The German Cement Industry as a CO2 Source for Other Industries

Abstract

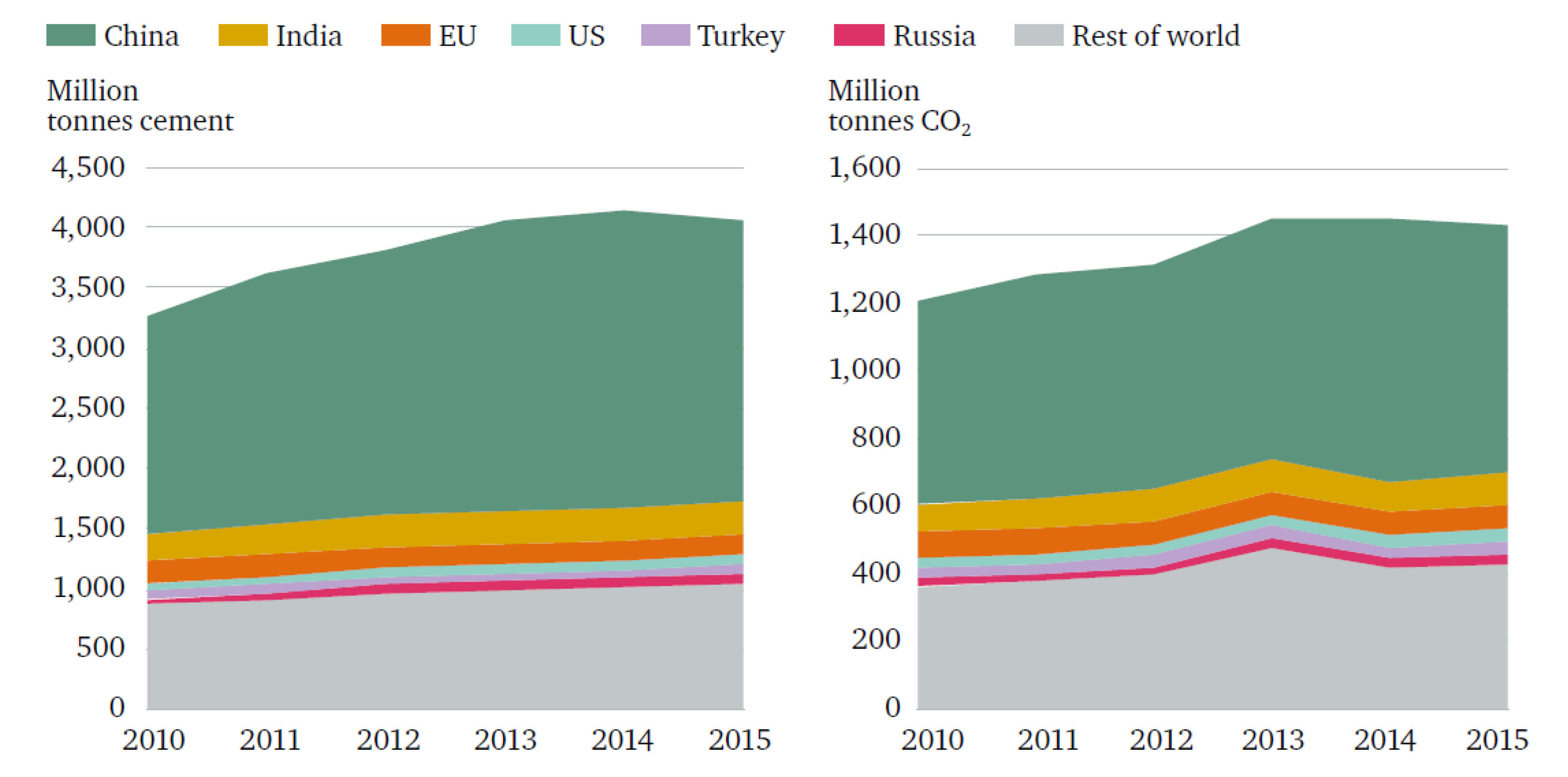

:1. Introduction

1.1. CO2 Demand for Synthetic Fuels

1.2. Approaches to Reduce Cement Demand

