Eco-Friendly Geopolymer Composites Prepared from Agro-Industrial Wastes: A State-of-the-Art Review

Abstract

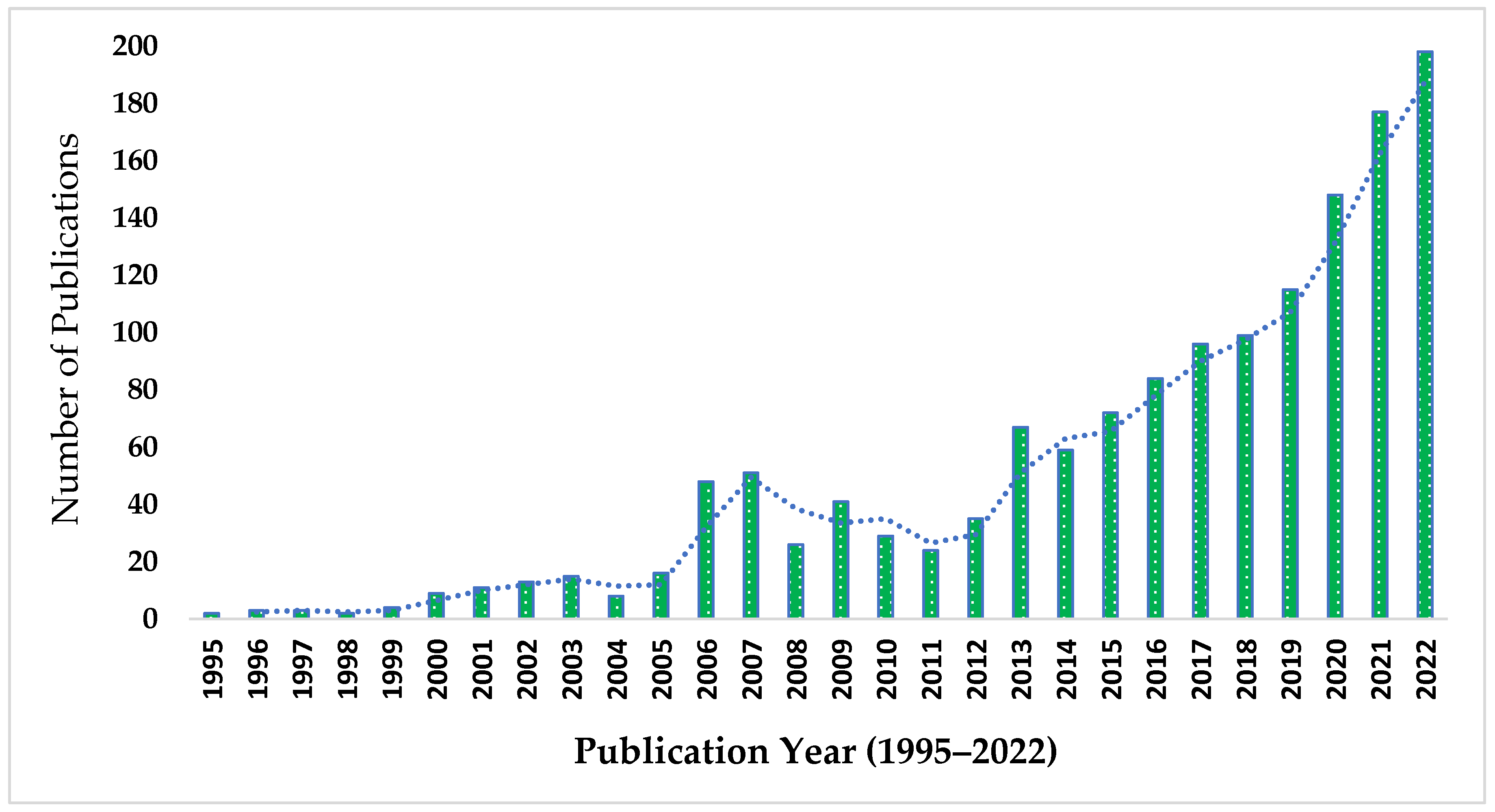

1. Introduction

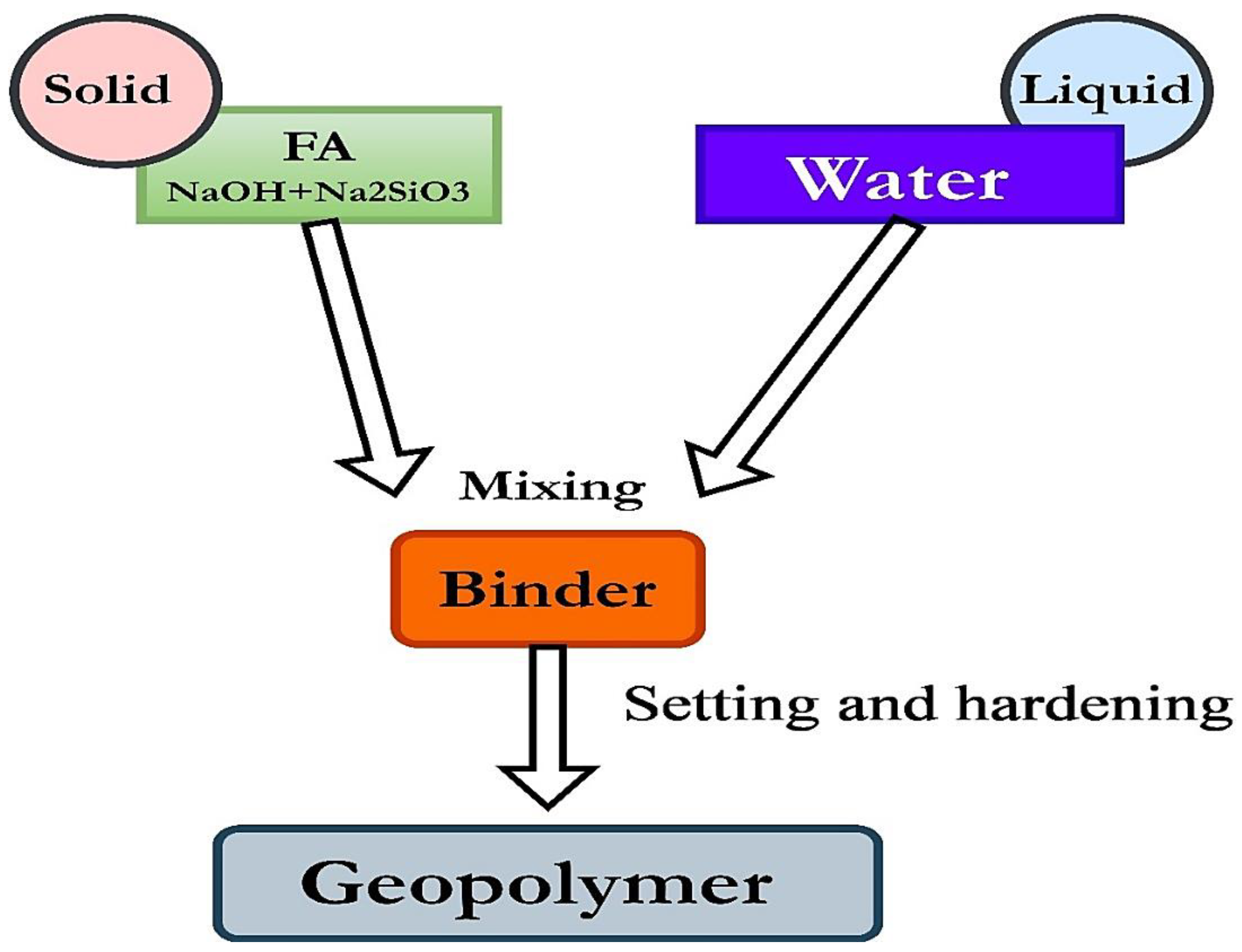

2. GP Elements (Composition)

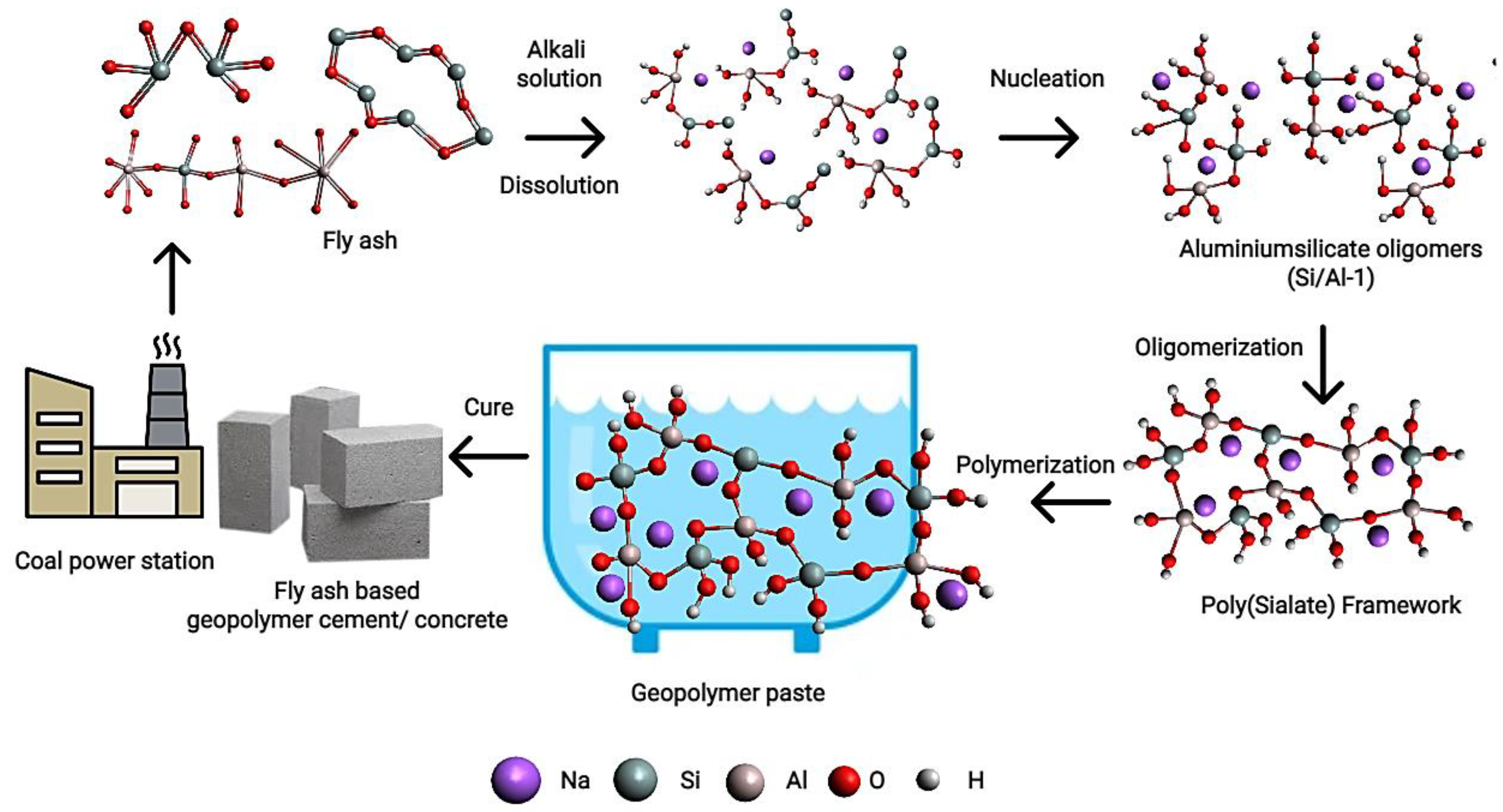

2.1. Fly Ash FA

2.2. Acid-Based Agro-Industrial Waste-Based Geopolymer Concrete

- Activation of the waste material: The agro-industrial waste source materials are first activated using an acid solution, typically hydrochloric acid or sulfuric acid. The acid reacts with the silica and alumina in the waste material, forming soluble silicates and aluminates [54];

- Formation of the geopolymer gel: The activated waste material is then mixed with an alkaline solution, typically sodium hydroxide or potassium hydroxide. This causes a chemical reaction between the soluble silicates and aluminates, resulting in the formation of a geopolymer gel. The gel binds together the waste particles, forming a solid material with cement-like properties [55];

- Solidification of the geopolymer concrete: The geopolymer concrete is then cast into the desired shape and left to solidify. During this process, the geopolymer gel continues to harden and strengthen, resulting in a final product that is strong, durable, and resistant to acid and alkali attack [56].

- Sustainable use of waste materials: The use of agro-industrial waste materials as raw materials for geopolymer concrete helps to reduce waste and promote sustainability. Agro-industrial waste materials such as rice-husk ash, sugarcane bagasse ash, and coconut shell ash can be used to make geopolymer concrete, which reduces the amount of waste that goes to landfills [59];

- Lower carbon footprint: The production of acid-based agro-industrial waste-based geopolymer concrete results in significantly lower carbon dioxide emissions compared to traditional cement production. This is because the production of geopolymer concrete does not require high-temperature kiln firing, which is responsible for a significant portion of the carbon dioxide emissions associated with cement production [60];

- Improved durability: Acid-based agro-industrial waste-based geopolymer concrete has been found to have better durability compared to traditional concrete. This is because geopolymer concrete has a higher resistance to acid and alkali attacks, as well as a lower permeability, which helps to prevent the penetration of water and other harmful substances [61];

- Cost-effective: The use of agro-industrial waste materials as raw materials for geopolymer concrete can be cost-effective, as these waste materials are often inexpensive and readily available. Additionally, the production of geopolymer concrete can help reduce costs associated with traditional cement production, as well as reduce energy and transportation costs associated with waste disposal [62].

