Consideration of Unidirectional Cyclic Loading on Bond in Reinforced Lightweight Concrete in Standards

Abstract

:1. Introduction

2. Materials and Methods

- F is the pull-out force;

- lb is the bonding length;

- ⌀ is the diameter of the reinforcing bar;

- is a constant (=3.14);

- d1 is the displacement on the loaded end of the bonded length (after subtraction of the elongation of the steel bar);

- and d2 is the displacement on the unloaded end of the bonded length.

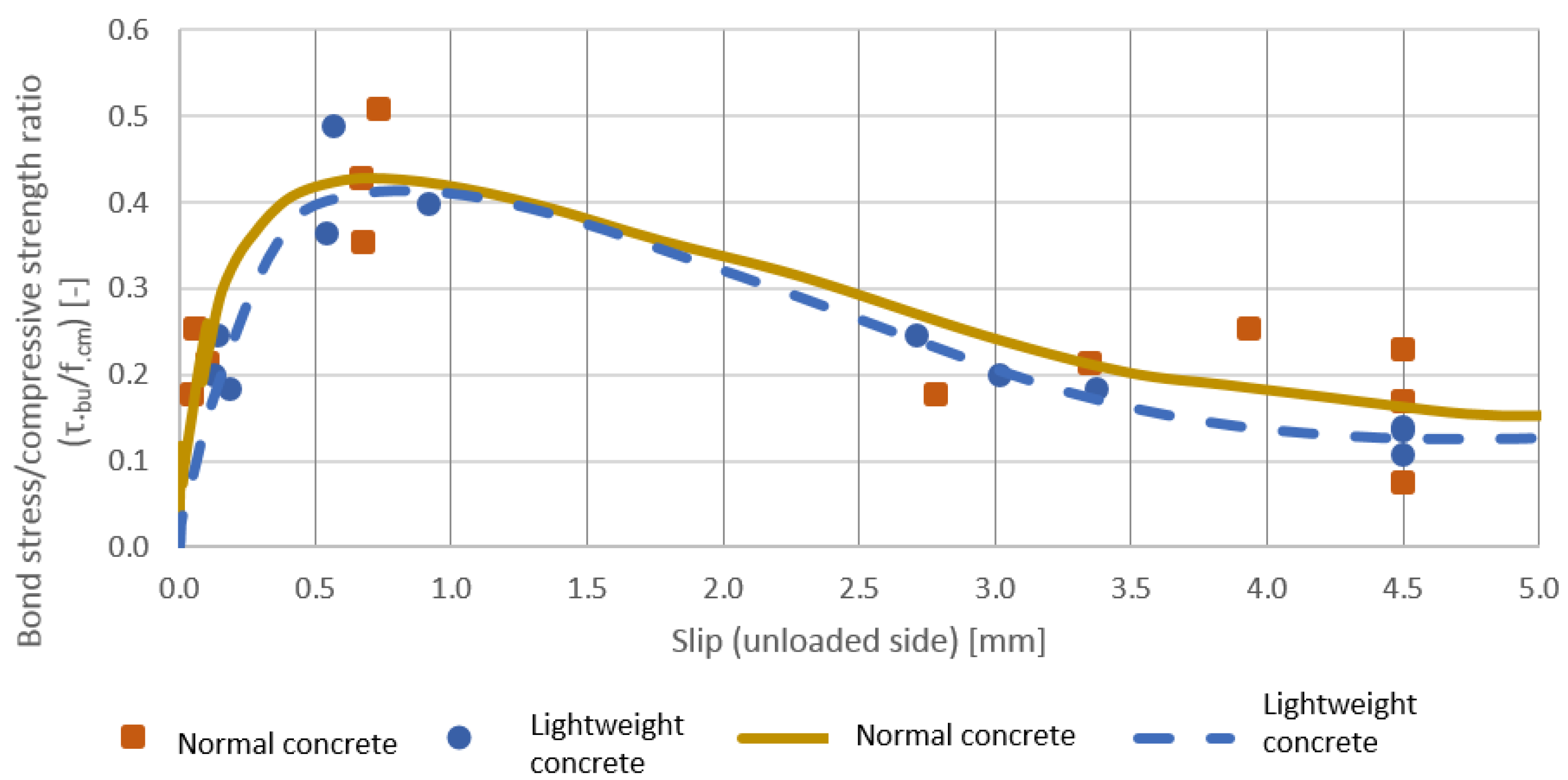

- the phenomenon was similar in both cases;

- the bond stress of the normal concrete was higher (on average, approximately 5 N/mm);

- the slip at the unloaded end was in the range of 0.5–1.0 mm for both concretes;

- the initial slope of the diagram was higher in case of the normal concrete;

- the residual stresses were in the range of 5–10 N/mm2 for both concretes.

- at 43% (8594 kN): 3;

- at 56% (11,172 N): 3;

- at 69% (13,750 N): 5;

- at 77% (15,468 N): 5;

- at 86% (17,187 N): 10;

- at 93% (18,500 N): 20 (if any);

- at 100% (20,000 N): 20 (if any).