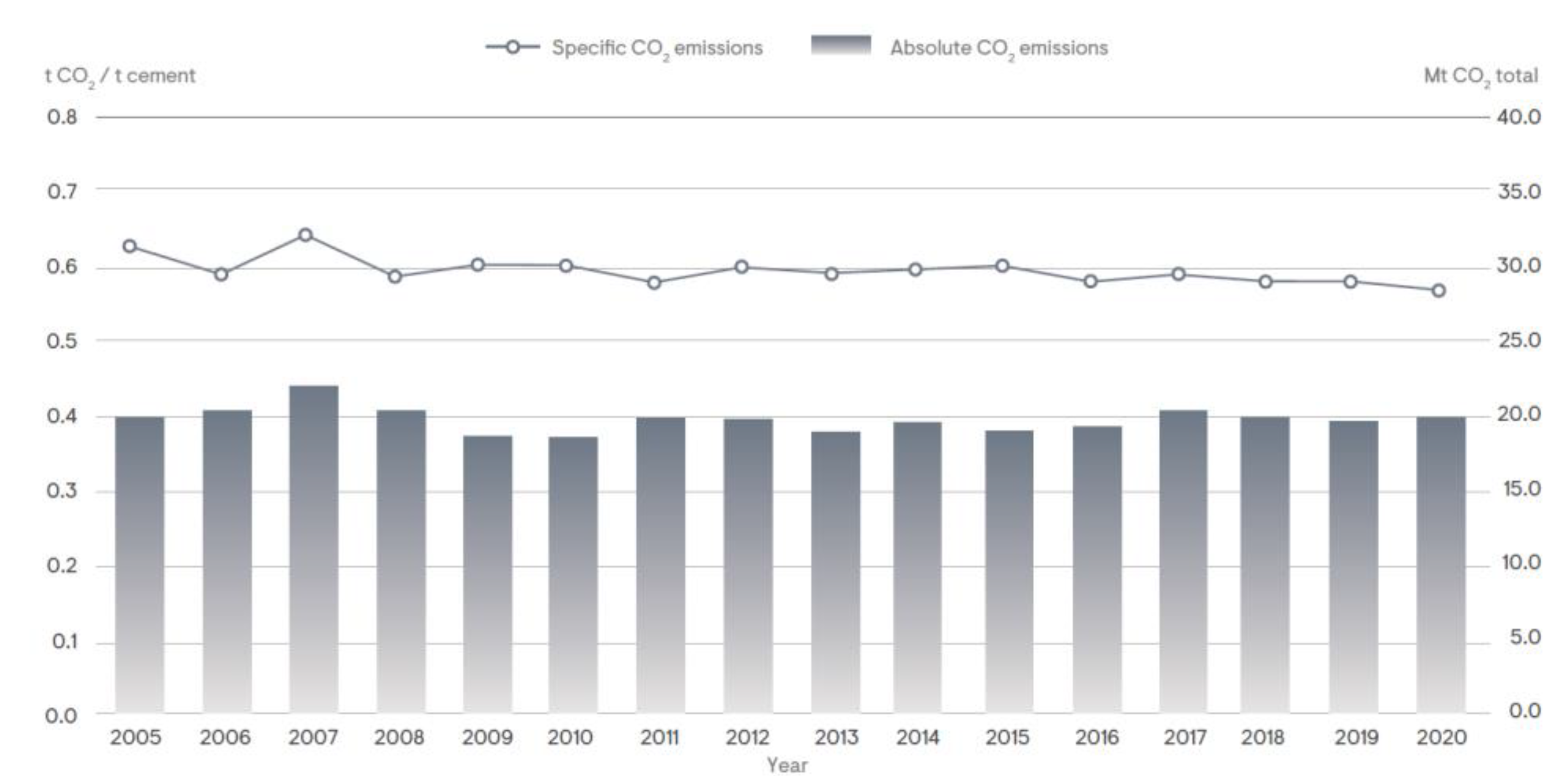

1.3. CO2 Reduction Measures during Cement Production

1.4. CO2 Separation, Storage and/or Usage

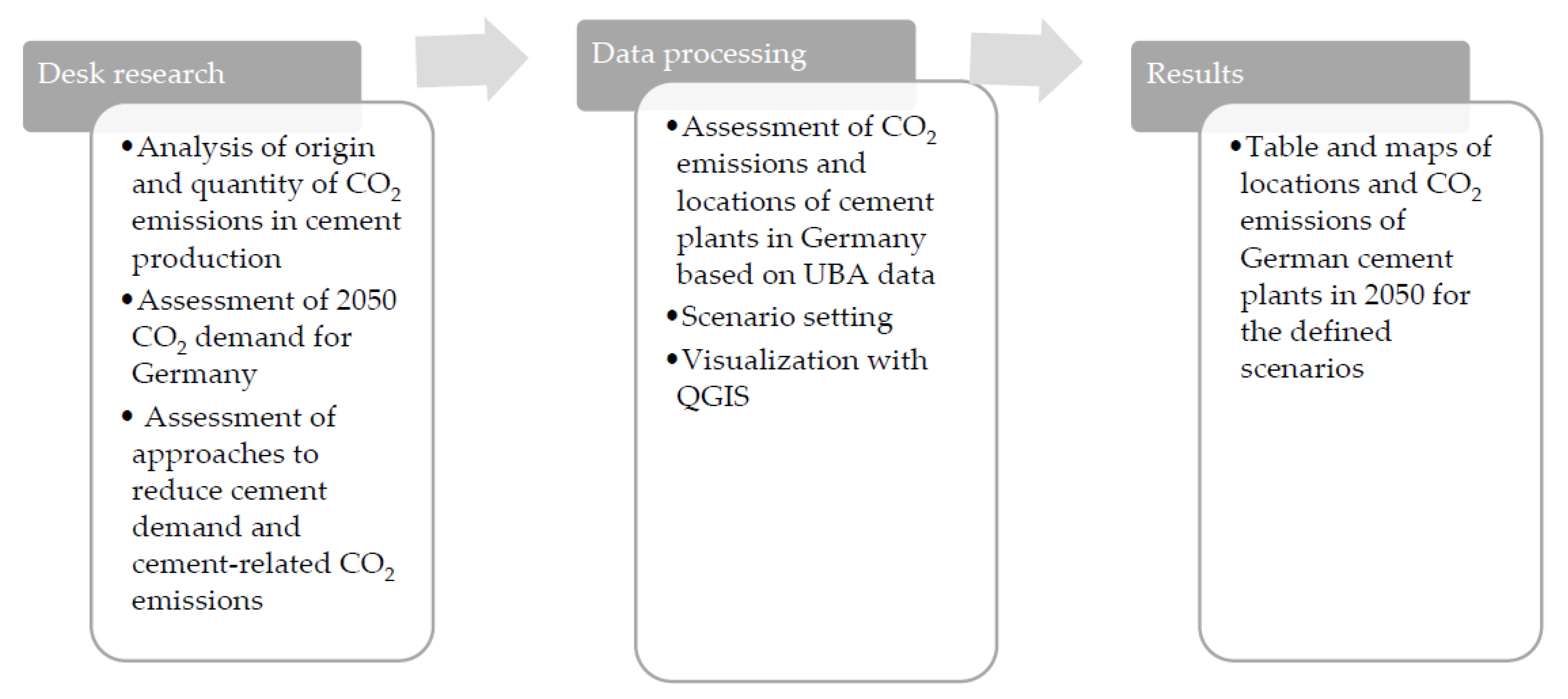

