Abstract

Fiber-reinforced asphalt concrete (FRAC) was tested using limestone, PG 64-22 binder, and 20% reclaimed asphalt pavement (RAP). After mixing fibers with different lengths and dosages, they were extracted and recovered to evaluate their dispersion in the FRAC. The uniaxial fatigue test, IDEAL CT test, and flow number test were performed on FRAC with different fiber lengths and asphalt contents. The balanced mix design (BMD) approach was then used to analyze the uniaxial and flow number test results in order to evaluate the effect of aramid fibers on fatigue and rutting resistance of the pavement. The dispersion test showed that the 19 mm and 10 mm aramid fibers at a dosage rate of 0.5 g/kg provided the best dispersion. The 19 mm fibers showed better performance test results than the 10 mm and 38 mm fibers. The BMD approach provided ranges of asphalt contents to produce mixes with certain resistances to fatigue and rutting. The BMD approach also demonstrated the effect of fibers with different lengths on increasing the resistance to fatigue and rutting. The study concluded that the 19 mm fibers with a dosage of 0.5 g/kg produce best results. The BMD approach is a good tool that can be used to refine the mix ingredients, including additives such as fibers, in order to optimize pavement resistance to various distresses such as fatigue cracking and rutting.

1. Introduction

1.1. Background

The brittle nature of asphalt concrete may result in the development and propagation of cracks when subjected to tensile stresses. The addition of fibers to the mix increases its tensile strength since the fibers bridge across cracks and micro-cracks and carry the tensile forces. Therefore, fiber-reinforced asphalt concrete (FRAC) can sustain higher magnitudes and larger numbers of repetitions of tensile stresses. This effectively may reduce the potential of development/propagation of various types of cracks such as fatigue cracking, thermal cracking, and block cracking. In addition to increasing the tensile strength, the shear strength of the mix may also improve. Since pavement rutting occurs mostly due to shear, the addition of fibers may result in reducing the rutting potential under traffic loads. Also, fibers in FRAC keep cracks tight. Tight cracks allow interlocking of the two sides of the crack, which in turn allows load to be transferred from one side of the crack to the other.

Fibers are usually stronger than bulk objects made of the same materials. The reason is that materials have several types of internal defects at the atomic scale, such as point defects, missing atoms and line defects. A fracture usually starts at the location of these defects. Since fibers have very small diameters, with near crystal size, they have very few atomic defects. These minimal atomic defects make fibers very strong as compared to buck materials. For example, a glass plate fractures at stresses of 10–20 kPa, yet glass fibers have strengths of 3–5 GPa or more (more than 300 times stronger) [1,2].

Several types of fiber have been attempted for reinforcing and improving resistance to cracking and rutting in asphalt concrete mixtures with different degrees of success. These fibers include synthetic polymeric fibers, glass fibers, and waste or recycled fibers [3,4]. Previous studies have shown that the addition of fibers to dense and open graded asphalt concrete mixtures could change the viscoelasticity of the mixture [5]. It also improves different properties of asphalt mixtures including increasing dynamic modulus [6], relaxation ability and rutting resistance [4,7,8,9], resistance to the low-temperature anti-cracking properties, fatigue cracking and reflective cracking [10,11,12,13,14,15], tensile strength and resistance moisture susceptibility [16,17].

Laboratory studies have shown that different types of fibers increase fatigue life and reduce permanent deformation of the asphalt mixtures [17,18]. Stempihar et al. [19] concluded that a fiber-reinforced, porous asphalt friction course could qualify for several sustainable site credits. In addition, the minimal upfront cost of fibers makes this product attractive because the cost can be recouped by an approximate 1-year extension in service life. In addition, recent studies have shown that the mechanical performance of FRAC are significantly affected by the state of fibers distribution [20,21] and asphalt mixtures composition [20,22].

It is important that fibers are well dispersed in the FRAC in order to be more effective in bridging cracks and microcracks and, therefore, strengthening the mix. In addition to fiber dispersion, fiber length and fiber dosage play an important role in strengthening FRAC. When fiber length and/or dosage are increased in the mix, the fiber efficiency increases. However, too long and/or too many fibers can reduce the workability of the mixture and may result in uneven distribution of the fibers in the mix. Therefore, an optimal fiber length and dosage can increase the strength of the FRAC without scarifying workability.

1.2. Balanced Mix Design

The changing nature of the asphalt technology increased the use of additives such as fibers, polymers, and blending modifications created the necessity for agencies to look beyond volumetric asphalt mixture design and incorporate performance testing for cracking and rutting. With these changes in asphalt technology, the dependency on Marshall or Superpave mix design became outdated. The incorporation of performance testing in the mix design became necessary, which resulted in developing the balanced mix design approach [23]. In this approach, the need to address cracking and rutting performance is addressed by setting a maximum asphalt content where the rutting criterion is exceeded and setting the minimum asphalt content by the failure point of the cracking criterion. Therefore, the goal of the BMD is to achieve the combination and proportions of binder, aggregate, and additives to pass the criteria of performance tests for cracking and permanent deformation for a given level of traffic, climate, and pavement structure [24,25,26].

