Abstract

Tropical firewood species are of foremost importance for charcoal production worldwide. The objective of this study was to evaluate the impact of the moisture content of tropical fuelwood on charcoal production in modified Argentinean half-orange kilns in terms of yield, quality, and economic viability. Ten tropical species from the state of Quintana Roo, Mexico, were selected for charcoal production. The data were analyzed using a completely randomized design. The moisture content of the firewood was 48.99–79.31%. Temperatures close to 500 °C were obtained in the three kilns, as well as production yields of 28% with a consumption of 6.4 m3 of firewood and 38% with a consumption of 4.5–5 m3. Charcoal moisture values of less than 8%, volatile material of 20–30%, ash < 8%, fixed carbon of 60–70%, and higher heating values of 28–30 MJ kg−1 were obtained. Burn I obtained the highest energy yield of 54%, with a production of 20.87 MWh of charcoal recovered. The production cost of the kiln for the producer is USD 0.00825 (MXN 0.16) per MJ.

1. Introduction

Charcoal is the main energy source for cooking food and heating in many countries. A total of 17% of the world’s wood is processed into charcoal, and it has also become an important source of energy in the metallurgical sector for other countries. World production in the last five years ranged from 523 to 556 million tons. The countries with the highest production in 2021 were Brazil, Egypt, and Nigeria, with 6.4, 4.8, and 4.8 million tons, respectively [1,2].

Fossil fuels represent the main resource for the generation of energy and heat worldwide, but their reserves have been reduced, and, consequently, fuel prices are increasing. In addition, the use of these fuels is causing environmental damage and is responsible for greenhouse gas emissions. For its part, charcoal production is an economically and environmentally important activity since it generates a livelihood for more than 40 million people worldwide. When its production comes from forests with forest management, it represents a sustainable biofuel, generates neutral carbon dioxide emissions, and, compared to fossil fuels, has a low sulfur and nitrogen content [2,3,4,5,6].

Tropical firewood species are significant for charcoal production worldwide. A study conducted by Hnag [7] with 150 charcoal samples from 11 European countries revealed that 46% of the charcoal analyzed came from subtropical and tropical species. Specifically, in Mexico, the production of charcoal is around 1 million tons, of which 139,048 tons were exported in 2021 [8,9], with the firewood of the genus Quercus being the most used (48.84%), followed by other broadleaves (36.46%), tropical common species (14.35%), and pine (0.34%) [10].

According to data from the National Survey of Occupation and Employment (ENOE), in 2023, in Mexico, there are currently 13,600 people working in charcoal production, 78% of whom depend exclusively on this income, with an average national wage of MXN 5000 per month (USD 298) for a five-day work week. For the southern region, the highest income was reported at MXN 8500 (USD 472.22) per month [11].

One of the key factors for determining the efficient use of firewood as a fuel is moisture content [12]. There is limited information on the effect of firewood moisture on the quality of charcoal produced. Lubwama et al. [13] established that the moisture content of firewood has a direct effect on the combustion characteristics and higher heating values of the charcoal produced. However, there is abundant information on the effect of firewood moisture on combustion in residential and industrial boilers. Reports indicate that fresh firewood, with a moisture content above 50%, has only half the heating value of dry firewood [14]. On the other hand, burning wet firewood in boilers reduces combustion temperatures, delays the ignition time, and increases emissions of carbon monoxide (CO), methane (CH4), non-methane volatile organic compounds (NMVOCs), and formaldehyde (CH2O) [15].

The type of kiln used for charcoal production depends on the producers’ economic situation and how much charcoal they want to make, type of vegetation, climate, topography, and final use. In some parts of the world, such as Africa, charcoal is the primary fuel to satisfy cooking and heating demands. On the other hand, in Brazil, the highest percentage of charcoal is directed to the metallurgical industry, while in Mexico, most of the production is used for recreational grilling activities, although in communities where access to LP gas is scarce, charcoal represents the first source of use [16,17,18,19,20,21].

In Mexico, charcoal production is carried out using technologies such as traditional kilns, including mood earth and pits, as well as masonry kilns, including Brazilian beehive kilns and hot-tail kilns. On the other hand, metallic kilns are also used, such as the retort, cevag, and metallic industrial kilns. Regarding the production system in Mexico’s southeast region, modified Argentinian half-orange kilns are used, where charcoal is produced from tropical species. Producers collect firewood daily, sourced from trees felled during the day. The firewood is transported using small trucks with a capacity of 2 to 3 cubic meters (m3). Due to these daily routines, it is not feasible to accumulate a substantial quantity of firewood in the storage yard. Consequently, the drying period under ambient weather conditions typically lasts only 3 days.

The modified Argentinean half-orange kilns hold up to 12 m3 of firewood and yield an average of two tons of charcoal. The carbonization process reaches temperatures of around 500 °C and lasts for approximately eight days. Ignition occurs at the top of the door, and the fire moves upward to initiate carbonization and then downward through the kiln. During carbonization, operators observe different smoke colors, aiding in process control. It starts with a white color, indicating initial wood moisture loss. It then transitions to dark gray, signaling the removal of volatile components. Subsequently, a blue hue appears, indicating the transformation of firewood into charcoal. At this stage, the upper vents are closed to decrease the flame, and when smoke emerges from the lower vents, it signifies the completion of carbonization. The chimney is then sealed, allowing the kiln to cool down.

As a result of this, charcoal made from tropical species is produced from fresh cut firewood, so its moisture content is high (>60%). According to Nigatu [22], for an efficient carbonization process, the moisture content should be less than 30%. However, to date, there is no information available to establish the effect that firewood moisture content has on charcoal quality under real production conditions. Therefore, the objective of this study was to evaluate the impact of the moisture content of tropical firewood on charcoal production in modified half-orange kilns in terms of yield, quality, and economic viability.

