Toward Autonomous Pavement Inspection: An End-to-End Vision-Based Framework for PCI Computation and Robotic Deployment

Abstract

1. Introduction

Research Goal and Objectives

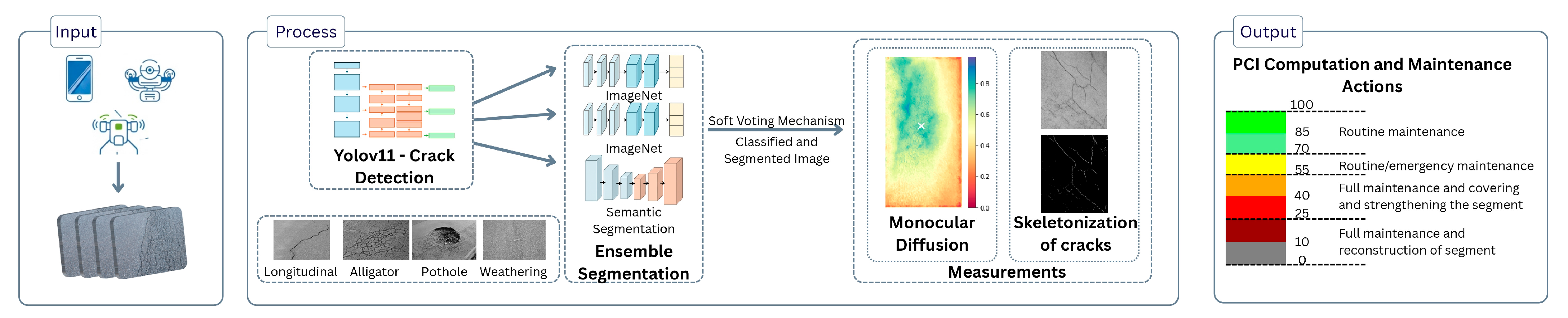

2. Literature Review

2.1. Object Detection in Pavement Inspection

2.2. Quantitative Distress Measurement Techniques

