Abstract

This article presents results on the use of a new material as a solidifying agent and/or color-fixing agent. A special polysaccharide material extracted from the prickly pear cactus (Opuntia ficus indica) was tested on historical materials and modern papers. An old book from the 18th century was chosen as historical material. From the mentioned book 42 pages were taken, on which a conservation and restoration pretreatment was performed before applying the polysaccharide material: sampling, fiber analysis, dry cleaning, ink solubility, pH test, thickness measurement and wet cleaning. The paper sheets provided for the test were divided into 4 groups, 3 of which were treated with gel and one left untreated as a reference. The division into groups is not only due to the different method of application, but also due to the process of gel extraction. The effect of the treatment was analyzed using FTIR-ATR. To test the mucilage as color-fixing agent 2 samples were prepared using watercolor papers colored with 6 different watercolors applied to 2.5 cm2 samples for each color in two rows of different intensity. One of the 2 samples was treated with gel, but both were immersed for 3 times in a water-ethanol solution for approximately 20 min as is standard practice in conservation and restoration. After washing, both specimens were subjected to colorimetric analysis to assess their differences. The results provided satisfactory evidence for the protection of paints sensitive to aqueous treatments and suggest the use of mucilage as a new material in cleaning method for water-soluble media.

1. Introduction

In recent years, the growing attention paid to environmental sustainability in all sectors has naturally affected the preservation of cultural heritage. This has led to the emergence of so-called green conservation, which has two main objectives: to reduce the risk of exposure of conservators/restorers to harmful substances and to solve the economic and environmental problem of chemical waste disposal. Both objectives can be achieved with the development of protective coatings based on green materials derived from wastes and plant proteins [1,2,3].

The discussion on the synthesis of green products for the conservation of cultural heritage is still open, since all compounds used for this purpose must also respect other constraints, such as the ethical codes dictated by the E.C.C.O. (European Confederation of Conservator-Restorers’ Organization). Every conservator-restorer has a duty to use only products, materials and processes that do not harm cultural heritage, the environment and/or people. Therefore, we should choose materials that are compatible with the cultural heritage, stable, non-toxic, neutral and reversible, even completely if possible [4].

In our opinion, such a material could be a polysaccharide gel from the prickly pear. The prickly pear (Opuntia ficus indica) is a plant grown as an ornamental in many countries around the Mediterranean. In some of these countries, such as Italy, these plants are also used in the food industry for the production of Indian figs, which can be processed into snacks, juices or jams [5], but their use is even broader, as all edible parts of the plant are currently used to produce a variety of products. This is because they are a good source of phytochemicals such as phenolics, vitamin C, vitamin E, polysaccharides, and betalains that are antioxidant, anticancer, antiatherosclerotic, and/or hepatoprotective [6]. For this reason, in recent years there have been numerous researches on the nutritional, curative and cosmetic properties of products obtained from the cactus [7,8,9,10]. In some of these cases, the plants need to be pruned regularly to remove the cladodes, which are then discarded as waste. Accordingly, our study describes the optimal extraction of mucilage from the waste of Opuntia cladodes and its use as a solidifying and color-fixing agent for paper materials.

2. Materials and Methods

The mucilage were extracted and separated from Opuntia waste cladodes from two different geographical areas on the Adriatic Sea: Dubrovnik (Croatia) and Marche (Italy).

Two different extraction methods have been used to obtain prickly pear mucilage [11,12]: mechanical post-maceration (MPM) and maceration (MA).

The first part of mechanical post-maceration (MPM) and maceration (MA) is the same: after removing the outer skin of prickly pear cladodes the inner pulp must be cut into small pieces of the order of 1 cm3. The cut pulp is immersed in distilled water (1:1) and left in the dark for 24 h (Figure 1)

Figure 1.

Preliminary treatment of prickly pear cladodes.

Only in this point the two procedures differ:

- -

- Mechanical post maceration MPM: The pulps, left in the dark for 24 h, must be filtered and blended. In this way we obtain a dense green gel (Figure 2).

Figure 2. MPM procedure: Filtering after maceration and blending of the solid fraction.

Figure 2. MPM procedure: Filtering after maceration and blending of the solid fraction.

- -

- Maceration MA: The pulps left in the dark for 24 h must be separated from the liquid through mesh filters from 2 mm to 250 microns. In this case, the separated liquid is recovered, resulting in mostly transparent mucilage with a slightly less dense consistency than in the MPM process (Figure 3).

