Corrosion Effect of Biodiesel-Diesel Blend on Different Metals/Alloy as Automotive Components Materials

Abstract

1. Introduction

Problem Statement

2. Materials and Methods

2.1. Materials

2.2. Corrosion Experiment

2.3. Corrosion Analysis

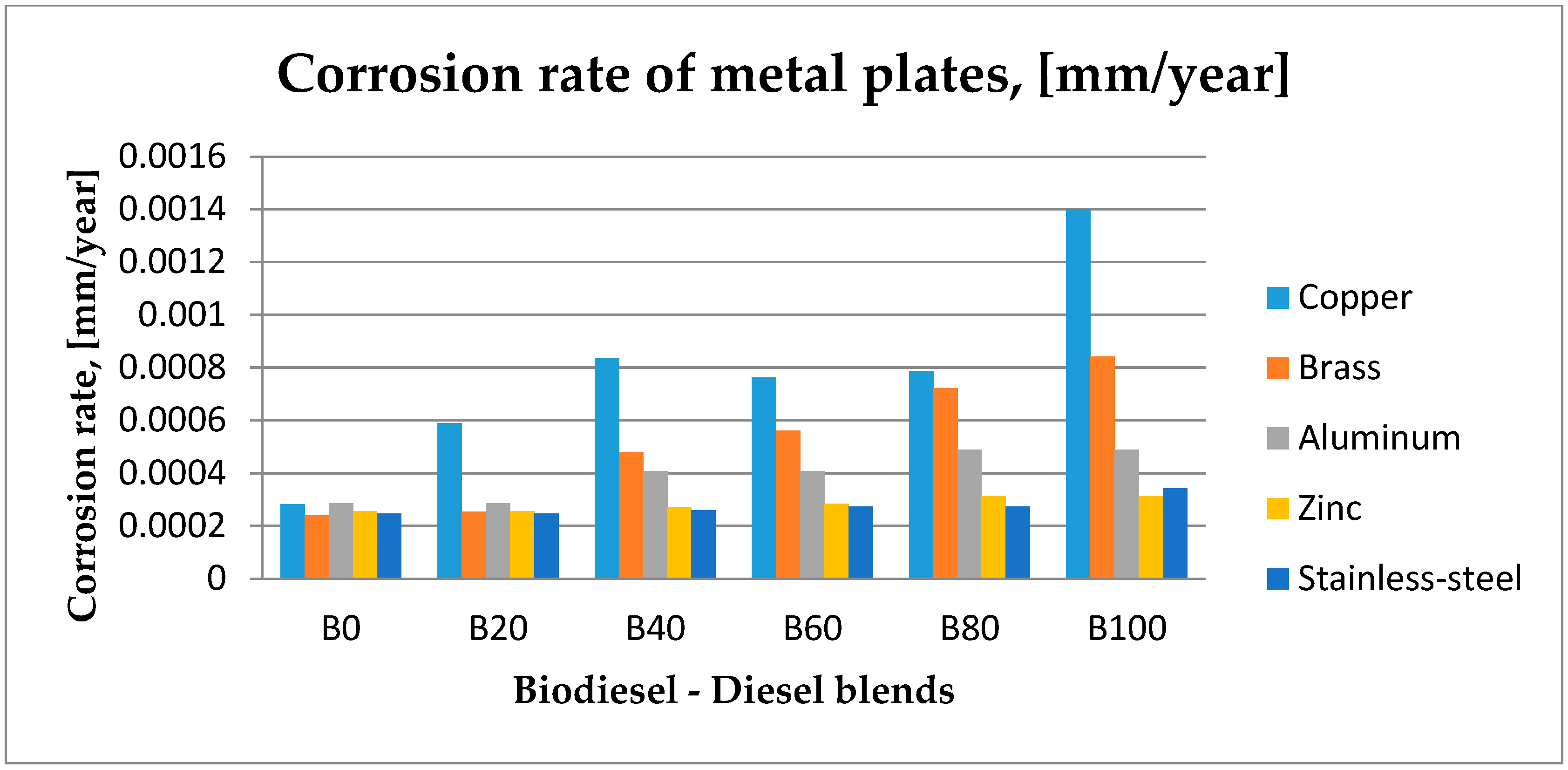

3. Results

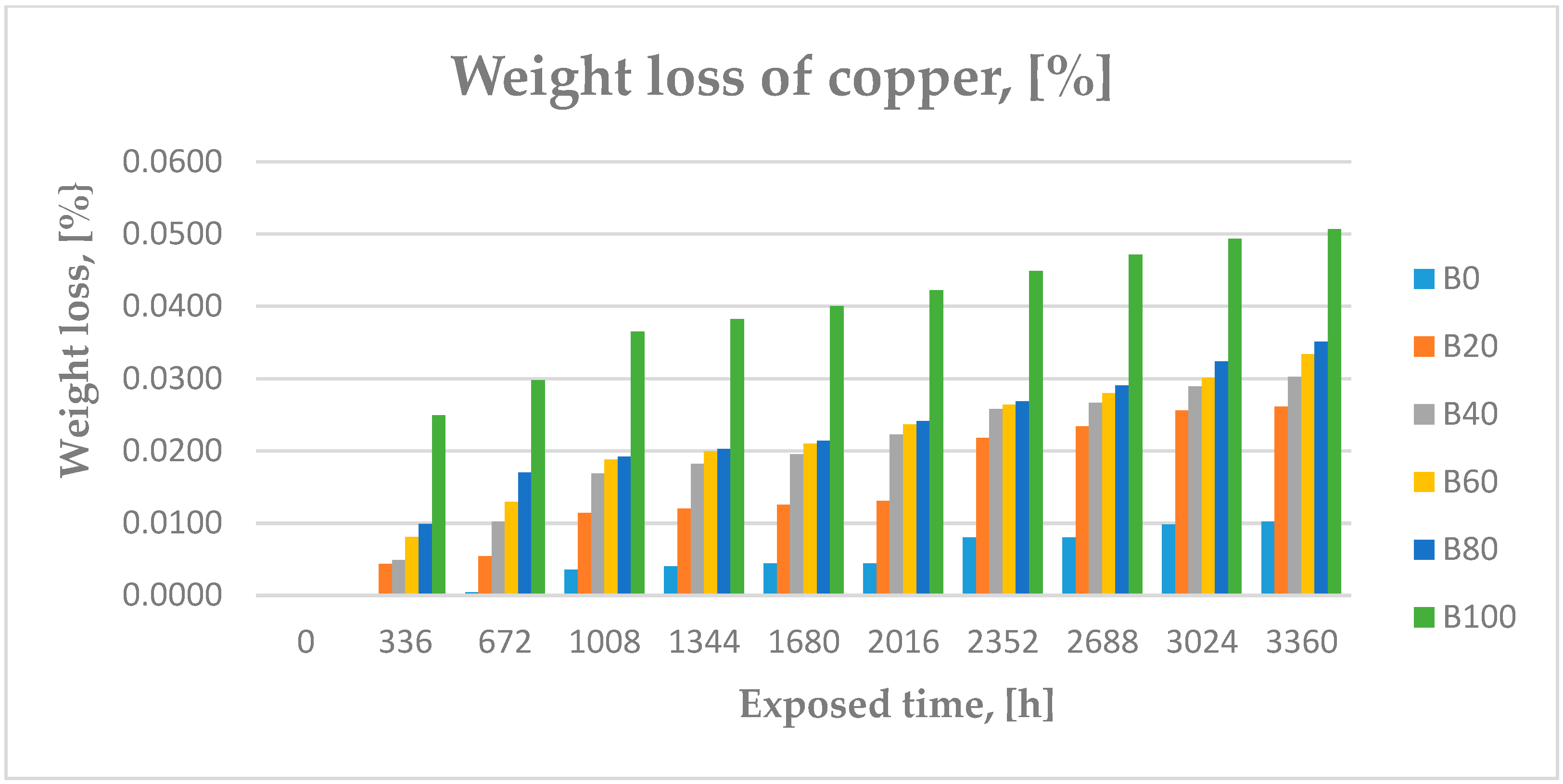

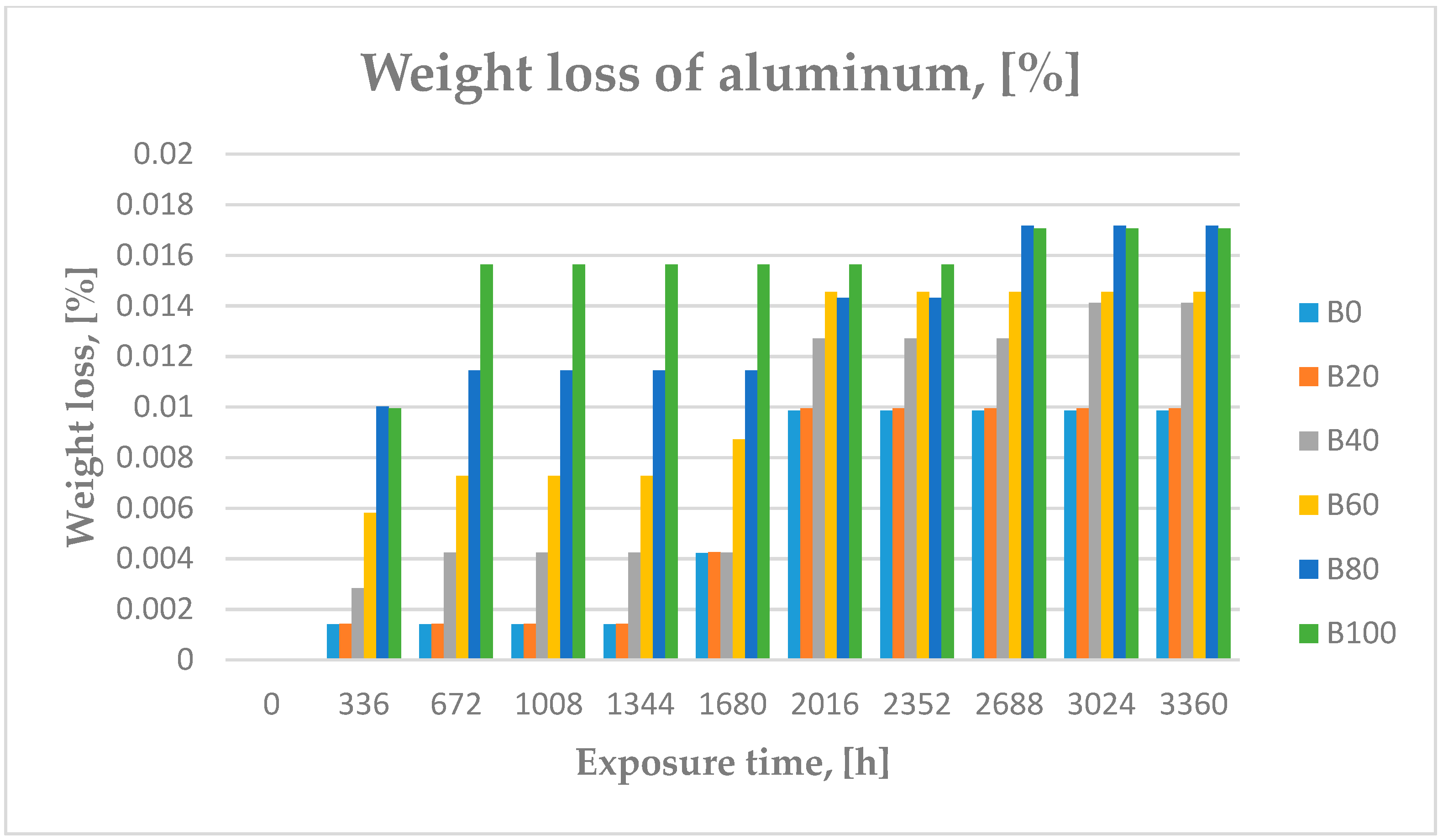

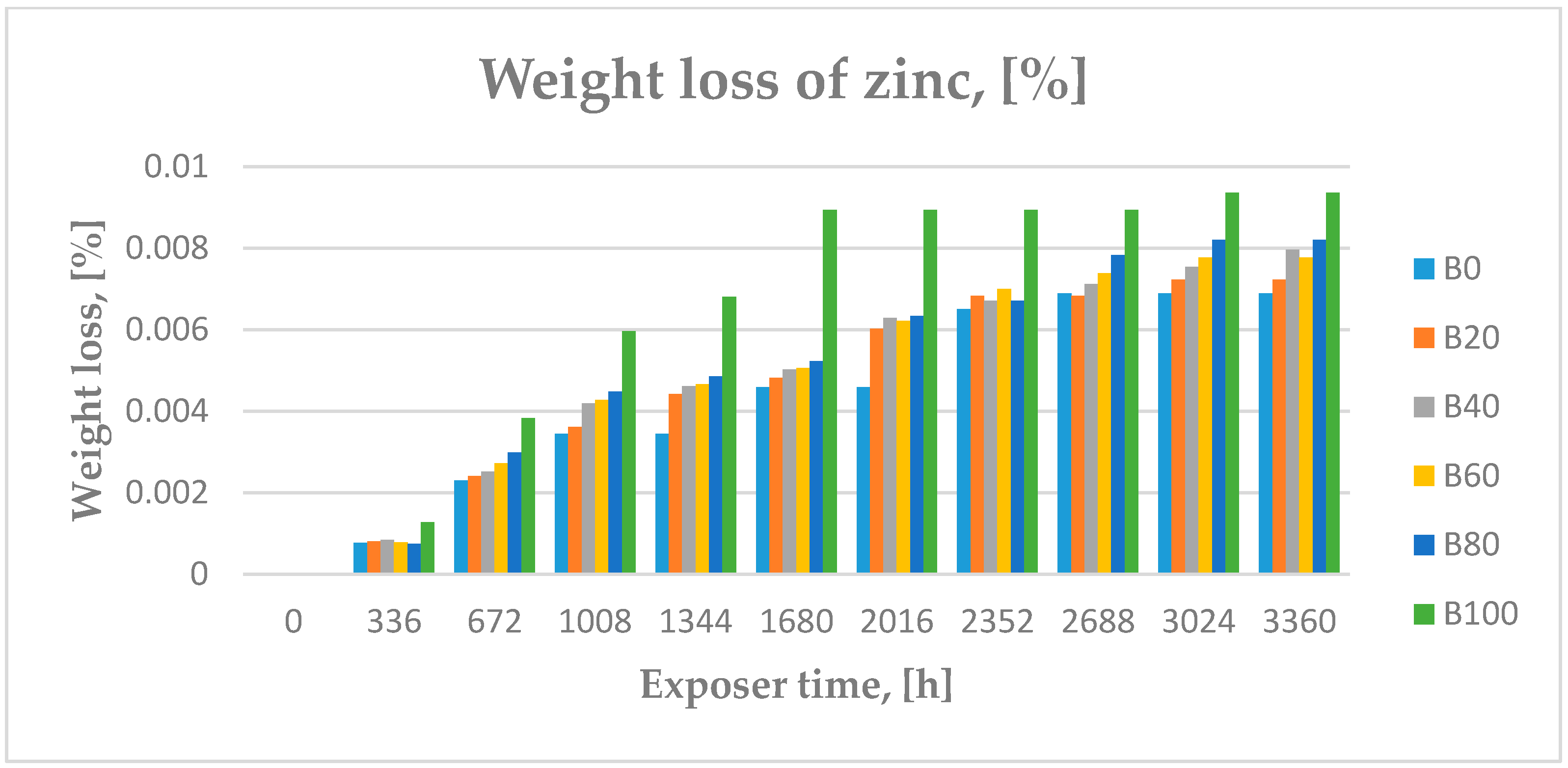

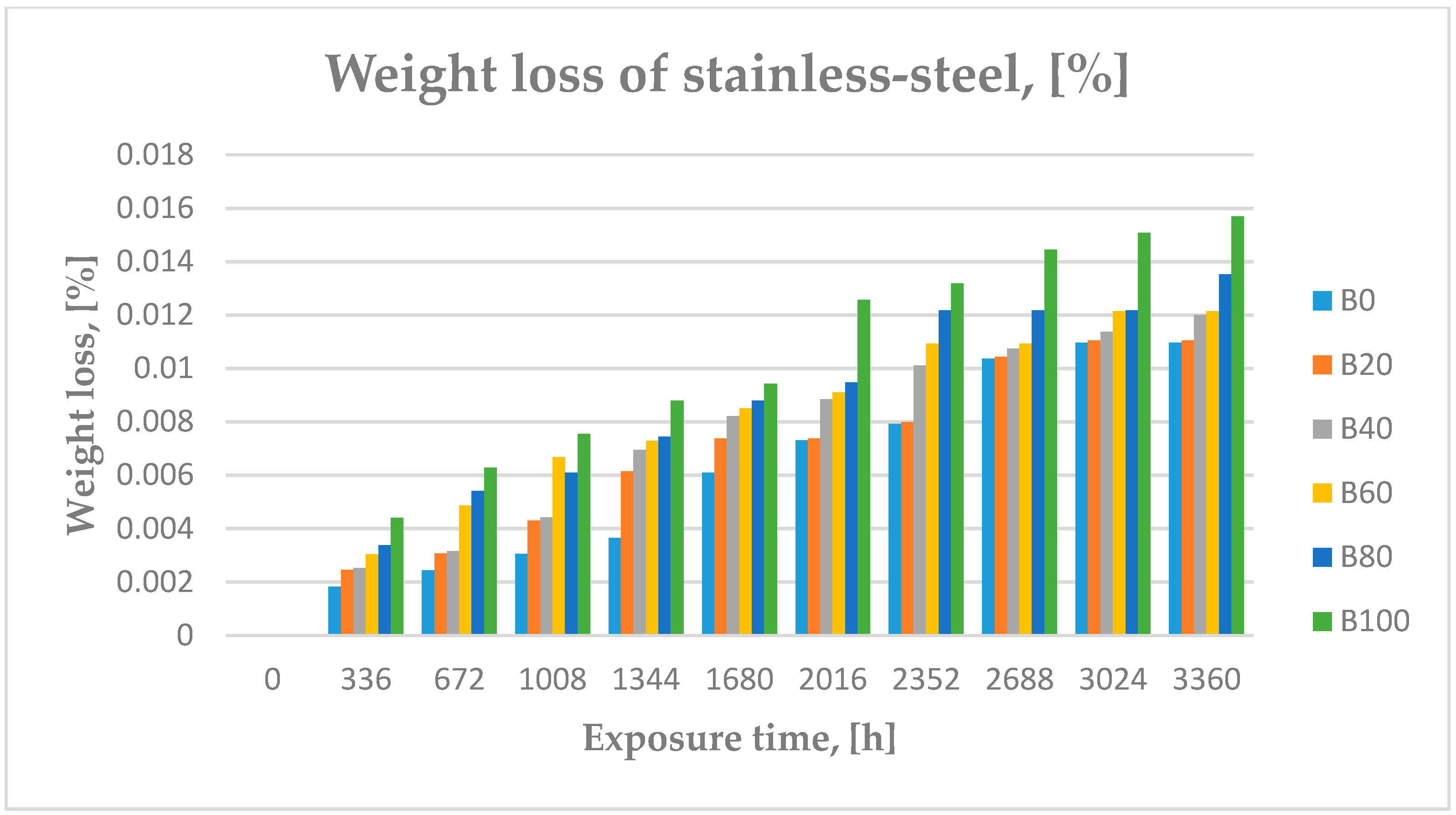

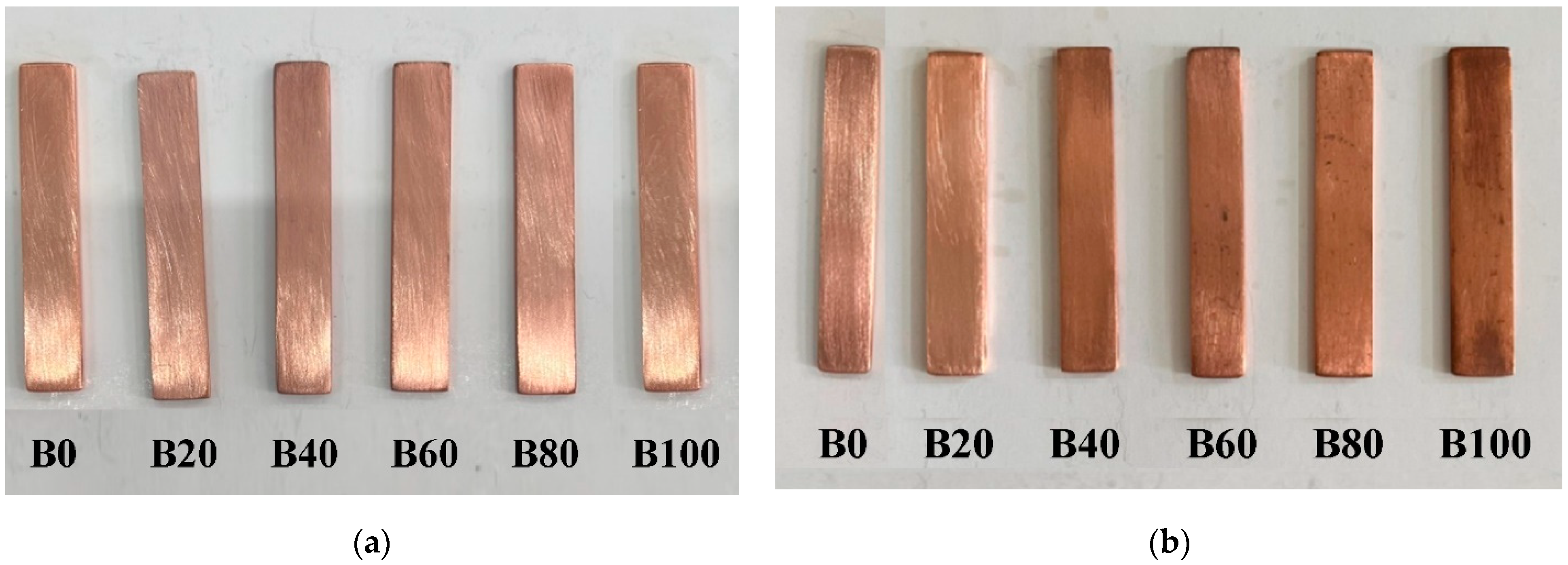

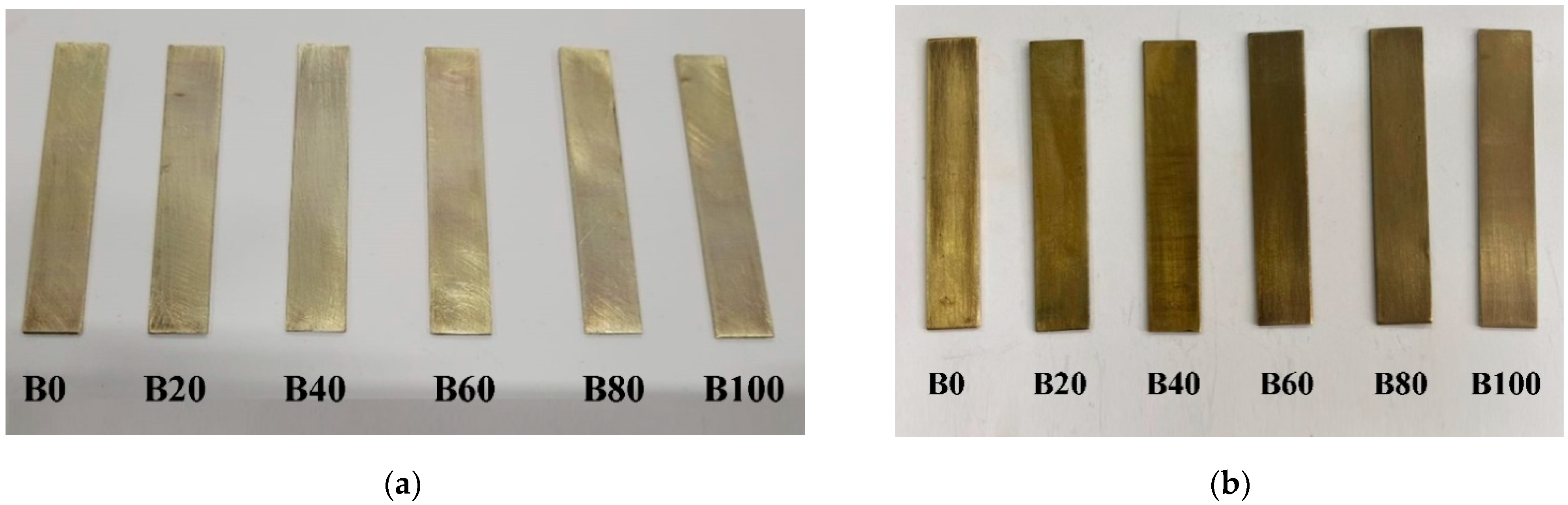

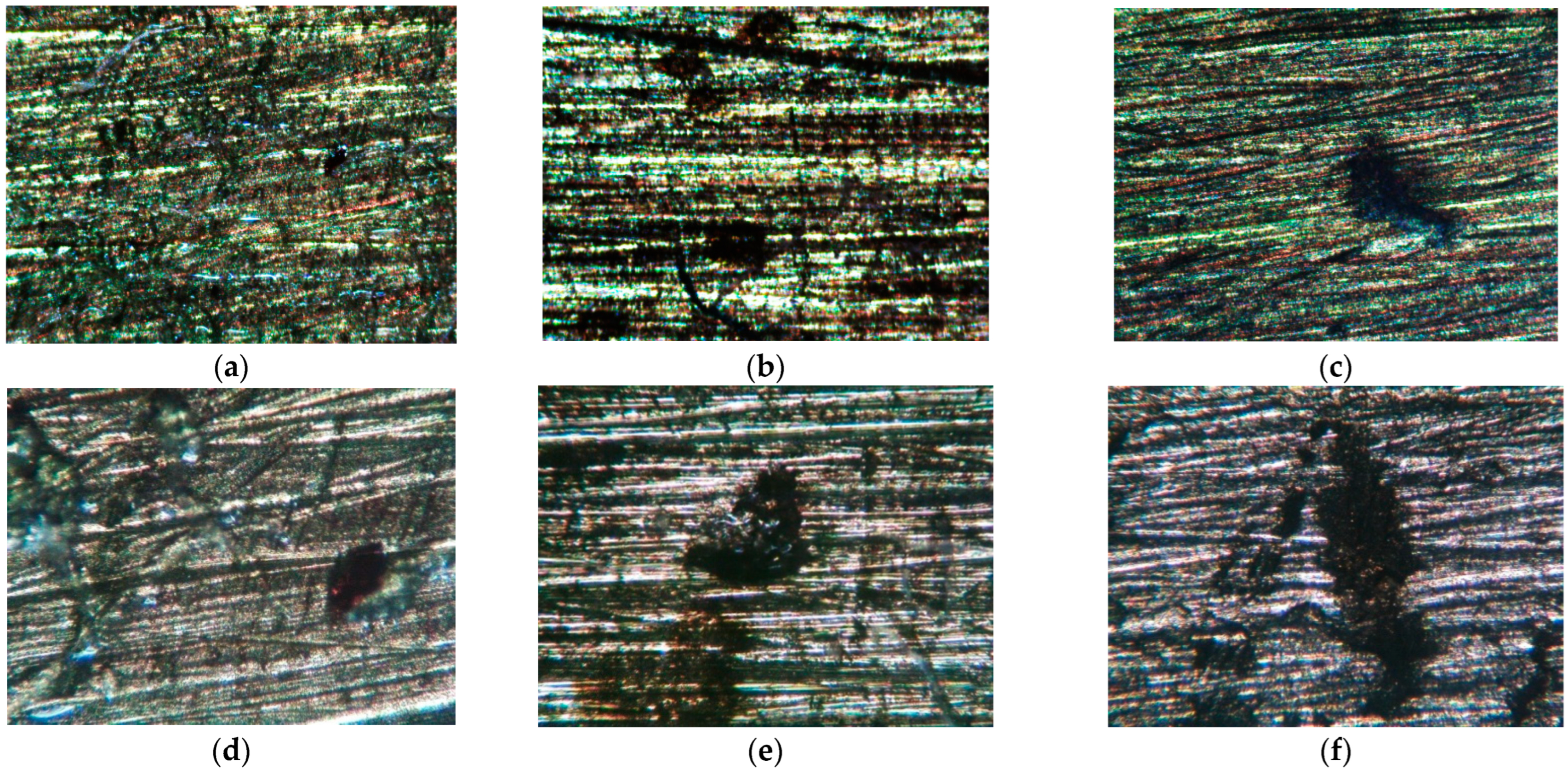

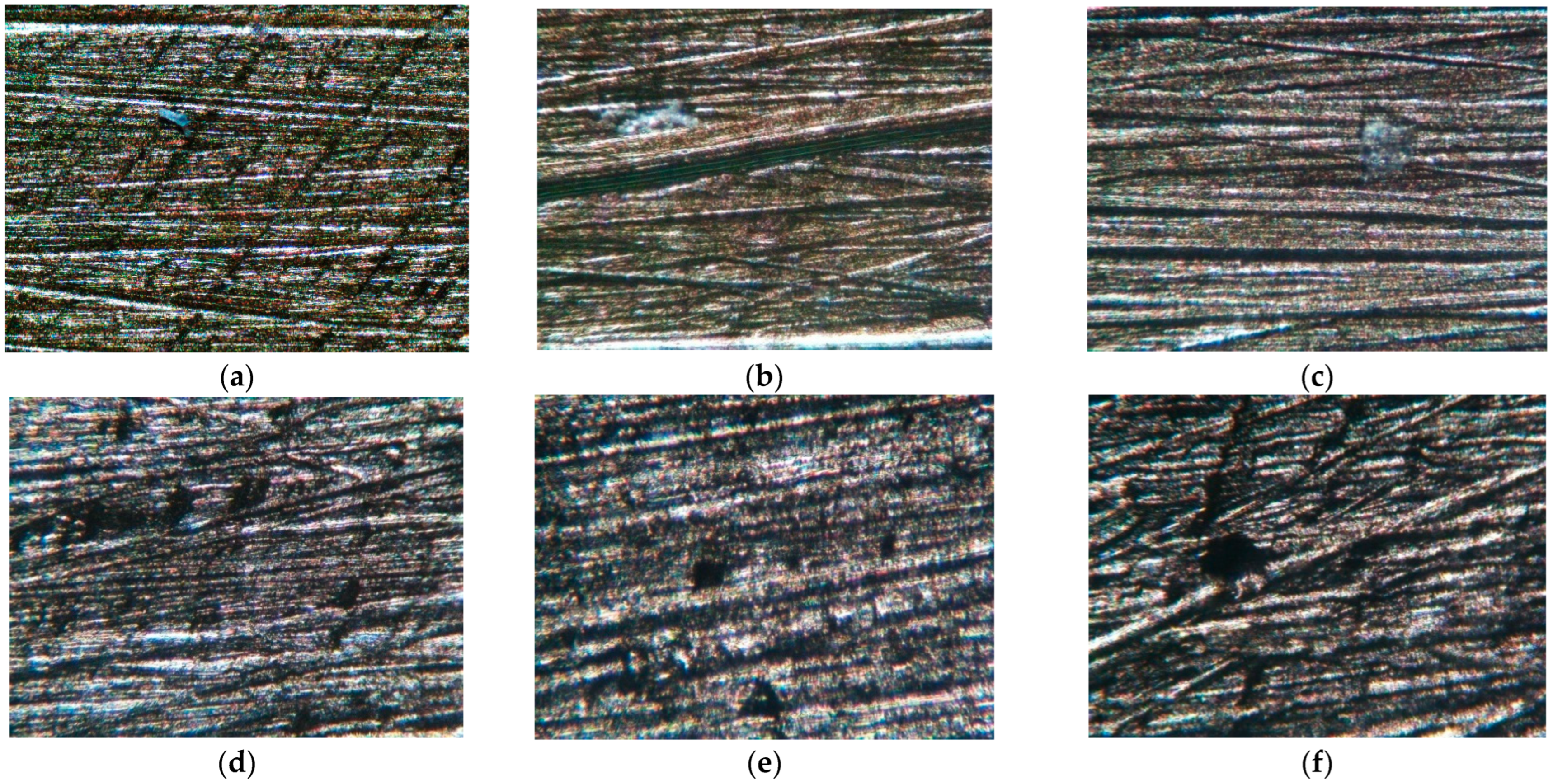

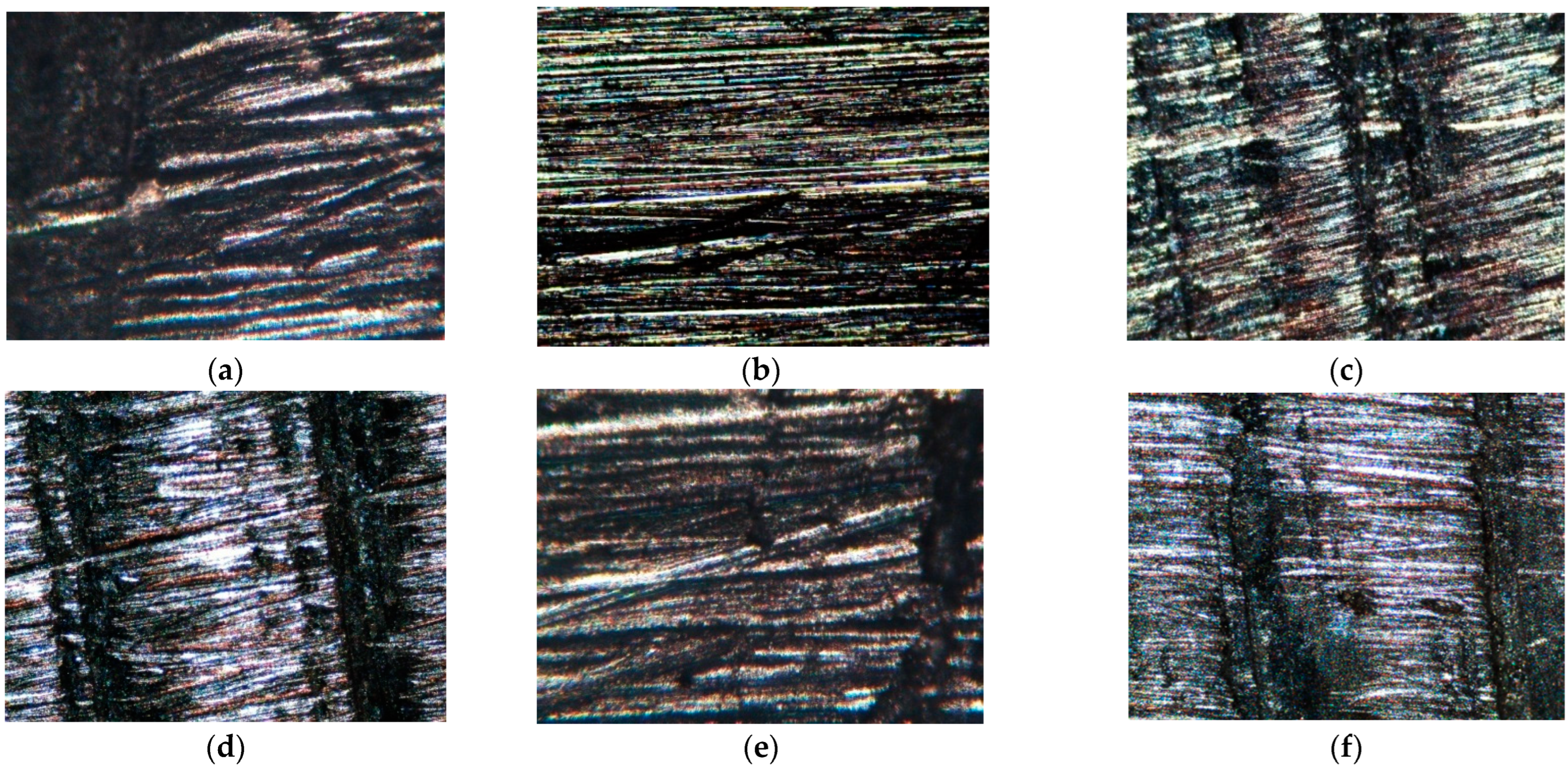

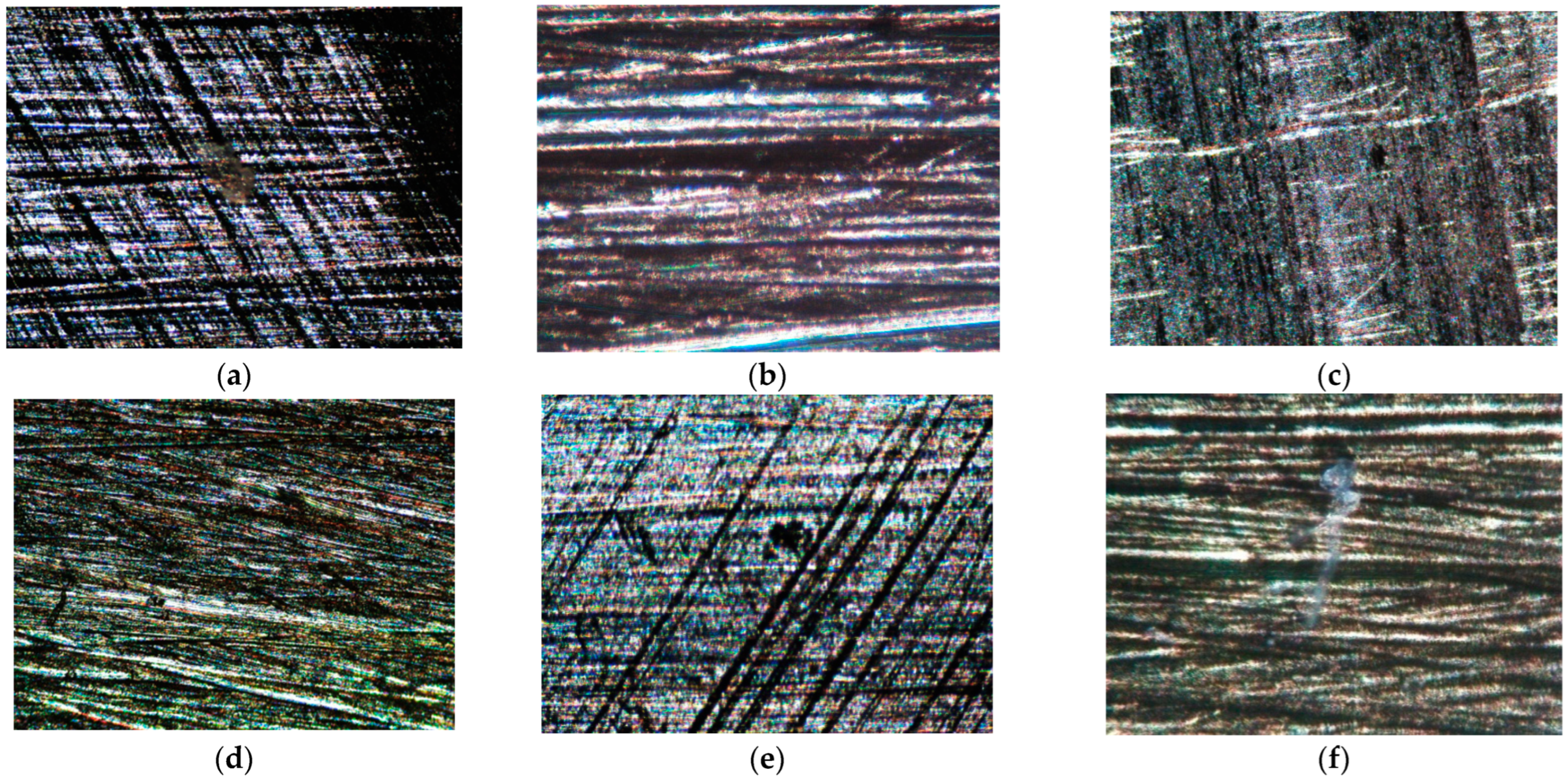

Changes in Mass and Appearance of Metalsplates

4. Discussion

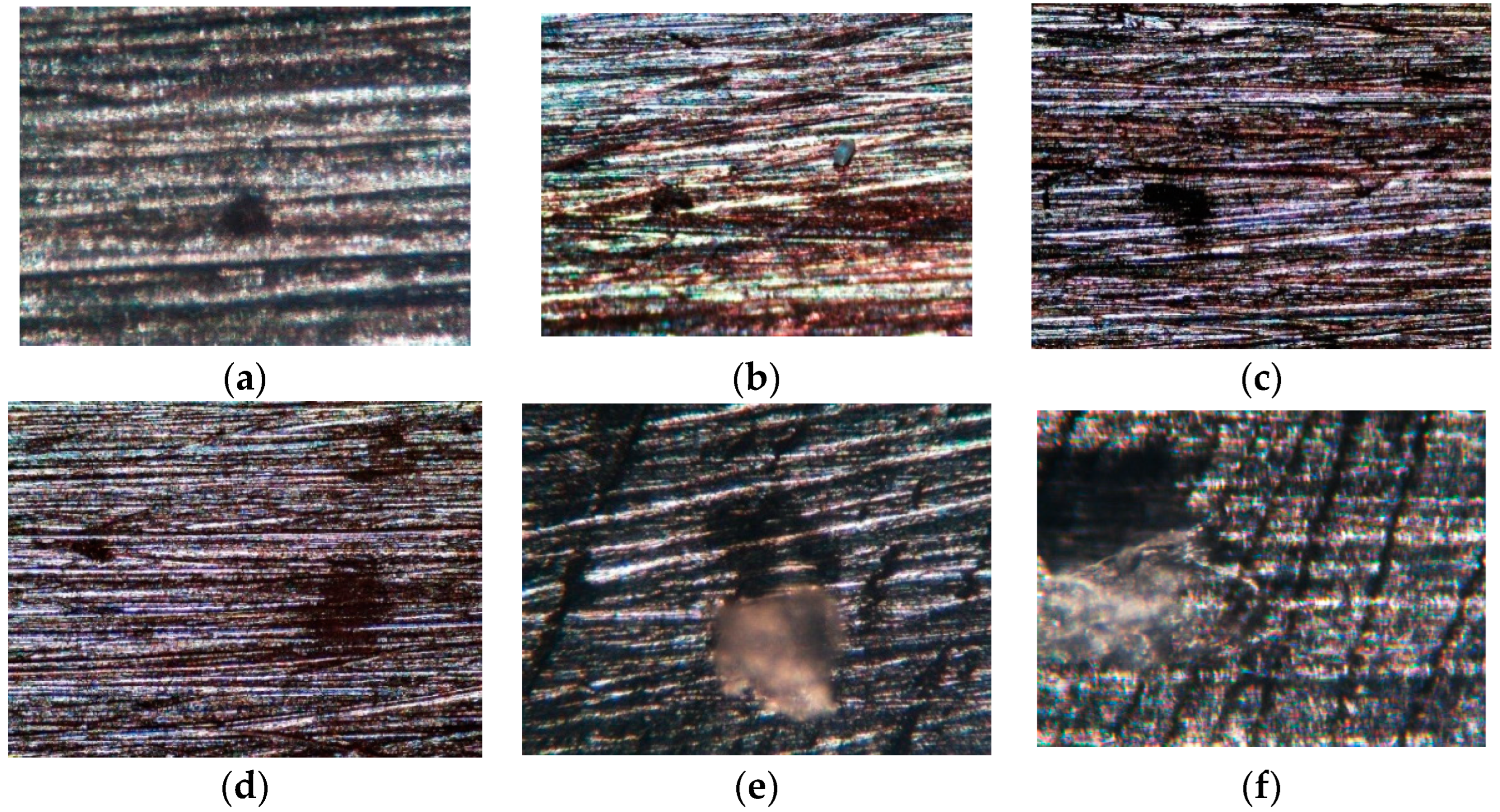

4.1. Mass Loss and Changes in Surface Morphology

4.2. Changes in Biodiesel Properties

5. Conclusions

- Copper and brass are susceptible to corrosion in biodiesel-diesel blends, whereas aluminum, zinc, and stainless steel exhibit high corrosion resistance.

