Recent Advances of Conductive Hydrogels for Flexible Electronics

Abstract

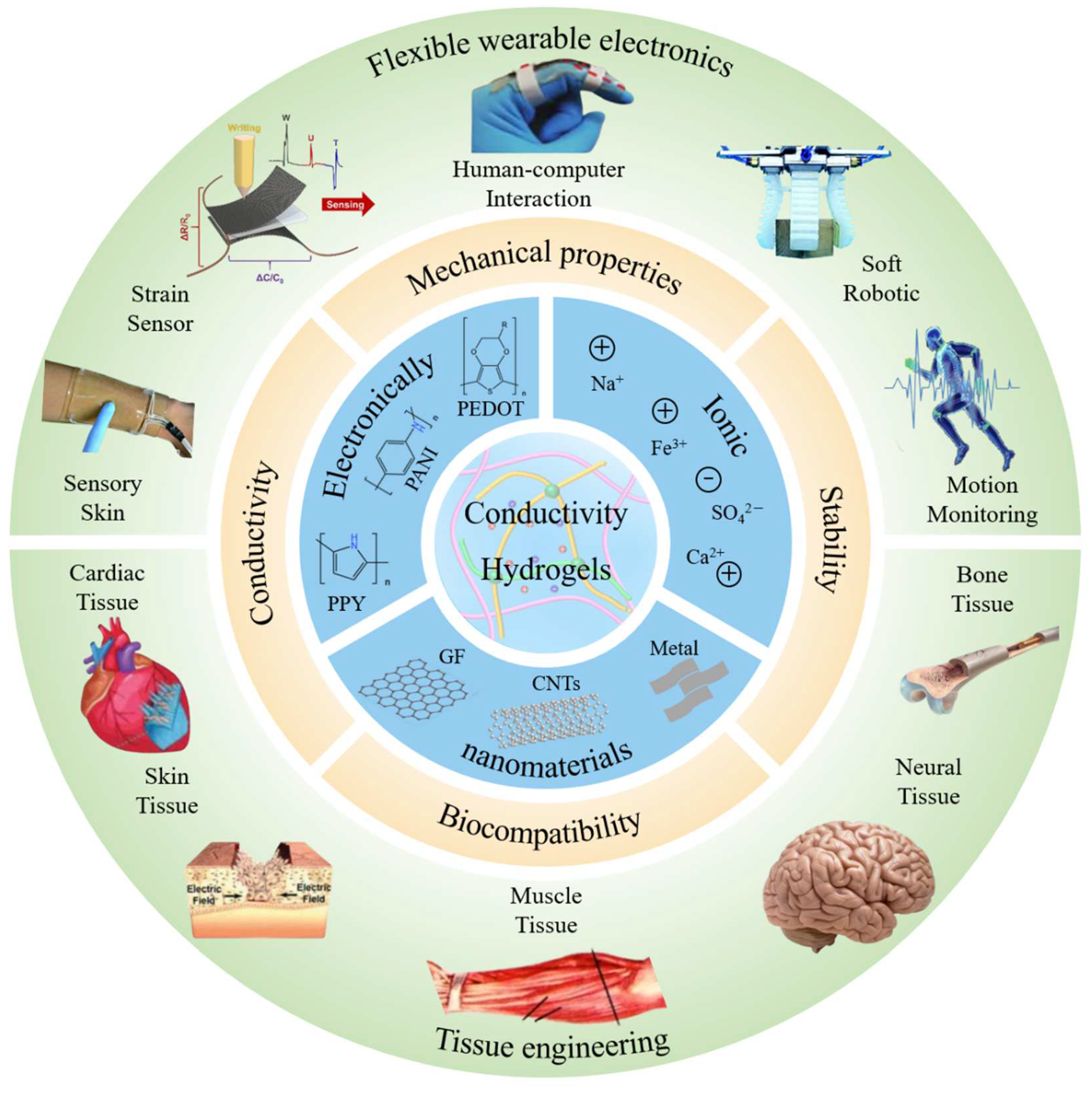

1. Introduction

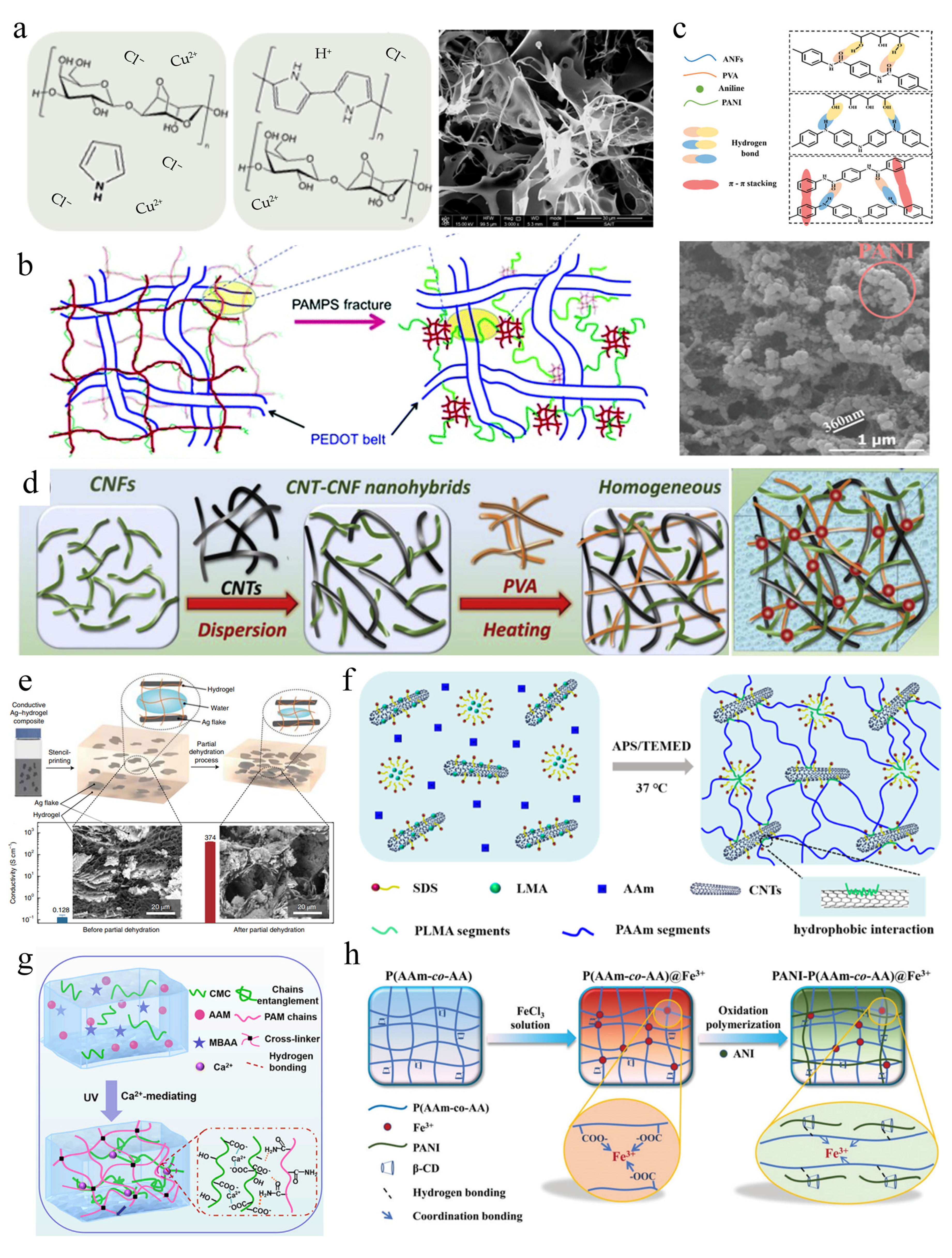

2. Fabrication of Conductive Hydrogels

2.1. Electronic Conductive Hydrogels

2.2. Nanoparticle Conductive Hydrogels

2.3. Ion Conductive Hydrogels

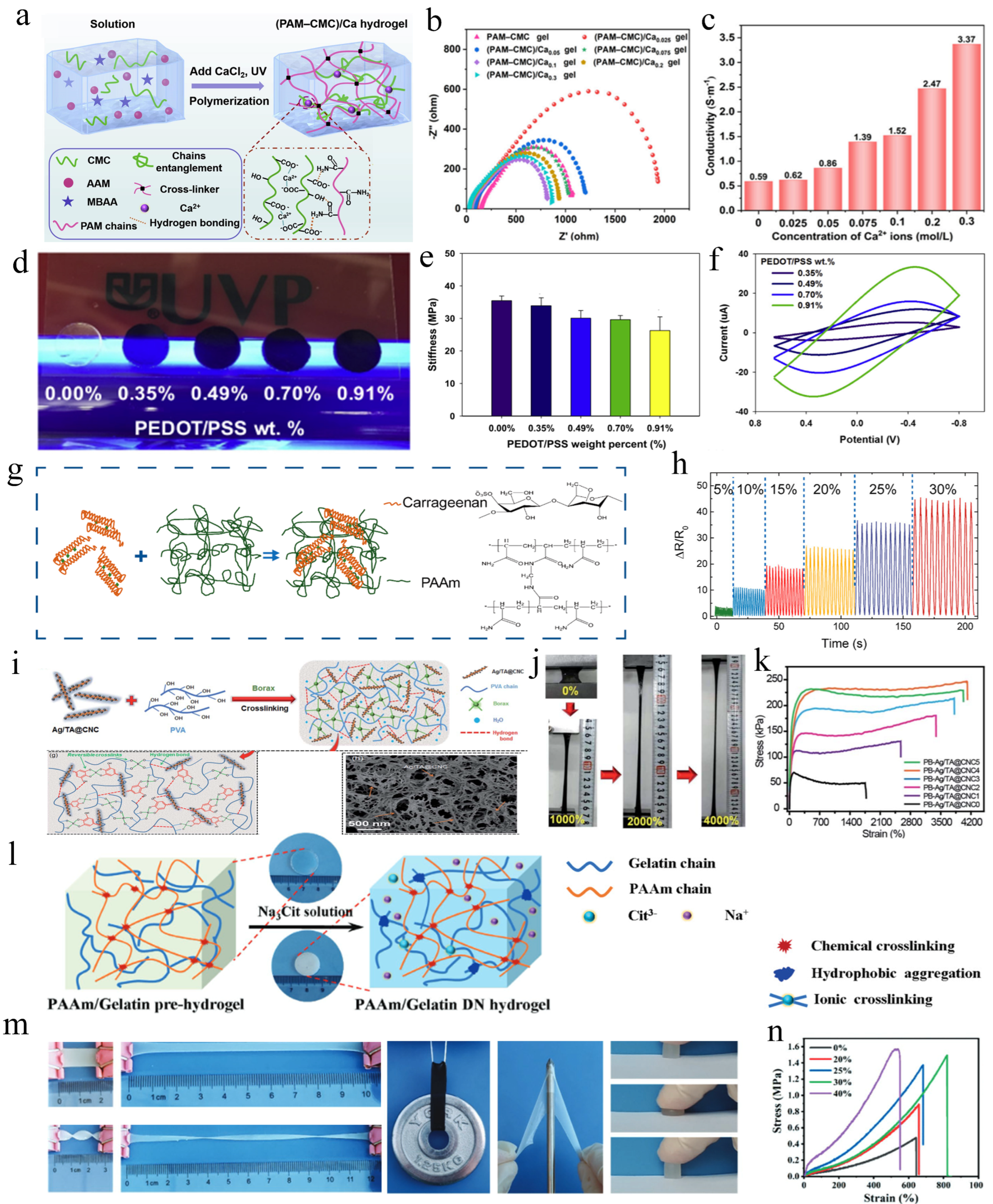

3. Key Properties and Enhancement Strategies of Conductive Hydrogels

3.1. Conductivity

| Conductive Components | Conductivity (S cm−1) | References | |

|---|---|---|---|

| Electronic conductive hydrogels | PEDOT: PSS | 10−2–4.38 × 103 | [69,70] |

| PPY | 10−2–7.5 × 103 | [71,72,73,74,75] | |

| PANI | 10−2–2 × 102 | [76,77,78] | |

| Nanoparticle conductive hydrogels | K+, Li+ | 0.02–0.0736 | [79,80] |

| Ca2+ | 0.0337 | [19] | |

| Fe3+ | 0.00216 | [81] | |

| Ion conductive hydrogels | CNTs | 0.082 | [82] |

| MXene | 0.01092 | [83] | |

| Silver | >350 | [50] |

3.2. Mechanical Strength and Flexibility

3.3. Long-Term Stability

3.4. Biocompatibility

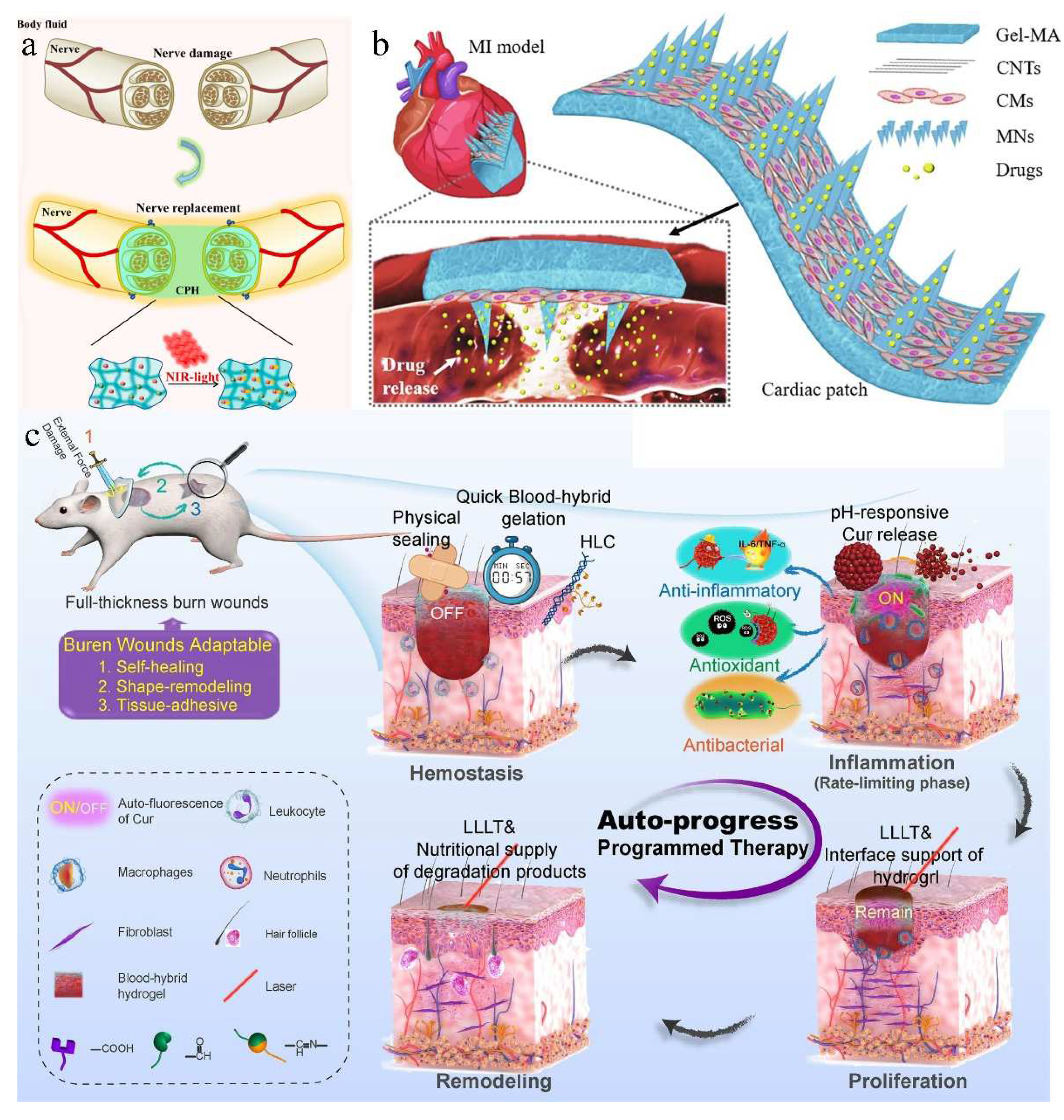

4. Application Demonstration in Flexible Electronics

4.1. Applications in Tissue Engineering

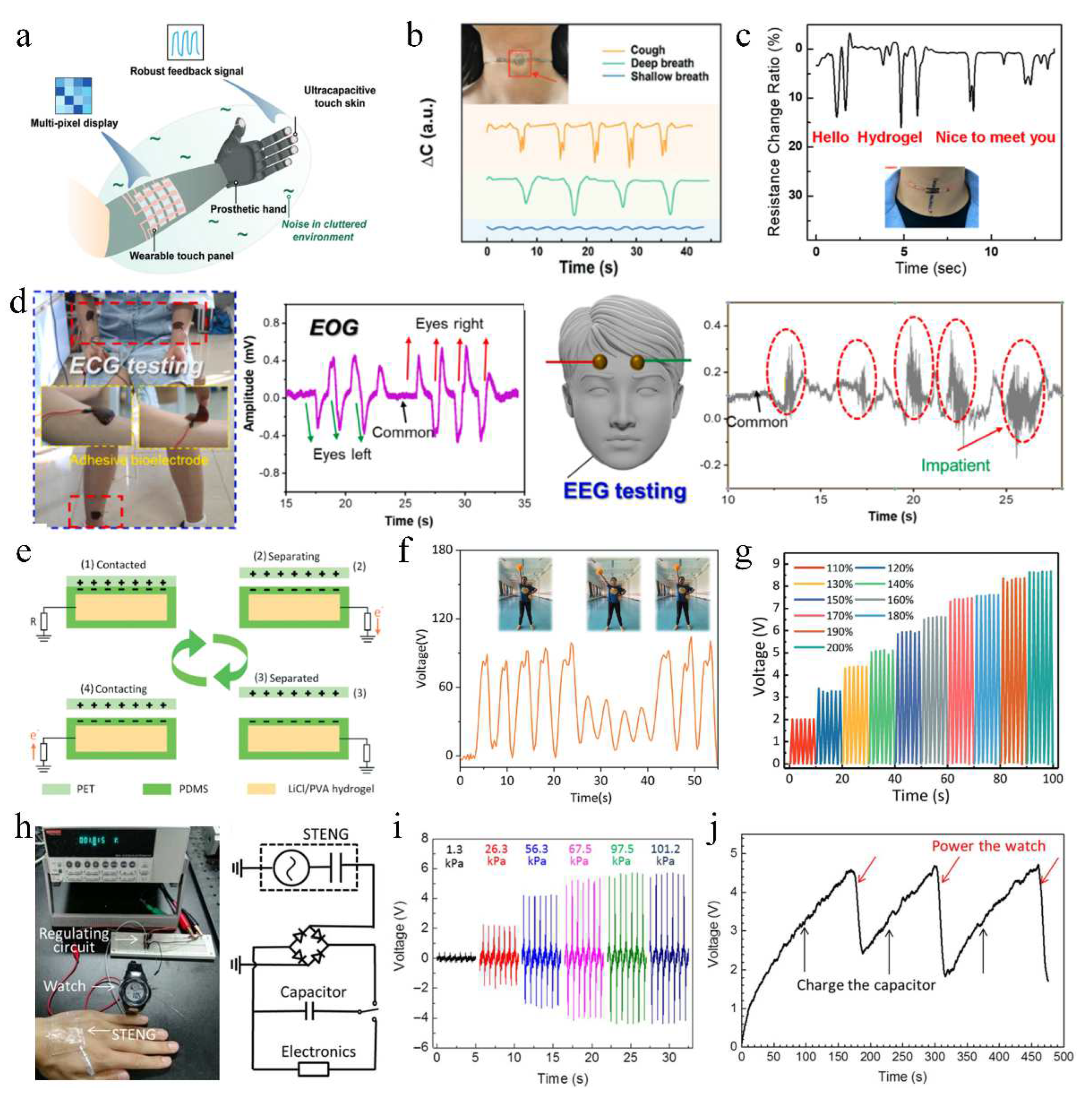

4.2. Applications in Soft Wearable Devices

5. Conclusions and Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, X.; Yang, Z.; Wang, Y.; Zhang, G.; Shao, Y.; Jia, H.; Cao, T.; Wang, R.; Liu, D. Remote Controlling DNA Hydrogel by Magnetic Field. ACS Appl. Mater. Interfaces 2017, 9, 1995–2000. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, Y.; Li, Q.; Yu, C.; Chu, W. Natural Polymer-based Stimuli-responsive Hydrogels. Curr. Med. Chem. 2020, 27, 2631–2657. [Google Scholar] [CrossRef]

- Wu, L.; Li, L.; Qu, M.; Wang, H.; Bin, Y. Mussel-inspired Self-adhesive, Antidrying, and Antifreezing Poly(acrylic Acid)/bentonite/polydopamine Hybrid Glycerol-hydrogel and the Sensing Application. ACS Appl. Polym. Mater. 2020, 2, 3094–3106. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, T.; Yang, M.; Gao, W.; Wu, S.; Wang, K.; Dong, F.; Dang, J.; Zhou, D.; Zhang, J. Hydrogel Pressure Distribution Sensors Based on an Imaging Strategy and Machine Learning. ACS Appl. Electron. Mater. 2021, 3, 3599–3609. [Google Scholar] [CrossRef]

- Su, X.; Hao, D.; Xu, X.; Guo, X.; Li, Z.; Jiang, L. Hydrophilic/hydrophobic Heterogeneity Anti-biofouling Hydrogels with Well-regulated Rehydration. ACS Appl. Mater. Interfaces 2020, 12, 25316–25323. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, X.; Li, X.; Ma, C.; Chu, X.; Wang, L.; Xu, W. A Review on Recent Advances of Protein-polymer Hydrogels. Eur. Polym. J. 2022, 162, 110881. [Google Scholar] [CrossRef]