According to the NCHRP 20-07 Project [23], BMD is defined as an “asphalt mix design using performance tests on appropriately conditioned specimens that address multiple modes of distress taking into consideration mix aging, traffic, climate and location within the pavement structure”. Currently, three approaches are being used by some states. The first and basic approach is to run performance tests to verify the volumetric design. The second approach is to run performance tests to modify the volumetric design. The third approach is to design the mix based on performance testing with limited or no initial consideration of the volumetric requirements. Currently, the first approach is the most commonly used method employed by some states. The second approach has been tried by a few states at different degrees. The third approach has been tried by a limited number of states, but it has not been fully utilized as a “true” BMD.

The BMD of asphalt mixtures has recently been gaining gradual acceptance by some states [27,28,29,30,31]. The BMD can be potentially a good methodology in demonstrating the effect of adding fibers to asphalt concrete and showing how fibers can increase pavement resistance to both cracking and rutting. Currently, there is no systematic BMD study for fiber-reinforced asphalt concrete perhaps because the dispersion of fibers in the FRAC is currently not well known for different fiber lengths and dosages.

1.3. Scope of the Study

The objective of this study is to evaluate the effect of aramid fibers on the cracking and rutting resistance of asphalt concrete under different conditions. The fiber dispersion throughout the FRAC under different fiber lengths and dosages is evaluated. Laboratory fatigue and rutting tests with and without fibers are conducted at various fiber lengths and asphalt binder contents. Test results are then analyzed using the balanced mix design approach to evaluate the effect of fibers on increasing the FRAC resistance to fatigue cracking and rutting.

2. Experimental Program

2.1. Materials

In this study, an Ohio surface mix was used consisting of PG 64-22 binder, densely graded limestone aggregate with 9 mm nominal maximum size, and 20% RAP. The virgin mix was designed using the Marshall procedure and produced a design with asphalt content of 5.2% by weight of mix. The gradation of the mix design is given in Table 1. The asphalt in the 20% RAP was estimated as 1%, resulting in a total asphalt content of 6.2%. A blend of polyethylene and aramid fibers (poly-aramid fiber blend) was used, consisting of 12.7% aramid fibers and 87.3% polyethylene as recommended by the manufacturer (see Figure 1). Since aramid fibers only cannot be easily distributed in the asphalt mixture, the addition of polyethylene ensures uniform distribution in the asphalt mixture. The polyethylene melts during mixing in the hot-mix asphalt plant leaving the aramid fibers dispersed in the asphalt mixture [20,22]. Table 2 summarizes the physical properties of the polyethylene and aramid fibers. It should be noted that the volumetric properties of mixtures (i.e., Gmm, void content, etc.) were not notably affected by the presence of fibers.

Table 1.

Mix Gradation.

Figure 1.

Photo of polyethylene and aramid fiber blend.

Table 2.

Properties of polyethylene and aramid fibres.

2.2. Fiber Mixing Method

Dispersion and distribution of fibers is a key factor in maximizing the reinforcing benefits in any composite material. In a study by Noorvand et al. [21], an optimal fiber mixing procedure was developed on the basis of a three-layer fiber mixing system, which was used in this study. In this method, one full batch of aggregate was approximately divided to three thirds. The first third of the aggregates was poured and spread as the first layer into the mixing bucket and then half of the aramid fibers was evenly spread on the top of the first layer of aggregate. This process was repeated for the second layer of aggregate and second half of the aramid fibers. After pouring the third and final layer of aggregates into the mixing bucket, the appropriate amount of asphalt binder was added to a crater created in the middle of the aggregate. Next, the proportioned amount of polyethylene fibers was added directly to the hot asphalt binder and the mix was blended for 90 s. The binder was initially preheated 10 °C higher than the target mixing temperature to account for the heat lost.

2.3. Extraction and Fiber Recovery Test

To evaluate dispersion, aramid fibers were extracted using a procedure developed and described elsewhere [21,22], which is essentially the same as ASTM D2172 except that attention is given to observing, separating, and cleaning the fibers in the mixture after soaking the mixture and centrifuging off the solvent. In this test, the state of dispersed aramid fibers in asphalt concrete was broken down to four conditions: bundles (as supplied by the manufacturer), agitated bundles, clusters, individuals. Conceptually, individual fibers are more effective at bridging cracks and strengthening the asphalt mix than bundles, agitated bundles, or clusters. The percentage of individual fibers weight as related to the total weight of fibers was used as an indication of the effectiveness of fiber dispersion.

2.4. Mechanical Tests

Three different mechanical test protocols were also carried out to evaluate the effects of changing asphalt content and fiber length on the cracking and rutting properties of FRAC. The following three lab tests were performed:

- Flow number test, as a measure of rutting resistance;

- Uniaxial fatigue test, as a measure of fatigue cracking resistance;

- IDEAL CT test, as a measure of cracking resistance.

In all cases, tests were performed at the specified temperature using an IPC UTM-25 machine equipped with an environmental chamber. All specimens were prepared at target air voids between 6% and 7%. This air void content was chosen because it is commonly encountered in practice immediately after construction and is, therefore, the most critical air void content. All specimens were compacted with the gyratory compactor with the diameter of 150 mm. Specimens were then cut/cored to their final geometry. The following variables were used:

- Asphalt contents used: 5.4%, 5.8%, 6.2% (design asphalt content), and 6.6%;

- Fiber lengths: 10, 19 and 38 mm.