2. Materials and Methods

2.1. Data Sources Used

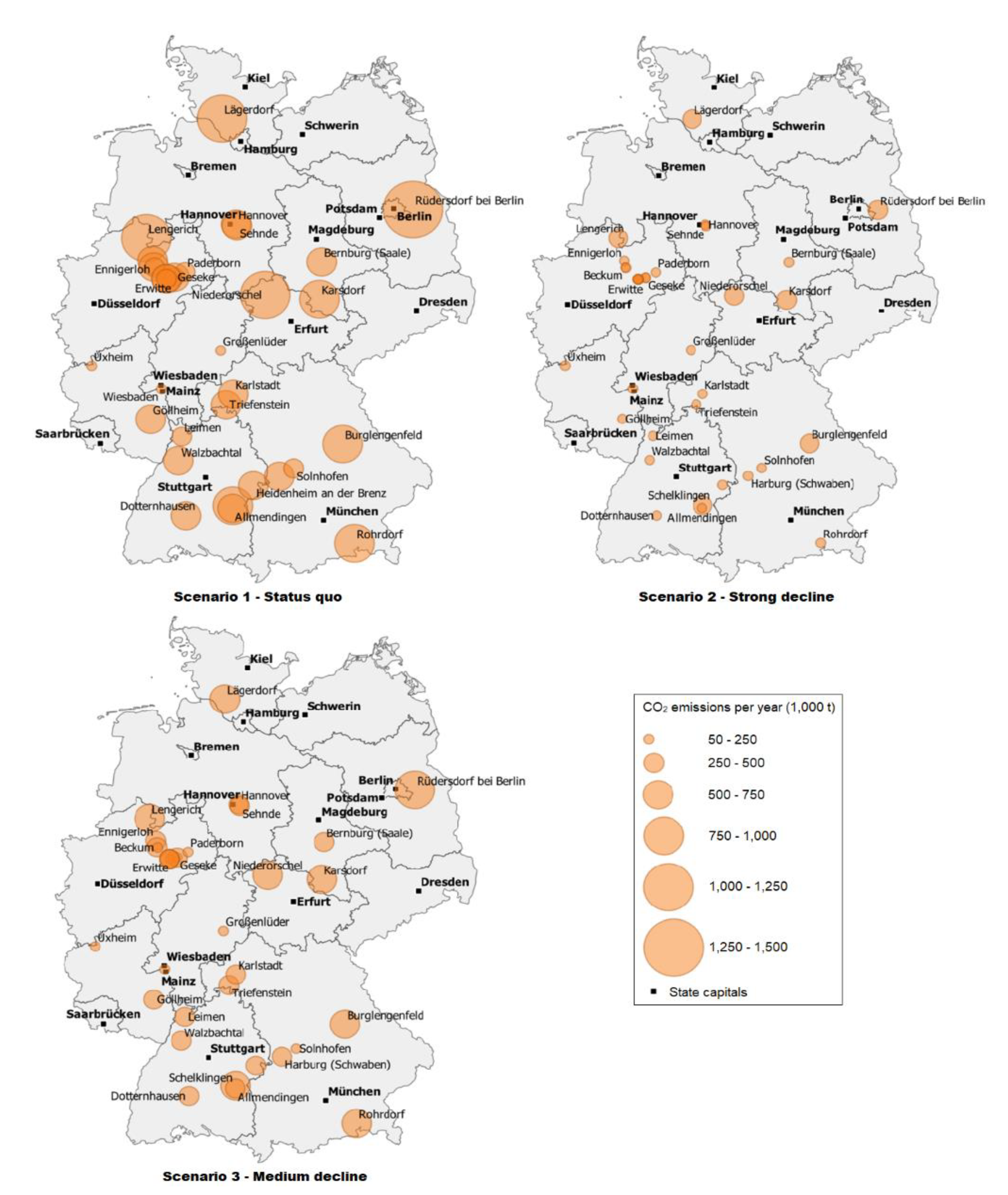

2.2. Scenario Setting

3. Results

4. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Watts, J. Concrete: The Most Destructive Material on Earth. Available online: https://www.theguardian.com/cities/2019/feb/25/concrete-the-most-destructive-material-on-earth (accessed on 9 May 2022).