2. Materials and Methods

2.1. Site Description and Kiln Characteristics

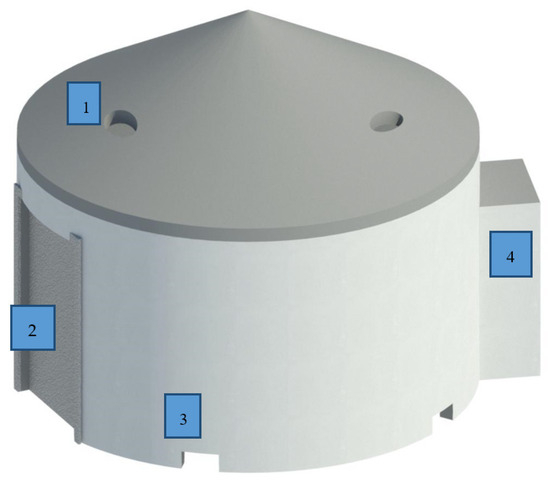

This research was conducted in the Río Escondido Ejido, Othón Pompeyo Blanco, Quintana Roo, Mexico (18°52′32″ N, 88°44′59″ W). The charcoal was produced in half-orange kilns, which were modified by changing the ceiling to a semi-spherical shape, like in the Brazilian beehive kiln. The dimensions of the kiln are 3.5 m, 2.4 m, and 10 cm for diameter, height, and wall thickness, respectively. It has a nominal capacity of 12 m3 and produces 2000 kg of charcoal. The kiln has three vents at the top, four vents at the bottom, and a chimney. The kiln is divided into three sections for the accommodation of firewood (Figure 1). The first is responsible for ensuring ignition, as well as generating energy to dry the rest of the firewood. Usually, little charcoal is collected in the first stowage because most of the firewood is consumed during the process. The second stowage is the one with the highest charcoal production since it obtains the heat of the first stowage, thus ensuring its transformation process. The third stowage receives the heat of the second, but there is a risk that partially charred wood pieces are obtained instead of charcoal in the lower area. For this reason, in this research, the samples were placed in the second stowage to ensure complete carbonization (Figure 2). Figure 3 shows the charcoal production operation diagram.

Figure 1.

Structure of a modified half-orange kiln. (1) Upper vent; (2) door; (3) lower vent; (4) kiln chimney.

Figure 2.

Carbonization process in a modified half-orange kiln. (A) Firewood arrangement: (1) first stacking, (2) second stacking, (3) third stacking; (B) firewood-to-charcoal transformation process; (C) blue smoke at the bottom of the kiln, indicating that carbonization is complete; (D) sample of recovered charcoal.

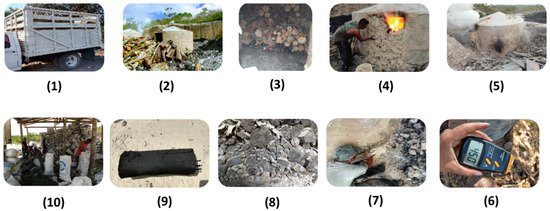

Figure 3.

(1) Arrival of timber at the storage yard; (2) drying of firewood in the storage yard; (3) arrangement of firewood for charring; (4) ignition of the oven from the top of the inlet; (5) gaseous emissions during the carbonization process; (6) temperature measurement (°C) using thermocouples; (7) suffocation of the vents, a sign that the carbonization process is complete; (8) view of charcoal; (9) recovery of test pieces; (10) packaging of charcoal in 19 kg bags.

2.2. Species Selection

The species selection was based on their abundance and use as firewood in the Río Escondido region of Quintana Roo, Mexico [23]. The selection of these species was based on their condition, with priority given to environmentally damaged but energy-intensive timbers. The charcoal was produced from the following tropical species: Haematoxylon campechianum, Gymnanteheas lucida, Vitex gaumeri, Manilkara zapota, Metopium brownei, Lysiloma bahamensis, Psidia piscipula, Coccoloba spicata, Diospyrus cuneata, and Croton reflexifolius.

Three carbonization processes (Burns) were conducted. In each Burn, three firewood samples (small logs) of each of the ten species were selected and marked. The samples were pieces of firewood with diameters ranging from 10 to 20 cm and lengths of 50 to 80 cm. Prior to each of the three Burns, all samples were marked with nails, washers, and wire to distinguish between species and repetitions, facilitating identification at the end of each Burn. The diameter, length, weight, and moisture content were measured for each sample of each species at the beginning of each Burn. The samples were positioned in the second section of the kiln to ensure thorough carbonization and to ensure complete recovery of the charcoal.

2.3. Carbonization Process

The temperature and carbonization duration were continuously monitored throughout the three Burns, and heating ramps were calculated. The temperature inside the kilns was recorded using standard type k, 5 m thermocouples and an Extech thermometer (VIR50); the thermocouples were placed in the middle of the kiln at a height of 2.2 m. The carbonization process ended when the fire reached the lower vents (Figure 2C), immediately after which the vents were sealed to prevent the charcoal from being consumed. At the end of each Burn, the charcoal samples were weighed again and five phases of carbonization were also identified, as described by García-Quezada et al. [24].

2.4. Immediate Analysis

Physicochemical analyses were performed according to the ASTM international standard D 1762-84 [25]. The charcoal sample of each species and Burn was introduced into an SM 300 cutting mill at a speed of 1500 revolutions per minute (rpm) and sieved for five minutes at a speed of 100 rpm in an AS 200 analytical sieve, obtaining a particle size of 425 μm (mesh size 40).

2.5. Yield of Charcoal

The charcoal mass yield was determined by relating the charcoal mass (kg) to the firewood mass (kg) according to Basu’s [26] Equation (1).

where

- MY = mass yield (%);

- MC = mass of charcoal (kg);

- MGB = mass of green biomass (kg).

The charcoal yield (m3 ton−1) was obtained by relating the volume (m3) of each firewood sample to the mass (t) of the same pyrolyzed sample according to Equation (2) developed by Elyounssia et al. [27].

where

- Y = charcoal yield;

- V = volume of sample (m3);

- m = mass of pyrolyzed sample (ton).

2.6. Higher Heating Value

The higher heating value (HHV) was determined using a semi-automatic isoperibolic calorimeter (Model AC600, LECO Instruments Ltd., St. Joseph, UK), using the Spanish standard UNE-EN 18125:2018 [28].

2.7. Energy Efficiency of Charcoal Production

Energy yield (%) is defined as the portion of energy contained in the biomass that is recovered in the charcoal according to Equation (3) developed by Canal et al. [27].

where

- HHV charcoal = higher heating values of charcoal (MJ kg−1);

- HHV firewood = higher heating value of biomass (MJ kg−1).

The total HHV used and generated during the carbonization process in each Burn was calculated using Equations (5) and (6).

