50% FA dosage. At 90 days of age, they observed that SEM images of carbon-based HVFA showed hydrated FA, dense CSH gel, and CH crystals compared with that of Pc binders and HVFA binders without carbon, which showed irregular loose CSH gel and unhydrated FA and CH crystals, respectively. Similarly, Rakic et al. (2023) [106] used SEM to investigate the effects of Na2SO4, Na2CO3, and Na2SiO3 as chemical activators in HVFA binders containing 70% FA dosages. Using SEM image analysis, they observed that the HVFA pastes were significantly more porous than Pc binders. They reported the presence of unreacted clinker minerals observed as large irregular areas that appeared light grey in the SEM BSE images, similar to the observations of Supit et al. (2014). Rakic et al. (2023) [106] also reported that the hydration products of the HVFA binders were a mix of CASH, CSH, and aluminosilicate gels of different compositions. Using XRD analysis, Supit et al. (2014) [103] observed that the ultra-fine fly ash can effectively increase the CH consumption level of HVFA pastes and, hence, the production of additional CSH gels due to the higher amorphous SiO2 content in UFFA [10].

4. Discussion

The research trends indicate a negligible decrease in compressive strength at 35% FA but a considerable drop between 35% and 55% FA from 10% and 46% in compressive strength. Early strength has been noted to drop by over 60% at 70% FA and more. However, when additives are added to HVFA binders, performance is improved both in early and late stages. The inclusion of nanoparticles has been noted to reduce the drop in compressive strength to below 15%. HVFA binder incorporation of high FA content, e.g., 70% to 100% replacement of Pc, is still very difficult due to high carbonation, slow strength development, increased shrinkage, and other challenges highlighted in this research. The results revealed that in most of the findings, reduction in early-age tensile strength of HVFA and UHVFA binders has been observed, fluctuating from 11% to 26% at 40 to 70% FA. Additives have proved to enhance tensile strength in a similar manner as with compressive strength. A drop in tensile strength for 40 to 70% FA has been noted to follow an almost linear trend. While the inclusion of additives is important for enhancing the durability and strength properties of HVFA binders, a precise understanding or analysis of the FA used is crucial. This is even more important given that not only the FA varies based on the broad FA classification (Type F and C) but their properties also vary greatly within these classifications.

The review shows that there are varying findings pertaining to the performance of UHVFA and HVFA binders. However, the prospects are promising as the inclusion of certain nanoparticles and other materials blended with high volumes of FA > 50% has been shown to be feasible. To achieve this, proper mixes need to be advanced and different FA types may require their own mix designs. Nonetheless, UHVFA and HVFA binders can significantly lower CO2 emission by 70%, reduce embodied energy by up to 60%, and lower material costs by 15% [7]. For civil engineering projects where early compressive strength is not the determining factor of total performance, the practical application of HVFA is viable. The current work has described the various characteristics of HVFA binders with variable FA contents, ranging from close to 90% to 50%. The slow pozzolanic reaction of FA is the major cause of the HVFA binder’s low early-age strength. Research has shown the feasibility of enhancing this reactivity by using ultra-fine fly ash. Nano powders of SiO2 and CaCO3 have experimentally proved to enhance strength by improving hydration due to their high reactivity and smaller sizes. While industrial byproducts have been experimentally investigated on their ability to influence reactivity, silica fumes have proved to improve the reaction by creating a larger surface area.

5. Conclusions and Future Research

Analysis of Cl− penetration results indicates that as FA content approaches optima, the chloride penetration depth decreases at all stages. FA content of 35 to 55% has decreased early-age Cl− penetration depth by 1.5 to 1.8 times and 60% FA has been found to be optimum for Cl− resistance. The inclusion of nanoparticles also proved to enhance Cl− penetration by lowering it by over 80%. The research also establishes that in general, the early-age rate of HVFA binder water absorption is directly proportional to the FA content. As the FA content in HVFA/UHVFA binders approaches optima, the water absorption also increases significantly. However, the water absorption decreases at a late stage and the early-stage water absorption can be lowered by as much as 40% by adding nanoparticles.