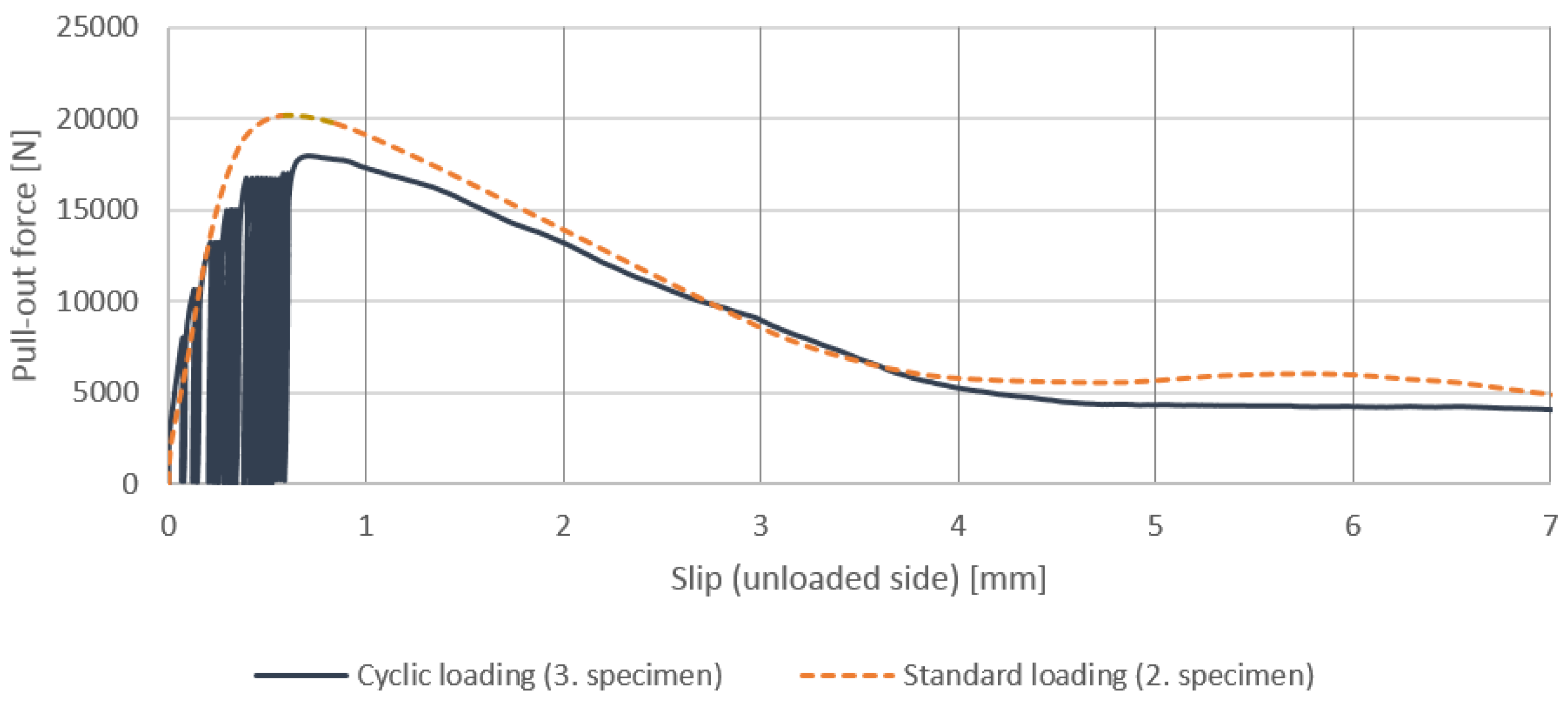

- For both concretes, the envelope curve of the cyclic loading was similar to the standard pull-out test, but in the case of the maximum load-bearing capacity, significant differences were observed. In conclusion, it could be stated that the envelope curve of the cyclic load always remained below the diagram of the corresponding standard pull-out test. In the case of normal concrete, the envelope curve ran closer to the standard diagram.