- Gagg, C.R. Engineering Failure Analysis: Cement and concrete as an engineering material: An historic appraisal and case study analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- International Energy Agency. Cement: Direct CO2 Intensity of Cement Production in the Net Zero Scenario, 2015–2030. Available online: https://www.iea.org/reports/cement (accessed on 9 May 2022).

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef] [Green Version]

- Chatham House. Making Concrete Change: Innovation in Low-Carbon Cement and Concrete; Chatham House: London, UK, 2018; ISBN 978-1-78413-272-9. [Google Scholar]

- Statista GmbH. Cement Production Worldwide from 1995 to 2021. Available online: https://www.statista.com/statistics/1087115/global-cement-production-volume/ (accessed on 9 May 2022).

- CEMBUREAU—The European Cement Association. Key Facts & Figures: Main World Producers in 2018; The European Cement Association: Brussels, Belgium, 2020. [Google Scholar]

- Deutsche Emissionshandelsstelle (DEHSt) im Umweltbundesamt. Treibhausgasemissionen 2019 (Kurzfassung)—Emissionshandelspflichtige Stationäre Anlagen und Luftverkehr in Deutschland (VET-Bericht 2019); Deutsche Emissionshandelsstelle (DEHSt) im Umweltbundesamt: Berlin, Germany, 2020; Available online: https://www.dehst.de/SharedDocs/downloads/DE/publikationen/VET-Bericht-2019_Summary.pdf?__blob=publicationFile&v=2 (accessed on 13 March 2022).

- Umweltbundesamt. Integration von Power to Gas/Power to Liquid in den Laufenden Transformationsprozess; Umweltbundesamt (UBA): Dessau-Roßlau, Germany, 2016; Available online: https://www.umweltbundesamt.de/sites/default/files/medien/1/publikationen/position_power_to_gas-power_to_liquid_web.pdf (accessed on 13 March 2022).

- Zentrum für Sonnenenergie- und Wasserstoff-Forschung Baden-Württemberg. E2-Fuels—CO2-Potentialatlas: Teilvorhabenbeschreibung im Rahmen des Verbundvorhabens—Modul I: Strombasierte Kraftstoffe und Energiesystemanalysen; Zentrum für Sonnenenergie- und Wasserstoff-Forschung Baden-Württemberg: Stuttgart, Germany, 2017. [Google Scholar]

- Wuppertal Institut für Klima; Umwelt; Energie gGmbH. Der Beitrag von Synthetischen Kraftstoffen zur Verkehrswende: Optionen und Prioritäten: Kurzstudie. 2019. Available online: https://www.greenpeace.de/sites/www.greenpeace.de/files/publications/kurzstudie_kraftstoffe_verkehrswende.pdf (accessed on 13 March 2022).

- Rudschies, W. Synthetische Kraftstoffe—Sind E-Fuels die Zukunft? Available online: https://www.adac.de/verkehr/tanken-kraftstoff-antrieb/alternative-antriebe/synthetische-kraftstoffe/ (accessed on 12 February 2022).

- Ludwig Bölkow Systemtechnik; Deutsche Energie-Agentur. E-FUELS STUDIE: Das Potenzial Strombasierter Kraftstoffe Für Einen Klimaneutralen Verkehr in der EU: Ein Gutachten von LBST und Dena. 2017. Available online: https://www.dena.de/themen-projekte/projekte/mobilitaet/e-fuels-the-potential-of-electricity-based-fuels-for-low-emission-transport-in-the-eu/ (accessed on 13 March 2022).