Overall, mechanical and durability challenges associated with HVFA binders have been addressable by several measures. However, as the FA content increases, the techniques may be limited, hence the need to further study the development of high-strength durable UHVFA binders. Numerous measures, such as high-temperature curing, w/b ratio optimisation, physical or chemical activation treatment, admixing nanomaterials at the proper dosage, and incorporating fibres, can be used to make up for the loss in mechanical and durability properties caused by the introduction of HVFA in cement-based materials. Table 5 presents a summary of common strength and durability tests for HVFA binders.

Table 5.

Summary of common strength and durability tests for HVFA binders.

Further research needs to account for the contradictions within the current literature as highlighted in this research. For instance, some studies in the literature report that FA reduces the shrinkage properties of HVFA binders while others highlight that FA increases the shrinkage properties. Further, this research notes that most research are limited to the incorporation of 60–70% FA content in HVFA binders because some important minimum specifications are not met when high FA content is incorporated in some mortar composites. Thus, the research on methods and additives to improve HVFA binders at very high FA content remains a grey area. Moreover, the research noted the analysis of HVFA binder strength properties in isolation of durability properties in most of the extant literature.

FA reactivity is dependent on multiple factors in optimised proportion; hence, modification of one parameter may negatively influence the other. For instance, high w/b ratios can optimise the strength of HVFA binders while compromising early-age durability as it may introduce cracking. Therefore, future research should explore the combined durability and strength impacts of various optimising parameters or additives to ensure optimal HVFA mixes. The research also noted the existence of a wide range of findings on strength and durability analysis of HVFA binders, even within the same FA classification, in some instances leading to contradictory conclusions. This highlights the need for researchers to avoid overgeneralisation and test FA from different power plants on a case-by-case basis to establish specific HVFA strength and durability properties thereof. Furthermore, these findings question the adequacy of existing FA classes, especially for purposes of generalising scientific findings. Thus, further research should consider advancing newer classification systems of FA.

Author Contributions

Conceptualization, D.R., F.O. and I.M.; methodology, D.R., F.O. and I.M.; software, D.R.; validation, D.R. and F.O.; formal analysis, F.O.; investigation, D.R. and F.O.; data curation, D.R. and F.O.; writing—original draft preparation, D.R.; writing—review and editing, F.O. and I.M.; supervision, F.O.; project administration, F.O. and I.M.; funding acquisition, I.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the National Research Foundation, NRF (Grant Number-SRUG2205035848). Opinions and conclusions are those of the authors and are not necessarily attributable to the NRF. The work is supported and part of collaborative research at the Centre of Applied Research and Innovation in the Built Environment (CARINBE).

Data Availability Statement

Data used is available from the corresponding author on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mehta, A.; Siddique, R. Sulfuric acid resistance of fly ash based geopolymer concrete. Constr. Build. Mater. 2017, 146, 136–143. [Google Scholar] [CrossRef]

- Zhu, H.; Hu, W.H.; Mehthel, M.; Villette, T.; Vidal, O.S.; Nasser, W.N.; Li, V.C. Engineered cementitious composites (ECC) with a high volume of volcanic ash: Rheological, mechanical, and micro performance. Cem. Concr. Compos. 2023, 139, 105051. [Google Scholar] [CrossRef]

- Juenger, G.; Winnefeld, F.; Provis, J.L.; Ideker, J. Advances in alternative cementitious binders. Cem. Concr. Res. 2011, 41, 1232–1243. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.J. 1—Introduction to geopolymers. In Geopolymers; Provis, J.L., Van Deventer, J.S.J., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Sawston, UK, 2009; pp. 1–11. [Google Scholar]

- Lloyd, R.R.; Provis, J.L.; van Deventer, J.S.J. Microscopy and microanalysis of inorganic polymer cements. 2: The gel binder. J. Mater. Sci. 2009, 44, 620–631. [Google Scholar]

- Shi, C.; Pavel, K.; Roy, D. Alkali-Activated Cements and Concretes. 2003. Available online: https://api.semanticscholar.org/CorpusID:136449923 (accessed on 25 November 2023).

