Analysis of Thermal Fatigue Behavior and Interface Optimization Design for Laminated Tungsten Plasma-Facing Material Under Steady-State Thermal Load

Abstract

1. Introduction

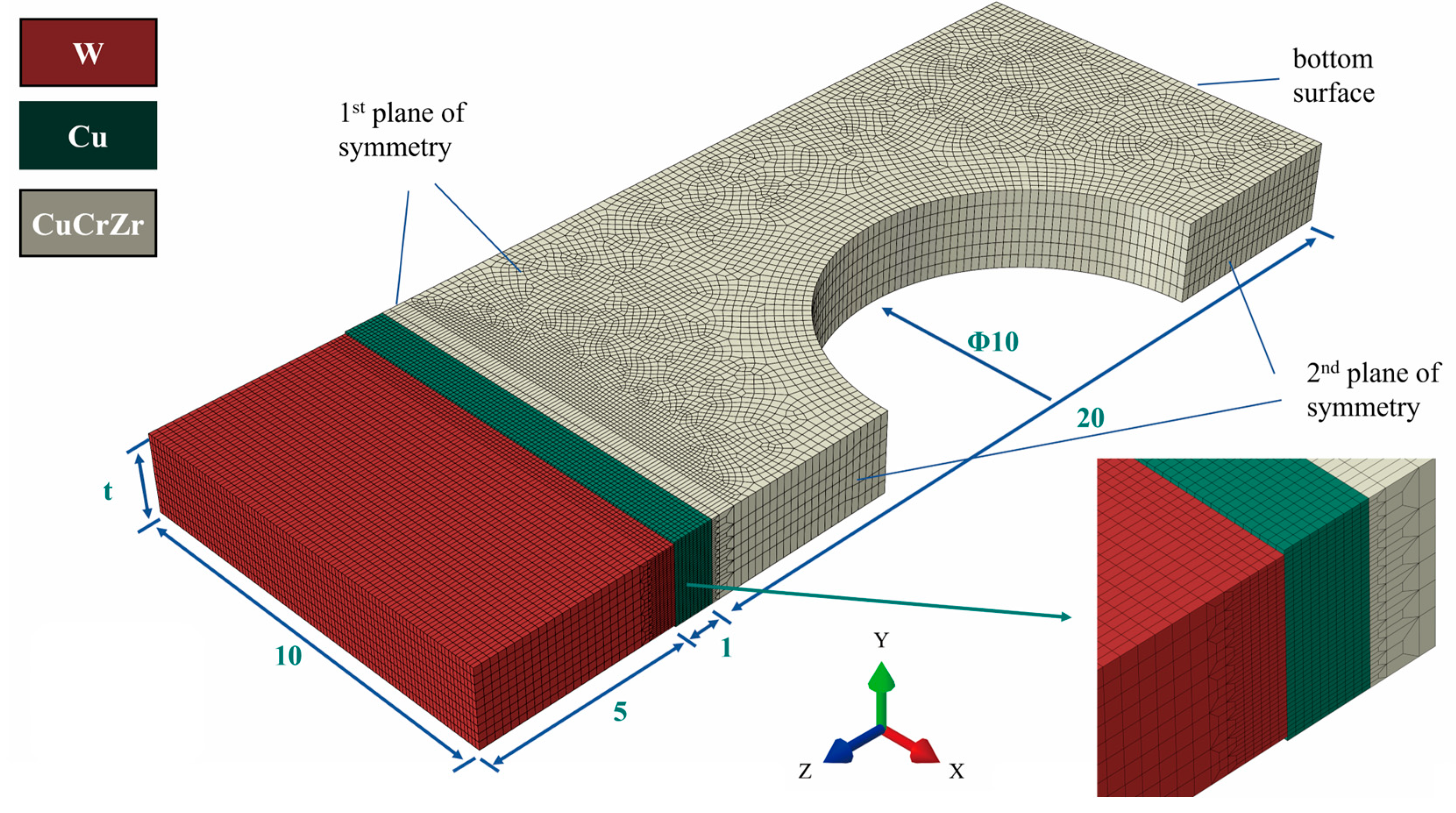

2. Finite Element Simulation Model

2.1. PFC Model