To determine the Burn energy efficiency, the HHV of firewood and charcoal expressed in Megajoules (MJ) was converted to Megawatt hours (MWh), following the conversion of 1 MJ equivalent to 0.0002777778 MWh, and then Equation (6) was developed.

2.8. Multivariate Exploratory Analysis

Multivariate analysis was used to identify which variables were correlated. Eleven variables related to the physical and chemical characteristics of firewood and charcoal were found to be correlated (Data are on Supplementary Material). The FactorMineR v2.4 package was used [29].

2.9. Charcoal Production Costs

The charcoal production costs of each Burn were based on information provided by producers in the Rio Escondido region. The price per cubic meter of firewood was set at MXN 300 (USD 16.66), while the labor costs for the master charcoal maker and his assistant were calculated per Burn of charcoal produced, amounting to MXN 1000 (USD 55.55). Finally, the selling price for the charcoal was established at MXN 10 per kg (USD 0.55).

2.10. Statistical Analysis

The data were statistically analyzed with a completely randomized experimental design. A Kolmogorov–Smirnov normality test was performed, yielding an unsatisfactory result (p < 0.05), so the variables were statistically analyzed with a non-parametric design using Kruskal–Wallis tests and a Dunn test comparison with a significance of α = 0.05. The procedures were performed with the package(s) and function(s) in RStudio® (2015) statistical software.

3. Results and Discussion

3.1. Carbonization Conditions

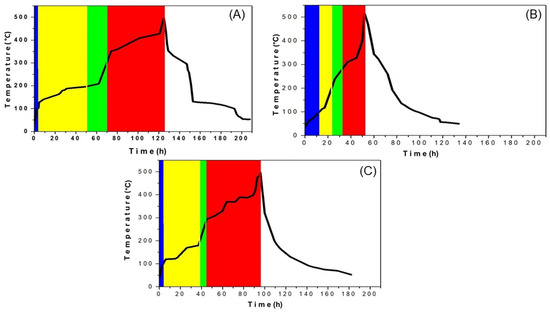

Five phases with different heating ramps were identified, and the final temperature and time taken for each of the phases in the three burns were recorded (Table 1). According to Costa et al. [30], the carbonization process is variable even if the same type of kiln and charcoal master are used. Burn I showed a carbonization time of 208 h (h) and a maximum temperature of 496 °C (Figure 4); phase 1 provided a heating ramp of 0.56 °C min−1 with a time of 3 h, which was the fastest of all Burns. Phase 2 presented a heating ramp of 0.03 °C min−1 and lasted 50 h; this phase was the longest, probably due to the high moisture content of the firewood used (average to 79.31%). Phases 3 and 4 maintained a heating ramp of 0.07 °C min−1 with a time of 18 and 53 h, respectively; thus, these phases showed the lowest heating ramps of the three Burns. Burn II reached a carbonization time of 134 h and a maximum temperature of 515 °C; phase 1 showed a heating ramp of 0.17 °C min−1 with a time of 10 h. Phase 2 presented a ramp of 0.12 °C min−1 with a time of 14 h, while phase 3 presented a ramp of 0.33 °C min−1, representing the fastest of all phases and Burns with a duration of four hours. Phase 4 presented a heating ramp of 0.16 °C min−1 with a duration of 24 h, phase 5, the cooling phase, had a ramp of −0.09 °C min−1. Burn III had a carbonization time of 182 h with a maximum temperature of 497 °C. Phase 1 lasted 4 h and had a heating ramp of 0.42 °C min−1, phase 2 showed a ramp of 0.05 °C min−1 and a time of 34 h, phase 3 had a heating ramp of 0.19 °C min−1 and a time of 7 h, phase 4 presented a heating ramp of 0.07 °C min−1 and a time of 51 h, and, lastly, phase 5 corresponding to the cooling period showed no difference with the other burns, presenting a temperature reduction of −0.09 °C min−1.

Table 1.

Burning time and heating ramps of each phase during carbonization in a modified half-orange kiln.

Figure 4.

Carbonization process in a modified half-orange kiln: blue color = phase 1; yellow color = phase 2; green color = phase 3; red color = phase 4; white color = phase 5; (A) Burn I; (B) Burn II; (C) Burn III.

The identification of the carbonization phases is important to understand the functioning of endothermic and exothermic reactions and how the different components of wood are released, as well as their emissions. In phase 1, the kiln is ignited, while in phase 2, the moisture content of the firewood is reduced by evaporation and the chemical bonds of the hemicellulose start to break down. The highest CO2 emissions occur mainly in phase 2, especially in hardwoods, due to the high content of glucuronic acid units and O-acetyl groups in the xylan structure, which degrades polysaccharides such as glucuronoxylan, xyloglucan, and glucomannan. In phase 3, the major degradation of cellulose and remaining hemicellulose occurs, releasing methanol (CH3OH), acetic acid (CH3COOH), tar, carbon monoxide (CO), methane (CH4), and hydrogen (H2). In phase 4, the hemicellulose and cellulose content is minimal and the fixation of the carbon content begins, so that the lignin content is the last available component, which consists of a mixture of guaiacyl and syringyl units, whereas grass lignin contains a mixture of all three units, mainly composed of CHC organic compounds; the carbon content is higher as the temperature increases and the release of H2 takes place at higher temperatures [31,32].

According to Missio et al. [33], the carbonization process with wet firewood (moisture content > 30%) generates an abrupt energetic process, which is observed in the variation of the heating ramp during the first four phases of Burn II. On the contrary, Jesus et al. [34] note that a high wood moisture content (>30%) can lead to slow heating and, consequently, charcoal devolatilization becomes an incomplete process, which is reflected in gravimetric yields below 30%. Zola et al. [35] point out that wood moisture content is one of the most important parameters at the time of pyrolysis. Also, Assis et al. [36] state that the pyrolysis process should not exceed 0.10 °C per minute, as slow pyrolysis will not occur and the product generated will not have disintegrated properly. Furthermore, according to Guo et al. [37], if a high fixed carbon content is desired, carbonization at a temperature higher than 600 °C is necessary. The cooling time in this type of kiln is proportional to the time taken for the carbonization process, although, for some producers, it is a slow process. Bustos-Vanegas et al. [38] note that the long cooling time of the charcoal bed is due to the insulation characteristics of the kiln building materials and the exothermic oxidation reactions that continue to occur in the charcoal bed during the cooling, depending on the oxygen concentration of the stagnant gases.