Three to four replicates were tested for each factor combination. Also, a fiber dosage of 0.05% by weight of asphalt mixture (0.5 g/kg or 1 lb/ton) was used in all the tests. The dosage level was used as per the recommendation of the manufacturer based on the results of previous studies [21,22,32,33]. Note that changing the fiber length and keeping the same dosage changes the number of fibers per unit weight of the mix. Therefore, any changes in the materials properties could be because of either: (1) changing fiber length, which changes the bond strength of fibers round cracks, or (2) changing the number of fibers, which changes the chance of fibers bridging across cracks.

2.4.1. Flow Number Test

The Repeated Load Permanent Deformation, also known as Flow Number test [AASHTO T 378], was conducted to determine the permanent deformation characteristics of the asphalt mixtures. In this test, cylindrical specimens 100 mm in diameter and 150 mm high are cored from gyratory prepared specimens. A haversine compressive pulse load consisting of a 0.1 s and 0.9 s dwell (rest) time was applied for the test duration, typically about three hours or 10,000 loading cycles. Results from the test typically are presented in terms of the cumulative permanent strain versus the number of loading cycles. Figure 2 illustrates a typical relationship between the cumulative plastic strain and number of load cycles and the test setup. The cumulative permanent strain curve can be divided into primary, secondary, and tertiary zones. The cycle number at which tertiary flow starts is referred to as the flow number (FN), which is correlated to the rutting resistance of asphalt concrete. The test was performed using asphalt concrete with and without fibers at 50 °C and 350 kPa axial stress.

Figure 2.

Repeated load permanent deformation test; (a) typical relationship between total cumulative plastic strain and number of load cycles and (b) specimen set-up.

2.4.2. Uniaxial Fatigue Test

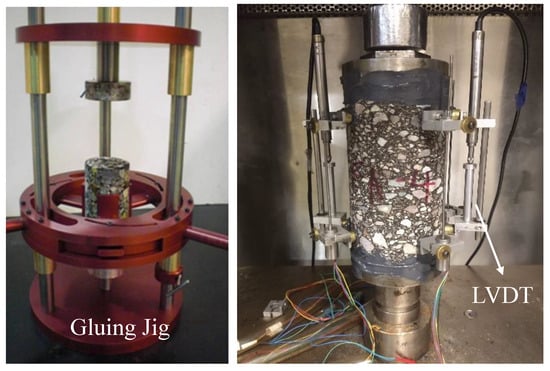

In this test, gyratory asphalt concrete specimens with and without fibers were prepared at air voids of 6.5 ± 0.5%. Cylindrical specimens of 75 and 150 mm in diameter and height, respectively, were cored from the gyratory plugs for testing. The specimen was then glued to the end plates. Figure 3 shows both the gluing jig used to ensure proper alignment and the uniaxial fatigue test setup. The specimen was instrumented with four axial LVDTs to monitor the on-specimen deformation. The uniaxial fatigue test was performed by applying a repeated tension-compression sinusoidal deformation along the axis of the specimen at 10 Hz frequency until failure. The test was also conducted at 20 °C, which simulates fatigue crack initiation at intermediate pavement service temperatures. The test was performed according to the AASHTO TP107 procedure and the damage characteristic function was determined as a measure of the fatigue life of asphalt concrete.

Figure 3.

Gluing jig and the uniaxial fatigue test setup.

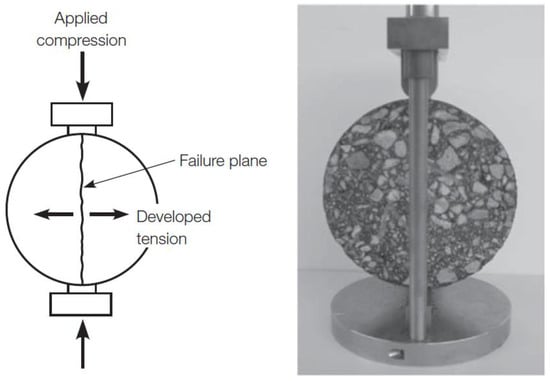

2.4.3. IDEAL CT (Indirect Tension) Test

It is important to evaluate the tensile strength of asphalt mixture in order to evaluate at what stress the material will start cracking. In this test, cylindrical specimens 150 mm in diameter and 51 mm in thickness were used. A compressive vertical load was applied along the vertical diameter as shown in Figure 4. The load was applied using two curved loading strips moving with a typical rate of deformation of 51 mm/minute. Tensile stresses were developed in the horizontal direction, and when these stresses reached the tensile strength, the specimen failed in tension along the vertical diameter. The test was performed at a 25 °C temperature.

Figure 4.

IDEAL CT (indirect tension) test.

The IDEAL CT test is the same as the indirect tensile strength test except using a different method of analysis. Instead of using the tensile strength only, it considers the post peak response of the material by evaluating the whole area under the curve [34]. Thus, the IDEAL CT test demonstrates how fibers bridge the crack and extend the cracking resistance of the material. The CT index is calculated using the area under the curve, which is more sensitive to material composition than the tensile strength [ASTM D 8225].