- Le Goff, G.C.; Srinivas, R.L.; Hill, W.A.; Doyle, P.S. Hydrogel Microparticles for Biosensing. Eur. Polym. J. 2015, 72, 386–412. [Google Scholar] [CrossRef]

- Cui, L.; Yao, Y.; Yim, E.K.F. The Effects of Surface Topography Modification on Hydrogel Properties. Appl. Bioeng. 2021, 5, 031509. [Google Scholar] [CrossRef]

- Volpi, M.; Paradiso, A.; Costantini, M.; Swie, W. Hydrogel-based Fiber Biofabrication Techniques for Skeletal Muscle Tissue Engineering. ACS Biomater. Sci. Eng. 2022, 8, 379–405. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Li, H. Incorporation of Bioglass Improved the Mechanical Stability and Bioactivity of Alginate/carboxymethyl Chitosan Hydrogel Wound Dressing. ACS Appl. Bio Mater. 2021, 4, 1677–1692. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Du, Z.; Deng, X.; Wang, T.; Yang, Z.; Zhou, W.; Wang, C. Dual Physically Cross-linked Hydrogels with High Stretchability, Toughness, and Good Self-recoverability. Macromolecules 2016, 49, 5660–5668. [Google Scholar] [CrossRef]

- Hu, J.; Hiwatashi, K.; Kurokawa, T.; Liang, S.M.; Wu, Z.L.; Gong, J.P. Microgel-reinforced Hydrogel Films with High Mechanical Strength and Their Visible Mesoscale Fracture Structure. Macromolecules 2011, 44, 7775–7781. [Google Scholar] [CrossRef]

- Samadi, N.; Sabzi, M.; Babaahmadi, M. Self-healing and Tough Hydrogels with Physically Cross-linked Triple Networks Based on Agar/PVA/graphene. Int. J. Biol. Macromol. 2018, 107, 2291–2297. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Xiang, N.; Zhang, H.; Sun, Y.; Lin, Z.; Hou, L. Preparation and Characterization of Poly(vinyl Alcohol)/sodium Alginate Hydrogel with High Toughness and Electric Conductivity. Carbohydr. Polym. 2018, 186, 377–383. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.-C.; Lee, H.-H.; Oh, K.H.; Sun, J.-Y. Highly Stretchable, Transparent Ionic Touch Panel. Science 2016, 353, 682–687. [Google Scholar] [CrossRef] [PubMed]

- Wei, J.; Xie, J.; Zhang, P.; Zou, Z.; Ping, H.; Wang, W.; Xie, H.; Shen, J.Z.; Lei, L.; Fu, Z. Bioinspired 3d Printable, Self-healable, and Stretchable Hydrogels with Multiple Conductivities for Skin-like Wearable Strain Sensors. ACS Appl. Mater. Interfaces 2021, 13, 2952–2960. [Google Scholar] [CrossRef] [PubMed]

- Su, G.; Yin, S.; Guo, Y.; Zhao, F.; Guo, Q.; Zhang, X.; Zhou, T.; Yu, G. Balancing the Mechanical, Electronic, and Self-healing Properties in Conductive Self-healing Hydrogel for Wearable Sensor Applications. Mater. Horiz. 2021, 8, 1795–1804. [Google Scholar] [PubMed]

