Abstract

Digging trenches on roads, sidewalks, or banks to accommodate public demands is required for the installation of water pipelines, natural gas lines, electric cables, and optical fibers. The soils extracted from these trenches always have substantial environmental and economic consequences, as these soils are frequently regarded as waste due to their poor engineering properties. As a result, a suitable location and method for disposing these excavated soils must be found, and this procedure is exceedingly costly, time consuming, and environmentally unfriendly. It is far more efficient to reuse these excavated soils for refilling the same trenches. This study is a part of a French national project. The national project aims to dig 5 to 25 cm wide trenches to install public utilities and to refill them using the same excavated material in the form of self-compacting mortar. The goal of this research is to determine the best ecofriendly binder for the soil excavated from various sites by conducting laboratory-scale physio-chemical and mechanical testing. This study examined the unconfined compressive strength (UCS) assessed by both destructive and non-destructive (ultrasonic) testing methods. By utilizing low CO2-emitting ecofriendly binders incorporating industrial byproducts (fly ash and GGBS), this work has broadened the possibility of reusing trench cuttings to refill the same trenches.

1. Introduction

Recycling and waste recovery are the foundation of the circular economy. As indicated in the recommendation issued by the European directives, that improvements in eco-design, prevention, and reuse of waste could achieve a net saving of up to EUR 600,000 million per year for European Enterprises [1]. Thus, it is in the context of sustainable development that the Marais group launched this national project, which concerns the recycling and recovery of trench-cuttings (TC). The Marais group founded in 1962 is a subsidiary of the Tesmec group. The research work for this study was conducted at the Continental and Coastal Morphodynamics Laboratory (M2C). M2C is a joint research unit (UMR 6143) with the University of Caen-Normandy.

The installation of public utilities such as electrical cables or optical fiber (fiber to the home—FTTH) on the road to facilitate connection to local utility services loops requires digging trenches on the road or the sidewalks [2]. The materials obtained from these trenches are mostly considered as waste and transported to a waste storage center for regrouping. These trenches are then filled with the mortar obtained from concrete plants far away from the sites. This process is very time consuming and costly. The digging of trenches and refilling after the installation is a material and energy-intensive activity with potential risks on environment. Transportation concerning the infrastructure in general and roadways in particular has a significant impact on the environment. As per a report published by US Environmental Protection Agency in 2013, the greenhouse gas (GHG) emissions linked with the transportation economic sector totaled 1829 million metric tons of CO2, out of a total of 6702 million metric tons of CO2 in the year 2011 [3,4]. The large greenhouse gas (GHG) emission in the transportation sector is linked to the transportation of heavy vehicles along the highways as they consume a large quantity of fuel. Therefore, transporting trench cuttings (TCs) to the waste management/storage center as well as the transportation of mortar from concrete plants to construction sites can be considered a highly non-ecofriendly solution along with being costly and time consuming. To reduce the climate impacts induced by construction, it is necessary to increase resource efficiency by reusing waste material or excavated material [5]. Excavated soil management is becoming a critical issue around the world, particularly in urban and industrial areas where construction development and the needs of optic fibers and cable connection all compete for the sustainable use of soil and aggregates resources. The world is searching for ways to save environment and to recycle excavated material. For example, in Finland, about 80 percent of concrete waste is recycled and the majority of these recycled materials are used in road construction and earth construction [6]. The French Public Work Federation (FNTP) in the past decades has also been seeking for more sustainable solutions for excavated materials, as recycling and recovered waste are the keystones for a circular economy.

This research is a small element of a national project that concerns recycling and the on-site valorization of the material obtained from trenches made on the roads in both urban and rural areas by converting it into a self-compacting mortar (SCM). To attain these objectives at the site, a special machine (Mac-H) has been designed, developed, and implemented by a French company. Mac-H is a mobile production center behind a suction-type slicer and can evaluate trench cuttings as a self-compacting material (Figure 1). Mac-H can dig the trench, receive the trench cutting by a belt conveyor, crush the trench cutting, sieve up to any desired range, and finally fill the trenches after mixing trench cuttings with ecofriendly binders. Recycling excavated material at the site can minimize GHG emissions, saving a lot of time and transportation costs.

Figure 1.

The combined mobile production unit for trenches (part A) and excavated material reprocessing unit (part B).

Mac-H has the capacity to continuously manufacture the self-compacting mortar (SCM) to backfill trenches on the sidewalks (urban areas) or banks (rural areas) and on the roads. SCM is a particular material that can pass through and fill the gaps of reinforcement and mold corners without any need for vibration and compaction during the placement process [7,8]. Two types of trench cuttings are considered, keeping in mind the origin and location of the site: one obtained from a site at the urban area, i.e., urban trench cutting (UTC), and the other one obtained from a site at the rural area, i.e., rural trench cuttings (RTCs). The nature of the recovered material is that they are partly granular and from urban areas, while mainly fine matrix (clay, silt, organic matter) materials are obtained in rural areas.

