Abstract

The application of Accelerated Bridge Construction methods (ABC) to build, renovate and rehabilitate aging bridges is most likely to reduce the economic and social impacts of projects. This is especially relevant in countries with severe winter climates, where bridge construction is typically interrupted during the winter period. The objective of this study is to present the state of the art related to elements, systems, connections and materials used for bridge superstructures in ABC projects and to highlight their adaptability to cold or northern climate countries. The literature review and presentation of results are based on the gathering of Prefabricated/Precast Bridge Elements and Systems (PBES) used for ABC projects in North America and which are also used in many countries around the world. Following this inventory, and after grouping the PBES, connections and materials, the authors were able to identify the possibility of adapting the ABC method for countries with cold and northern climates. Products that can be used down to −6 °C for connections are presented, and future research orientations are proposed.

1. Introduction

Bridges, such as overpasses or links over natural obstacles that allow for the passage of pedestrians, animals or vehicles [1], are designed to usually last between 50 and 100 years [2]. The severe climate conditions in cold or northern climate countries cause structures to deteriorate more quickly because of freeze/thaw cycles and the use of deicing salts. Challenges also arise during the construction of new bridges because the construction in cold climates has a big impact on productivity and causes many problems during the curing of concrete. In addition to the severe climate conditions, transportation has evolved, and, thus, loads have increased over time, resulting in bridges that are subjected to greater and more frequent loadings [1]. Slowed down by cold weather and having an impact on the economy and lives of people, the construction, replacement and rehabilitation of bridges must therefore be rethought in order to obtain faster and more durable results.

In Europe, Asia and North America, accelerated construction methods have been developed to reduce the economic and social impacts resulting from the construction or rehabilitation of structures. In the United States, the American Road and Transportation Association, the Federal Highway Administration and many state departments of transportation have joined their forces to develop a method called Accelerated Bridge Construction [3].

As the goals of accelerated bridge rehabilitation and construction evolve, questions arise about which methods are appropriate and effective for countries with cold and northern climates. For countries with severe winter climates, one might ask himself which systems, elements and/or connections perform best and can be standardized for accelerated projects.

The scope of this paper is to provide a comprehensive literature review on existing technologies and techniques that can be used and are relevant to accelerated bridge construction/rehabilitation projects. A significant portion of the literature comes from North America, which is a pioneer region in the use, development and standardization of precast bridge elements and systems. In this instance, it provides a meaningful portrait of the precast bridge elements and systems used around the world [4]. This literature review consists first of a synopsis of elements and systems used for accelerated bridge construction/rehabilitation projects in the United States and Canada and which are used in many countries around the world, with a particular focus on bridge superstructures. Secondly, the connection joints and materials that are most commonly used are presented. Finally, using the findings of the literature review, the authors will highlight the suitability of these technologies and techniques for cold and northern climates and will provide new directions for future research.

2. General Synopsis of Elements and Systems Used for ABC Projects around the World

This section introduces the concept of ABC and describes the elements and systems used in ABC projects.

2.1. Accelerated Bridge Construction (ABC)

2.1.1. What Is ABC?

ABC is a construction method that uses innovative planning, design, materials, and construction technologies in a safe and cost-effective manner to reduce on-site construction time when building new bridges or replacing and rehabilitating existing ones [3]. Unlike traditional methods, this construction method highlights the reduction of the economic and social impacts that occur during construction activities. By focusing on redefining the approach to project planning and procurement, ABC improves safety, quality, sustainability, social costs and environmental impacts. To do this, ABC is based on three main techniques. The first is the lateral sliding/skidding, which allows for the replacement of the superstructure of an existing obsolete bridge. The second is the technique of Self-Propelled Modular Transporters (SPMTs) which are self-propelled trailers, i.e., they do not need any vehicle to pull or push them, they can carry heavy loads while remaining easily maneuverable and they are modular, i.e., other trailers can be added transversely or longitudinally to form wider or longer transporters. The third is the off-site prefabrication of bridge elements and systems that are then conveyed and assembled with longitudinal or transversal joints directly on the site [5]. This article focuses on the latter technique, with an emphasis on the superstructure.

2.1.2. Why ABC?

First of all, ABC allows for a considerable reduction in the impact on traffic and road users. In fact, road users are affected by almost any type of construction because the road flow is often temporarily reduced, thus increasing the costs for a community. During the implementation of a project, the time of the impact on mobility can be evaluated according to five levels of the potential impact on traffic, ranging from 3 days to 3 months to several years. The goal of ABC is to move a project that was initially planned with conventional methods from a high potential impact level to a lower level [5]. Second, ABC enhances not only the safety of workers but also that of road users [5]. Finally, ABC enhances the quality of site work [5].

In sum, the goal of the ABC method is to significantly decrease the overall costs of a project. By reducing the construction time on site, and thus reducing the delays generated during the erection of a structure, by reducing the impacts on traffic and by improving the quality of the structures, the costs are reduced in that way.

2.2. Prefabricated/Precast Bridge Elements and Systems (PBES)

Culmo et al. [6] defined PBES as “structural components of a bridge that are constructed off-site or near site and include features that reduce the on-site construction time required for conventional bridge construction”. There are two main categories of PBES: (1) the precast element, which is a single structural component of a bridge; and (2) the precast system, which is defined as a set of structural components of a bridge.

2.2.1. Deck Elements

There are multiple deck elements that differ according to their material.

- Stay-in-place deck forming

This technique consists in not removing the formwork once the deck has been poured, thus saving construction time. There are two common types, depending on the material used.

- Steel Form

Galvanized corrugated steel deck forms can support the deck, deck reinforcement and poured concrete. It is intended to remain in place until the end of the structure’s life [4].

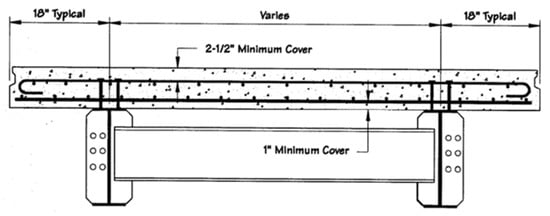

- Prestressed/reinforced concrete form

Partial-depth precast concrete deck panels constitute the lower portion of the bridge deck and are combined with a layer of cast-in-place reinforced concrete to form the complete structural deck [6].

- 2.

- Full-depth deck panels

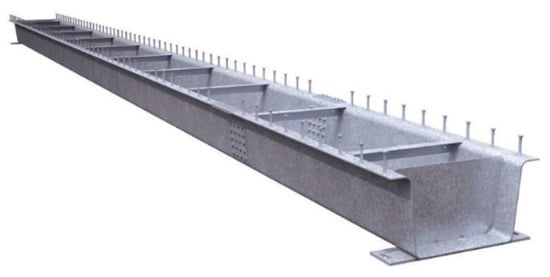

The use of full-depth deck panels is quite common in ABC projects, with several types available depending on the primary material used [7]. A full-depth precast concrete deck panel composite with steel girders is presented in Figure 1.

Figure 1.

Full-depth precast concrete deck panel (Photos courtesy of CIMA+).

- Prestressed/Reinforced Concrete Panel

Prestressed/reinforced concrete panels are deck elements that are cast with similar thicknesses as a conventional cast-in-place concrete deck, with the goal of mimicking it, and whose main differences are in the connection between the deck and the beams and the connections between the panels [6]. The main advantage of these panels is that they are well-known elements that are already used extensively, and, therefore, more documentation of their performance exists.