Figure 3. MA procedure: recovery of the filtrate.

Figure 3. MA procedure: recovery of the filtrate.

To eliminate the problem of acidity of the mucilage, in both cases, a 1 M calcium hydroxide solution can be added to the pulp, which must then rest in the dark for 24 h. For 50 g of pulp and 250 mL of distilled water, 2.5 mL of Ca(OH)2 can be added to obtain a neutral or slightly alkaline mucilage.

2.1. Chemical-Physical Characterization of the Material after the Extraction Process

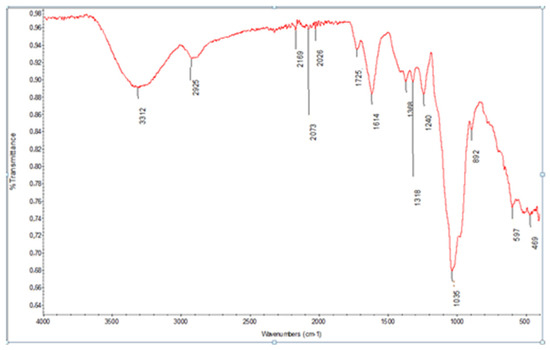

The substance extracted by the MA method has been characterized using FT-IR Alpha-II spectrometer by Bruker, the measurement range was 400–4000 cm−1 and the resolution was 4 cm−1 with 24 scans per sample. The recorded FTIR spectrum shows the characteristic bands of the mucilage of cactus cladodes [13,14,15] (Figure 4):

Figure 4.

FTIR spectrum of the substance extracted with the MA method from Opuntia ficus indica blades.

- -

- the stretching band around 3312 cm−1 and the bending one around 1425 cm−1 both typical of the hydroxyl groups, -OH,

- -

- the stretching band at 2925 cm−1 and the bending ones with a peak at 1614 cm−1, characteristics of the alkyl groups -CH, -CH2 and -CH3,

- -

- the bands observed at 1369 cm−1 and 1240 cm−1 are instead attributable to the characteristic vibrational modes of the pyranose ring [9],

- -

- the absorption peak at 1035 cm−1 that characterizes the single bond –C-O of the alcohols and related ether bridges present in the main chain of the polysaccharide [16].

A weak band was also observed at 1725 cm−1 indicating the presence of a carbonyl group -C=O probably of amide groups which indicates a possible contamination by protein materials during extraction [17].

2.2. The Use of Prickly Pear Mucilage as a Solidifying Agent for Historical Paper Materials

The sheets of paper used as historical material were taken from an old book from the 18th century.

Before applying the gel, the usual steps were carried out, which the procedure for the conservation and restoration of the paper [18] provides:

- Sampling: 42 pages were selected from the selected book, which were labeled and photographed from the front and back to obtain clear and precise documentation of the treated pages.

- Fiber analysis: this analysis is used to determine the composition of the paper with an aqueous solution of zinc chloride (ZnCl2) and potassium iodide (KI). The analysis confirms the absence of lignin, which means that the samples are mainly made of pure cellulose.

- Dry cleaning: dry cleaning is used to remove surface dirt. We used a yellow Akapad sponge and even a powder form for the stubbornness dirt. In both cases, the residues were removed with a soft bristle brush.

- Ink solubility test: this procedure is performed to select the optimal solution for wet cleaning. The test result shows that immersing sheets of paper in a water bath is the best method.

- pH test: this test is performed to check if deacidification of the samples is necessary. In all 42 samples, the measured pH was 7, so deacidification was not necessary.

- Thickness measurement: this analysis is performed before and after washing in order to verify any changes due to adhesive or material loss.

- Wet cleaning: wet cleaning is used to remove deeper dirt. In our case, it was performed by immersing the samples in a water bath three times for 20 min.

At this point, the samples ready for the application of the gel were divided into 4 groups according to the type of treatment they were subjected to.

The samples in the first group (labeled 1 to 12) were all treated with a mixture of MPM mucilage and distilled water in different ratios, applied with a brush (Figure 5a). Even though these mixtures were acidic (pH = 5/6), the acidity of the gel after application and drying did not change the pH of all samples, which remained neutral. To test whether they could become acidic in the future, all samples were cut in half and only one part was evaporated with an aqueous solution of calcium hydroxide, Ca(OH)2, at a pH of 9 (these samples were labeled 1a to 12a). The final pH of these halves was 7.5 (Table 1). In both cases, the pH values did not change even after a longer period of time. This means that treatment with Ca(OH)2 is not necessary.

