A Damage Constitutive Model for Rock Considering Crack Propagation Under Uniaxial Compression

Abstract

1. Introduction

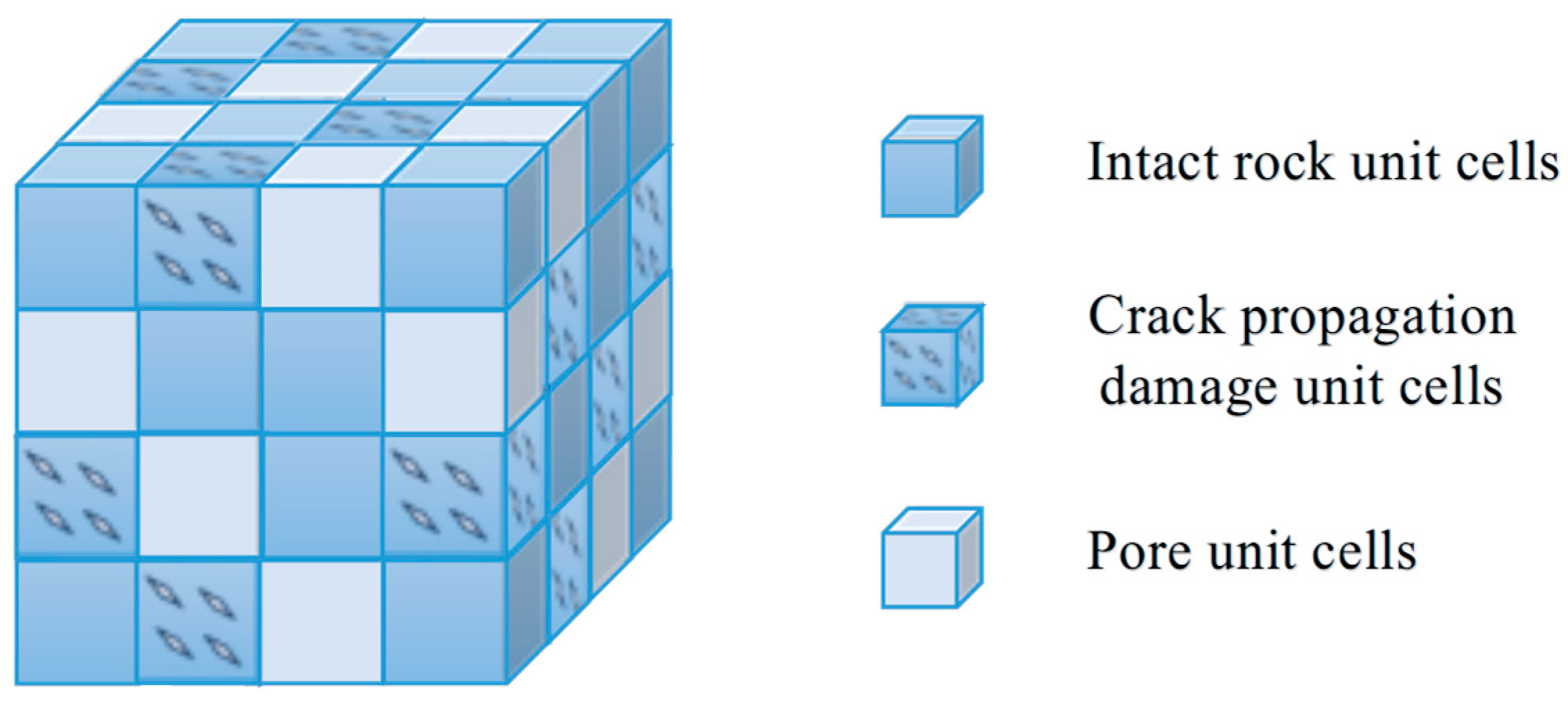

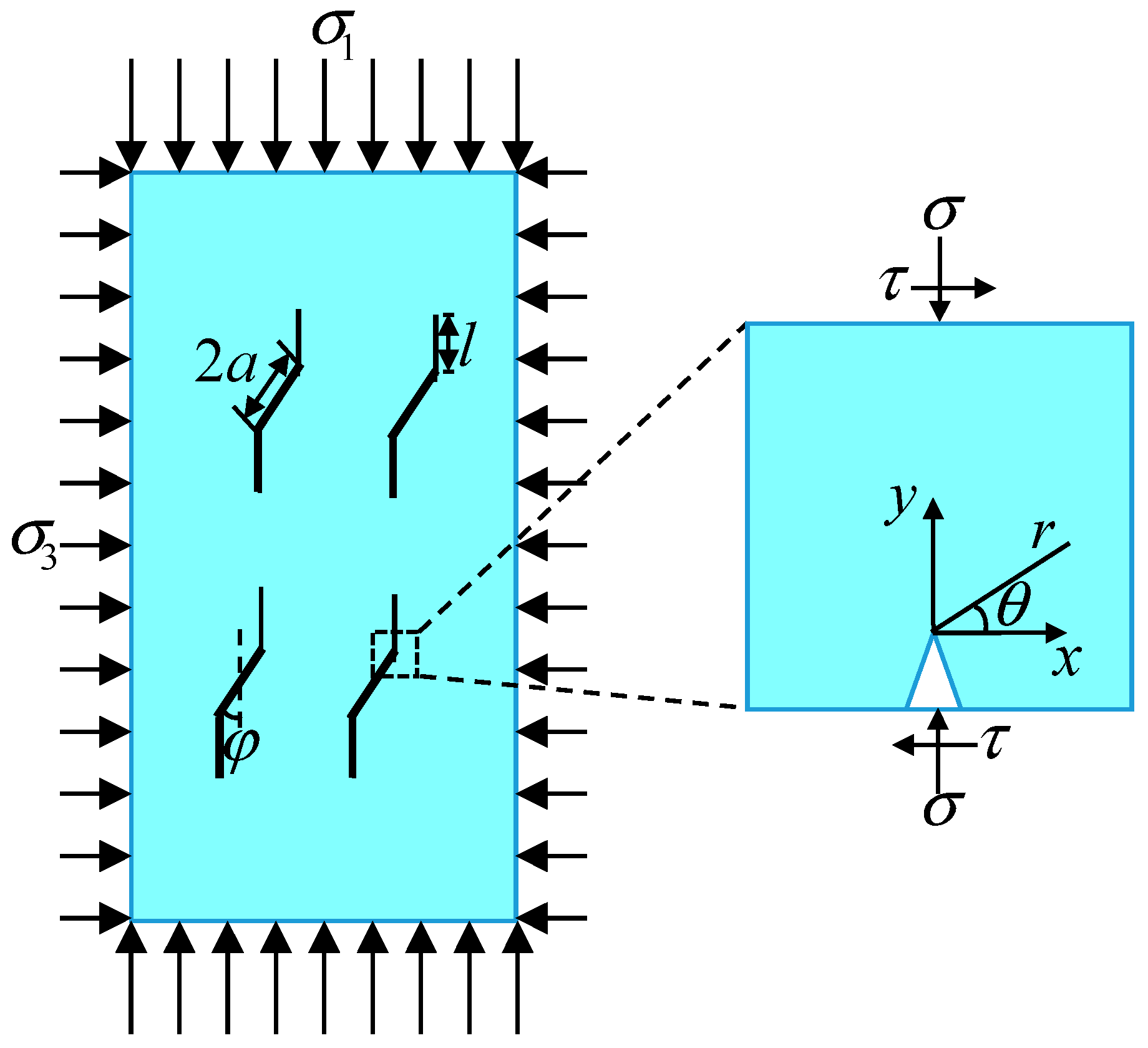

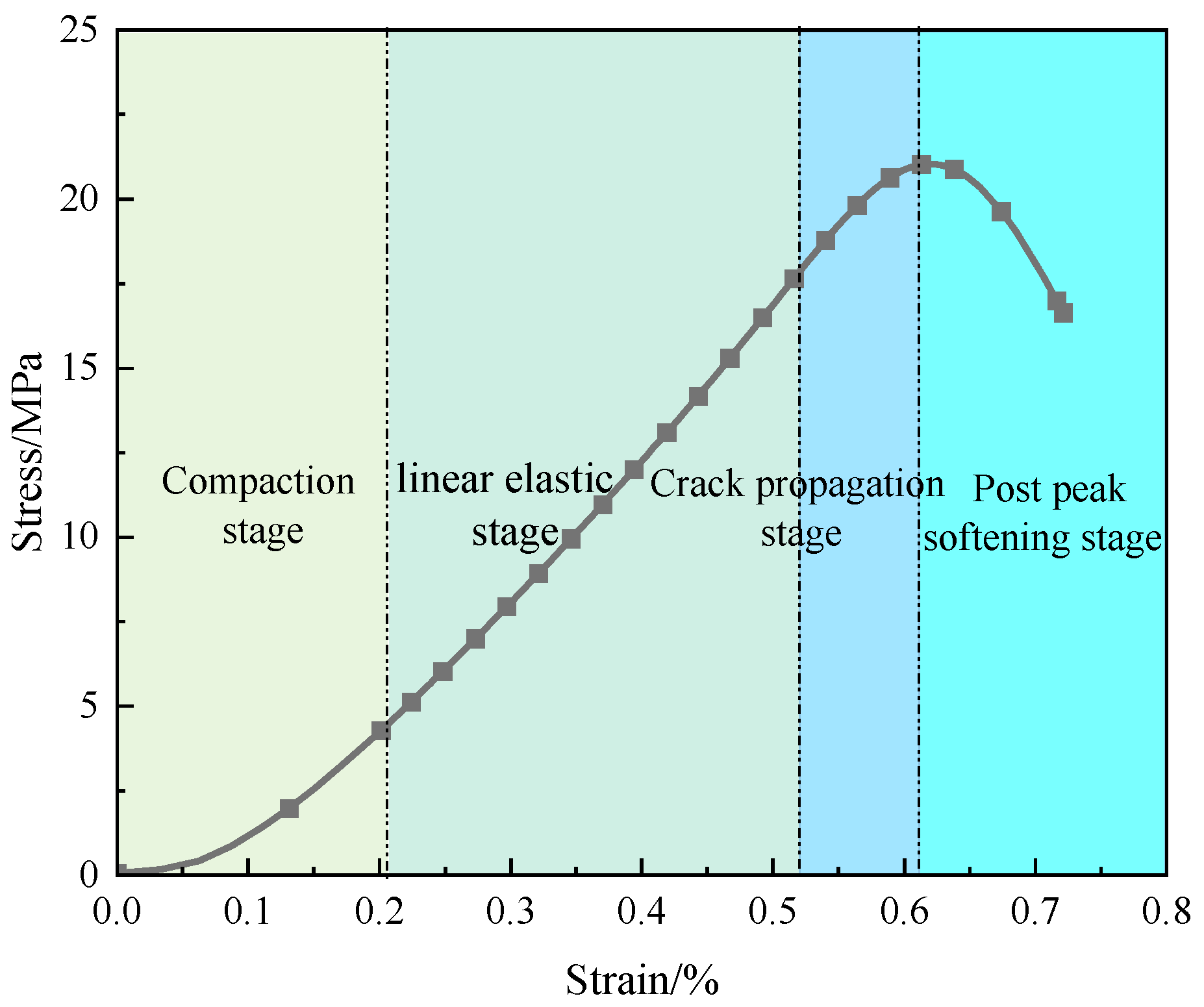