- The corrosion rate of copper and brass in biodiesel was, 5 and 3.5 times faster than that in diesel fuel, respectively. On the other side, the corrosion effects of biodiesel on aluminum, zinc, and stainless steel were minor, close to those of diesel.

- After 3360 h of immersion test, pitting corrosion was observed from optical photographs of metal surfaces, especially on higher biodiesel concentrations.

- Samples with lower biodiesel content exhibited a moderate decrease in resistance to degradation.

- With higher biodiesel content, degradation, as indicated by the TAN, became more pronounced, yet even in these circumstances, the maximum values were below the standard of 0.5 mg KOH/g.

- -

- The findings can guide automotive manufacturers in selecting appropriate materials for components that come into contact with biodiesel-diesel blends. For instance, if certain alloys are found to resist corrosion better than others, they can be preferred for specific applications.

- -

- The research can aid in optimizing biodiesel-diesel blend formulations to minimize corrosion. By understanding which metals/alloys are more susceptible to corrosion, fuel producers can adjust the blend composition or introduce additives to reduce corrosive effects.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aghbashlo, M.; Tabatabaei, M.; Mohammadi, P.; Khoshnevisan, B.; Rajaeifar, M.A.; Pakzad, M. Neat diesel beats waste-oriented biodiesel from the exergoeconomic and exergoenvironmental point of views. Energy Convers. Manag. 2017, 148, 1–15. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Tabatabaei, M.; Aghbashlo, M.; Khanali, M.; Demirbas, A. A comprehensive review on the environmental impacts of diesel/biodiesel additives. Energy Convers. Manag. 2018, 174, 579–614. [Google Scholar] [CrossRef]

- Takase, M.; Pappoe, A.N.M.; Afrifa, E.A.; Miyittah, M. High performance heterogeneous catalyst for biodiesel production from non-edible oil. Renew. Energy Focus 2018, 25, 24–30. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Tabatabaei, M.; Khalife, E.; Roodbar Shojaei, T.; Dadak, A. Exergoeconomic analysis of a DI diesel engine fueled with diesel/biodiesel (B5) emulsions containing aqueous nano cerium oxide. Energy 2018, 149, 967–978. [Google Scholar] [CrossRef]

- Hoang, A.T.; Pham, V.V. A study of emission characteristic, deposits, and lubrication oil degradation of a diesel engine running on preheated vegetable oil and diesel oil. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 611–625. [Google Scholar] [CrossRef]