Figure 5.

Application of the gel: (a) with a brush, (b) by immersion.

Table 1.

First group of samples (labeled 1-1a to 12-12a).

The samples in the second group (labeled 13 to 24) were treated with a mixture of MPM slime and Tylose MH -300 P (a powdered thickener that can be used with polar solvents) in various ratios. It is used when reversible and flexible gluing is required or as a paper adhesive) applied with a brush. The mixture was acidic and even if the acid did not affect the final pH in the previous group of samples, we decided to add ammonia to obtain mixtures with an ideal pH (8–9) for the paper material (Table 2).

Table 2.

Second group of samples (labeled 13 to 24).

For the third group (labeled 25 to 30), different application methods were used:

- -

- sample 25 was treated with MA mucilage gel treated with Ca(OH)2, which was applied with a brush. The pH of this gel was 9.7, while the pH of the treated sample was 8/9 (Figure 5a).

- -

- sample 26 was treated with MPM mucilage gel applied with a brush. The pH of the sheet after application of the gel was 9/10.

- -

- sample 27 was used to test the ability of the gel to remove rust stains, but without results.

- -

- sample 28 was not subjected to any treatment and was only used for visual comparison with samples 25 and 26 using a magnifying glass to see if the green mucilage leaves any traces of color on the paper. Sample 26 was indeed greener compared to 25.

- -

- sample 29 was treated with MA mucilage gel by immersion (Figure 5b).

- -

- sample 30 was treated with MPM mucilage gel by immersion.

Samples 31 to 42 were not treated with the gel and used as reference ones in subsequent analyses.

Considering that the different ratios of mucilage:water or mucilage:tylose did not give different pH values, only 7 treated samples (12, 12a, 24, 25, 26, 29, 30, 31) were selected from all the prepared samples for the subsequent preliminary aging analyzes, and only one of the untreated samples was selected as a reference sample (43). The selection of the seven samples results from the fact that in all cases the paper sheets were treated exclusively with mucilage obtained in different ways, i.e., at a different pH and/or with different techniques.

2.3. Preliminary Aging Test Using UV Light

Samples 12, 12a, 24, 25, 26, 29, 30, and 43 were irradiated with a common UV lamp with a 20 W tube for 48 and 96 h, respectively.

Considering that in these samples the support (paper) and the protective material (mucilage) belong to the same compound class and have similar FT-IR spectra, the FT-IR analyzes were performed in ATR mode to detect any vibrational differences in the functional groups of the two materials.

2.4. Use of Prickly Pear Mucilage as a Color Fixative on Watercolor Paper

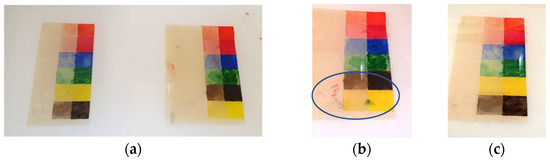

Although the cellulose fibers of the paper can tolerate polar solvents, so wet cleaning with water is usually not a problem, wet cleaning paper painted with watercolors can be a real challenge. In these cases, the most commonly used method for wet removal of impurities on watercolors is blotting on a vacuum table. Unfortunately, this cleaning method cannot remove all impurities from the paper support, unlike what the immersion method can do. For this reason, it was decided to test prickly pear gel to stabilize pigments so that watercolor paintings could also be subjected to immersion. The test as a color fixative was conducted on Fabriano Artistic Traditional 300 g/m2 Watercolor Paper®. Various Schmincke® watercolor paints (red, burgundy, blue, green, yellow and black) were applied to 2.5 cm2 samples for each color in two rows of different intensity (the intense colors at the top, the transparent ones at the bottom) (Figure 6). For each color, stability was tested before and after application of the mucilage.

Figure 6.

Sample preparation.

Before testing the fixing ability of the gel, the ink solubility test (see paragraph 2.3) was repeated with three solutions of distilled water and ethanol in the ratios 50:50, 70:30, and 30:70, respectively, with the 30:70 solution showing the highest stability and therefore selected for the wet treatment. Thus, the samples were immersed in the last solution for about 20 min and the procedure was repeated three times as in conservation and restoration practice (Figure 7a).