3. Results

3.1. Fiber Dispersion in Fiber-Reinforced Asphalt Concrete (FRAC)

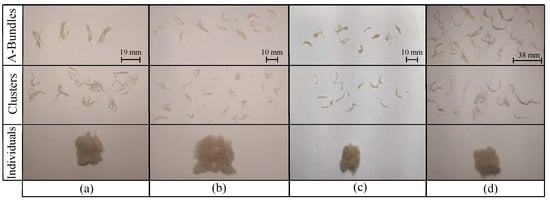

After fibers were extracted and recovered from the FRAC, fibers were visually separated to the different dispersion categories: bundles, agitated bundles (A-Bundles), clusters, and individuals. No fibers in the form of bundles as supplied by the manufacturer were observed. The other three categories were separated and weighed. Table 3 shows the relative percentages of the different fiber dispersion categories by weight after recovery for the different length and dosage combinations. The results show that the 10 mm fibers at 0.5 g/kg dosage have the highest dispersion with individual fibers of 59%. The 19 mm fibers at 0.5 g/kg dosage and the 10 mm fibers at 0.25 g/kg dosage have the same individual fiber quantity of 50%. The 38 mm fibers at 0.5 g/kg showed the least dispersion with individual fiber quantity of 33% only. Figure 5 shows images of the relative amounts of the different fiber categories after extraction and recovery for the different length and dosage combinations.

Table 3.

Relative percentages of the different fiber dispersion categories by weight after extraction and recovery for the different length and dosage combinations.

Figure 5.

Relative amounts of recovered aramid fibers for (a) 19 mm (0.5 g/kg), (b) 10 mm (0.5 g/kg), (c) 10 mm (0.25 g/kg), and (d) 38 mm (0.5 g/kg).

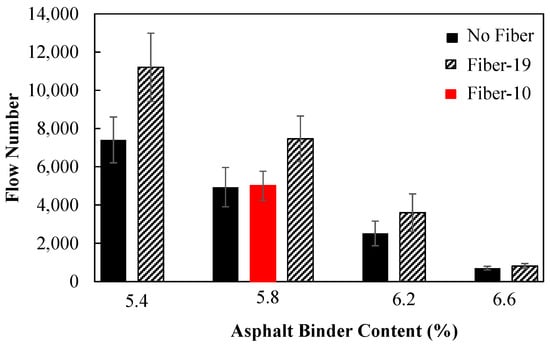

3.2. Flow Number Test

Figure 6 shows the flow number values for mixtures with and without fibers at different asphalt contents. The results show that the 19 mm fibers increased the flow numbers by 51% and 52% at 5.4% and 5.8% asphalt contents, respectively. The increases by 6.2% and 6.6% of asphalt content were only 12% and 14%, respectively. The 10 mm fibers were tested at 5.8% asphalt content only and showed 5% increase. Note that, the 10 mm fiber represents the case of 0.5 g/kg dosage level. The 10 mm fiber at lower dosage level (0.25 g/kg) did not show any difference compared with samples without fibers. Therefore, this fiber case was discarded from the rest of this study. The results suggest that fibers are more effective in improving the rutting resistance of asphalt concrete at lower binder contents. This finding was similarly found and supported in an earlier study by Noorvand et al. [22], which showed that there is a strong correlation between the reinforcement effectiveness of fibers and the asphalt binder content. The study suggested that the reduced effect of interparticle friction and the degree of interlock between aggregates at higher binder content may account for the reduced fiber reinforcement efficiency. Also, comparing 10- and 19-mm fibers, it is likely that longer fibers provided more effective bridging sites during fiber pullout under compression loading, which result in increasing the rutting resistance [20,35].

Figure 6.

Flow numbers for mixtures with and without fibers at different asphalt contents.

3.3. Uniaxial Fatigue Test

The dynamic modulus and phase angle were tracked throughout the entire fatigue test. Because of the repeated loading, macrocracks develop and gradually grow until failure. The test results were analyzed using the simplified viscoelastic continuum damage (S-VECD) approach for characterizing fatigue behavior. The number of cycles to failure (Nf) was defined as the number of cycles at which the phase angle showed a sharp decrease. This analysis approach as applied to asphalt concrete has been described in great detail elsewhere [36].

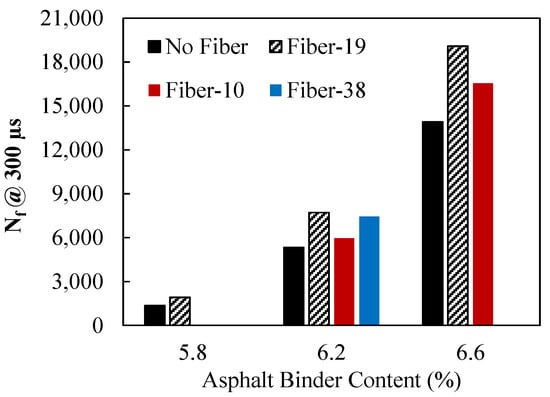

Figure 7 shows the number of cycles to failure, Nf, simulated at a 300 microstrain level for the different asphalt contents and fiber lengths. The results show that fibers increase fatigue lives in general as compared to mixtures without fibers. The 19 mm fibers showed the largest increase in fatigue lives among other fiber lengths with an increase between 40–50%. The 10 mm fibers showed an increase in fatigue lives of 12–19% only, while the 38 mm fibers showed a 40% increase at 6.2% asphalt content. The results also show that long fibers were more effective at enhancing the cracking resistance of asphalt concrete than short fibers [20,35]. It is also worth noting that 38 mm fibers were not dispersed in the mix as effectively as 19 mm fibers, otherwise it would potentially provide further benefit in resisting the fatigue cracking.

Figure 7.

Uniaxial fatigue test results at different asphalt contents and fiber lengths.