- Metallic materials (steel and aluminum)

Steel grids can also be used in ABC projects. There are two types. The first one is an open grid deck that does not require concrete fill [6] which is most commonly used for bridges that require very light decks, such as movable and suspension bridges. The second type is the concrete-filled grid that requires either a full fill, a partial fill of concrete, covering the top of the grid, or a placement of concrete above the grid, a system known as an exodermic deck. The steel grid has the advantage of being a lightweight system [5].

According to Culmo et al. [5], there are also identified metal panel deck systems that can provide a very long service life with a reduced weight compared to traditional concrete decks. There are three main systems: (1) the orthotropic deck shown in Figure 2, which is composed of a steel top plate, supported by open or closed ribs that are welded to its underside, on which the running surface is directly placed [5]; (2) the extruded aluminum deck, composed of extruded aluminum elements that are joined to form an orthotropic deck system [5]; (3) steel sandwich panels, which are similar systems to the orthotropic deck system except that they consist of a bottom plate, placed below the ribs, in addition to the top plate of the deck, forming a sandwich [5].

Figure 2.

Orthotropic deck (Photo courtesy of CIMA+).

- Timber

For low-traffic bridges, the prefabricated timber solution may be attractive. A glulam deck is composed of wood panels that are prefabricated using a glue-lamination process [5].

- Fiber-reinforced polymer

One system that is increasingly developing and gaining popularity is the prefabricated fiber-reinforced polymer deck panel, typically made with glass and carbon fibers, which offers the advantages of a high tensile strength, light weight, high fatigue resistance and good corrosion resistance over other structural materials [5].

Other systems under development are also promising, such as the UHPC-CFRP Waffle Deck Panel, an ultralightweight low-profile waffle slab of ultra-high-performance concrete reinforced with carbon-fiber-reinforced polymer (CFRP) bars, which reveals a comparable performance to that of a similar deck using high-strength steel reinforcement [8].

2.2.2. Girders

It is common to differentiate beams according to two materials: steel and concrete.

- Steel girders

Steel girders can be configured in many ways to form a superstructure framing system and can be combined with a precast concrete deck to form modular superstructure units. They are typically I-shaped and have the advantage of being designed from a material with known and defined properties [9,10].

- 2.

- Prestressed/Reinforced Concrete Girders

Precast prestressed, conventional or high-performance concrete girders are some of the most common types of precast superstructure elements [5]. Thus, many forms of precast girders are available, and each one has its own unique characteristics. There are four main types of girders:

- Precast concrete (PC) I-girders

These are prefabricated I-girders that can be post-tensioned and whose performance is surveyed and known [11,12]. There are three main types of I-beams in the U.S. which are PC-I type I to IV, PC-I type Wisconsin and PC-I type MI 1800 [9,13,14,15].

- Precast spread box girders

These are prefabricated girders that are shaped like a rectangular prism and have the advantage of having a small depth, allowing them to be used for a low-clearance site project [13].

- Precast bulb-tee girders (or New England Bulb Tee girders, NEBT)

These are precast girders with a significantly higher capacity than standard I-girders and can be used for projects requiring medium-range spans [9,16,17].

- Precast NU-I girders (University of Nebraska girders)

These are I-girders that are standardized according to different dimensions, knowing that the greater the height of the beam, the greater its span. These girders have the advantage of being able to be equipped with pre-stressing and post-tensioning, allowing them to cover long spans [18,19,20,21]. Precast NEBT girders are shown in Figure 3.

Figure 3.

Precast NEBT girder (Photo courtesy of CIMA+).

2.2.3. Modular Systems

Modular systems are systems consisting of one or more prefabricated element of a bridge that can be adapted to the project. They have the advantage of being able to be placed directly on the infrastructure according to the project’s needs. There are different types of modular systems depending on the main material used.

- Metallic systems

There are three common types.

- Topped multi-beam unit

This system is composed of modular elements themselves consisting of two or three steel beams topped by a precast reinforced concrete deck [5].

- Orthotropic systems

These are systems consisting of either a single-span orthotropic superstructure with ribs across the span of the bridge or an orthotropic deck T-girder that combines a steel girder with a portion of an orthotropic deck [5].

- Modular folded plate girder system

There are two main variations of this system. The first one is the modular folded plate girder bridge system, which is composed of folded plate girders in the form of a tube that are then inverted to accommodate a factory-cast concrete deck [22]; the second is the press-brake-formed tub girder, which is composed of folded plate girders in the form of trapezoidal boxes, as shown in Figure 4 for Valmont® U-BEAM™, on which a concrete deck is cast in a factory [22]. Both system variations can also accommodate full-depth precast deck panels or a cast-in-place slab.

Figure 4.

Folded plate girder, reprinted with permission from [22], 2022, Valmont Structures.

- 2.

- Modular precast concrete systems

- Inverted-T precast slab

This type of system is based on the Girder-Slab system used in France. The system can accommodate prestressing and is satisfactory for projects with small dimensions since its depth-to-span ratio is quite high [23,24].

- Precast Adjacent Box Girders

This type of system consists of precast beams with an integral deck separated by a closure joint, eliminating the need to form and pour a concrete deck on the site [6]. There are multiple shapes for these girders: in the form of a rectangular prism, which is an ideal choice for short-span bridges [25]; in the form of a trapezoid, which can be a closed or open box and has the advantage of spanning the entire bridge with a reduced number of girders compared to other box girders [26]; and a box girder with an integral deck that uses post-tensioning and has the advantage of having a low height, allowing for its use for sites with limited clearance [25].

- Double-Tee Girder

It is a system consisting of two precast/prestressed T-girders. The main advantage of the system is that the top flange of the girders directly serves as formwork for the cast-in-place deck [9,27,28].

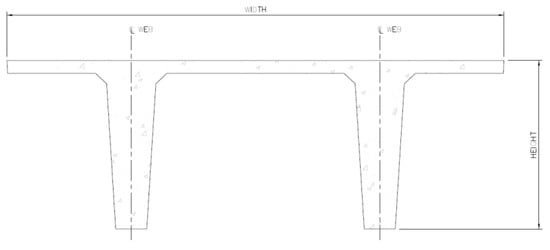

- Northeast Extreme Tee (NEXT) Beam

This system consists of two prefabricated/pre-stressed T-beams shown in Figure 5. There are two types. The first is the NEXT F beam, where the top flange is used to support a cast-in-place reinforced concrete deck, and the second type is the NEXT D beam consisting of a precast integral deck [29]. The system has the advantages of being satisfactory for projects with clearance limitations and having a higher load capacity than standard double-T and box girders [5,25].

Figure 5.

Section of a NEXT beam (Drawing courtesy of CIMA+).

- Decked Bulb-Tee Girder

This system is based on the same principle as that of the NEXT beams since it is composed of a bulb-tee girder and an integral deck. Unlike simple bulb-tee girders, here, the top flange of the girder is widened and thickened to allow for connections [5]. This type of system is more efficient than traditional AASHTO-I girders and has the advantage of having an integral deck [29].