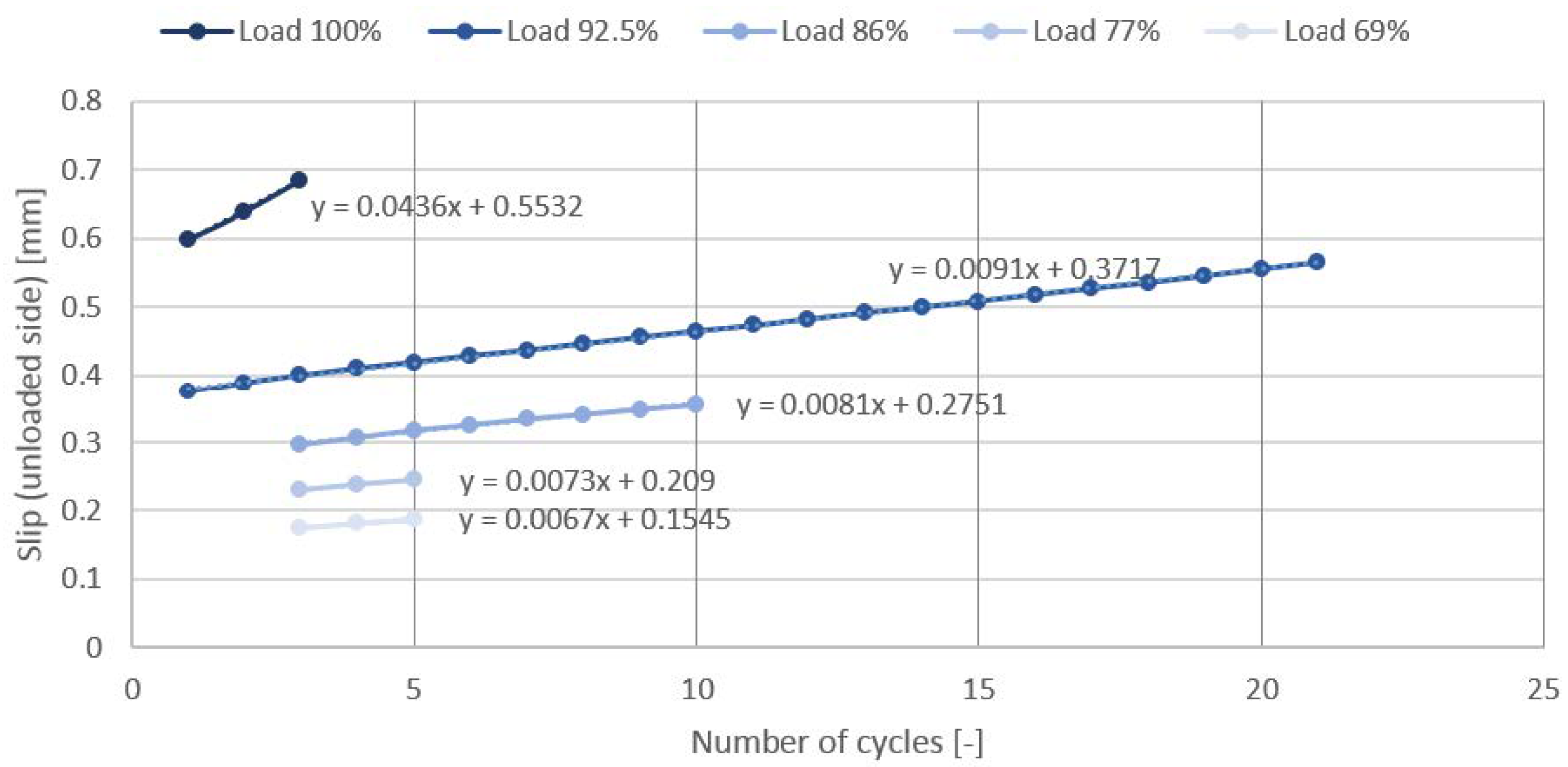

- At the unloaded end, until a given load level, no displacement was observed.

- It could be seen for the lightweight concrete that always the first cycle of the given load level produced the largest slip. After the first one, the cycles following under a given load level were similar to each other.

- The descending part of the cyclic load curve was similar to the standard one, as can be seen in Figure 2. This similarity is not surprising if considering that only the coarse aggregate fraction differed between the LWAC and NWC mixes and that the average density of LWAC (1770 kg/m3) was not too far below that of NWC [1]. This may indicate that simply changing the normal-weight coarse aggregate to a lightweight one does not influence the softening branch in the bond stress–slip curve so intensively as expected for usual LWAC (of less density) and also that the ductility in the bond is linked more to the paste rather than simply to the type of coarse aggregate.

- In the case of the normal concrete specimens, it was observed that the specimens could resist a maximum 26,000 N load multiple times without failure. This was due to the short time period, which was insufficient for the development of microcracks. It could lead us to the conclusion that the applicable number of cycles was a function of the loading rate; if one decreases the loading rate, the number of cycles (necessary for the failure) decreases in the case of the same concrete.

- Similar to lightweight concrete, for normal concrete, the first cycle of the given load level always produced the largest slip. However, after the first cycle, the following cycles in a given load level always became smaller and smaller. This was true only until the maximum bond stress was reached; after this, the first loop under the given load level became the smallest.

- The slip belonging to the maximum bond stress shifted relative to the standard diagram.

- The residual bond stress and the descending part of the diagrams were not affected by the loading scenario; they were similar to the standard diagram.

- The slope of the (re)loading paths was always the same, independently of the load level.

- The cyclic pull-out test caused plastic displacements (for both normal and lightweight concrete).

- in the case of bond stress, the normal concrete had a larger standard deviation;

- the initial slope of the diagram was smaller in the case of the lightweight concrete;

- the average curve of the normal concrete always enveloped the curve of the lightweight concrete, but the difference between the two curves was quite small; this indicated that the energy absorption capacity of the normal concrete was higher;

- the difference in the maximum stress was less than 3%;

- the fact that the lightweight concrete reached a given stress level at a larger slip than normal concrete indicated less favorable behavior in serviceability limit states.

- The standard pull-out test did not show a significant difference between the normal and lightweight aggregate concrete mixes until the maximum bond stress was reached. After this, the difference remained small and, in contrast to our expectations, the lightweight concrete did not show a more rigid behavior.

- The bond stress–slip curve of the standard pull-out test enveloped properly the same curve of the cyclic pull-out test for both concrete types.

- Both concrete mixes were able to resist the maximum pull-out force multiple times in the case of cyclic loading. This was possible because there was no time for the formation/further development of cracks or the rearrangement of the stresses. In the case of cyclic loading, not only the loading rate is important, but the time for which the maximum load was applied on the sample also influenced the results.

- In the case of low cycle number fatigue, there was no significant difference in the pull-out bond test results of the normal and lightweight aggregate concrete.