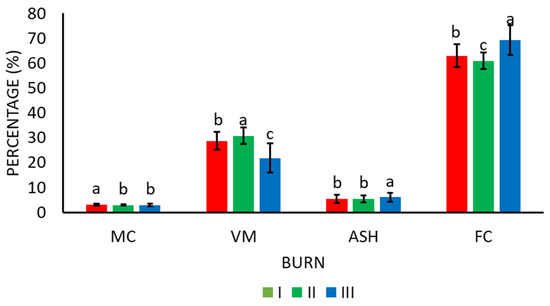

3.2. Proximal Analysis

A greater amount of volatile material, less fixed carbon, and a lower higher heating value were observed in Burn II (Figure 5), which implies a shorter carbonization time. Although Burn III had the highest temperature, the high heating ramp (higher than 0.1 °C min−1 in all phases) was not adequate for the carbonization process, and its carbonization time and heating ramp were short for the degradation of hemicellulose and cellulose, so the charcoal obtained had a higher content of volatile material [5,39]. Ronsse et al. [40] suggest that a rapid temperature increase is beneficial for producing gas and bio-oil, but it may not be the optimal method for charcoal production. Jesus et al. [34] noted that almost 100% of the water contained in the wood is part of the composition of the pyroligneous liquor, so the charcoal obtained is high in volatiles.

Figure 5.

Proximate analysis of charcoal produced in a modified half-orange kiln. MC = moisture content (%), VM = volatile material (%), ASH = ash content (%), FC = fixed carbon (%). Values with the same letter are statistically similar, according to Kruskal–Wallis (α = 0.05).

Burns I and III were similar in the carbonization process. It was observed that the burning time was similar with a marked difference in the drying phase of Burn I due to the high moisture content (79%). Phase 4 had the same heating ramp in both Burns (0.07 °C min−1), with a similar maximum temperature of 496 and 497 °C. The heating ramp was slow and long-lasting in all phases, ensuring that the degradation of hemicellulose and cellulose was conducted in a good way and that the volatile material values were acceptable for domestic use; the consequence of not exceeding temperatures of 500 °C is that a fixed carbon content greater than 75% is not obtained. Burn II represented the least energetically favorable Burn; its fast-heating ramps resulted in the highest percentages of volatile material and the lowest percentages of fixed carbon. Zobo et al. [41] evaluated the quality of charcoal made from Triplochiton scleroxylon and Distemonanthus benthamianus species in three types of kilns (Traditional Kiln, Traditional Improved Kiln, and Casamance Kiln), obtaining moisture values greater than 7%, 20–49% volatile material, 1.27–3.78% ash, 39–74.95% fixed carbon, and a higher heating value of 23.02–32.51 MJ kg−1. They conclude that charcoal properties are strongly influenced by the species and the type of kiln used. Moreover, Da Silva et al. [42,43] suggest that species should be pretreated before carbonization to obtain better results, such as lower moisture, reduced volatiles, and increased fixed carbon. According to Barros et al. [43], one way to avoid charcoal heterogeneity is to segregate the raw material before pyrolysis into groups with similar wood properties. The adoption of this technique could improve kiln productivity and charcoal quality, with the latter defined by the type of end use. Compliance with EN export standard 1860-2 [44] requires a moisture content of less than 8%, ash of less than 8%, and fixed carbon of at least 75%, while for domestic consumption without export purposes, it requires a moisture content of less than 10%, ash of less than 8%, fixed carbon greater than 60%, and volatile material of less than 30% [45,46]. According to Singh et al. [47] and Ighalo et al. [48], to obtain a fixed carbon content higher than 80%, carbonization at 600–1100 °C is necessary.

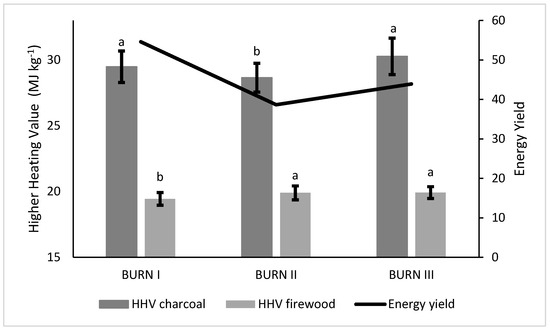

3.3. Energy Efficiency of Charcoal Production

The charcoal produced in Burn III presented the best energy characteristics (p < 0.05). The charcoal had the highest percentage in fixed carbon, the least volatile material (69.3 and 21.8%, respectively), and the highest heating value (30.27 MJ kg−1), while the value of the biomass was 19.4–19.9 MJ kg−1 (Figure 6). The energy yield was highest for Burn I (54.5%), followed by Burn III (43.91%), while Burn II had the lowest value (38.65%). Canal et al. [49] obtained an energy yield of 51.83% with Eucalyptus sp., while the higher charcoal heating value (31 MJ kg−1) produced at different moisture percentages showed no significant difference. The lack of a significant difference in the higher heating value may be attributed to the carbonization process having the same time and final temperature values. Moreover, Sangsuk et al. [50] obtained 40–48% energy efficiency using drum kilns with a heat distribution pipe and tamarind wood and corncob, with a moisture content of 20–24%.

Figure 6.

Higher heating value (MJ kg−1) of firewood and charcoal produced in modified half-orange kiln. Values with the same letter are statistically equal, according to Kruskal–Wallis (α = 0.05).

The kiln energy efficiency was higher in Burn I (33.53%), generating 20.87 MWh in charcoal (Table 2). Leme et al. [51] demonstrate that it is possible to generate electric light using the gases emitted during carbonization, with the steam Rankine cycle conversion technology capable of generating 0.93 MWh per ton of charcoal produced. According to data from the INEGI [52], of the thermal energy consumed in Mexico, the largest proportion is used for cooking food. The main fuel is gas LP gas at 79%, followed by firewood and charcoal at 11%, and natural gas at 7%. These values change for the tropical region, with LP gas being the main fuel at 64.8%, while the use of firewood and charcoal increases drastically to 31.8%, showing that the energy use and forest management of tropical species is of great importance for the region. Based on the MWh charcoal recovered, Burn I was the most suitable for energy recovery. While LP gas generates more energy (12.64 kWh/kg) than charcoal (8.33 kWh/kg), the latter is a renewable fuel and is cheaper to use for people with low incomes.