3.4. IDEAL CT Test

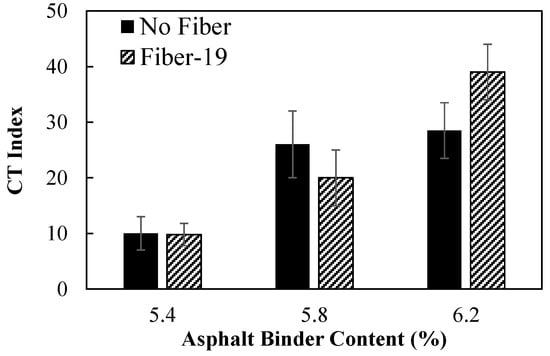

Specimens with and without 19 mm aramid fibers were tested and the CT indices were compared. Figure 8 shows the average CT index values for specimens with and without fibers at different asphalt contents. The results show that the 19 mm fibers increased the CT index by about 55% at the design asphalt content of 6.2%. Additionally, the CT index calculation did not show a benefit of fibers with 5.4% and 5.8% asphalt content. These results also suggest that the appropriate cracking test in identifying the benefit of reinforcing fibers in asphalt concrete is imperative. While the uniaxial cyclic fatigue test consistently exhibited the benefit of fibers in improving the cracking resistance of asphalt concrete at all binder levels, the monotonic IDT test configuration only showed the fiber efficiency at relatively higher asphalt binder contents.

Figure 8.

CT index values for mixtures with and without fibers at different asphalt contents.

3.5. Effect of Fibers on Balanced Mix Design (BMD)

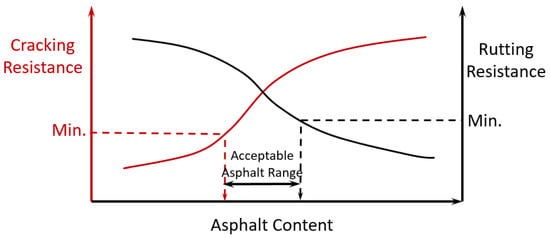

Applying the concept of BMD can be an excellent tool in demonstrating how aramid fibers can extend pavement life by increasing the resistance to pavement distresses such as fatigue cracking and rutting. For a conventional asphalt concrete without fibers, Figure 9 shows that increasing asphalt content increases cracking resistance but decreases rutting resistance. Increasing asphalt makes the asphalt concrete mixture more flexible and, therefore, increases the fatigue life by increasing the number of repeated stresses before cracking. On the other hand, increasing asphalt increases lubrication between aggregate particles and, therefore, reduces stability and increases the chance of permanent deformation. Thus, the asphalt concrete ingredients need to be properly controlled in order to balance between fatigue cracking resistance and rutting resistance. If the cracking and rutting limits are known, the BMD can be used to determine an acceptable range of asphalt content that satisfies both cracking and rutting resistance requirements as shown in Figure 9. The BMD approach provides flexibility to the designer to change the asphalt content to control cracking and rutting service lives.

Figure 9.

Concept of balanced mix design (BMD).

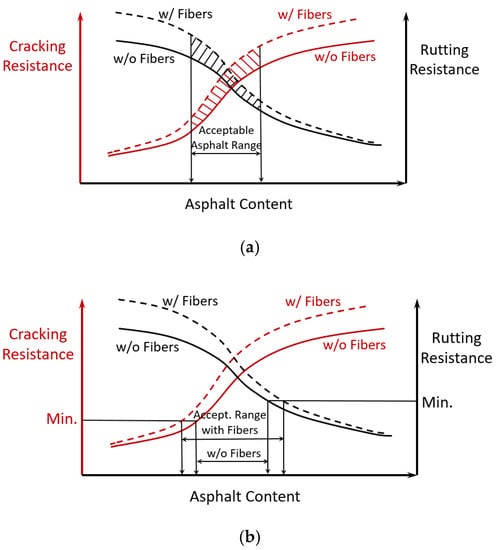

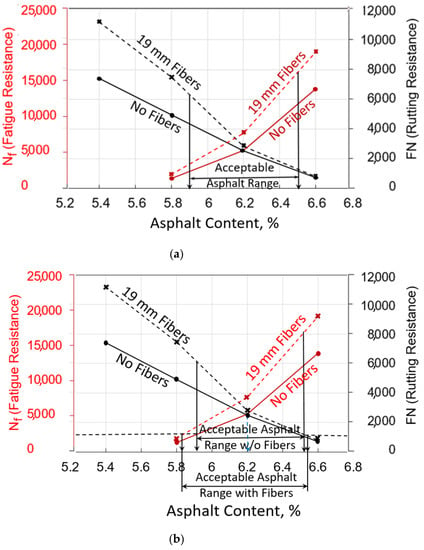

Figure 10 shows a conceptual effect of fibers on the BMD, given that fibers increase both cracking and rutting resistances as discussed earlier. Two methods can be used to evaluate the effect of fibers on improving cracking and rutting resistances as shown in Figure 10a,b. If the acceptable range of asphalt content for the mix without fibers is fixed, Figure 10a shows the increase in cracking and rutting resistances due to the use of fibers. Alternatively, if the minimum cracking and rutting resistance requirements are fixed, Figure 10b shows the increase in the acceptable range of asphalt content due to the use of fibers.

Figure 10.