- Yu, J.; Leung, C.K.Y. Strength improvement of strain-hardening cementitious composites with ultrahigh-volume fly ash. J. Mater. Civ. Eng. 2017, 29, 05017003. [Google Scholar] [CrossRef]

- Yu, J.; Li, G.; Leung, C.K.Y. Hydration and physical characteristics of ultrahigh-volume fly ash-cement systems with low water/binder ratio. Constr. Build. Mater. 2018, 161, 509–518. [Google Scholar] [CrossRef]

- Yu, J.; Mishra, D.K.; Wu, C.; Leung, C.K.Y. Very high volume fly ash green concrete for applications in India. Waste Manag. Res. 2018, 36, 520–526. [Google Scholar] [CrossRef]

- Promentilla, M.A.B.; Sugiyama, T.; Hitomi, T.; Takeda, N. Quantification of tortuosity in hardened cement pastes using synchrotron-based X-ray computed microtomography. Cem. Concr. Res. 2009, 39, 548–557. [Google Scholar] [CrossRef]

- Sun, Q.; Zhu, H. Mix proportion of fly ash concrete based on stable paste to aggregate ratio, Liaoning Gongcheng Jishu Daxue Xuebao (Ziran Kexue Ban). J. Liaoning Tech. Univ. (Nat. Sci. Ed.) 2012, 31, 370–373. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84863502921&partnerID=40&md5=0dde9035fb05b346f24fe998038e172c (accessed on 25 November 2023).

- Vaishnavi, M.; Kanta Rao, M. Durability of High Volume Flyash Concrete; Matsagar, V., Ed.; Springer: New Delhi, India, 2015; pp. 1823–1835. [Google Scholar] [CrossRef]

- Herath, C.; Gunasekara, C.; Law, D.W.; Setunge, S. Permeation and Carbonation of Nano-HVFA Composites: Long-Term Studies. J. Mater. Civ. Eng. 2023, 35. [Google Scholar] [CrossRef]

- Sugandhini, H.K.; Nayak, G.; Shetty, K.K.; Kudva, L.P. Behavior of a high-volume fly ash fiber-reinforced cement composite toward magnesium sulfate: A long-term study. Innov. Infrastruct. Solut. 2023, 8, 328. [Google Scholar] [CrossRef]

- Provis, J.L.; Fernández-Jiménez, A.; Kamseu, E.; Leonelli, C.; Palomo, A. Binder chemistry—Low-calcium alkali-activated materials. RILEM State Art Rep. 2014, 13, 93–123. [Google Scholar] [CrossRef]

- Donatello, S.; Kuenzel, C.; Palomo, A.; Fernández-Jiménez, A. High temperature resistance of a very high volume fly ash cement paste. Cem. Concr. Compos. 2014, 45, 234–242. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Swathi, V.; Asadi, S.S. An experimental investigation on mechanical, durability and Microstructural Properties of high-volume fly ash based concrete. J. Build. Pathol. Rehabil. 2022, 7, 36. [Google Scholar] [CrossRef]

- Swathi, V.; Asadi, S.S.; Poluraju, P. An integrated methodology for structural performance of high-volume fly ash concrete beams using hybrid fibers. Mater. Today Proc. 2020, 27, 1630–1635. [Google Scholar] [CrossRef]

- American Society for Testing and Materials, Building Standards. Available online: https://www.astm.org/products-services/standards-and-publications/standards/building-standards.html (accessed on 25 November 2023).