3. Results and Discussion

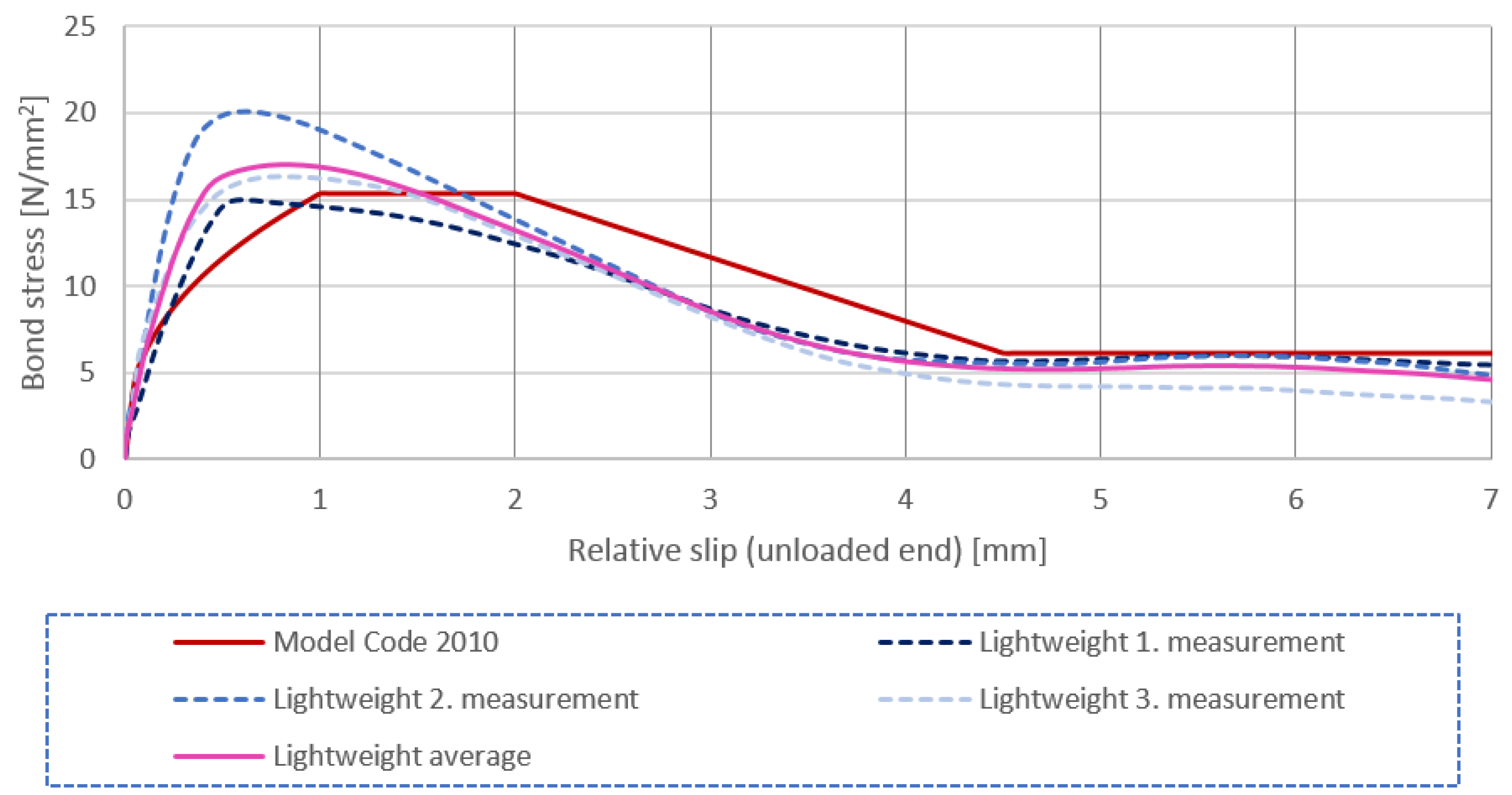

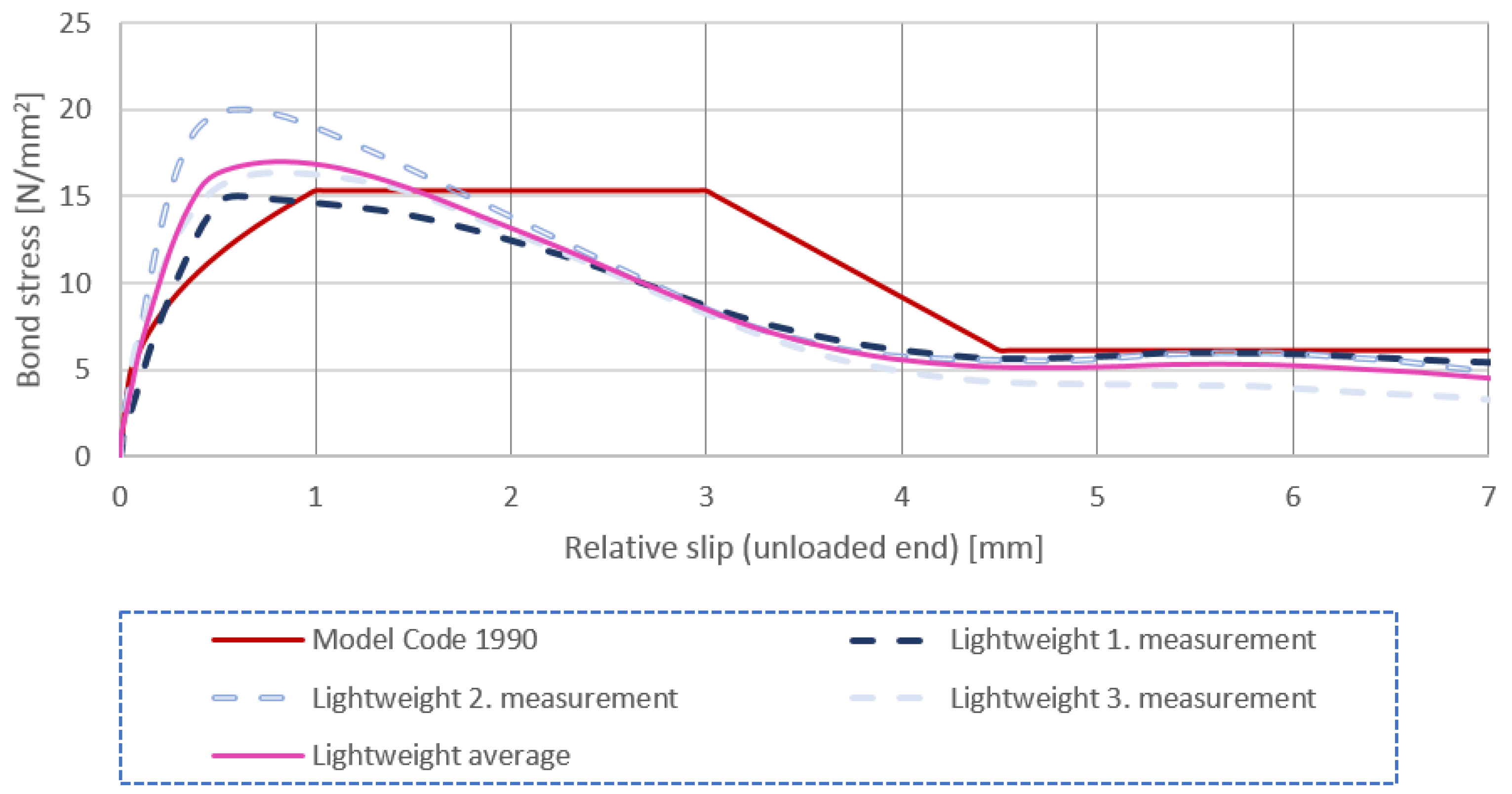

3.1. Standard Pull-Out Test

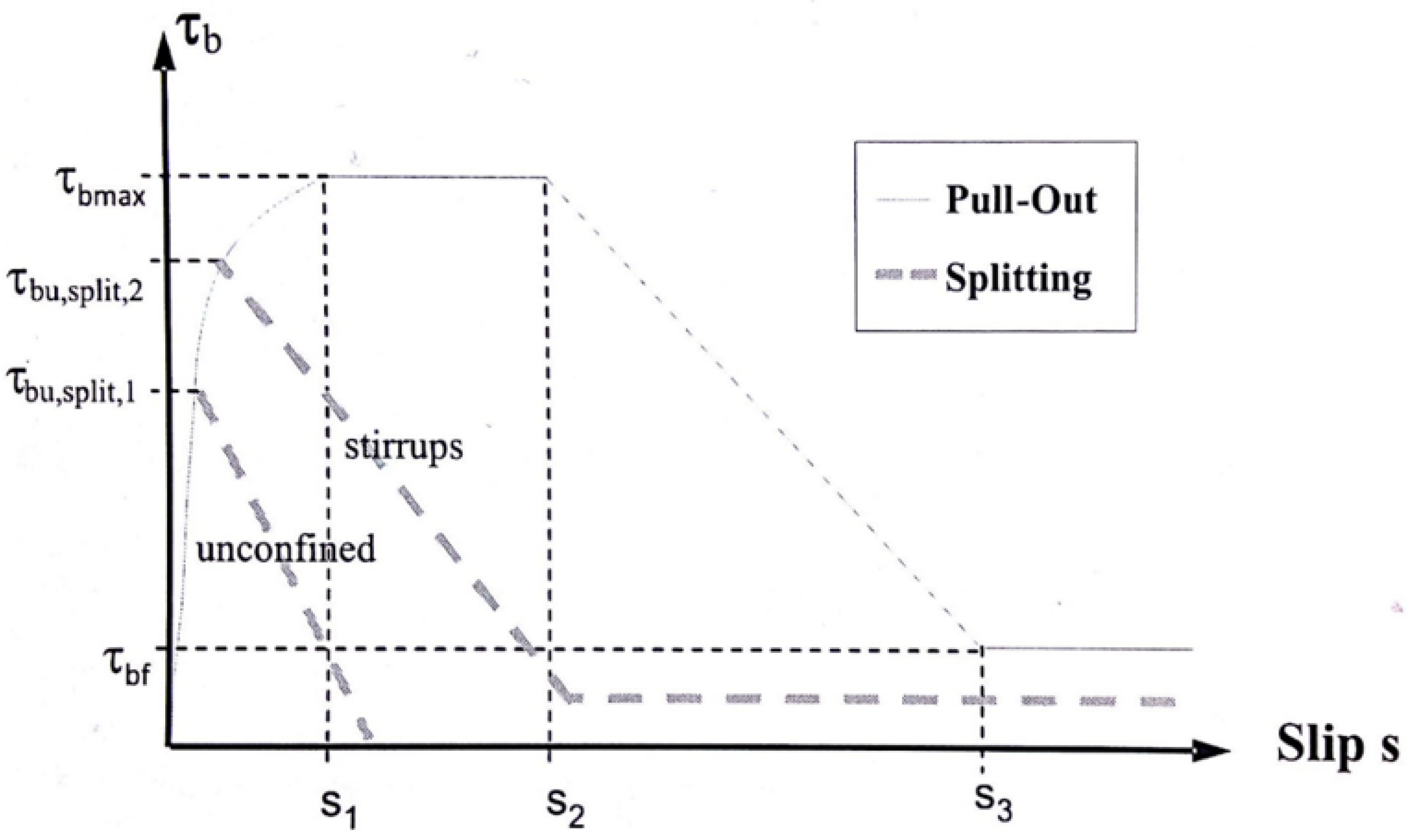

- : maximum bond stress ;

- : residual bond stress ;

- : slip values separating the slip ranges mm;

- or 3 mm (3 mm in Model Code 1990; 2 mm in Model Code 2010);

- clear distance between the ribs;

- : constant .

Comparison of Bond Strength Based on the Standard Pull-Out Test

- : factor taking into account the surface characteristics (in case of ribbed steel, );

- : factor taking into account the position of reinforcing bar during casting (;

- : factor taking into account the diameter of the reinforcing bar for mm: (;

- : factor taking into account the yield strength of the steel bar for = 500 MPa: (;

- : safety factor: 1.5;

- : characteristic value of the compressive strength of concrete [N/mm].

- : effect of concrete covering ;

- : effect of lateral reinforcement; if there is no reinforcement, ;

- : effect of lateral stresses; in the present case, .