2. Materials and Methods

2.1. Research Approach

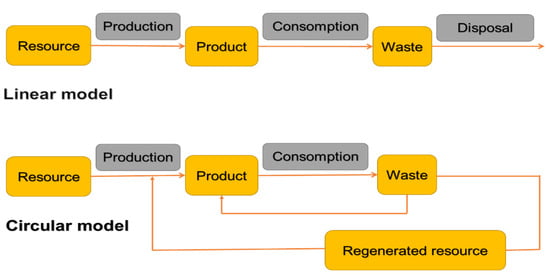

The construction sectors in France and around the world are facing a progressive depletion of natural resources as the escalation in the demand of traditional hydraulic binders increases day by day. The manufacture of cement requires huge quantities of non-renewable resources, i.e., raw material and fossil fuels. It is estimated that cement production generates almost 6% of total carbon dioxide produced by human activity and therefore, it is an essential sector for CO2 emission mitigation strategies [9]. Ongoing urbanization will further increase the need for natural resources [10]. Circular consumption is an indispensable part of a circular economic system for sustaining the economic growth of any country or organization, as well as minimizing environmental problems and resource depletion [11]. However, the problem of making circular consumption practical is a big challenge. The circular economic concept and its 3R model (reduce, reuse, and recycle) promote the transition of a linear model into a circular model. The conventional method follows the linear model of waste management, i.e., resource–product-waste. The process is as follows: Dig a trench, excavate, and transport the waste material to waste management centers; install the optical fibers; and finally fill the trench by mortar, which is prepared far away from the working site. The linear model is environmentally degrading, costly, and time consuming. On the other hand, the reuse of trench cuttings (circular model) will reduce waste management costs, decreases the use of natural resources, and limits the logistics at the site as well on highways. The linear and circular models for waste management produced and explained by Yang et al. in 2014 are provided in the Figure 2 [11]. The binders used in this study (A1, A2, A3) are ecofriendly as they mostly consist of industrial byproducts. Indeed, by convention, a waste product has no carbon footprint, except for its transport. Therefore, the manufacture of these ecobinders produce very little CO2 compared to the manufacturie of conventional hydraulic binders.

Figure 2.

Linear excavated soil management model vs. circular excavated soil management model.

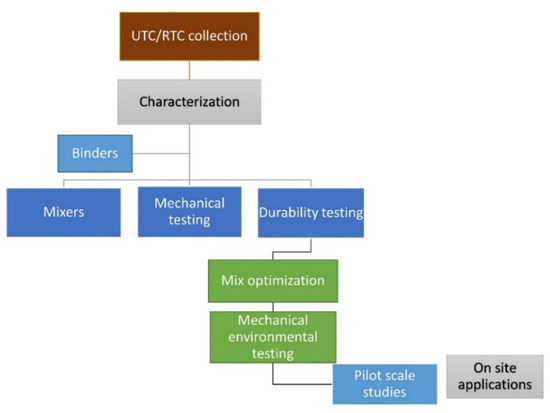

The characterization of the sediments is the first step in any recovery process. It allows the determination of a set of properties necessary to choose a valuation chain to optimize this process. Once the necessary characteristics have been identified, laboratory scale testing is the next step. along with the selection of suitable ecofriendly binders. Mechanical and durability testing indicate whether self-compacting mortars are suitable for use in pilot scale experiments. If mechanical testing does not yield promising results, repeat the laboratory scale experiments with different binders at higher doses or with excavated soil pre-treatment before adding ecobinders. Real-time experiments are the final stage of any excavated soil recovery process. Figure 3 provides the strategy for reusing trench-cuttings, i.e., rural (RTC) and urban cuttings (UTC).

Figure 3.

Excavated soils recovery process (RTC = rural trench cuttings; UTC = urban trench cuttings).

2.2. Methodology

Concrete is one of the widely used construction material for decades. Concrete mortar is generally used to refill the trenches made on roadways. However, the cement used to prepare the concrete mortar is not an ecofriendly solution. The manufacture of cement requires huge quantities of non-renewable resources such as raw material and fossil fuels. It is estimated that cement production generates almost 6% of total carbon dioxide produced by human activity [12]. Keeping in mind the environmental concerns, the use of cement should be minimized.

The objectives of this study are as follows:

- -

- Use of low carbon ecobinder to minimize the use of cement, which is one of the biggest producers of carbon dioxide;

- -

- Minimize large greenhouse gas (GHG) emissions in the transportation sector that are linked to the transportation of heavy vehicles along the highways as they consume a large quantity of fuel;

- -

- Find the most sustainable solution for excavated material by reusing them on the spot;

- -

- Minimize the waste and maximize the circular economy;

- -

- Compare the unconfined compressive strength (UCS) measured using non-destructive and destructive methods;

- -

- Make a qualitative evaluation of self-compacting mortar (SCM).

The first concern is the selection of the ecobinder, i.e., low carbon binder. Many studies [13,14,15] on the excavated material to be reused for construction works have shown that the addition of a hydraulic and/or pozzolanic binder can fulfill the required mechanical characteristics criteria for the material to be used as road construction. However, the chemistry of trench cutting is very complex and variable. The trench cuttings are very heterogenous depending on the origin (rural or urban) of the working site. Therefore, the type of binder and its amount requires making them feasible for use as construction materials. The incorporation of industrial by-products such as fly ash (FA) and ground granulated blast-furnace slag (GGBS) instead of ordinary Portland cement (OPC) seems interesting, as it allows the co-valorization of two wastes (dredged sediments and industrial by-products) and, thus, can eliminate them both. Pozzolanic binders (with alkaline activator) can evince mechanical properties [16] and thermal stability [17,18] compared to OPC. Three types of ecobinders used in this study are presented in Table 1. Additives are anhydrous products.