- Hoang, A.T.; Pham, V.V. Impact of jatropha oil on engine performance, emission characteristics, deposit formation, and lubricating oil degradation. Combust. Sci. Technol. 2019, 191, 504–519. [Google Scholar] [CrossRef]

- Chandran, D.; Ng, H.K.; Lau, H.L.N.; Gan, S.; Choo, Y.M. Investigation of the effects of palm biodiesel dissolved oxygen and conductivity on metal corrosion and elastomer degradation under novel immersion method. Appl. Therm. Eng. 2016, 104, 294–308. [Google Scholar] [CrossRef]

- Yeşilyurt, M.K.; Öner, İ.V.; Yilmaz, E.Ç. Biodiesel Induced Corrosion and Degradation: A Review. Pamukkale Üniv. Mühendislik Bilim. Derg. 2019, 25, 60–70. [Google Scholar] [CrossRef]

- Hoang, A.T.; Tabatabaei, M.; Aghbashlo, M. A review of the effect of biodiesel on the corrosion behavior of metals/alloys in diesel engines. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 2923–2943. [Google Scholar] [CrossRef]

- Fraer, R.; Dinh, H.; Proc, K.; McCromick, R.L.; Chandler, K.; Buchholz, B. Operating Experience and Teardown Analysis for Engines Operated on Biodiesel Blends (B20); SAE International 2005-01-3641; Rosemont, IL, USA, 2005; p. NREL/CP-540-38509. Available online: https://www.sae.org/publications/technical-papers/content/2005-01-3641/ (accessed on 14 December 2023).

- DOE/GO-102006-2356; Biodiesel Handling and Guidelines. 3rd ed. Department of Energy: Washington, DC, USA, 2006.

- Haseeb, A.S.M.A.; Masjuki, H.H.; Ann, L.J.; Fazal, M.A. Corrosion characteristics of copper and leaded bronze in palm biodiesel. Fuel Process. Technol. 2010, 91, 329–334. [Google Scholar] [CrossRef]

- Ahmmad, M.S.; Hassan, H.; Bin, M.; Kalam, M.A. Comparative corrosion characteristics of automotive materials in Jatropha biodiesel. Int. J. Green Energy 2018, 15, 393–399. [Google Scholar] [CrossRef]

- Thangavelu, S.K.; Ahmed, A.S.; Ani, F.N. Impact of metals on corrosive behavior of biodiesel–Diesel–Ethanol (BDE) alternative fuel. Renew. Energy 2016, 94 Pt C, 1–9. [Google Scholar] [CrossRef]

- Sgroi, M.; Bollito, G.; Saracco, G.; Specchia, S. BIOFEAT: Biodiesel fuel processor for a vehicle fuel cell auxiliary power unit: Study of the feed system. J. Power Sources 2005, 149, 8–14. [Google Scholar] [CrossRef]