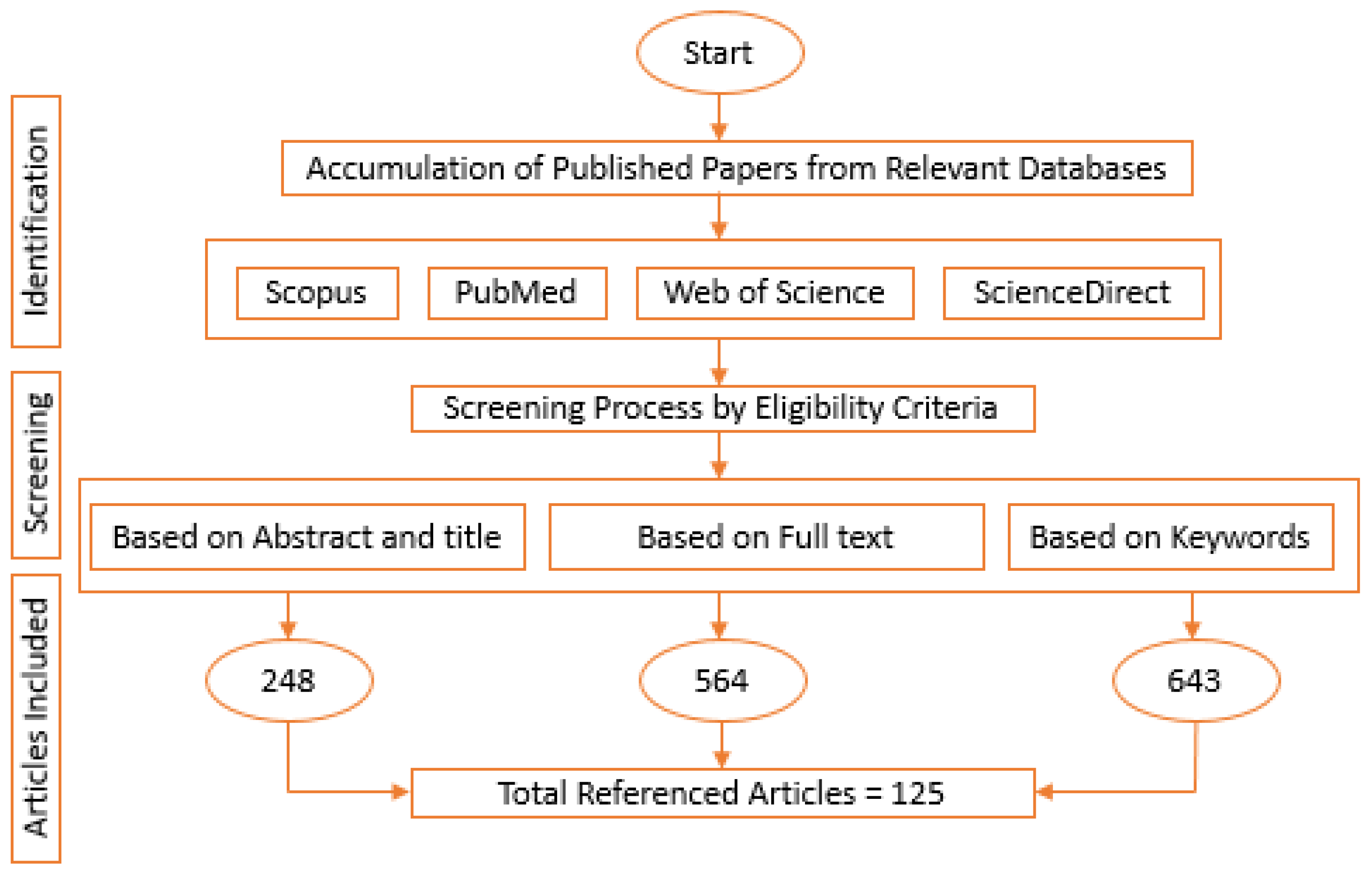

3. Methodology

4. Geo Polymerization Overview

4.1. Parameters for the Mixture of GP

4.2. Effects of Potential Hydrogen (PH)

5. Properties of Agro-Industrial Waste (AIW) Ashes

5.1. Industrial-Agro-Waste Ashes-Based AAB Microstructural Properties

5.2. Industrial-Agro-Waste Ashes-Based AAB Mechanical Strength Properties

6. Conclusions

- RH–SiO2 was noted to contain the maximum silica content, whereas other agro-waste ashes that were studied had silica contents greater than 55%. SA was noted to contain the highest alumina content of approximately 10% for agro-waste ashes. Industrial ashes (GGBFS and FA) contain more alumina and less silica when compared to agro-waste ashes;

- The agro-waste ashes were noted to contain greater reactions in terms of LOI due to fibers present in the ash specimens. Hence, proper procedures for refining and sieving were utilized in helping to reduce LOI. Among the AIW ashes, specific gravity variation features were noted to be important to SBA and hence create a minimum reaction, while POA and FA have similar results ranging from 2.2 to 2.5;

- The AIW ashes contain different microstructural features varying from fibrous, spherical, irregular, and prismatic particles, as detected in the micrographs of GGBFS, SA, and SBA. RH–SiO2 and POA had cellularly irregular porous structures, whereas FA had solid and hollow spherical-shaped particles of varying sizes;

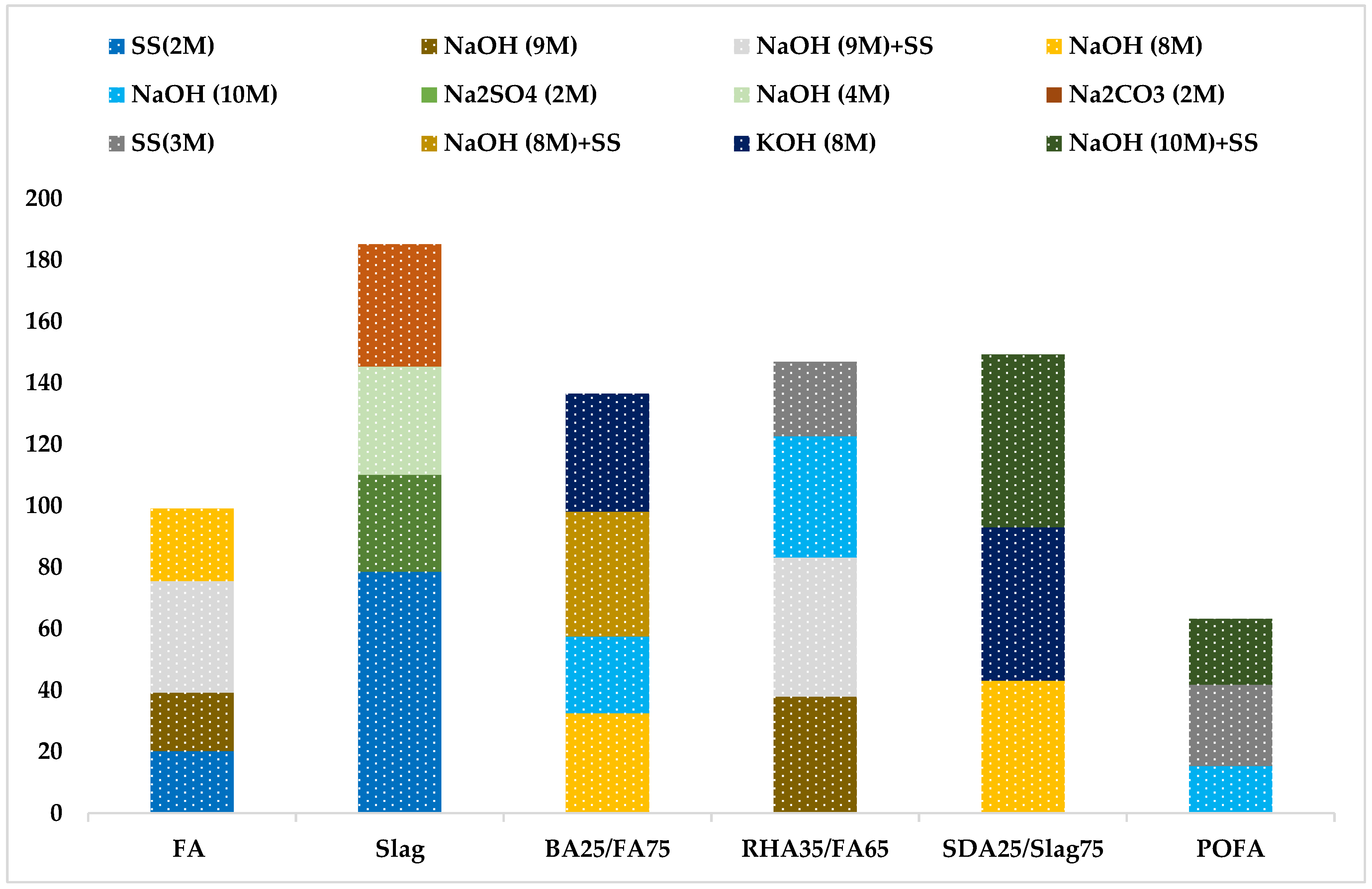

- The influence of metallic alkaline activators was evaluated, with NH+SS being the most effective once mixed with AIW ash source materials. Additionally, the compressive strength rises significantly with the increase in molar concentration from 8 to 10 M for GGBFS, FA, SA, and SBA. Nevertheless, a decrease in strength was noticeable with an increase in molar concentration at approximately 10 M for the POA source material;

