Laboratory Study on Non-Destructive Evaluation of Polyethylene Liquid Storage Tanks by Thermographic and Ultrasonic Methods

Abstract

1. Introduction

2. Sample Preparation and Methods

2.1. Survey

- A determination of how many brine tanks are currently in service in the USA, including their capacity range, age range and the most common material type for in-service brine tanks.

- How do state DOTs maintain their ASTs in different seasons?

- What area(s) of a ASTs is (are) the most likely area(s) for a tank failure?

- What provisions and regulations do state DOTs follow to evaluate the condition of their tanks and how do they decide when to remove a tank from service?

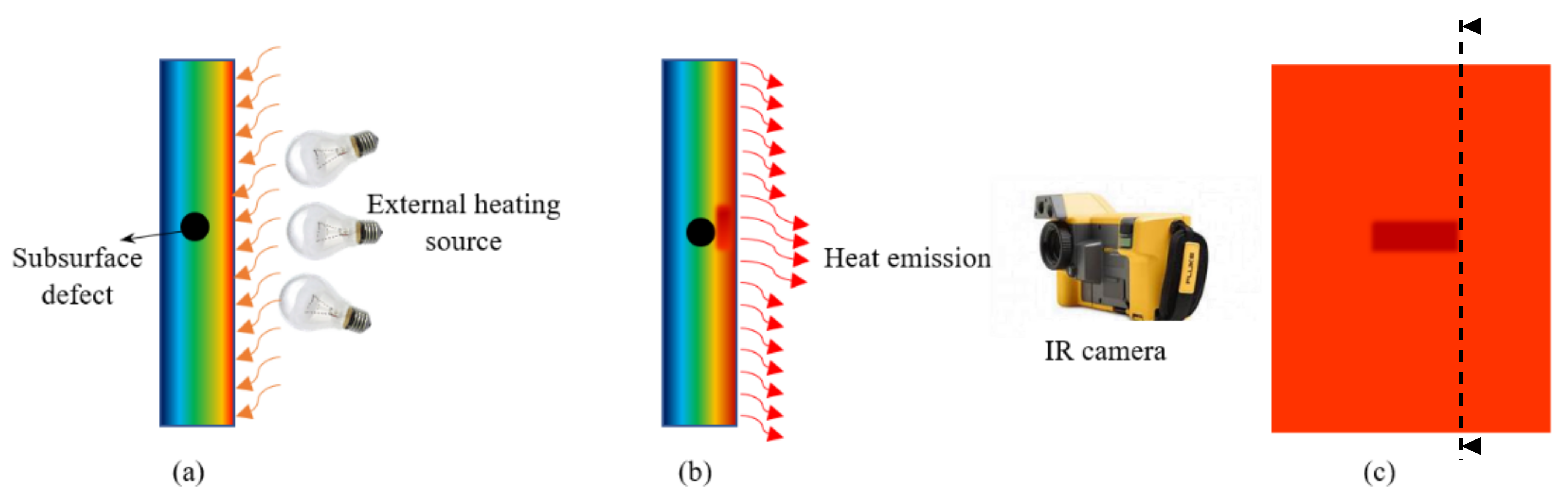

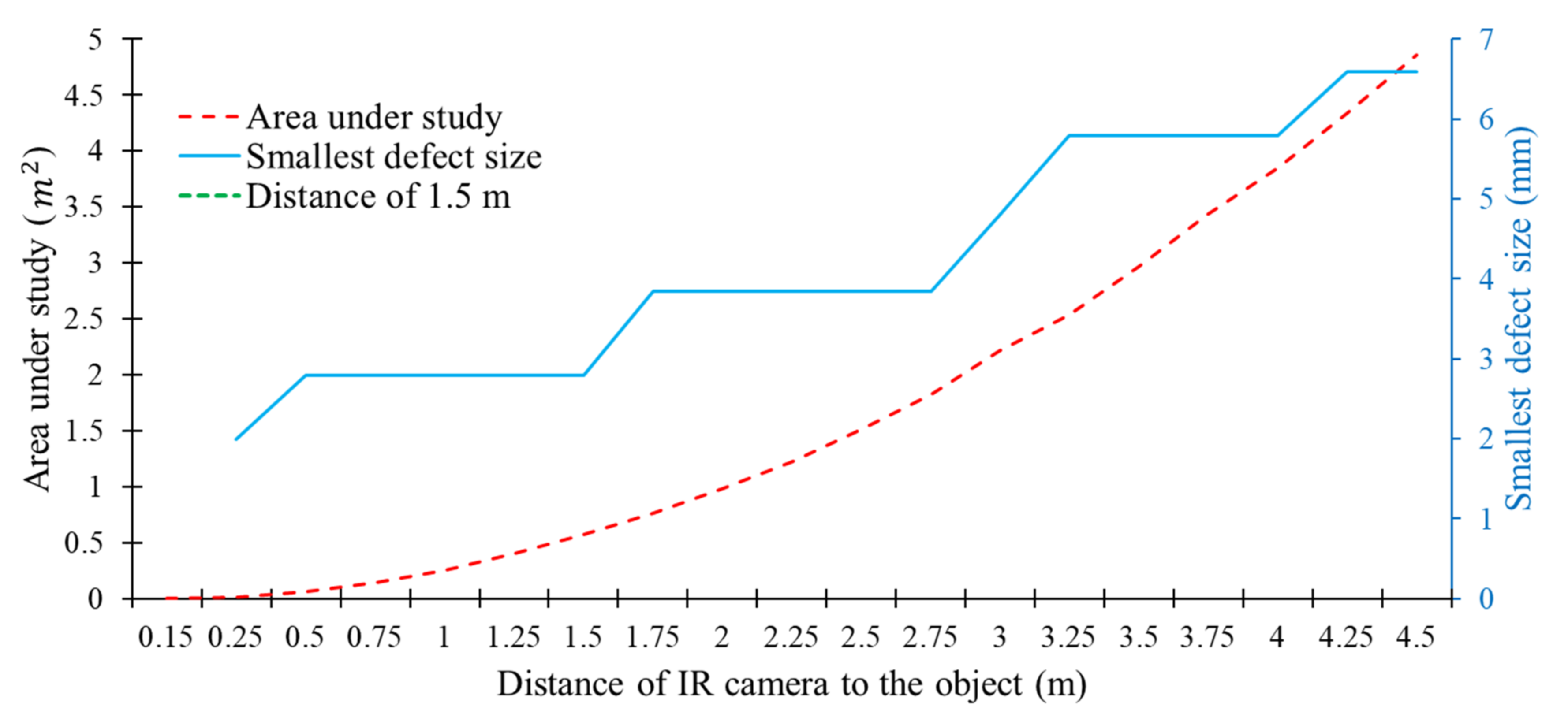

2.2. Infrared Thermography (IRT)