- Fazal, M.A.; Haseeb, A.S.M.A.; Masjuki, H.H. Effect of temperature on the corrosion behavior of mild steel upon exposure to palm biodiesel. Energy 2011, 35, 3328–3334. [Google Scholar] [CrossRef]

- Baena, L.M.; Calderón, J.A. Effects of palm biodiesel and blends of biodiesel with organic acids on metals. Heliyon 2020, 6, e03735. [Google Scholar] [CrossRef] [PubMed]

- Hu, E.; Xu, Y.; Hu, X.; Pan, L.; Jiang, S. Corrosion behaviors of metals in biodiesel from rapeseed oil and methanol. Renew. Energy 2012, 37, 371–378. [Google Scholar] [CrossRef]

- Geller, D.P.; Adams, T.T.; Goodrum, J.W.; Pendergrass, J. Storage stability of poultry fat and diesel fuel mixtures: Part II—Chemical properties. Fuel 2010, 89, 792–796. [Google Scholar] [CrossRef]

- Aquino, I.P.; Hernandez, R.P.B.; Chicoma, D.L.; Pinto, H.P.F.; Aoki, I.V. Influence of light, temperature and metallic ions on biodiesel degradation and corrosiveness to copper and brass. Fuel 2012, 102, 795–807. [Google Scholar] [CrossRef]

- Fazal, M.A.; Suhaila, N.R.; Haseeb, A.S.M.A.; Rubaiee, S. Sustainability of additive-doped biodiesel: Analysis of its aggressiveness toward metal corrosion. J. Clean. Prod. 2018, 181, 508–516. [Google Scholar] [CrossRef]