Table 1.

Composition of ecobinders used in the study.

FA, which is the part of binder A1, constitute fluidized bed ash from the Emile Huchet power station located in the department of Moselle, France. Physio-chemical characteristics are presented in Table 2. GGBS, which makes up 75% of binder A2 and 45% of A3, is certified in accordance with the requirements of standard NF EN 197-1, and it is composed mainly of oxides of calcium, magnesium, aluminum, silicate (Table 2), less than 1% crystalline silica, and less than 2 ppm water soluble chromium VI. Additives in each binder are gypsum and/or anhydrite.

Table 2.

Physio-chemical characterization of the materials.

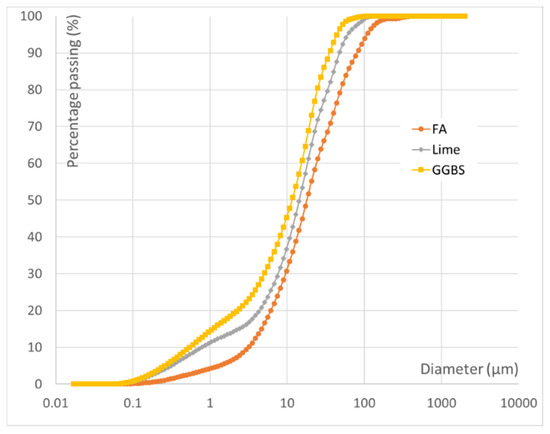

The particle size distributions were measured with a laser particle sizer as per standard ISO 13320-1 for each material (Figure 4).

Figure 4.

Raw material particle size distribution.

Recycling urban trench-cuttings (UTCs) is not complicated, and traditional hydraulic binders can fulfill the mechanical strengths criteria to be reused in road construction. UTC is generally a granular soil mainly consisting of road and sidewalks layers. On the other hand, recycling rural trench-cuttings (RTCs), which comprises mainly cohesive soils, is sometimes complicated as these cuttings contain clay and silt. Therefore, different types of ecobinders are recommended because of the heterogeneity of the trench cuttings. Slumps tests were performed to determine the amount of water required for the required consistency class of various mixtures. After that, for each mixture, 18 typical 4 × 4 × 16 cm3 samples were molded and tested after 7, 14, 28, and 60 days. Each day, three samples were tested for unconfined compressive strength (UCS) and tensile strength, with the average of three being used as a reference. The early strength, i.e., 7 days, was required to understand the beginning of the hardening of mixtures and to declare how many days vehicle traffic could be possible for on-site applications. Both UCS and tensile strength were tested destructively and nondestructively. Comparisons were conducted to understand the scope of non-destructive testing (NDT). NDT can be performed using a variety of techniques, such as the electrical resistivity method, tomography, and so on. The ultrasonic method was used in this study to determine the UCS of self-compacting mortar.

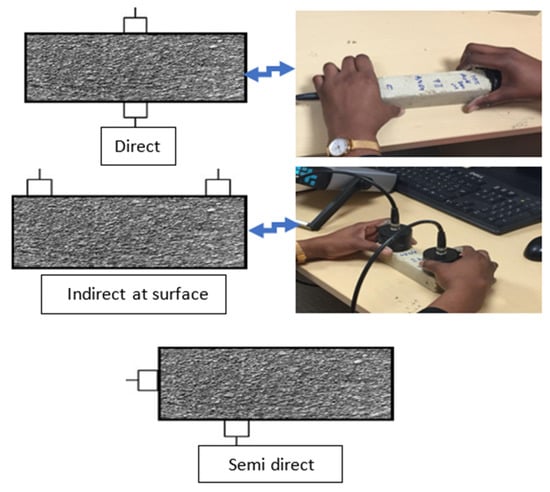

In civil engineering, ultrasonic techniques are not only widely used for the control of ordinary concretes but also for special mortars or cement-stabilized soils such as self-compacting (case of our study) and ultra-high- performance fiber concrete [19]. The method consists of measuring the pulse velocity of the ultrasound passing through the material using a generator and a receiver (transducers). It is now possible to make measurements on site using portable hardware such as PUNDIT (Portable Ultrasonic Nondestructive Digital Indicating Tester), which was used in this study. The measurement is essentially based on the transmission of ultrasonic waves and the measurement of its transfer time. Three types of configurations of two transducers can be used and are illustrated in Figure 5: (a) direct, (b) indirect at surface, and (c) semi-direct.

Figure 5.

Different configurations for two transducers.

Whenever possible, the direct layout is recommended as this allows maximum signal transmissions between transducers. The semi-direct layout is less sensitive than the direct layout but is more sensitive than the indirect layout. The path length is the distance between the center of each transducer. The main types of ultrasonic propagations are two modes, P (longitudinal waves) and S (transverse waves), depending on the mechanical properties of the materials. In reality, the method of determining the speed of ultrasonic waves in the case of concretes is defined by French standard NF P 12504-4. The ultrasonic velocity can be related to the mechanical properties of concrete, i.e., compressive strength, using empirical correlations or making our own correlations.