2.3. Ultrasonic Testing (UT)

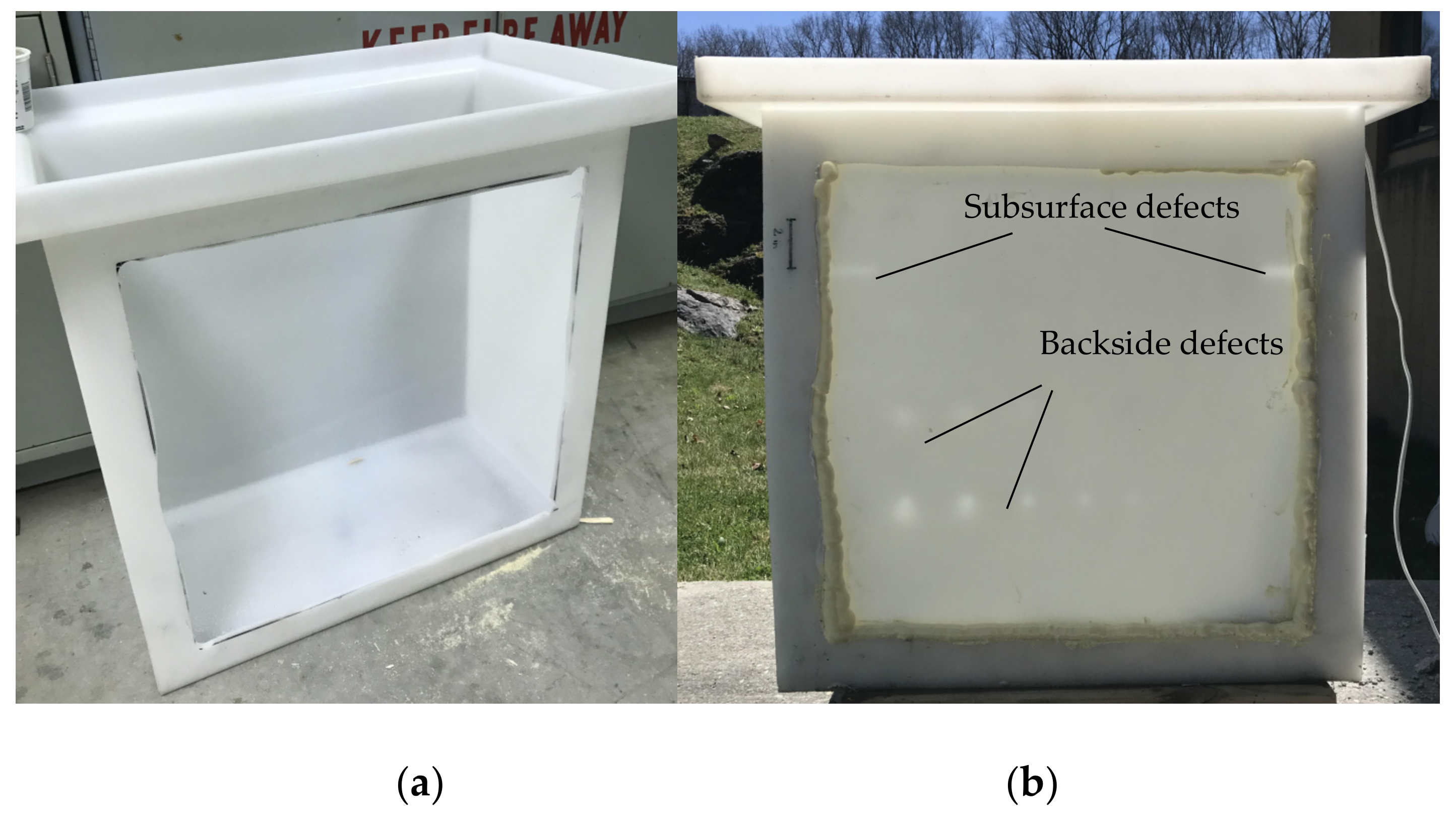

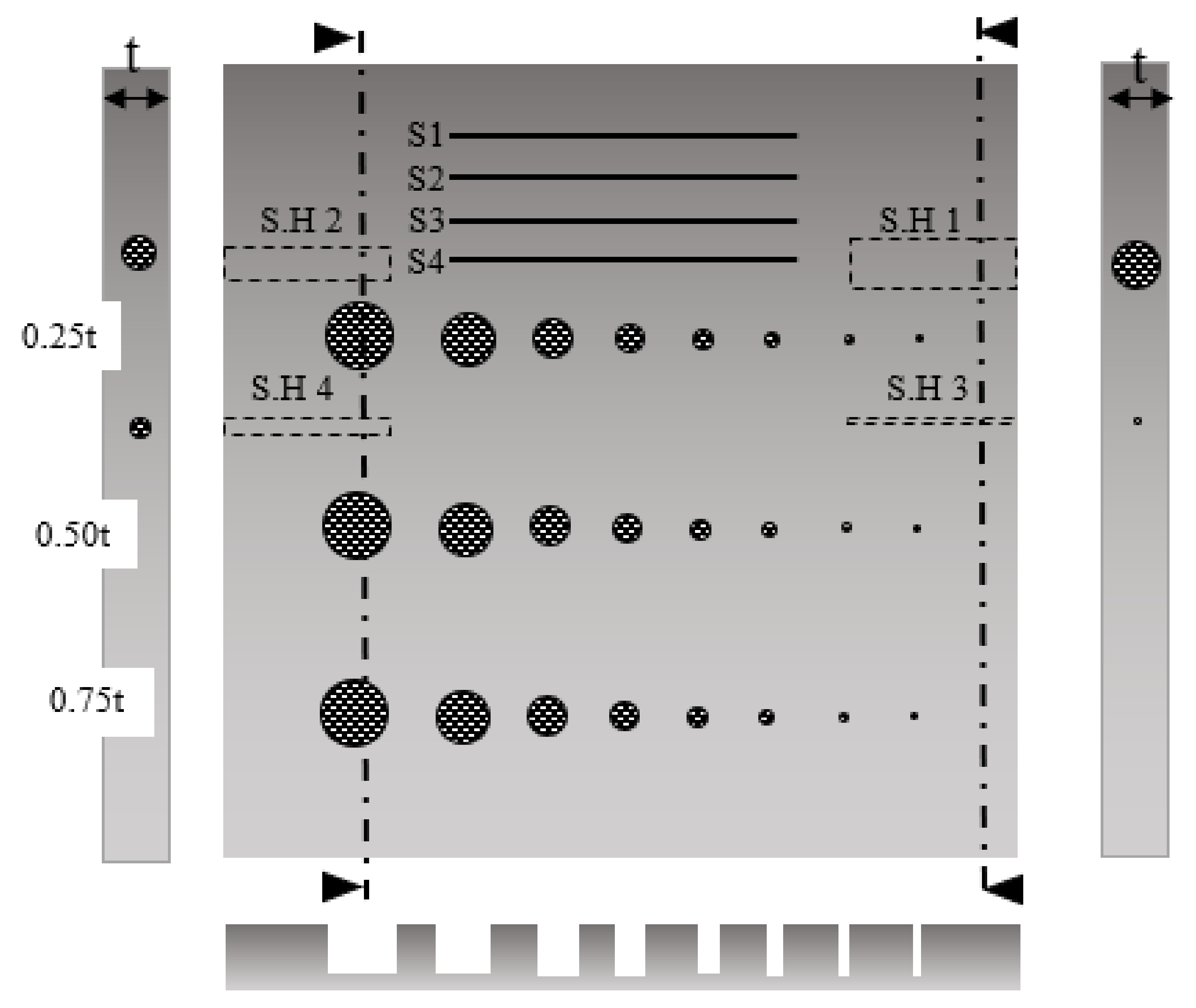

2.4. Specimen Preparation

3. Results and Discussion

3.1. Survey

3.2. IRT

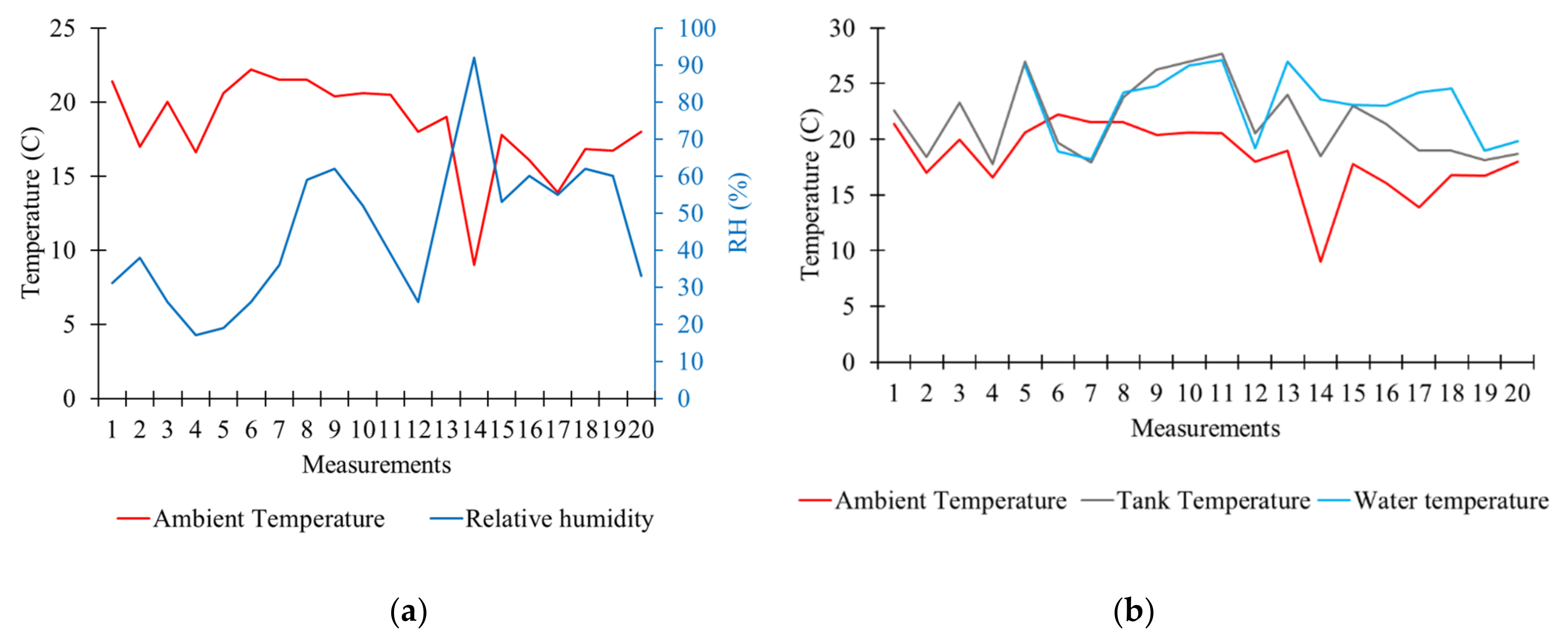

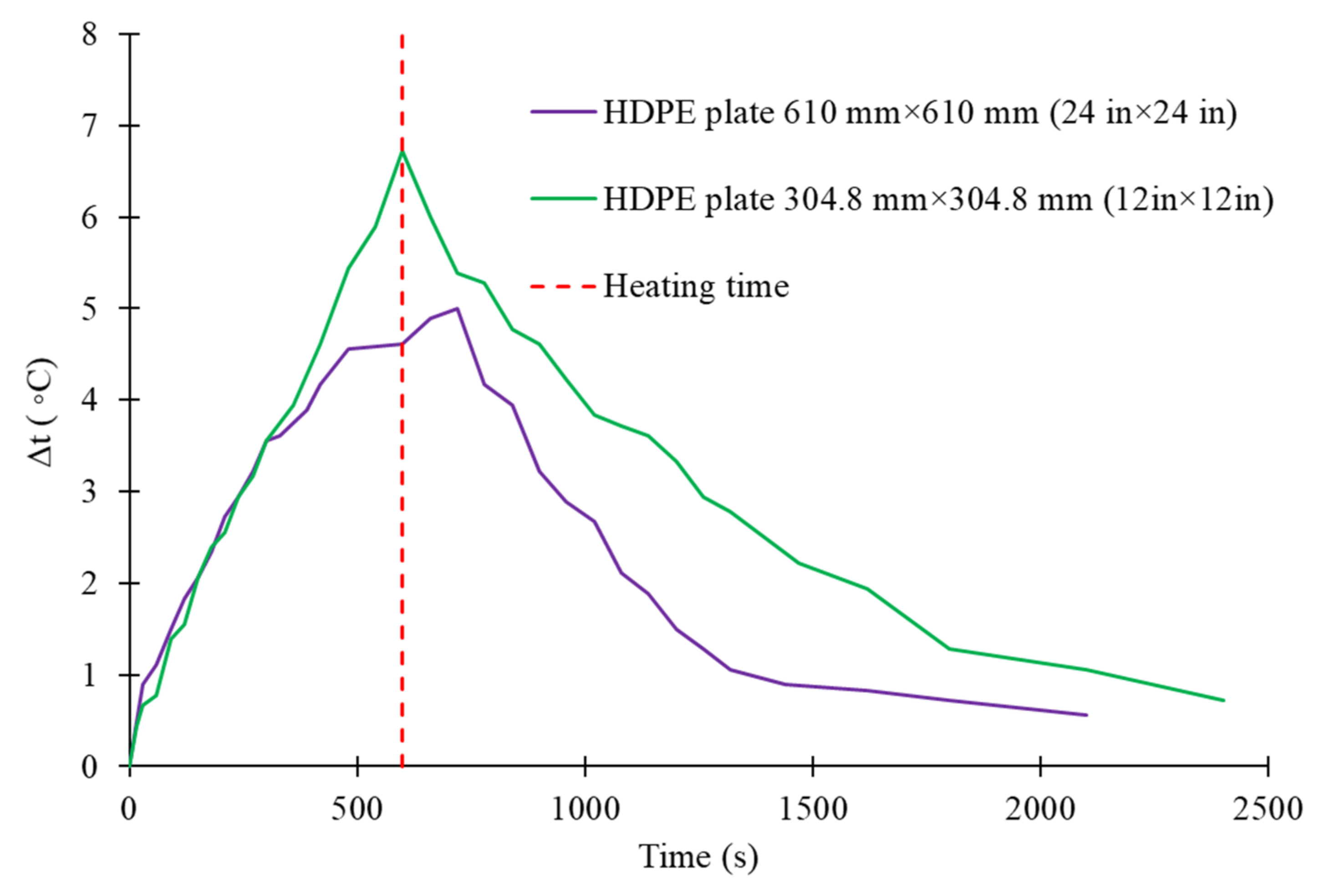

3.2.1. Impact of Specimen Dimension on Heat Transfer

3.2.2. Defect Detection with Active IRT on HDPE