- Precast Segmental Box Girder

This system is primarily used for segmental construction, which involves the prefabrication of elements forming the deck of a bridge, which are lifted on site and post-tensioned together in the process of successive corbel construction [5]. The girders are typically trapezoidal precast/prestressed concrete box sections, as shown in Figure 6, that are connected through shear keys and lateral post-tensioning to form the entire superstructure [29]. The advantage of the system is that it is a cost-effective option for large projects and allows for the crossing of large waterways [30].

Figure 6.

Precast segmental box girder (Photo courtesy of CIMA+).

- Pi-Girder

The system consists of two girders and an integral deck, forming a U-shape. Its advantage is that it is well suited for sites with limited clearance [31,32].

- 3.

- Mixed steel–concrete systems

- Precast modified beam-in-slab

It is a composite system consisting of steel beams covered with concrete with an integral deck. The system has the advantages of being suitable for sites with limited clearance and providing additional corrosion protection for the steel beams that are embedded in the concrete [33].

- INVERSET™ system

It is a patented system designed in the 1980s in Oklahoma [34] consisting of steel beams with an integral composite concrete deck [35], as shown in Figure 7.

Figure 7.

Typical INVERSET™ system, reprinted with permission from [34], 2009, FHWA.

- Decked Steel Girder System

This composite system consists of steel girders and an integral deck. Because the deck is integrated into the system, it is suitable for sites with limited clearance [36].

- 4.

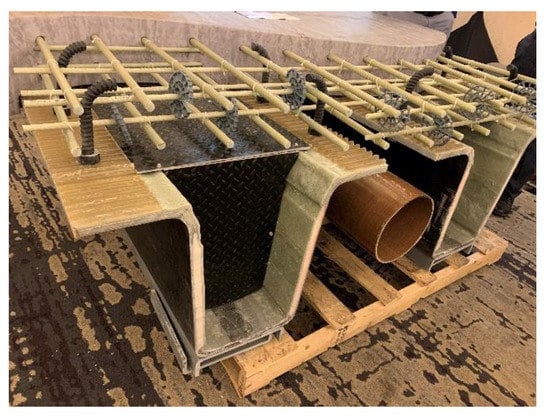

- FRP girder system

FRP girders are developed and used in ABC methods. The FRP girders are composites with a concrete slab reinforced with FRP rebars. This system is already used in many states in the United-States. Figure 8 shows a sample of FRP tub girders used in a bridge constructed in Westerly, RI, USA. This example was presented in the Composite Bridge Design Workshop at the Florida International University on 7 December 2022.

Figure 8.

Sample of an FRP tub girder composite with a concrete slab.

- 5.

- Timber systems

There are two main systems.

- Laminated deck span system

This system is composed of adjacent wood members that are laid side by side to form solid timber panels that can be used to span the entire length of the bridge [5].

- Laminated girder deck system

It is a system with the purpose of supporting deck panels that are similar to bridge spans, but the panels extend transversely from one girder to the other [5].

2.2.4. Barriers

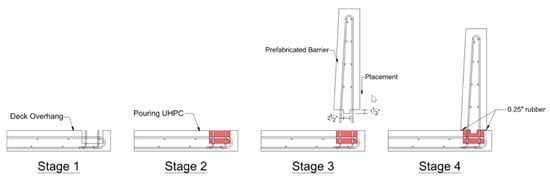

Barriers, railings or parapets are elements that can be prefabricated continuously with the slab, independently of it or cast in place. Figure 9 shows the stages of construction of prefabricated barriers using UHPC [37].

Figure 9.

Example of an UHPC connection for a prefabricated barrier system, reprinted with permission from [37], 2022, ABC-UTC.

2.3. Most Commonly Used PBES in Short- and Medium-Span Bridges

Not all PBESs are suitable for all types of bridges and all types of spans. Therefore, this section reviews the PBESs that are best suited for each category of bridge span.

Let us break down bridge spans according to the following classification, as mentioned in most consulted references, rounded to 1 m:

- Short span: 6 to 18 m [38];

- Short to low-medium range: 18 m to 40 m [38];

- Medium range: from 40 m to 80 m [38];

- High-medium range: over 80 m up to 125 m [38].

Table 1, Table 2, Table 3 and Table 4 provide the most commonly used PBESs in short- and medium-span bridges.

Table 1.

PBESs suitable for a short span: 6 to 18 m.

Table 2.

PBESs suitable for a short- to low-medium-range span: from 18 to 40 m.

Table 3.

PBESs suitable for a medium-range span: from 40 to 80 m.

Table 4.

PBESs suitable for a high-medium-range span: from 80 m to 125 m.

3. General Synopsis of Connection Joints

Joints between elements have two functions: first, to provide space to install filler materials that are either used to seal the joint or to make a structural connection; and second, to allow for the adjustment of the elements during erection to accommodate their tolerance [41]. Joints play an essential role, as they allow for the transmission of mechanical forces between adjoining elements [42]. Because of this, they are an important detail and must be designed to minimize leakage, cracking and, thus, corrosion and deterioration. Therefore, the joints must receive special attention, and the shrinkage, the quality of the grout and the type of coating must necessarily be considered and optimized to ensure the integrity of the structure. A distinction is made between closure joints and shear keys.

3.1. Closure Joints

There are four main types of closure joints used in conjunction with PBES for ABC projects.

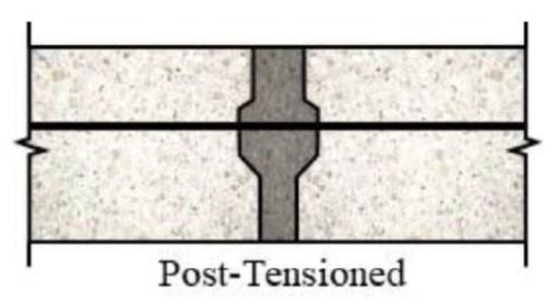

- Post-tensioned connections

This type of joint uses female-to-female connections and is applied using high-strength steel strands or bars that are secured through the deck panels [43], as illustrated in Figure 10. The post-tensioning is typically placed at the mid-depth of the panels and runs the length of the deck [7]. Post-tensioned joints have been used since 1997 in the United States. They have a good construction speed, have very good durability, are easily accessible for inspection and have very little need for early maintenance. Nevertheless, these joints are quite expensive [34].

Figure 10.

Post-tensioned joint, reprinted with permission from [43], 2019, ABC-UTC.

- 2.

- Mechanical Connections

This type of joint is used to connect prefabricated bridge elements. It is possible to use a coupler with a sealed dowel or a welded coupler. However, because of long-term performance problems due to corrosion, this connection is no longer commonly used. The welded coupler has the poorest performance among the other connections [43].

- 3.

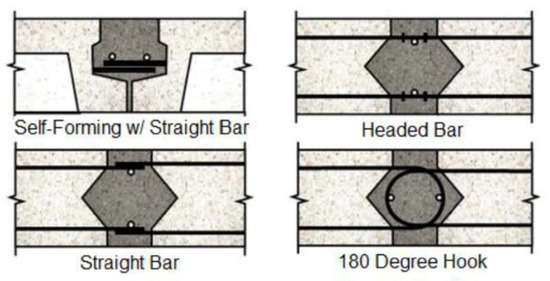

- Ultra-High-Performance Concrete Connections

This type of joint allows the transverse reinforcing bars to be developed over a minimum embedment length as short as eight times the bar diameter, thus reducing the width of the closure joint [43]. Four joint details using ultra-high-performance concrete are illustrated in Figure 11.

