Batteryless Electronic System Printed on Glass Substrate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Device Manufacturing

2.2. Device Characterization

3. Results and Discussion

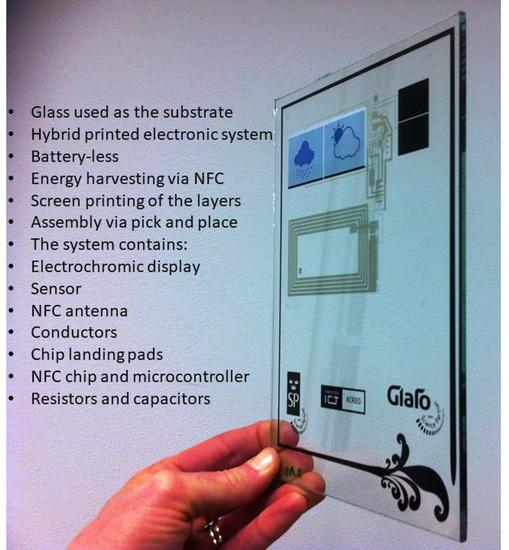

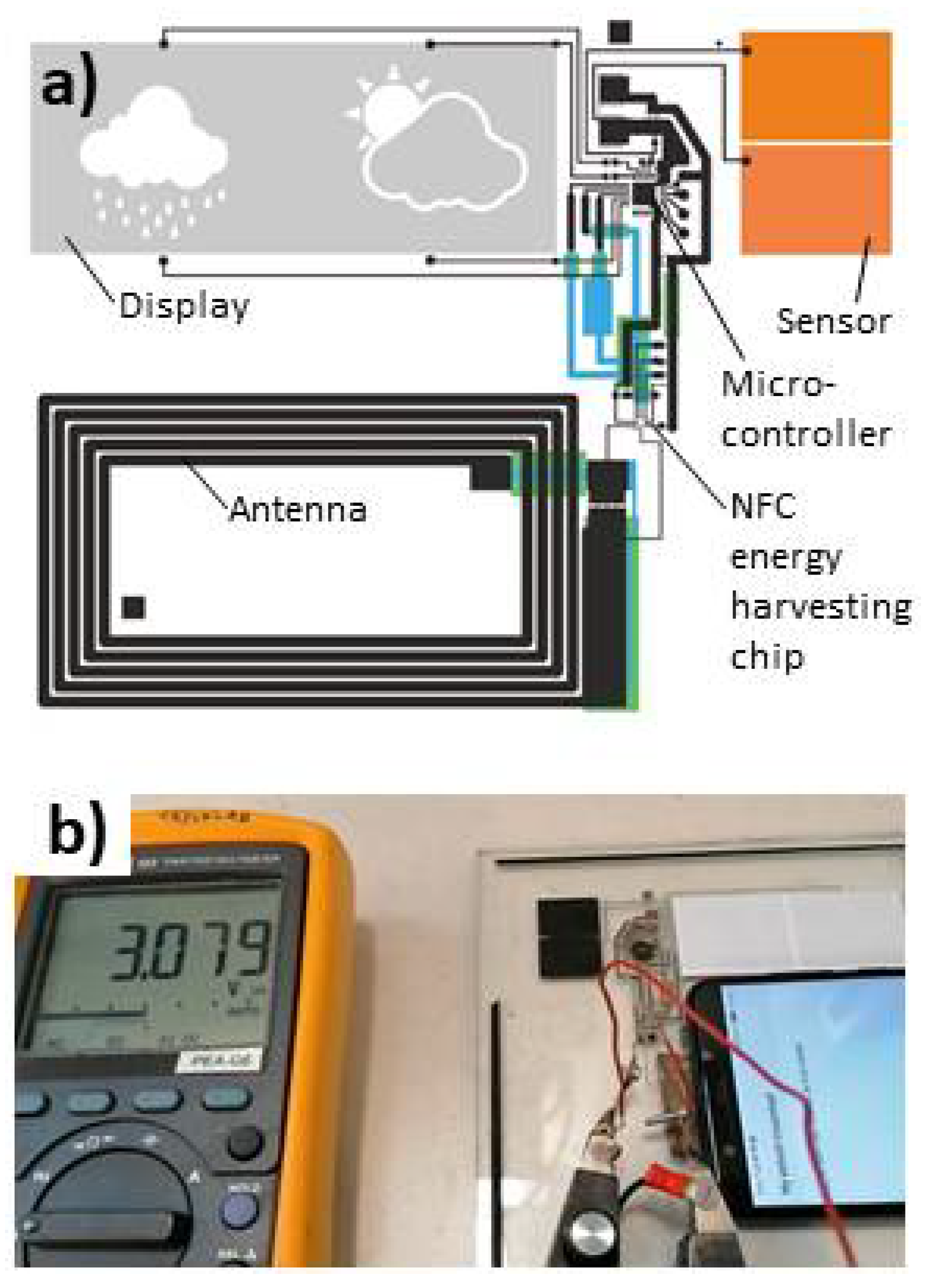

3.1. Design and Manufacturing of the System

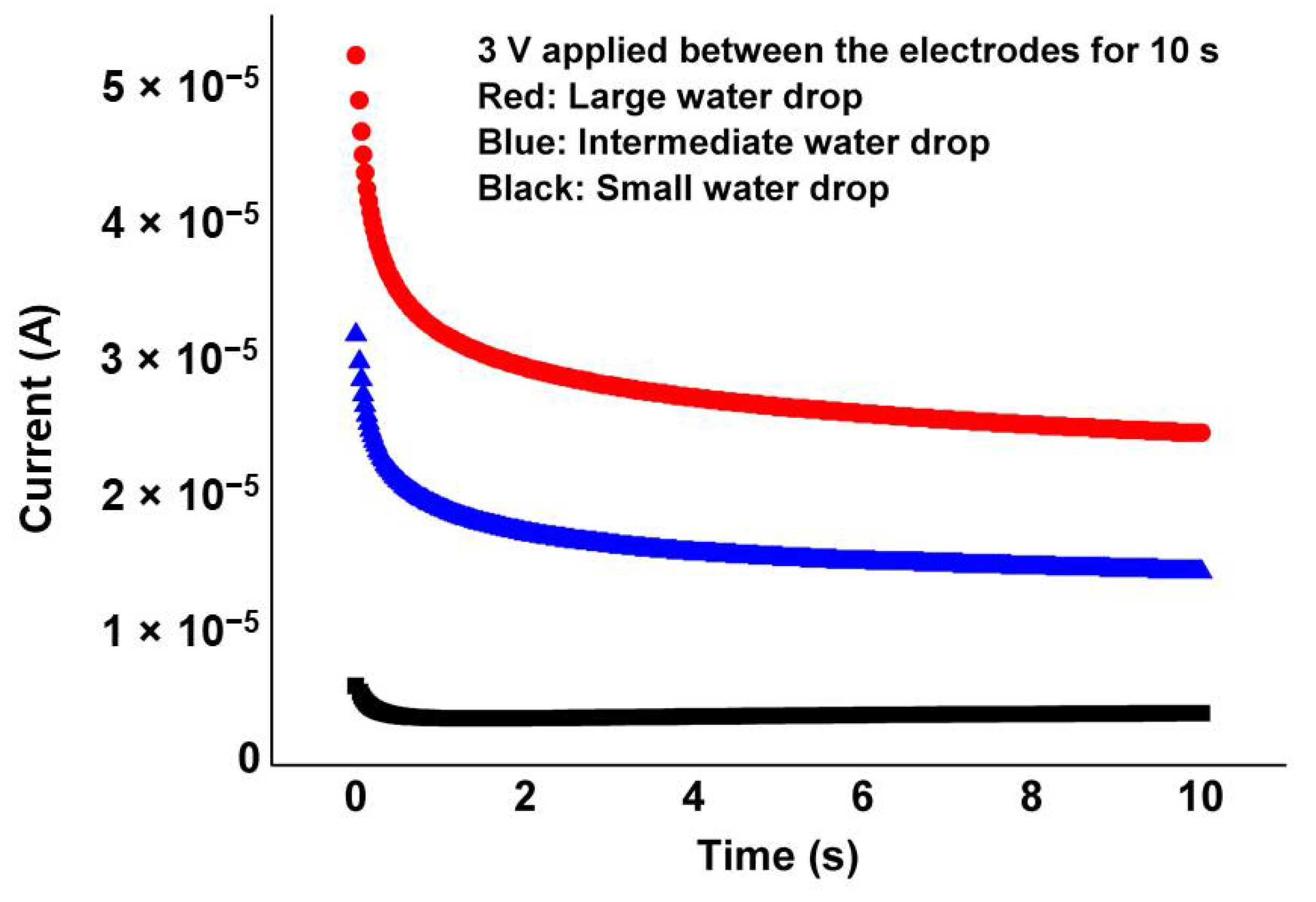

3.2. Sensor Device

3.3. Electrochromic Display

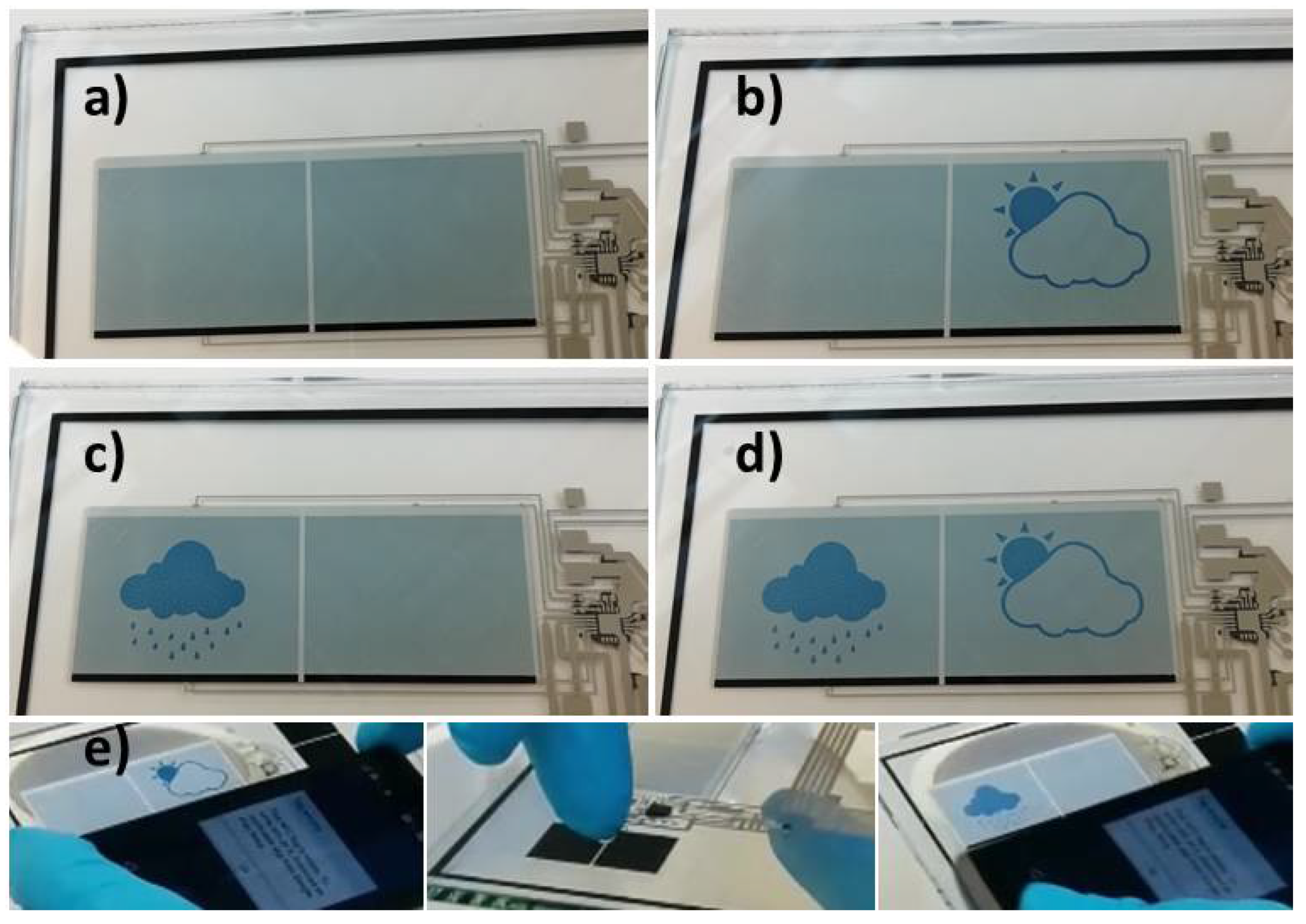

3.4. System Demonstration

- The sensor status was controlled, by measuring the current between the sensor electrodes, as described in Figure 2;

- If the sensor was dry, the microcontroller simultaneously switched the rain and sun segment of the electrochromic display to its white (OFF) and blue (ON) state, respectively;

- If a water drop bridged the sensor electrodes, the microcontroller simultaneously switched the rain and sun segments of the electrochromic display to their blue (ON) and white (OFF) state, respectively;