Regarding the reliability of the evaluation of the properties of concrete, it is necessary to specify problems encountered for four kinds: implementation, the calibration of the measurement, the interpretation of data, and the exploitation of the results [20]. During implementation, the measured speed can be affected by several factors such as the coupling gel influencing the repeatability of the measurements, the type of transducer, the presence of reinforcements, and the measurement conditions, i.e., humidity, temperature, and the lateral conditions of the medium crossed, etc. [21]. Non-destructive testing (NDT) methods are based on well-known physical principles (propagation of mechanical or electromagnetic waves, measurements of electric fields, etc.).

To measure UCS with direct or destructive method, a simple compressive strength test according to UCS was also used by using a destructive (conventional) method. As per French standard NFP 12390-3, rectangular test samples were placed between the trays of a press and experienced increasing axial forces until fracture, as depicted in Figure 6. The maximum value of the force makes it possible to calculate the uniaxial compressive strength UCS of the specimen as follows:

where A is the surface of the section of the test sample, and F is maximum axial force.

UCS = F/A

Figure 6.

Press-machine (left), flexural test (right top), and compression test (right bottom).

UCS testing was carried out on a press machine equipped with a compression force sensor with a maximum capacity of 10 kN (accuracy: ±0.1%) and a displacement capture device able to measure up to ±10 mm (accuracy: ±0.02 mm), as well as a device for the automatic acquisition of curve application/deformation (Figure 6). The control of the application of the load is carried out according to the rate of deformation imposed, i.e., 1.93 mm/min as per French standard NFP 12390-3.

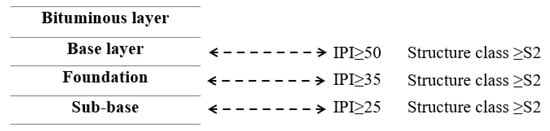

To reuse excavated soils or sediments for road construction, it is necessary to understand the specific requirements for road construction defined by the federal or local authorities of that area. As per French standard, a minimum and a maximum unconfined compressive strength (UCS) are recommended: a minimum 2 to 4 MPa to ensure the bearing capacity of vehicles and a maximum ≤8 MPa to ensure their re-excavation for base layer, while for the foundation and sub-base, the UCS should be ≥1 MPa. To reuse TC for road construction, a minimum unconfined compressive strength of 2 MPa is needed. Other than that, Proctor and tensile strength tests are also recommended by French rules and regulations for road construction. To obtain the required strengths, the excavated soils must be treated with a high proportion of pozzolanic/hydraulic binders, as made in soil stabilization techniques. The Proctor test evaluates the compaction properties of excavated materials (European Standard, NF EN 13286-2, 2005). The immediate bearing capacity (IPI index), which determines the capacity of a material to support the circulation of the building machines under construction, is also recommended (European Standard, NF EN 13286-47). The recommended characteristics for the different road layers as specified in French standards are provided in Figure 7 [22].

Figure 7.

Scheme of road section and recommended engineering characteristics (SETRA-LCPC, 1998 [23]).

2.3. Origin and Characteristics of Tested Soils

The excavated soils or trench cutting were collected from three sites, Yzernay, Villeray, and Angers, located in the west of France. To reference the different excavated trench cuttings, the initials of each site location were used. The second letter is either N, which stands for natural, i.e., natural or raw excavated soil without any physical or chemical action, or with M, which stands for machine process, i.e., trench cuttings crushed and sieved to 12 mm by the Mac-H (Table 3).

Table 3.

Location and reference of each sample.

Two types of TC were collected from the Yzernay site during a two-day site visit in March 2019. TC that became processed through Mac-H is termed as machine trench cuttings (MTCs), and the raw trench cutting is called natural trench cutting (NTC). Benici et al., (2007) verified that the specimen with a better fineness and a narrower particle size distribution had the highest compressive strength [24]. MTC has finer and narrower size distribution compared to NTC (Figure 8). Two samples (NTC) were collected from the Villeray site located in La Bouëxière along the road D106 on 1 April 2021. The third sampling location is Angers. The NTCs from this site were taken from the urban pavement and, therefore, contain grave bitumen mixed with gravel (0/40 mm) and silts in layers of depths.

Figure 8.

NTC (left) and MTC (right) from Yzernay site.

The characterizations of the excavated soils with respect to its physical properties are significant in decision making with respect to either reusing it or disposing [25]. The characterization of samples allows the determination of a set of properties necessary to choose a valuation chain to optimize the recycling process. Therefore, the physicochemical characteristics of TC, the contaminants interaction with the TC matrix, the amount of excavated soil or sediment, and the local environmental factors must all be considered when designing an appropriate sediment recovery strategy [26].

Before employing ecobinders to make mortar, it is important to understand TC’s geotechnical characteristics. Different forms of TC necessitate different ecobinders in terms of type and quantity. The usage of the ecobinder is also affected by the presence of contaminants. The presence of a high amount of organic matter content, for example, might cause problems with cement hydration, and the presence of acidic substances can lower the pH of trench-cutting and, hence, stymie pozzolanic reactions [27]. Trench-cutting may be unfeasible from an economic standpoint due to the demand for a huge volume of hydraulic binders. Figure 9 depicts natural samples gathered from each location. Table 4 outlines the geotechnical tests performed on TC prior to determining if it could be utilized as a self-placing mortar after being treated with an ecobinder.