- However, the review also identified some challenges associated with the production of agro-industrial waste-based geopolymer concrete, including the variability in the chemical composition of the waste material and the potential environmental and health hazards associated with the acid activation process. Further research is needed to optimize the production process and improve the long-term durability and sustainability of agro-industrial waste-based geopolymer concrete;

- The expensive barrier of the activators was also a major limitation in the apps of AA binder concrete, paving the way for the development of cost-effective materials. Moreover, identifying locally sourced AIW for GP concrete and the definition of mixture proportion standardization for certain materials are the main issues in assessing the feasibility at industrial scales. Additionally, more research is needed to fully understand the long-term durability and sustainability of geopolymer concrete, standardization, and industrial-scale production;

- Furthermore, the use of agro-industrial waste-based geopolymer concrete has emerged as a promising and sustainable solution to traditional cement-based concrete. The review study examined the literature on the use of AIW materials in geopolymer concrete production;

- Further research is required to optimize the AIW ashes incorporation into AA binder GP concretes and to investigate the long-term performance of the materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Komnitsas, K.; Zaharaki, D. Geopolymerisation: A review and prospects for the minerals industry. Miner. Eng. 2007, 20, 1261–1277. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Ahmed, H.U.; Al Dughaishi, H.; Al Lawati, J.; Sabri, M.M.; Alkhatib, F.; Milad, A. Fly Ash-Based Geopolymer Composites: A Review of the Compressive Strength and Microstructure Analysis. Materials 2022, 15, 7098. [Google Scholar] [CrossRef] [PubMed]

- Srividya, T.; Kannan Rajkumar, P.R.; Sivasakthi, M.; Sujitha, A.; Jeyalakshmi, R. A state-of-the-art on development of geopolymer concrete and its field applications. Case Stud. Constr. Mater. 2022, 16, e00812. [Google Scholar]

- Arafa, S.; Milad, A.; Yusoff, N.I.M.; Al-Ansari, N.; Yaseen, Z.M. Investigation into the permeability and strength of pervious geopolymer concrete containing coated biomass aggregate material. J. Mater. Res. Technol. 2021, 15, 2075–2087. [Google Scholar] [CrossRef]

- Umar, T.; Tahir, A.; Umeokafor, N.; Nawarathna, A.; Zia, A.; Honnur Vali, M.S. An experimental investigation on strength characteristics of concrete using Wastepaper Sludge Ash (WPSA). In Proceedings of the Twelth International Conference on Construction in the 21st Century (CITC-12), Amman, Jordan, 16–19 May 2022. [Google Scholar]

- Alaneme, G.U.; Iro, U.I.; Milad, A.; Olaiya, B.C.; Otu, O.N.; Chibuisi, U.P.; Agada, J. Mechanical Properties Optimization and Simulation of Soil–Saw Dust Ash Blend Using Extreme Vertex Design (EVD) Method. Int. J. Pavement Res. Technol. 2023, 16, 1–27. [Google Scholar] [CrossRef]

- Milad, A.; Ali, A.S.B.; Babalghaith, A.M.; Memon, Z.A.; Mashaan, N.S.; Arafa, S.; Md. Yusoff, N.I. Utilisation of Waste-Based Geopolymer in Asphalt Pavement Modification and Construction—A Review. Sustainability 2021, 13, 3330. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Feuerborn, H.-J. Calcareous ash in Europe-a reflection on technical and legal issues. In Proceedings of the 2nd Hellenic Conference on Utilization of Industrial By-Products in Construction, Aiani Kozani, Greece, 1 June 2009. [Google Scholar]

- Pavithra, P.; Reddy, M.S.; Dinakar, P.; Rao, B.H.; Satpathy, B.K.; Mohanty, A.N. A mix design procedure for geopolymer concrete with fly ash. J. Clean. Prod. 2016, 133, 117–125. [Google Scholar] [CrossRef]

- Umar, T.; Egbu, C.; Tahir, A.; Honnurvali, M.S.; Saidani, M.; Al-Bayati, A.J. Developing a Sustainable Concrete using Ceramic Waste Powder. In Proceedings of the 11th International Conference on Construction in the 21st Century (CITC-11), London, UK, 9–11 September 2019. [Google Scholar]

- Agor, C.D.; Mbadike, E.M.; Alaneme, G.U. Evaluation of sisal fiber and aluminum waste concrete blend for sustainable construction using adaptive neuro-fuzzy inference system. Sci. Rep. 2023, 13, 2814. [Google Scholar] [CrossRef]

- Mahmoodi, O.; Siad, H.; Lachemi, M.; Dadsetan, S.; Sahmaran, M. Development of normal and very high strength geopolymer binders based on concrete waste at ambient environment. J. Clean. Prod. 2021, 279, 123436. [Google Scholar] [CrossRef]

- da Silva Fernandes, F.A.; de Oliveira Costa, D.D.S.; Rossignolo, J.A. Influence of Sintering on Thermal, Mechanical and Technological Properties of Glass Foams Produced from Agro-Industrial Residues. Materials 2022, 15, 6669. [Google Scholar] [CrossRef]

- Ibe Iro, U.; Alaneme, G.U.; Milad, A.; Olaiya, B.C.; Otu, O.N.; Isu, E.U.; Amuzie, M.N. Optimization and Simulation of Saw Dust Ash Concrete Using Extreme Vertex Design Method. Adv. Mater. Sci. Eng. 2022, 2022, 5082139. [Google Scholar] [CrossRef]

- Gan, V.J.L.; Cheng, J.C.P.; Lo, I.M.C.; Chan, C.M. Developing a CO2-e accounting method for quantification and analysis of embodied carbon in high-rise buildings. J. Clean. Prod. 2017, 141, 825–836. [Google Scholar] [CrossRef]

- Chi, M.; Liu, Y.; Huang, R. Mechanical and microstructural characterization of alkali-activated materials based on fly ash and slag. Int. J. Eng. Technol. 2015, 7, 59. [Google Scholar] [CrossRef]

- Assi, L.N.; Carter, K.; Deaver, E.; Ziehl, P. Review of availability of source materials for geopolymer/sustainable concrete. J. Clean. Prod. 2020, 263, 121477. [Google Scholar] [CrossRef]

- Li, N.; Shi, C.; Zhang, Z.; Wang, H.; Liu, Y. A review on mixture design methods for geopolymer concrete. Compos. Part B. Eng. 2019, 178, 107490. [Google Scholar] [CrossRef]

- Reddy, M.S.; Dinakar, P.; Rao, B.H. Mix design development of fly ash and ground granulated blast furnace slag based geopolymer concrete. J. Build. Eng. 2018, 20, 712–722. [Google Scholar] [CrossRef]

- Kefiyalew, Z.; Ekaputri, J.J. Review on Alkali-Activated Fly Ash Based Geopolymer Concrete. Mater. Sci. Forum 2016, 841, 162–169. [Google Scholar]

- Alaneme, G.U.; Attah, I.C.; Mbadike, E.M.; Dimonyeka, M.U.; Usanga, I.N.; Nwankwo, H.F. Mechanical strength optimization and simulation of cement kiln dust concrete using extreme vertex design method. Nanotechnol. Environ. Eng. 2022, 7, 467–490. [Google Scholar] [CrossRef]