- Myadaraboina, H.; Law, D.; Patanikuni, I. Very high volume fly ash concrete utilizing microash and hydrated lime, with silica fume. Adv. Cem. Res. 2022, 34, 388–398. [Google Scholar] [CrossRef]

- Gunasekara, C.; Law, D.W.; Setunge, S. Design of ternary blend high-volume fly ash concrete mixes using hydrated lime. In Proceedings of the 6th International Conference on Durability of Concrete Structures, ICDCS 2018, Leeds, UK, 18–20 July 2018; pp. 127–134. [Google Scholar]

- Alaka, H.A.; Oyedele, L.O. High volume fly ash concrete: The practical impact of using superabundant dose of high range water reducer. J. Build. Eng. 2016, 8, 81–90. [Google Scholar] [CrossRef]

- Kumar, S.; Rai, B. A review of durability properties of SCC with high volume fly Ash. Int. J. Civ. Eng. Technol. 2018, 9, 1023–1038. [Google Scholar]

- Babu, T.S.R.; Neeraja, D. A experimental study of natural admixture effect on conventional concrete and high volume class F flyash blended concrete. Case Stud. Constr. Mater. 2017, 6, 43–62. [Google Scholar] [CrossRef]

- Ortega, J.M.; Branco, F.G.; Pereira, L. Long-Term Behavior Related to Water Ingress in Mortars Which Combine Expanded and Natural Cork Lightweight Aggregates and Eco-Friendly Cements. Buildings 2023, 13, 1651. [Google Scholar] [CrossRef]

- Maurya, S.K.; Kothiyal, N.C. Effect of graphene oxide and functionalized carbon nanotubes on mechanical and durability properties of high-volume fly-ash cement nanocomposite. Eur. J. Environ. Civ. Eng. 2023, 28, 859–875. [Google Scholar] [CrossRef]

- Baert, G.; Poppe, A.-M.; De Belie, N. Strength and durability of high-volume fly ash concrete. Struct. Concr. 2008, 9, 101–108. [Google Scholar] [CrossRef]

- Kan, L.; Shi, R.; Zhu, J. Effect of fineness and calcium content of fly ash on the mechanical properties of Engineered Cementitious Composites (ECC). Constr. Build. Mater. 2019, 209, 476–484. [Google Scholar] [CrossRef]

- Assi, L.N.; Deaver, E.E.; ElBatanouny, M.K.; Ziehl, P. Investigation of early compressive strength of fly ash-based geopolymer concrete. Constr. Build. Mater. 2016, 112, 807–815. [Google Scholar] [CrossRef]

- Jayalin, D.; Vellingiri, N.; Janaki Raman, S. Experimental research on durability properties of high-volume fly ash concrete with polypropylene fibre. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 1039–1042. [Google Scholar]

- Turk, K.; Nehdi, M.L. Coupled effects of limestone powder and high-volume fly ash on mechanical properties of ECC. Constr. Build. Mater. 2018, 164, 185–192. [Google Scholar] [CrossRef]

- Ye, H.; Huang, L. Shrinkage Characteristics of Alkali-Activated High-Volume Fly-Ash Pastes Incorporating Silica Fume. J. Mater. Civ. Eng. 2020, 32, 04020307. [Google Scholar] [CrossRef]

- Henry, M.; Yamashita, H.; Nishimura, T.; Kato, Y. Properties and mechanical-environmental efficiency of concrete combining recycled rubber with waste materials. Int. J. Sustain. Eng. 2012, 5, 66–75. [Google Scholar] [CrossRef]

- Babalu, R.; Anil, A.; Sudarshan, K.; Amol, P. Compressive strength, flexural strength, and durability of high-volume fly ash concrete. Innov. Infrastruct. Solut. 2023, 8, 154. [Google Scholar] [CrossRef]

- Kumar, P.; Kaushik, S.K. Interfacial transition zone in HSC—Effect of fly ash and micro silica. Indian Concr. J. 2005, 79, 19–24. [Google Scholar]

- Bilodeau, A.; Mohan Malhotra, V. High-volume fly ash system: Concrete solution for sustainable development. ACI Struct. J. 2000, 97, 41–48. [Google Scholar]

- Naik, T.R.; Ramme, B.W.; Kraus, R.N.; Siddique, R. Long-term performance of high-volume fly ash concrete pavements. ACI Mater. J. 2003, 100, 150–155. [Google Scholar]

- Bouzoubaâ, N.; Bilodeau, A.; Sivasundaram, V.; Chakraborty, A.K. Mechanical properties and durability characteristics of high- volume fly ash concrete made with ordinary portland cement and blended portland fly ash cement. Am. Concr. Inst. ACI Spec. Publ. 2007, SP-242, 303–320. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84907163749&partnerID=40&md5=e4ed213d8a9c7183b3c92abf0c395de5 (accessed on 25 November 2023).