Figure 11.

Joints using ultra-high-performance concrete, reprinted with permission from [43], 2019, ABC-UTC.

- 4.

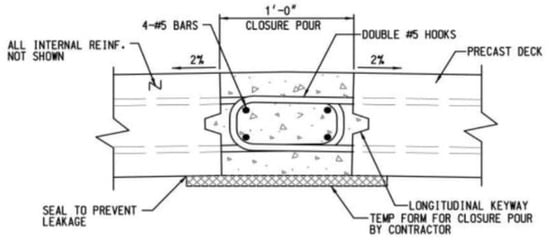

- Connections using normal-strength concrete

This type of joint is composed of several types of joint details including 180- or 90-degree hooked bars, straight bars, headed bars and spiral reinforcement [43]:

- The headed bar is used to connect precast deck modules. The use of 15 M headed rebar bases provides a satisfactory structural performance for narrow closure joints. The main issue of this type of connection is the enlarged size of the head at the end, which reduces the concrete cover at that location [43];

- The 180-degree hooked bar (or full hook), as shown in Figure 12, is employed to offer a remedy for the issue that headed bars present [43]. Generally, it makes sense to use this type of joint in the longitudinal direction [7]. For the United States, the AASHTO LRFD Specifications indicate a bend diameter that results in a deck thickness greater than 240 mm, yet the deck thickness is typically less than 215 mm, and, therefore, the use of full hooked bars will result in an increase in the deck thickness [43]. The hooked bar detail has a very good construction speed and durability and is easily accessible for inspection [34];

Figure 12. Details of a closure joint with a 180-degree hooked bar, reprinted with permission from [34], 2009, FHWA.

Figure 12. Details of a closure joint with a 180-degree hooked bar, reprinted with permission from [34], 2009, FHWA.

- A straight bar (or straight reinforcement) is one of the most common methods of joining precast decks, despite the fact that straight bars require wider closure joints for the development of bar tension [43]. Thus, it is best used in the longitudinal direction, where the joint between panels follows the line of the beam [7]. The straight bar detail has very good durability and is easily accessible for inspection [34];

- Spiral reinforcement consists of winding the straight bars of adjacent slabs with spiral reinforcement in the closure joint. This method of reinforcement is rarely used because its construction is difficult [43].

- 5.

- Performance

The three closure joints identified as having no lifetime performance issues are post-tensioned joints, ultra-high-performance concrete joints with straight bars and joints with full hook bars (180-degree hook) [43].

3.2. Shear Keys

Based on their shape, four types of shear keys are used to transmit the shear between adjacent segments or parts of the bridge: the diamond or rectangle shear key, the straight shear key, the U-shaped shear key and the V-shaped shear key [43].

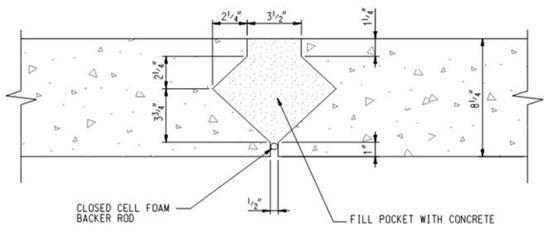

- Diamond or rectangular shear key

This key, shown in Figure 13,, is a type of linear joint that is primarily used to provide shear transfers and connect full-depth precast decks together or, in some cases, to connect precast girders together. The disadvantage of this type of connection is related to its shape, which promotes the possibilities for void formation, debonding and porous grouting at the corners [43]. Despite this, the key has the advantages of being easily assembled, quick to construct and inexpensive and having decent durability, and it is easily accessible for inspection [34]. It is the most used type of closure and is recommended in the AASHTO LRFD Specifications for ABC, both longitudinally and transversely [43].

Figure 13.

Diamond shear key, reprinted with permission from [34], 2009, FHWA.

- 2.

- Straight Shear Key

This key is normally used to connect full-depth precast panels to each other and precast decks to precast concrete girders. This connection has straight, or nearly straight, sides that allow for better concrete placement and a lesser risk of void formation [43].

- 3.

- U-Shaped Shear Key

This key is similar to the straight shear key but is normally used to connect partial-depth precast deck panels, full-deck precast girders and, in some cases, longitudinal connections of precast slabs to steel girders. The joint is cast in both longitudinal and transverse directions to ensure the continuity and negative moment transfer at the piers and includes longitudinal and transverse reinforcement; if not, post-tensioning can be used. The joint is not commonly used [43]. The U-shaped key is very quick and easy to construct and has very good durability, but it is not readily visible for inspection [34].

- 4.

- V-Shaped Shear Key

This key is normally used to connect two prestressed T-girders, two double beams or, in some cases, full-depth or partial-depth deck panels. To form the V-shape of the joint, it is common to place a smooth lateral connecting rod between two connecting plates. These keys are primarily used in the longitudinal direction, normally extending the full length of the girder and spaced at intervals equal to the width of the girder. The joint is not commonly used [43]. The V-shaped shear key is quick and easy to construct, is inexpensive, has good durability and is easy to inspect [34].

3.3. PBES Connections

This subsection lists the most used connections for specific PBESs.

- Full-depth deck panels

To connect full-depth deck panels, it is common to use longitudinal joints, which are parallel to the load-bearing girders, and transverse joints, which are perpendicular to the load-bearing girders or follow the inclination of the bridge. The two most common combinations of transverse and longitudinal joints are: conventional concrete joints with straight or hooked bars placed longitudinally and joints with longitudinal post-tensioning placed transversely; and ultra-high-performance concrete joints with straight bars placed longitudinally and transversely [7].

- 2.

- Girders with an integral deck

These girders require a connection at the edge of the deck, where adjacent girders meet [6]. There are several types of connections: conventional reinforced concrete closure joints with conventional reinforcement; grout-reinforced closure joints; closure joints with headed or hooked bars; ultra-high-performance concrete joints with straight or hooked bars; welded plate connections; and transverse post-tensioning [6].

3.4. Materials Used in Conjunction with PBESs

Whether used for prefabricated elements and systems or for their connections, the materials and their performance are a major issue for the durability of the structure. For example, the materials chosen for making joints and precast elements are relatively similar, since the materials used for closing joints must have equal or greater durability compared to the connected elements [42].

For closure joints, the materials used must meet special durability criteria such as having a low permeability, low shrinkage, high adhesion and satisfactory freeze–thaw resistance [42]. In addition to normal- and high-strength concrete, two other materials are more commonly used: (1) ultra-high-performance concrete; and (2) cementitious grouts.

3.4.1. Ultra-High-Performance Concrete

Ultra-high-performance concrete is a cementitious composite material with discontinuous fiber reinforcement, a compressive strength greater than 140 MPa, pre- and post-crack tensile strengths greater than 5 MPa and increased durability due to their discontinuous fiber reinforcement [44]. A range of mechanical properties of ultra-high-performance concrete is presented in Table 5.

Table 5.

Mechanical properties of ultra-high-performance concrete [7].