- Wongsa, A.; Wongkvanklom, A.; Tanangteerapong, D.; Chindaprasirt, P. Comparative study of fire-resistant behaviors of high-calcium fly ash geopolymer mortar containing zeolite and mullite. J. Sustain. Cem. Based Mater. 2020, 9, 307–321. [Google Scholar] [CrossRef]

- Wong, C.L.; Mo, K.H.; Alengaram, U.J.; Yap, S.P. Mechanical strength and permeation properties of high calcium fly ash-based geopolymer containing recycled brick powder. J. Build. Eng. 2020, 32, 101655. [Google Scholar] [CrossRef]

- Ling, Y.; Wang, K.; Wang, X.; Hua, S. Effects of mix design parameters on heat of geopolymerization, set time, and compressive strength of high calcium fly ash geopolymer. Constr. Build. Mater. 2019, 228, 116763. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, Q. The making of Class C fly ash as high-strength precast construction material through geopolymerization. Min. Metall. Explor. 2020, 37, 1603–1616. [Google Scholar] [CrossRef]

- Abdullah, M.M.A.B.; Kamarudin, H.; Bnhussain, M.; Khairul Nizar, I.; Rafiza, A.R.; Zarina, Y. The relationship of NaOH molarity, Na2SiO3/NaOH ratio, fly ash/alkaline activator ratio, and curing temperature to the strength of fly ash-based Geopolymer. In Advanced Materials Research; Trans Tech Publications Ltd.: Geneva, Switzerland, 2011. [Google Scholar]

- Palomo, A.; Grutzeck, M.; Blanco, M. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Swanepoel, J.; Strydom, C. Utilisation of fly ash in a geopolymeric material. Appl. Geochem. 2002, 17, 1143–1148. [Google Scholar] [CrossRef]

- Sathonsaowaphak, A.; Chindaprasirt, P.; Pimraksa, K. Workability and strength of lignite bottom ash geopolymer mortar. J. Hazard. Mater. 2009, 168, 44–50. [Google Scholar] [CrossRef]

- Ogbonna, C.; Mbadike, E.M.; Alaneme, G.U. Effects of Cassava-Peel-Ash on Mechanical Properties of Concrete. Umudike J. Eng. Technol. (UJET) 2020, 6, 61–75. [Google Scholar]

- Kuun Reddy, S.R.; Bala Murugan, S. Experimental and microstructural assessment of ternary blended geopolymer concrete with different Na2SiO3-to-NaOH volume ratios. Innov. Infrastruct. Solut. 2020, 5, 33. [Google Scholar] [CrossRef]

- Mansour, M.A.; Ismail, M.H.B.; Imran Latif, Q.B.a.; Alshalif, A.F.; Milad, A.; Bargi, W.A.A. A Systematic Review of the Concrete Durability Incorporating Recycled Glass. Sustainability 2023, 15, 3568. [Google Scholar] [CrossRef]

- Hardjito, D.; Rangan, B.V. Development and Properties of Low Calcium Fly Ash Based Geopolymer Concrete; Research Report GC 1; Curtin University of Technology: Perth, Australia, 2005. [Google Scholar]

- Winnefeld, F.; Leemann, A.; Lucuk, M.; Svoboda, P.; Neuroth, M. Assessment of phase formation in alkali activated low and high calcium fly ashes in building materials. Construct. Build. Mater. 2010, 24, 1086–1093. [Google Scholar] [CrossRef]

- Rattanasak, U.; Chindaprasirt, P. Influence of NaOH solution on the synthesis of fly ash geopolymer. Miner. Eng. 2009, 22, 1073–1078. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.E. On the development of fly ash-based geopolymer concrete. Mater. J. 2004, 101, 467–472. [Google Scholar]

- Alaneme, G.U.; Mbadike, E.M. Experimental investigation of Bambara nut shell ash in the production of concrete and mortar. Innov. Infrastruct. Solut. 2021, 6, 66. [Google Scholar] [CrossRef]

- Mishra, A.; Choudhary, D.; Jain, N.; Kumar, M.; Sharda, N.; Dutt, D. Effect of concentration of alkaline liquid and curing time on strength and water absorption of geopolymer concrete. ARPN J. Eng. Appl. Sci. 2008, 3, 14–18. [Google Scholar]

- Dzunuzovic, N.; Komljenovic, M.; Nikolic, V.; Ivanovic, T. External sulfate attack on alkali-activated fly ash-blast furnace slag composite. Construct. Build. Mater. 2017, 157, 737–747. [Google Scholar] [CrossRef]

- Nuaklong, P.; Jongvivatsakul, P.; Pothisiri, T.; Sata, V.; Chindaprasirt, P. Influence of rice husk ash on mechanical properties and fire resistance of recycled aggregate high-calcium fly ash geopolymer concrete. J. Clean. Prod. 2020, 252, 119797. [Google Scholar] [CrossRef]

- Dineshkumar, M.; Umarani, C. Effect of Alkali Activator on the Standard Consistency and Setting Times of Fly Ash and GGBS-Based Sustainable Geopolymer Pastes. Adv. Civ. Eng. 2020, 2020, 2593207. [Google Scholar] [CrossRef]

- Ewa, D.E.; Ukpata, J.O.; Otu, O.N.; Memon, Z.A.; Alaneme, G.U.; Milad, A. Scheffe’s Simplex Optimization of Flexural Strength of Quarry Dust and Sawdust Ash Pervious Concrete for Sustainable Pavement Construction. Materials 2023, 16, 598. [Google Scholar] [CrossRef]

- Wardhono, A.; Gunasekara, C.; Law, D.W.; Setunge, S. Comparison of long term performance between alkali activated slag and fly ash geopolymer concretes. Constr. Build. Mater. 2017, 143, 272–279. [Google Scholar] [CrossRef]

- Ramujee, K.; PothaRaju, M. Mechanical properties of geopolymer concrete composites. Mater. Today Proc. 2017, 4, 2937–2945. [Google Scholar] [CrossRef]

- Wallah, S.E. Creep behaviour of fly ash-based geopolymer concrete. Civ. Eng. Dimens. 2010, 12, 73–78. [Google Scholar]

- Xie, T.; Ozbakkaloglu, T. Behavior of low-calcium fly and bottom ash-based geopolymer concrete cured at ambient temperature. Ceram. Int. 2015, 41, 5945–5958. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, Y.; Xiao, R.; Polaczyk, P.; Zhang, M.; Hu, W.; Bai, Y.; Huang, B. A comparative study on geopolymers synthesized by different classes of fly ash after exposure to elevated temperatures. J. Clean. Prod. 2020, 270, 122500. [Google Scholar] [CrossRef]

- Rahmadina, A.; Ekaputri, J.J. Mechanical properties of geopolymer concrete exposed to combustion. In Green Infrastructure for Future World, Proceedings of the 6th International Conference of Euro Asia Civil Engineering Forum 2017, Seoul, Republic of Korea, 22–25 August 2017; Park, J.-W., Ayli, H., Hardjasaputra, H., Thayaalan, P., Eds.; EDP Sciences: Seoul, Republic of Korea, 2017; Volume 138, pp. 1–10. [Google Scholar]

- Payakaniti, P.; Chuewangkam, N.; Yensano, R.; Pinitsoontorn, S.; Chindaprasirt, P. Changes in compressive strength, microstructure and magnetic properties of a high-calcium fly ash geopolymer subjected to high temperatures. Constr. Build. Mater. 2020, 265, 120650. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay YW, D.; Tan, M.J. Additive manufacture of geopolymer for sustainable built environment. J. Clean. Prod. 2018, 167, 281–288. [Google Scholar] [CrossRef]