- For continuous monitoring, the mobile phone needs to be kept in close proximity to the NFC antenna. However, once one demonstration cycle has been completed, the semi-bistable property of the electrochromic displays ensures that the respective color of the display segments is maintained, hence, the mobile phone can be removed until it is needed to initialize a subsequent demonstration cycle.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rim, Y.S.; Bae, S.-H.; Chen, H.; De Marco, N.; Yang, Y. Recent progress in materials and devices toward printable and flexible sensors. Adv. Mater. 2016, 28, 4415–4440. [Google Scholar] [CrossRef] [PubMed]

- Sekitani, T.; Someya, T. Stretchable, Large-area Organic Electronics. Adv. Mater. 2010, 22, 2228–2246. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Zheng, Y.; Liu, N.; Ai, N.; Wang, Q.; Wu, S.; Zhou, J.; Hu, D.; Yu, S.; Han, S.; et al. All-solution processed polymer light-emitting diode displays. Nat. Commun. 2013, 4, 1971. [Google Scholar] [CrossRef] [PubMed]

- Tobjörk, D.; Österbacka, R. Paper electronics. Adv. Mater. 2011, 23, 1935–1961. [Google Scholar] [CrossRef] [PubMed]

- Cao, R.; Pu, X.; Du, X.; Yang, W.; Wang, J.; Guo, H.; Zhao, S.; Yuan, Z.; Zhang, C.; Li, C.; et al. Screen-Printed Washable Electronic Textiles as Self-Powered Touch/Gesture Tribo-Sensors for Intelligent Human–Machine Interaction. ACS Nano 2018, 12, 5190–5196. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, J.; Bazaka, K.; Anderson, L.J.; White, R.D.; Jacob, M.V. Materials and methods for encapsulation of OPV: A review. Renew. Sustain. Energy Rev. 2013, 27, 104–117. [Google Scholar] [CrossRef]

- Yu, D.; Yang, Y.-Q.; Chen, Z.; Tao, Y.; Liu, Y.-F. Recent progress on thin-film encapsulation technologies for organic electronic devices. Opt. Commun. 2016, 362, 43–49. [Google Scholar] [CrossRef] [Green Version]

- Cho, A.R.; Kim, E.H.; Park, S.Y.; Park, L.S. Flexible OLED encapsulated with gas barrier film and adhesive gasket. Synth. Met. 2014, 193, 77–80. [Google Scholar] [CrossRef]

- Castro-Hermosa, S.; Top, M.; Dagar, J.; Fahlteich, J.; Brown, T.M. Quantifying Performance of Permeation Barrier—Encapsulation Systems for Flexible and Glass-Based Electronics and Their Application to Perovskite Solar Cells. Adv. Electron. Mater. 2019, 5, 1800978. [Google Scholar] [CrossRef] [Green Version]

- Uddin, A.; Upama, M.B.; Yi, H.; Duan, L. Encapsulation of Organic and Perovskite Solar Cells: A Review. Coatings 2019, 9, 65. [Google Scholar] [CrossRef] [Green Version]