Table 2.

Energy efficiency in the carbonization process in a modified half-orange kiln.

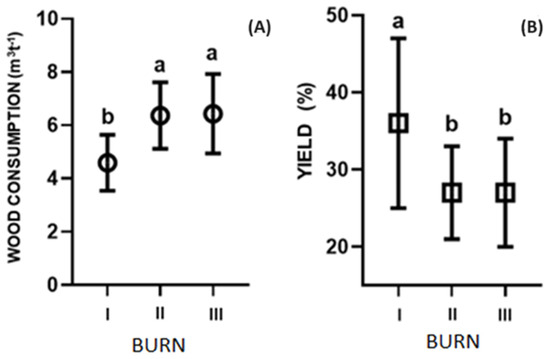

3.4. Charcoal Yield

Burn I had lower fuelwood consumption (4.59 m3t−1) and higher mass yield (36%) compared to Burns II and III, which consumed 6.36 m3t−1 and 6.43 m3t−1, respectively (p < 0.05). This consumption is consistent with the findings of Argueta [53], who reported firewood consumption of 6.5 m3t−1 in a pit-type kiln using Pithecellobium ebano, Haematoxylum brasiletto, and Sargentea gregii. The high consumption of firewood may be related to the high moisture content in the firewood prior to the carbonization process (Figure 7), although the firewood used is pretreated in the storage area to reduce the moisture content; this is affected by the high relative humidity of the environment, which ranges from 74 to 82% [54]. Firewood moisture content showed significant statistical differences among Burns (p < 0.05); Burn I exhibited a higher moisture content due to less time in the storage area, while Burns II and III had more seasoning time in the open air, resulting in a lower moisture content.

Figure 7.

Charcoal production yield in a modified half-orange kiln: (A) cubic meters needed to produce one ton of charcoal; (B) mass yield. Values with the same letter are statistically equal, according to Kruskal–Wallis (α = 0.05).

The operation of masonry kilns consists of burning part of the firewood to provide energy to the system, characterized as autothermal [55]. This operation depends on the moisture content of the firewood; if the firewood is dry, the initial firewood consumption will be low, but if the firewood has a high moisture content, it will increase its consumption by drying, thus affecting the carbonization time as there will be a greater demand for heat/energy in the thermal decomposition of the material with higher moisture [34]. Furthermore, Chandrasekaran et al. [56] noted that the carbonization temperature is a key factor affecting charcoal yield and higher heating value, as an increase in the carbonization temperature will result in a low charcoal yield.

3.5. Cost of Charcoal Production

A cubic meter of firewood placed in the storage yard has a cost of MXN 300 (USD 16.66), so 12 m3 of firewood is needed to make a Burn at a cost of MXN 3600 (USD 200). Production costs include the payment of an assistant and the master charcoal burner, who each receive a salary of MXN 1000 per Burn (USD 55.55), making the total cost to the producer to MXN 2.19, 3.04, and 3.07 per kg (USD 0.12, 0.16, and 0.17 USD) for Burns I, II, and III, respectively. Based on weight, Burn I had the highest charcoal production with 2549 kg, while Burns II and III had lower production at 1839.62 and 1819.60 kg, respectively (Table 3). On the other hand, Burn III had higher energy production at the time of marketing, with a cost of MXN 0.33 (USD 0.018) per MJ. It was observed that having a high yield is economically favorable for the producer; on the other hand, charcoal with a high volatile material content and low higher heating value increases the MJ costs, affecting the consumer. Information from the Government of Mexico [21] indicates that the per-liter price of LP gas in the tropical region is MXN 17.50 (USD 0.97), while charcoal purchased at its production site costs MXN 5 (USD 0.27). Mexico’s tropical region contains the most marginalized areas in the country; for this reason, it is possible that firewood and charcoal use is higher in this region compared to other regions of the country.

Table 3.

Cost of charcoal production, from producer to collector, in a modified half-orange kiln.

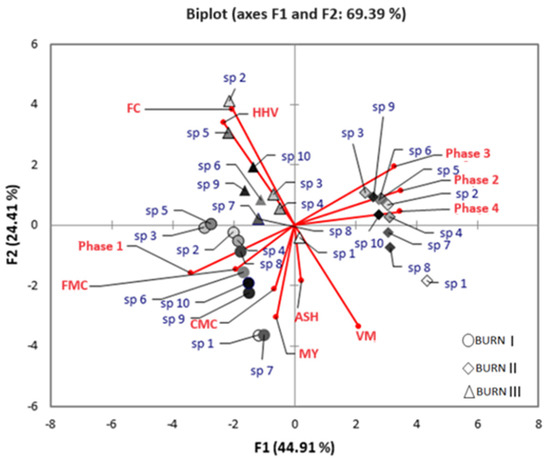

3.6. Principal Component Analysis (PCA)

Principal component analysis revealed a separation of charcoal from each Burn. Burn III was classified within the higher heating value and fixed carbon quadrant. It was noted that certain charcoals from particular species exhibited a significant deviation from the majority. This was particularly evident in the case of species 1 and 8, characterized by an increase in moisture and ash content, while species 3 presented a higher percentage of volatile material without a significant decrease in higher heating value. On the other hand, Burns I and II showed greater heterogeneity in the physicochemical patterns; the species corresponding to Burn II presented an effect towards volatile material, while the species from Burn I were oriented towards yield and volatile material (Figure 8).

Figure 8.

Principal component analysis (PCA) representing the two main components. CMC = charcoal moisture content (%), FMC = firewood moisture content, VM = volatile material (%), FC = fixed carbon (%), ASH = ash content (%), HHV = higher heating value, MY = yield.

The results revealed distinct patterns that suggest a notable effect of some species on the Burn, such as species 3, which presented a high higher heating value, species 1 towards a higher yield, and species 8 towards a higher ash content and moisture content, which indicates the need for future research that delves into the advantages and disadvantages in the production of charcoal in relation to tropical firewood species, an objective that is beyond the scope of this research. Costa et al. [57] failed to determine clusters in a PCA analysis, which they attributed to the fact that temperature was not considered, whereas in the present study, the charcoal groups were differentiated.