2.3. PCI Computation Pipelines

3. Research Gap and Novelty

4. Methodology

4.1. Data Acquisition and Preparation

4.2. Frame Extraction

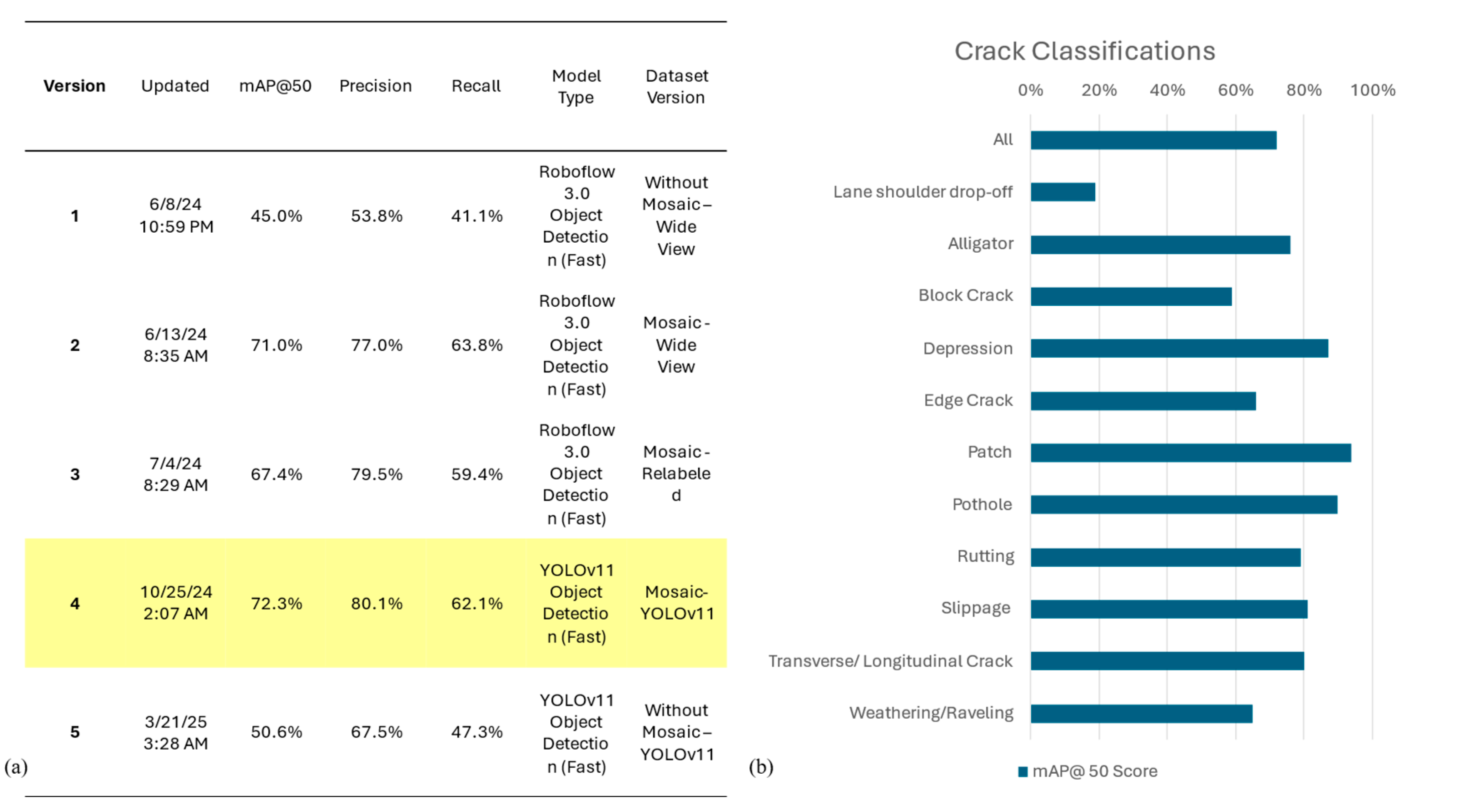

4.3. Pavement Distress Classification

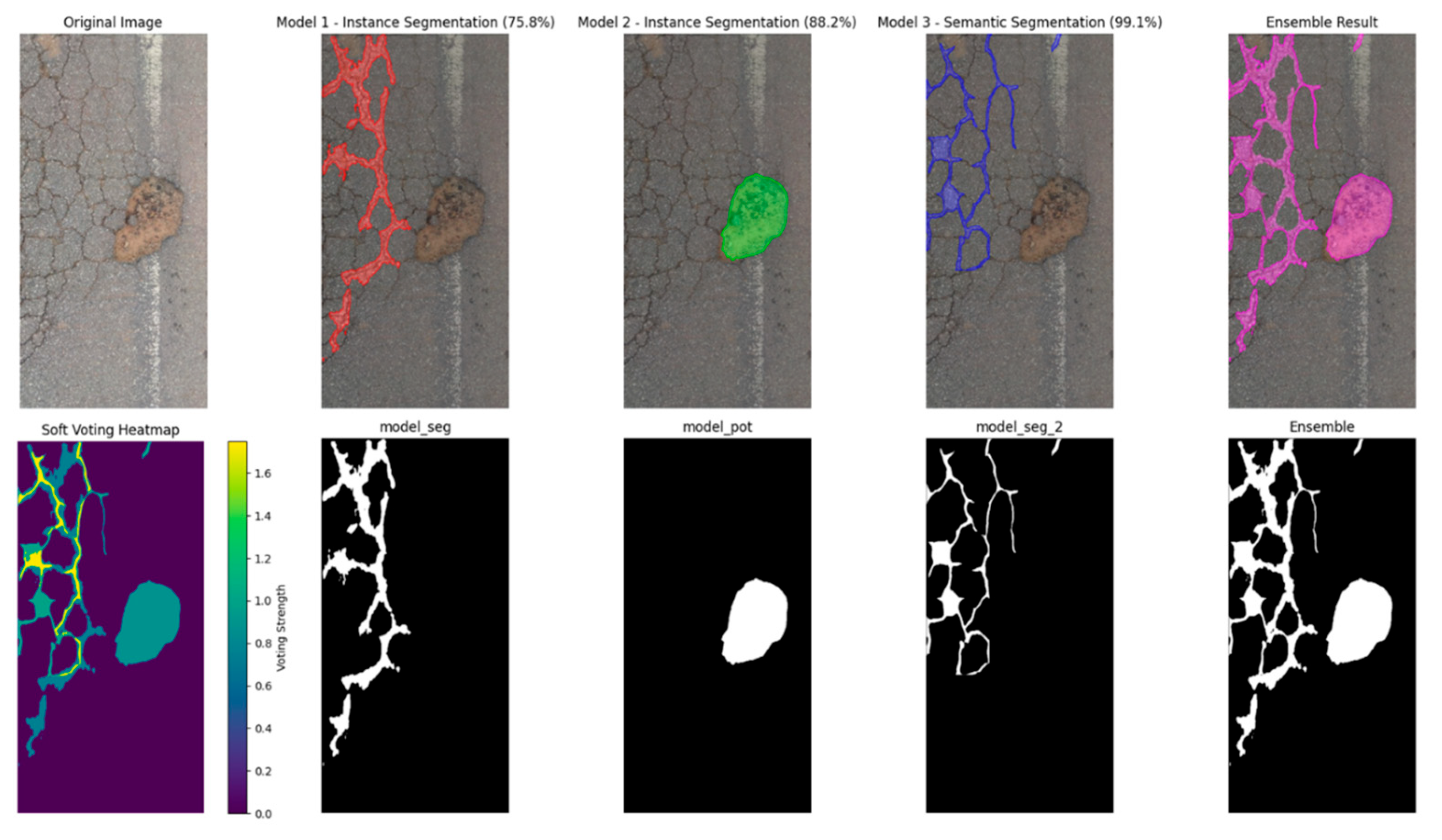

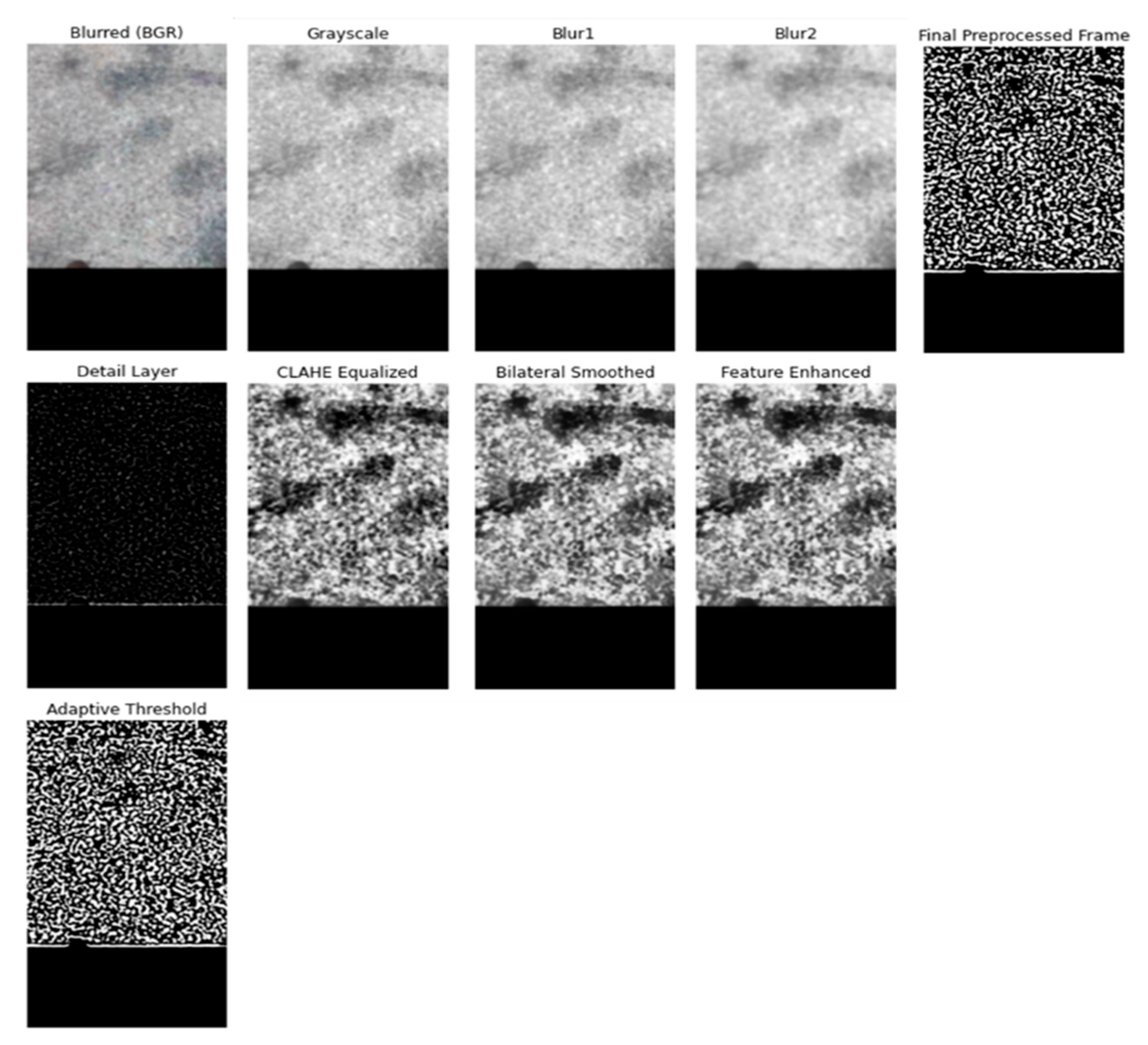

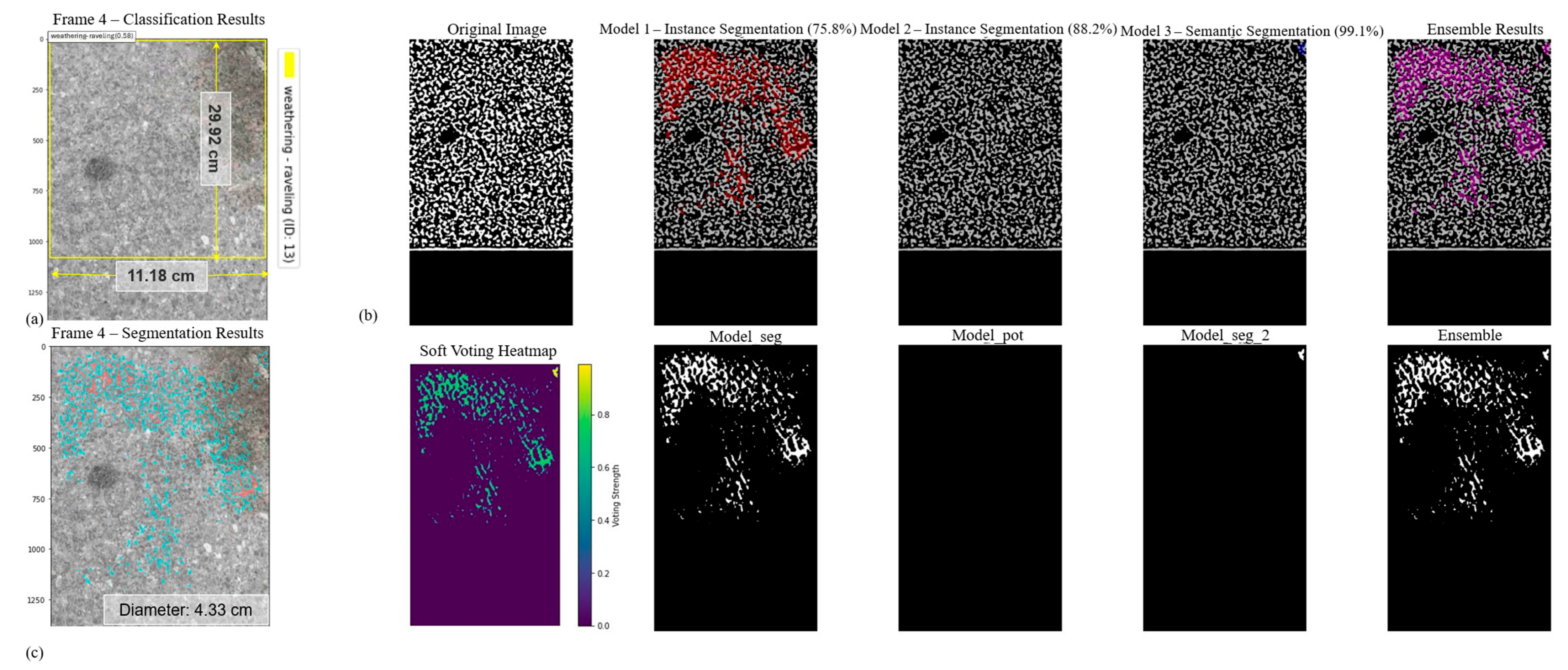