2. Damage Constitutive Model

3. Damage Evolution Equation

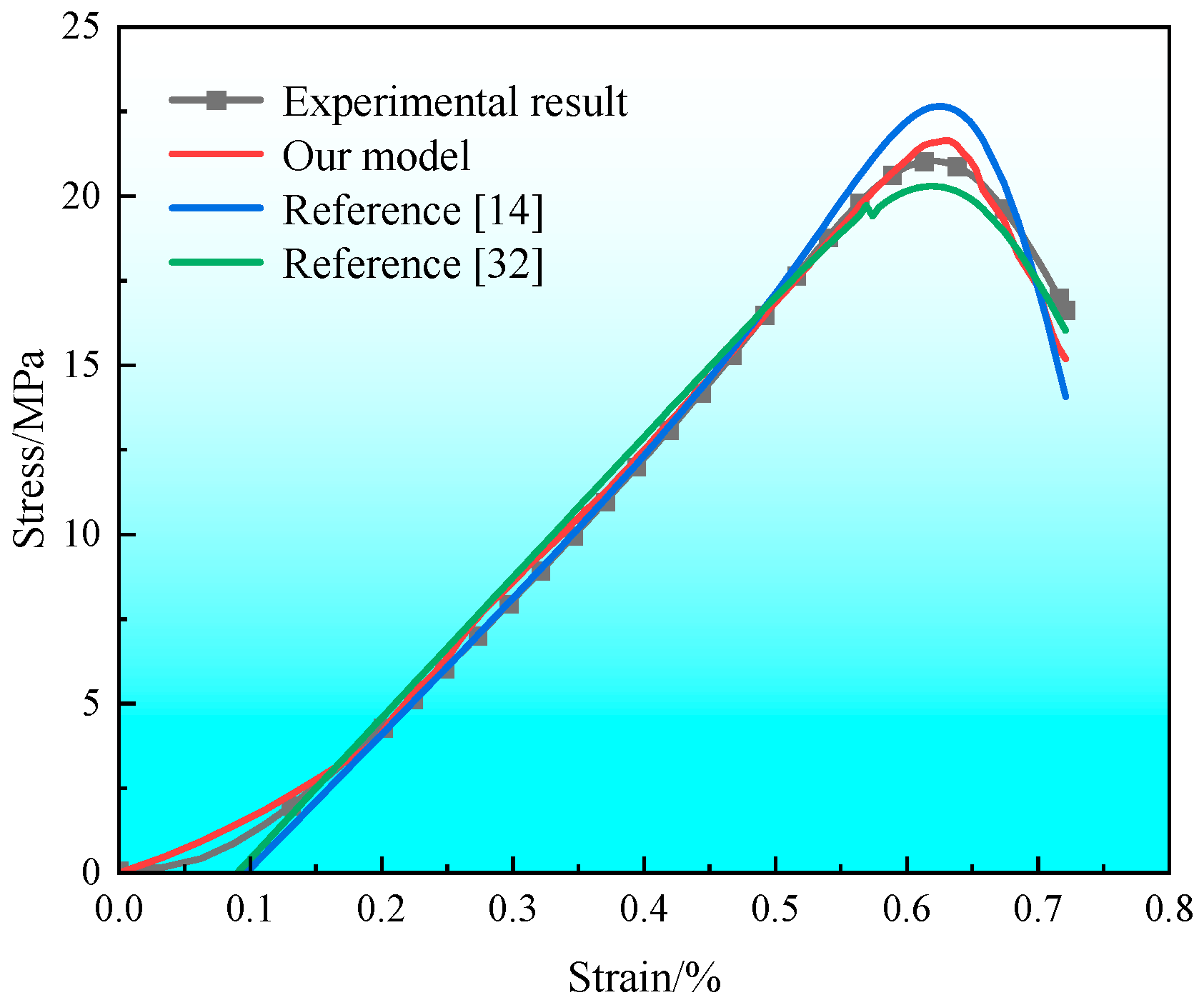

4. Model Parameter Determination and Verification

4.1. Model Parameter Determination

4.1.1. Strength Parameters