- Kugelmeier, C.L.; Monteiro, M.R.; da Silva, R.; Kuri, S.E.; Sordi, V.L.; Della Rovere, C.A. Corrosion behavior of carbon steel, stainless steel, aluminum and copper upon exposure to biodiesel blended with petrodiesel. Energy 2021, 226, 120344. [Google Scholar] [CrossRef]

- Thangarasu, V.; Balaji, B.; Ramanathan, A. Experimental investigation of tribo-corrosion and engine characteristics of Aegle Marmelos Correa biodiesel and its diesel blends on direct injection diesel engine. Energy 2019, 171, 879–892. [Google Scholar] [CrossRef]

- Sterpu, A.E.; Dumitru, A.I.; Popa, M.F. Corrosion behavior of steel in biodiesel of different origin. Ovidius Univ. Ann. Chem. 2012, 23, 143–148. [Google Scholar] [CrossRef]

- Decote, P.A.P.; Negris, L.; Vidoto, A.P.; Mendes, L.A.N.; Flores, E.M.M.; Vicente, M.A.; Santos, M.F.P. Determination of the total acid number of Brazilian crude oil samples: Theoretical and experimental evaluation of three standard methods. Fuel 2022, 313, 122642. [Google Scholar] [CrossRef]

- Wang, H.; Tang, H.; Wilson, J.; Salley, S.O.; Ng, S. Total Acid Number Determination of Biodiesel and Biodiesel Blends. J. Am. Oil Chem. Soc. 2008, 85, 1083–1086. [Google Scholar] [CrossRef]

- SR EN 14103. Standard Test Method for Determination of Ester and Linolenic Acid Methyl Ester Contents in Fatty Acid Methyl Esters (FAME). Available online: https://standards.iteh.ai/catalog/standards/cen/2eb3696f-7f13-49f2-846e-0ebd8f4c42ea/en-14103-2020 (accessed on 14 December 2023).

- SR EN 16300. Standard Test Method for Determination of Iodine Value in Fatty Acid Methyl Esters (FAME). Available online: https://cdn.standards.iteh.ai/samples/35004/c156163013804b67a2331c72f24562ac/SIST-EN-16300-2012.pdf (accessed on 14 December 2023).

- SR EN ISO 12185. Standard Test Methods for Crude Oils and Petroleum Products—Determination of Density—Oscillating U-tube Method. Available online: https://cdn.standards.iteh.ai/samples/367/9c903f5ef3284d23a5cfb5412b91506e/SIST-EN-ISO-12185-1998.pdf (accessed on 14 December 2023).

- SR EN ISO 3104. Standard Test Methods for Petroleum Products—Transparent and Opaque Liquids—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. Available online: https://cdn.standards.iteh.ai/samples/67965/c8a7502f7eed44eab5c798eaee73fe41/ISO-3104-2020.pdf (accessed on 14 December 2023).

- SR EN ISO 12937. Standard Test Methods for Determination of Water—Coulometric Karl Fischer Titration Method. Available online: https://cdn.standards.iteh.ai/samples/2730/d1f8ee11083a4fbc84aad409e4bcf40f/ISO-12937-2000.pdf (accessed on 14 December 2023).

- SR EN 14110. Standard Test Methods for Fat and Oil Derivatives—Fatty Acid Methyl Esters—Determination of Methanol Content. Available online: https://cdn.standards.iteh.ai/samples/64247/3cb8686024644c7bb52f45eab89d5e0b/SIST-EN-14110-2019.pdf (accessed on 14 December 2023).

- SR EN ISO 3679. Standard Test Methods for Determination of Pass-No-Pass Flammability and Flash Point. Fast Closed-Vessel Equilibrium Method. Available online: https://cdn.standards.iteh.ai/samples/29076/342956b390f44d48a60f739b6cd14bb3/ISO-3679-2004.pdf (accessed on 14 December 2023).

- SR EN ISO 20884. Standard Test Methods for Petroleum products—Determination of Sulfur Content of Automotive Fuels—Wavelength-Dispersive X-ray Fluorescence Spectrometry. Available online: https://standards.iteh.ai/catalog/standards/cen/2156a459-967a-46dc-9f39-84ec125456ba/en-iso-20884-2019 (accessed on 14 December 2023).

- SR EN 14112. Standard Test Methods for Fat and Oil Derivatives—Fatty Acid Methyl Esters (FAME)—Determination of Oxidation Stability (Accelerated Oxidation Test). Available online: https://cdn.standards.iteh.ai/samples/66922/49757a201d91465c837f02ac2541337d/SIST-EN-14112-2021.pdf (accessed on 14 December 2023).

- SR EN 14104. Standard Test Methods for Fat and Oil Derivates. Fatty Acid Methyl Ester (FAME). Determination of Acid Value. Available online: https://cdn.standards.iteh.ai/samples/70045/1a81e80332be42e299fa8d3f5cdc20f2/SIST-EN-14104-2021.pdf (accessed on 14 December 2023).

- SR EN 14105. Standard Test Methods for Fat and Oil Derivatives. Fatty Acid Methyl Esters (FAME). Determination of Free and Total Glycerol and Mono-, di-, Triglyceride Contents. Available online: https://cdn.standards.iteh.ai/samples/66921/3bcfc94d6a8248a484e874ea42d649df/SIST-EN-14105-2021.pdf (accessed on 14 December 2023).

- SR EN 116/AC. Standard Test Methods for Diesel Engine Fuels. Determination of Cold Filter Plugging Point. Available online: https://standards.iteh.ai/catalog/standards/cen/f0b4bc72-e8b9-4969-b957-8e6ce72f489d/en-116-2015 (accessed on 14 December 2023).

- SR EN 23015. Standard Test Methods for Petroleum Products—Determination of Cloud Point. Available online: https://standards.iteh.ai/catalog/standards/cen/616161ad-c21a-4355-8482-0a4f1dae8a47/en-23015-1994 (accessed on 14 December 2023).

- SR EN 12662. Standard Test Methods for Liquid Petroleum Products—Determination of Total Contamination in Middle Distillates, Diesel Fuels and Fatty acid Methyl Esters. Available online: https://cdn.standards.iteh.ai/samples/33063/6ce689c2e25c487c94728b343aca06eb/SIST-EN-12662-2014.pdf (accessed on 14 December 2023).

- ASTM D 4052-22. Standard Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter. Available online: https://cdn.standards.iteh.ai/samples/112378/1e427858c52b4fff89a470b85eeda29d/ASTM-D4052-22.pdf (accessed on 14 December 2023).

- ASTM D 1500-12. Standard Test Method for ASTM Color of Petroleum Products (ASTM Color Scale). Available online: https://cdn.standards.iteh.ai/samples/83766/6e4dbd875aee4069b0729429ba8387f1/ASTM-D1500-12.pdf (accessed on 14 December 2023).

- ASTM D 93-20. Standard Test Methods for Flash Point by Pensky-Martens Closed Cup Tester. Available online: https://cdn.standards.iteh.ai/samples/106978/1302886874ea49afb428f047cc06313a/ASTM-D93-20.pdf (accessed on 14 December 2023).

- SR EN ISO 20846. Standard Test Methods for Petroleum products—Determination of Sulfur Content of Automotive Fuels—Ultraviolet Fluorescence Method. Available online: https://cdn.standards.iteh.ai/samples/74313/a425278694264f5e83a5583af8f65cf2/ISO-20846-2019.pdf (accessed on 14 December 2023).

- SR EN ISO 2160. Standard Test Methods for Petroleum Products. Corrosiveness to Copper. Copper Strip Test. Available online: https://cdn.standards.iteh.ai/samples/6951/bf3676429b7d4e3182795258b7e281e5/ISO-2160-1985.pdf (accessed on 14 December 2023).

- SR EN ISO 10370. Standard Test Methods for Petroleum Products—Determination of Carbon Residue—Micro Method. Available online: https://cdn.standards.iteh.ai/samples/57081/58db305ae9c5498db6ecb951674cf4e0/ISO-10370-2014.pdf (accessed on 14 December 2023).

- SR EN ISO 6245. Standard Test Methods for Petroleum Products. Determination of Ash. Available online: https://cdn.standards.iteh.ai/samples/31156/247005c940e042f7a79ff4e0c5d6edba/ISO-6245-2001.pdf (accessed on 14 December 2023).

- SR EN ISO 4264. Standard Test Methods for Petroleum Products—Calculation of Cetane Index of Middle-Distillate Fuels by the four Variable Equation. Available online: https://cdn.standards.iteh.ai/samples/45627/c254c9d0f08545ce9abc39ea6d1eb404/ISO-4264-2007.pdf (accessed on 14 December 2023).