In addition, its low permeability makes it a very suitable material for northern climates experiencing freeze/thaw actions. Indeed, ultra-high-performance concrete is composed of different fine materials and has a very dense structure, thus implying that the amount of water it absorbs is reduced. As a result, the low transport and presence of water and ions in ultra-high-performance concrete structures in turn greatly improve durability performance, such as chemical and frost resistance [45]. Ultra-high-performance concrete is composed of Portland cement, fine sand, ground quartz, high-performance water reducing admixture (HRWR), accelerating admixture, steel fibers and water.

Ultra-high-performance concrete is often used to make the joints between the elements. Indeed, the reinforcing steel has a strong adhesion with the ultra-high-performance concrete; it is possible to develop reinforcing bars on a very short length. The minimum embedment length of a rebar in ultra-high-performance concrete can be eight times the diameter of the bar. This reduces the width of the closure joint and allows the transverse reinforcement to be developed over a short length [46].

In sum, with higher compressive and tensile strengths than conventional concrete, among other things, ultra-high-performance concrete is an optimized material for accelerated construction and is proving to be a long-term durable material, resulting in lower maintenance and repair costs. Ultra-high-performance concrete is much more durable than conventional concrete and high-strength concrete, but it still has some degradation characteristics after long-term freezing and chemical actions that still lead to material deterioration [45].

3.4.2. Cementitious Grouts

For pockets and joints, a durable, low-shrinkage, early high-strength and high freeze/thaw-resistant type of cementitious grout is used. Non-shrink cementitious grouts are the most used materials for precast full-depth deck panel connections because they are economical and can reach the desired characteristics [7]. Epoxy grouts are also common, but they normally have a lower modulus of elasticity and are relatively more expensive than cement-based grouts [7].

3.5. Adaptability of ABC to Cold Weather

Countries with cold or northern climates are exposed to arid weather in winter. Structures made of concrete deteriorate mainly due to freeze/thaw actions. Indeed, a concrete structure can suffer damages such as surface spalling caused by its exposure to freeze/thaw in the presence of moisture, deicing salts, insufficient entrained air or an inadequate air bubble network.

To resist freezing/thawing, it is necessary to increase the volume of air by using a chemical admixture (air entraining agent), leading to better air distribution [47]. Additionally, a concrete mixture that has fine pores with a low W/C ratio will help prevent the freeze/thaw cycle because less water can freeze [48]. The factors influencing freeze/thaw resistance are the ratio of the water to the binder, the volume of air entrained and the drying period before freezing exposure [49].

Several solutions can also be combined in order to optimize the costs and the quality of concrete structures. Some solutions may help in adapting to cold weather by altering the chemical properties of concrete, as, for example, with the use of accelerators, allowing for an increase in the initial resistance of concrete and improving its behavior against freezing [50], or with the use of antifreeze for concrete hardening at temperatures going down to −7 °C, which allows for the extension of the concreting period without using protective methods [51,52]. When the aforementioned measures are not sufficient, it is possible to use solutions affecting the concrete environment through protective methods such as insulation in the form of blankets covering the concrete or in the form of formwork [50] or the use of heated protective enclosures with air heated between 10 °C and 20 °C, which allow the concrete to reach maturity [53].

4. Canadian Experience in PBESs, Materials and Products

This section describes the PBESs used in Canada. Furthermore, it presents different materials and products that are compatible with severe winter construction conditions.

4.1. PBESs Already Used in Canada

The first recorded use of precast elements in Canada for bridge construction was in 1952 with the Mosquito Creek Bridge in North Vancouver, British Columbia. The structure is composed of precast prestressed slab beams [54]. Recently, the bridge has been replaced with a precast superstructure [55].

In 1990, in British Columbia, the Esker Overhead Bridge was built. The bridge is composed of precast concrete and steel elements including precast I-beams [56].

In 2001, the first bridge in Alberta using NU-I precast girder technology was erected. The technology was used for the Oldman River Bridge in Taber [57] and was also used for the Bow River Bridge in Calgary in 2002 [58]. Alberta has used this technology many times and published a manual for bridge design using this technology [57].

In Saskatchewan, side-by-side prefabricated and prestressed box girders were used for the McOrmond and Boychuk interchanges in 2019 [59,60].

In 2003, in Winnipeg in the province of Manitoba, a bridge composed of a trapezoidal box girder system was built [61].

The province of Ontario has also been home to bridge projects composed of precast elements and systems, such as the Moose Creek Bridge built in 2004 using precast I-girders [54].

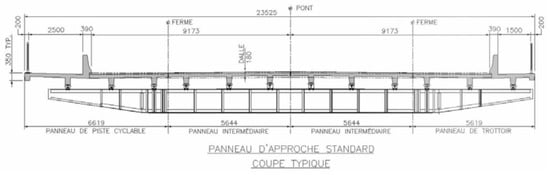

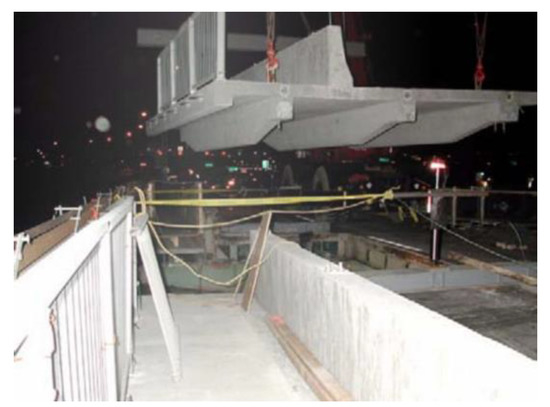

Precast elements and systems have also been used in Quebec, such as the new Samuel de Champlain Bridge in Montreal, which used precast elements and accelerated construction techniques [62]. Between 2000 and 2002, the Jacques-Cartier bridge had its deck replaced to extend its lifespan. The original deck was replaced by an integrated deck system, composed of high-performance precast concrete panels made up of three variable inertia ribs, as shown in Figure 14 and Figure 15. The joints were post-tensioned both longitudinally and transversely [63].

Figure 14.

Typical section of the standard approach panel of the new Jacques-Cartier bridge deck, reprinted with permission from [63], 2002, Mailhot, G.

Figure 15.

Installation of a prefabricated panel for the replacement of the Jacques-Cartier Bridge deck, reprinted with permission from [63], 2002, Mailhot, G.

4.2. Materials and Products Suitable for Use in Cold Weather Regions

It is recognized that ABC projects can be carried out in areas with severe winter temperatures, but the work is generally concentrated in the warmer seasons of the year. Nevertheless, cold weather construction is becoming increasingly feasible as more and more products are developed that allow for it. This subsection presents materials and products that are compatible with construction in cold weather.

In the following, the products are classified according to their category of use.

- Hardening accelerator

A hardening accelerator can be used as an additive (that can be chloride-free) for cementitious mortars, concretes and grouts to allow for applications at low temperatures. Its application temperature can be down to −5 °C [64].

- 2.

- Flowable cementitious grout

A flowable cementitious grout can be used with a low-temperature substrate. It was used mainly for grouting piles and anchoring rebar in pile jackets in permafrost installations. Its application temperature can be down to −10 °C and can reach a compressive strength of 28 MPa after 24 h when the substrate temperature is −10 °C [64].

- 3.

- Grout/Mortar/Anchoring System

- A mortar can be used as a low-temperature, rapid curing, vinyl ester grout/mortar and injection resin for repairing concrete or for grouting base plates and various types of anchoring. Its application temperature can be down to −40 °C, and it cures down to −20 °C [64].