4.1.2. Strain Parameters

4.1.3. Initial Damage

4.1.4. Mesoscopic Crack Parameters

4.2. Model Validation

5. Model Parameter Impact Analysis

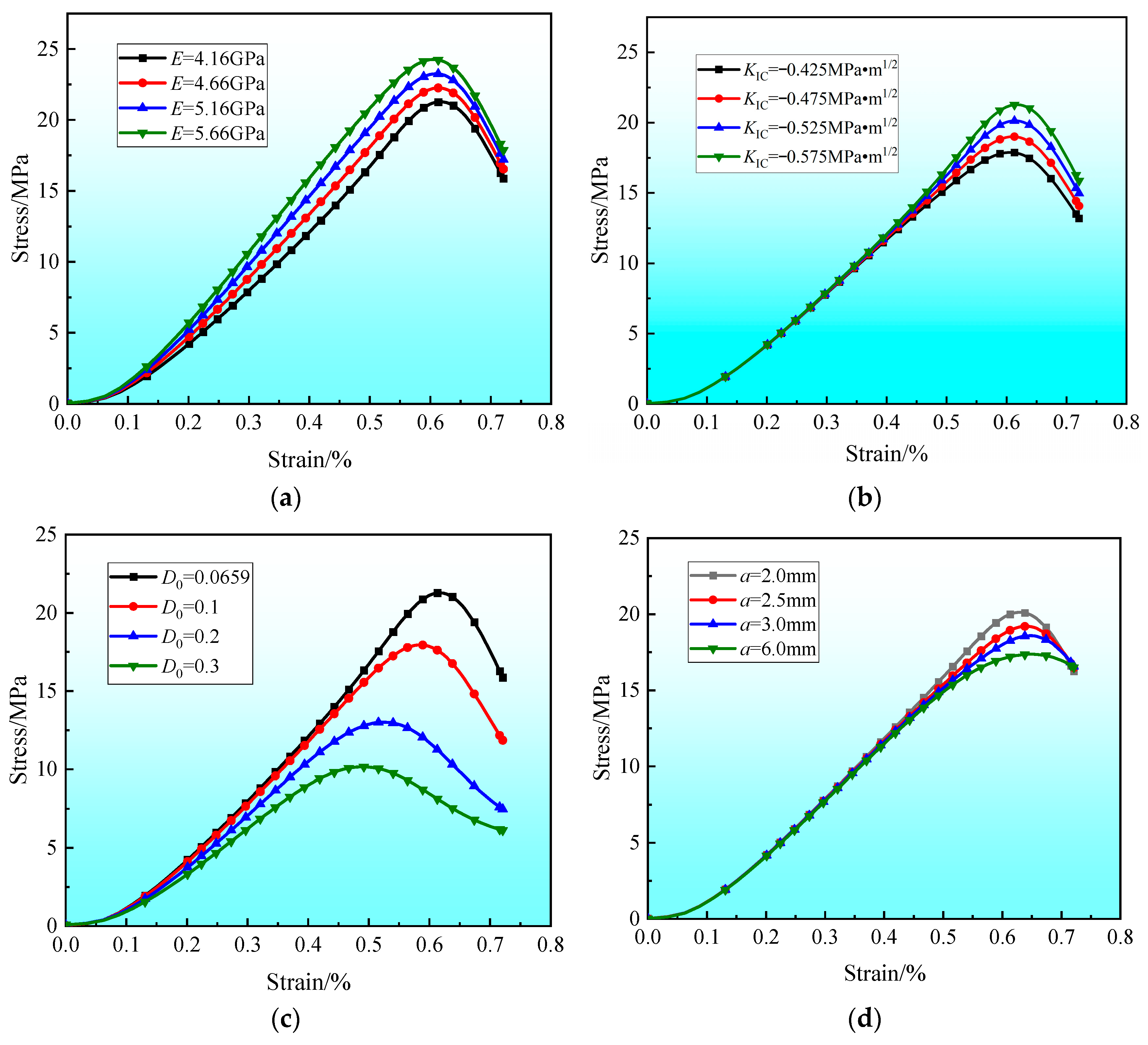

5.1. Effects of Model Parameters on the Modeled Rock Mechanical Properties

5.2. Effects of Model Parameters on the Modeled Crack Propagation Length

6. Conclusions

- (1)

- This study constructed the rock meso-structure generalization model based on phenomenological theory and solved the effective stress of rock damage unit cells by leveraging the static equilibrium relationship between the unit cells and fracture mechanics. These methods better characterized the strength of the rock crack propagation damage unit cells.