- Agora Verkehrswende; Agora Energiewende; Frontier Economics. Die Zukünftigen Kosten Strombasierter Synthetischer Brennstoffe: Studie. 2018. Available online: https://www.agora-energiewende.de/fileadmin2/Projekte/2017/SynKost_2050/Agora_SynCost-Studie_WEB.pdf (accessed on 13 March 2022).

- Statista GmbH. Europäische Union & Euro-Zone: Anteile der Mitgliedsstaaten am Bruttoinlandsprodukt (BIP) im Jahr 2019. 2020. Available online: https://de.statista.com/statistik/daten/studie/347262/umfrage/anteile-der-laender-am-bruttoinlandsprodukt-bip-in-eu-und-euro-zone/#professional (accessed on 13 March 2022).

- InformationsZentrum Beton GmbH. Betonrecycling—Verwertung Bestehender Substanz. Available online: https://www.beton.org/wissen/nachhaltigkeit/betonrecycling/ (accessed on 13 March 2022).

- Mellwitz, R. Recyclingbeton—Baustoff der Zukunft? Available online: https://www.schwenk.de/recyclingbeton-baustoff-der-zukunft/ (accessed on 24 February 2022).

- Umweltbundesamt. Dekarbonisierung der Zementindustrie. 2020. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/376/dokumente/factsheet_zementindustrie.pdf (accessed on 13 March 2022).

- Churkina, G.; Organschi, A.; Reyer, C.P.O.; Ruff, A.; Vinke, K.; Liu, Z.; Reck, B.K.; Graedel, T.E.; Schellnhuber, H.J. Buildings as a Global Carbon Sink. Available online: https://www.nature.com/articles/s41893-019-0462-4.epdf?sharing_token=ItCoZcQ2_jSb2npjr9KcodRgN0jAjWel9jnR3ZoTv0P6mBTrWA4qmHEFgX4wpsdkahu8LdxQzI1IExticfdf4It-6oKbCjtmb6mQJkJdXvl4M-C_AX7MEtumt8rjkl4i87J8nOJjOUjYB5CtWNmbess8EAfzE4wSKk_nSCTZyCxo0yyrYBPFo75l1ZbMzohg1p1TU4v9eQBlulpoSiHrdOdBrxVWj1PH7szOGBwt4rQ%3D&tracking_referrer=www.sueddeutsche.de (accessed on 12 February 2022).

- InformationsZentrum Beton GmbH. Geopolymere. 2020. Available online: https://www.beton.wiki/index.php?title=Geopolymere (accessed on 13 March 2022).

- Verein Deutscher Zementwerke, e.V. Zementindustrie im Überblick 2019/2020; Verein Deutscher Zementwerke e.V: Berlin, Germany, 2019; Available online: https://www.vdz-online.de/publikationen/zementindustrie-im-ueberblick/ (accessed on 13 March 2022).

- Verein Deutscher Zementwerke, e.V. Umweltdaten der Deutschen Zementindustrie 2020. Available online: https://www.vdz-online.de/wissensportal/publikationen/umweltdaten-der-deutschen-zementindustrie-2020 (accessed on 12 February 2022).

- Verein Deutscher Zementwerke, e.V. Umweltdaten der Deutschen Zementindustrie 2019. Available online: https://www.vdz-online.de/wissensportal/publikationen/umweltdaten-der-deutschen-zementindustrie-2019 (accessed on 10 September 2020).

- InformationsZentrum Beton GmbH. Zemente und Ihre Herstellung. 2017. Available online: https://www.beton.org/fileadmin/beton-org/media/Dokumente/PDF/Service/Zementmerkbl%C3%A4tter/B1.pdf (accessed on 13 March 2022).

- Forschungszentrum Jülich GmbH. Technologiebericht 2.3 CO2-Abscheidung und -Speicherung (CCS) Innerhalb des Forschungsprojekts TF_Energiewende. Available online: https://epub.wupperinst.org/frontdoor/deliver/index/docId/7051/file/7051_CCS.pdf (accessed on 13 March 2022).