Figure 7.

(a) Samples in a tub immersed in the solution, (b) untreated sample–color is unstable (see marked area), (c) sample treated with mucilage-color is stable.

A piece of blotting paper was placed on the untreated colored paper dipped in the 1 dm3 solution mentioned above to observe whether the pigment left traces of color on it. The test showed that all untreated colors were unstable in this solution: Immediately after immersion, dissolution of part of the red and green color of the untreated sample was observed (Figure 7b).

The treated samples were prepared by applying three layers of the gel (pH = 5) with a brush to the more intense colors and only one layer to the more transparent parts. The test, performed as before using blotting paper, showed greater stability for all the colors protected with the gel: the colors of the untreated sample are dissolved, as can be seen from the floating traces (Figure 7b), while the colors treated with the gel are wash-resistant (no floating traces, Figure 7c) and especially for the more intense colors (Figure 7c). The same process was repeated with a gel treated with Ca(OH)2 to obtain a more alkaline solution (pH = 9.7). Visual observation for these treatments showed the same results.

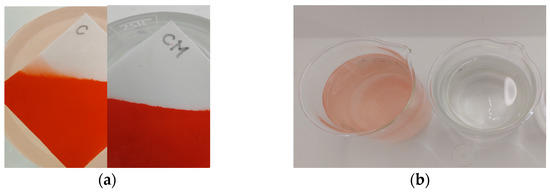

In another test, 2 samples of the same paper were prepared but colored only with red Schmincke® watercolor paint applied to half of the 4 cm2 samples. The choice of red color was determined by the fact that it proved to be the most sensitive color. The samples were designated as C (color) and CM (color + mucilage). Both samples were thus immersed in the bath, which this time was prepared with water only, to test whether the mucilage could also fix the color in this case. The color loss of the samples was diagnosed visually on the paper and from the coloration of the water bath (Figure 8). The samples were air dried before each wash. The mucilage used in this case is MA with alkaline pH, which gave the best results.

Figure 8.

(a) Results after washing the untreated sample (C) and the treated sample (CM), (b) baths after the washing treatment for C (left) and CM (right).

2.5. The Characterization of Tested Samples by Colorimetric Analyses

Although the effect of the gel can be observed with the naked eye, colorimetric analyses were performed on all samples using the NH310 Handheld Colorimeter to evaluate the color changes of the samples after washing without or with protective agent. The NH310 Handheld Colorimeter is a portable instrument used on fabrics, paper, plastic parts and construction materials. It is possible to perform color difference analysis according to formula:

∆E*= [(∆L*)2 + (∆a*)2 + (∆b*)2]1/2

∆E*, in this case, stands for the difference between the color of the sample before washing (standard color) and the color of the sample after washing. ∆L* represents a lightness difference between the two colors. ∆a* stands for a redness or greenness difference between the two colors and ∆b* stands for a blueness-yellowness difference between two colors.

The lower the ∆E* value, the closer the sample is to the standard. A ∆E* value of 0 means that the two colors are identical. The greater the ∆E* value, the greater the difference between the two colors, which in our case means that a greater part of the color was lost during washing.

2.6. Reversibility Test

Although it was found that the MA mucilage at modified pH gave good results both as a firming agent and as a color-fixing agent, the reversibility of the gel must be demonstrated in view of the fact that the above-mentioned gel is to be used for cultural heritage.

Three samples were prepared for analysis: Fabriano Artistic Traditional 300 g/m2 Watercolor Paper® was cut into 9 cm2 squares. Each sample was weighed before and after application of the MA gel to prove that the gel remained on the paper. The samples were dipped in the gel and then completely air dried. The samples were then placed in a bath containing a prepared 70:30 water:ethanol solution for 20 min. They were then left in air until completely dry and reweighed to check how much gel had been removed. The analytical balance used has a resolution of 0.01, which is accurate enough for our study.