- (2)

- Based on geometric damage theory and the conservation-of-energy principle, we proposed to characterize rock damage by using the crack propagation length, thus providing a new idea for the quantitative study of rock crack propagation damage evolution.

- (3)

- Based on damage theory and meso-mechanics, we built a rock damage constitutive model upon mesoscopic crack propagation. The validation analysis showed that the proposed model could better reflect the mechanical behavior of the rock during crack propagation, and the model parameters had clear physical meaning.

- (4)

- The crack propagation length exhibits an S-shaped increase trend with the strain. Under the same strain, an increased initial crack length parameter, a decreased crack propagation speed, and an increased crack propagation length limit led to increased rock crack propagation length.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Z.; Liu, X.; Zhao, K.; Liang, Z.; Gong, B.; You, X. Experimental Study on Acoustic Emission Features and Energy Dissipation Properties during Rock Shear-Slip Process. Materials 2024, 17, 4684. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhao, Y.; Yang, T.; Wang, S. Mechanical behavior and micro-crack propagation mode of fault stick-slip under various roughness conditions. Geomech. Geophys. Geo-Energy Geo-Resour. 2025, 11, 1. [Google Scholar] [CrossRef]

- Yang, H.; Wei, Y.; Feng, L.; Zhang, S.; Zhang, X.; Liang, P. Study on the influence of non-bedding fissures on the instability and failure of anti-dip bedding rock slopes. Bull. Eng. Geol. Environ. 2025, 84, 143. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, H.; Feng, X.; Yang, C.; Ou, K.; Chen, Y. Fracture characteristics and damage mechanisms of heat-treated sandstone with combined hole-joint flaws under uniaxial compression. Theor. Appl. Fract. Mech. 2025, 136, 104845. [Google Scholar] [CrossRef]

- Ketan, A.; Tanusree, C.; Seshagiri, R. Experimental Study on Stiffness Degradation of Rock Under Uniaxial Cyclic Sinusoidal Compression Loading. Rock Mech. Rock Eng. 2019, 52, 4785–4797. [Google Scholar] [CrossRef]

- Zhang, J.; Kikumoto, M.; Yasuhara, H.; Ogata, S.; Kishida, K. Modeling the shearing behavior of discontinuous rock mass incorporating dilation of joint aperture. Int. J. Rock Mech. Min. Sci. 2022, 153, 105101. [Google Scholar] [CrossRef]

- Alessio, G.; Matteo, O.; Marco, P.; Michael, B.; Ana, I.; Nick, C.; Vincent, T. Large deformation numerical assessment of rock anchor response under axial loading for offshore renewable energy applications. Comput. Geotech. 2024, 173, 106563. [Google Scholar] [CrossRef]

- Mousumi, M.; Giang, D.; Arash, M.; Ha, H.; Luming, S.; Abbas, E.; Federico, M. Capturing pressure- and rate-dependent behaviour of rocks using a new damage-plasticity model. Int. J. Impact Eng. 2017, 110, 208–218. [Google Scholar] [CrossRef]

- Liu, W.; Yin, S.; Thanh, H.; Soltanian, M.; Yu, Q.; Yang, S.; Li, Y.; Dai, Z. Advancements and development trend in statistical damage constitutive models for rock: A comprehensive review. Nat. Hazards 2025, 121, 3703–3744. [Google Scholar] [CrossRef]