- Liu, Z.; Wang, Y.; Ren, Y.; Jin, G.; Zhang, C.; Chen, W.; Yan, F. Poly(ionic Liquid) Hydrogel-based Anti-freezing Ionic Skin for a Soft Robotic Gripper. Mater. Horiz. 2020, 7, 919–927. [Google Scholar] [CrossRef]

- Bai, J.; Wang, R.; Wang, X.; Liu, S.; Wang, X.; Ma, J.; Qin, Z.; Jiao, T. Biomineral Calcium-ion-mediated Conductive Hydrogels with High Stretchability and Self-adhesiveness for Sensitive Iontronic Sensors. Cell Rep. Phys. Sci. 2021, 2, 100623. [Google Scholar] [CrossRef]

- Sun, L.; Zhu, X.; Zhang, X.; Chen, G.; Bian, F.; Wang, J.; Zhou, Q.; Wang, D.; Zhao, Y. Induced Cardiomyocytes-integrated Conductive Microneedle Patch for Treating Myocardial Infarction. Chem. Eng. J. 2021, 414, 128723. [Google Scholar] [CrossRef]

- Korupalli, C.; Li, H.; Nguyen, N.; Mi, F.-L.; Chang, Y.; Lin, Y.-J.; Sung, H.-W. Conductive Materials for Healing Wounds: Their Incorporation in Electroactive Wound Dressings, Characterization, and Perspectives. Adv. Healthc. Mater. 2021, 10, 2001384. [Google Scholar] [CrossRef] [PubMed]

- Zhou, N.; Wang, T.; Chen, S.; Hu, Q.; Cheng, X.; Sun, D.; Vupputuri, S.; Qiu, B.; Liu, H.; Guo, Z. Conductive Polyaniline Hydrogel Enhanced Methane Production from Anaerobic Wastewater Treatment. J. Colloid Interface Sci. 2021, 581, 314–322. [Google Scholar] [CrossRef] [PubMed]

- Lemos Morais, J.P.; Bernardino, D.V.; Batista, B.D.S.; Pereira, W.O.; Borges Amaral, F.M.; Meneses Pedra Branca, M.C.; Gasparin, F.P.; Dos Santos, A.O.; Bezerra Sombra, A.S.; Mendes, F.; et al. Conductive Polymer Blend Based on Polyaniline and Galactomannan: Optical and Electrical Properties. Synth. Met. 2023, 295, 1442–1452. [Google Scholar] [CrossRef]

- Sun, X.; Wang, H.; Ding, Y.; Yao, Y.; Liu, Y.; Tang, J. Fe3+-coordination Mediated Synergistic Dual-network Conductive Hydrogel as a Sensitive and Highly-stretchable Strain Sensor with Adjustable Mechanical Properties. J. Mater. Chem. B 2022, 10, 1442–1452. [Google Scholar] [CrossRef] [PubMed]

- Hur, J.; Im, K.; Kim, S.W.; Kim, J.; Chung, D.-Y.; Kim, T.-H.; Jo, K.H.; Hahn, J.H.; Bao, Z.; Hwang, S.; et al. Polypyrrole/agarose-based Electronically Conductive and Reversibly Restorable Hydrogel. Acs Nano 2014, 8, 10066–10076. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Cong, Y.; Fu, J. Stretchable and Tough Conductive Hydrogels for Flexible Pressure and Strain Sensors. J. Mater. Chem. B 2020, 8, 3437–3459. [Google Scholar] [CrossRef] [PubMed]

- Rivero, R.E.; Molina, M.A.; Rivarola, C.R.; Barbero, C.A. Pressure and Microwave Sensors/actuators Based on Smart Hydrogel/conductive Polymer Nanocomposite. Sens. Actuators B Chem. 2014, 190, 270–278. [Google Scholar] [CrossRef]