3.2.3. Impact of Water Temperature on Defect Detection in Active IRT

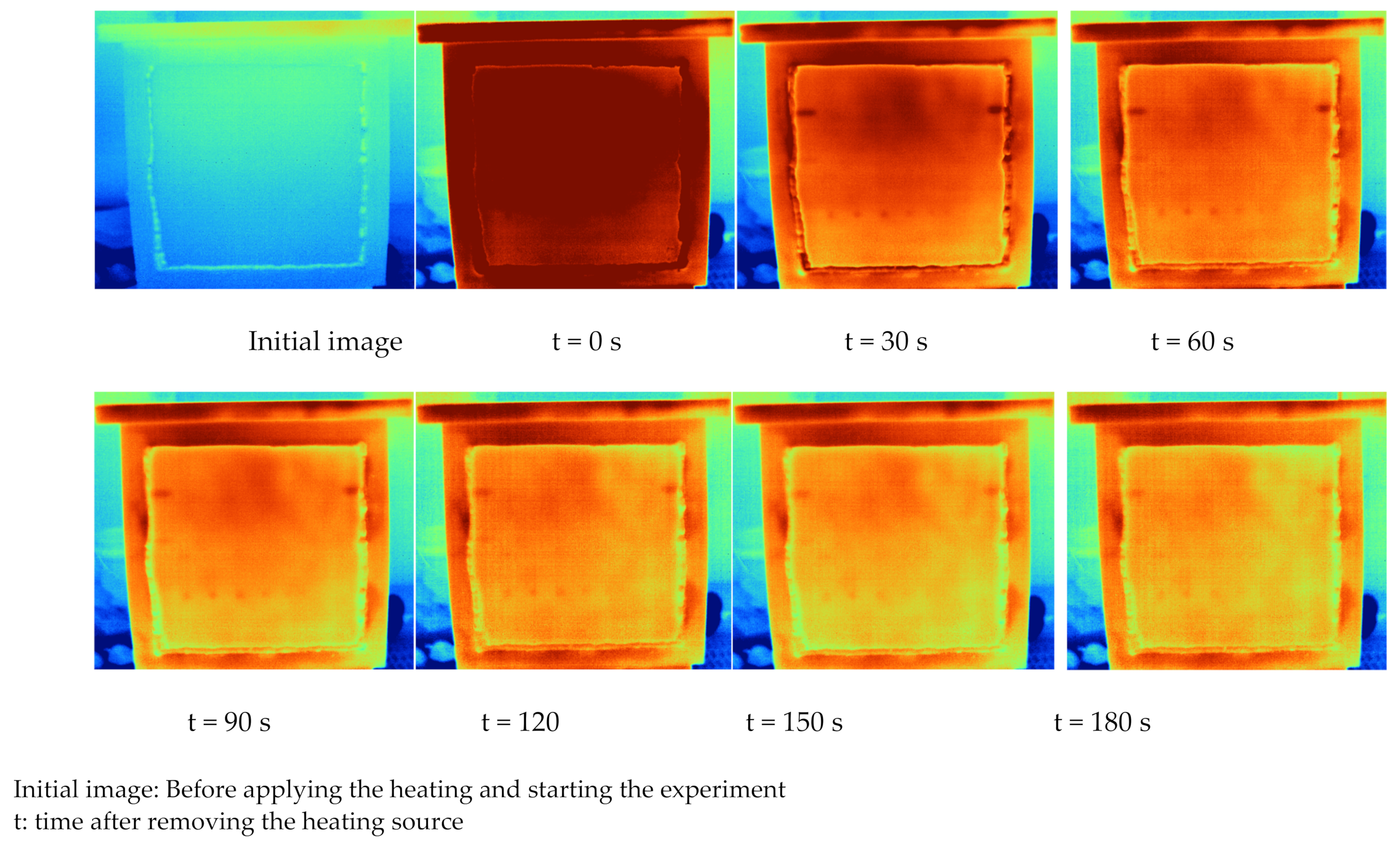

3.2.4. Indirect Transmission IRT

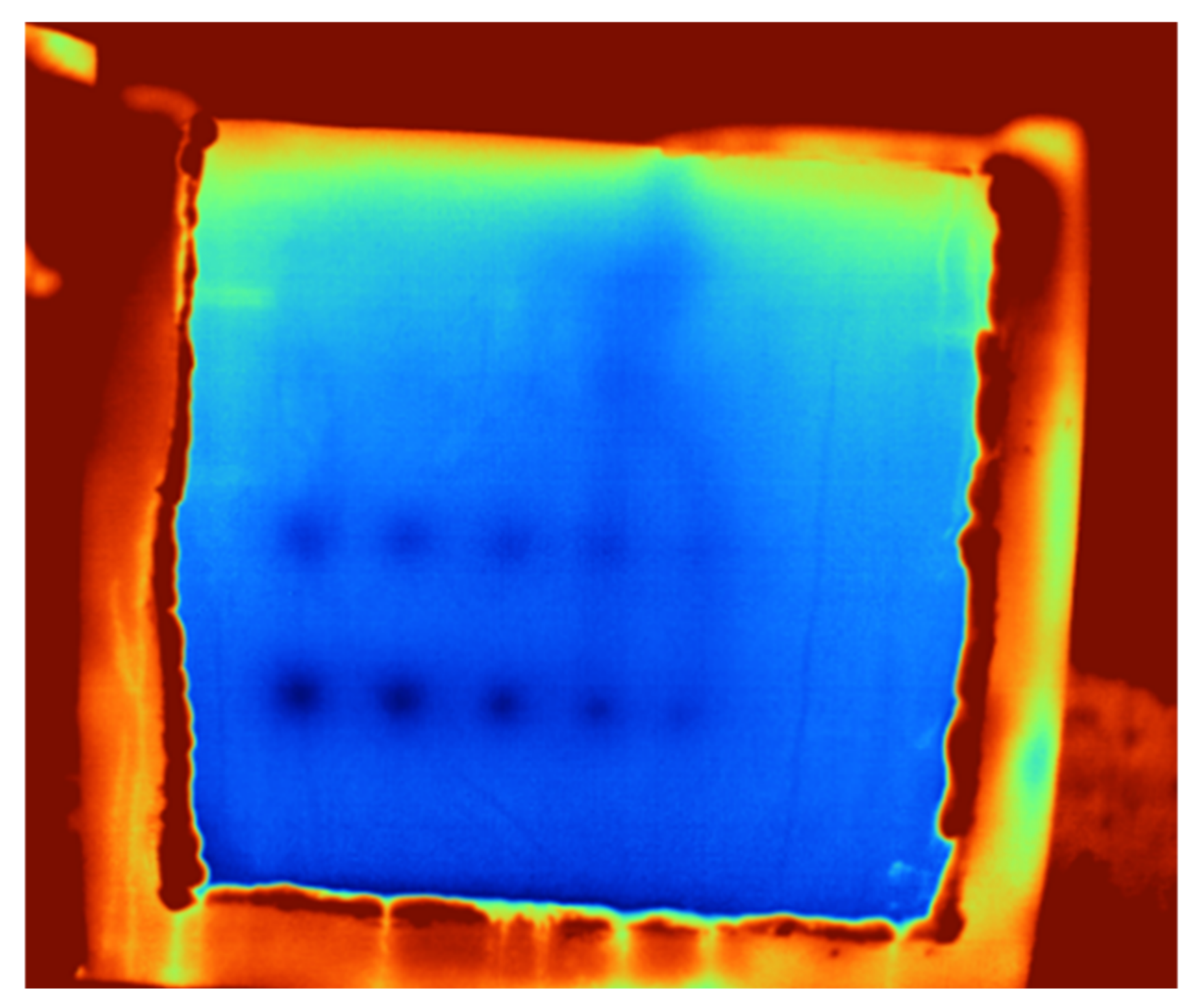

3.2.5. Passive IRT

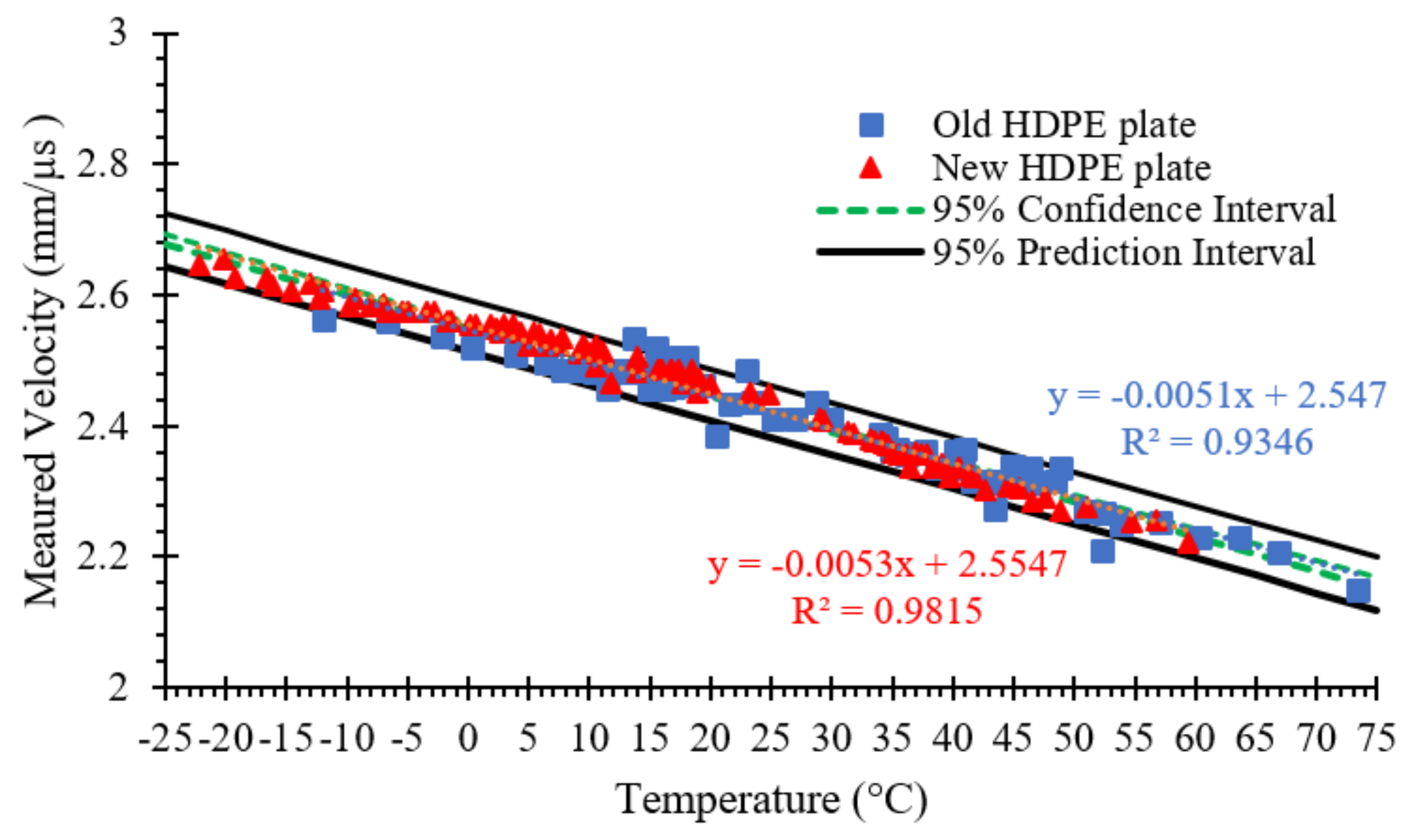

3.3. Ultrasonic Testing (UT)

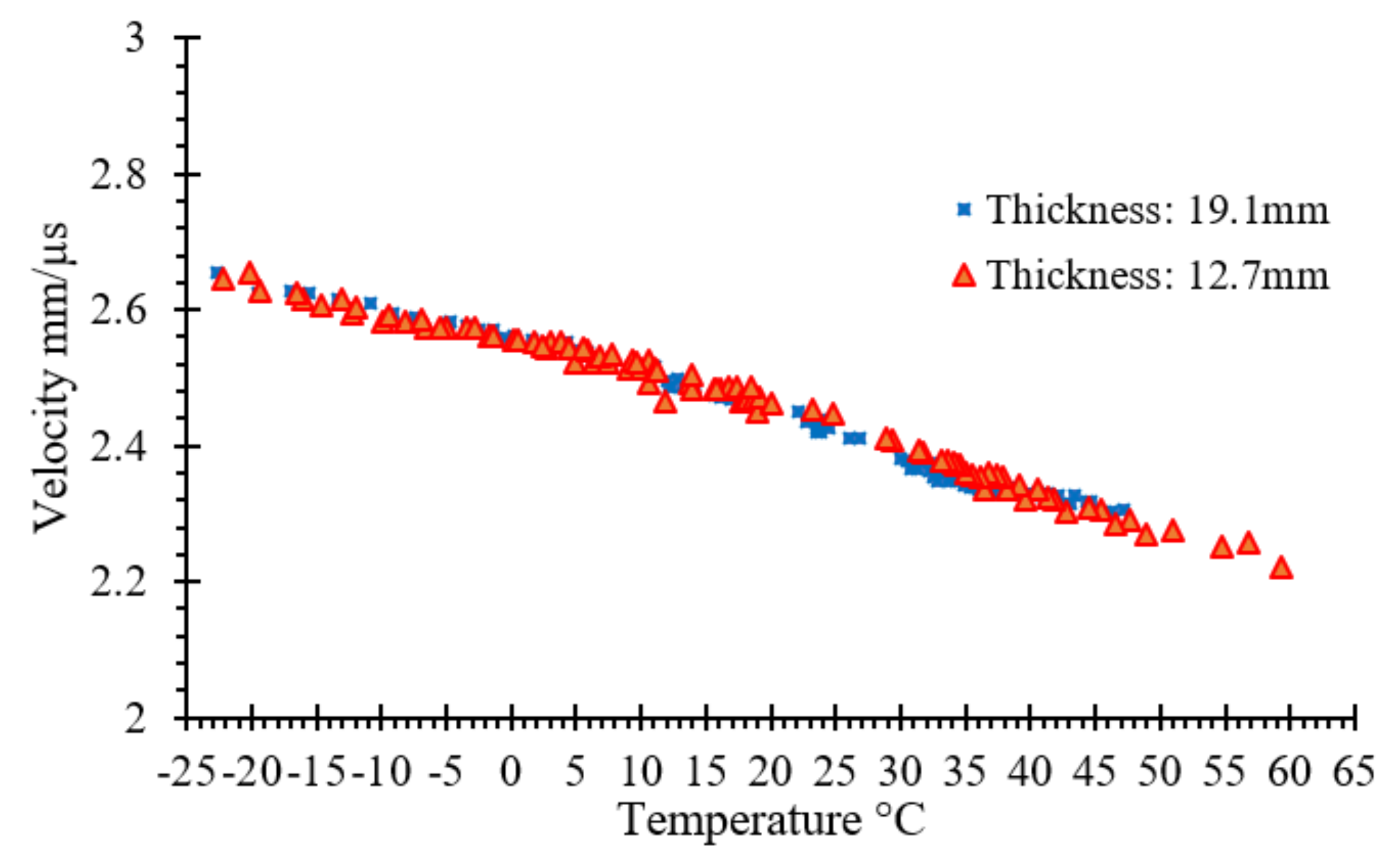

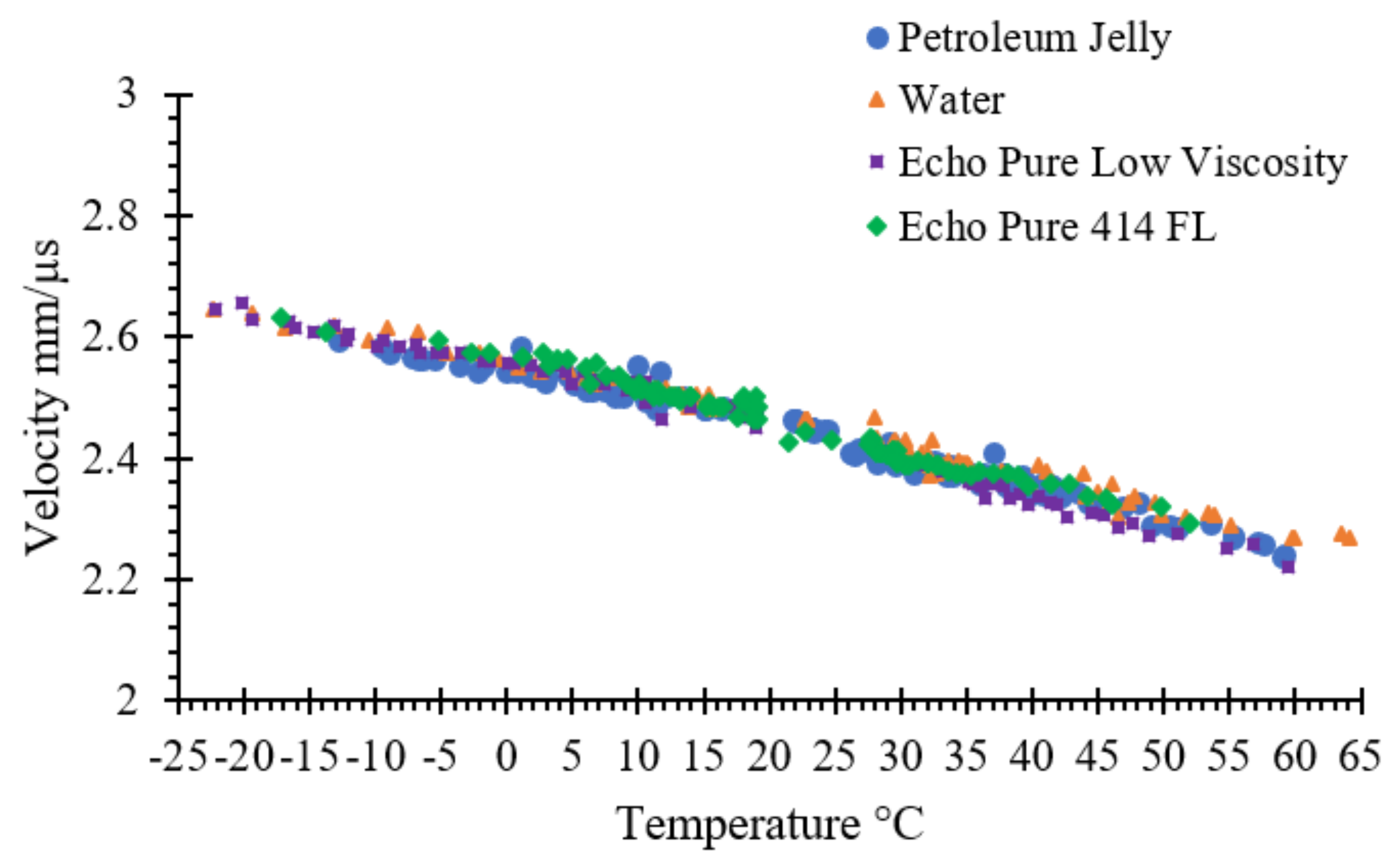

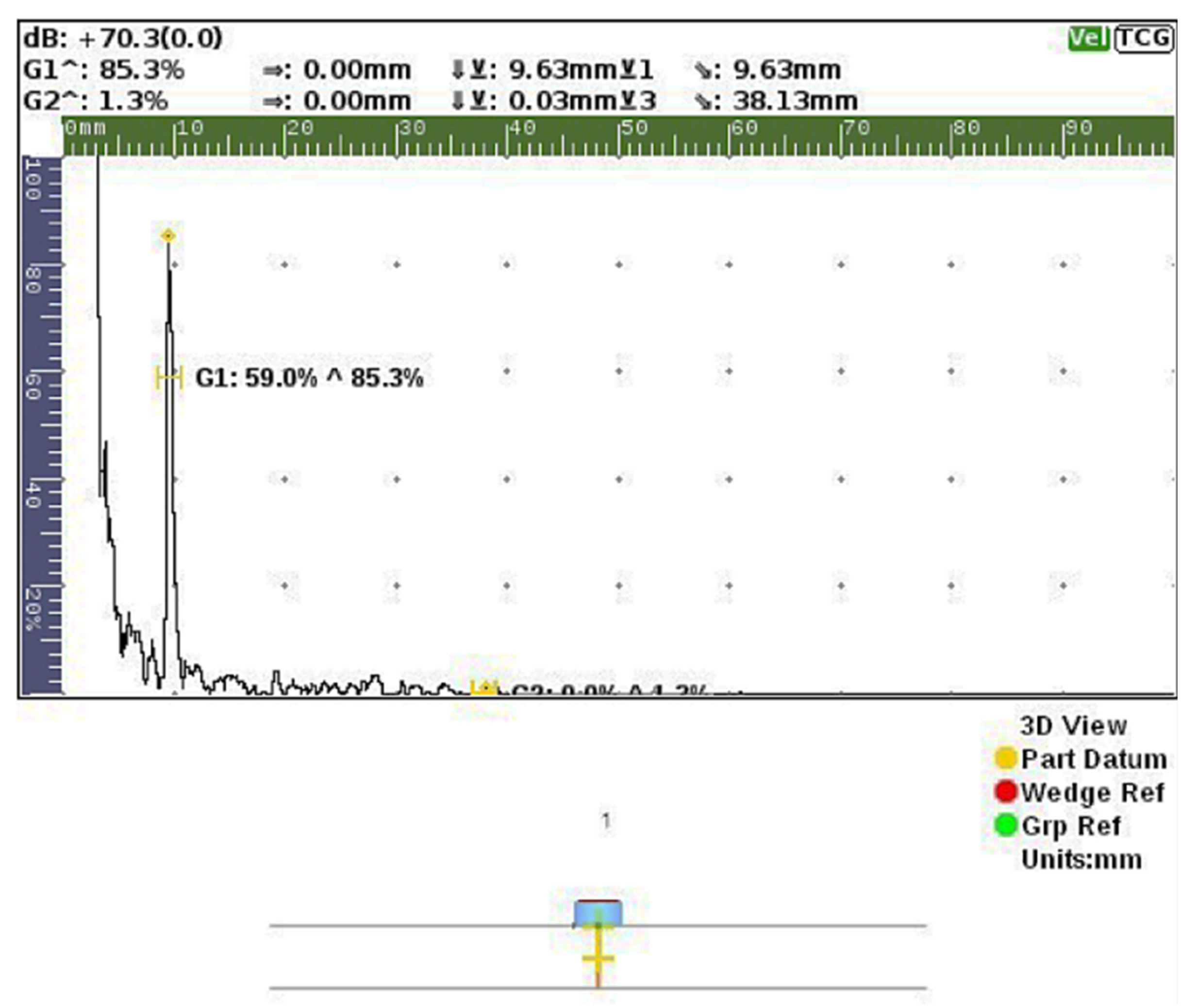