- eecomm GmbH. TU Darmstadt: CO2-Reduktion mit Carbonate-Looping vor Marktreife. 2017. Available online: https://www.ee-news.ch/de/erneuerbare/article/35684/tu-darmstadt-co2-reduktion-mit-carbonate-looping-vor-marktreife (accessed on 13 March 2022).

- Helbig, M. Experimentelle Untersuchung des Langzeitverhaltens des Carbonate-Looping-Verfahrens im Megawatt-Technikum. Master’s Thesis, Technische Universität Darmstadt, Darmstadt, Germany, 2018. [Google Scholar]

- Verein Deutscher Zementwerke, e.V. CO2-Abscheidung bei der Zementherstellung. 2019. Available online: https://www.vdz-online.de/fileadmin/Forschung/1.pdf (accessed on 13 March 2022).

- Verein Deutscher Zementwerke, e.V. CLEANKER—CO2–Abscheidung Mittels Integriertem Calcium Looping Prozess; Verein Deutscher Zementwerke e.V: Düsseldorf, Germany, 2017. [Google Scholar]

- Viebahn, P.; Scholz, A.; Zelt, O. Entwicklungsstand und Forschungsbedarf von Direct Air Capture: Ergebnis einer multidimensionalen Analyse. Energiewirtschaftliche Tagesfrage 2019, 69, 30–33. [Google Scholar]

- Hoenig, V.; Koring, K.; Fleiger, P.; Müller, C.; Palm, S.; Reiners, J. Energieeffizienz bei der Zementherstellung; Teil 1. Cem. Int. 2013, 11, 50–67. [Google Scholar]

- Bundesinstitut für Bau-, Stadt- und Raumforschung im Bundesamt für Bauwesen und Raumordnung. Zukunft Bauen: Forschung für die Praxis | Band 06: Materialströme im Hochbau: Potenziale für eine Kreislaufwirtschaft. 2017. Available online: https://www.bbsr.bund.de/BBSR/DE/veroeffentlichungen/zukunft-bauen-fp/2017/band-06-dl.pdf;jsessionid=1FE40FBD439A132598D856405480BC9F.live21304?__blob=publicationFile&v=1 (accessed on 13 March 2022).

- de Kleijne, K.; Hanssen, S.; van Dinteren, L.; Huijbregts, M. Limits to Paris Compatibility of CO2 Capture and Utilization. Available online: https://www.researchgate.net/publication/358718939_Limits_to_Paris_compatibility_of_CO2_capture_and_utilization (accessed on 9 May 2022).

| Scenario 1—Status Quo | Scenario 2—Strong Decline | Scenario 3—Medium Decline | |

|---|---|---|---|

| Decline until 2050 | - | 70% | 35% |

| Key assumption | Cement demand and clinker-cement factor remain constant | Alternative production processes and products | Less strongly reduced cement demand or CO2 emissions |

| 2050 CO2 emissions [t/a] | 21 million | 6 million | 14 million |

| Coverage of 2050 CO2 demand * | 15% | 5% | 10% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Winter, C.; Schröter, B.; Fidaschek, S. The German Cement Industry as a CO2 Source for Other Industries. Fuels 2022, 3, 342-352. https://doi.org/10.3390/fuels3020021

Winter C, Schröter B, Fidaschek S. The German Cement Industry as a CO2 Source for Other Industries. Fuels. 2022; 3(2):342-352. https://doi.org/10.3390/fuels3020021

Chicago/Turabian StyleWinter, Christoph, Bastian Schröter, and Stefan Fidaschek. 2022. "The German Cement Industry as a CO2 Source for Other Industries" Fuels 3, no. 2: 342-352. https://doi.org/10.3390/fuels3020021

APA StyleWinter, C., Schröter, B., & Fidaschek, S. (2022). The German Cement Industry as a CO2 Source for Other Industries. Fuels, 3(2), 342-352. https://doi.org/10.3390/fuels3020021