- Li, T.; Liang, B.; Ye, Z.; Zhang, L.; Xu, S.; Tu, T.; Zhang, Y.; Cai, Y.; Zhang, B.; Fang, L.; et al. An Integrated and Conductive Hydrogel-paper Patch for Simultaneous Sensing of Chemical-electrophysiological Signals. Biosens. Bioelectron. 2022, 198, 113855. [Google Scholar] [CrossRef]

- Yang, Z.; Ma, J.; Bai, B.; Qiu, A.; Losic, D.; Shi, D.; Chen, M. Free-standing PEDOT/polyaniline Conductive Polymer Hydrogel for Flexible Solid-state Supercapacitors. Electrochim. Acta 2019, 322, 134769. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Lu, H.; Wang, Y.; Xu, J.; Zhu, J.; Zhang, C.; Liu, T. Cryopolymerization Enables Anisotropic Polyaniline Hybrid Hydrogels with Superelasticity and Highly Deformation-tolerant Electrochemical Energy Storage. Nat. Commun. 2020, 11, 62. [Google Scholar] [CrossRef]

- Wang, J.; Lin, Y.; Mohamed, A.; Ji, Q.; Jia, H. High Strength and Flexible Aramid Nanofiber Conductive Hydrogels for Wearable Strain Sensors. J. Mater. Chem. C 2021, 9, 575–583. [Google Scholar] [CrossRef]

- Gebeyehu, E.K.; Sui, X.; Adamu, B.F.; Beyene, K.A.; Tadesse, M.G. Cellulosic-based Conductive Hydrogels for Electro-active Tissues: A Review Summary. Gels 2022, 8, 140. [Google Scholar] [CrossRef] [PubMed]

- Lin, F.; Wang, Z.; Shen, Y.; Tang, L.; Zhang, P.; Wang, Y.; Chen, Y.; Huang, B.; Lu, B. Natural Skin-inspired Versatile Cellulose Biomimetic Hydrogels. J. Mater. Chem. A 2019, 7, 26442–26455. [Google Scholar] [CrossRef]

- Kim, Y.S.; Cho, K.; Lee, H.J.; Chang, S.; Lee, H.; Kim, J.H.; Koh, W.-G. Highly Conductive and Hydrated Peg-based Hydrogels for the Potential Application of a Tissue Engineering Scaffold. React. Funct. Polym. 2016, 109, 15–22. [Google Scholar] [CrossRef]

- Xia, S.; Song, S.; Jia, F.; Gao, G. A Flexible, Adhesive and Self-healable Hydrogel-based Wearable Strain Sensor for Human Motion and Physiological Signal Monitoring. J. Mater. Chem. B 2019, 7, 4638–4648. [Google Scholar] [CrossRef] [PubMed]

- Han, L.; Lu, X.; Wang, M.; Gan, D.; Deng, W.; Wang, K.; Fang, L.; Liu, K.; Chan, C.W.; Tang, Y.; et al. A Mussel-inspired Conductive, Self-adhesive, and Self-healable Tough Hydrogel as Cell Stimulators and Implantable Bioelectronics. Small 2017, 13, 1601916. [Google Scholar]

- Park, J.; Jeon, J.; Kim, B.; Lee, M.S.; Park, S.; Lim, J.; Yi, J.; Lee, H.; Yang, H.S.; Lee, J.Y. Electrically Conductive Hydrogel Nerve Guidance Conduits for Peripheral Nerve Regeneration. Adv. Funct. Mater. 2020, 30, 2003759. [Google Scholar]

- Qin, Z.; Sun, X.; Yu, Q.; Zhang, H.; Wu, X.; Yao, M.; Liu, W.; Yao, F.; Li, J. Carbon Nanotubes/hydrophobically Associated Hydrogels as Ultrastretchable, Highly Sensitive, Stable Strain, and Pressure Sensors. ACS Appl. Mater. Interfaces 2020, 12, 4944–4953. [Google Scholar] [CrossRef]

- Han, J.; Wang, H.; Yue, Y.; Mei, C.; Chen, J.; Huang, C.; Wu, Q.; Xu, X. A Self-healable and Highly Flexible Supercapacitor Integrated by Dynamically Cross-linked Electro-Conductive Hydrogels Based on Nanocellulose-templated Carbon Nanotubes Embedded in a Viscoelastic Polymer Network. Carbon 2019, 149, 1–18. [Google Scholar] [CrossRef]

- Wu, N.; Wang, X.; Das, C.M.; Ma, M.; Qiao, N.; Fan, T.; Zhang, H.; Xu, G.; Yong, K.-T. Bioengineering Applications of Black Phosphorus and Their Toxicity Assessment. Environ. Sci.-Nano 2021, 8, 3452–3477. [Google Scholar] [CrossRef]

- An, D.; Fu, J.; Xie, Z.; Xing, C.; Zhang, B.; Wang, B.; Qiu, M. Progress in the Therapeutic Applications of Polymer-decorated Black Phosphorus and Black Phosphorus Analog Nanomaterials in Biomedicine. J. Mater. Chem. B 2020, 8, 7076–7120. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.-H.; Du, X.-S. Self-healable and Redox Active Hydrogel Obtained Via Incorporation of Ferric Ion for Supercapacitor Applications. Chem. Eng. J. 2022, 446, 137244. [Google Scholar] [CrossRef]

- Homaeigohar, S.; Tsai, T.-Y.; Young, T.-H.; Yang, H.J.; Ji, Y.-R. An Electroactive Alginate Hydrogel Nanocomposite Reinforced by Functionalized Graphite Nanofilaments for Neural Tissue Engineering. Carbohydr. Polym. 2019, 224, 115112. [Google Scholar] [CrossRef] [PubMed]

- Rastin, H.; Zhang, B.; Mazinani, A.; Hassan, K.; Bi, J.; Tran Thanh, T.; Losic, D. 3d Bioprinting of Cell-laden Electroconductive Mxene Nanocomposite Bioinks. Nanoscale 2020, 12, 16069–16080. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.-J.; Cao, W.-T.; Ma, M.-G.; Wan, P. Ultrasensitive Wearable Soft Strain Sensors of Conductive, Self-healing, and Elastic Hydrogels with Synergistic “soft and Hard” Hybrid Networks. ACS Appl. Mater. Interfaces 2017, 9, 25559–25570. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Dang, C.; Liu, H.; Wang, M.; Feng, X.; Zhang, C.; Kang, J.; Qi, H. Highly Strong and Transparent Ionic Conductive Hydrogel as Multifunctional Sensors. Macromol. Mater. Eng. 2020, 305, 2000475. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Y. A Functional Triboelectric Nanogenerator Based on the Licl/pva Hydrogel for Cheerleading Training. Mater. Technol. 2022, 37, 2752–2757. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Z.; Jiang, D.; Guo, N.; Wang, Y.; Ding, T.; Weng, L. A Highly Stretchable, Sensing Durability, Transparent, and Environmentally Stable Ion Conducting Hydrogel Strain Sensor Built by Interpenetrating Ca2+-sa and Glycerol-PVA Double Physically Cross-linked Networks. Adv. Compos. Hybrid Mater. 2022, 5, 1712–1729. [Google Scholar] [CrossRef]

- Zhao, S.; Tseng, P.; Grasman, J.; Wang, Y.; Li, W.; Napier, B.; Yavuz, B.; Chen, Y.; Howell, L.; Rincon, J.; et al. Programmable Hydrogel Ionic Circuits for Biologically Matched Electronic Interfaces. Adv. Mater. 2018, 30, 1800598. [Google Scholar] [CrossRef]

- Ohm, Y.; Pan, C.; Ford, M.J.; Huang, X.; Liao, J.; Majidi, C. An Electrically Conductive Silver–polyacrylamide–alginate Hydrogel Composite for Soft Electronics. Nat. Electron. 2021, 4, 185–192. [Google Scholar] [CrossRef]

- Li, Z.; Cui, C.; Zhang, Z.; Meng, X.; Yan, Q.; Ouyang, J.; Xu, W.; Niu, Y.; Zhang, S. The Investigation of a Multi-functional Peptide as Gelator, Dyes Separation Agent and Metal Ions Adsorbent. Chemistryselect 2019, 4, 7838–7843. [Google Scholar] [CrossRef]

- Ji, S.; Wan, C.; Wang, T.; Li, Q.; Chen, G.; Wang, J.; Liu, Z.; Yang, H.; Liu, X.; Chen, X. Water-resistant Conformal Hybrid Electrodes for Aquatic Endurable Electrocardiographic Monitoring. Adv. Mater. 2020, 32, 2001496. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.; Ma, P.X.; Guo, B. Conductive Biomaterials for Muscle Tissue Engineering. Biomaterials 2020, 229, 119584. [Google Scholar] [CrossRef] [PubMed]

- Guo, B.; Ma, P.X. Conducting Polymers for Tissue Engineering. Biomacromolecules 2018, 19, 1764–1782. [Google Scholar] [CrossRef] [PubMed]

- Radisic, M.; Park, H.; Shing, H.; Consi, T.; Schoen, F.J.; Langer, R.; Freed, L.E.; Vunjak-novakovic, G. Functional Assembly of Engineered Myocardium by Electrical Stimulation of Cardiac Myocytes Cultured on Scaffolds. Proc. Natl. Acad. Sci. USA 2004, 101, 18129–18134. [Google Scholar] [CrossRef] [PubMed]