Figure 9.

Visuals of all three natural trench cuttings.

Table 4.

Geotechnical properties testing standards.

MTC had the largest diameter of 12 mm (crushed and sieved by Mac-H) while NTC was only sieved (manually), keeping the maximum diameter at less than 20 mm. The geotechnical properties determined using the French standard are tabulated in Table 5.

Table 5.

Geotechnical characterization of each trench cuttings.

The characteristics of the TC from the Angers site have not been examined because of a lack of debris. All that can be said is that the Anger cuttings were collected from the urban pavement and contain grave bitumen (4 cm) mixed with gravel (0/40 mm) and silts in layers of depths. The trench cutting from Angers visually provide similar disruptions as of Villeray. The aim of mechanically studying Angers TC is to strengthen the results from other sites.

TC from Yzernay (both MTC and NTC) belongs to soil class A1, while the TC from Villeray belongs to soil class A2 according GTR classification [28]. Soil class A2 is for clay-clay sands, silts, clays, and marbles with little plastic arenes, while soil class A1 is for silt, little plastic, loess, alluvial silts, fine sands, and little polluted arenes, as explained by GTR (2000) [28].

2.4. Mix Design for SCM

The idea of producing self-compacting mortar (SCM) first appeared in Japan in 1986. Indeed, Japan was the pioneer in the development of this new technique [6]. SCM offers a wide range of possibilities for very interesting uses in several fields, including the construction, reinforcement, and repair of structures: application of thin films in places of difficult access; construction of prefabricated elements with high strength; molding; and the development of concrete for any use (concrete poured under water for repairs, confined concrete, piles, etc.) [29].

The depth of the trenches is limited to 0.5 m and their width should not exceed 25 cm. The small width of the trenches limits the consolidation process of mortar. Therefore, a laboratory approach is recommended to understand the behavior of self-compacting mortar in the small trenches.

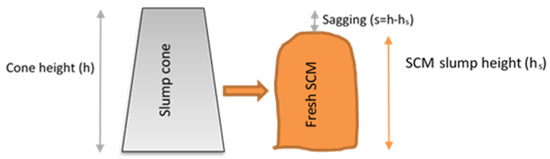

The consistency class of mortars made by mixing TC and ecobinders could be defined using a slump test. The cone is filled with the mortar in two layers by pushing each layer 25 times with the iron rod, and the cone is then removed vertically upward to observe how much material sagged after the removal of the cone (Figure 10).

Figure 10.

Sagging in slump test.

Depending upon the results of sagging in millimeters, the consistency of the mortar can be defined using standard NF EN 206 (Table 6).

Table 6.

Slump test cone parameters utilized to understand SCM.

French standard NF EN 12350-2 defined the size of the standard cone (cone of Abrams). To understand the scale effect, two different cones were used to determine the consistency class of mortar. By examining the experimentation results, it was proved that there is no scale effect as long as long as both cones have the same dimension ratio.

h1/h2 = D1/D2 = d1/d2

Within NTC, some big boulders and every gravel of sizes greater than 20 mm have been removed by sieving. On the other hand, for MTC, big boulders and all types of gravels became crushed by Mec-H and a final diameter of 12 mm has been obtained. Water content needed for the mortar made from each TC to have S5 consistency class is listed in Table 7.

Table 7.

Amount of water needed to make each mixture a SCM.

3. Results

3.1. Testing Results for Yzernay TC

Yzernay soil has been extracted from the side of a road; hence, it can be considered as a rural trench cutting (RTC). The Mec-H mobile production (Figure 11) unit is in operation along a departmental road in the rural zone for the installation of a flexible pipe for a water network.

Figure 11.

The Mec-H mobile production unit on Yzernay site.

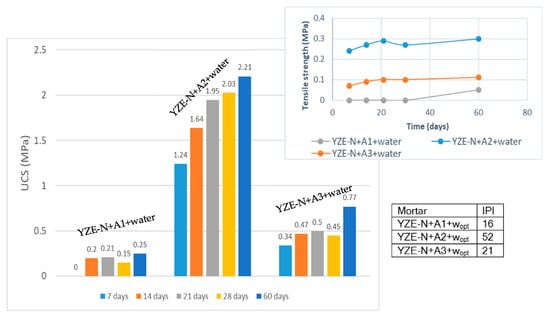

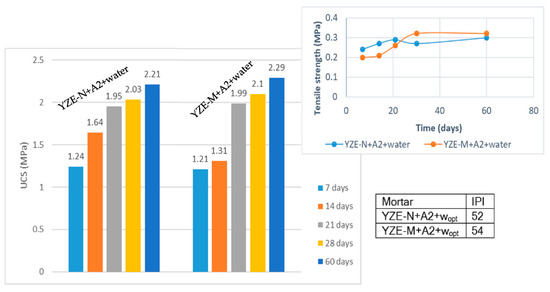

YZE-N-01 and YZE-N-02 were mixed together and termed YZE-N. All upcoming testing was performed on YZE-N. The UCS, tensile strength, and CBR results for Yzernay TC after mixing with all three types of binders are presented in Figure 12.

Figure 12.