Conceptual effect of fibers on BMD: (a) improving cracking and rutting resistance, and (b) increasing the acceptable range of asphalt content.

3.5.1. BMD of 19 mm Fibers

Using the test results obtained earlier, Figure 11 applies the BMD approach on laboratory test results using the 19 mm fibers. For this Ohio asphalt concrete with a design asphalt content of 6.2%, the Ohio Department of Transportation (ODOT) job mix formula (JMF) allows for 6.2 ± 0.3% asphalt content. In this figure, the scales of fatigue resistance and rutting resistance were adjusted so that the fatigue and rutting curves would meet at 6.2% asphalt content. In this study, the specific cracking and rutting resistance numbers of traffic repetitions to failure are not known. Therefore, the acceptable range of asphalt content corresponding to the asphalt concrete without fibers was used as a datum. The new cracking and rutting resistance limits for the FRAC were then compared to those of asphalt concrete without fibers.

Figure 11.

Effect of fibers on BMD: (a) improving cracking and rutting resistance, and (b) increasing the acceptable range of asphalt content.

Considering the acceptable asphalt content range of 6.2 ± 0.3%, Figure 11a shows that fibers increased Nf (fatigue life) from 2300 to 3400 at 5.9% asphalt content and from 12,000 to 16,000 at 6.5% asphalt content, which is an increase of 30–40%. The figure also shows that fibers increased FN (rutting resistance) from 1100 to 1300 at 5.9% asphalt content and from 4300 to 6300 at 6.5% asphalt content, which is an increase of 10–40%. Using this approach, the designer can select the design of asphalt content, within the acceptable range, in order to maximize either cracking resistance or rutting resistance depending on the common type of distress in the region.

Figure 11b shows that adding fibers increased the acceptable range of asphalt content by about 10% using the same minimum cracking and rutting resistance requirements. The advantage of this increase is that the material can be more forgiving even if the contractor does not exactly follow the JMF requirements.

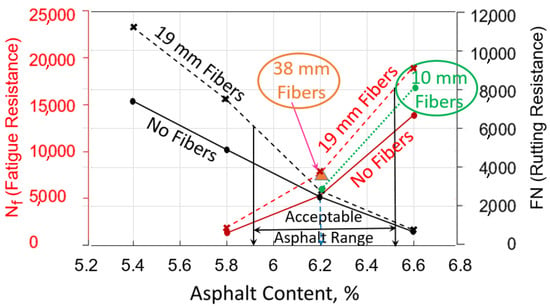

3.5.2. BMD of 10- and 38-mm Fibers

Figure 12 shows the effect 10- and 38-mm fibers within the acceptable range of asphalt content. The figure shows that the 10- and 38-mm fibers increased the fatigue and rutting resistances at 6.2% and 6.6% asphalt contents, but not as much as the 19 mm fibers. These results show that the 19 mm fibers are more effective in increasing cracking and rutting resistance than the 10- and 38-mm fibers. Note that the number of tests on asphalt mixtures with 10 and 38 mm used in this study was limited and did not cover the whole range of asphalt content.

Figure 12.

Effect 10 and 38 mm fibers within the acceptable range of asphalt content.

4. Summary and Conclusions

The addition of fibers to asphalt concrete has been recently used in an attempt to enhance its fatigue and rutting resistance. When the pavement section is subjected to tensile stresses, fibers bridge across cracks and reduce their initiation and propagation. Thus, FRAC can sustain larger numbers of load repetitions before the development of fatigue failure. Also, the addition of fibers keeps the aggregate particles close to each other and maintains aggregate interlock. This, in turn, would increase the shear resistance and reduce the rutting potential of the pavement section. It is also important to select the appropriate length and dosage of fibers so that fibers would be well dispersed throughout the mixture.

The concept of balanced mix design (BMD) of asphalt concrete has been lately introduced in order to address the recent changes in the asphalt technology and the use of additives, such as fibers and polymers. The goal of the BMD is to achieve the combination and proportions the asphalt mixture and additives to pass the criteria of performance tests for cracking and rutting. Since asphalt content has opposite effects on cracking and rutting resistance, there should be an optimal range of asphalt content that would provide an acceptable level of cracking and rutting resistance. The main objective of this study was to evaluate the effect of aramid fibers on the cracking and rutting resistance of asphalt concrete under different conditions using the BMD approach.

In this study, FRAC was tested using limestone, PG 64-22 binder, and 20% RAP. The dispersion of fibers in the FRAC was evaluated using a fiber extraction and recovery test for different fiber lengths and dosages. The flow number test, uniaxial fatigue test, and IDEAL CT test were conducted on FRAC with different fiber lengths and asphalt contents. The BMD approach was then used to analyze the uniaxial and flow number test results in order to evaluate the effect of aramid fibers on fatigue and the rutting resistances of the pavement. The following conclusions were derived.

- The dispersion test showed that the 19 mm and 10 mm aramid fibers were separated into individual fibers more than the 38 mm fibers.

- The flow number test showed that the 19 mm fibers improved rutting resistance at 5.4–6.6% asphalt contents by 12–51%. The 10 mm fibers did not show much effect.

- The uniaxial fatigue test showed that the 19 mm fibers increased the fatigue life by 37–45%, which was larger than the increase of the 10- and 38-mm fibers.