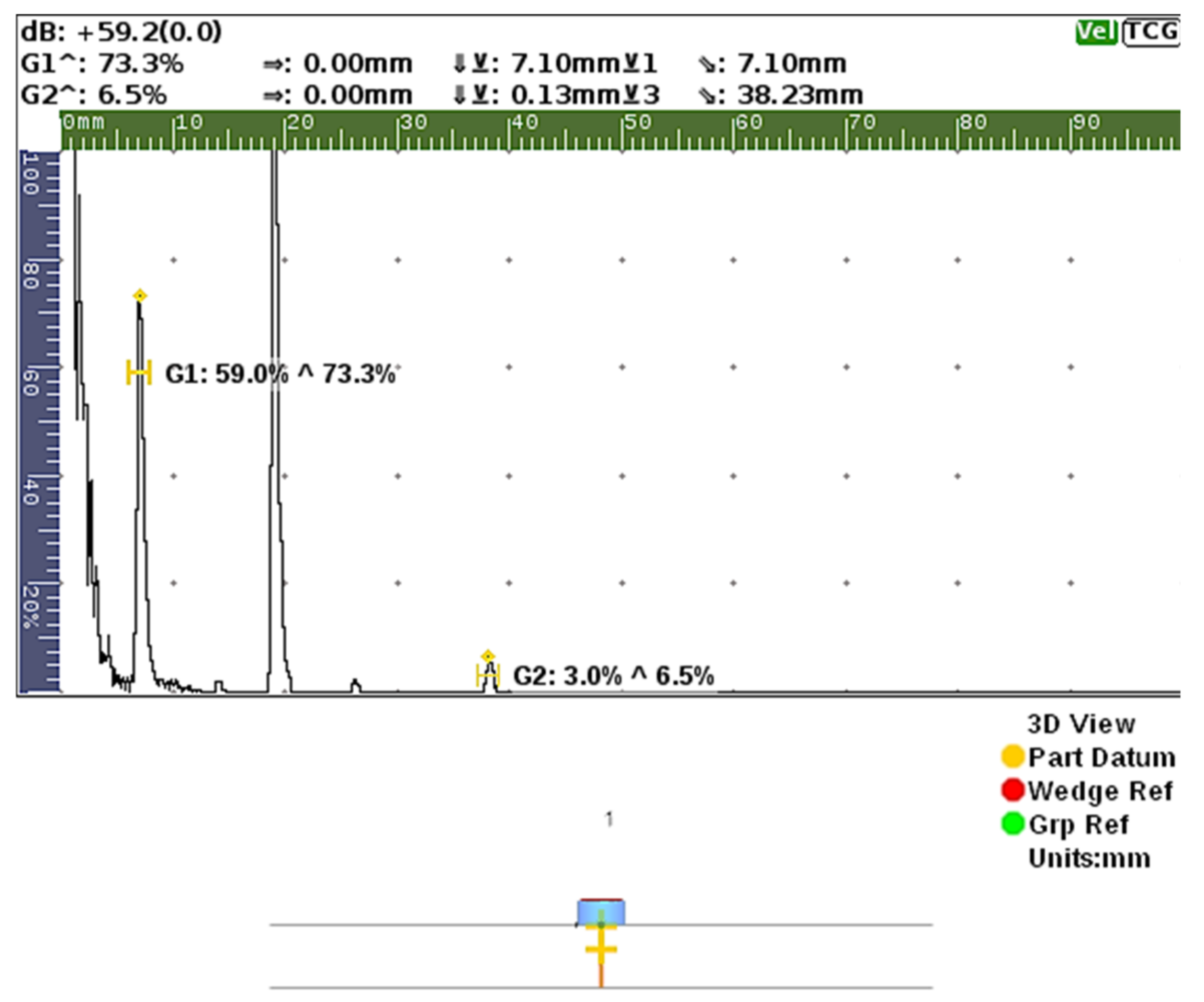

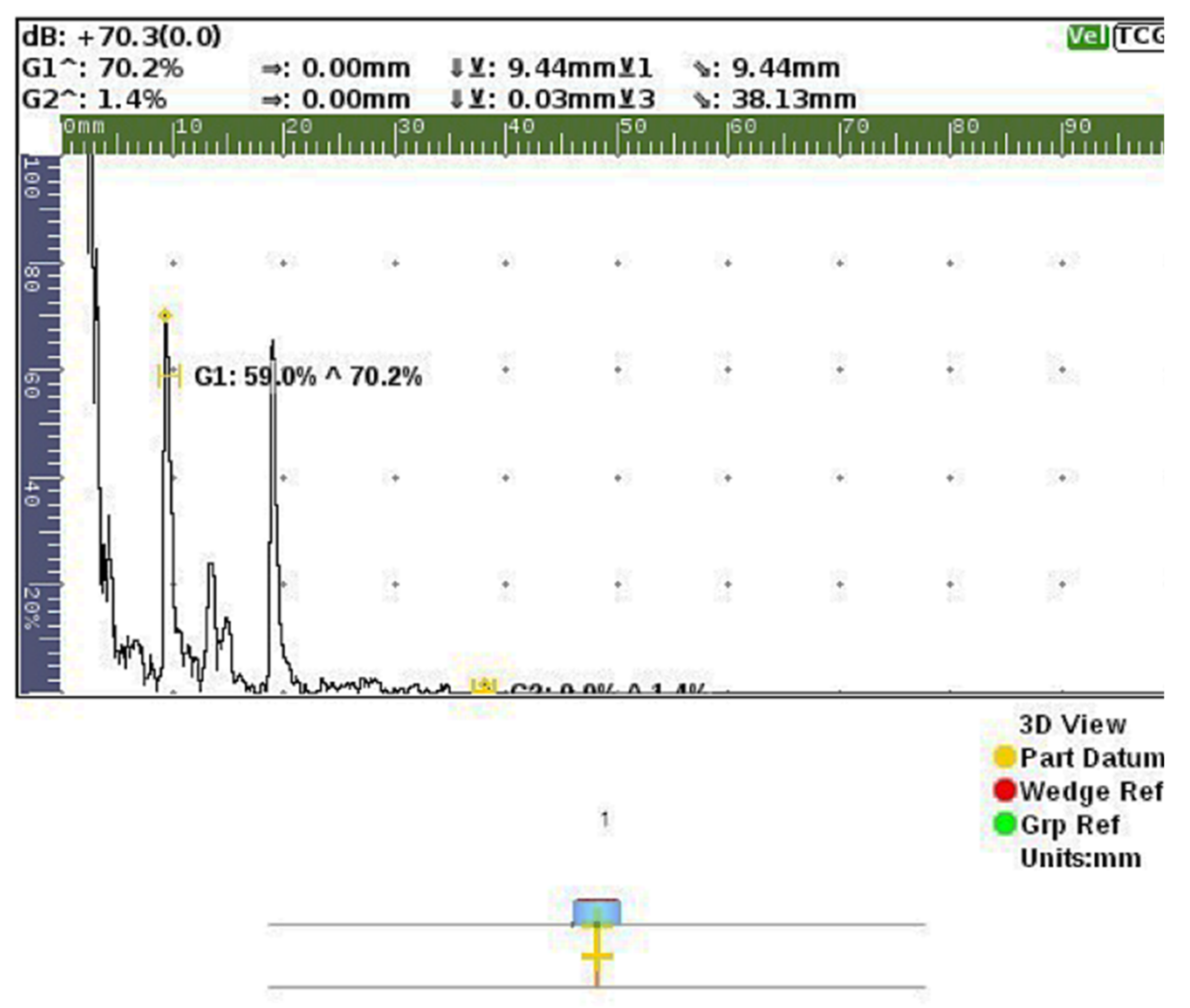

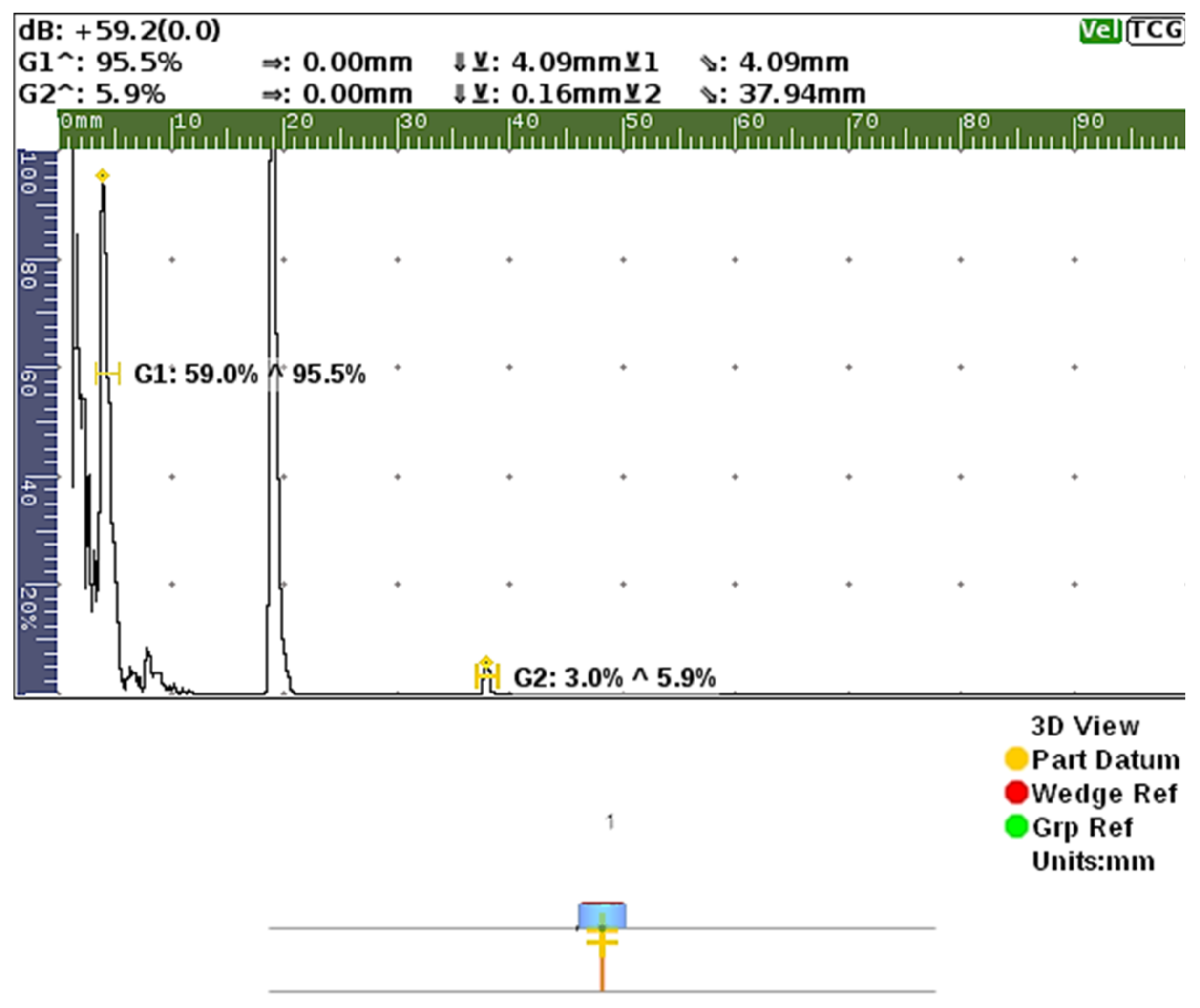

3.3.1. Pulse-Echo Ultrasonic Testing (PEUT)

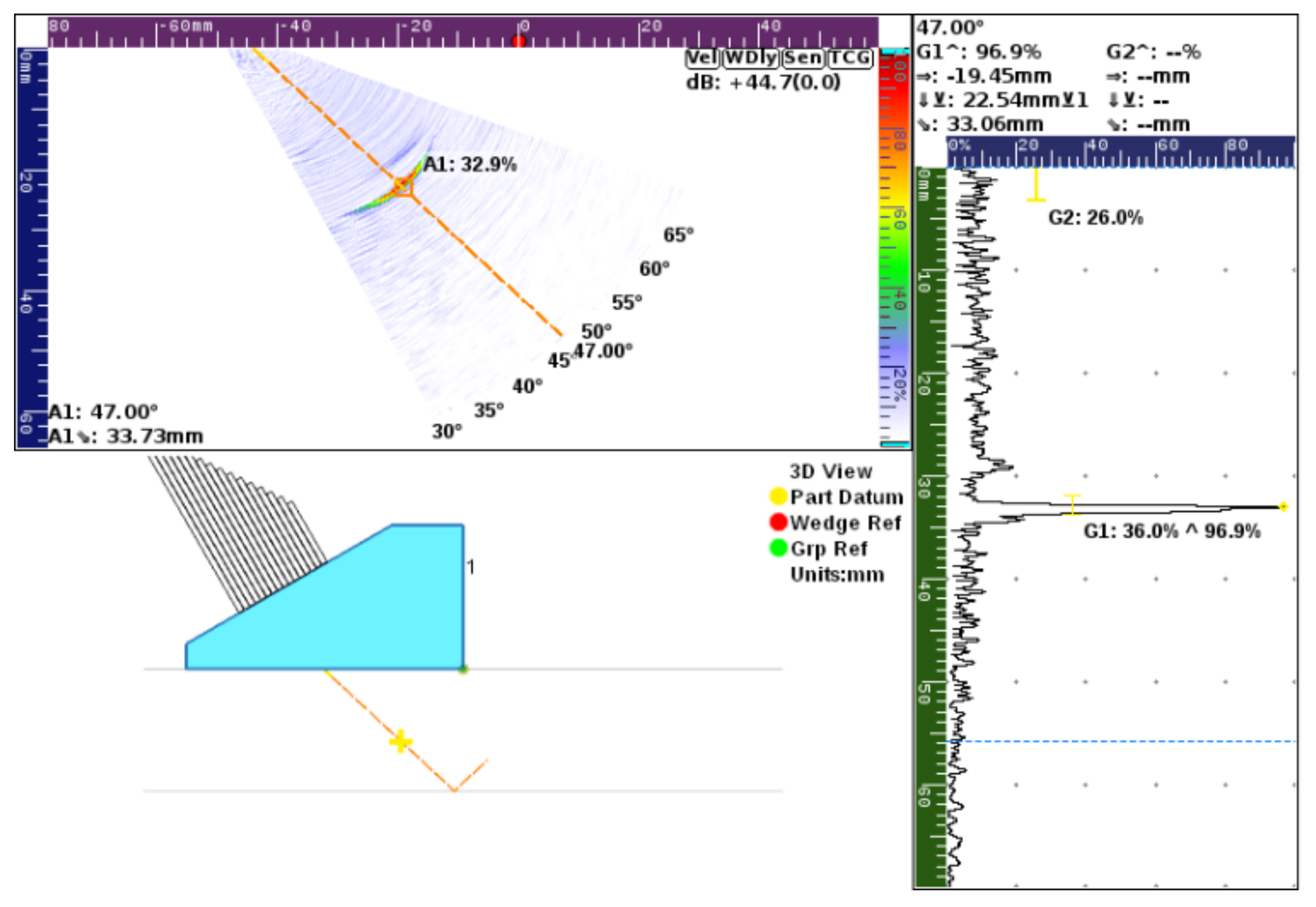

3.3.2. Phased Array Ultrasonic Testing (PAUT)

4. Conclusions

- IRT has shown the potential to detect leakage and some subsurface abnormalities in HDPE plates.