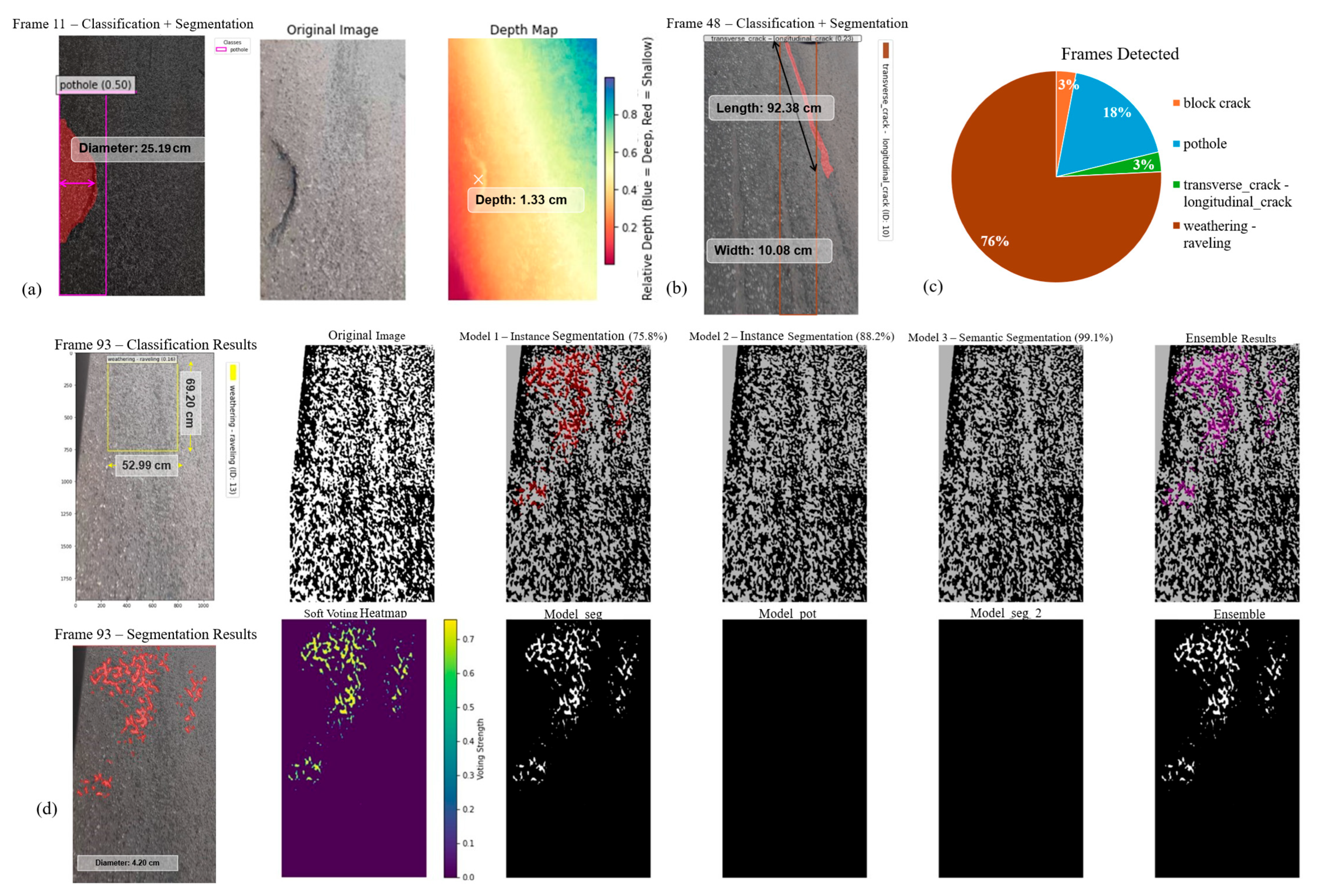

4.4. Ensemble Segmentation of Distress Regions

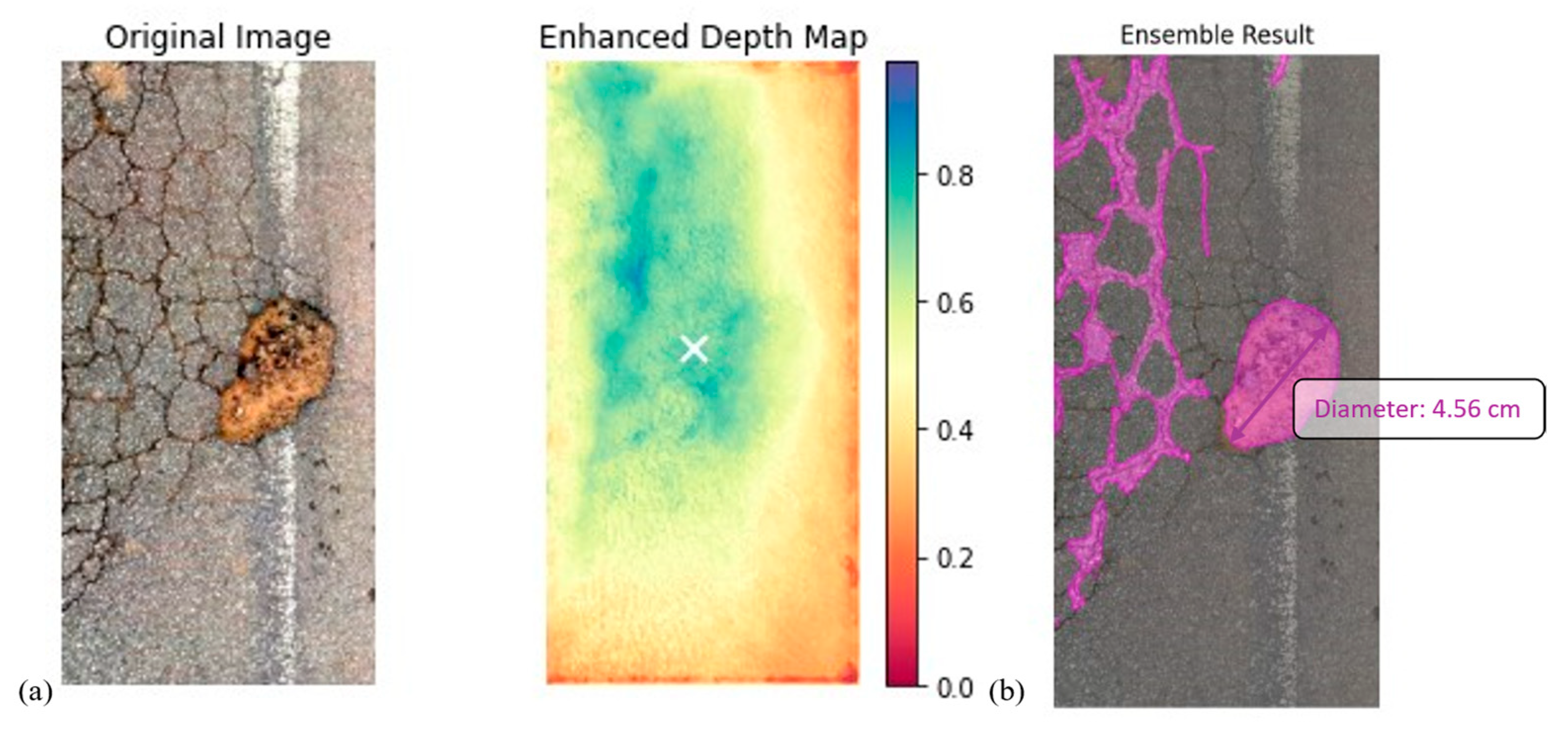

4.5. Quantitative Measurement and Severity Classification

- C(h) represents the calibration factor for a given camera height h;

- a, b, and c are the coefficients determined through the curve-fitting process;