- A convenient, low-temperature modified-methacrylate structural repair mortar/grouting system can be used for repairing concrete, grouting base plates and patching roadways, bridge decks and floors. Its application temperature can be down to −10 °C or −25 °C with an additive [64].

- 4.

- Anchoring Gel

An anchoring gel can be used as a cold-weather epoxy acrylate hybrid for water-saturated conditions for the heavy-duty anchoring of rebar, threaded rods and epoxy-coated smooth dowels in concrete, brick and stone masonry. Its application temperature can be down to −26 °C [64].

- 5.

- Structural Adhesive

A structural adhesive can be used as a high-modulus, high-strength, solvent-free and moisture-tolerant structural epoxy resin paste adhesive for the structural bonding of precast, post-tensioned concrete bridge segments and the sealing of joints between concrete segments. Its application temperature can be down to −6 °C [65].

Thus, there are many materials and products that are suitable for ABC methods for bridges built or repaired in severe winter climate conditions. Currently, for connections, only one product is used and can be applied down to −6 °C. Nevertheless, products for repairs, anchors or seals exist and can be applied for temperatures below −6 °C. These products are good items for future research regarding their possible use in connection joints.

5. Performance and Sustainability of the PBESs

Although the PBESs have been used in many bridges for decades, the majority of these systems were implemented in ABC projects in the last two decades, and long-term performance tracking is not available for all types of elements and systems. One of the most commonly used systems is the Full-Depth Precast Concrete (FDPC) deck panels. Garber and Shahrokhinasab investigated the performance of Full-Depth Precast Concrete deck panels compared to Cast-in-Place decks [66]. Their investigation is based on the bridge inspection data and the survey responses received from the Departments of Transportation (DOTs) of 31 states that have this type of structure in their inventories. There is a total of 301 projects that were reported to have FDPC deck panels and were constructed mainly in the last three decades. Only 24 bridges were built before 1990, whereas 160 bridges were built between 2010 and 2019. The largest number of these bridges were built in cold and very cold weather regions, such as 125 bridges built in the state of New York and 40 bridges built in the state of Alaska. Two parameters were calculated to characterize the performance of the investigated system. The first parameter is the deterioration rate based on the inspection data from the National Bridge Inventory (NBI). The second parameter is the estimated service life of the deck, which represents the time it takes for the deck rating to reach a rating of 5. Note that the rating is scaled from 0 to 9, and a deck rating of 4 is the threshold for the need for deck repair. The following are the main results obtained:

- i.

- The average deterioration rate for bridges with FDPC deck panels was found to be slightly higher than that for bridges with CIP decks (−0.12 compared to −0.09). This leads to a slightly longer estimated service life for bridges with CIP decks, which was found to be 35 years compared to 33 years for bridges with FDPC deck panels.

- ii.

- The deterioration rates for bridges with different types of transverse and longitudinal joints are presented. Although these values are highly scattered, we can observe that transverse mechanical welded joints, the UHPC with 180 °C hooks and the conventional concrete joints with 180 °C hooks perform the worst. They have a deterioration rate of −0.13, −0.40 and −0.17, respectively, with an estimated service life of less than 30 years. The small number of bridges per type of joint and the relatively recent construction for most of them do not allow to draw recommendations from this study about which joints have the best performance.

- iii.

- The deterioration rate for bridges with FDPC deck panels in very cold weather regions was found to be higher than that for bridges with CIP decks in the same regions (−0.08 compared to −0.05). This leads to a shorter estimated service life for bridges with FDPC deck panels, which was found to be 35 years compared to 38 years for bridges with CIP decks. Both FDPC and CIP decks showed the same deterioration rate in the cold weather regions, which was −0.09 along the period of inspections; however, the estimated service life for FDPC decks was found to be 33 years compared to 35 years for CIP decks in cold regions.

- iv.

- The deterioration rate is increasing for FDPC deck panels with a high volume of traffic compared to CIP decks. For an Average Debit Truck Traffic (ADTT) of more than 6000, the deterioration rate of FDPC deck panels is −0.16 compared to −0.09 for CIP decks. This leads to an estimated service life of 28 years for FDPC deck panels compared to one of 34 years for CIP decks.

- v.

- Other factors, such as the type of wearing surface and the main span material, are also found to influence the performance of FDPC deck panels. However, there is no influence found for the construction type regarding the performance of FDPC deck panels; new construction and rehabilitation projects showed the same deterioration rate and the same estimated service life.

The researchers concluded that the study results suggest that, overall, bridges with FDPC deck panels performed similarly to CIP bridges; however, there is room for the improvement of joint design and construction.

Although no other studies were found for the long-term performance and sustainability of the systems previously discussed in this paper, Mehrabi et al. [67] established considerations for the superstructure system and elements selection while beginning an ABC project by identifying their own advantages and disadvantages, based on the lessons learned from the PBES projects implemented in recent years.

6. Conclusions

Based on the present findings about the state of the art of the elements, systems, connections and materials for the execution of ABC projects, adaptability for severe cold climate conditions seems promising. During the review of the literature, the main prefabricated elements and systems used in ABC projects were stated, which allowed us to draw a portrait of the most used PBESs for short- to medium-span bridges. The performance of FDPC deck panels compared to CIP decks was also reviewed, and the main findings were reported. Furthermore, the review of the literature concerning connections and their materials allowed for the identification of the most efficient technologies to be used in conjunction with the previously portrayed PBES. Finally, as the materials used for connections are critical for the durability and adaptability of the ABC method for countries with severe winter climates, materials and products that are the most suitable for the present issues were looked at. Thus, by taking note of existing projects in Canada that have borrowed steps from the ABC method and by noting products and materials applicable to low temperatures, one can see that adaptability is possible. Research can be undertaken or continued with a focus on specific products, particularly those that are used for sealing, anchoring or repair and which are applicable at very low temperatures. Those products could possibly be used for connections of PBES elements.

Author Contributions

Conceptualization, L.A.; M.H. and J.J.; methodology, L.A., M.H. and J.J.; writing—original draft preparation, L.A. and M.H.; writing—review and editing, M.H., J.J. and L.G.; supervision, M.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Éditions Eyrolles. Available online: https://www.editions-eyrolles.com/Dico-BTP/definition.html?id=7196 (accessed on 4 October 2022).

- Hassan, M. (École de Technologie Supérieure, Montréal, Québec, Canada). Personal communication, 2021.

- U.S. Department of Transportation Federal Highway Administration. Available online: https://www.fhwa.dot.gov/bridge/abc/ (accessed on 4 October 2022).

- Hällmark, R.; White, H.; Collin, P. Prefabricated bridge construction across Europe and America. Pract. Period. Struct. Des. Constr. 2012, 17, 82–92. [Google Scholar] [CrossRef]

- Culmo, M.P.; Lord, B.; Huie, M.; Beerman, B. Accelerated Bridge Construction: Experience in Design, Fabrication and Erection of Prefabricated Bridge Elements and Systems: Final Manual; United States, Federal Highway Administration, Office of Bridge Technology: Washington, DC, USA, 2011.