3. Results

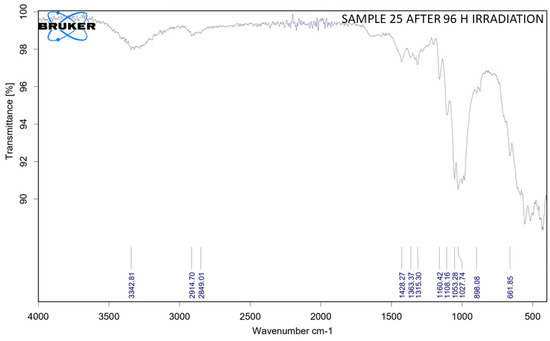

3.1. Chemical-Physical Characterization of Preliminary Aging Test

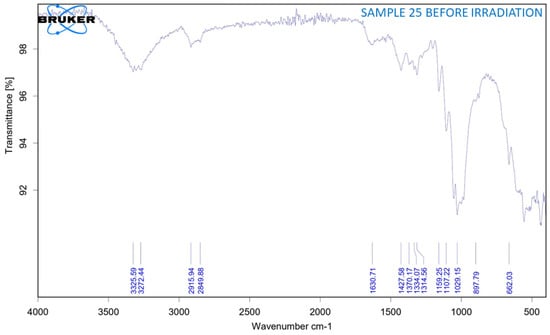

From the results of the FT-IR analyzes, a clear deterioration of the paper material can be deduced for all untreated samples irradiated for 96 h: the bands of the functional groups of the paper are significantly altered both in intensity and in definition (Figure 9). The results for the samples treated with mucilage (Figure 10 and Figure 11) are different, as they do not appear to be as degraded.

Figure 9.

FTIR spectrum of sample 43 (untreated) after UV irradiation for 96 h.

Figure 10.

FTIR spectrum of sample 25 before UV irradiation.

Figure 11.

FTIR spectrum of sample 25 after UV irradiation for 96 h.

It is interesting to note that the mucilage treated samples do not degrade as much, proving that the mucilage plays a protective role against degradation during prolonged UV irradiation. The best results are obtained with sample 25, which is the most alkaline of all the samples tested.

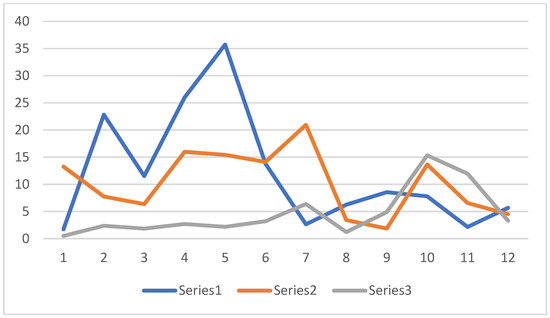

3.2. Results Obtained of the Colorimetric Analysis

The results of the colorimetric analysis are given in Table 3, Table 4 and Table 5, while the comparison of the ΔE* calculated for the three series of samples is shown in Figure 12.

Table 3.

Results of the colorimetric analysis for untreated samples.

Table 4.

Results of the colorimetric analysis for samples treated with mucilage pH = 5.

Table 5.

Results of the colorimetric analysis for samples treated with mucilage pH = 9.7.

Figure 12.

ΔE* graphic for the tree series: series 1-untreated samples, series 2-samples treated with gel pH = 5, series 3-samples treated with gel pH = 9.7.

From the graphic chart, it can be deduced that the best results were obtained for the samples treated with alkaline mucilage, since for them the lowest ΔE* values were obtained for most colors, which means that the color before and after washing are closest to each other [19]. This conclusion could not be drawn from the visual analysis alone, where both gels appeared to behave in the same way.

3.3. Results of Reversibility Test

From the results in Table 6, the gel was completely removed in all three cases by immersion in a bath of water and ethanol, proving that the process is reversible.

Table 6.

Masses of samples without gel, with gel and after washing.

4. Discussion and Conclusions

In their standard practice as solidifying agent and/or colors-fixative, paper conservators usually choose between natural and synthetic agents. The former, such as gelatin, starch, cellulose ethers… have advantages such as good penetration and adhesion, ease of preparation and reversibility. The synthetic agents such as acrylic resins, polyvinyl acetate (PVA)… have advantages such as fast drying, water resistance and strong adhesion.

Unfortunately, synthetic solidifying agent and/or fixatives can often have negative effects on the paper, such as discoloration, brittleness, and loss of flexibility over time. In addition, they may not be as effective in preventing further deterioration of the paper [20,21]. The natural properties of cactus gel, on the other hand, have been shown to provide effective consolidation while maintaining the original color and flexibility of the paper.