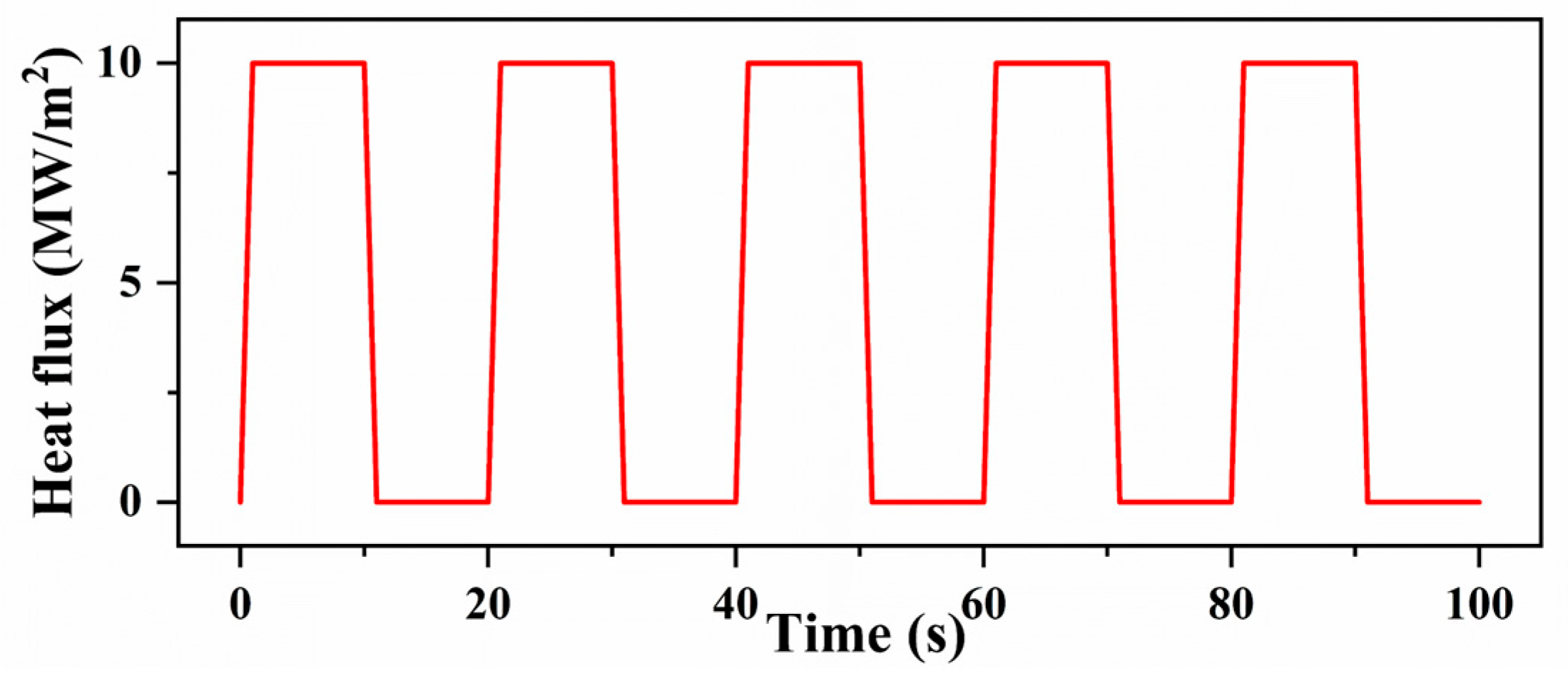

2.2. Boundary Conditions

3. Results and Discussion

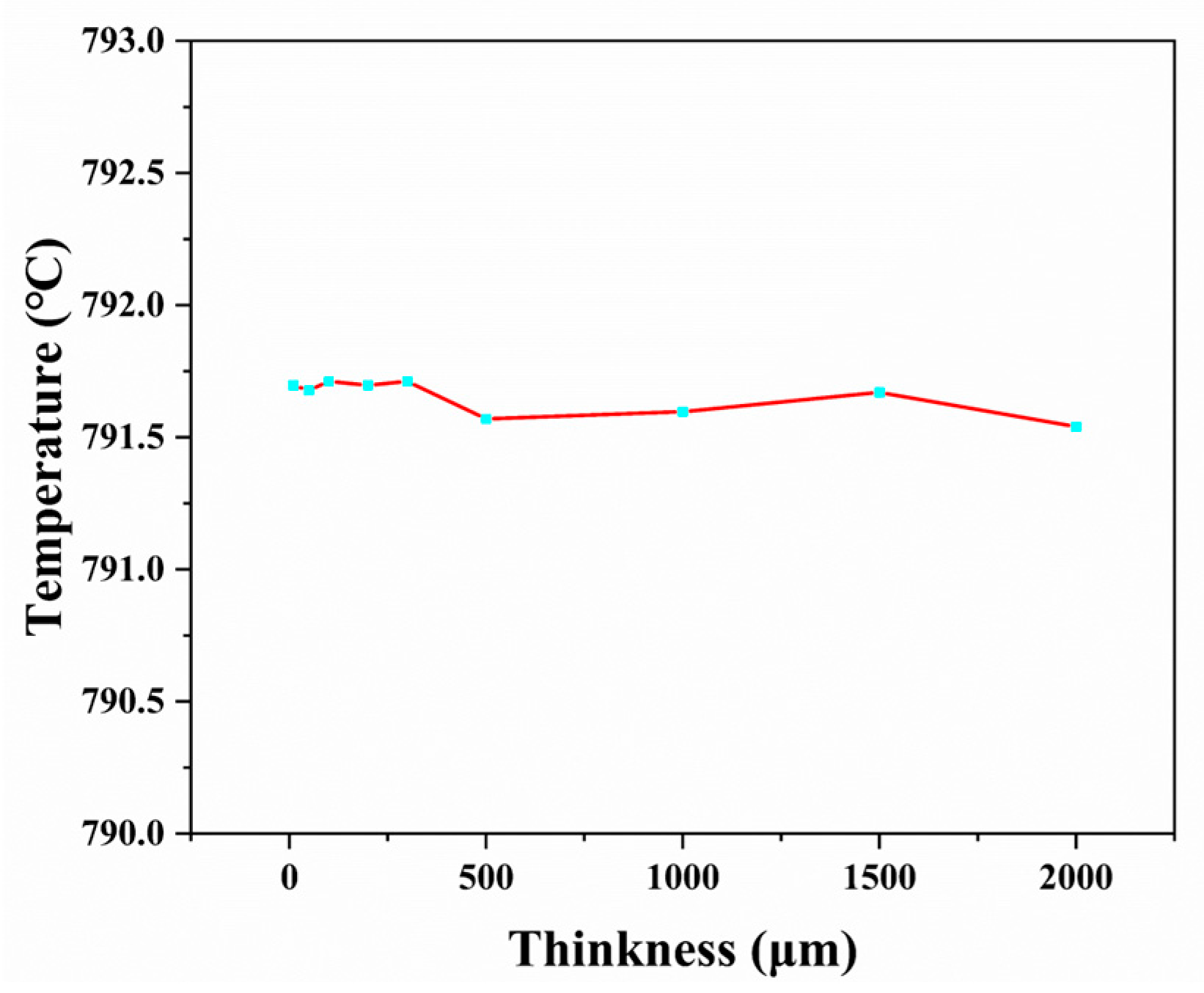

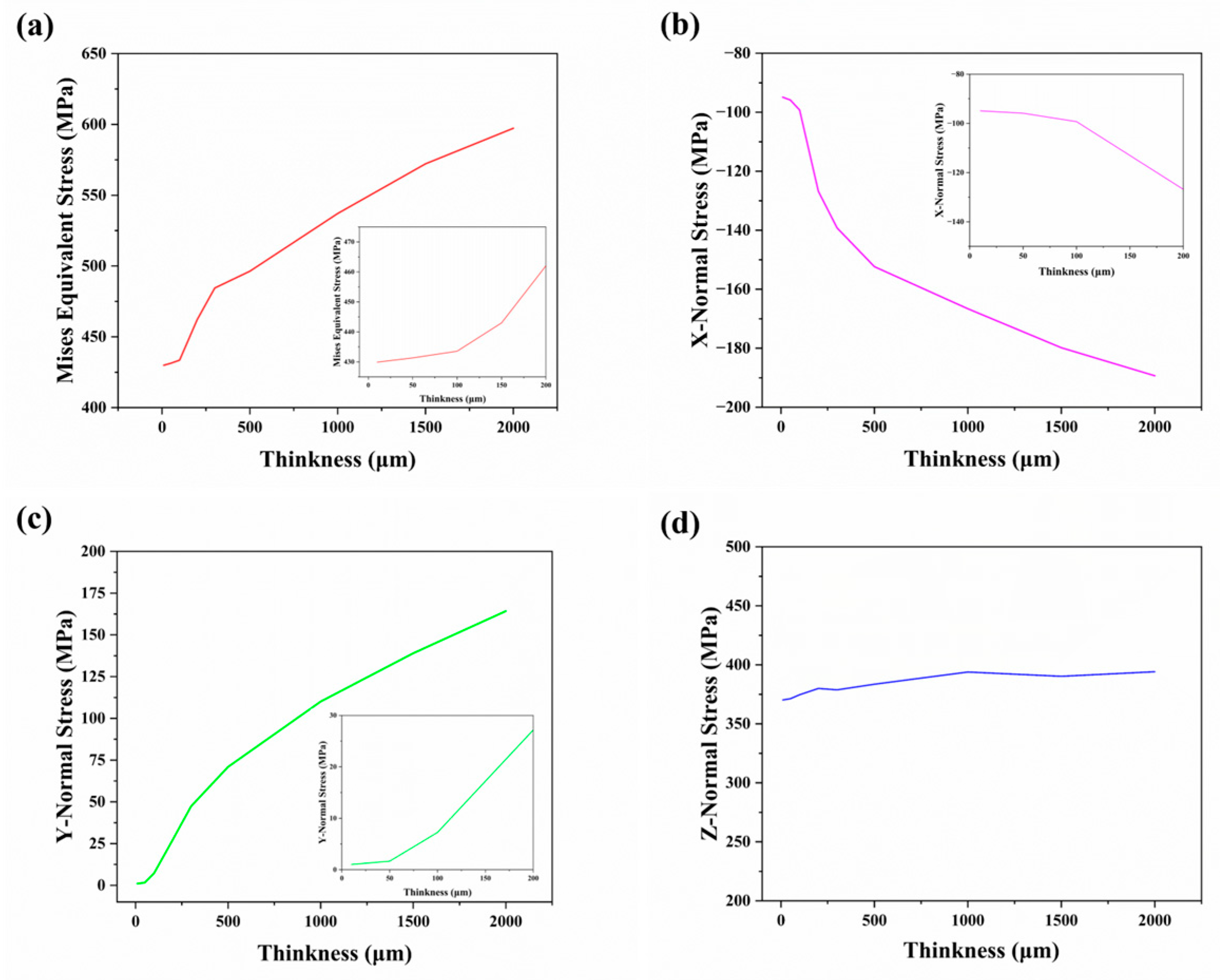

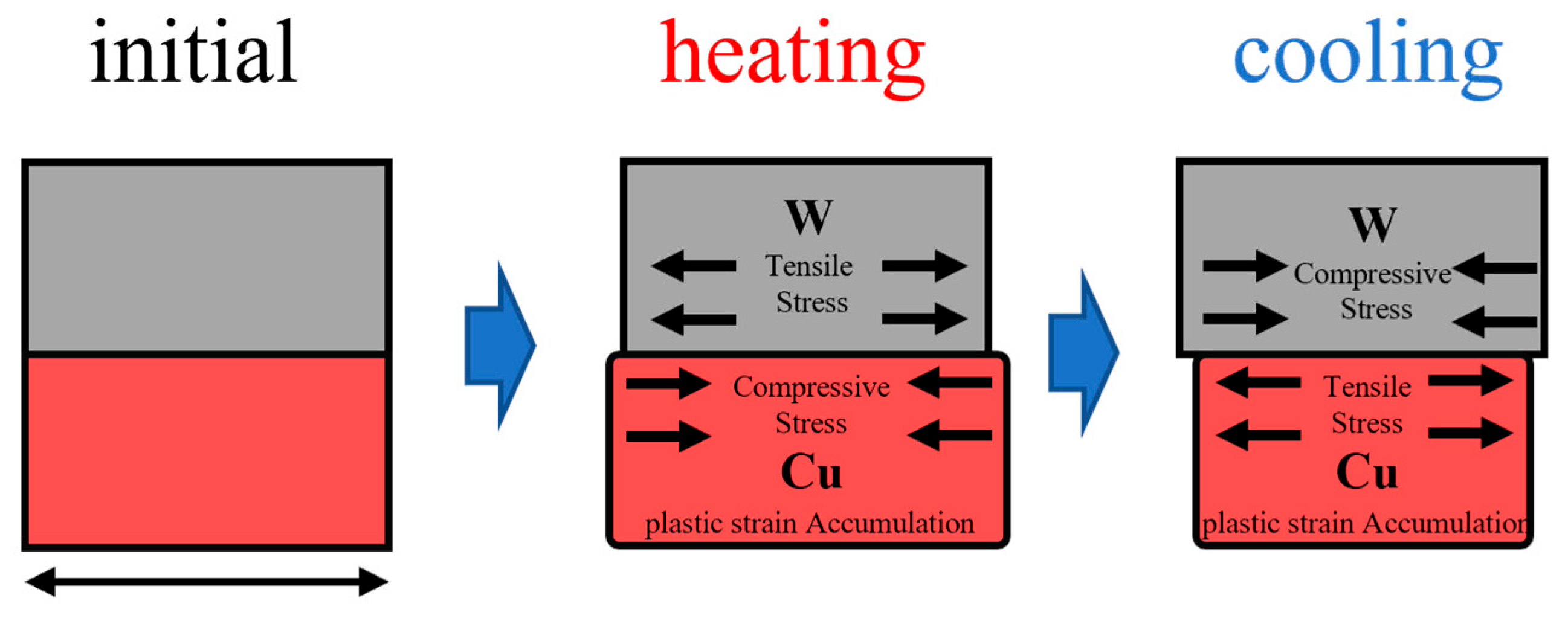

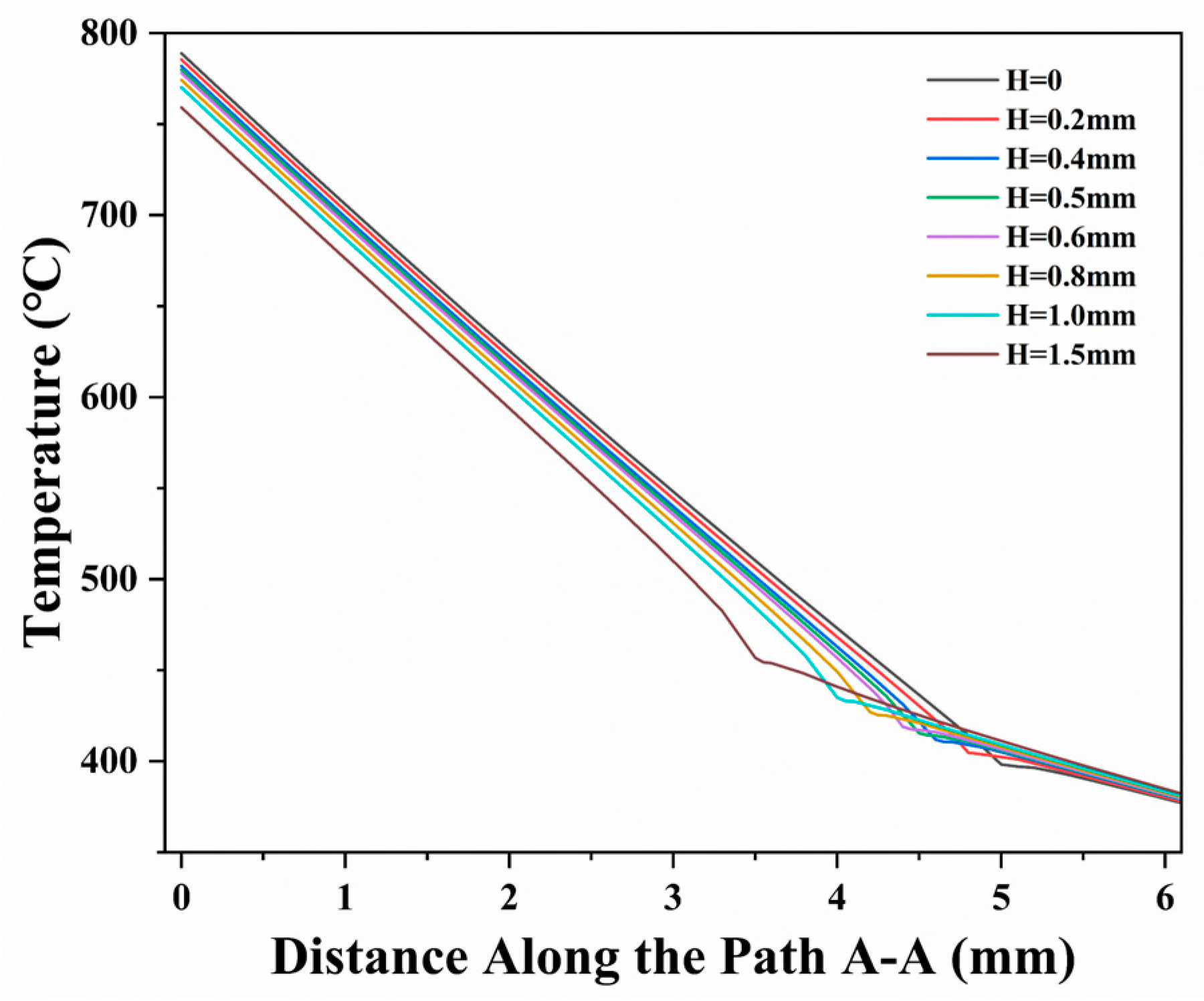