Pearson’s correlation analysis showed that volatile material content has a significant negative correlation with fixed carbon and higher heating value, while fixed carbon correlates with the heating ramp of phase 4, so for a higher percentage of fixed carbon, a slow ramp up in phase 4 is necessary. The moisture content of the wood significantly correlates with the four carbonization phases, so if the moisture content is high, the carbonization time will be slow, making the carbonization process last longer. In addition, it was observed that phases 2 and 4 correlate positively with volatile material, so a fast-heating ramp favors the presence of volatile material (Table 4).

Table 4.

Pearson correlation analysis of 11 variables representative of the carbonization process.

The moisture content of the wood influences the charring process in tropical species, since the moisture content was 79.31, 48.99, and 50.68% for Burns I, II, and III, respectively; this percentage corresponds not only to moisture, but also represents the pyrolignic acid content, which is removed from the wood as the charring temperature rises. Therefore, according to Jesus [18], the higher the moisture content, the longer the carbonization time, the higher the temperature, and the longer and slower the heating ramp time needed to remove the pyrolignic acid from the wood. In addition, Hasan et al. [58] stated that during the pyrolysis process, some reactions result in some heavy radicals in the tar re-binding to the charcoal, thereby reducing the tar yield and increasing the charcoal yield; therefore, although Burn I had a very high carbonization process temperature, the firewood used in it had a very high moisture percentage, so the yield was very high since the firewood was not completely carbonized.

4. Conclusions

Wood moisture content influences the carbonization process, increasing the processing time and quality of the charcoal. The moisture content in tropical firewood species favors energy efficiency when charcoal is produced, generating more HHV and MWh per total production. A high moisture content, low temperature, and, consequently, longer processing times increase the charcoal production yield.

Modified half-orange kilns are efficient under different conditions even when the firewood has a high moisture content (>50%). The charcoal produced from tropical species with a high moisture content in modified medium-orange kilns could satisfy the demand for this type of solid biofuel, mainly in the south-central part of the country, with efficiency and quality conditions for this type of product being acceptable for national conditions of use.

Overall, the presented results regarding the quality and yield of charcoal are associated with a specific type of kiln, although the emissions from each burn were not extensively quantified. Future studies should explore different types of kilns and utilize various firewood species, considering spatio-temporal dynamics. These studies should encompass the examination of emissions during carbonization and include a comprehensive life cycle analysis. Additionally, it would be advisable to conduct an in-depth evaluation of the sustainability implications of incorporating controlled firewood drying processes.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/fuels5010001/s1.

Author Contributions

Conceptualization, J.G.-Q., A.C.-P. and R.M.-L.; methodology, J.G.-Q. and A.C.-P.; software, J.G.-Q., A.C.-P. and R.M.-L.; validation, A.C.-P., R.M.-L., J.A.P.-R. and V.N.-R.; formal analysis, J.G.-Q., A.C.-P., R.M.-L., J.A.P.-R. and V.N.-R.; resources, A.C.-P., R.M.-L., J.A.P.-R. and C.W.; data curation, J.G.-Q. and A.C.-P.; writing—original draft preparation, J.G.-Q., A.C.-P. and R.M.-L.; writing—review and editing, J.G.-Q., A.C.-P., R.M.-L., J.A.P.-R. and C.W.; visualization, A.C.-P., J.A.P.-R. and C.W.; supervision, A.C.-P. and R.M.-L.; project administration, A.C.-P.; funding acquisition, A.C.-P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available in Supplementary Material.

Acknowledgments

We thank CONAHCYT for the student scholarship.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Broadhead, J. Revisión de Las Estimaciones de FAOSTAT Relativas al Combustible de Madera. Unasylva 2002, 53, 41–45. [Google Scholar]

- FAO. The Charcoal Transition: Greening the Charcoal Value Chain to Mitigate Climate Change and Improve Local Livelihoods; FAO: Roma, Italy, 2017; ISBN 9789251096802. [Google Scholar]

- Hasan, M.; Haseli, Y.; Karadogan, E. Correlations to Predict Elemental Compositions and Heating Value of Torrefied Biomass. Energies 2018, 11, 2443. [Google Scholar] [CrossRef]

- Pereira, E.G.; Fauller, H.; Magalhães, M.; Guirardi, B.; Martins, M.A. Potential Use of Wood Pyrolysis Coproducts: A Review. Environ. Prog. Sustain. Energy 2022, 41, e13705. [Google Scholar] [CrossRef]

- Wilk, M.; Magdziarz, A.; Kalemba, I.; Gara, P. Carbonisation of Wood Residue into Charcoal during Low Temperature Process. Renew. Energy 2016, 85, 507–513. [Google Scholar] [CrossRef]

- Lima, M.D.R.; Patrício, E.P.S.; Junior, U.D.O.B.; de Assis, M.R.; Xavier, C.N.; Bufalino, L.; Trugilho, P.F.; Hein, P.R.G.; de Paula Protásio, T. Logging Wastes from Sustainable Forest Management as Alternative Fuels for Thermochemical Conversion Systems in Brazilian Amazon. Biomass Bioenergy 2020, 140, 105660. [Google Scholar] [CrossRef]

- Haag, V.; Zemke, V.T.; Lewandrowski, T.; Zahnen, J.; Hirschberger, P.; Bick, U.; Koch, G. The European Charcoal Trade. IAWA J. 2020, 41, 463–477. [Google Scholar] [CrossRef]

- Arias-Chalico, T. Situación Actual y Escenarios Para el Desarrollo de Biocombustibles Sólidos en México Hacia 2024 y 2030; Red Mexicana de Bioenergía: Morelia, Mexico, 2018. [Google Scholar]

- FAO. Forestry Production and Trade. Available online: https://unece.org/forests/data-forest-products-production-and-trade (accessed on 22 September 2023).

- SEMERNAT—Secretaría de Medio Ambiente y Recursos Naturales. Anuario Estadístico de La Producción Agrícola y Ganadera 2016. Sist. Integr. Estadística Agrar. 2016, 1, 1–156. [Google Scholar]

- Gobierno de Mexico Productores de Carbón Vegetal. Available online: https://www.economia.gob.mx/datamexico/es/profile/occupation/productores-de-carbon-vegetal (accessed on 3 December 2023).