- IRT is useful for locating shallow subsurface defects that are located at less than half of the thickness of HDPE plates.

- Water temperature can impact IRT measurements of an HDPE tank by influencing the minimum detectable defect size and time of appearance of the defects on the thermograms.

- Transmission IRT helps to detect the shallow anomalies in HDPE water tanks with less energy in a shorter amount of time.

- For HDPE with high thermal attenuation properties and very low thermal conductivity, the passive IRT works best when there is a very high positive initial thermal gradient over the thickness of the specimen.

- UT is sensitive to both interior and subsurface abnormalities of HDPE plates.

- UT is highly accurate in determining flaw position and estimating flaw size and shape in HDPE plates.

- PAUT is a powerful technique that can help to detect and characterize multiple stacked defects in HDPE plates.

- Ultrasonic testing can be used as a complement to IRT for a more detailed inspection of HDPE ASTs.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ketcham, S.; Minsk, L.D.; Blackburn, R.R.; Fleege, E.J. Manual of Practice for an Effective Anti-Icing Program: A Guide for Highway Winter Maintenance Personnel; Federal Highway Administration: Washington, DC, USA, 1996.

- Whitford, F.; Salomon, S.; Oltman, D.; Obermeyer, J.; Hawkins, S.; Pearson, M.; Overstreet, B.; Titus, M.; Lambert, S.; Hawkins, M. Poly Tanks for Farms and Businesses: Preventing Catastrophic Failures, Report PPP-77. 2008. Available online: https://www.extension.purdue.edu/extmedia/ppp/ppp-77.pdf (accessed on 13 August 2021).

- Cornell, J.R.; Baker, M.A. Catastrophic tank failures: Highlights of Past Failures along with Proactive Tanks Designs. In Proceedings of the US EPA Fourth Biennial Freshwater Spills Symposium (FSS 2002) Sheraton Cleveland City Centre Hotel, Cleveland, OH, USA, 19–21 March 2002. [Google Scholar]

- Abell, D.H. A Study of the Cause of Failure of Rotationally Molded, High-Density Polyethylene, Sodium Hypochlorite Storage Tanks, Brigham Young University. 2011. Available online: http://hdl.lib.byu.edu/1877/etd4342 (accessed on 13 August 2021).

- Whitford, F.; Hawkins, S.; Holland, L.; Carr, B.; Meredith, D.; Ileleji, K.; Campbell, D.; Gentry, L.; Hamby, L.; Roach, M.; et al. Aboveground Petroleum Tanks: A Pictoral Guide, Report PPP-73. 2007. Available online: https://www.extension.purdue.edu/extmedia/PPP/PPP-73.pdf (accessed on 13 August 2021).

- Myers, P.E. Aboveground Storage Tanks; McGraw-Hill Education: New York, NY, USA, 1997. [Google Scholar]

- Atherton, W.; Ash, J.W. Review of Failures, Causes & Consequences in the Bulk Storage Industry. 2007. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.489.7637&rep=rep1&type=pdf (accessed on 28 September 2021).

- U.S. Chemical Safety and Hazard Investigation Board, Allied Terminals, Inc. Catastrophic Tank Collapse, Report 2009-03-I-VA; U.S. Chemical Safety Board: Washington, DC, USA, 2009.

- United States Environmental Protection Agency. Office of Solid Waste and Emergency Response, Rupture Hazard from Liquid Storage Tanks, EPA 550-F-09-004; United States Environmental Protection Agency: Washington, DC, USA, 2009.

- Carrasco, F.; Saurina, J.; Colom, X. FTIR and DSC study of HDPE structural changes and mechanical properties variation when exposed to weathering aging during Canadian winter. J. Appl. Polym. Sci. 1996, 60, 153–159. [Google Scholar] [CrossRef]

- Hsueh, H.-C.; Kim, J.H.; Orski, S.; Fairbrother, A.; Jacobs, D.; Perry, L.; Hunston, D.; White, C.; Sung, L. Micro and macroscopic mechanical behaviors of high-density polyethylene under UV irradiation and temperature. Polym. Degrad. Stab. 2020, 174, 109098. [Google Scholar] [CrossRef]

- Mohan, B.C.; Jeyasekhar, M.C. Combination of infrared thermography and computed radiography nondestructive methods detect oil and gas storage tank drainage pipe blockage. In Proceedings of the 3rd Singapore International Non-destructive Testing Conference and Exhibition, Singapore, 4–5 December 2019; p. 8. [Google Scholar]

- Nisbet, R.T.; Pesce, M.D. NDT of welded steel tanks. NDT Tech. 2011, 10, 1–4. [Google Scholar]

- Kalra, L.P.; Shen, W.; Gu, J. A wall climbing robotic system for non destructive inspection of above ground tanks. In Proceedings of the 2006 Canadian Conference on Electrical and Computer Engineering, Ottawa, ON, Canada, 7–10 May 2006; p. 9376469. [Google Scholar] [CrossRef]

- Blakeley, B.; Emmanouilidis, C.; Hrissagis, K. Above-ground storage tank inspection using the ‘Robot Inspector’. Insight Non-Destructive Test. Cond. Monit. 2005, 47, 705–708. [Google Scholar] [CrossRef]

- Lowe, P.S.; Duan, W.; Kanfoud, J.; Gan, T.-H. Structural Health Monitoring of Above-Ground Storage Tank Floors by Ultrasonic Guided Wave Excitation on the Tank Wall. Sensors 2017, 17, 2542. [Google Scholar] [CrossRef]

- Spicer, M.; Hagglund, F.; Troughton, M. Development and validation of an automated ultrasonic system for the non-destructive evaluation of welded joints in thermoplastic storage tanks. In Proceedings of the 11th European Conference on Non-Destructive Testing, Prague, Czech Republic, 6–11 October 2014. [Google Scholar]

- Lourenço, T.; Matias, L.; Faria, P. Anomalies detection in adhesive wall tiling systems by infrared thermography. Constr. Build. Mater. 2017, 148, 419–428. [Google Scholar] [CrossRef]

- Barreira, E.; de Freitas, V.P. Evaluation of building materials using infrared thermography. Constr. Build. Mater. 2007, 21, 218–224. [Google Scholar] [CrossRef]

- Lagüela, S.; Díaz-Vilariño, L.; Roca, D. Infrared thermography: Fundamentals and applications. In Non-Destructive Techniques for the Evaluation of Structures and Infrastructure; Riveiro, B., Solla, M., Eds.; CRC Press: Boca Raton, FL, USA, 2016; pp. 113–138. [Google Scholar] [CrossRef]

- Verspeek, S.; Peeters, J.; Ribbens, B.; Steenackers, G. Excitation Source Optimisation for Active Thermography. Proceedings 2018, 2, 439. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Oguocha, I.N.; Panigrahi, S. Thermal diffusivity, thermal conductivity, and specific heat of flax fiber–HDPE biocomposites at processing temperatures. Compos. Sci. Technol. 2008, 68, 1753–1758. [Google Scholar] [CrossRef]

- Zhu, B.; Qiu, X.; Zhong, S.C.; Bin Fu, X.; Yang, X.X. Active Infrared Thermography for Defect Detection of Polyethylene Pipes. Adv. Mater. Res. 2014, 1044–1045, 700–703. [Google Scholar] [CrossRef]

- Murariu, A.C.; Lozanović-Šajić, J.V. Temperature and heat effects on polyethylene behaviour in the presence of imperfections. Therm. Sci. 2016, 20, 1703–1712. [Google Scholar] [CrossRef]

- Murariu, A.C.; Bîrdeanu, A.-V.; Cojocaru, R.; Safta, V.I.; Dehelean, D.; Boţilă, L.; Ciucă, C. Application of Thermography in Materials Science and Engineering. In Infrared Thermogr; Prakash, R.V., Ed.; InTech: London, UK, 2012; pp. 27–52. [Google Scholar]

- Omar, M.A.; Zhou, Y.; Parvataneni, R.; Planting, E. Calibrated Pulse-Thermography Procedure for Inspecting HDPE. Res. Lett. Mater. Sci. 2008, 2008, 186427. [Google Scholar] [CrossRef][Green Version]

- Azad, M.J.; Tavallali, M.S. A novel computational supplement to an IR-thermography based non-destructive test of electrofusion polyethylene joints. Infrared Phys. Technol. 2018, 96, 30–38. [Google Scholar] [CrossRef]

- Doaei, M.; Tavallali, M.S. Intelligent screening of electrofusion-polyethylene joints based on a thermal NDT method. Infrared Phys. Technol. 2018, 90, 1–7. [Google Scholar] [CrossRef]

- Genest, M.; Ouellet, S.; Williams, K. Infrared thermography for inspection of aramid and ultra-high-molecular-weight polyethylene armour systems. In Thermosense: Thermal Infrared Applications XL; International Society for Optics and Photonics: Bellingham, WA, USA, 2018; Volume 10661, p. 106610V. [Google Scholar] [CrossRef]

- Kočiš, Š.; Figura, Z. Ultrasonic Measurements and Technologies; Springer: Boston, MA, USA, 1996. [Google Scholar] [CrossRef]

- Schmerr, L.W., Jr. Fundamentals of Ultrasonic Phased Arrays; Solid Mechanics and Its Applications; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Saleh, B. Introduction to Subsurface Imaging; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar] [CrossRef]

- Frederick, C.; Porter, A.; Zimmerman, D. High-density polyethylene piping butt-fusion joint examination using ultrasonic phased array. J. Press. Vessel Technol. 2010, 132, 051501. [Google Scholar] [CrossRef]

- Qin, Y.; Shi, J.; Zheng, J.; Hou, D.; Guo, W. An Improved Phased Array Ultrasonic Testing Technique for Thick-Wall Polyethylene Pipe Used in Nuclear Power Plant. J. Press Vessel Technol. 2019, 141, 41403. [Google Scholar] [CrossRef]

- Guo, W.; Shi, J.; Hou, D. Research on phased array ultrasonic technique for testing butt fusion joint in polyethylene pipe. In Proceedings of the 2016 IEEE Far East NDT New Technology & Application Forum, Nanchang, China, 22–24 June 2016; pp. 1–5. [Google Scholar]

- Zheng, J.; Shi, J.; Guo, W. Development of Nondestructive Test and Safety Assessment of Electrofusion Joints for Connecting Polyethylene Pipes. J. Press. Vessel. Technol. 2012, 134, 021406. [Google Scholar] [CrossRef]

- Miao, C.; Qin, Y.; Guo, W.; An, C.; Ling, Z.; Chen, Z. Ultrasonic phased array inspection with water wedge for butt fusion joints of polyethylene pipe. In Proceedings of the Pressure Vessels and Piping Conference, San Antonio, TX, USA, 14–19 July 2019; p. PVP2019-93500. [Google Scholar] [CrossRef]