Opuntia ficus-indica gel has also shown good results as a solidifying agent in artificial aging tests under a UV lamp. It was found that the samples, especially 25 and 26 (treated with a gel prepared by the method MA with a modified pH of 9), did not degrade even after 96 h of irradiation. In further studies, it could be interesting to investigate the effects of using a thermal chamber to also test the effect of heat on the treated paper.

The gel was also tested as a color- fixative. The results were satisfactory and were confirmed by colorimetric analysis, in addition to a simple visual observation that showed a significant loss of color layers on untreated samples.

Considering that in this case all tests were performed on “modern” paper samples, further experiments on historical samples could be planned.

It is important to emphasize that the tests performed showed that the application of the gel is reversible.

From these results, it appears that the use of mucilage could be considered in the field of paper conservation and restoration. In particular, the alkaline mucilage, which gave the best results, has all the important properties essential for application to cultural heritage, unlike other conventional materials commonly used as solidifying and color-fixing agents. Indeed, the gel appears to be stable, non-toxic, neutral and reversible.

And although in recent years the use of prickly pear, due to its properties, has attracted great interest not only in food research, but also in medicine and cosmetics, we have found few articles on its use in the field of conservation-restoration and only on its use as solidifying agent for lime mortars [22]. This confirms that our research is at least innovative, and considering the good results obtained, it would be appropriate to further investigate its applications in the conservation and restoration of paper and other materials.

Author Contributions

Conceptualization, L.E., T.D. and G.R.; methodology, L.E., T.D., G.R., S.C. and G.B.; data curation L.E., T.D. and G.R.; writing—original draft preparation, L.E., T.D. and G.R.; writing—review and editing; visualization. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Macchia, A.; Luvidi, L.; Fernanda, P.; La Russa, M.F.; Ruffolo, S. Green Conservation of Cultural Heritage. International Workshop. Int. J. Conserv. Sci. 2016, 7, 185–357. [Google Scholar]

- Chemat, F.; Abert-Vian, M.; Fabiano-Tixier, A.S.; Strube, J.; Uhlenbrock, L.; Gunjevic, V.; Cravotto, G. Green extraction of natural products. Origins, current status, and future challenges. TrAC Trends Anal. Chem. 2019, 118, 248–263. [Google Scholar] [CrossRef]

- Arreche, R.; Vázquez, P. Green biocides to control biodeterioration in materials science and the example of preserving WorldHeritage Monuments. Curr. Opin. Green Sustain. Chem. 2020, 25, 100359. [Google Scholar] [CrossRef]

- Available online: https://www.wipo.int/export/sites/www/tk/en/databases/creative_heritage/docs/ecco_guidelines.pdf (accessed on 30 March 2023).

- Cota-Sánchez, J.H. Nutritional Composition of the Prickly Pear (Opuntia Ficus-Indica) Fruit. In Nutritional Composition of Fruit Cultivars; Academic Press: Cambridge, MA, USA, 2016; pp. 691–712. [Google Scholar] [CrossRef]

- Barba, F.J.; Putnik, P.; Bursać Kovačević, D.; Poojary, M.M.; Roohinejad, S.; Lorenzo, J.M.; Koubaa, M. Impact of Conventional and Non-Conventional Processing on Prickly Pear (Opuntia Spp.) And Their Derived Products: From Preservation of Beverages to Valorization of by-Products. Trends Food Sci. Technol. 2017, 67, 260–270. [Google Scholar] [CrossRef]

- Palmieri, N.; Suardi, A.; Stefanoni, W.; Pari, L. Opuntia ficus-indica as an Ingredient in New Functional Pasta: Consumer Preferences in Italy. Foods 2021, 10, 803. [Google Scholar] [CrossRef] [PubMed]

- Contreras-Padilla, M.; Rivera-Muñoz, E.M.; Gutiérrez-Cortez, E.; del López, A.R.; Rodríguez-García, M.E. Characterization of crystalline structures in Opuntia ficus-indica. J. Biol. Phys. 2015, 41, 99–112. [Google Scholar] [CrossRef] [PubMed]

- Vicidomini, C.; Roviello, V.; Roviello, G.N. In Silico Investigation on the Interaction of Chiral Phytochemicals from Opuntia ficus-indica with SARS-CoV-2 Mpro. Symmetry 2021, 13, 1041. [Google Scholar] [CrossRef]