- Ludvigsson, M.; Leisner, P.; Schödt, B.; Dyreklev, P.; Nilssson, D.; Norberg, B.; Bäck, L.G.; Malmros, I.; Clausén, U.; Andersson Ersman, P. Laminated display based on printed electronics. In Engineered Transparency 2016—Glass in Architecture and Structural Engineering, Proceedings of Glasstec 2016, Düsseldorf, Germany, 20–23 September 2016; Schneider, J., Weller, B., Eds.; Ernst and Sohn: Berlin, Germany, 2016; ISBN 978-3-433-03187-2. [Google Scholar]

- Azens, A.; Granqvist, C.G. Electrochromic smart windows: Energy efficiency and device aspects. J. Solid State Electrochem. 2003, 7, 64–68. [Google Scholar] [CrossRef]

- Hrehorova, E.; Rebros, M.; Pekarovicova, A.; Bazuin, B.; Ranganathan, A.; Garner, S.; Merz, G.; Tosch, J.; Boudreau, R. Gravure Printing of Conductive Inks on Glass Substrates for Applications in Printed Electronics. J. Disp. Technol. 2011, 7, 318–324. [Google Scholar] [CrossRef]

- Epishine—Harvesting Light. Available online: https://www.epishine.com/ (accessed on 16 September 2021).

- Andersson Ersman, P; Lassnig, R.; Strandberg, J.; Dyreklev, P. Flexible Active Matrix Addressed Displays Manufactured by Screen Printing. Adv. Eng. Mater. 2021, 23, 2000771. [Google Scholar] [CrossRef]

- Andersson Ersman, P.; Lassnig, R.; Strandberg, J.; Tu, D.; Keshmiri, V.; Forchheimer, R.; Fabiano, S.; Gustafsson, G.; Berggren, M. All-printed large-scale integrated circuits based on organic electrochemical transistors. Nat. Commun. 2019, 10, 5053. [Google Scholar] [CrossRef] [Green Version]

- Corning Willow Glass. Available online: https://www.corning.com/worldwide/en/innovation/corning-emerging-innovations/corning-willow-glass.html (accessed on 16 September 2021).

- Schott—Glass Made of Ideas. Available online: https://www.schott.com/innovation/en/ultra-thin-glass-the-epic-flex/ (accessed on 16 September 2021).

- ASTM D3359—Standard Test Methods for Rating Adhesion by Tape Test. Available online: https://www.astm.org/Standards/D3359.htm (accessed on 4 October 2021).

- RISE Research Institutes of Sweden—Electrochromic Displays. Available online: https://www.ri.se/en/what-we-do/expertises/electrochromic-displays (accessed on 16 September 2021).

- Kawahara, J.; Andersson Ersman, P.; Engquist, I.; Berggren, M. Improving the color switch contrast in PEDOT: PSS-based electrochromic displays. Org. Electron. 2012, 13, 469–474. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andersson Ersman, P.; Åhlin, J.; Westerberg, D.; Sawatdee, A.; Arvén, P.; Ludvigsson, M. Batteryless Electronic System Printed on Glass Substrate. Electron. Mater. 2021, 2, 527-535. https://doi.org/10.3390/electronicmat2040037

Andersson Ersman P, Åhlin J, Westerberg D, Sawatdee A, Arvén P, Ludvigsson M. Batteryless Electronic System Printed on Glass Substrate. Electronic Materials. 2021; 2(4):527-535. https://doi.org/10.3390/electronicmat2040037

Chicago/Turabian StyleAndersson Ersman, Peter, Jessica Åhlin, David Westerberg, Anurak Sawatdee, Patrik Arvén, and Mikael Ludvigsson. 2021. "Batteryless Electronic System Printed on Glass Substrate" Electronic Materials 2, no. 4: 527-535. https://doi.org/10.3390/electronicmat2040037

APA StyleAndersson Ersman, P., Åhlin, J., Westerberg, D., Sawatdee, A., Arvén, P., & Ludvigsson, M. (2021). Batteryless Electronic System Printed on Glass Substrate. Electronic Materials, 2(4), 527-535. https://doi.org/10.3390/electronicmat2040037