- Yip, C.K.; Lukey, G.C.; Van Deventer, J.S.J. The coexistence of geopolymeric gel and calcium silicate hydrate at the early stage of alkaline activation. Cem. Concr. Res. 2005, 35, 1688–1697. [Google Scholar] [CrossRef]

- Kumar, A.S.; Muthukannan, M.; Arunkumar, K.; Sriram, M.; Vigneshwar, R.; Sikkandar, A.G. Development of eco-friendly geopolymer concrete by utilizing hazardous industrial waste materials. Mater. Today Proc. 2022, 66, 2215–2225. [Google Scholar] [CrossRef]

- Koushkbaghi, M.; Alipour, P.; Tahmouresi, B.; Mohseni, E.; Saradar, A.; Sarker, P.K. Influence of different monomer ratios and recycled concrete aggregate on mechanical properties and durability of geopolymer concretes. Constr. Build. Mater. 2019, 205, 519–528. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, Z.; Da, J.; KRan Sui, Z. Factors influencing bonding strength of geopolymer-aggregate interfacial transition zone. Adv. Mater. Res. 2011, 224, 1–7. [Google Scholar]

- Bidwe, S.S.; Hamane, A.A. Effect of different molarities of Sodium Hydroxide solution on the Strength of Geopolymer concrete. Am. J. Eng. Res. 2015, 4, 139–145. Available online: https://www.ajer.org/papers/v4(03)/S04301390145.pdf (accessed on 12 December 2022).

- Kamseu, E.; Moungam, L.M.B.À.; Cannio, M.; Billong, N.; Chaysuwan, D.; Melo, U.C.; Leonelli, C. Substitution of sodium silicate with rice husk ash-NaOH solution in metakaolin based geopolymer cement concerning reduction in global warming. J. Clean. Prod. 2017, 142, 3050–3060. [Google Scholar] [CrossRef]

- Aliabdo, A.; Elmoaty, A.; Salem, H.A. Effect of water addition, plasticizer and alkaline solution constitution on fly ash based geopolymer concrete performance. Constr. Build. Mater. 2016, 121, 694–703. [Google Scholar] [CrossRef]

- Alaneme, G.U.; Mbadike, E.M.; Attah, I.C.; Udousoro, I.M. Mechanical behaviour optimization of saw dust ash and quarry dust concrete using adaptive neuro-fuzzy inference system. Innov. Infrastruct. Solut. 2022, 7, 122. [Google Scholar] [CrossRef]

- Ishwarya, G.; Singh, B.; Deshwal, S.; Bhattacharyya, S.K. Effect of sodium carbonate/sodium silicate activator on the rheology, geopolymerization and strength of fly ash/slag geopolymer pastes. Cem. Concr. Compos. 2019, 97, 226–238. [Google Scholar]

- Yang, G.; Zhao, J.; Wang, Y. Durability properties of sustainable alkali-activated cementitious materials as marine engineering material: A review. Mater. Today Sustain. 2022, 17, 100099. [Google Scholar] [CrossRef]

- Sanni, S.H.; Khadiranaikar, R.B. Performance of geopolymer concrete under severe environmental conditions. Int. J. Civ. Struct. Eng. 2012, 3, 396–407. [Google Scholar]

- Silva, F.G.S.; Fiuza Junior, R.A.; da Silva, J.S.; de Brito, C.M.S.R.; Andrade, H.M.C.; Gonçalves, J.P. Consumption of calcium hydroxide and formation of C–S–H in cement pastes. J. Therm. Anal. Calorim. 2014, 116, 287–293. [Google Scholar] [CrossRef]

- Rahman, S.S.; Khattak, M.J. Roller compacted geopolymer concrete using recycled concrete aggregate. Constr. Build. Mater. 2021, 283, 122624. [Google Scholar] [CrossRef]

- Quedou, P.G.; Wirquin, E.; Bokhoree, C. Sustainable concrete: Potency of sugarcane bagasse ash as a cementitious material in the construction industry. Case Stud. Constr. Mater. 2021, 14, e00545. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Alaneme, G.U.; Onyia, M.E.; Bui Van, D.; Diomonyeka, M.U.; Nnadi, E.; Ogbonna, C.; Odum, L.O.; Aju, D.E.; Abel, C.; et al. Comparative modeling of strength properties of hydrated-lime activated rice-husk-ash (HARHA) modified soft soil for pavement construction purposes by artificial neural network (ANN) and fuzzy logic (FL). J. Kejuruter. 2021, 33, 365–384. [Google Scholar] [CrossRef]

- Habert, G.; De Lacaillerie, J.D.E.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2017, 103, 21–34. [Google Scholar] [CrossRef]

- van Jaarsveld, J.G.; van Deventer, J.S.J.; Lukey, G.C. The effect of composition and temperature on the properties of fly ash- and kaolinite-based geopolymers. Chem. Eng. J. 2002, 89, 63–73. [Google Scholar] [CrossRef]

- Abdel-Gawwad, H.A.; Abo-El-Enein, S.A. A novel method to produce dry geopolymer cement powder. HBRC J. 2016, 12, 13–24. [Google Scholar] [CrossRef]

- Nazari, A.; Maghsoudpour, A.; Sanjayan, J.G. Characteristics of boroaluminosilicate geopolymers. Constr. Build. Mater. 2014, 70, 262–268. [Google Scholar] [CrossRef]

- Pacheco-torgal, F. Alkali-Activated Binders: A Review Part 1. Historical Background, Terminology. React. Mech. Hydration Prod. 2008, 22, 1305–1314. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers and geopolymeric new materials. J. Therm. Anal. Calorim. 1989, 35, 429–441. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Cement a Review; Published in Geopolymer Science and Technics, Technical Paper, 21; Geopolymer Institute Library: Saint-Quentin, France, 2013. [Google Scholar]

- Duxson, P.; Lukey, G.C.; Separovic, F.; van Deventer, J.S.J. Effect of alkali cations on aluminum incorporation in geopolymeric gels. Ind. Eng. Chem. Res. 2005, 44, 832–839. [Google Scholar] [CrossRef]

- Ogbonna, C.; Mbadike, E.; Alaneme, G. Characterisation and use of Cassava peel ash in concrete production. Comput. Eng. Phys. Model. 2020, 3, 11–20. [Google Scholar] [CrossRef]

- Uwadiegwu, A.G.; Michael, M.E. Characterization of Bambara Nut Shell Ash (BNSA) in Concrete Production. J. Kejuruter. 2021, 33, 621–634. [Google Scholar] [CrossRef]

- Alaneme, G.U.; Mbadike, E.M. Optimization of strength development of bentonite and palm bunch ash concrete using fuzzy logic. Int. J. Sustain. Eng. 2021, 14, 835–851. [Google Scholar] [CrossRef]

- Athira, G.; Bahurudeen, A.; Vishnu, V.S. Availability and accessibility of sugarcane bagasse ash for its utilization in Indian cement plants: A GIS-based network analysis. Sugar Tech 2020, 22, 1038–1056. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Chalee, W.; Rattanasak, U. Comparative study on the characteristics of fly ash and bottom ash geopolymers. Waste Manag. 2009, 29, 539–543. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, K.; Wang, S.; Wang, Z.; Yang, Z.; Shumuye, E.D.; Gong, X. Effect of elevated temperature on mechanical properties of high-volume fly ash-based geopolymer concrete, mortar and paste cured at room temperature. Polymers 2021, 13, 1473. [Google Scholar] [CrossRef]