- h denotes the camera height in centimeters.

4.6. Digitalizing the Deduct Curves

4.7. Segment-Level PCI Aggregation and Maintenance Mapping

5. Results and Discussion

5.1. Model Performance

5.2. Segmentation Evaluation

5.3. Quantitative Distress Analysis

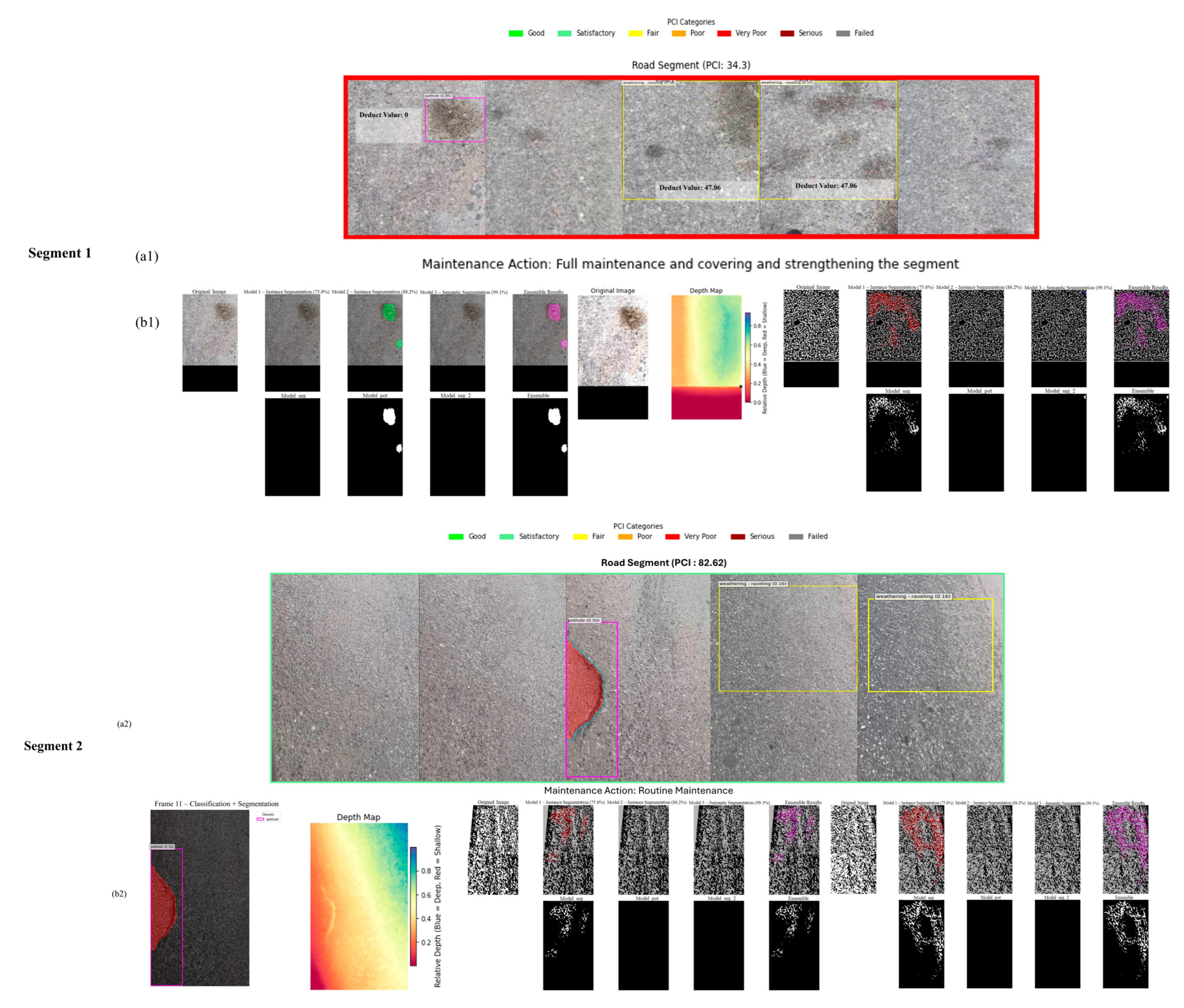

5.4. PCI Computation and Validation

5.5. Manual PCI Validation

6. Discussion and Limitations

7. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cheng, M.-Y.; Hoang, N.-D. A Swarm-Optimized Fuzzy Instance-based Learning approach for predicting slope collapses in mountain roads. Knowl. Based Syst. 2015, 76, 256–263. [Google Scholar] [CrossRef]