3.1. Thermomechanical Analysis

3.2. Analysis of Optimization Results for the PFC Structure

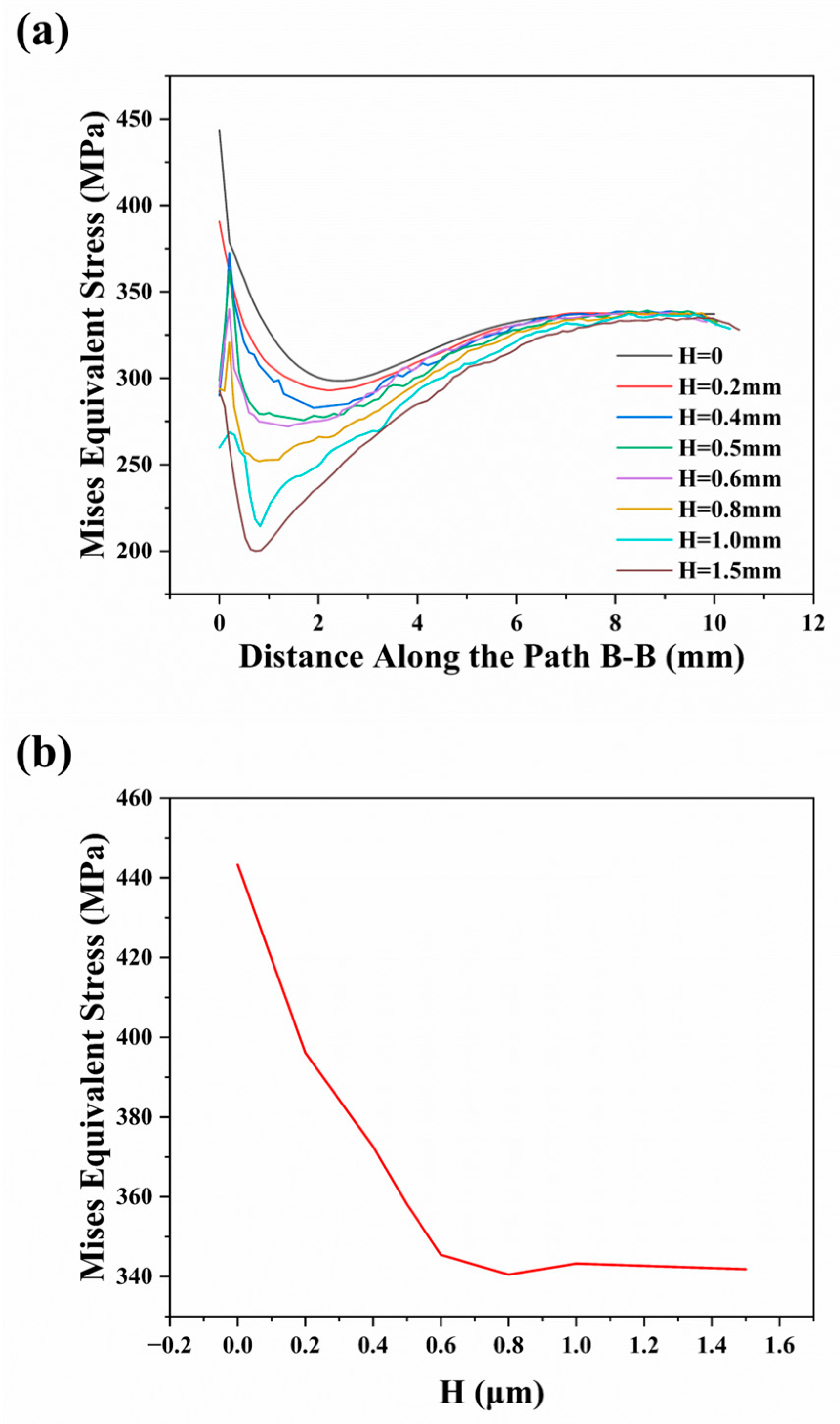

3.2.1. Interface Optimization Design

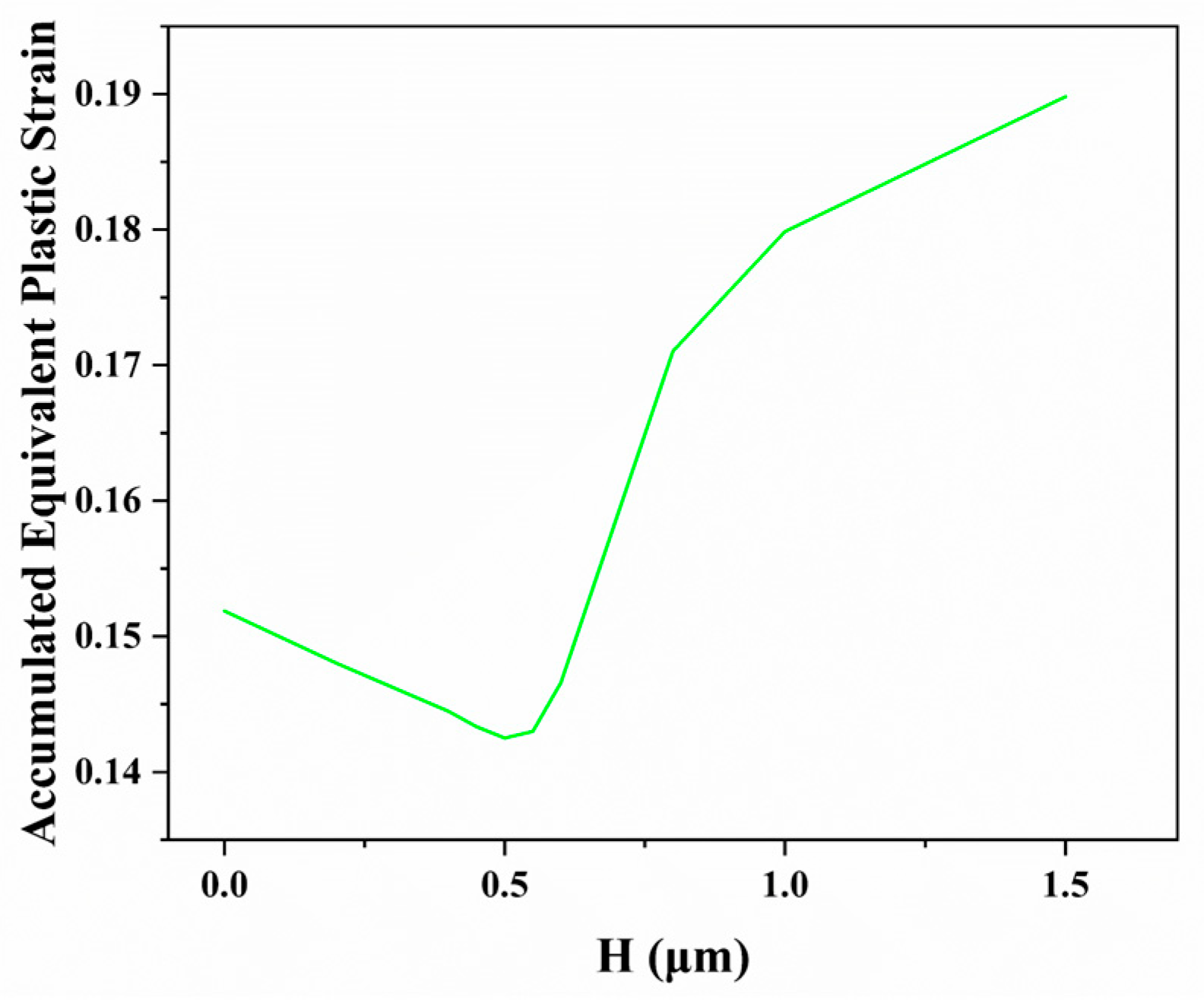

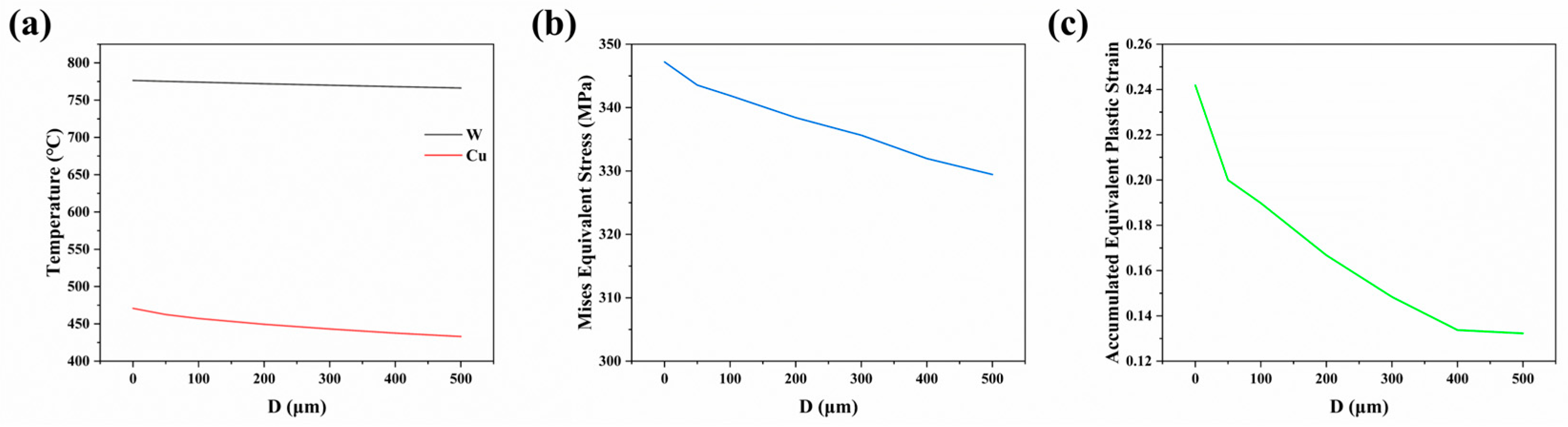

3.2.2. Influence of Parameters H and D on Thermal–Mechanical Properties of PFC

4. Conclusions

- (1)

- Laminated tungsten PFM: It was found that as the axial thickness of the tungsten sheets decreases from the millimeter scale to the micrometer level, the thermal mismatch deformation δ in the Y direction between the tungsten and the copper exhibits a significant decreasing trend. This geometric size effect directly leads to a systematic reduction in the normal stress in the Y direction at the interface. When the thickness is reduced to 10 μm, the normal stress in the Y direction approaches nearly zero. This phenomenon fundamentally confirms the notably improved thermal deformation compatibility of the materials at the micrometer scale, offering a new approach for regulating interfacial stress.