- Stavi, I. Ecosystem services related with Opuntia ficus-indica (prickly pear cactus): A review of challenges and opportunities. Agroecol. Sustain. Food Syst. 2022, 46, 815–841. [Google Scholar] [CrossRef]

- Scognamiglio, F.; Mirabile Gattia, D.; Roselli, G.; Persia, F.; De Angelis, U.; Santulli, C. Thermoplastic Starch Films Added with Dry Nopal (Opuntia Ficus Indica) Fibers. Fibers 2019, 7, 99. [Google Scholar] [CrossRef]

- Allegra, A.; Inglese, P.; Sortino, G.; Settanni, L.; Todaro, A.; Liguori, G. The influence of Opuntia ficus-indica mucilage edible coating on the quality of ‘Hayward’ kiwifruit slices. Postharvest Biol. Technol. 2016, 120, 45–51. [Google Scholar] [CrossRef]

- Rivera Cañón, A.F.; Carrillo, C.H.; Cuaspud, J.G. Evaluation of physicochemical properties of Nopal (Opuntia Ficus-Indica) as bio coagulant-flocculant for water treatment. J. Phys. Conf. Ser. 2021, 2046, 012057. [Google Scholar] [CrossRef]

- Luna-Sosa, B.; MartíNez-áVila, G.C.; Rodriguez-Fuentes, H.; Pastrana, L.M.; Azevedo, A.G.; Gonzalez-Sandoval, D.C.; Cerqueira, M.A.; Rojas, R. Extraction and characterization of mucilage from Opuntia ficus-indica cultivated on hydroponic system. Not. Bot. Horti Agrobot. Cluj-Napoca 2022, 50, 12460. [Google Scholar] [CrossRef]

- Souza, C.M.P.; Almeida, F.S.; Junior, V.F.V.; De Lima Damasceno, B.P.G.; Medeiros, A.C.D.; Santana, D.P.; Silva, J.A. Characterization of atomized extract of Opuntia ficusindica (L.) Mill. and assessment of its pharmaceutical potential. Rev. Cienc. Farm. Basica Apl. 2014, 35, 195–203. [Google Scholar]

- Ciriminna, R.; Fidalgo, A.; Avellone, G.; Danzì, C.; Timpanaro, G.; Locatelli, M.; Carnaroglio, D.; Meneguzzo, F.; Ilharco, L.M.; Pagliaro, M. Integral extraction of Opuntia ficus-indica peel bioproducts via microwave-assisted hydrodiffusion and hydrodistillation. ACS Sustain. Chem. Eng. 2019, 7, 7884–7891. [Google Scholar] [CrossRef]

- Bernardino-Nicanor, A.; Montañez-Soto, J.L.; Conde-Barajas, E.; Negrete-Rodríguez, M.D.L.L.X.; Teniente-Martínez, G.; Vargas-León, E.A.; Juárez-Goiz, J.M.S.; Acosta-García, G.; González-Cruz, L. Spectroscopic and structural analyses of Opuntia Robusta mucilage and its potential as an edible coating. Coatings 2018, 8, 466. [Google Scholar] [CrossRef]

- Available online: https://unesdoc.unesco.org/ark:/48223/pf0000006446?posInSet=5&queryId=469ab71d-b206-4cfd-9dad-00941e634265 (accessed on 30 March 2023).

- Mokrzycki, W.; Tatol, M. Color difference Delta E—A survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- Charola, A.E.; Tucci, A.; Koestler, R. On the reversibility of treatments with acrylic/silicone resin mixtures. J. Am. Inst. Conserv. 1986, 25, 83–92. [Google Scholar] [CrossRef]

- Brückle, I.; Thornton, J.; Nichols, K.; Strickler, G. Cyclododecane: Technical note on some uses in paper and objects conservation. J. Am. Inst. Conserv. 1999, 38, 162–175. [Google Scholar] [CrossRef]

- Alisi, C.; Bacchetta, L.; Bojorquez, E.; Falconieri, M.; Gagliardi, S.; Insaurralde, M.; Martinez, M.F.F.; Orozco, A.M.; Persia, F.; Sprocati, A.R.; et al. Mucilages from Different Plant Species Affect the Characteristics of Bio-Mortars for Restoration. Coatings 2021, 11, 75. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).