UCS and tensile strength results for Yzernay TC mortar with all three ecobinders.

In comparison to A1 and A3, Yzernay TC treated with A2 ecobinder produced better results. Because the IPI index at optimal water content (wopt) is greater than 50, UCS at 28 days is greater than 2 MPa, and the material class is S2; this mortar can be reused in road building.

NTC and MTC are to be compared in this section to understand the benefits of crushing and sieving using the Mac-H mobile production unit. As A1 and A3 are not efficient, the mechanical parameters will be compared for NTC and MTC using only the A2 ecobinder (Figure 13). The two samples from machine TC were combined because they had nearly identical characteristics and were given the name YZE-M. Figure 13 shows the test findings for YZE-M.

Figure 13.

Comparison between NTC and MTC from Yzernay site.

When compared to the mortar manufactured with NTC, the MTC mortar produces somewhat superior outcomes. This is due to the rocks that were crushed in MTC, which resulted in decreased clay percentage. Of effect, the organic matter content is an undesirable component in a construction material [28] as it interferes with the hydration of cement. Furthermore, an abundance of clay is not conducive to cement hydration. MTC reduces the relative percentage of these two components, which could explain a little increase in mechanical characteristics. In addition, an increase in the cementing agent, carbonates, was detected (Table 8), which is linked to an increase in mechanical characteristics.

Table 8.

Mineral composition of each TC.

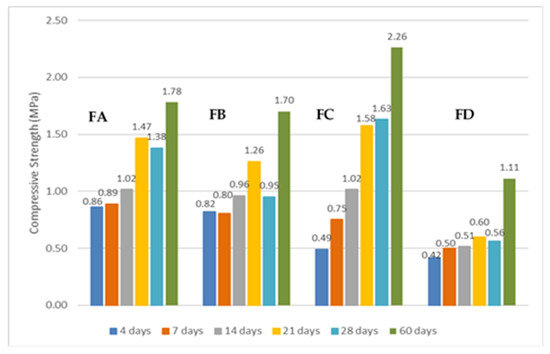

3.2. Testing Results for Villeray TC

The TC in this section is from a trench site operating on the side of a road for gas pipeline installation. Both Yzernay and Villeray TC were classified as RTC because they were excavated from the side of a road. It has already been determined that the A2 ecobinder is particularly effective for various types of TC. The question now is how much binder should be used to achieve the maximum possible strength for this type of TC. Four combinations have been proposed for SCM optimization. The ecobinder (A2) dosage was gradually increased by weight from 10% (ref. FA) to 12% (ref. FB), 14% (ref. FC), and 16% (ref. FC) (ref. FD). The water content of each formulation was kept constant. The outcomes of the testing are presented in Figure 14.

Figure 14.

Effects of increase percentage of ecobinder on Villeray TC.

It can be seen that until 14 percent of ecobinder A2, there is a gradual increase in UCS, followed by a sharp decrease. The fact that there is still an unreactive ecobinder due to its high percentage could explain the sudden decrease in UCS (FD).

3.3. Testing Results for Angers TC

FA and FC produce better results than FB and FD. FA has a greater initial day UCS value, but FC has the highest UCS value at 21, 28, and 60 days. Using prior results as a guide, this section will only look at the 10 percent and 14 percent binder dosages, but with different TCs extracted from the Angers site. Angers TC will be tested with 10% (ref. NA) and 14% (ref. NC) of A2 ecobinder to obtain a firm idea which percentage is better in terms of mechanical as well as an economical point of view. Figure 15 provides unconfined compressive strengths for Angers trench cutting with the addition of 10% and 14% of ecobinder A2.

Figure 15.

Angers TC testing for 10% and 14% of A2.

It can clearly be observed from Figure 15 that NC (14% binder dosage) provides better UCS values each day compared to NA (10% binder dosage) but is not very economical.

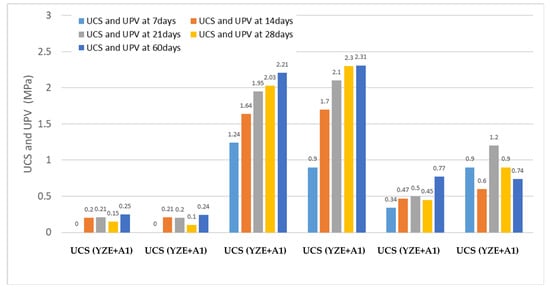

3.4. UCS Measurements with Non-Destructive Testing (NDT)

On the same samples that were subjected to destructive UCS testing in the Controlab press machine, non-destructive testing was performed beforehand by utilizing a PUNDIT portable instrument. SCM was prepared and tested for trench cuttings from Yzernay via both methods to understand the scope and accuracy of the NDT method. Strength values from the Controlab® press machine (destructive method) were termed as UCS, and ultrasonic resistance values were represented by UPV (Ultrasonic pulse velocity).