- Lim, C.-H.; Yoon, Y.-S.; Kim, J.-H. Genetic algorithm in mix proportioning of high-performance concrete. Cem. Concr. Res. 2004, 34, 409–420. [Google Scholar] [CrossRef]

- Nnaemeka, O.F.; Singh, N.B. Durability properties of geopolymer concrete made from fly ash in presence of kaolin. Mater. Today 2020, 29, 781–784. [Google Scholar] [CrossRef]

- Çevik, A.; Alzeebaree, R.; Humur, G.; Ni¸s, A.; Gül¸san, M.E. Effect of nano-silica on the chemical durability and mechanical performance of fly ash based geopolymer concrete. Ceramics 2018, 44, 12253–12264. [Google Scholar] [CrossRef]

- Charkhtab Moghaddam, S.; Madandoust, R.; Jamshidi, M.; Nikbin, I.M. Mechanical properties of fly ash-based geopolymer concrete with crumb rubber and steel fiber under ambient and sulfuric acid conditions. Constr. Build. Mater. 2021, 281, 122571. [Google Scholar] [CrossRef]

- Al-Qutaifi, S.; Nazari, A.; Bagheri, A. Mechanical properties of layered geopolymer structures applicable in concrete 3D-printing. Constr. Build. Mater. 2018, 176, 690–699. [Google Scholar] [CrossRef]

- Mahmoodi, O.; Siad, H.; Lachemi, M.; Dadsetan, S.; Sahmaran, M. Development of ceramic tile waste geopolymer binders based on pre-targeted chemical ratios and ambient curing Construct. Build. Mater. 2020, 258, 120297. [Google Scholar] [CrossRef]

- Paiva, H.; Yliniemi, J.; Illikainen, M.; Rocha, F.; Ferreira, V.M. Mine Tailings Geopolymers as a Waste Management Solution for A More Sustainable Habitat. Sustainability 2019, 11, 995. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 3rd ed.; France Geopolymer Institute: Saint-Quentin, France, 2011. [Google Scholar]

- Hanjitsuwan, S.; Hunpratub, S.; Thongbai, P.; Maensiri, S.; Sata, V.; Chindaprasirt, P. Effects of NaOH concentrations on physical and electrical properties of high calcium fly ash geopolymer paste. Cem. Concr. Compos. 2014, 45, 9–14. [Google Scholar] [CrossRef]

- Chimmaobi, O.; Mbadike, E.M.; Alaneme, G.U. Experimental Investigation of Cassava Peel Ash in the Production of Concrete and Mortar. Umudike J. Eng. Technol. 2020, 6, 10–21. [Google Scholar] [CrossRef]

- Van Jaarsveld, J.G.S.; van Deventer, J.S.J. Effect of the alkali metal activator on the properties of fly ash-based geopolymer. Ind. Eng. Chem. Res. 1999, 38, 3932–3941. [Google Scholar] [CrossRef]

- Xu, Q.; Ji, T.; Gao, S.-J.; Yang, Z.; Wu, N. Characteristics and Applications of Sugar Cane Bagasse Ash Waste in Cementitious Materials. Materials 2019, 12, 39. [Google Scholar] [CrossRef]

- Rajamma, R.; Labrincha, J.A.; Ferreira, V.M. Alkali-activation of biomass fly ash-metakaolin blends. Fuel 2012, 98, 265–271. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Filho, R.D.T.; Tavares, L.M.; Fairbairn, E.M.R. Experimental characterization of binary and ternary blended-cement concretes containing ultrafine residual rice husk and sugar cane bagasse ashes. Construct. Build. Mater. 2012, 29, 641–646. [Google Scholar] [CrossRef]

- Monita, O.; Kamaldi, A.; Sitompul, I.R.; Diyanto, I.; Saputra, E. Properties of geopolymer concrete from local fly ash (FA) and palm oil fuel ash (POFA). Mater. Sci. Forum. 2015, 803, 110–114. [Google Scholar]

- Amran, M.; Murali, G.; Fediuk, R.; Vatin, N.; Vasilev, Y.; Abdelgader, H. Palm Oil Fuel Ash-Based Eco-Efficient Concrete: A Critical Review of the Short-Term Properties. Materials 2021, 14, 332. [Google Scholar] [CrossRef]

- Sumrerng, R.; Chindaprasirt, P. Strength and Porosity of Bagasse Ash-based Geopolymer Mortar. J. Appl. Sci. 2014, 14, 586–591. [Google Scholar]

- Part, W.K.; Ramli, M.; Cheah, C.B. An overview on the influence of various factors on the properties of geopolymer concrete derived from industrial by-products. Constr. Build. Mater. 2015, 77, 370–395. [Google Scholar] [CrossRef]

- Siyal, A.A.; Azizli, K.A.; Man, Z.; Ullah, H. Effects of parameters on the setting time of fly ash based geopolymers using taguchi method. Procedia Eng. 2016, 148, 302–307. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. Sustainable geopolymer concrete using ground granulated blast furnace slag and rice husk ash: Strength and permeability properties. J. Clean. Prod. 2018, 205, 49–57. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. Sulfuric acid resistance of fly ash based geopolymer concrete. Constr. Build. Mater. 2017, 146, 136–143. [Google Scholar] [CrossRef]

- Hamada, H.M.; Jokhio, G.A.; Yahaya, F.M.; Humada, A.M.; Gul, Y. The present state of the use of palm oil fuel ash (POFA) in concrete. Construct. Build. Mater. 2018, 175, 26–40. [Google Scholar] [CrossRef]

- Sultana, M.S.; Rahman, A. Characterization of calcined sugarcane bagasse sugarcane waste ash for industrial use. In Proceedings of the International Conference on Mechanical, Industrial and Materials Engineering 2013 (ICMIME2013), Wuhan, China, 9–11 August 2013; pp. 508–513. [Google Scholar]

- Ríos-Parada, V.; Jimenez-Quero, V.G.; Valdez-Tamez, P.L.; Montes-García, P. Characterization and use of an untreated Mexican sugarcane bagasse ash as supplementary material for the preparation of ternary concretes. Construct. Build. Mater. 2017, 157, 83–95. [Google Scholar] [CrossRef]

- Satya, Y.S.D.; Saputra, E.; Olivia, M. Performance of blended fly ash (FA) and palm oil fuel ash (POFA) geopolymer mortar in acidic peat environment. Mater. Sci. Forum. 2017, 841, 83–89. [Google Scholar]

- Nadziri, N.; Ismail, I.; Hamdan, S. Binding gel characterization of alkaliactivated binders based on palm oil fuel ash (POFA) and fly ash. J. Sustain. Cem. Mater. 2018, 7, 1–14. [Google Scholar]

- Ranjbar, N.; Mehrali, M.; Alengaram, U.J.; Metselaar, H.S.C.; Jumaat, M.Z. Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar under elevated temperatures. Construct. Build. Mater. 2014, 65, 114–121. [Google Scholar] [CrossRef]

- Attah, I.C.; Etim, R.K.; Alaneme, G.U.; Ekpo, D.U. Scheffe’s approach for single additive optimization in selected soils amelioration studies for cleaner environment and sustainable subgrade materials. Cleaner Materials 2022, 5, 100126. [Google Scholar] [CrossRef]

- Gregory, C. Ezeokpube, Isiguzo Edwin Ahaneku, George Uwadiegwu Alaneme, Imoh Christopher Attah, Roland Kufre Etim, Bamidele Charles Olaiya, and Iberedem Monday Udousoro. Assessment of Mechanical Properties of Soil-Lime-Crude Oil-Contaminated Soil Blend Using Regression Model for Sustainable Pavement Foundation Construction. Adv. Mater. Sci. Eng. 2022, 2022, 7207842. [Google Scholar]