- Lugo, A.E.; Gucinski, H. Function, effects, and management of forest roads. For. Ecol. Manag. 2000, 133, 249–262. [Google Scholar] [CrossRef]

- Bukhsh, Z.A.; Stipanovic, I.; Saeed, A.; Doree, A.G. Maintenance intervention predictions using entity-embedding neural networks. Autom. Constr. 2020, 116, 103202. [Google Scholar] [CrossRef]

- Issa, A.; Samaneh, H.; Ghanim, M. Predicting pavement condition index using artificial neural networks approach. Ain Shams Eng. J. 2022, 13, 101490. [Google Scholar] [CrossRef]

- Tafida, A.; Alaloul, W.S.; Zawawi, N.A.B.W.; Musarat, M.A.; Sani, A.A. Advancing smart transportation: A review of computer vision and photogrammetry in learning-based dimensional road pavement defect detection. Comput. Sci. Rev. 2025, 56, 100729. [Google Scholar] [CrossRef]

- Tedeschi, A.; Benedetto, F. A real-time automatic pavement crack and pothole recognition system for mobile Android-based devices. Adv. Eng. Inform. 2017, 32, 11–25. [Google Scholar] [CrossRef]

- Wang, A.; Lang, H.; Peng, Y.; Chen, X.; Qian, J. Selecting and optimizing distress feature descriptors from multi-source images for pavement distress classification. Int. J. Transp. Sci. Technol. 2025, inpress. [Google Scholar] [CrossRef]

- Wang, W.; Wang, M.; Li, H.; Zhao, H.; Wang, K.; He, C.; Wang, J.; Zheng, S.; Chen, J. Pavement crack image acquisition methods and crack extraction algorithms: A review. J. Traffic Transp. Eng. 2019, 6, 535–556. [Google Scholar] [CrossRef]

- Garilli, E.; Bruno, N.; Autelitano, F.; Roncella, R.; Giuliani, F. Automatic detection of stone pavement’s pattern based on UAV photogrammetry. Autom. Constr. 2021, 122, 103477. [Google Scholar] [CrossRef]

- Liu, F.; Liu, J.; Wang, L.; Al-Qadi, I.L. Multiple-type distress detection in asphalt concrete pavement using infrared thermography and deep learning. Autom. Constr. 2024, 161, 105355. [Google Scholar] [CrossRef]

- Ranjbar, S.; Nejad, F.M.; Zakeri, H. Image-based severity analysis of Asphalt pavement bleeding using a metaheuristic-boosted fuzzy classifier. Autom. Constr. 2024, 166, 105655. [Google Scholar] [CrossRef]

- Ashraf, A.; Sophian, A.; Bawono, A.A. Crack Detection, Classification, and Segmentation on Road Pavement Material Using Multi-Scale Feature Aggregation and Transformer-Based Attention Mechanisms. Constr. Mater. 2024, 4, 655–675. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, S.; Song, W.; Li, Y.; Teng, Q. A novel convolutional neural network for enhancing the continuity of pavement crack detection. Sci. Rep. 2024, 14, 30376. [Google Scholar] [CrossRef]

- Naseri, A.; Golroo, A.; Parsaei, A. Comparison of different deep learning algorithms in pavement crack detection. Road Mater. Pavement Des. 2025, 1–18. [Google Scholar] [CrossRef]

- Zhang, J.; Xia, H.; Li, P.; Zhang, K.; Hong, W.; Guo, R. A Pavement Crack Detection Method via Deep Learning and a Binocular-Vision-Based Unmanned Aerial Vehicle. Appl. Sci. 2024, 14, 1778. [Google Scholar] [CrossRef]

- Nafaa, S.; Ashour, K.; Mohamed, R.; Essam, H.; Emad, D.; Elhenawy, M.; Ashqar, H.I.; Hassan, A.A.; Alhadidi, T.I. Automated Pavement Cracks Detection and Classification Using Deep Learning. In Proceedings of the 2024 IEEE 3rd International Conference on Computing and Machine Intelligence (ICMI), Mt Pleasant, MI, USA, 13–14 April 2024; pp. 1–5. [Google Scholar]

- Cano-Ortiz, S.; Iglesias, L.L.; del Árbol, P.M.R.; Lastra-González, P.; Castro-Fresno, D. An end-to-end computer vision system based on deep learning for pavement distress detection and quantification. Constr. Build. Mater. 2024, 416, 135036. [Google Scholar] [CrossRef]

- Zhang, A.A.; Shang, J.; Li, B.; Hui, B.; Gong, H.; Li, L.; Zhan, Y.; Ai, C.; Niu, H.; Chu, X.; et al. Intelligent pavement condition survey: Overview of current researches and practices. J. Road Eng. 2024, 4, 257–281. [Google Scholar] [CrossRef]

- Galata, S.; Walkington, I.; Lane, T.; Kiriakoulakis, K.; Dick, J.J. Rapid detection of microfibres in environmental samples using open-source visual recognition models. J. Hazard. Mater. 2024, 480, 135956. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yuan, C.; Wang, X. Real-time instance-level detection of asphalt pavement distress combining space-to-depth (SPD) YOLO and omni-scale network (OSNet). Autom. Constr. 2023, 155, 105062. [Google Scholar] [CrossRef]

- Kyem, B.A.; Kofi, E.; Denteh, O.; Kofi, J.; Student, A.P.; Tutu, K.A.; Aboah, A. Advancing Pavement Distress Detection in Developing Countries: A Novel Deep Learning Approach with Locally-Collected Datasets. arXiv 2024, arXiv:2408.05649. [Google Scholar] [CrossRef]