- (2)

- In the study on interface geometry optimization, the conventional flat interface was modified into a curved structure. Experimental data indicate that as the distance H of the highest point of the Cu region increases, the stress concentration zone undergoes significant spatial redistribution, shifting gradually from the initial tungsten vertex location toward the central area. Quantitative analysis shows that when the value of H exceeds 600 μm, stress concentration no longer occurs at the original vertex position. This improvement effectively mitigates the risk of interfacial fatigue failure, thereby enhancing the service life of the PFC joint.

- (3)

- The study further revealed that interface optimization must be coordinated with the overall structural design. As H gradually increases, the deformation space within the Cu/CuCrZr region becomes progressively constrained. By increasing the value of D, sufficient space for deformation accommodation can be provided, thereby reducing plastic strain in copper. This geometric compatibility relationship fundamentally reflects a dynamic balance between the material’s deformation capacity and external constraints. Its optimization design requires comprehensive consideration to achieve the optimal balance between stress relief effectiveness and structural reliability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- El-Morshedy, S.E.-D. Thermal-hydraulic modelling and analysis of ITER tungsten divertor monoblock. Nucl. Mater. Energy 2021, 28, 101035. [Google Scholar] [CrossRef]

- Jiang, M.; Pan, Z.; Huang, S.; Zhou, Z.; Su, Y. Thermomechanical measurements for a flat-type divertor mock-up: A benchmark for simulation. Nucl. Mater. Energy 2023, 36, 101483. [Google Scholar] [CrossRef]

- Zhou, Z.; Pintsuk, G.; Linke, J.; Ma, Y.; Roedig, M. Performance of the different swaged tungsten grades under transient high heat loads. Phys. Scr. 2009, T138, 014058. [Google Scholar] [CrossRef]

- Wei, B.; Zhou, R.; Xu, D.; Chen, R.; Chen, P.; Cheng, J. Achieving high-strength W/W-10Cu joints by vacuum diffusion bonding with FeCoCu interlayer. Fusion Eng. Des. 2023, 191, 113553. [Google Scholar] [CrossRef]

- Crescenzi, F.; Bachmann, C.; Richou, M.; Roccella, S.; Visca, E.; You, J.-H. Design study of ITER-like divertor target for DEMO. Fusion Eng. Des. 2015, 98–99, 1263–1266. [Google Scholar] [CrossRef]

- Richou, M.; Gallay, F.; Chu, I.; Li, M.; Magaud, P.; Missirlian, M.; Rocella, S.; Visca, E.; You, J.H. Status on the W monoblock type high heat flux target with graded interlayer for application to DEMO divertor. Fusion Eng. Des. 2017, 124, 338–343. [Google Scholar] [CrossRef]

- Li, M.; You, J.-H. Cracking behavior of tungsten armor under ELM-like thermal shockloads II: A revised prediction for crack appearance map. Nucl. Mater. Energy 2016, 9, 598–603. [Google Scholar] [CrossRef]

- Gwon, H.; Takeuchi, Y.; Kasada, R.; Konishi, S. Evaluation of heat transfer by sublimation for the application to the divertor heat sink for high fusion energy conversion. Fusion Eng. Des. 2014, 89, 1003–1008. [Google Scholar] [CrossRef]

- Khirwadkar, S.S.; Singh, K.P.; Patil, Y.; Khan, M.S.; Buch, J.J.U.; Patel, A.; Tripathi, S.; Jaman, P.M.; Rangaraj, L.; Divakar, C. Fabrication and characterization of tungsten and graphite based PFC for divertor target elements of ITER like tokamak application. Fusion Eng. Des. 2011, 86, 1736–1740. [Google Scholar] [CrossRef]

- Alba, R.; Iglesias, R.; Angeles Cerdeira, M. Materials to Be Used in Future Magnetic Confinement Fusion Reactors: A Review. Materials 2022, 15, 6591. [Google Scholar] [CrossRef]

- Jiang, D.; Long, J.; Han, J.; Cai, M.; Lin, Y.; Fan, P.; Zhang, H.; Zhong, M. Comprehensive enhancement of the mechanical and thermo-mechanical properties of W/Cu joints via femtosecond laser fabricated micro/nano interface structures. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2017, 696, 429–436. [Google Scholar] [CrossRef]

- Li, M.; You, J.-H. Structural impact of armor monoblock dimensions on the failure behavior of ITER-type divertor target components: Size matters. Fusion Eng. Des. 2016, 113, 162–170. [Google Scholar] [CrossRef]

- Lu, M.; Han, L.; Zhao, Q.; Qiu, J.; Zhou, J.; Hu, D.; Mou, N.; Chen, X. Microchannel cooling technique for dissipating high heat flux on W/Cu flat-type mock-up for EAST divertor. Plasma Sci. Technol. 2022, 24, 095602. [Google Scholar] [CrossRef]

- Tivey, R.; Ando, T.; Antipenkov, A.; Barabash, V.; Chiocchio, S.; Federici, G.; Ibbott, C.; Jakeman, R.; Janeschitz, G.; Raffray, R.; et al. ITER divertor, design issues and research and development. Fusion Eng. Des. 1999, 46, 207–220. [Google Scholar] [CrossRef]

- Li, Q.; Xie, C.; Wang, W.; Wang, J.; Wang, X.; Gao, Q.; Chen, Z.; Peng, W.; Yang, Z.; Luo, G.-N. Optimization of W/Cu monoblock mock-up with FGM interlayer for CFETR devertor targets. Fusion Eng. Des. 2019, 147, 111262. [Google Scholar] [CrossRef]