- The IDEAL CT test showed that 19 mm fibers increased the CT index by about 55% at the design asphalt content of 6.2%. Fibers, however, did not show much effect at 5.4% and 5.8% asphalt contents.

- Using the balanced mix design approach, the 19 mm fibers improved both fatigue and rutting resistances within the acceptable range of binder content (6.2 ± 0.3%). The 19 mm fibers also increased the acceptable binder range by 10% using the same minimum cracking and rutting resistances requirements. The 10 mm and 38 mm fibers also increased fatigue resistance, but not as much as the 19 mm fibers.

- The 19 mm fibers with a dosage of 0.5 g/kg showed the best overall results.

- The BMD approach is a good tool that can be used to refine the asphalt mix ingredients, including additives such as fibers, in order to optimize pavement resistance to various distresses such as fatigue cracking, rutting.

The results of this study provide an attempt to demonstrate the effect of changing asphalt content on the resistance to fatigue cracking and rutting. More work is still needed to establish a “true” BMD, in which pavement performance would become an integral part of asphalt concrete mix design.

Author Contributions

Conceptualization, M.M. and H.N.; Methodology, M.M., K.K. and H.N.; Formal analysis, H.N., M.M. and S.C.B.; Investigation, H.N. and S.C.B.; Writing—original draft preparation, M.M. and H.N.; Writing—review and editing, H.N., K.K. and M.M.; Supervision, K.K. and M.M.; Funding acquisition, M.M. and K.K. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to acknowledge the FORTA Corporation for the financial support and for providing the fibers.

Data Availability Statement

All data generated in this study is reported in the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Callister, W.D., Jr.; Rethwisch, D.G. Fundamentals of Materials Science and Engineering: An Integrated Approach, 3rd ed.; John Wiley and Sons: New York, NY, USA, 2020. [Google Scholar]

- Mamlouk, M.S.; Zaniewski, J.P. Materials for Civil and Construction Engineers, 4th ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- Abtahi, S.M.; Sheikhzadeh, M.; Hejazi, S.M. Fiber-reinforced asphalt-concrete–A review. Constr. Build. Mater. 2010, 24, 871–877. [Google Scholar] [CrossRef]

- National Academies of Sciences, Engineering, and Medicine; Transportation Research Board; National Cooperative Highway Research Program; McDaniel, R.S. Fiber Additives in Asphalt Mixtures; National Academies Press: Washington, DC, USA, 2015. [Google Scholar]

- Huang, H.; White, T.D. Dynamic Properties of Fiber-Modified Overlay Mixture. Transp. Res. Rec. J. Transp. Res. Board 1996, 1545, 98–104. [Google Scholar] [CrossRef]

- Wu, S.; Ye, Q.; Li, N.; Yue, H. Effects of Fibers on the Dynamic Properties of Asphalt Mixtures. J. Wuhan Univ. Technol. -Mater. Sci. Educ. 2007, 22, 733–736. [Google Scholar] [CrossRef]

- Mahrez, A.; Karim, M.R.; bt Katman, H.Y. Fatigue and Deformation Properties of Glass Fiber Reinforced Bituminous Mixes. J. East. Asia Soc. Trans. Stud. 2005, 6, 997–1007. [Google Scholar]

- Behbahani, H.; Nowbakht, S.; Fazaeli, H.; Rahmani, J. Effects of Fiber Type and Content on the Rutting Performance of Stone Matrix Asphalt. J. Appl. Sci. 2009, 9, 1980–1984. [Google Scholar] [CrossRef] [Green Version]

- Peltonen, P.V. Characterization and Testing of Fibre-Modified Bitumen Composites. J. Mater. Sci. 1991, 26, 5618–5622. [Google Scholar] [CrossRef]

- Tapkın, S. The effect of polypropylene fibers on asphalt performance. Build. Environ. 2008, 43, 1065–1071. [Google Scholar] [CrossRef]

- Jahromi, S.G.; Khodaii, A. Carbon Fiber Reinforced Asphalt Concrete. Arab. J. Sci. Eng. 2008, 33, 355–364. [Google Scholar]

- Serfass, J.P.; Samanos, J. Fiber-Modified Asphalt Concrete Characteristics, Applications and Behavior. Asph. Pav. Tech. 1996, 65, 193–230. [Google Scholar]

- Maurer, D.A.; Malasheskie, G.J. Field performance of fabrics and fibers to retard reflective cracking. Geotext. Geomembr. 1989, 8, 239–267. [Google Scholar] [CrossRef]

- Ye, Q.; Wu, S.; Li, N. Investigation of the dynamic and fatigue properties of fiber-modified asphalt mixtures. Int. J. Fatigue 2009, 31, 1598–1602. [Google Scholar] [CrossRef]

- Wu, S.; Ye, Q.; Li, N. Investigation of rheological and fatigue properties of asphalt mixtures containing polyester fibers. Constr. Build. Mater. 2008, 22, 2111–2115. [Google Scholar] [CrossRef]

- Mitchell, M.R.; Link, R.E.; Kaloush, K.E.; Biligiri, K.P.; Zeiada, W.A.; Rodezno, M.C.; Reed, J.X. Evaluation of Fiber-Reinforced Asphalt Mixtures Using Advanced Material Characterization Tests. J. Test. Eval. 2010, 38, 400–411. [Google Scholar] [CrossRef] [Green Version]