- : factor taking into account the position of the reinforcing bar (for “good” bond conditions, = 1; in other cases, = 0.7);

- : factor taking into account the diameter of the reinforcing bar (for d < 32 mm, = 1);

- : design value of the tensile strength of concrete [N/mm], limited above C60/75;

3.2. Consideration of Cyclic Pull-Out Test in Standards (Bond Fatigue)

3.2.1. Bond Fatigue Calculation Based on Cyclic Pull-Out Tests According to the Eurocode

- : tensile strength of concrete (N = 1);

- N: number of cycles;

- R: minimum and maximum stress ratio of the cycle ;

- : maximum stress level (after N cycles) in all load cycles;

- : minimum stress level after N cycles (present case: ).

- : measured number of cycles at a given “i” load level;

- : possible maximum number of cycles at a given “i” load level resulting in fatigue failure;

- : damage (adequate if ).

3.2.2. Bond Fatigue Calculation Based on Cyclic Pull-Out Test According to the Model Code 2010

- N: number of cycles;

- : bond strength of concrete after N (constant) cycles of loading;

- : bond strength of concrete based on standard (static, monotonic) loading.

4. Conclusions

- The applied lightweight aggregate concrete was designed for structural applications fulfilling all the requirements of at least the LC30/33 strength class. Thus, its mix contained lightweight aggregates only in the coarse aggregate (4/8) fraction and resulted in an average dry density of 1770 kg/m3.

- The results of the compressive and splitting tensile strength tests showed sufficient correlations with the values calculated from the expressions of the Eurocode and the Model Code 2010.

- The pull-out test results showed a higher standard deviation than those obtained from the compression and the splitting tensile strength tests.

- It was observed, for lightweight mixes, that the bond stress–slip diagram showed a good correlation with the corresponding one of the Model Code (especially with the Model Code 2010); however, the Model Code 2010 formula for the characteristic bond strength highly underestimates the actual characteristic bond strength of the material. There is a huge margin in the standard for the bond strength.

- The bond stress–slip figure of the Model Code 2010 approximates higher slips compared to our measurements in the ascending range.

- The expressions to calculate the fatigue bond strength in the Model Code 2010 and in several Eurocode national annexes were analyzed. While these expressions are fairly similar to each other, it was concluded the Model Code 2010 gave the most accurate estimation of the S-N curve. In this case, the difference between the measured and calculated pull-out force values was found to be only 4.69%.

- Both types of concretes were able to withstand the maximum pull-out force in the case of cyclic loading. This was explained by the higher loading rate during cycle tests, which retarded crack propagation and the following stress redistribution in the specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kovács, T.; Gyurkó, Z.; Jakab, L.; Nemes, R. Influence of Unidirectional Cyclic Loading on Bond between Steel Bars Embedded in Lightweight Aggregate Concrete. Solids 2022, 3, 28. [Google Scholar] [CrossRef]

- Kovács, T.; Nemes, R. Bond between strands and high-strength lightweight aggregate concrete. In Proceedings of the CCC 2015 Hainburg, 11th Central European Congress on Concrete Engineering, Hainburg an der Donau, Austria, 1–2 October 2015. [Google Scholar]

- Ganesan, N.; Indira, P.V.; Sabeena, M.V. Bond stress slip response of bars embedded in hybrid fibre reinforced high performance concrete. Constr. Build. Mater. 2014, 50, 108–115. [Google Scholar] [CrossRef]

- Wang, L.; Yi, J.; Xi, H.; Fan, L. Experimental study of a pull-out test of corroded steel and concrete using the acoustic emission monitoring method. Constr. Build. Mater. 2016, 122, 163–170. [Google Scholar] [CrossRef]

- Mitchell, D.W.; Marzouk, H. Bond characteristics of high-strength lightweight concrete. ACI Struct. J. 2003, 104, 22–29. [Google Scholar]

- Campione, G.; Cucchiara, L.; La Mendola, L.; Papia, M. Steel–concrete bond in lightweight fiber reinforced concrete under monotonic and cyclic actions. Eng. Struct. 2005, 27, 881–890. [Google Scholar] [CrossRef]

- Chen, H.J.; Huang, C.H.; Kao, Z.Y. Experimental investigation on steel–concrete bond in lightweight and normal weight concrete. Struct. Eng. Mech. 2004, 17, 141–152. [Google Scholar] [CrossRef]

- Abed, M.A.; Alkurdi, Z.; Fort, J.; Cerny, R.; Sólyom, S. Bond Behavior of FRP Bars in Lightweight SCC under Direct Pull-Out Conditions: Experimental and Numerical Investigation. Materials 2022, 15, 3555. [Google Scholar] [CrossRef] [PubMed]

- Al-Fouadi, W.K.A.; Mohammed, A.H.; Abdullah, K. Experimental and analytical study on behavior of pull-out failure of reinforcing bar embedded in concrete blocks. Struct. Concr. 2019, 20, 171–184. [Google Scholar] [CrossRef]

- Pul, S. Loss of concrete-steel bond strength under monotonic and cyclic loading of lightweight and ordinary concretes. Iran. J. Sci. Technol. Trans. B Eng. 2010, 34, 397–406. [Google Scholar]

- Faleschini, F.; Hofer, L.; Zanini, M.A.; dalla Benetta, M.; Pellegrino, C. Experimental behavior of beam-column joints made with EAF concrete under cyclic loading. Eng. Struct. 2017, 139, 81–95. [Google Scholar] [CrossRef]

- Qu, Z.; Xie, J.; Wang, T.; Kishiki, S. Cyclic loading test of double K-braced reinforced concrete frame subassemblies with buckling restrained braces. Eng. Struct. 2017, 127, 1–14. [Google Scholar] [CrossRef]