- Thompson, B.C.; Richardson, R.T.; Moulton, S.E.; Evans, A.J.; O’leary, S.; Clark, G.M.; Wallace, G.G. Conducting Polymers, Dual Neurotrophins and Pulsed Electrical Stimulation—Dramatic Effects on Neurite Outgrowth. J. Control Release 2010, 141, 161–167. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.-R.; Kim, C.-C.; Sun, J.-Y. Stretchable Ionics—A Promising Candidate for Upcoming Wearable Devices. Adv. Mater. 2018, 30, 1704403. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Yang, H.; Meng, H.; Sun, Y.; Zheng, J.; Ma, D.; Xu, X. Three-dimensional Conductive Gel Network as an Effective Binder for High-performance Si Electrodes in Lithium-ion Batteries. ACS Appl. Mater. Interfaces 2015, 7, 15961–15967. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Wan, C.; Yang, Y.; Yang, H.; Wang, S.; Dai, Z.; Ji, K.; Jiang, H.; Chen, X.; Long, Y. Highly Stretchable, Elastic, and Ionic Conductive Hydrogel for Artificial Soft Electronics. Adv. Funct. Mater. 2019, 29, 1806220. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, R.; Liu, J.; Zhao, L.; Yu, Y. High Strength and Conductive Hydrogel with Fully Interpenetrated Structure from Alginate and Acrylamide. E-Polymers 2021, 21, 391–397. [Google Scholar] [CrossRef]

- Qi, J.; Wang, A.c.; Yang, W.; Zhang, M.; Hou, C.; Zhang, Q.; Li, Y.; Wang, H. Hydrogel-based Hierarchically Wrinkled Stretchable Nanofibrous Membrane for High Performance Wearable Triboelectric Nanogenerator. Nano Energy 2020, 67, 104206. [Google Scholar] [CrossRef]

- Dong Nyoung, H.; Lee, S.-J.; Timsina, R.; Qiu, X.; Castro, N.J.; Zhang, L.G. Development of 3d Printable Conductive Hydrogel with Crystallized Pedot:pss for Neural Tissue Engineering. Mater. Sci. Eng. C-Mater. Biol. Appl. 2019, 99, 582–590. [Google Scholar]

- Wang, S.; Yu, L.; Wang, S.; Zhang, L.; Chen, L.; Xu, X.; Song, Z.; Liu, H.; Chen, C. Strong, Tough, Ionic Conductive, and Freezing-tolerant All-natural Hydrogel Enabled by Cellulose-bentonite Coordination Interactions. Nat. Commun. 2022, 13, 3408. [Google Scholar] [CrossRef] [PubMed]

- Yao, X.; Zhang, S.; Qian, L.; Wei, N.; Nica, V.; Coseri, S.; Han, F. Super Stretchable, Self-healing, Adhesive Ionic Conductive Hydrogels Based on Tailor-made Ionic Liquid for High-performance Strain Sensors. Adv. Funct. Mater. 2022, 32, 2204565. [Google Scholar] [CrossRef]

- Cai, G.; Wang, J.; Qian, K.; Chen, J.; Li, S.; Lee, P.S. Extremely Stretchable Strain Sensors Based on Conductive Self-healing Dynamic Cross-links Hydrogels for Human-motion Detection. Adv. Sci. 2017, 4, 1600190. [Google Scholar] [CrossRef] [PubMed]

- Shao, C.; Wang, M.; Meng, L.; Chang, H.; Wang, B.; Xu, F.; Yang, J.; Wan, P. Mussel-inspired Cellulose Nanocomposite Tough Hydrogels with Synergistic Self-healing, Adhesive, and Strain-sensitive Properties. Chem. Mater. 2018, 30, 3110–3121. [Google Scholar] [CrossRef]

- Han, S.; Liu, C.; Lin, X.; Zheng, J.; Wu, J.; Liu, C. Dual Conductive Network Hydrogel for a Highly Conductive, Self-healing, Anti-freezing, and Non-drying Strain Sensor. ACS Appl. Polym. Mater. 2020, 2, 996–1005. [Google Scholar] [CrossRef]

- Pan, X.; Wang, Q.; Guo, R.; Ni, Y.; Liu, K.; Ouyang, X.; Chen, L.; Huang, L.; Cao, S.; Xie, M. An integrated transparent, UV-filtering organohydrogel sensor via molecular-level ion conductive channels. J. Mater. Chem. A 2019, 7, 4525–4535. [Google Scholar] [CrossRef]

- Shi, H.; Liu, C.; Jiang, Q.; Xu, J. Effective Approaches to Improve the Electrical Conductivity of PEDOT:PSS: A Review. Adv. Electron. Mater. 2015, 1, 1500017. [Google Scholar] [CrossRef]

- Kayser, L.V.; Lipomi, D.J. Stretchable Conductive Polymers and Composites Based on PEDOT and PEDOT:PSS. Adv. Mater. 2019, 31, 1806133. [Google Scholar] [CrossRef]

- Fonner, J.M.; Schmidt, C.E.; Ren, P. A Combined Molecular Dynamics and Experimental Study of Doped Polypyrrole. Polymer 2010, 51, 4985–4993. [Google Scholar] [CrossRef] [PubMed]

- Li, X.F.; Kolega, J. Effects of Direct Current Electric Fields on Cell Migration and Actin Filament Distribution in Bovine Vascular Endothelial Cells. J. Vasc. Res. 2002, 39, 391–404. [Google Scholar] [CrossRef] [PubMed]

- Li, X.-G.; Wei, F.; Huang, M.-R.; Xie, Y.-B. Facile Synthesis and Intrinsic Conductivity of Novel Pyrrole Copolymer Nanoparticles with Inherent Self-stability. J. Phys. Chem. B 2007, 111, 5829–5836. [Google Scholar] [CrossRef]

- Golabi, M.; Padiolleau, L.; Chen, X.; Jafari, M.J.; Sheikhzadeh, E.; Turner, A.P.F.; Jager, E.W.H.; Beni, V. Doping Polypyrrole Films with 4-n-pentylphenylboronic Acid to Enhance Affinity Towards Bacteria and Dopamine. PLoS ONE 2016, 11, e0166548. [Google Scholar] [CrossRef] [PubMed]

- Song, R.-B.; Wu, Y.; Lin, Z.-Q.; Xie, J.; Tan, C.H.; Loo, J.S.C.; Cao, B.; Zhang, J.-R.; Zhu, J.-J.; Zhang, Q. Living and Conducting: Coating Individual Bacterial Cells with In Situ Formed Polypyrrole. Angew. Chem.-Int. Ed. 2017, 56, 10516–10520. [Google Scholar] [CrossRef] [PubMed]

- Xu, D.; Fan, L.; Gao, L.; Xiong, Y.; Wang, Y.; Ye, Q.; Yu, A.; Dai, H.; Yin, Y.; Cai, J.; et al. Micro-nanostructured Polyaniline Assembled in Cellulose Matrix Via Interfacial Polymerization for Applications in Nerve Regeneration. ACS Appl. Mater. Interfaces 2016, 8, 17090–17097. [Google Scholar] [CrossRef]

- Lee, I.; Luo, X.; Cui, X.T.; Yun, M. Highly Sensitive Single Polyaniline Nanowire Biosensor for the Detection of Immunoglobulin G and Myoglobin. Biosens. Bioelectron. 2011, 26, 3297–3302. [Google Scholar] [CrossRef] [PubMed]

- Lai, J.; Yi, Y.; Zhu, P.; Shen, J.; Wu, K.; Zhang, L.; Liu, J. Polyaniline-based Glucose Biosensor: A Review. J. Electroanal. Chem. 2016, 782, 138–153. [Google Scholar] [CrossRef]

- Guan, L.; Yan, S.; Liu, X.; Li, X.; Gao, G. Wearable Strain Sensors Based on Casein-driven Tough, Adhesive and Anti-freezing Hydrogels for Monitoring Human-motion. J. Mater. Chem. B 2019, 7, 5230–5236. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Niu, W.; Zhang, S. Extremely Stretchable, Sticky and Conductive Double-network Ionic Hydrogel for Ultra-stretchable and Compressible Supercapacitors. Chem. Eng. J. 2020, 387, 124105. [Google Scholar] [CrossRef]

- Zhang, X.; Cai, J.; Liu, W.; Liu, W.; Qiu, X. Synthesis of Strong and Highly Stretchable, Electrically Conductive Hydrogel with Multiple Stimuli Responsive Shape Memory Behavior. Polymer 2020, 188, 122147. [Google Scholar] [CrossRef]

- Han, L.; Liu, K.; Wang, M.; Wang, K.; Fang, L.; Chen, H.; Zhou, J.; Lu, X. Mussel-inspired Adhesive and Conductive Hydrogel with Long-lasting Moisture and Extreme Temperature Tolerance. Adv. Funct. Mater. 2018, 28, 1704195. [Google Scholar] [CrossRef]

- Pi, M.; Jiang, L.; Wang, Z.; Cui, W.; Shi, L.; Ran, R. Robust and Ultrasensitive Hydrogel Sensors Enhanced by Mxene/cellulose Nanocrystals. J. Mater. Sci. 2021, 56, 8871–8886. [Google Scholar] [CrossRef]

- Chen, G.; Matsuhisa, N.; Liu, Z.; Qi, D.; Cai, P.; Jiang, Y.; Wan, C.; Cui, Y.; Leow, W.R.; Liu, Z.; et al. Plasticizing Silk Protein for On-skin Stretchable Electrodes. Adv. Mater. 2018, 30, 1800129. [Google Scholar] [CrossRef]

- Li, Z.; Xu, W.; Wang, X.; Jiang, W.; Ma, X.; Wang, F.; Zhang, C.; Ren, C. Fabrication of Pva/paam Ipn Hydrogel with High Adhesion and Enhanced Mechanical Properties for Body Sensors and Antibacterial Activity. Eur. Polym. J. 2021, 146, 110253. [Google Scholar] [CrossRef]