- Xu, Q.; Chen, H.; Prozzi, J.A. Performance of fiber reinforced asphalt concrete under environmental temperature and water effects. Constr. Build. Mater. 2010, 24, 2003–2010. [Google Scholar] [CrossRef]

- Lee, S.J.; Rust, J.P.; Hamouda, H.; Kim, Y.R.; Borden, R.H. Fatigue Cracking Resistance of Fiber-Reinforced Asphalt Concrete. Text. Res. J. 2005, 75, 123–128. [Google Scholar] [CrossRef]

- Stempihar, J.J.; Souliman, M.; Kaloush, K.E. Fiber-Reinforced Asphalt Concrete as Sustainable Paving Material for Airfields. Transp. Res. Rec. J. Transp. Res. Board 2012, 2266, 60–68. [Google Scholar] [CrossRef]

- Noorvand, H. Advancing Knowledge of Mechanically-Fiber Reinforced Asphalt Concrete. Ph.D. Thesis, Arizona State University, Tempe, AZ, USA, 2020. [Google Scholar]

- Noorvand, H.; Salim, R.; Medina, J.; Stempihar, J.; Underwood, B.S. Effect of Synthetic Fiber State on Mechanical Performance of Fiber Reinforced Asphalt Concrete. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 42–51. [Google Scholar] [CrossRef]

- Noorvand, H.; Castro, S.; Underwood, B.S.; Kaloush, K.E. Evaluating interaction of fibre reinforcement mechanism with mesostructure of asphalt concrete. Int. J. Pavement Eng. 2020, 1–18. [Google Scholar] [CrossRef]

- West, R.; Rodezno, C.; Leiva, F.; Yin, F. Development of a Framework for Balanced Mix Design. NCHRP Proj. 2018, 7–20. [Google Scholar]

- Newcomb, D.; Zhou, F. Balanced Design of Asphalt Mixtures; MN/RC 2018-22; Texas A&M Transportation Institute: College Station, TX, USA, June 2018. [Google Scholar]

- Mohammad, L.N.; Kim, M.; Challa, H. Development of Performance Based Specifications for Louisiana Asphalt Mixtures; FHWA/LA.14/558; Louisiana Transportation Research Center: Baton Rouge, LA, USA, February 2016. [Google Scholar]

- Zhou, F.; Hu, S.; Scullion, T. Integrated Asphalt (Overlay) Mixture Design, Balancing Rutting and Cracking Requirements; FHWA/TX-06/0-5123-1; Texas Transportation Institute, Texas A&M University: College Station, TX, USA, October 2006. [Google Scholar]

- Zhou, F.; Steger, R.; Mogawer, W. Development of a coherent framework for balanced mix design and production quality control and quality acceptance. Constr. Build. Mater. 2021, 287, 123020. [Google Scholar] [CrossRef]

- Sreedhar, S.; Coleri, E.; Obaid, I.A.; Kumar, V. Development of a Balanced Mix Design Method in Oregon to Improve Long-Term Pavement Performance. Transp. Res. Rec. J. Transp. Res. Board 2021, 2675, 1121–1137. [Google Scholar] [CrossRef]

- Diefenderfer, S.D.; Boz, I.; Habbouche, J. Balanced Mix Design for Surface Asphalt Mixtures: Phase I: Initial Roadmap Development and Specification Verification; FHWA/VTRC 21-R15; Virginia Transportation Research Council (VTRC): Charlottesville, VA, USA, May 2021. [Google Scholar]

- Hajj, E.Y.; Aschenbrener, T.B. Case Studies on the Implementation of Balanced Mix Design and Performance Tests for Asphalt Mixtures: Louisiana Department of Transportation & Development (LaDOTD). UNR Pavement Eng. Sci. Program. 2021. Available online: https://www.eng.auburn.edu/research/centers/ncat/files/Louisiana-Case-Study.pdf (accessed on 24 December 2021).

- Elias, N.G.; Hand, A.J.T.; Sebaaly, P.E.; Hajj, E.Y.; Piratheepan, M.; Gibson, S. Local agency transition to balanced mix design. Int. J. Pavement Eng. 2021, 1–11. [Google Scholar] [CrossRef]

- Klinsky, L.M.G.; Kaloush, K.E.; Faria, V.C.; Bardini, V.S.S. Performance characteristics of fiber modified hot mix asphalt. Constr. Build. Mater. 2018, 176, 747–752. [Google Scholar] [CrossRef] [Green Version]

- Slebi-Acevedo, C.J.; Lastra-González, P.; Indacoechea-Vega, I.; Castro-Fresno, D. Laboratory assessment of porous asphalt mixtures reinforced with synthetic fibers. Constr. Build. Mater. 2020, 234, 117224. [Google Scholar] [CrossRef]

- Zhou, F.; Im, S.; Sun, L.; Scullion, T. Development of an IDEAL cracking test for asphalt mix design and QC/QA. Road Mater. Pavement Des. 2017, 18, 405–427. [Google Scholar] [CrossRef]

- Noorvand, H.; Mamlouk, M.; Kaloush, K.E. Evaluation of Optimum Fiber Length in Fiber Reinforced Asphalt Concrete. J. Mater. Civ. Eng. 2022, inpress.

- Underwood, B.S.; Kim, Y.R.; Guddati, M.N. Improved calculation method of damage parameter in viscoelastic continuum damage model. Int. J. Pavement Eng. 2010, 11, 459–476. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).