- Hagglund, F.; Robson, M.; Troughton, M.J.; Spicer, W.; Pinson, I.R. A novel phased array ultrasonic testing (PAUT) system for on-site inspection of welded joints in plastic pipes. In Proceedings of the 11th European Conference on Non-Destructive Testing (ECNDT), Prague, Czech Republic, 6–10 October 2014. [Google Scholar]

- Thorpe, N.; Acebes, M.; Wylie, D.; Troughton, M.; Gilmour, O.; Roy, O.; Benoist, G.; Dweik, R. Ultrasonic phased array non-destructive testing and in-service inspection system for high integrity polyethylene pipe welds with automated analysis software. In Proceedings of the 12th European Conference on Non-Destructive Testing (ECNDT 2018), Gothenburg, Sweden, 11–15 June 2018. [Google Scholar]

- Egerton, J.S.; Lowe, M.; Huthwaite, P.; Halai, H.V. Ultrasonic attenuation and phase velocity of high-density polyethylene pipe material. J. Acoust. Soc. Am. 2017, 141, 1535–1545. [Google Scholar] [CrossRef]

- Troughton, M.; Spicer, M.; Hagglund, F. Development and assessment of a phased array ultrasonic inspection system for polyethylene pipe joints. In Proceedings of Proceedings of the Technical Conference & Exhibition, Las Vegas, NV, USA, 28–30 April 2014; pp. 2016–2021. [Google Scholar]

- Spicer, M.; Troughton, M.; Hagglund, F. Development and assessment of ultrasonic inspection system for polyethylene pipes. In Pressure Vessels and Piping Conference; American Society of Mechanical Engineers: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Mažeika, L.; Šliteris, R.; Vladišauskas, A. Measurement of velocity and attenuation for ultrasonic longitudinal waves in the polyethylene samples. Ultragarsas Ultrasound 2010, 65, 12–15. [Google Scholar]

- Adachi, K.; Harrison, G.; Lamb, J.; North, A.M.; Pethrick, R.A. High frequency ultrasonic studies of polyethylene. Polymer 1981, 22, 1032–1039. [Google Scholar] [CrossRef]

- Arnold, N.D.; Guenther, A.H. Experimental determination of ultrasonic wave velocities in plastics as functions of temperature. I. Common plastics and selected nose-cone materials. J. Appl. Polym. Sci. 1966, 10, 731–743. [Google Scholar] [CrossRef]

- Carlson, J.; Van Deventer, J.; Scolan, A.; Carlander, C. Frequency and Temperature Dependence of Acoustic Properties of Polymers Used in Pulse-Echo Systems; IEEE: New York, NY, USA, 2004; pp. 885–888. [Google Scholar] [CrossRef]

- Alnaimi, S.; Elouadi, B.; Kamal, I. Structural, thermal and morphology characteristics of low density polyethylene produced by QAPCO. In Proceedings of the 8th International Symposium on Inorganic Phosphate Materials, Agadir, Morocco, 13–19 September 2015; pp. 13–19. [Google Scholar]

- Hunter, E.; Oakes, W.G. The effect of temperature on the density of polythene. Trans. Faraday Soc. 1945, 41, 49–56. [Google Scholar] [CrossRef]

- Maigel’dinov, I.A.; Tsyur, K.I. The thermomechanical properties of crystalline polymers—I. Polyethylene. Polym. Sci. USSR. 1963, 4, 864–874. [Google Scholar] [CrossRef]

| Detector resolution | 640 × 480 (307, 200 pixels) |

| Field of view | 34 °H × 24 °V |

| Temperature measurement range | −20 °C to 1000 °C (−4 °F to 1832 °F) |

| Accuracy | ±2 °C or 2% (whichever is greater) |

| Thermal sensitivity (NETD) | ≤0.05 °C at 30 °C target temp (50 mK) |

| Frame rate | 60 Hz |

| Infrared spectral band | 7.5 μm to 14 μm (long wave) |

| Emissivity | 0.78 |

| Background | 23 °C |

| Transmission | 100% |

| Range | −20 °C to 100 °C |

| Temperature level span | [O.T-5 °C, O.T + 10 °C] |

| Palette | Blue-Red [Ultra contrast] |

| Auto capture | 18 images every 10s |

| Voltage mono | 100 V |

| Mono pulse damping | 50 ohms |

| Pulse type | Spike |

| Probe diameter | 12.70 mm |

| Reference amplitude | 80.0% |

| Range Path | 100.0 mm |

| Travel mode | Half path |

| Acquired frequency | 100 MHz |

| Defect Name | Description | Depth from Interior Side (mm) | Diameter(s) (mm) |

|---|---|---|---|

| S1 | Scratch | 1 | N/A |

| S2 | Scratch | 2 | N/A |

| S3 | Scratch | 3 | N/A |

| S4 | Scratch | 5 | N/A |

| S.H 1 | Side hole | 0.125t | 0.75 t * |

| S.H 2 | Side hole | 0.25t | 0.50 t |

| S.H 3 | Side hole | 5.55 & 8.73 | 0.1 t (1/16 inch drill bit was used for all plates) |

| S.H 4 | Side hole | 0.375t | 0.25 t |

| R1 | Partial hole | 0.25 t | Diameters from left to right: 25.40, 19.99, 15.01, 9.98, 7.01, 5.00, 2.79, and 1.59 |

| R2 | Partial hole | 0.50 t | Diameters from left to right: 25.40, 19.99, 15.01, 9.98, 7.01, 5.00, 2.79, and 1.59 |

| R3 | Partial hole | 0.75 t | Diameters from left to right: 25.40, 19.99, 15.01, 9.98, 7.01, 5.00, 2.79, and 1.59 |

| Measurement | Initial Surface Temperature (°C) | Initial Thermal Gradient (°C) | Relative Humidity (%) | Defect Name | Defect Depth from the Surface (mm) | Minimum Size (mm) | δtapp (°C) | tapp (s) | δtdis (°C) | tdis (s) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 22.6 | 0 | 31 | R3 | 3.175 | 5 | 12.3 | 20 | 0 | 10,000 |

| R2 | 6.35 | 15.01 | 9.9 | 60 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 12.3 | 20 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 12.3 | 20 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 12.3 | 20 | 0 | 10,000 | ||||

| 2 | 18.4 | 0 | 38 | R3 | 3.175 | 7.01 | 11.9 | 20 | 0 | 10,000 |

| R2 | 6.35 | 15.01 | 11.9 | 20 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 11.9 | 20 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 11.9 | 20 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 11.9 | 20 | 0 | 10,000 | ||||

| 3 | 23.3 | 0 | 26 | R3 | 3.175 | 2.79 | 14.8 | 20 | 0 | 10,000 |

| R2 | 6.35 | 14.29 | 13.4 | 50 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 14.8 | 20 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 14.8 | 20 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 14.7 | 30 | 0 | 10,000 | ||||

| 4 | 17.8 | 0 | 17 | R3 | 3.175 | 2.79 | 12.2 | 10 | 0 | 10,000 |

| R2 | 6.35 | 14.29 | 11.7 | 40 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 12.2 | 10 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 12.2 | 10 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 12.2 | 10 | 0 | 10,000 | ||||

| 5 | 27 | 0.4 | 19 | R3 | 3.175 | 5 | 13.1 | 20 | 0 | 10,000 |

| R2 | 6.35 | 9.98 | 10.9 | 70 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 13.1 | 20 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 13.1 | 20 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 13.1 | 20 | 0 | 10,000 | ||||

| 6 | 19.7 | 0.82 | 26 | R3 | 3.175 | 5 | 12.3 | 20 | 0 | 10,000 |

| R2 | 6.35 | 9.98 | 11.5 | 60 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 12.3 | 20 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 12.3 | 20 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 12.3 | 20 | 0 | 10,000 | ||||

| 7 | 17.9 | −0.32 | 36 | R3 | 3.175 | 5 | 11.5 | 20 | 0 | 10,000 |

| R2 | 6.35 | 15.01 | 11.4 | 30 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 11.5 | 20 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 11.5 | 20 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 11.5 | 30 | 0 | 10,000 | ||||

| 8 | 23.8 | −0.42 | 59 | R3 | 3.175 | 7.01 | 11.7 | 20 | 0 | 10,000 |

| R2 | 6.35 | 15.01 | 11.4 | 50 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 11.7 | 20 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 11.7 | 20 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 11.7 | 30 | 0 | 10,000 | ||||

| 9 | 26.3 | 1.52 | 62 | R3 | 3.175 | 5 | 13.3 | 10 | 0 | 10,000 |

| R2 | 6.35 | 9.98 | 12.9 | 50 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 13.3 | 10 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 13.3 | 10 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 13.2 | 20 | 0 | 10,000 | ||||

| 10 | 27 | 0.4 | 52 | R3 | 3.175 | 5 | 13 | 20 | 0 | 10,000 |

| R2 | 6.35 | 15.01 | 10.7 | 70 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 13 | 20 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 13 | 20 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 13 | 20 | 0 | 10,000 | ||||

| 11 | 27.7 | 0.59 | 39 | R3 | 3.175 | 5 | 12.4 | 20 | 0 | 10,000 |

| R2 | 6.35 | 9.98 | 11 | 70 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 12.4 | 20 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 12.4 | 20 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 12.4 | 20 | 0 | 10,000 | ||||

| 12 | 20.5 | 1.3 | 26 | R3 | 3.175 | 2.79 | 12.8 | 0 | 0 | 10,000 |

| R2 | 6.35 | 7.01 | 12.6 | 50 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 12.8 | 0 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 12.8 | 0 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 12.8 | 0 | 0 | 10,000 | ||||

| 13 | 24 | −3 | 60 | R3 | 3.175 | 7.01 | 13.9 | 30 | 0 | 10,000 |

| R2 | 6.35 | 15.01 | 13.6 | 60 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 13.9 | 30 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 13.9 | 30 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 13.8 | 40 | 0 | 10,000 | ||||

| 14 | 18.5 | −5.1 | 92 | R3 | 3.175 | 9.98 | 12.3 | 30 | 0 | 10,000 |

| R2 | 6.35 | 15.01 | 11.6 | 70 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 12.3 | 30 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 12.3 | 30 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 12.3 | 40 | 0 | 10,000 | ||||

| 15 | 23 | −0.1 | 53 | R3 | 3.175 | 5 | 14 | 20 | 0 | 10,000 |

| R2 | 6.35 | 14.29 | 13.6 | 50 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 14 | 20 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 14 | 20 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 13.8 | 30 | 0 | 10,000 | ||||

| 16 | 21.4 | −1.6 | 60 | R3 | 3.175 | 7.01 | 13.4 | 30 | 0 | 10,000 |

| R2 | 6.35 | 15.01 | 13 | 70 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 13.4 | 30 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 13.4 | 30 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 13.2 | 40 | 0 | 10,000 | ||||

| 17 | 19 | −5.2 | 55 | R3 | 3.175 | 7.01 | 12.4 | 30 | 0 | 10,000 |

| R2 | 6.35 | 15.01 | 11.7 | 70 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 12.4 | 30 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 12.4 | 30 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 12.4 | 40 | 0 | 10,000 | ||||

| 18 | 19 | −5.6 | 62 | R3 | 3.175 | 7.01 | 12.5 | 30 | 0 | 10,000 |

| R2 | 6.35 | 15.01 | 11.7 | 80 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 12.5 | 30 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 12.5 | 30 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 12.5 | 40 | 0 | 10,000 | ||||

| 19 | 18.1 | −0.9 | 60 | R3 | 3.175 | 7.01 | 13.2 | 20 | 0 | 10,000 |

| R2 | 6.35 | 15.01 | 12.8 | 50 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 13.2 | 20 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 13.2 | 20 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 13.2 | 20 | 0 | 10,000 | ||||