- Naficy, S.; Razal, J.M.; Spinks, G.M.; Wallace, G.G.; Whitten, P.G. Electrically Conductive, Tough Hydrogels with Ph Sensitivity. Chem. Mater. 2012, 24, 3425–3433. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.; Niu, Y.; Ma, S.; Xue, Z.; Song, A.; Zhang, S.; Xu, W.; Ren, C. Fabrication of Cs/sa Double-network Hydrogel and Application in Ph-controllable Drug Release. Chemistryselect 2019, 4, 14036–14042. [Google Scholar] [CrossRef]

- Zhan, J.; Wu, Y.; Wang, H.; Liu, J.; Ma, Q.; Xiao, K.; Li, Z.; Li, J.; Luo, F.; Tan, H. An Injectable Hydrogel with Ph-sensitive and Self-healing Properties Based on 4armpegda and N-carboxyethyl Chitosan for Local Treatment of Hepatocellular Carcinoma. Int. J. Biol. Macromol. 2020, 163, 1208–1222. [Google Scholar] [CrossRef]

- Czakkel, O.; Berke, B.; Laszlo, K. Effect of Graphene-derivatives on the Responsivity of Pnipam-based Thermosensitive Nanocomposites—A Review. Eur. Polym. J. 2019, 116, 106–116. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, J.; Gong, Y.; Zhang, H.; Xu, T.; Nie, L.; Fu, J. Ultrastretchable Strain Sensors and Arrays with High Sensitivity and Linearity Based on Super Tough Conductive Hydrogels. Chem. Mater. 2018, 30, 8062–8069. [Google Scholar] [CrossRef]

- Wei, J.; Wang, Q. Hofmeister Effect-aided Assembly of Enhanced Hydrogel Supercapacitor with Excellent Interfacial Contact and Reliability. Small Methods 2019, 3, 1900558. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, Q.; Wang, Q.; Zhou, L.; Gao, G. Bio-based Hydrogel Transducer for Measuring Human Motion with Stable Adhesion and Ultrahigh Toughness. ACS Appl. Mater. Interfaces 2021, 13, 24173–24182. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Yao, F.; Wang, C.; Qin, Z.; Zhang, H.; Yu, Q.; Zhang, H.; Dong, X.; Wei, Y.; Li, J. Ionically Conductive Hydrogel with Fast Self-recovery and Low Residual Strain as Strain and Pressure Sensors. Macromol. Rapid Commun. 2020, 41, 2000185. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, L.; Lu, A. Transparent, Ant freezing, Ionic Conductive Cellulose Hydrogel with Stable Sensitivity at Subzero Temperature. ACS Appl. Mater. Interfaces 2019, 11, 41710–41716. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Daoud, W.A. Hybrid Conductive Hydrogels for Washable Human Motion Energy Harvester and Self-powered Temperature-stress Dual Sensor. Nano Energy 2019, 66, 104080. [Google Scholar] [CrossRef]

- Mo, J.; Dai, Y.; Zhang, C.; Zhou, Y.; Li, W.; Song, Y.; Wu, C.; Wang, Z. Design of Ultra-stretchable, Highly Adhesive and Self-healable Hydrogels Via Tannic Acid-enabled Dynamic Interactions. Mater. Horiz. 2021, 8, 3409–3416. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Li, T.; Miao, L.; Kaur, P.; Men, S.; Wang, Q.; Gong, X.; Fang, Y.; Zhai, C.; Zhang, S.; et al. A Highly Sensitive and Ultra-stretchable Zwitterionic Liquid Hydrogel-based Sensor as Anti-freezing Ionic Skin. J. Mater. Chem. A 2022, 10, 3970–3988. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Yin, Y.; Liu, J.; Li, P.; Zhao, Y.; Bai, D.; Zhao, H.; Han, X.; Chen, Q. High-strength and Injectable Supra-molecular Hydrogel Self-assembled by Monomeric Nucleoside for Tooth-extraction Wound Healing. Adv. Mater. 2022, 34, 2108300. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Suo, Z. Hydrogel Ionotronics. Nat. Rev. Mater. 2018, 3, 125–142. [Google Scholar] [CrossRef]

- Chen, F.; Zhou, D.; Wang, J.; Li, T.; Zhou, X.; Gan, T.; Handschuh-wang, S.; Zhou, X. Rational Fabrication of Anti-freezing, Non-drying Tough Organohydrogels by One-pot Solvent Displacement. Angew. Chem.-Int. Ed. 2018, 57, 6568–6571. [Google Scholar] [CrossRef]

- Xie, Z.; Li, H.; Mi, H.-y.; Feng, P.-y.; Liu, Y.; Jing, X. Freezing-tolerant, Widely Detectable and Ultra-sensitive Composite Or-ganohydrogel for Multiple Sensing Applications. J. Mater. Chem. C 2021, 9, 10127–10137. [Google Scholar] [CrossRef]

- Wang, M.X.; Chen, Y.M.; Gao, Y.; Hu, C.; Hu, J.; Tan, L.; Yang, Z. Rapid Self-recoverable Hydrogels with High Toughness and Excellent Conductivity. ACS Appl. Mater. Interfaces 2018, 10, 26610–26617. [Google Scholar]

- Wu, Z.; Shi, W.; Ding, H.; Zhong, B.; Huang, W.; Zhou, Y.; Gui, X.; Xie, X.; Wu, J. Ultrastable, Stretchable, Highly Conductive and Transparent Hydrogels Enabled by Salt-percolation for High-performance Temperature and Strain Sensing. J. Mater. Chem. C 2021, 9, 13668–13679. [Google Scholar] [CrossRef]

- Yang, N.; Qi, P.; Ren, J.; Yu, H.; Liu, S.; Li, J.; Chen, W.; Kaplan, D.L.; Ling, S. Polyvinyl Alcohol/silk Fibroin/borax Hydrogel Ionotronics: A Highly Stretchable, Self-healable, and Biocompatible Sensing Platform. ACS Appl. Mater. Interfaces 2019, 11, 23632–23638. [Google Scholar] [CrossRef] [PubMed]

- Morelle, X.P.; Illeperuma, W.R.; Tian, K.; Bai, R.; Suo, Z.; Vlassak, J.J. Highly Stretchable and Tough Hydrogels Below Water Freezing Temperature. Adv. Mater. 2018, 30, 1801541. [Google Scholar] [CrossRef] [PubMed]

- Shuai, L.; Guo, Z.H.; Zhang, P.; Wan, J.; Pu, X.; Wang, Z.L. Stretchable, Self-healing, Conductive Hydrogel Fibers for Strain Sensing and Triboelectric Energy-harvesting Smart Textiles. Nano Energy 2020, 78, 105389. [Google Scholar] [CrossRef]

- He, P.; Wu, J.; Pan, X.; Chen, L.; Liu, K.; Gao, H.; Wu, H.; Cao, S.; Huang, L.; Ni, Y. Anti-freezing and Moisturizing Conductive Hydrogels for Strain Sensing and Moist-electric Generation Applications. J. Mater. Chem. A 2020, 8, 3109–3118. [Google Scholar] [CrossRef]

- Chen, W.; Bu, Y.; Li, D.; Liu, C.; Chen, G.; Wan, X.; Li, N. High-strength, Tough, and Self-healing Hydrogel Based on Car-boxymethyl Cellulose. Cellulose 2019, 27, 853–865. [Google Scholar] [CrossRef]

- Lu, X.; Li, Y.; Feng, W.; Guan, S.; Guo, P. Self-healing Hydroxypropyl Guar Gum/poly (acrylamide-co-3-acrylamidophenyl Bo-ronic Acid) Composite Hydrogels with Yield Phenomenon Based on Dynamic PBA Ester Bonds and H-bond. Colloids Surf. A-Physicochem. Eng. Asp. 2019, 561, 325–331. [Google Scholar] [CrossRef]

- Zhang, Y.s.; Khademhosseini, A. Advances in Engineering Hydrogels. Science 2017, 356, eaaf3627. [Google Scholar] [CrossRef]

- Sasaki, M.; Karikkineth, B.c.; Nagamine, K.; Kaji, H.; Torimitsu, K.; Nishizawa, M. Highly Conductive Stretchable and Bio-compatible Electrode-hydrogel Hybrids for Advanced Tissue Engineering. Adv. Healthc. Mater. 2014, 3, 1919–1927. [Google Scholar] [CrossRef] [PubMed]

- Sontyana, A.G.; Mathew, A.P.; Cho, K.-H.; Uthaman, S.; Park, I.-K. Biopolymeric in Situ Hydrogels for Tissue Engineering and Bioimaging Applications. Tissue Eng. Regen. Med. 2018, 15, 575–590. [Google Scholar] [CrossRef] [PubMed]

- Peng, S.; Liu, S.; Sun, Y.; Xiang, N.; Jiang, X.; Hou, L. Facile preparation and characterization of poly(vinyl alcohol)-NaCl-glycerol supramolecular hydrogel electrolyte. Eur. Polym. J. 2018, 106, 206–213. [Google Scholar] [CrossRef]

- Hua, D.; Gao, S.; Zhang, M.; Ma, W.; Huang, C. A Novel Xanthan Gum-based Conductive Hydrogel with Excellent Mechanical, Biocompatible, and Self-healing Performances. Carbohydr. Polym. 2020, 247, 116743. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Xu, J.; Gao, F.; Du, X.; Du, Z.; Cheng, X.; Wang, H. Self-healable and Recyclable Polyurethane-polyaniline Hydrogel Toward Flexible Strain Sensor. Compos. Part B-Eng. 2021, 219, 108965. [Google Scholar] [CrossRef]

- Zhao, L.; Ren, Z.; Liu, X.; Ling, Q.; Li, Z.; Gu, H. A Multifunctional, Self-Healing, Self-Adhesive, and Conductive Sodium Alginate/Poly(vinyl alcohol) Composite Hydrogel as a Flexible Strain Sensor. ACS Appl. Mater. Interfaces 2021, 13, 11344–11355. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Peng, Q.; Thundat, T.; Zeng, H. Stretchable, Injectable, and Self-healing Conductive Hydrogel Enabled by Multiple Hydrogen Bonding Toward Wearable Electronics. Chem. Mater. 2019, 31, 4553–4563. [Google Scholar] [CrossRef]