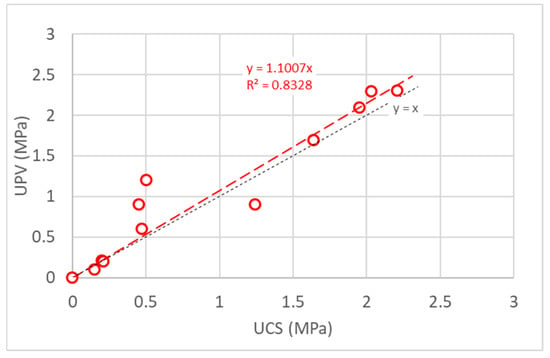

The aim of double testing (destructive and non-destructive) on same samples was to increase the reliability of the compression resistance values. There is a very good agreement between the compressive strength and ultrasonic pulse velocity resistance. It can be observed from the results that the NDT method is reliable and provides results very close to destructive methods, as illustrated in Figure 16. A slight overestimation is observable. Figure 17 explains the relation between UCS (compression strength through direct method) and UPV (compression strength through indirect method) for YZE + A2.

Figure 16.

UCS and UPV values for YZE-N self-compacting mortars.

Figure 17.

UPV-UCS relation for self-compacting mortars with raw Yzernay trench cuttings.

4. Conclusions

This research study on self-compacting mortar made from industrial byproducts (slags and fly ash) with only a trace of clinkers in the A2 binder suggests that trench cuttings can be recycled. It also demonstrates the difficulties in developing an appropriate formulation to achieve acceptable SCM strength performances using both destructive and non-destructive methods. Factors such as humidity, aggregate size, binder composition, and trench cutting structure can all contribute to this difficulty. Further research is required to refine the formulations obtained by considering the various parameters influencing the strength and workability of self-compacting mortar.

Moreover, with respect to the use of ecobinders for the trench cuttings tested, the following has been observed:

- -

- Considering SCM at 10% A2, strengths increase with time for YZE-N as well as YZE-M mixtures. Both TCs treated with the A2 ecobinder produced a UCS above 2 MPa at 28 days. The IPI index and concrete class for YZE-N and YZE-M confirm the suitability of these TCs to be reused as base layers as well as sub-base layer in road construction.

- -

- At 28 days, resistance to VIL-N was marginally reduced, which might be explained by the fact that the mortars had not yet hardened completely and still included some water. From a young age to the 28th day, these SCM do not reach the necessary resistance of 2 MPa. At 10% of ecobinder A2, the UCS value for ANG-N (NA) reached 1.99 MPa after 28 days.

- -

- Both VIL-N and ANG-N have greater UCS growth when SCM is at 14 percent of ecobinder A2. It is true that VIL-N UCS does not reach 2 MPa after 28 days, but it is close enough to what was confirmed after 60 days. ANG-N (NC), on the other hand, produces a UCS more than 2 MPa at 28 and 60 days.

- -

- Finally, when comparing SCM samples at 16 percent A2, the UCS values remain very low compared to SCM samples at other proportions. This is due to an excess of un-reacted binder.

In general, employing these environmentally friendly binders instead of standard hydraulic binders to reuse trench cuttings to refill the same trench is no longer out of reach. TC obtained from trenches made on the road or side of road in both rural and urban areas treated with ecobinders proved to be suitable material for sub-base layers as well as base layers in road construction; therefore, they can efficiently refill the same trenches.

Author Contributions

Conceptualization, A.H. and D.L.; methodology and experimental work, A.H. and I.N.; data analysis, A.H., D.L. and I.N.; writing—original draft preparation, A.H. and D.L.; review and editing, D.L.; supervision, D.L.; project administration, D.L., S.M. and P.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to the fact that all the results are reported in the internal reports of laboratory.

Acknowledgments

The authors thank the Higher Education Commission of Pakistan for the PhD fellowship of A. Hassan. Technical support was provided by the Groupe Marais company (excavated soils) and the M2C laboratory of Caen Normandie University (UniCaen). Special thanks goes to E. Bayonne and M. Legrain for their help in excavated soil characterization.

Conflicts of Interest

The authors have no conflicts of interest.

References

- Deselnicu, D.C.; Militāru, G.; Deselnicu, V.; Zăinescu, G.; Albu, L. Towards a circular economy–a zero waste programme for Europe. In Proceedings of the 7th International Conference on Advanced Materials and Systems (ICAMS), Bucharest, Romania, 18–20 October 2018; The National Research & Development Institute for Textiles and Leather-INCDTP: Bucharest, Romania; pp. 563–568. [Google Scholar]

- Dhervilly, P.; Levacher, D. Reuse of Excavated Soils from Mini-Trenches “The RecysoilsR national Project”; Geo-Environmental Engineering, Concordia University: Montreal, QC, Canada, 2019. [Google Scholar]

- Yang, R.; Kang, S.; Ozer, H.; Al-Qadi, I.L. Environmental and economic analyses of recycled asphalt concrete mixtures based on material production and potential performance. Resour. Conserv. Recycl. 2015, 104, 141–151. [Google Scholar] [CrossRef]

- USEPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2011; U.S. Environmental Protection Agency (USEPA): Washington, DC, USA, 2013. [Google Scholar]

- Blengini, G.A.; Garbarino, E. Resources and waste management in Turin (Italy): The role of recycled aggregates in the sustainable supply mix. J. Clean. Prod. 2010, 18, 1021–1030. [Google Scholar] [CrossRef]