| 20 | 18.7 | −1.1 | 33 | R3 | 3.175 | 5 | 13.2 | 20 | 0 | 10,000 |

| R2 | 6.35 | 15.01 | 12.9 | 50 | 0 | 10,000 | ||||

| S.H 1 | 1.59 | 9.525 | 13.2 | 20 | 0 | 10,000 | ||||

| S.H 2 | 3.175 | 6.35 | 13.2 | 20 | 0 | 10,000 | ||||

| S.H 4 | 4.76 | 3.175 | 13.1 | 30 | 0 | 10,000 |

| Measurement | Initial Surface Temperature (°C) | Initial Thermal Gradient (°C) | Relative Humidity (%) | Defect Name | Defect Depth from the Surface (mm) | Minimum Size (mm) | δtapp (°C) | tapp (s) | δtdis (°C) | tdis (s) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 22 | 0 | 35 | R3 | 4.76 | 5 | 1.05 | 0 | 0 | 10,000 |

| S.H 1 | 2.38 | 14.29 | 1.67 | 0 | 0 | 10,000 | ||||

| S.H 2 | 4.76 | 9.53 | 1.67 | 0 | 0 | 10,000 | ||||

| S.H 4 | 7.14 | 4.76 | 0.78 | 0 | 0 | 10,000 | ||||

| 2 | 22 | 0 | 36 | R3 | 4.76 | 5 | 1.05 | 0 | 0 | 10,000 |

| R2 | 9.53 | 15.01 | 2.22 | 220 | 2 | 270 | ||||

| S.H 1 | 2.38 | 14.29 | 1.67 | 0 | 0 | 10,000 | ||||

| S.H 2 | 4.76 | 9.53 | 1.67 | 0 | 0 | 10,000 | ||||

| S.H 4 | 7.14 | 4.76 | 0.78 | 0 | 0 | 10,000 | ||||

| 3 | 23.6 | 0 | 25 | R3 | 4.76 | 5 | 3.17 | 20 | 0 | 10,000 |

| S.H 1 | 2.38 | 14.29 | 3.5 | 10 | 0 | 10,000 | ||||

| S.H 2 | 4.76 | 9.53 | 3.5 | 10 | 0 | 10,000 | ||||

| S.H 4 | 7.14 | 4.76 | 2.5 | 30 | 1.89 | 140 | ||||

| 4 | 26.1 | 0 | 25 | R3 | 4.76 | 7.01 | 9.88 | 10 | 0 | 10,000 |

| R2 | 9.53 | 9.98 | 6.28 | 30 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 9.88 | 10 | 0 | 10,000 | ||||

| S.H 2 | 4.76 | 9.53 | 9.88 | 10 | 0 | 10,000 | ||||

| S.H 4 | 7.14 | 4.76 | 9.88 | 20 | 0 | 10,000 | ||||

| 5 | 23.3 | 0 | 29 | R3 | 4.76 | 2.79 | 14.55 | 30 | 0 | 10,000 |

| R2 | 9.53 | 7.01 | 11.28 | 100 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 14.55 | 30 | 0 | 10,000 | ||||

| S.H 2 | 4.76 | 9.53 | 14.55 | 30 | 0 | 10,000 | ||||

| S.H 4 | 7.14 | 4.76 | 13.39 | 50 | 0 | 10,000 | ||||

| 6 | 24.8 | 0 | 29 | R3 | 4.76 | 5 | 10.06 | 0 | 0 | 10,000 |

| R2 | 9.53 | 15.01 | 7.33 | 60 | 5.94 | 130 | ||||

| S.H 1 | 2.38 | 14.29 | 10.06 | 0 | 0 | 10,000 | ||||

| S.H 2 | 4.76 | 9.53 | 10.06 | 0 | 0 | 10,000 | ||||

| S.H 4 | 7.14 | 4.76 | 7.94 | 30 | 5.28 | 150 | ||||

| 7 | 22.7 | 0 | 34 | R3 | 4.76 | 7.01 | 9.83 | 0 | 0 | 10,000 |

| R2 | 9.53 | 9.98 | 6.27 | 70 | 5.33 | 120 | ||||

| S.H 1 | 2.38 | 14.29 | 9.83 | 0 | 0 | 10,000 | ||||

| S.H 2 | 4.76 | 9.53 | 9.83 | 0 | 0 | 10,000 | ||||

| S.H 4 | 7.14 | 4.76 | 7.72 | 30 | 4.77 | 150 | ||||

| 8 | 26.5 | 0 | 16 | R3 | 4.76 | 2.79 | 10.33 | 10 | 0 | 10,000 |

| R2 | 9.53 | 9.98 | 9.05 | 30 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 10.33 | 10 | 0 | 10,000 | ||||

| S.H 2 | 4.76 | 9.53 | 10.33 | 10 | 0 | 10,000 | ||||

| S.H 4 | 7.14 | 4.76 | 9.55 | 20 | 0 | 10,000 | ||||

| 9 *,† | 24 | −20.5 | 35 | R3 | 4.76 | 5 | 5.55 | 0 | 0 | 10,000 |

| R2 | 9.53 | 5 | 5.55 | 0 | 0 | 10,000 | ||||

| R1 | 14.29 | 5 | 5.55 | 0 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 5.55 | 0 | 0 | 10,000 | ||||

| S.H 2 | 4.76 | 9.53 | 5.55 | 0 | 0 | 10,000 | ||||

| S.H 4 | 7.14 | 4.76 | 5.55 | 0 | 0 | 10,000 | ||||

| 10 | 25 | −0.78 | 36 | R3 | 4.76 | 5 | 10.1 | 10 | 0 | 10,000 |

| R2 | 9.53 | 9.98 | 8.44 | 50 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 10.1 | 10 | 3.3 | 200 | ||||

| S.H 2 | 4.76 | 9.53 | 10.1 | 10 | 3.3 | 200 | ||||

| S.H 4 | 7.14 | 4.76 | 10.1 | 10 | 4.44 | 180 | ||||

| 11 | 28 | −0.22 | 40 | R3 | 4.76 | 7.01 | 8.94 | 20 | 0 | 10,000 |

| R2 | 9.53 | 15.01 | 5.55 | 110 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 8.94 | 20 | 4.39 | 180 | ||||

| S.H 2 | 4.76 | 9.53 | 8.94 | 20 | 4.39 | 180 | ||||

| S.H 4 | 7.14 | 4.76 | 8.94 | 20 | 4.88 | 150 | ||||

| 12 | 25.9 | −1.8 | 21 | R3 | 4.76 | 9.98 | 9.27 | 10 | 0 | 10,000 |

| R2 | 9.53 | 15.01 | 5.17 | 130 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 10.5 | 0 | 5.72 | 100 | ||||

| S.H 2 | 4.76 | 9.53 | 10.5 | 0 | 5.72 | 100 | ||||

| S.H 4 | 7.14 | 4.76 | 9.27 | 10 | 6.27 | 80 | ||||

| 13 | 13 | −3.6 | 63 | R3 | 4.76 | 9.98 | 10.55 | 10 | 0 | 10,000 |

| R2 | 9.53 | 15.01 | 5.78 | 130 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 11.3 | 0 | 6.05 | 120 | ||||

| S.H 2 | 4.76 | 9.53 | 11.3 | 0 | 6.05 | 120 | ||||

| S.H 4 | 7.14 | 4.76 | 10.55 | 10 | 7.33 | 60 | ||||

| 14 | 17 | −3.1 | 48 | R3 | 4.76 | 7.01 | 9.5 | 0 | 0 | 10,000 |

| R2 | 9.53 | 7.01 | 8.5 | 40 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 9.5 | 20 | 6.05 | 170 | ||||

| S.H 2 | 4.76 | 9.53 | 9.5 | 20 | 6.05 | 170 | ||||

| S.H 4 | 7.14 | 4.76 | 9.5 | 20 | 6.44 | 140 | ||||

| 15 † | 8.3 | −5.9 | 51 | R3 | 4.76 | 9.98 | 6.5 | 40 | 0 | 10,000 |

| R2 | 9.53 | 15.01 | 3.06 | 140 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 9.11 | 0 | 2.94 | 150 | ||||

| S.H 2 | 4.76 | 9.53 | 9.11 | 0 | 2.94 | 150 | ||||

| S.H 4 | 7.14 | 4.76 | 6.5 | 40 | 3.06 | 140 | ||||

| 16 | 18.2 | −0.8 | 60 | R3 | 4.76 | 5 | 9.83 | 20 | 0 | 10,000 |

| R2 | 9.53 | 9.98 | 7.44 | 70 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 7.44 | 70 | 4.72 | 200 | ||||

| S.H 2 | 4.76 | 9.53 | 7.44 | 70 | 4.72 | 200 | ||||

| S.H 4 | 7.14 | 4.76 | 8.77 | 50 | 6.11 | 150 | ||||

| 17 | 21.7 | −2.9 | 25 | R3 | 4.76 | 9.98 | 10.8 | 0 | 0 | 10,000 |

| R2 | 9.53 | 15.01 | 6.11 | 160 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 10.8 | 0 | 6.11 | 130 | ||||

| S.H 2 | 4.76 | 9.53 | 10.8 | 0 | 6.11 | 130 | ||||

| S.H 4 | 7.14 | 4.76 | 9.44 | 10 | 7.11 | 90 | ||||

| 18 | 24 | −3 | 59 | R3 | 4.76 | 9.98 | 10.38 | 10 | 0 | 10,000 |

| R2 | 9.53 | 15.01 | 5.56 | 150 | 4.44 | 260 | ||||

| S.H 1 | 2.38 | 14.29 | 8.94 | 30 | 5.56 | 150 | ||||

| S.H 2 | 4.76 | 9.53 | 8.33 | 40 | 5.94 | 120 | ||||

| S.H 4 | 7.14 | 4.76 | 8.33 | 40 | 12.2 | 80 | ||||

| 19 | 18.2 | 8.42 | 37 | R3 | 4.76 | 5 | 10.1 | 0 | 0 | 10,000 |

| R2 | 9.53 | 7.01 | 10.1 | 0 | 0 | 10,000 | ||||

| S.H 1 | 2.38 | 14.29 | 10.1 | 0 | 0 | 10,000 | ||||

| S.H 2 | 4.76 | 9.53 | 10.1 | 0 | 0 | 10,000 | ||||

| S.H 4 | 7.14 | 4.76 | 10.1 | 0 | 3.22 | 180 | ||||

| 20 † | 30.6 | −5.18 | 39 | R3 | 4.76 | 9.98 | 5.06 | 470 | 4.6 | 530 |

| S.H 1 | 2.38 | 14.29 | 5.28 | 450 | 5 | 500 | ||||

| S.H 2 | 4.76 | 9.53 | 5.06 | 470 | 5 | 500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behravan, A.; deJong, M.M.; Brand, A.S. Laboratory Study on Non-Destructive Evaluation of Polyethylene Liquid Storage Tanks by Thermographic and Ultrasonic Methods. CivilEng 2021, 2, 823-851. https://doi.org/10.3390/civileng2040045

Behravan A, deJong MM, Brand AS. Laboratory Study on Non-Destructive Evaluation of Polyethylene Liquid Storage Tanks by Thermographic and Ultrasonic Methods. CivilEng. 2021; 2(4):823-851. https://doi.org/10.3390/civileng2040045

Chicago/Turabian StyleBehravan, Amir, Matthew M. deJong, and Alexander S. Brand. 2021. "Laboratory Study on Non-Destructive Evaluation of Polyethylene Liquid Storage Tanks by Thermographic and Ultrasonic Methods" CivilEng 2, no. 4: 823-851. https://doi.org/10.3390/civileng2040045

APA StyleBehravan, A., deJong, M. M., & Brand, A. S. (2021). Laboratory Study on Non-Destructive Evaluation of Polyethylene Liquid Storage Tanks by Thermographic and Ultrasonic Methods. CivilEng, 2(4), 823-851. https://doi.org/10.3390/civileng2040045