- Dzurenda, L.; Banski, A. Influence of Moisture Content of Combusted Wood on the Thermal Efficiency of a Boiler. Arch. Thermodyn. 2017, 38, 63–74. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, C.; Ssempijja, I.; Lubwama, H. Thermal and Mechanical Characteristics of Local Firewood Species and Resulting Charcoal Produced by Slow Pyrolysis. Biomass Convers. Biorefin. 2021, 13, 6689–6704. [Google Scholar] [CrossRef]

- Kwiatkowski, D.; Słowiński, K.; Kożuch, A. Analysis of correct firewood seasoning by selected homeowners in the podkarpacie (Subcarpathian) region. Acta Silvestria 2019, 56, 37–47. [Google Scholar] [CrossRef]

- Price-Allison, A.; Lea-Langton, A.R.; Mitchell, E.J.S.; Gudka, B.; Jones, J.M.; Mason, P.E.; Williams, A. Emissions Performance of High Moisture Wood Fuels Burned in a Residential Stove. Fuel 2019, 239, 1038–1045. [Google Scholar] [CrossRef]

- Castellanos-Potenciano, B.P.; Carrillo, N.; Hernández, A. El comercio del carbón vegetal y su transitar hacia la bioeconomía en México. C3-BIOECONOMY Circ. Sustain. Bioeconomy 2021, 2, 55–68. [Google Scholar] [CrossRef]

- Bailis, R.; Rujanavech, C.; Dwivedi, P.; de Oliveira Vilela, A.; Chang, H.; de Miranda, R.C. Innovation in Charcoal Production: A Comparative Life-Cycle Assessment of Two Kiln Technologies in Brazil. Energy Sustain. Dev. 2013, 17, 189–200. [Google Scholar] [CrossRef]

- Surup, G.R.; Trubetskaya, A.; Tangstad, M. Charcoal as an Alternative Reductant in Ferroalloy Production: A Review. Processes 2020, 8, 1432. [Google Scholar] [CrossRef]

- Sola, P.; Schure, J.; Eba’a Atyi, R.; Gumbo, D.; Okeyo, I.; Awono, A. Woodfuel Policies and Practices in Selected Countries in Sub-Saharan Africa—A Critical Review. Bois For. Trop. 2019, 340, 27–41. [Google Scholar]

- Chidumayo, E.N.; Gumbo, D.J. The Environmental Impacts of Charcoal Production in Tropical Ecosystems of the World: A Synthesis. Energy Sustain. Dev. 2013, 17, 86–94. [Google Scholar] [CrossRef]

- Gobierno de Mexico Infografía Cocción de Alimentos. Available online: https://www.gob.mx/conuee/documentos/infografia-coccion-de-alimentos (accessed on 20 November 2023).

- Nigatu, G.; Bekele, T.; Fantu, W. Impact of Moisture Content and Mound Size on Recovery and Quality of Charcoal from Prosopis Juliflora. DC. in Rift Valley of Ethiopia. Afr. J. Plant Sci. Biotechnol. 2012, 6, 66–72. [Google Scholar]

- SEMARNAT—Secretaría de Medio Ambiente y Recursos Naturales. Documento Tecnico Unificado Ejido Ncpe Rio Escondido; SEMARNAT: Bacalar, Mexico, 2015; pp. 1–167. [Google Scholar]

- García-Quezada, J.; Musule-Lagunes, R.; Prieto-Ruíz, J.A.; Vega-Nieva, D.J.; Carrillo-Parra, A. Evaluation of Four Types of Kilns Used to Produce Charcoal from Several Tree Species in Mexico. Energies 2023, 16, 333. [Google Scholar] [CrossRef]

- ASTM D1762-84; Standard Test Method for Chemical Analysis of Wood Charcoal. ASTM: West Conshohocken, PA, USA, 2021; pp. 1–2.

- Basu, P.; Rao, S.; Dhungana, A. An Investigation into the Effect of Biomass Particle Size on Its Torrefaction. Can. J. Chem. Eng. 2013, 91, 466–474. [Google Scholar] [CrossRef]

- Elyounssi, K.; Blin, J.; Halim, M. High-Yield Charcoal Production by Two-Step Pyrolysis. J. Anal. Appl. Pyrolysis 2010, 87, 138–143. [Google Scholar] [CrossRef]

- UNE-EN 18125; Biocombustibles Sólidos Determinación Del Poder Calorífico. UNE: Madrid, Spain, 2018.

- Lê, S.; Josse, J.; Rennes, A.; Husson, F. FactoMineR: An R Package for Multivariate Analysis. J. Stat. Softw. 2008, 25, 1–18. [Google Scholar] [CrossRef]

- Costa, A.C.P.R.; Ramalho, F.M.G.; Ribeiro, L.C.; Trugilho, P.F.; Hein, P.R.G. Classification of Commercial Charcoal for Domestic Use by near Infrared Spectroscopy. Biomass Bioenergy 2019, 127, 105280. [Google Scholar] [CrossRef]

- Wang, S.; Dai, G.; Yang, H.; Luo, Z. Lignocellulosic Biomass Pyrolysis Mechanism: A State-of-the-Art Review. Prog. Energy Combust. Sci. 2017, 62, 33–86. [Google Scholar] [CrossRef]

- Font Palma, C. Modelling of Tar Formation and Evolution for Biomass Gasification: A Review. Appl. Energy 2013, 111, 129–141. [Google Scholar] [CrossRef]

- Missio, A.L.; Mattos, B.D.; Gatto, D.A.; de Lima, E.A. Thermal Analysis of Charcoal from Fast-Growing Eucalypt Wood: Influence of Raw Material Moisture Content. J. Wood Chem. Technol. 2014, 34, 191–201. [Google Scholar] [CrossRef]

- Jesus, M.S.; Napoli, A.; Trugilho, P.F.; Abreu Júnior, Á.A.; Martinez, C.L.M.; Freitas, T.P. Energy and Mass Balance in the Pyrolysis Process of Eucalyptus Wood. Cerne 2018, 24, 288–294. [Google Scholar] [CrossRef]

- Zola, F.C.; Colmenero, J.C.; Aragão, F.V.; Rodrigues, T.; Junior, A.B. Multicriterial Model for Selecting a Charcoal Kiln. Energy 2020, 190, 116377. [Google Scholar] [CrossRef]