- Culmo, M.P.; Marsh, L.; Stanton, J. Recommended AASHTO Guide Specifications for ABC Design and Construction, 1st ed.; The National Academies Press: Washington, DC, USA, 2018. [Google Scholar]

- Shahrokhinasab, E.; Garber, D. ABC-UTC Guide for: Full-Depth Precast Concrete (FDPC) Deck Panels (May 2019), ABC-UTC. Available online: https://abc-utc.fiu.edu/wp-content/uploads/sites/52/2019/05/ABC-UTC-Guide-to-FDPC-Deck-Panels.pdf (accessed on 16 January 2023).

- Ghasemi, S.; Mirmiran, A.; Xiao, Y.; Mackie, K. Novel UHPC-CFRP waffle deck panel system for accelerated bridge construction. J. Compos. Constr. 2016, 20, 04015042. [Google Scholar] [CrossRef]

- Chung, P.; Wolfe, R.; Ostrom, T.; Hida, S. Accelerated Bridge construction applications in California—A lessons learned report (August 2008). Caltrans CADOT. Available online: https://dokumen.tips/documents/accelerated-bridge-construction-applications-in-i-caltrans-engineering-services.html?page=1 (accessed on 16 January 2023).

- Richardson, M.W.; Scott, D.L.; Tremblay, J.A. Concrete Bridges in New Hampshire. ASPIRE 2009, 9, 48–50. [Google Scholar]

- Bardow, A.K.; Seraderian, R.L.; Culmo, M.P. Design, fabrication and construction of the New England Bulb-Tee girder. PCI J. 1997, 42, 30–40. [Google Scholar] [CrossRef]

- Optimized Sections for High-Strength Concrete Bridge Girders–Effect of Deck Concrete Strength. (October 2006), U.S. Department of Transportation Federal Highway Administration. Available online: https://www.fhwa.dot.gov/publications/research/infrastructure/structures/05058/05058.pdf (accessed on 16 January 2023).

- Abudayyeh, O. A Sensor Network System for the Health Monitoring of the Parkview Bridge Deck; Michigan, Dept. of Transportation: Lansing, MI, USA, 2010.

- MDOT-BDM. Michigan Bridge Design Manual (BDM), 5th ed.; Michigan Department of Transportation (MDOT): Lansing, MI, USA, 2011.

- Attanayake, U.; Abudayyeh, O.; Cooper, J.; Mohammed, A.W.; Aktan, H. First full-depth deck-panel accelerated bridge construction project in Michigan: Constructability challenges and lessons learned. J. Perform. Constr. Facil. 2014, 28, 128–135. [Google Scholar] [CrossRef]

- Lavallee, R.; Cadman, K. New England Bulb Tee girder brings strength, elegance and economy to Jetport Interchange Bridge. PCI J. 2001, 46, 68–75. [Google Scholar] [CrossRef]

- Fouad, F.H.; Rizk, T.; Stafford, E.L.; Hamby, D. A Prefabricated Precast Concrete Bridge System for the State of Alabama; University Transportation Center for Alabama: Tuscaloosa, AL, USA, 2006. [Google Scholar]

- Geren, K.L.; Tadros, M.K. The NU precast/prestressed concrete bridge I-girder series. PCI J. 1994, 39, 26–39. [Google Scholar] [CrossRef]

- Beacham, M.; Derrick, D. Longer Bridge spans with Nebraska’s NU I-girders. TR News 1999, 203, 42–43. [Google Scholar]

- Hanna, K.; Morcous, G.; Tadros, M.K. Design Aids of NU I-Grinder Bridges. Neb. Dep. Transp. Res. Rep. 2010, 64, 1–439. [Google Scholar]

- Morcous, G.; Hanna, K.; Tadros, M.K. Impact of 0.7-inch diameter strands on NU I-girders. Neb. Dep. Transp. Res. Rep. 2011, 88, 1–204. [Google Scholar]

- Valmont Structures. Available online: https://az276020.vo.msecnd.net/valmontproduction/docs/librariesprovider97/bridge---technical-docs/valmont-bridge-u-beam-specification-guide-and-catalog-_-valmont-bridge-systems.pdf?sfvrsn=c49eaa39_2 (accessed on 3 December 2022).

- Bell, C.M.; French, C.E.; Shield, C.K. Application of precast decks and other elements to bridge structures. Minn. Dep. Transp. Res. Rep. 2006, 37, 1–271. [Google Scholar]

- French, C.; Shield, C.; Klaseus, D.; Smith, M.; Eriksson, W.; Ma, Z.; Zhu, P.; Lewis, S.; Chapman, C.E. Cast-in-Place Concrete Connections for Precast Deck Systems; NCHRP Project 10-71; Transportation Research Board: Washington, WA, USA, 2011. [Google Scholar]

- Culmo, M.P.; Seraderian, R.L. Development of the northeast extreme tee (NEXT) beam for accelerated bridge construction. PCI J. 2010, 55, 86–101. [Google Scholar] [CrossRef]

- Badie, S.S.; Kamel, M.R.; Tadros, M.K. Precast pretensioned trapezoidal box beam for short span bridges. PCI J. 1999, 44, 48–59. [Google Scholar] [CrossRef]

- PCI Committee. Fabrication and shipment cracks in prestressed hollow-core slabs and double-tees. PCI J. 1983, 28, 1–24. [Google Scholar]

- Li, L.; Ma, Z.; Griffey, M.E.; Oesterle, R.G. Improved longitudinal joint details in decked bulb tees for accelerated bridge construction: Concept development. J. Bridge Eng. 2010, 15, 327–336. [Google Scholar] [CrossRef]

- Culmo, M.P.; Seraderian, R. Guidelines for Accelerated Bridge Construction Using Precast/Prestressed Concrete Elements Including Guideline Details, 2nd ed.; Precast/Prestressed Concrete Institute Northeast (PCINE): Chicago, IL, USA, 2014. [Google Scholar]

- Freyermuth, C.L. AASHTO-PCI-ASBI Segmental Box Girder Standards: A new product for grade separations and interchange bridges. PCI J. 1997, 42, 32–42. [Google Scholar] [CrossRef]

- Graybeal, B.A. Structural Behaviour of a 2nd Generation Ultra-High Performance Concrete Pi-Girder; United States, Federal Highway Administration, Office of Infrastructure Research and Development: Washington, DC, USA, 2009.

- Rouse, J.; Wipf, T.J.; Phares, B.; Fanous, F.; Berg, O. Design, Construction, and Field-Testing of an Ultra High Performance Concrete Pi-Girder Bridge; Iowa State University, Institute for Transportation: Ames, IA, USA, 2011. [Google Scholar]

- Klaiber, W.; Wipf, T.; Wineland, V. Precast Concrete Elements for Accelerated Bridge Construction: Laboratory Testing, Field-Testing, and Evaluation of a Precast Concrete Bridge, Black Hawk County; Iowa State University, Center for Transportation Research and Education: Ames, IA, USA, 2009. [Google Scholar]

- Culmo, M.P. Connection Details for Prefabricated Bridge Elements and Systems; United States, Federal Highway Administration, Office of Bridge Technology: Washington, DC, USA, 2009.