- Yang, E.-H.; Yang, Y.; Li, V.C. Use of high volumes of fly ash to improve ECC mechanical properties and material greenness. ACI Mater. J. 2007, 104, 620–628. [Google Scholar]

- Kumar, B.; Sinha, S.; Chakravarty, H. Effect of nano iron oxide on strength and durability characteristics of high-volume fly ash concrete for pavement construction. Int. J. Recent Technol. Eng. 2019, 8, 4365–4373. [Google Scholar] [CrossRef]

- Yu, J.; Mishra, D.K.; Hu, C.; Leung, C.K.Y.; Shah, S.P. Mechanical, environmental and economic performance of sustainable Grade 45 concrete with ultrahigh-volume Limestone-Calcined Clay (LCC). Resour. Conserv. Recycl. 2021, 175, 105846. [Google Scholar] [CrossRef]

- Herath, C.; Law, D.W.; Gunasekara, C.; Setunge, S. Sulphate and acid resistance of HVFA concrete incorporating nano silica. Constr. Build. Mater. 2023, 392, 132004. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Z.; Yang, Y.; Yao, Y. Measurement and correlation of ductility and compressive strength for engineered cementitious composites (ECC) produced by binary and ternary systems of binder materials: Fly ash, slag, silica fume and cement. Constr. Build. Mater. 2014, 68, 192–198. [Google Scholar] [CrossRef]

- Zhang, W.; Yao, X.; Yang, T.; Liu, C.; Zhang, Z. Increasing mechanical strength and acid resistance of geopolymers by incorporating different siliceous materials. Constr. Build. Mater. 2018, 175, 411–421. [Google Scholar] [CrossRef]

- Poon, C.S.; Lam, L.; Wong, Y.L. Study on high strength concrete prepared with large volumes of low calcium fly ash. Cem. Concr. Res. 2000, 30, 447–455. [Google Scholar] [CrossRef]

- Hossain, M.M.; Karim, M.R.; Elahi, M.M.A.; Zain, M.F.M. Water absorption and sorptivity of alkali-activated ternary blended composite binder. J. Build. Eng. 2020, 31, 101370. [Google Scholar] [CrossRef]

- Zhu, Y.; Yang, Y.Z.; Yao, Y. Effect of high volumes of fly ash on flowability and drying shrinkage of engineered cementitious composites. Mater. Sci. Forum 2011, 675–677, 61–64. [Google Scholar] [CrossRef]

- Xi, X.; Jiang, S.; Yin, C.; Wu, Z. Experimental investigation on cement-based foam developed to prevent spontaneous combustion of coal by plugging air leakage. Fuel 2021, 301, 121091. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.L.; Poon, C.S. Degree of hydration and gel/space ratio of high-volume fly ash/cement systems. Cem. Concr. Res. 2000, 30, 747–756. [Google Scholar] [CrossRef]

- Palla, R.; Karade, S.R.; Mishra, G.; Sharma, U.; Singh, L.P. High strength sustainable concrete using silica nanoparticles. Constr. Build. Mater. 2017, 138, 285–295. [Google Scholar] [CrossRef]

- Wallah, S.E.; Rangan, B.V. Low-Calcium Fly Ash-Based Geopolymer Concrete: Long-Term Properties; Research Report GC2; Faculty of Engineering, Curtin University of Technology: Perth, Australia, 2006. [Google Scholar]

- Bouzoubaâ, N.; Zhang, M.H.; Malhotra, V.M. Mechanical properties and durability of concrete made with high-volume fly ash blended cements using a coarse fly ash. Cem. Concr. Res. 2001, 31, 1393–1402. [Google Scholar] [CrossRef]

- Velandia, D.; Lynsdale, C.; Provis, J.L.; Ramirez, F. Activated hybrid cementitious system, a green alternative for concrete production. Am. Concr. Inst. ACI Spec. Publ. 2017, SP 320, 1–10. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85043367483&partnerID=40&md5=1cc77f6d38b03c733083620d0bc052db (accessed on 25 November 2023).