- El-Mandouh, M.A.; Omar, M.S.; Elnaggar, M.A.; El-Maula, A.S.A. Cyclic Behavior of High-Strength Lightweight Concrete Exterior Beam-Column Connections Reinforced with GFRP. Buildings 2022, 12, 179. [Google Scholar] [CrossRef]

- Ashtiani, M.S.; Dhaka, R.P.; Scott, A.N.; Bull, D.K. Cyclic beam bending test for assessment of bond slip behavior. Eng. Struct. 2013, 56, 1684–1697. [Google Scholar] [CrossRef]

- Zhandarov, S.; Mäder, E. Determining the interfacial toughness from force–displacement curves in the pull-out and microbond tests using the alternative method. Int. J. Adhes. Adhes. 2016, 65, 11–18. [Google Scholar] [CrossRef]

- CEB-FIP Model Code 1990 for Concrete Structures; Ernst and Sohn: Lausanne, Switzerland, 1990.

- Desnerck, P.; Lee, J.M.; Morley, C.T. Bond behaviour of reinforcing bars in cracked concrete. Constr. Build. Mater. 2015, 94, 126–136. [Google Scholar] [CrossRef]

- Alavi-Fard, M.; Marzouk, H. Bond of high strength concrete under monotonic pull out loading. Mag. Concr. Res. 2004, 56, 545–557. [Google Scholar] [CrossRef]

- Patel, V.J.; Van, B.C.; Henry, R.S.; Clifton, G.C. Effect of reinforcing steel bond on the cracking behaviour of lightly reinforced concrete members. Constr. Build. Mater. 2015, 96, 238–247. [Google Scholar] [CrossRef]

- CEB-FIP Model Code 2010 for Concrete Structures; Internation Federation for Structural Concrete (fib): Lausanne, Switzerland, 2010.

- European Committee for Standardization. Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings; CEN: Brussels, Belgium, 2004; 225p. [Google Scholar]

- Windisch, A. A Modified Pull-out Test and New Evaluation Methods for a More Real Local Bond-Slip Relationship. Mater. Struct. 1985, 18, 181–184. [Google Scholar] [CrossRef]

- Balázs, G.L.; Koch, R.; Harre, W. Verbund von Stahl in Beton unter Betriebsbeanspruchung. In Deutscher Ausschuss für Stahlbeton-30; Forschungskolloquium: Sttutgart, Germany, 1994; pp. 167–176. [Google Scholar]

- Song, X.; Wu, Y.; Gu, X.; Chen, C. Bond behaviour of reinforcing steel bars in early age concrete. Constr. Build. Mater. 2015, 94, 209–217. [Google Scholar] [CrossRef]

- Miner, M.A. Cumulative damage in fatigue. J. Appl. Mech. 1945, 67, 159–164. [Google Scholar] [CrossRef]

- Tepfers, R. A Theory of Bond Applied to Overlapped Tensile Reinforcement Splices for Deformed Bars; Division of Concrete Structures, Chalmers University of Technology: Göteborg, Sweden, 1973; p. 328. [Google Scholar]

| Type of Concrete | Average Density [kg/m3] | Strength Class | Average Compressive Strength [N/mm2] | Std. Deviation of Compressive Strength [N/mm2] | Average Splitting Tensile Strength [N/mm2] | Std. Deviation of Splitting Tensile Strength [N/mm2] |

|---|---|---|---|---|---|---|

| Normal weight concrete | 2357 | C30/37 | 51.19 | 1.04 | 3.63 | 0.11 |

| Lightweight concrete | 1770 | LC30/33 | 41.09 | 3.10 | 2.58 | 0.13 |

| Notation | Dimension | Model Code 1990 | Model Code 2010 |

|---|---|---|---|

| [N/mm] | 37.57 | 37.57 | |

| [mm] | 4.50 | 4.50 | |

| [N/mm] | 15.32 | 15.32 | |

| [mm] | 1.00 | 1.00 | |

| [mm] | 3.00 | 2.00 | |

| [mm] | 4.50 | 4.50 | |

| [−] | 0.40 | 0.40 | |

| [N/mm] | 6.13 | 6.13 |

| # | Measured Strength Values | Model Code (Compressive and Bond Strength) | EN (Tensile and Bond Strength) | Measured Bond Strength | ||||

|---|---|---|---|---|---|---|---|---|

| N/mm | ||||||||

| 1 | 42.03 | 2.62 | 36.15 | 1.47 | 3.96 | 2.357 | 3.71 | 14.93 |

| 2 | 41.09 | 2.72 | 20.04 | |||||

| 3 | 41.83 | 2.40 | 16.32 | |||||

| 4 | 39.40 | 2.31 | 15.43 | |||||

| Characteristic value (): | 3.96 | 3.71 | 13.60 = | |||||

| Model Code | Eurocode | ||

|---|---|---|---|

| N/mm | 3.96 | 3.71 | |

| N/mm | 13.60 | ||

| / | - | 3.44 | 3.66 |

| Load Intensity | Bond Strength Ratio | Applied Number of Cycles, | |||

|---|---|---|---|---|---|

| 1. Specimen | 2. Specimen | 3. Specimen | Average | ||

| [kN] | [-] | [-] | [-] | [-] | [-] |

| 8.594 | 0.43 | 3 | 3 | 3 | 3.0 |

| 11.172 | 0.56 | 3 | 3 | 3 | 3.0 |

| 13.750 | 0.69 | 5 | 5 | 5 | 5.0 |

| 15.468 | 0.77 | 5 | 5 | 5 | 5.0 |

| 17.187 | 0.86 | 10 | 10 | 10 | 10.0 |

| 18.500 | 0.93 | 20 | 20 | 1 | 13.7 |

| 20.000 | 1.00 | 6 | 10 | 0 | 5.3 |

| Standard Pull-Out Force | Loading Step | Load Ratio | Applied Number of Load Cycles | Calculated Possible Number of Load Cycles (Swedish) | Damage |