- Guo, G.; Zhang, Z. Road damage detection algorithm for improved YOLOv5. Sci. Rep. 2022, 12, 15523. [Google Scholar] [CrossRef]

- Yuan, Q.; Shi, Y.; Li, M. A Review of Computer Vision-Based Crack Detection Methods in Civil Infrastructure: Progress and Challenges. Remote Sens. 2024, 16, 2910. [Google Scholar] [CrossRef]

- Ren, M.; Zhang, X.; Chen, X.; Zhou, B.; Feng, Z. YOLOv5s-M: A deep learning network model for road pavement damage detection from urban street-view imagery. Int. J. Appl. Earth Obs. Geoinf. 2023, 120, 103335. [Google Scholar] [CrossRef]

- Guo, K.; He, C.; Yang, M.; Wang, S. A pavement distresses identification method optimized for YOLOv5s. Sci. Rep. 2022, 12, 3542. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, Y.; Zhang, Z.; Lu, N.; Zhang, Z.; Zhang, F.; He, X. A Pavement Distress Detection Method Based on Yolov5 Model. In Proceedings of the 2022 41st Chinese Control Conference (CCC), Hefei, China, 25–27 July 2022; pp. 6564–6569. [Google Scholar] [CrossRef]

- Zuo, H.; Li, Z.; Gong, J.; Tian, Z. Intelligent Road Crack Detection and Analysis Based on Improved YOLOv8. In Proceedings of the 2025 8th International Conference on Advanced Algorithms and Control Engineering (ICAACE), Shanghai, China, 21–23 March 2025; pp. 1192–1195. [Google Scholar]

- de Souza, Á.M.; de Oliveira, C.E.; Decker, P.H.B.; Corrêa, A.L.D.S.C.; Amorim, G.E.R.; Fontenele, H.B. Defect detection using YOLOv8 for determining the condition of asphalt pavements. Re-vista ALCONPAT. Rev. Alconpat 2025, 15, 79–91. [Google Scholar] [CrossRef]

- Wang, S.; Cai, B.; Wang, W.; Li, Z.; Hu, W.; Yan, B.; Liu, X. Automated detection of pavement distress based on enhanced YOLOv8 and synthetic data with textured background modeling. Transp. Geotech. 2024, 48, 101304. [Google Scholar] [CrossRef]

- Aung, Y.Y.; Lwin, M.M. Real-Time Object Distance Estimation Based on YOLOv8 Using Webcam. In Proceedings of the 2024 IEEE Conference on Computer Applications (ICCA), Yangon, Myanmar, 16 March 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Tian, Z.; Yang, F.; Yang, L.; Wu, Y.; Chen, J.; Qian, P. An Optimized YOLOv11 Framework for the Efficient Multi-Category Defect Detection of Concrete Surface. Sensors 2025, 25, 1291. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Wang, K.; Fang, T.; Su, L.; Chen, R.; Fei, X. Comprehensive Performance Evaluation of YOLOv11, YOLOv10, YOLOv9, YOLOv8 and YOLOv5 on Object Detection of Power Equipment. In Proceedings of the 2025 37th Chinese Control and Decision Conference (CCDC), Xiamen, China, 16–19 May 2025; pp. 1281–1286. [Google Scholar]

- Li, Q.; Wu, T.; Xu, T.; Lei, J.; Liu, J. A Novel YOLO Algorithm Integrating Attention Mechanisms and Fuzzy Information for Pavement Crack Detection. Int. J. Comput. Intell. Syst. 2025, 18, 158. [Google Scholar] [CrossRef]

- Sabouri, M.; Mohammadi, M. A novel approach for automatic asphalt pavement crack length estimation. Road Mater. Pavement Des. 2024, 25, 2530–2548. [Google Scholar] [CrossRef]

- Yuan, Y.; Ge, Z.; Su, X.; Guo, X.; Suo, T.; Liu, Y.; Yu, Q. Crack Length Measurement Using Convolutional Neural Networks and Image Processing. Sensors 2021, 21, 5894. [Google Scholar] [CrossRef]

- Wang, S.; Dong, Q.; Chen, X.; Chu, Z.; Li, R.; Hu, J.; Gu, X. Measurement of Asphalt Pavement Crack Length Using YOLO V5-BiFPN. J. Infrastruct. Syst. 2024, 30, 04024005. [Google Scholar] [CrossRef]

- Ibragimov, E.; Kim, Y.; Lee, J.H.; Cho, J.; Lee, J.-J. Automated Pavement Condition Index Assessment with Deep Learning and Image Analysis: An End-to-End Approach. Sensors 2024, 24, 2333. [Google Scholar] [CrossRef] [PubMed]

- Cai, G.; Tian, H.; Liu, L.; Liu, X.; Liu, S. Research progress of intelligent testing technology and evaluation methods for subgrade engineering. J. Road Eng. 2025, 5, 164–183. [Google Scholar] [CrossRef]

- Yang, X.; Huang, R.; Meng, Y.; Liang, J.; Rong, H.; Liu, Y.; Tan, S.; He, X.; Feng, Y. Overview of the application of Ground-Penetrating Radar, Laser, infrared thermal Imaging, and ultrasonic in nondestructive testing of road surface. Measurement 2023, 224, 113927. [Google Scholar] [CrossRef]

- Yang, Z.; Lan, X.; Wang, H. Comparative Analysis of YOLO Series Algorithms for UAV-Based Highway Distress Inspection: Performance and Application Insights. Sensors 2025, 25, 1475. [Google Scholar] [CrossRef]

- Baka. Road Damage dét Object Detection Model by Baka. Available online: https://universe.roboflow.com/baka-1ravj/road-damage-det (accessed on 24 July 2025).

- Sensor Street CRACK. Pavement Image Dataset II Model > Overview. Available online: https://universe.roboflow.com/sensor-street-crack/pavement-image-dataset-ii (accessed on 23 July 2025).