- Chen, H.; Song, Y.; Guo, H.; Miao, L.; Chen, X.; Su, Z.; Zhang, H. Hybrid Porous Micro Structured Finger Skin Inspired Self-Powered Electronic Skin System for Pressure Sensing and Sliding Detection. Nano Energy 2018, 51, 496–503. [Google Scholar] [CrossRef]

- Ren, Z.; Ke, T.; Ling, Q.; Zhao, L.; Gu, H. Rapid Self-healing and Self-adhesive Chitosan-based Hydrogels by Host-guest In-teraction and Dynamic Covalent Bond as Flexible Sensor. Carbohydr. Polym. 2021, 273, 108965. [Google Scholar] [CrossRef]

- Kim, M.; Ahn, Y.; Lee, K.; Jung, W.; Cha, C. In Situ Facile-forming Chitosan Hydrogels with Tunable Physicomechanical and Tissue Adhesive Properties by Polymer Graft Architecture. Carbohydr. Polym. 2020, 229, 115538. [Google Scholar] [CrossRef]

- Hurtado, A.; Cano-Vicent, A.; Tuñón-Molina, A.; Aparicio-Collado, J.L.; Salesa, B.; Serra, R.S.I.; Serrano-Aroca, Á. Engineering Alginate Hydrogel Films with Poly(3-hydroxybutyrate-co-3-valerate) and Graphene Nanoplatelets: Enhancement of Antiviral Activity, Cell Adhesion and Electroactive Properties. Int. J. Biol. Macromol. 2022, 219, 694–708. [Google Scholar] [CrossRef]

- Wang, M.; Rojas, O.J.; Ning, L.; Li, Y.; Niu, X.; Shi, X.; Qi, H. Liquid Metal and Mxene Enable Self-Healing Soft Electronics Based on Double Networks of Bacterial Cellulose Hydrogels. Carbohydr. Polym. 2023, 301, 120330. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Wang, Y.; Chen, H.; Jiang, W.; Zhu, C.; Toufouki, S.; Yao, S. A New Deep Eutectic Solvent-agarose Gel with Hydroxylated Fullerene as Electrical “switch” System for Drug Release. Carbohydr. Polym. 2022, 296, 119939. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Xue, J.; Ma, B.; Wu, J.; Chang, J.; Gelinsky, M.; Wu, C. Black Bioceramics: Combining Regeneration with Therapy. Adv. Mater. 2020, 32, 2005140. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.-L.; Li, S.-J.; Yang, R. Biomedical Titanium Alloys and Their Additive Manufacturing. Rare Met. 2016, 35, 661–671. [Google Scholar] [CrossRef]

- Ma, Z.; Sameoto, D. A Review of Electrically Driven Soft Actuators for Soft Robotics. Micromachines 2022, 13, 1881. [Google Scholar] [CrossRef]

- Ricotti, L.; Fujie, T.; Vazao, H.; Ciofani, G.; Marotta, R.; Brescia, R.; Filippeschi, C.; Corradini, I.; Matteoli, M.; Mattoli, V.; et al. Boron Nitride Nanotube-mediated Stimulation of Cell Co-culture on Micro-engineered Hydrogels. PLoS ONE 2013, 8, e71707. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Rubakhin, S.S.; Enright, M.J.; Sweedler, J.V.; Nuzzo, R.G. 3d Particle-free Printing of Biocompatible Conductive Hydrogel Platforms for Neuron Growth and Electrophysiological Recording. Adv. Funct. Mater. 2021, 31, 2010246. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Li, C.; Li, G.; Yu, D.; Song, Z.; Wang, H.; Liu, X.; Liu, H.; Liu, W. Development of Conductive Hydrogels for Fabricating Flexible Strain Sensors. Small 2022, 18, 2101518. [Google Scholar] [CrossRef]

- Qin, C.; Lu, A. Flexible, Anti-freezing Self-charging Power System Composed of Cellulose Based Supercapacitor and Triboelectric Nanogenerator. Carbohydr. Polym. 2021, 274, 118667. [Google Scholar] [CrossRef]

- Long, Y.; Bai, M.; Liu, X.; Lu, W.; Zhong, C.; Tian, S.; Xu, S.; Ma, Y.; Tian, Y.; Zhang, H.; et al. A Zwitterionic Cellulose-based Skin Sensor for the Real-time Monitoring and Antibacterial Sensing Wound Dressing. Carbohydr. Polym. 2022, 297, 119974. [Google Scholar] [CrossRef]

- Xu, Z.; Zhou, F.; Yan, H.; Gao, G.; Li, H.; Li, R.; Chen, T. Anti-freezing Organohydrogel Triboelectric Nanogenerator Toward Highly Efficient and Flexible Human-machine Interaction At −30 °C. Nano Energy 2021, 90, 106614. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, L.; Guo, B.; Shao, Y.; Ma, P.X. Electroactive Biodegradable Polyurethane Significantly Enhanced Schwann Cells Myelin Gene Expression and Neurotrophin Secretion for Peripheral Nerve Tissue Engineering. Biomaterials 2016, 87, 18–31. [Google Scholar] [CrossRef]

- Kharkar, P.M.; Kiick, K.L.; Kloxin, A.M. Designing Degradable Hydrogels for Orthogonal Control of Cell Microenvironments. Chem. Soc. Rev. 2013, 42, 7335–7372. [Google Scholar] [CrossRef]

- Saracino, G.A.A.; Cigognini, D.; Silva, D.; Caprini, A.; Gelain, F. Nanomaterials Design and Tests for Neural Tissue Engineering. Chem. Soc. Rev. 2013, 42, 225–262. [Google Scholar] [CrossRef]

- Thompson, T.; Steffert, T.; Ros, T.; Leach, J.; Gruzelier, J. Eeg Applications for Sport and Performance. Methods 2008, 45, 279–288. [Google Scholar] [CrossRef]

- George, J.; Hsu, C.-C.; Nguyen, L.T.B.; Ye, H.; Cui, Z. Neural Tissue Engineering with Structured Hydrogels in Cns Models and Therapies. Biotechnol. Adv. 2020, 42, 107370. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, S.; Ren, X.; Zhang, J.; Lin, Q.; Zhao, Y. Supramolecular Adhesive Hydrogels for Tissue Engineering Applications. Chem. Rev. 2022, 122, 5604–5640. [Google Scholar] [CrossRef]

- Yuk, H.; Lu, B.; Zhao, X. Hydrogel Bioelectronics. Chem. Soc. Rev. 2019, 48, 1642–1667. [Google Scholar] [CrossRef]

- Cooke, M.E.; Jones, S.W.; Ter Horst, B.; Moiemen, N.; Snow, M.; Chouhan, G.; Hill, L.J.; Esmaeli, M.; Moakes, R.J.A.; Holton, J.; et al. Structuring of Hydrogels Across Multiple Length Scales for Biomedical Applications. Adv. Mater. 2018, 30, 1705013. [Google Scholar] [CrossRef]

- He, L.; Xiao, Q.; Zhao, Y.; Li, J.; Reddy, S.; Shi, X.; Su, X.; Chiu, K.; Ramakrishna, S. Engineering an Injectable Electroactive Nanohybrid Hydrogel for Boosting Peripheral Nerve Growth and Myelination in Combination with Electrical Stimulation. ACS Appl. Mater. Interfaces 2020, 12, 53150–53163. [Google Scholar] [CrossRef]

- Liu, X.; Miller, A.L.; Park, S.; Waletzki, B.E.; Zhou, Z.; Terzic, A.; Lu, L. Functionalized Carbon Nanotube and Graphene Oxide Embedded Electrically Conductive Hydrogel Synergistically Stimulates Nerve Cell Differentiation. ACS Appl. Mater. Interfaces 2017, 9, 14677–14690. [Google Scholar] [CrossRef]

- Roshanbinfar, K.; Vogt, L.; Greber, B.; Diecke, S.; Boccaccini, A.R.; Scheibel, T.; Engel, F.B. Electroconductive Biohybrid Hydrogel for Enhanced Maturation and Beating Properties of Engineered Cardiac Tissues. Adv. Funct. Mater. 2018, 28, 1803951. [Google Scholar] [CrossRef]

- Spencer, A.R.; Sani, E.S.; Soucy, J.R.; Corbet, C.C.; Primbetova, A.; Koppes, R.A.; Annabi, N. Bioprinting of a Cell-laden Conductive Hydrogel Composite. ACS Appl. Mater. Interfaces 2019, 11, 30518–30533. [Google Scholar] [CrossRef]

- Sheng, F.; Zhang, B.; Zhang, Y.; Li, Y.; Cheng, R.; Wei, C.; Ning, C.; Dong, K.; Wang, Z.L. Ultrastretchable Organogel/silicone Fiber-helical Sensors for Self-powered Implantable Ligament Strain Monitoring. ACS Nano 2022, 16, 10958–10967. [Google Scholar] [CrossRef]

- Dong, M.; Shi, B.; Liu, D.; Liu, J.-H.; Zhao, D.; Yu, Z.-H.; Shen, X.-Q.; Gan, J.-M.; Shi, B.-L.; Qiu, Y.; et al. Conductive Hydrogel for a Photothermal-responsive Stretchable Artificial Nerve and Coalescing with a Damaged Peripheral Nerve. ACS Nano 2020, 14, 16565–16575. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, S.; Xiao, Z.; Liu, X.; Wu, C.; Wu, K.; Liu, A.; Wei, D.; Sun, J.; Zhou, L.; et al. Magnetoelectric Nanoparticles Incorporated Biomimetic Matrix for Wireless Electrical Stimulation and Nerve Regeneration. Adv. Healthc. Mater. 2021, 10, 2100695. [Google Scholar] [CrossRef]