- Assis, M.R.; Brancheriau, L.; Napoli, A.; Trugilho, P.F. Factors Affecting the Mechanics of Carbonized Wood: Literature Review. Wood Sci. Technol. 2016, 50, 519–536. [Google Scholar] [CrossRef]

- Guo, Y.; Bustin, R.M. FTIR Spectroscopy and Reflectance of Modern Charcoals and Fungal Decayed Woods: Implications for Studies of Inertinite in Coals. Int. J. Coal Geol. 1998, 37, 29–53. [Google Scholar] [CrossRef]

- Bustos-Vanegas, J.D.; Arêdes, M.; Gomes, A.; Mellmann, J. Experimental Characterization of Self-Heating Behavior of Charcoal from Eucalyptus Wood. Fuel 2019, 244, 412–418. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels Production through Biomass Pyrolysis—A Technological Review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Ronsse, F.; Nachenius, R.W.; Prins, W. Carbonization of Biomass; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9780444632906. [Google Scholar]

- Mfomo, J.Z.; Biwolé, A.B.; Fongzossie, E.F.; Ekassi, G.T.; Hubert, D.; Ducenne, H.; Tamba, J.G.; Mouangue, R. Carbonization Techniques and Wood Species Influence Quality Attributes of Charcoals Produced from Industrial Sawmill Residues in Eastern Cameroon. Bois For. Trop. 2020, 345, 63–72. [Google Scholar] [CrossRef]

- da Silva, C.M.S.; Carneiro, A.D.C.O.; Vital, B.R.; Figueiró, C.G.; Fialho, L.d.F.; de Magalhães, M.A.; Carvalho, A.G.; Cândido, W.L. Biomass Torrefaction for Energy Purposes—Definitions and an Overview of Challenges and Opportunities in Brazil. Renew. Sustain. Energy Rev. 2018, 82, 2426–2432. [Google Scholar] [CrossRef]

- Barros, J.A.S.; Krause, M.C.; Lazzari, E.; Bjerk, T.R.; do Amaral, A.L.; Caramão, E.B.; Krause, L.C. Chromatographic Characterization of Bio-Oils from Fast Pyrolysis of Sugar Cane Residues (Straw and Bagasse) from Four Genotypes of the Saccharum Complex. Microchem. J. 2018, 137, 30–36. [Google Scholar] [CrossRef]

- EN 1860-2:2005; Applicances, Solid Fuels and Firelighters for Barbecueing—Part 2: Barbecue Charcoal and Barbecue Charcoal Briquettes—Requiriments and Test Methods. AENOR: Madrid, Spain, 2005.

- FAO. Métodos Simples Para Fabricar Carbón Vegetal; FAO: Roma, Italy, 1983. [Google Scholar]

- Antal, M.J.; Grønli, M. The Art, Science, and Technology of Charcoal Production. Ind. Eng. Chem. Res. 2003, 42, 1619–1640. [Google Scholar] [CrossRef]

- Singh, A.K.; Singh, R.; Sinha, O.P. Characterization of Charcoals Produced from Acacia, Albizia and Leucaena for Application in Ironmaking. Fuel 2022, 320, 123991. [Google Scholar] [CrossRef]

- Ighalo, J.O.; Eletta, O.A.A.; Adeniyi, A.G. Biomass Carbonisation in Retort Kilns: Process Techniques, Product Quality and Future Perspectives. Bioresour. Technol. Rep. 2022, 17, 100934. [Google Scholar] [CrossRef]

- Canal, W.D.; Carvalho, A.; Figueiró, C.; Carneiro, A.; Fialho, L.; Donato, D.B. Impact of Wood Moisture in Charcoal Production and Quality. Floresta Ambiente 2020, 27, 1–7. [Google Scholar] [CrossRef]

- Sangsuk, S.; Buathong, C.; Suebsiri, S. High-Energy Conversion Efficiency of Drum Kiln with Heat Distribution Pipe for Charcoal and Biochar Production. Energy Sustain. Dev. 2020, 59, 1–7. [Google Scholar] [CrossRef]

- Leme, M.M.V.; Venturini, O.J.; Lora, E.E.S.; Rocha, M.H.; Luz, F.C.; de Almeida, W.; de Moura, D.C.; de Moura, L.F. Electricity Generation from Pyrolysis Gas Produced in Charcoal Manufacture: Technical and Economic Analysis. J. Clean. Prod. 2018, 194, 219–242. [Google Scholar] [CrossRef]

- INEGI. Encuesta Nacional Sobre Consumo de Energéticos en Viviendas Particulares (ENCEVI); INEGI: Aguascalientes, Mexico, 2018. [Google Scholar]

- Argueta Spínola, C. Descripción y Análisis de Dos Métodos de Producción de Carbón Vegetal en el Estado de Tamaulipas. In Tesis Licenciatura; Universidad Autónoma Chapingo: Texcoco, Mexico, 2006. [Google Scholar]

- Weather-Atlas. Available online: https://www.weather-atlas.com/es/mexico/chetumal (accessed on 26 November 2023).

- Sparrevik, M.; Cornelissen, G.; Sparrevik, M.; Adam, C.; Martinsen, V.; Cornelissen, G.; Cornelissen, G. Emissions of Gases and Particles from Charcoal/Biochar Production in Rural Areas Using Medium-Sized Traditional and Improved “Retort” Kilns. Biomass Bioenergy 2015, 72, 65–73. [Google Scholar] [CrossRef]

- Chandrasekaran, A.; Subbiah, S.; Bartocci, P.; Yang, H.; Fantozzi, F. Carbonization Using an Improved Natural Draft Retort Reactor in India: Comparison between the Performance of Two Woody Biomasses, Prosopis Juliflora and Casuarina Equisetifolia. Fuel 2021, 285, 119095. [Google Scholar] [CrossRef]

- da Costa, P. La Producción del Carbón Vegetal. In Enérgia—Investigaciones en América del Sur; Chiacchiaring, H., Ed.; Universidad Nacional del Sur: Bahia Blanca, Argentina; Ediuns: Bahia Blanca, Argentina, 2017; pp. 69–88. [Google Scholar]

- Hasan, M.M.; Hu, X.; Gunawan, R.; Li, C.Z. Pyrolysis of Large Mallee Wood Particles: Temperature Gradients within a Pyrolysing Particle and Effects of Moisture Content. Fuel Process. Technol. 2017, 158, 163–171. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).