- Dettenborn, T.; Forsman, J.; Rämö, P.; Pieksemä, J.; Suominen, M.; Korkiala-Tanttu, L. Utilization of crushed concrete aggregate in urban earth construction: Streets and pipe trenches. In Geotechnical Engineering for Infrastructure and Development; ICE publishing: London, UK, 2015. [Google Scholar] [CrossRef]

- Okamura, H.; Ouchi, M. Self-Compacting Concrete. J. Adv. Concr. Technol. 2003, 1, 5–15. [Google Scholar] [CrossRef]

- Bonen, D.; Shah, S.P. Fresh and hardened properties of self-consolidating concrete. Prog. Struct. Eng. Mater. 2004, 7, 14–26. [Google Scholar] [CrossRef]

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- Huang, S.-L.; Yeh, C.-T.; Chang, L.-F. The transition to an urbanizing world and the demand for natural resources. Curr. Opin. Environ. Sustain. 2010, 2, 136–143. [Google Scholar] [CrossRef]

- Yang, Q.Z.; Zhou, J.; Xu, K. A 3R Implementation Framework to Enable Circular Consumption in Community. Int. J. Environ. Sci. Dev. 2014, 5, 217. [Google Scholar] [CrossRef]

- Potgieter, J.H. An Overview of Cement production: How “green” and sustainable is the industry? Environ. Manag. Sustain. Dev. 2012, 1, 14–37. [Google Scholar] [CrossRef]

- Wilk, C.M. Solidification/stabilization treatment and examples of use at port facilities. In Port Development in the Changing World; Curtis, S.A., Ed.; ASCE Conference Proceedings: Houston Ports, TX, USA, 2004; pp. 1–10. [Google Scholar] [CrossRef]

- Said, I.; Missaoui, A.; Lafhaj, Z. Reuse of Tunisian marine sediments in paving blocks: Factory scale experiment. J. Clean. Prod. 2015, 102, 66–77. [Google Scholar] [CrossRef]

- Wang, S.L.; Baaj, H. Treatment of weak subgrade materials with cement and hydraulic road binder (HRB). Road Mater. Pavement Des. 2021, 22, 1756–1779. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2006, 42, 2917–2933. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Van Deventer, J.S.J. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Kong, D.L.; Sanjayan, J.G. Effect of elevated temperatures on geopolymer paste, mortar and concrete. Cem. Concr. Res. 2010, 40, 334–339. [Google Scholar] [CrossRef]

- Bian, H. Etude Expérimentale de L’endommagement de BFUHP Sous Sollicitations Physique, Chimique et Mécanique. Ph.D. Thesis, L’insa Rennes, Rennes, France, 2009; 184p. [Google Scholar]

- Garnier, V.; Abraham, O.; Dondonne, E.; Marlot, D. Méthodes D’évaluation Non Destructive par Propagation D’ondes Mécaniques. In Guide Méthodologique de L’évaluation Non Destructive des Ouvrages en Béton Armé; Association Française de Génie Civil: Paris, France, 2005; pp. 201–223. [Google Scholar]

- Garnier, V. Ultrasounds through Transmission. In Non-Destructive Assessment of Concrete Structures; Springer: Berlin, Germany, 2012; pp. 17–27. [Google Scholar]

- SETRA-LCPC. Assises de Chaussées: Guide D’application des Normes Pour le Réseau Routier National; SETRA-LCPC: Nantes, France, 1998; 90p. [Google Scholar]

- Dubois, V.; Abriak, N.E.; Zentar, R.; Ballivy, G. The use of marine sediments as a pavement base material. Waste Manag. 2009, 29, 774–782. [Google Scholar] [CrossRef] [PubMed]

- Binici, H.; Aksogan, O.; Cagatay, I.H.; Tokyay, M.; Emsen, E. The effect of particle size distribution on the properties of blended cements incorporating GGBFS and natural pozzolan (NP). Powder Technol. 2007, 177, 140–147. [Google Scholar] [CrossRef]

- Pebbles, V.; Thorp, S. Waste to Resource: Beneficial Use of Great Lakes Dredged Material; Great Lakes Commission: Ann Arbor, MI, USA, 2001; 16p. [Google Scholar]

- Kribi, S. Décomposition des Matières Organiques et Stabilisation des Métaux Lourds Dans les Sédiments de Dragage. Ph.D. Thesis, INSA Lyon, Lyon, France, 2005; 220p. Available online: http://theses.insa-lyon.fr/publication/2005ISAL0064/these.pdf (accessed on 10 March 2022).

- Kujala, K.; Makikyro, M.; Lehto, O. Effect of humus on the binding reaction in stabilized soils, Grouting and Deep Mixing. In Proceedings of the IS-TOKYO 96. The Second International Conference on Ground Improvement Geosystems, Tokyo, Japan, 14–17 May 1996; Balkema: Rotterdam, The Netherlands, 1996; pp. 14–17. [Google Scholar]

- GTR. Réalisation des Remblais et des Couches de Forme-Fascicule 1–Principes Généraux; SETRA-LCPC: Nantes, France, 2000; 102p, ISBN 2.11.085.707-2. [Google Scholar]

- Hugues, L. Remblayage de Tranchées en Matériau Autocompactant Recyclé (MAC R), CoTITA Méditerranée Nouvelles Solutions Economiques et Performantes; Centre d’Études Techniques de l’Équipement Méditerranée: Bron, France, 2013; 18p. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).