- SPL Project. PAVEMENT Model > Overview. Available online: https://universe.roboflow.com/spl-project/pavement-gvib5 (accessed on 23 July 2025).

- Infrastructure. Ycroad Model > Overview. Available online: https://universe.roboflow.com/infrastructure/ycroad (accessed on 23 July 2025).

- Mcmaster. Pavement Crack Detection Object Detection Model by Mcmaster. Available online: https://universe.roboflow.com/mcmaster-vkq5k/pavement-crack-detection-r4n7n (accessed on 23 July 2025).

- Team. Crack Object Detection Model by Team. Available online: https://universe.roboflow.com/team-eukwb/crack-ypk4t (accessed on 23 July 2025).

- TUM. Road_Defect Model > Overview. Available online: https://universe.roboflow.com/tum-z9rop/road_defect/dataset/3 (accessed on 23 July 2025).

- Neil Gogte Institute of Technology. Road Health and Safety Object Detection Dataset by Neil Gogte Institute of Technology. Available online: https://universe.roboflow.com/neil-gogte-institute-of-technology/road-health-and-safety (accessed on 23 July 2025).

- RoadSurvey. Road_Detection Object Detection Model by RoadSurvey. Available online: https://universe.roboflow.com/roadsurvey/road_detection-twdhw (accessed on 23 July 2025).

- Amirkabir University of Technology. AV Model > Overview. Available online: https://universe.roboflow.com/amirkabir-university-of-technology-qazbm/uav-ghnuu (accessed on 23 July 2025).

- Salehsane Crop Shode. SaneSalehCropped Model > Overview. Available online: https://universe.roboflow.com/salehsane-crop-shode/sanesalehcropped (accessed on 23 July 2025).

- Pavement Distresses Detection. Asphalt-Road-Pavement-Distresses-Detection Model > Overview. Available online: https://universe.roboflow.com/pavement-distresses-detection/asphalt-road-pavement-distresses-detection (accessed on 23 July 2025).

- New Workspace. Patch Dataset > Overview. Available online: https://universe.roboflow.com/new-workspace-lhsm6/patch-amn4a (accessed on 23 July 2025).

- Wijaya, K. 4 Class Kerusakan Jalan Dataset > Overview. Available online: https://universe.roboflow.com/krisna-wijaya-sxuzy/4-class-kerusakan-jalan (accessed on 23 July 2025).

- Priyadarshini, S. Damage Classification Dataset > Overview. Available online: https://universe.roboflow.com/suprava-priyadarshini/damage-classification-wt2us (accessed on 23 July 2025).

- Pothole. Pothole Detection System Object Detection Dataset by Pothole. Available online: https://universe.roboflow.com/pothole-sa6sb/pothole-detection-system-qaqxu (accessed on 23 July 2025).

- 2333 Model > Overview. Available online: https://universe.roboflow.com/ii-atajc/2333 (accessed on 23 July 2025).

- Psjsila Workspace. Road Crack Dataset > Overview. Available online: https://universe.roboflow.com/psjsilaworkspace/road-crack-n2zbd (accessed on 23 July 2025).

- Skripsi. Road Damage Model > Overview. Available online: https://universe.roboflow.com/skripsi-4ywsf/road-damage-zxiub (accessed on 24 July 2025).

- Sohar, C. Developing Deep Vision-Based Advanced Defects Detection System for Roads in Oman Object Detection Model by Cas Sohar. Available online: https://universe.roboflow.com/cas-sohar/developing-deep-vision-based-advanced-defects-detection-system-for-roads-in-oman (accessed on 23 July 2025).

- Forest Road Distress. Distress Dataset > Overview. Available online: https://universe.roboflow.com/forest-road-distress/distress (accessed on 23 July 2025).

- Vishwesh, A.K. Pothole Dataset > Overview. Available online: https://universe.roboflow.com/vishwesh-ak/pothole-r4gd5 (accessed on 23 July 2025).

- The American University of the Middle East. Pothole Detection Dataset > Overview. Available online: https://universe.roboflow.com/the-american-university-of-the-middle-east/pothole-detection-3uuq2 (accessed on 23 July 2025).

- Khanam, R.; Hussain, M. YOLOv11: An Overview of the Key Architectural Enhancements. arXiv 2024, arXiv:2410.17725. [Google Scholar] [CrossRef]

- Department of the Army. Pavement Maintenance Management; Technical Manual TM 5-623; Headquarters, Department of the Army: Washington, DC, USA, 1982. Available online: https://www.wbdg.org/FFC/ARMYCOE/COETM/ARCHIVES/tm_5_623.pdf (accessed on 23 July 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Desouky, N.E.; Torky, A.A.; Elbheiri, M.; Eid, M.S.; Ibrahim, M. Toward Autonomous Pavement Inspection: An End-to-End Vision-Based Framework for PCI Computation and Robotic Deployment. Automation 2025, 6, 67. https://doi.org/10.3390/automation6040067

Desouky NE, Torky AA, Elbheiri M, Eid MS, Ibrahim M. Toward Autonomous Pavement Inspection: An End-to-End Vision-Based Framework for PCI Computation and Robotic Deployment. Automation. 2025; 6(4):67. https://doi.org/10.3390/automation6040067

Chicago/Turabian StyleDesouky, Nada El, Ahmed A. Torky, Mohamed Elbheiri, Mohamed S. Eid, and Mohamed Ibrahim. 2025. "Toward Autonomous Pavement Inspection: An End-to-End Vision-Based Framework for PCI Computation and Robotic Deployment" Automation 6, no. 4: 67. https://doi.org/10.3390/automation6040067

APA StyleDesouky, N. E., Torky, A. A., Elbheiri, M., Eid, M. S., & Ibrahim, M. (2025). Toward Autonomous Pavement Inspection: An End-to-End Vision-Based Framework for PCI Computation and Robotic Deployment. Automation, 6(4), 67. https://doi.org/10.3390/automation6040067