- ASTM D 2500-17a. Standard Test Method for Cloud Point of Petroleum Products and Liquid Fuels. Available online: https://cdn.standards.iteh.ai/samples/99033/1f30ba3334a04c668e23c632698ab322/ASTM-D2500-17a.pdf (accessed on 14 December 2023).

- ASTM D 6371-17a. Standard Test Method for Cold Filter Plugging Point of Diesel and Heating Fuels. Available online: https://cdn.standards.iteh.ai/samples/97393/c8ce7f68eaa742ffbcb5e060dac8df13/ASTM-D6371-17.pdf (accessed on 14 December 2023).

- ASTM E 203-16. Standard Test Method for Water Using Volumetric Karl Fischer Titration. Available online: https://cdn.standards.iteh.ai/samples/94281/136a27289f5444cf837cf8e242aa84f0/ASTM-E203-16.pdf (accessed on 14 December 2023).

- SR EN ISO 3405. Standard Test Method for Petroleum and Related Products from Natural or Synthetic Sources—Determination of Distillation Characteristics at Atmospheric Pressure. Available online: https://cdn.standards.iteh.ai/samples/67956/379a350656fd40f2b3e2f0d5a12e8751/ISO-3405-2019.pdf (accessed on 14 December 2023).

- SR EN 14078. Standard Test Method for Liquid Petroleum Products—Determination of Fatty Acid Methyl Ester (FAME) Content in Middle Distillates. Infrared Spectrometry Method. Available online: https://standards.iteh.ai/catalog/standards/cen/2bcb7edd-f6da-43f0-818c-e7ecafe87907/en-14078-2014 (accessed on 14 December 2023).

- ASTM D 1250. 19e1-Standard Guide for the Use of the Joint API and ASTM Adjunct for Temperature and Pressure Volume Correction Factors for Generalized Crude Oils, Refined Products, and Lubricating Oils: API MPMS Chapter 11.1. Available online: https://cdn.standards.iteh.ai/samples/106185/269487f113384090a0024462ba429b4c/ASTM-D1250-19e1.pdf (accessed on 14 December 2023).

- Nguyen, X.P.; Vu, H.N. Corrosion of the Metal Parts of Diesel Engines in Biodiesel-Based Fuels. Int. J. Renew. Energy Dev. 2019, 8, 119–132. [Google Scholar] [CrossRef]

- Liu, J.; Fang, Y.K. The dissolved oxygen on the corrosion of 20R steel by biodiesel. Corros. Protet. 2009, 30, 711–713. (In Chinese) [Google Scholar]

- Román, A.S.; Barrientos, M.S.; Noceras, M.Á.; Méndez, C.M.; Ares, A.E. Resistance to corrosion of Al-Cu alloy in biodiesel. Matéria 2018, 23, e12052. [Google Scholar]

- Rocabruno-Valdés, C.I.; Hernández, J.A.; Juantorena, A.U.; Arenas, E.G.; Lopez-Sesenes, R.; Salinas-Bravo, V.M.; González-Rodriguez, J.G. An electrochemical study of the corrosion behavior of metals in canola biodiesel. Corros. Eng. Sci. Technol. 2018, 53, 153–162. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Z.; Zhao, H.; Zhang, X.; Hu, Z.; Wu, Z.; Li, L. A study on the effects of biodiesels on the properties of elastomers, metals and plastics in diesel fuel system. Auto. Eng. 2008, 30, 875–879. (In Chinese) [Google Scholar]

| Analysis | Result | Conditions | Methods |

|---|---|---|---|

| Ester content, % | 97.9 | Min 96.5 | [27] |

| C 18.3—Methyl Linoleate, % | 4 | - | [27] |

| Saturated fatty acids esters content, % | 16 | [27] | |

| Iodine value, g/100g | 80 | Max. 120 | [28] |

| Appearance at 15 degrees | Clear | Clear | Visual |

| Density at 15 °C, kg/m3 | 883.1 | 880–900 | [29] |

| Cinematic viscosity at 40 °C, mm2/s | 4.50 | 3.50–5.00 | [30] |

| Water content, % | 0.023 | Max. 0.050 | [31] |

| Methanol, % | 0.10 | Max. 0.20 | [32] |

| Flash point, °C | 123 | Min. 101 | [33] |

| Sulfur, mg/kg | <10.0 | Max. 10.0 | [34] |

| Oxidation stability at 110 °C, h | 8.4 | Min. 8.0 | [35] |

| Acid value, mg KOH/g | 0.28 | Max. 0.50 | [36] |

| Monoglyceride, % | 0.63 | Max. 0.70 | [37] |

| Diglyceride, % | 0.13 | Max. 0.20 | [37] |

| Triglyceride, % | 0.03 | Max. 0.20 | [37] |

| Free glycerol, % | 0.02 | Max. 0.02 | [37] |

| Total glycerol, % | 0.21 | Max. 0.25 | [37] |

| Cold filter plugging point, °C | −11 | Max. −10 | [38] |

| Cloud point, °C | −3 | Max. −3 | [39] |

| Total contamination, mg/kg | 17 | Max. 24 | [40] |

| Analysis | Result | Conditions | Methods |

|---|---|---|---|

| Density at 15 °C, g/cm3 | 0.827 | 0.82–0.845 | [41] |

| ASTM Color, ASTM unit. | 0.5 | Max. 2.0 | [42] |

| Flash point PENSKY MARTENS, °C | 59 | Min. 55 | [43] |

| Sulfur, mg/kg | 9.0 | Max. 10.0 | [44] |

| Cinematic viscosity at 40 °C, mm2/s | 2.60 | 2.00–4.50 | [30] |

| Corrosion on copper (3 h/100 °C) | 1a | 1 class | [45] |

| Carbon residue, % | 0.025 | Max. 0.3 | [46] |

| Ash oxide, % | 0.004 | Max. 0.01 | [47] |

| Cetane index, | 54.5 | Min. 46 | [48] |

| Cloud point, °C | −4 | [49] | |

| Cold filter plugging point, °C | −17 | Max. −15 | [50] |

| Water content KF, mg/kg | 100 | Max. 200 | [51] |

| Distillation at 250 °C, % vol. | 39 | Max. 65 | [52] |

| Distillation at 350 °C, % vol. | 93 | Min. 85 | [52] |

| Distillation at 95% vol., °C | 355 | Max. 360 | [52] |

| FAME, % vol. | 0 | Max. 7 | [53] |

| Density at 15 °C in air, g/cm3 | 0.8259 | - | [41,54] |

| Appearance | Clear | Clear | Visual |

| Total Acid Number (TAN), [mg KOH/g] | B0 | B20 | B40 | B60 | B80 | B100 |

|---|---|---|---|---|---|---|

| As received | 0.256 | 0.265 | 0.275 | 0.284 | 0.291 | 0.298 |

| Copper | 0.258 | 0.269 | 0.289 | 0.301 | 0.307 | 0.318 |

| Brass | 0.257 | 0.268 | 0.286 | 0.294 | 0.303 | 0.316 |

| Aluminum | 0.256 | 0.271 | 0.278 | 0.287 | 0.295 | 0.299 |

| Zinc | 0.257 | 0.270 | 0.279 | 0.287 | 0.295 | 0.300 |

| Stainless steel | 0.256 | 0.267 | 0.278 | 0.283 | 0.293 | 0.299 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sterpu, A.E.; Simedrea, B.G.; Chis, T.V.; Săpunaru, O.V. Corrosion Effect of Biodiesel-Diesel Blend on Different Metals/Alloy as Automotive Components Materials. Fuels 2024, 5, 17-32. https://doi.org/10.3390/fuels5010002

Sterpu AE, Simedrea BG, Chis TV, Săpunaru OV. Corrosion Effect of Biodiesel-Diesel Blend on Different Metals/Alloy as Automotive Components Materials. Fuels. 2024; 5(1):17-32. https://doi.org/10.3390/fuels5010002

Chicago/Turabian StyleSterpu, Ancaelena Eliza, Bianca Georgiana Simedrea, Timur Vasile Chis, and Olga Valerica Săpunaru. 2024. "Corrosion Effect of Biodiesel-Diesel Blend on Different Metals/Alloy as Automotive Components Materials" Fuels 5, no. 1: 17-32. https://doi.org/10.3390/fuels5010002

APA StyleSterpu, A. E., Simedrea, B. G., Chis, T. V., & Săpunaru, O. V. (2024). Corrosion Effect of Biodiesel-Diesel Blend on Different Metals/Alloy as Automotive Components Materials. Fuels, 5(1), 17-32. https://doi.org/10.3390/fuels5010002