- Bagheri, B.; Zarrintaj, P.; Surwase, S.S.; Baheiraei, N.; Saeb, M.R.; Mozafari, M.; Kim, Y.C.; Park, O.O. Self-gelling Electroactive Hydrogels Based on Chitosan-aniline Oligomers/agarose for Neural Tissue Engineering with On-demand Drug Release. Colloids Surf. B-Biointerfaces 2019, 184, 2320–2327. [Google Scholar] [CrossRef]

- Martin-Granados, C.; Mccaig, C.D. Harnessing the Electric Spark of Life to Cure Skin Wounds. Adv. Wound Care 2014, 3, 127–138. [Google Scholar] [CrossRef]

- Guo, A.; Song, B.; Reid, B.; Gu, Y.; Forrester, J.V.; Jahoda, C.A.B.; Zhao, M. Effects of Physiological Electric Fields on Migration of Human Dermal Fibroblasts. J. Investig. Dermatol. 2010, 130, 2320–2327. [Google Scholar] [CrossRef]

- Fang, X.; Jin, Q.; Jing, F.; Zhang, H.; Zhang, F.; Mao, H.; Xu, B.; Zhao, J. Integrated Biochip for Label-free and Real-time Detection of Dna Amplification by Contactless Impedance Measurements Based on Interdigitated Electrodes. Biosens. Bioelectron. 2013, 44, 241–247. [Google Scholar] [CrossRef]

- Yao, S.; Myers, A.; Malhotra, A.; Lin, F.; Bozkurt, A.; Muth, J.F.; Zhu, Y. A Wearable Hydration Sensor with Conformal Nanowire Electrodes. Adv. Healthc. Mater. 2017, 6, 1601159. [Google Scholar] [CrossRef]

- Yu, R.; Zhang, H.L.; Guo, B.L. Conductive Biomaterials as Bioactive Wound Dressing for Wound Healing and Skin Tissue Engineering. Nano-Micro Lett. 2022, 14, 1. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Wu, C.; Pei, X.; Cong, Y.; Zhang, R.; Fu, J. Antibacterial Zwitterionic Polyelectrolyte Hydrogel Adhesives with Adhesion Strength Mediated by Electrostatic Mismatch. ACS Appl. Mater. Interfaces 2020, 12, 46816–46826. [Google Scholar] [CrossRef]

- Shen, S.; Fan, D.; Yuan, Y.; Ma, X.; Zhao, J.; Yang, J. An Ultrasmall Infinite Coordination Polymer Nanomedicine-composited Biomimetic Hydrogel for Programmed Dressing-chemo-low Level Laser Combination Therapy of Burn Wounds. Chem. Eng. J. 2021, 426, 130610. [Google Scholar] [CrossRef]

- Venkatalaxmi, A.; Padmavathi, B.s.; Amaranath, T. A General Solution of Unsteady Stokes Equations. Fluid Dyn. Res. 2004, 35, 229–236. [Google Scholar] [CrossRef]

- Manouchehri, S.; Bagheri, B.; Rad, S.H.; Nezhad, M.N.; Kim, Y.C.; Park, O.O.; Farokhi, M.; Jouyandeh, M.; Ganjali, M.R.; Yazdi, M.K.; et al. Electroactive Bio-epoxy Incorporated Chitosan-oligoaniline As an Advanced Hydrogel Coating for Neural Interfaces. Prog. Org. Coat. 2019, 131, 389–396. [Google Scholar] [CrossRef]

- Wang, P.; Pu, Y.; Ren, Y.; Yang, R.; Zhang, W.; Tan, X.; Xue, W.; Liu, S.; Li, S.; Chi, B. Dynamic Regulable Sodium Alginate/poly(γ-glutamic Acid) Hybrid Hydrogels Promoted Chondrogenic Differentiation of Stem Cells. Carbohydr. Polym. 2022, 275, 118692. [Google Scholar] [CrossRef]

- Huang, H.; Han, L.; Li, J.; Fu, X.; Wang, Y.; Yang, Z.; Xu, X.; Pan, L.; Xu, M. Super-stretchable, Elastic and Recoverable Ionic Conductive Hydrogel for Wireless Wearable, Stretchable Sensor. J. Mater. Chem. A 2020, 8, 10291–10300. [Google Scholar] [CrossRef]

- Gao, W.; Ota, H.; Kiriya, D.; Takei, K.; Javey, A. Flexible Electronics Toward Wearable Sensing. Acc. Chem. Res. 2019, 52, 523–533. [Google Scholar] [CrossRef]

- Shen, Z.; Zhu, X.; Majidi, C.; Gu, G. Cutaneous Ionogel Mechanoreceptors for Soft Machines, Physiological Sensing, and Amputee Prostheses. Adv. Mater. 2021, 33, 2102069. [Google Scholar] [CrossRef]

- Peng, K.; Zheng, L.; Zhou, T.; Zhang, C.; Li, H. Light Manipulation for Fabrication of Hydrogels and Their Biological Applications. Acta Biomater. 2022, 137, 20–43. [Google Scholar] [CrossRef]

- Lin, Y.-L.; Zheng, S.; Chang, C.-W.; Lee, M.-J.; Chen, Y.-F.; Chen, J.-T. Photoresponsive Single-ion Nanocomposite Hydrogels: Competition of Host-guest Interactions. Macromolecules 2022, 55, 8940–8949. [Google Scholar] [CrossRef]

- Pang, Y.; Wei, C.; Li, R.; Wu, Y.; Liu, W.; Wang, F.; Zhang, X.; Wang, X. Photothermal Conversion Hydrogel Based Mini-eye Patch for Relieving Dry Eye with Long-term Use of the Light-emitting Screen. Int. J. Nanomed. 2019, 14, 5125–5133. [Google Scholar] [CrossRef]

- Shao, C.; Meng, L.; Cui, C.; Yang, J. An Integrated Self-healable and Robust Conductive Hydrogel for Dynamically Self-adhesive and Highly Conformable Electronic Skin. J. Mater. Chem. C 2019, 7, 15208–15218. [Google Scholar] [CrossRef]

- Wang, Q.; Pan, X.; Guo, J.; Huang, L.; Chen, L.; Ma, X.; Cao, S.; Ni, Y. Lignin and Cellulose Derivatives-induced Hydrogel with Asymmetrical Adhesion, Strength, and Electriferous Properties for Wearable Bioelectrodes and Self-powered Sensors. Chem. Eng. J. 2021, 414, 128903. [Google Scholar] [CrossRef]

- Pang, Q.; Hu, H.; Zhang, H.; Qiao, B.; Ma, L. Temperature-responsive Ionic Conductive Hydrogel for Strain and Temperature Sensors. ACS Appl. Mater. Interfaces 2022, 14, 26536–26547. [Google Scholar] [CrossRef]

- Lei, H.; Zhao, J.; Ma, X.; Li, H.; Fan, D. Antibacterial Dual Network Hydrogels for Sensing and Human Health Monitoring. Adv. Healthc. Mater. 2021, 10, 2101089. [Google Scholar] [CrossRef]

- Li, G.; Zhang, X.; Sang, M.; Wang, X.; Zuo, D.; Xu, J.; Zhang, H. A Supramolecular Hydrogel Electrolyte for High-performance Supercapacitors. J. Energy Storage 2021, 33, 101931. [Google Scholar] [CrossRef]

- Guan, Q.; Lin, G.; Gong, Y.; Wang, J.; Tan, W.; Bao, D.; Liu, Y.; You, Z.; Sun, X.; Wen, Z.; et al. Highly Efficient Self-healable and Dual Responsive Hydrogel-based Deformable Triboelectric Nanogenerators for Wearable Electronics. J. Mater. Chem. A 2019, 7, 13948–13955. [Google Scholar] [CrossRef]

- Zhou, G.; Yang, L.; Li, W.; Chen, C.; Liu, Q. A Regenerable Hydrogel Electrolyte for Flexible Supercapacitors. Iscience 2020, 23, 101502. [Google Scholar] [CrossRef] [PubMed]

- Pu, X.; Liu, M.; Chen, X.; Sun, J.; Du, C.; Zhang, Y.; Zhai, J.; Hu, W.; Wang, Z.L. Ultrastretchable, Transparent Triboelectric Nanogenerator as Electronic Skin for Biomechanical Energy Harvesting and Tactile Sensing. Sci. Adv. 2017, 3, e1700015. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Yang, B.; Jiang, Z.; Liu, Y.; Zhou, L.; Liu, Z.; Tang, L. Recent Advances of Conductive Hydrogels for Flexible Electronics. Electron. Mater. 2024, 5, 101-131. https://doi.org/10.3390/electronicmat5030008

Wang J, Yang B, Jiang Z, Liu Y, Zhou L, Liu Z, Tang L. Recent Advances of Conductive Hydrogels for Flexible Electronics. Electronic Materials. 2024; 5(3):101-131. https://doi.org/10.3390/electronicmat5030008

Chicago/Turabian StyleWang, Jingyu, Bao Yang, Zhenyu Jiang, Yiping Liu, Licheng Zhou, Zejia Liu, and Liqun Tang. 2024. "Recent Advances of Conductive Hydrogels for Flexible Electronics" Electronic Materials 5, no. 3: 101-131. https://doi.org/10.3390/electronicmat5030008

APA StyleWang, J., Yang, B., Jiang, Z., Liu, Y., Zhou, L., Liu, Z., & Tang, L. (2024). Recent Advances of Conductive Hydrogels for Flexible Electronics. Electronic Materials, 5(3), 101-131. https://doi.org/10.3390/electronicmat5030008