- Versace, J.; Ramirez, J.A. Implementation of Full-Width Precast Bridge Deck Panels: A Synthesis Study. Purdue Univ. West Lafayette Indiana 2004. [Google Scholar] [CrossRef]

- LaViolette, M.D.; Evans, D.; Nelson, J.; Sivakumar, B. ABC Modular Bridge Demonstration Project Design and Construction. In Proceedings of the Precast/Prestressed Concrete Institute 57th Annual Convention and National Bridge Conference, Salt Lake City, UT, USA, 22–26 October 2011. [Google Scholar]

- Azizinamini, A.; Mantawy, I.M.; Anwer, M.A. Use of All Lightweight Concrete in Conjunction with UHPC Connection for Prefabricated Barrier System. In Proceedings of the 2022 ABC-UTC Research Day 1, Miami, FL, USA, 7 April 2022. [Google Scholar]

- Aktan, H.; Attanayake, U. Improving Bridges with Prefabricated Precast Concrete Systems; Michigan, Dept. of Transportation, Office of Research Administration: Lansing, MI, USA, 2013.

- Canadian Precast/Prestressed Concrete Institute. Available online: https://www.cpci.ca/en/about_us/project_month/march_2018/ (accessed on 4 October 2022).

- Moran, J. The Fast 14 project. Public Roads 2012, 75, 18–23. [Google Scholar]

- Culmo, M.P.; Halling, M.W.; Maguire, M.; Mertz, D. Recommended Guidelines for Prefabricated Bridge Elements and Systems Tolerances and Recommended Guidelines for Dynamic Effects for Bridge Systems; NCHRP Project 12-98; Transportation Research Board: Washington, WA, USA, 2017. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). LRFD Guide Specifications for Accelerated Bridge Construction, 1st ed.; AASHTO: Washington, DC, USA, 2018. [Google Scholar]

- Jahromi, A.J.; Mantawy, I.M.; Azizinamini, A. ABC-UTC Guide for: Service Life Design of Longitudinal Deck Closure Joints (May 2019), ABC-UTC. Available online: https://abc-utc.fiu.edu/wp-content/uploads/sites/52/2019/06/Guide-for-Longitudinal-Closure-Joints-Full-V6-Final.pdf (accessed on 16 January 2023).

- Russell, H.G.; Graybeal, B.A.; Russell, H.G. Ultra-High Performance Concrete: A State-of-the-Art Report for the Bridge Community; United States, Federal Highway Administration, Office of Infrastructure Research and Development: McLean, VA, USA, 2013.

- Zhou, Z.; Qiao, P. Durability of ultra-high-performance concrete in tension under cold weather conditions. Cem. Concr. Compos. 2018, 94, 94–106. [Google Scholar] [CrossRef]

- Yuan, J.; Graybeal, B.A. Bond Behaviour of Reinforcing Steel in Ultra-High Performance Concrete; United States, Federal Highway Administration, Office of Infrastructure Research and Development: McLean, VA, USA, 2014.

- Laldji, S. (École de Technologie Supérieure, Montréal, Québec, Canada). Personal communication, 2022.

- Lamothe, S.; (École de Technologie Supérieure, Montréal, Québec, Canada). Personal communication, 2022.

- Pigeon, M. La durabilité au gel du béton. Mater. Struct. 1989, 22, 3–14. [Google Scholar] [CrossRef]

- ACI Committee 306. Guide to Cold Weather Concreting, 1st ed.; American Concrete Institute: Farmington Hills, MI, USA, 2016. [Google Scholar]

- Korhonen, C. New developments in cold-weather concreting. In Cold Regions Engineering: Cold Regions Impacts on Transportation and Infrastructure; American Society of Civil Engineers Library: Reston, VA, USA, 2002; pp. 531–537. [Google Scholar]

- Nmai, C.K. Cold weather concreting admixtures. Cem. Concr. Compos. 1998, 20, 121–128. [Google Scholar] [CrossRef]

- Mamillan, M. Une analyse des rapports généraux présentés au Colloque international de la RILEM, Moscou, 14–16 octobre 1975. Matériaux Et Constr. 1976, 9, 129–140. [Google Scholar] [CrossRef]

- Fowler, J.R.; Eng, P. Accelerated Bridge construction. In Proceedings of the Annual Conf. & Exhibition of the Transportation Association of Canada, Charlottetown, PE, Canada, 17–20 September 2006; pp. 1–21. [Google Scholar]

- The ACEC-BC Awards. Available online: https://acecbcawards.com/2022-awards/2022-transportation-bridges/mosquito-creek-bridge-replacement/ (accessed on 4 October 2022).

- Mills, D.; Chow, K.T.; Marshall, S.L. Design-Construction of Esker Overhead. PCI J. 1991, 36, 44–51. [Google Scholar] [CrossRef]

- Technical Services Branch Alberta Transportation. Alberta Transportation NU Girder Bridge Design and Detailing Manual, 1st ed.; Alberta Department of Transportation: Valleyview, AB, Canada, 2018. [Google Scholar]

- Canadian Precast/Prestressed Concrete Institute. Available online: https://www.cpci.ca/en/about_us/project_month/april_2002/ (accessed on 4 October 2022).

- Daviau-Desnoyers, D.; Hassan, M. Design and construction of Boychuk Interchange. In Proceedings of the 10th International Conference on Short and Medium Span Bridges, Québec, QC, Canada, 31 July–3 August 2018. [Google Scholar]

- Marosi, M.; Hassan, M. Design and Construction of the Boychuck and McOrmond Interchanges. In Proceedings of the Annual Conference of the Canadian Society for Civil Engineering, CSCE, Saskatoon, SK, Canada, 27–30 May 2020. [Google Scholar]

- Canadian Precast/Prestressed Concrete Institute. Available online: https://www.cpci.ca/en/about_us/project_month/april_2006/ (accessed on 4 October 2022).

- Nader, M. Accelerated Bridge construction of the new Samuel De Champlain Bridge. J. Bridge Eng. 2020, 25, 05019015. [Google Scholar] [CrossRef]

- Carlin, G.; Beaudoin, P.; Mailhot, G.; Cap, R. Jacques Cartier Bridge Re-Decking Project—An Owner’s Perspective. In Proceedings of the Transportation: From Vision to Reality. Annual Conference and Exhibition of the Transportation Association of Canada (TAC), Winnipeg, MB, Canada, 15–18 September 2002. [Google Scholar]

- Sika Canada—Cold Conditions Products Brochure. Available online: https://can.sika.com/content/dam/dms/ca01/c/Cold_condition-EN.pdf (accessed on 4 October 2022).

- Sika Canada—Anchoring & Injection Resins. Available online: https://can.sika.com/en/construction/anchoring-injectionresins/segmental-bridgeadhesives/sikadur-31-sba-normalset.html (accessed on 4 October 2022).

- Garber, D.; Shahrokhinasab, E. Performance Comparison of In-Service, Full-Depth Precast Concrete Deck Panels to Cast-in-Place Decks. Report No. ABC-UTC-2013-C3-FIU03-Final. Florida International University. March 2019. Available online: https://abc-utc.fiu.edu/wp-content/uploads/sites/52/2019/05/FDPC-Deck-Panel-Performance-Final-Report_v10-2.pdf (accessed on 14 January 2023).

- Merhabi, A.; Torrelba, A. Available ABC Bridge Systems-Quarterly Progress Report (November 30, 2019), ABC-UTC. Available online: https://abc-utc.fiu.edu/wp-content/uploads/sites/52/2019/12/ProgressReport-FIU-2016-2-4-November2019.pdf (accessed on 3 December 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).