- Donatello, S.; Palomo, A.; Fernández-Jiménez, A. Durability of very high-volume fly ash cement pastes and mortars in aggressive solutions. Cem. Concr. Compos. 2013, 38, 12–20. [Google Scholar] [CrossRef]

- Samhitha, K.V.; Reddy, V.S.; Rao, M.V.S.; Shrihari, S. Performance evaluation of high-strength high-volume fly ash concrete. Int. J. Recent Technol. Eng. 2019, 8, 5990–5994. [Google Scholar] [CrossRef]

- Doven, A.G.; Pekrioglu, A. Material properties of high-volume fly ash cement paste structural fill. J. Mater. Civ. Eng. 2005, 17, 686–693. [Google Scholar] [CrossRef]

- Mohammed, T.; Aguayo, F.; Nodehi, M.; Ozbakkaloglu, T. Engineering properties of structural lightweight concrete containing expanded shale and clay with high volume class F and class C fly ash. Struct. Concr. 2023, 24, 4029–4046. [Google Scholar] [CrossRef]

- Huang, C.H.; Lin, S.K.; Chang, C.S.; Chen, H.J. Mix proportions and mechanical properties of concrete containing very high-volume of Class F fly ash. Constr. Build. Mater. 2013, 46, 71–78. [Google Scholar] [CrossRef]

- Liu, J.; Li, A.; Yang, Y.; Wang, X.; Yang, F. Dry-wet cyclic sulfate attack mechanism of high-volume fly ash self-compacting concrete. Sustainability 2022, 14, 13052. [Google Scholar] [CrossRef]

- Feng, Q.-G.; Yang, Y.; Yang, L.-F.; Chen, Z.; Zhu, H.-Y. Durability of high-volume fly ash concrete with low water binder. Wuhan Ligong Daxue Xuebao/J. Wuhan Univ. Technol. 2009, 31, 148–150+154. [Google Scholar]

- Flegar, M.; Ram, K.; Serdar, M.; Bosnar, K.; Scrivener, K. Durability Challenges of Low-Grade Calcined Clay Opposed to High-Volume Fly Ash in General Purpose Concrete. Adv. Civ. Eng. Mater. 2023, 12, 237–250. [Google Scholar] [CrossRef]

- Gu, P.; Beaudoin, J.J.; Zhang, M.-H.; Malhotra, V.M. Performance of steel reinforcement in Portland cement and high-volume fly ash concretes exposed to chloride solution. ACI Mater. J. 1999, 96, 551–558. [Google Scholar]

- He, Z.-H.; Du, S.-G.; He, L.-L. Compressive strengths of high volume fly ash concrete containing rice husk ash. J. Adv. Microsc. Res. 2016, 11, 72–76. [Google Scholar] [CrossRef]

- Supit, S.; Shaikh, F. Durability properties of high-volume fly ash concrete containing nano-silica. Mater. Struct. 2015, 48, 2431–2445. [Google Scholar] [CrossRef]

- Bürge, T.A. High strength lightweight concrete with condensed silica fume. In American Concrete Institute, ACI Special Publication; American Concrete Institute: Farmington Hills, MI, USA, 1983; pp. 731–745. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85114486182&partnerID=40&md5=fdfb43b43846819e8146152fab89ae36 (accessed on 25 November 2023).