|---|---|---|---|---|---|

| [kN] | [kN] | [-] | [-] | [-] | [-] |

| 20.000 | 8.594 | 0.43 | 3.0 | 211,793,393 | 1.41647 × 10 |

| 11.172 | 0.56 | 3.0 | 2,780,508 | 1.07894 × 10 | |

| 13.750 | 0.69 | 5.0 | 36,504 | 0.00014 | |

| 15.468 | 0.77 | 5.0 | 2031 | 0.002 | |

| 17.187 | 0.86 | 10.0 | 113 | 0.088 | |

| 18.500 | 0.93 | 13.7 | 12 | 1.098 | |

| 20.000 | 1.00 | 5.3 | 1 | 5.333 | |

| : | 6.523 |

| Standard Pull-Out Force | Loading Step | Load Ratio | Applied Number of Load Cycles | Calculated Possible Max Number of Load Cycles (Swedish) | Damage |

|---|---|---|---|---|---|

| [kN] | [kN] | [-] | [-] | [-] | [-] |

| 21.209 | 8.594 | 0.41 | 3.0 | 482,449,866 | 6.22 × 10 |

| 11.172 | 0.53 | 3.0 | 8,108,225 | 3.70 × 10 | |

| 13.750 | 0.65 | 5.0 | 136,270 | 3.67 × 10 | |

| 15.468 | 0.73 | 5.0 | 8941 | 0.001 | |

| 17.187 | 0.81 | 10.0 | 587 | 0.017 | |

| 18.500 | 0.87 | 13.7 | 73 | 0.188 | |

| 20.000 | 0.94 | 5.3 | 7 | 0.757 | |

| : | 0.962 ∼ 1.0 |

| Standard Pull-Out Force (Table 6) | Multiplier (Ratio) | Standard Pull-Out Force II (Table 7) |

|---|---|---|

| [N] | [-] | [N] |

| 20,000 | 1.0604 | 21,209 |

| Italian | Spanish |

|---|---|

| Dutch | Belgian |

| where : stress amplitude () | where X: factor dependent on the risk of error |

| Std. Pull-Out Force | Load Steps | Damage | ||||

|---|---|---|---|---|---|---|

| Swedish | Italian | Spanish | Dutch | Belgian | ||

| [kN] | [kN] | [-] | [-] | [-] | [-] | [-] |

| 20.000 | 8.594 | 1.41647 × 10 | 3.16 × 10 | 1.62 × 10 | 1.95 × 10 | 1.177 × 10 |

| 11.172 | 1.07894 × 10 | 7.1 × 10 | 4.23 × 10 | 8.22 × 10 | 4.453 × 10 | |

| 13.750 | 0.00014 | 0.00265 | 0.00184 | 0.00058 | 0.0000028 | |

| 15.468 | 0.002 | 0.021 | 0.016 | 0.007 | 0.00015 | |

| 17.187 | 0.088 | 0.336 | 0.285 | 0.169 | 0.015 | |

| 18.500 | 1.098 | 2.237 | 2.049 | 1.551 | 0.432 | |

| 20.000 | 5.333 | 5.333 | 5.333 | 5.333 | 5.333 | |

| Damage (): | 6.523 | 7.930 | 7.685 | 7.061 | 5.781 | |

| Multiplier: | 1.0604 | 1.0977 | 1.0905 | 1.0741 | 1.0718 | |

| Std. Pull-Out Force II: | 21209 | 21.954 | 21.810 | 21.482 | 21.436 | |

| Modified Damage (): | 0.962 | 0.987 | 0.997 | 0.996 | 1.009 | |

| Std. Pull-Out Force | Load Steps | Damage |

|---|---|---|

| Model Code | ||

| [kN] | [kN] | [-] |

| 20.000 | 8.594 | 2.76135 × 10 |

| 11.172 | 2.44042 × 10 | |

| 13.750 | 3.59464 × 10 | |

| 15.468 | 0.000033 | |

| 17.187 | 0.0061 | |

| 18.500 | 0.264 | |

| 20.000 | 5.333 | |

| Damage (): | 5.603 | |

| Multiplier: | 1.0469 | |

| Std. Pull-Out Force II: | 20937 | |

| Modified Damage (): | 1.047 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gyurkó, Z.; Kovács, T.; Jakab, L.; Nemes, R. Consideration of Unidirectional Cyclic Loading on Bond in Reinforced Lightweight Concrete in Standards. CivilEng 2023, 4, 68-82. https://doi.org/10.3390/civileng4010006

Gyurkó Z, Kovács T, Jakab L, Nemes R. Consideration of Unidirectional Cyclic Loading on Bond in Reinforced Lightweight Concrete in Standards. CivilEng. 2023; 4(1):68-82. https://doi.org/10.3390/civileng4010006

Chicago/Turabian StyleGyurkó, Zoltán, Tamás Kovács, Levente Jakab, and Rita Nemes. 2023. "Consideration of Unidirectional Cyclic Loading on Bond in Reinforced Lightweight Concrete in Standards" CivilEng 4, no. 1: 68-82. https://doi.org/10.3390/civileng4010006

APA StyleGyurkó, Z., Kovács, T., Jakab, L., & Nemes, R. (2023). Consideration of Unidirectional Cyclic Loading on Bond in Reinforced Lightweight Concrete in Standards. CivilEng, 4(1), 68-82. https://doi.org/10.3390/civileng4010006