- Song, H.; Qi, C.; Peng, J.; Guo, P.; Lai, J.; Cheng, L.; Yuan, Y.; Wang, B.; Lu, G. Resistance to deuterium-induced blistering in laminated microstructure tungsten. Nucl. Mater. Energy 2025, 43, 101921. [Google Scholar] [CrossRef]

- Xiao, S.; Ma, Y.; Tian, L.; Li, M.; Qi, C.; Wang, B. Decrease of blistering on Helium irradiated tungsten surface via transversal release of helium from the grooved surfaces. Nucl. Mater. Energy 2020, 23, 100746. [Google Scholar] [CrossRef]

- Qi, C.; Qi, Y.; Song, H.; Wang, X.; Xiao, S.; Wang, B. Finite Element Analysis and Experimental Verification of Thermal Fatigue of W-PFM with Stacked Structure. Metals 2024, 14, 555. [Google Scholar] [CrossRef]

- Li, C.; Zhu, D.; Wang, B.; Chen, J. Theoretical analysis on the damages for tungsten plasma facing surface under superposition of steady-state and transient heat loads. Fusion Eng. Des. 2018, 132, 99–106. [Google Scholar] [CrossRef]

- Wang, S.-M.; Li, J.-S.; Wang, Y.-X.; Zhang, X.-F.; Ye, Q. Thermal Shock Behavior Analysis of Tungsten-Armored Plasma-Facing Components for Future Fusion Reactor. Acta Metall. Sin.-Engl. Lett. 2018, 31, 515–522. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Mi, B.; Zhao, J.; Zhang, C. Microstructure-based crack formation in tungsten exposed to cyclic transient heating. J. Nucl. Mater. 2023, 583, 154555. [Google Scholar] [CrossRef]

- Panayotis, S.; Hirai, T.; Barabash, V.; Amzallag, C.; Escourbiac, F.; Durocher, A.; Komarov, V.; Martinez, J.M.; Merola, M. Fracture modes of ITER tungsten divertor monoblock under stationary thermal loads. Fusion Eng. Des. 2017, 125, 256–262. [Google Scholar] [CrossRef]

- Zhang, K.; von Mueller, A.; Greuner, H.; You, J.-H. Stress analysis of divertor plasma-facing component designs using tungsten particle-reinforced copper composite heat sink. Fusion Eng. Des. 2020, 154, 111510. [Google Scholar] [CrossRef]

- Li, M.; You, J.-H. Interpretation of the deep cracking phenomenon of tungsten monoblock targets observed in high-heat-flux fatigue tests at 20 MW/m2. Fusion Eng. Des. 2015, 101, 1–8. [Google Scholar] [CrossRef]

- Li, M.; Werner, E.; You, J.-H. Low cycle fatigue behavior of ITER-like divertor target under DEMO-relevant operation conditions. Fusion Eng. Des. 2015, 90, 88–96. [Google Scholar] [CrossRef]

| Material | Temperature (°C) | Thermal Conductivity (Wm−1K−1) | Coefficient of Thermal Expansion (10−6K−1) | Young’s Modulus (GPa) | Poisson’s Ratio | Yield Strength (MPa) | Tangent Modulus (GPa) |

|---|---|---|---|---|---|---|---|

| W | 20 | 173 | 4.5 | 398 | 0.28 | 1360 | 1.3 |

| 200 | 156 | 396 | 1154 | ||||

| 500 | 133 | 4.7 | 390 | 854 | 1 | ||

| 800 | 118 | 379 | 0.29 | 604 | |||

| 1000 | 111 | 5.4 | 368 | 465 | 0.8 | ||

| 1500 | 101 | 5.6 | 333 | 0.3 | 204 | ||

| OFHC-Cu | 20 | 403 | 16.7 | 125 | 0.34 | 69 | 1.5 |

| 200 | 392 | 17.2 | 115 | 60 | 1.3 | ||

| 400 | 379 | 17.8 | 100 | 48 | 0.9 | ||

| 700 | 360 | 18.9 | 70 | 30 | 0.6 | ||

| CuCrZr | 200 | 326 | 16.7 | 128 | 0.32 | 293 | 0.9 |

| 250 | 343 | 17.2 | 118 | 0.42 | 257 | 0.7 | |

| 400 | 347 | 17.8 | 106 | 238 | |||

| 500 | 348 | 18.2 | 103 | 0.52 | 195 | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, J.; Qi, Y.; Wang, B.; Wang, B. Analysis of Thermal Fatigue Behavior and Interface Optimization Design for Laminated Tungsten Plasma-Facing Material Under Steady-State Thermal Load. Modelling 2025, 6, 136. https://doi.org/10.3390/modelling6040136

Lai J, Qi Y, Wang B, Wang B. Analysis of Thermal Fatigue Behavior and Interface Optimization Design for Laminated Tungsten Plasma-Facing Material Under Steady-State Thermal Load. Modelling. 2025; 6(4):136. https://doi.org/10.3390/modelling6040136

Chicago/Turabian StyleLai, Junyun, Yanfei Qi, Bing Wang, and Bo Wang. 2025. "Analysis of Thermal Fatigue Behavior and Interface Optimization Design for Laminated Tungsten Plasma-Facing Material Under Steady-State Thermal Load" Modelling 6, no. 4: 136. https://doi.org/10.3390/modelling6040136

APA StyleLai, J., Qi, Y., Wang, B., & Wang, B. (2025). Analysis of Thermal Fatigue Behavior and Interface Optimization Design for Laminated Tungsten Plasma-Facing Material Under Steady-State Thermal Load. Modelling, 6(4), 136. https://doi.org/10.3390/modelling6040136