- Kumar, B.; Sinha, S.; Chakravarty, H. Study of Effect of Nano-Silica on Strength and Durability Characteristics of High-Volume Fly Ash Concrete for Pavement Construction. Civ. Eng. J. 2019, 5, 1341–1352. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M. Compressive strength and durability of high-volume fly ash concrete reinforced with calcium carbonate nanoparticles. Fill. Reinf. Adv. Nanocomposites 2015, 275–307. [Google Scholar] [CrossRef]

- Solikin, M.; Setunge, S.; Patnaikuni, I. The influence of lime water as mixing water on the compressive strength development of high volume ultra fine fly ash mortar. In Proceedings of the ISEC 2011—6th International Structural Engineering and Construction Conference: Modern Methods and Advances in Structural Engineering and Construction, Zurich, Switzerland, 21–26 June 2011; pp. 1169–1174. Available online: https://rpsonline.com.sg/proceedings/9789810879204/html/978-981-08-7920-4_S3-M027.xml (accessed on 25 November 2023). [CrossRef]

- Fu, C.; Ling, Y.; Ye, H.; Jin, X. Chloride resistance and binding capacity of cementitious materials containing high volumes of fly ash and slag. Mag. Concr. Res. 2021, 73, 55–68. [Google Scholar] [CrossRef]

- Li, G. Properties of high-volume fly ash concrete incorporating nano-SiO2. Cem. Concr. Res. 2004, 34, 1043–1049. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, Y.; Jiang, Q.; Sun, G. In-situ monitoring of early-age electrical resistivity change process of cement-based materials. Dongnan Daxue Xuebao (Ziran Kexue Ban)/J. Southeast Univ. (Nat. Sci. Ed.) 2012, 42, 378–382. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M. Mechanical and durability properties of high volume fly ash (HVFA) concrete containing calcium carbonate (CaCO3) nanoparticles. Constr. Build. Mater. 2014, 70, 309–321. [Google Scholar] [CrossRef]

- El-Chabib, H.; Ibrahim, A. The performance of high-strength flowable concrete made with binary, ternary, or quaternary binder in hot climate. Constr. Build. Mater. 2013, 47, 245–253. [Google Scholar] [CrossRef]

- Jia, Y.; Aruhan, B.; Yan, P. Natural and accelerated carbonation of concrete containing fly ash and GGBS after different initial curing period. Mag. Concr. Res. 2012, 64, 143–150. [Google Scholar] [CrossRef]

- Balakrishnan, B.; Maghfouri, M.; Alimohammadi, V.; Asadi, I.; Roychand, R. The acid and chloride permeability resistance of masonry cement plaster mortar incorporating high-volume fly ash content. J. Build. Eng. 2024, 86, 108783. [Google Scholar] [CrossRef]

- Rashad, A.M.; Khalil, M.H.; El-Nashar, M.H. Insulation efficiency of alkali-activated lightweight mortars containing different ratios of binder/expanded perlite fine aggregate. Innov. Infrastruct. Solut. 2021, 6, 156. [Google Scholar] [CrossRef]

- Shi, C.; Day, R.L. Chemical Activation of Lime-Slag Blends. In SP-153: Fly Ash, Silica Fume, Slag, and Natural Pozzolans in Concrete Proceedings Fifth International Conference Milwauk; American Concrete Institute: Farmington Hills, MI, USA, 1995; Available online: https://api.semanticscholar.org/CorpusID:138690716 (accessed on 25 November 2023).

- Kumar, P.; Singh, N. Influence of recycled concrete aggregates and Coal Bottom Ash on various properties of high volume fly ash-self compacting concrete. J. Build. Eng. 2020, 32, 101491. [Google Scholar] [CrossRef]

- Malhotra, V.M. High-performance HVFA concrete: A solution to the infrastructural needs of India. Indian Concr. J. 2002, 76, 103–107. [Google Scholar]

- Van den Heede, P.; Gruyaert, E.; De Belie, N. Transport properties of high-volume fly ash concrete: Capillary water sorption, water sorption under vacuum and gas permeability. Cem. Concr. Compos. 2010, 32, 749–756. [Google Scholar] [CrossRef]

- Joseph, G.; Ramamurthy, K. Influence of fly ash on strength and sorption characteristics of cold-bonded fly ash aggregate concrete. Constr. Build. Mater. 2009, 23, 1862–1870. [Google Scholar] [CrossRef]

- Supit, S.; Shaikh, A. Correction to: Durability properties of high-volume fly ash concrete containing nano-silica. Mater. Struct./Mater. Et Constr. 2021, 54, 237. [Google Scholar] [CrossRef]