- Bagheri, A.; Nazari, A.; Hajimohammadi, A.; Sanjayan, J.G.; Rajeev, P.; Nikzad, M.; Ngo, T.; Mendis, P. Microstructural study of environmentally friendly boroaluminosilicate geopolymers. J. Clean. Prod. 2018, 18, 805–812. [Google Scholar] [CrossRef]

- Zabihi, S.M.; Tavakoli, H.; Mohseni, E. Engineering and microstructural properties of fiber-reinforced rice husk-ash based geopolymer concrete. J. Mater. Civ. Eng. 2018, 30, 8. [Google Scholar] [CrossRef]

- Qu, Z.; Liu, Z.; Si, R.; Zhang, Y. Effect of Various Fly Ash and Ground Granulated Blast Furnace Slag Content on Concrete Properties: Experiments and Modelling. Materials 2022, 15, 3016. [Google Scholar] [CrossRef]

- Karim, M.R.; Zain, M.F.M.; Jamil, M.; Lai, F.C. Development of a zero-cement binder using slag, fly ash, and rice husk ash with chemical activator. Ann. Mater. Sci. Eng. 2015, 2015, 147065. [Google Scholar] [CrossRef]

- Basri, M.S.M.; Mustapha, F.; Mazlan, N.; Ishak, M.R. Optimization of Rice Husk Ash-Based Geopolymers Coating Composite for Enhancement in Flexural Properties and Microstructure Using Response Surface Methodology. Coatings 2020, 10, 165. [Google Scholar] [CrossRef]

- Ekinci, A.; Hanafi, M.; Aydin, E. Strength, Stiffness, and Microstructure of Wood-Ash Stabilized Marine Clay. Minerals 2020, 10, 796. [Google Scholar] [CrossRef]

- Trochez, J.J.; Mejia de Gutierrez, R.; Rivera, J.; Bernal, S.A. Synthesis of geopolymer from spent FCC: Effect of SiO2/Al2O3 and Na2O/SiO2 molar ratios. Mater. Construcción 2015, 65, e046. [Google Scholar]

- Bayuaji, R.; Yasin, A.K.; Susanto, T.E.; Darmawan, M.S. A Review in Geopolymer Binder with Dry Mixing Method (Geopolymer cement). AIP Conf. Proc. 2017, 1887, 020022. [Google Scholar]

- Camp, C.V.; Pezeshk, S.; Hansson, H. Flexural design of reinforced concrete frames using a genetic algorithm. J. Struct. Eng. 2003, 129, 105–115. [Google Scholar] [CrossRef]

- Topcu, I.B.; Sarıdemir, M. Prediction of compressive strength of concrete containing fly ash using artificial neural networks and fuzzy logic. Comput. Mater. Sci. 2008, 41, 305–311. [Google Scholar] [CrossRef]

- Gopinath, A.; Bahurudeen, A.; Vishnu, V.S. Quantification of geographical proximity of sugarcane bagasse ash sources to ready-mix concrete plants for sustainable waste management and recycling. Waste Manag. Res. 2020, 39, 2. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Kurtis, K.E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cement Concr. Res. 2017, 97, 41–49. [Google Scholar] [CrossRef]

- Sisol, M.; Kudelas, D.; Marcin, M.; Holub, T.; Varga, P. Statistical Evaluation of Mechanical Properties of Slag Based AlkaliActivated Material. Sustainability 2019, 11, 5935. [Google Scholar] [CrossRef]

- Al Bakri, A.M.; Kamarudin, H.; Bnhussain, M.; Liyana, J.; Ruzaidi, C.M. Nano Geopolymer for Sustainable Concrete using Fly Ash Synthesized by High Energy Ball Milling. Appl. Mech. Mater. 2013, 314, 69–173. [Google Scholar]

- Zou, Y.; Zheng, C.; Alzahrani, A.M.; Ahmad, W.; Ahmad, A.; Mohamed, A.M.; Khallaf, R.; Elattar, S. Evaluation of Artificial Intelligence Methods to Estimate the Compressive Strength of Geopolymers. Gels 2022, 8, 271. [Google Scholar] [CrossRef]

| MgO | SO3 | TiO2 | K2O | CaO | SiO2 | Al2O3 | Fe2O3 | Na2O | (LOI) | FA Class | References |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.46 | 0.1 | 2.02 | 0.95 | 0.93 | 60.42 | 31.06 | 3.34 | - | F | [42] | |

| 0.98 | 0.88 | - | 2.46 | 3.23 | 49.9 | 24 | 14.4 | - | 3.5 | C | [43] |

| 0.97 | 0.05 | - | 1 | 1.29 | 57.9 | 31.1 | 5.07 | 0.09 | 0.8 | F | [44] |

| 0.76 | 0.31 | - | 0.23 | 0.31 | 65.6 | 26.5 | 5.49 | 0.36 | 0.41 | F | [45] |

| 0.6 | 0.2 | - | 0.9 | 0.2 | 70.3 | 23.1 | 1.4 | 0.4 | 2 | F | [46] |

| 1 | 0.4 | - | 1 | 0.5 | 62.3 | 28.1 | 2.1 | 0.5 | 2.5 | F | [47] |

| Authors | Geo Polymerization Materials | GP Chemical Composition | Results |

|---|---|---|---|

| Jiang et al. [48] | Na2SiO3 and NaOH sols alkaline activators with Class F FA as source material. | NaOH of 8 M, sodium oxide of 8.3%, silica of 28.7%, and 63% water. | Improved thermal–mechanical property of produced GP. |

| Rahmadina and Ekaputri [49] | Na2SiO3 and NaOH sols were the activators, while Class F FA was the source material. | NaOH of 8 M, sodium oxide of 18.5%, silica of 36.4%, and 45.1% water. | GP compressive strength increased up to 27%, and porosity has an effect on its mechanical property. |

| Payakaniti et al. [50] | NaOH and Na2SiO3 sols alkaline activators with Class C calcium lignite FA as source material. | NaOH of 10 M, sodium silicate of 12.53% by sodium oxide weight, silica of 30.24%, and 57.23% water. | The mechanical behavior of GP paste improved due to the geopolymerization reaction. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alawi, A.; Milad, A.; Barbieri, D.; Alosta, M.; Alaneme, G.U.; Imran Latif, Q.B.a. Eco-Friendly Geopolymer Composites Prepared from Agro-Industrial Wastes: A State-of-the-Art Review. CivilEng 2023, 4, 433-453. https://doi.org/10.3390/civileng4020025

Alawi A, Milad A, Barbieri D, Alosta M, Alaneme GU, Imran Latif QBa. Eco-Friendly Geopolymer Composites Prepared from Agro-Industrial Wastes: A State-of-the-Art Review. CivilEng. 2023; 4(2):433-453. https://doi.org/10.3390/civileng4020025

Chicago/Turabian StyleAlawi, Asiya, Abdalrhman Milad, Diego Barbieri, Moad Alosta, George Uwadiegwu Alaneme, and Qadir Bux alias Imran Latif. 2023. "Eco-Friendly Geopolymer Composites Prepared from Agro-Industrial Wastes: A State-of-the-Art Review" CivilEng 4, no. 2: 433-453. https://doi.org/10.3390/civileng4020025

APA StyleAlawi, A., Milad, A., Barbieri, D., Alosta, M., Alaneme, G. U., & Imran Latif, Q. B. a. (2023). Eco-Friendly Geopolymer Composites Prepared from Agro-Industrial Wastes: A State-of-the-Art Review. CivilEng, 4(2), 433-453. https://doi.org/10.3390/civileng4020025