- Rahmat, S.; Tangtermsirikul, S.; Saengsoy, W. Properties of Pastes and Mortars Containing Ammonia Contaminated Fly Ash. Master’s Thesis, Thammasat University, Bangkok, Thailand, 2021. [Google Scholar]

- Han, J.; Fang, H.; Wang, K. Design and control shrinkage behavior of high-strength self-consolidating concrete using shrinkage-reducing admixture and super-absorbent polymer. J. Sustain. Cem. Based Mater. 2014, 3, 182–190. [Google Scholar] [CrossRef]

- Gu, C.; Yao, J.; Yang, Y.; Huang, J.; Ma, L.; Ni, T.; Liu, J. The relationship of compressive strength and chemically bound water content of high-volume fly ash-cement mortar. Materials 2021, 14, 6273. [Google Scholar] [CrossRef]

- Adesina, A.; Das, S. Development of sustainable engineered cementitious composites using recycled concrete aggregates-feasibility study based on mechanical properties. ACI Mater. J. 2021, 118, 97–107. [Google Scholar] [CrossRef]

- Şahmaran, M.; Li, V.C. Durability properties of micro-cracked ECC containing high volumes fly ash. Cem. Concr. Res. 2009, 39, 1033–1043. [Google Scholar] [CrossRef]

- Araujo, A.; Da Silva, N.; Sá, T.; Caldas, L.; Toledo Filho, R. Potential of Earth-Based Bamboo Bio-Concrete in the Search for Circular and Net-Zero Carbon Solutions to Construction Industry. IOP Conf. Ser. Earth Environ. Sci. Inst. Phys. 2022, 1122, 012043. [Google Scholar] [CrossRef]

- Li, Z.; Gong, J.; Du, S.; Wu, J.; Li, J.; Hoffman, D.; Shi, X. Nano-montmorillonite modified foamed paste with a high volume fly ash binder. RSC Adv. 2017, 7, 9803–9812. [Google Scholar] [CrossRef]

- Shirgir, B.; Hassani, A.; Khodadadi, A. Experimental study on permeability and mechanical properties of nanomodified porous concrete. Transp. Res. Rec. 2011, 2240, 30–35. [Google Scholar] [CrossRef]

- Jalal, M.; Mansouri, E.; Sharifipour, M.; Pouladkhan, A.R. Mechanical, rheological, durability and microstructural properties of high performance self-compacting concrete containing SiO2 micro and nanoparticles. Mater. Des. 2012, 34, 389–400. [Google Scholar] [CrossRef]

- Duran-Herrera, A.; De-León-Esquivel, J.; Bentz, D.P.; Valdez-Tamez, P. Self-compacting concretes using fly ash and fine limestone powder: Shrinkage and surface electrical resistivity of equivalent mortars. Constr. Build. Mater. 2019, 199, 50–62. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K.M. Performance evaluation of natural fiber reinforced high volume fly ash foam concrete cladding. Adv. Concr. Constr. 2021, 11, 151–161. [Google Scholar]

- Sugandhini, H.K.; Nayak, G.; Shetty, K.K.; Kudva, L.P. The Durability of High-Volume Fly Ash-Based Cement Composites with Synthetic Fibers in a Corrosive Environment: A Long-Term Study. Sustainability 2023, 15, 11481. [Google Scholar] [CrossRef]

- Hashimoto, S.; Kubota, K.; Ando, K.; Diko, Y.; Honda, S.; Iwamoto, Y. Effect of Grinding Treatment of Fly Ash on Compressive Strength of Hardened Geopolymers using Warm Press Method. In Proceedings of the MATEC Web Confence Engineering Technology International Conference 2016 (ETIC 2016), Ho Chi Minh City, Vietnam, 5–6 August 2016; Volume 97, p. 01120. Available online: https://www.matec-conferences.org/articles/matecconf/abs/2017/11/matecconf_etic2017_01120/matecconf_etic2017_01120.html (accessed on 25 November 2023). [CrossRef]