- Gu, Q.; Zhang, Q.; Dai, W.; Quan, X.; Ye, S.; Li, T. A novel statistical damage constitutive model of rock joints considering normal stress and joint roughness. Int. J. Damage Mech. 2025, 34, 326–351. [Google Scholar] [CrossRef]

- Yang, L.; Wu, B.; Xu, Y.; Fu, Y.; Xia, K. Damage Evolution During Rock Dynamic Compression Revealed by Wavelet Analysis of Acoustic Emission Signals. Rock Mech. Rock Eng. 2023, 57, 1527–1535. [Google Scholar] [CrossRef]

- Chen, J.; Che, A.; Wang, L. Cumulative damage evolution rule of rock slope based on shaking table test using VMD-HT. Eng. Geol. 2023, 314, 107003. [Google Scholar] [CrossRef]

- Zhang, Z.; Song, Z.; Lai, J.; Qiu, J.; Cheng, Y.; Zhang, J. Critical slowing down precursor information for the acoustic emission response characteristics of defective tuffs. Theor. Appl. Fract. Mech. 2024, 129, 104220. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, C.; Cao, W.; Zhao, M. Statistical meso-damage model for quasi-brittle rocks to account for damage tolerance principle. Environ. Earth Sci. 2016, 75, 862–873. [Google Scholar] [CrossRef]

- Xie, S.; Lin, H.; Wang, Y.; Chen, Y.; Xiong, W.; Zhao, Y.; Du, S. A statistical damage constitutive model considering whole joint shear deformation. Int. J. Damage Mech. 2020, 29, 988–1008. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, X.; Xu, L.; Du, X.; Wang, S.; Tomás, M.; Azzam, R. Comparative study of multiple statistical damage mechanics models for rock behaviors under high temperature. Constr. Build. Mater. 2024, 447, 138049. [Google Scholar] [CrossRef]

- Ru, W.; Hu, S.; Zhou, A.; Luo, P.; Gong, H.; Zhang, C.; Zhou, X. Study on Creep Characteristics and Nonlinear Fractional-Order Damage Constitutive Model of Weakly Cemented Soft Rock. Rock Mech. Rock Eng. 2023, 56, 8061–8082. [Google Scholar] [CrossRef]

- Yu, X.; Zuo, J.; Mao, L.; Li, Y.; Yang, L. Crack propagation behavior failure prediction of rocks with non-parallel conjugate flaws: Insights from the perspective of acoustic emission and DIC. Theor. Appl. Fract. Mech. 2024, 134 Pt A, 104709. [Google Scholar] [CrossRef]

- Zhang, W.; Ma, Q.; Liu, X.; Wang, E.; Xie, W.; Song, D. Study on crack propagation mechanism and acoustic-thermal sensitivity analysis of pre-cracked weakly cemented rock. Theor. Appl. Fract. Mech. 2024, 133 Pt B, 104619. [Google Scholar] [CrossRef]

- Kolawole, O. Mechanistic Study of Microbial Altered Properties in Dolostones. Rock Mech. Rock Eng. 2022, 56, 1099–1111. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Q.; Liu, X.; Liu, Q.; Wang, X. Mechanical and microstructural characteristics and damage constitutive model of limestone under acid corrosion. J. Build. Eng. 2025, 108, 112903. [Google Scholar] [CrossRef]

- Sarah, W.; Nicolas, F.; Edward, A.; Mark, K.; David, B.; Mohammad, S. Coupled micro-computed tomography and micromechanical experiment on the failure of discontinuous porphyry rock. Int. J. Rock Mech. Min. Sci. 2025, 194, 106180. [Google Scholar] [CrossRef]

- Shao, Y.; Yang, J.; Kim, J.; He, C.; Song, J.; Yin, H.; Leem, J. Strain localization-controlled rock failure using digital volume correlation technology: In situ compression tests on 3D-printed rock-like samples with a single initial flaw. J. Rock Mech. Geotech. Eng. 2025, 17, 4329–4348. [Google Scholar] [CrossRef]

- Ryan, C. Consistent linearization of micromorphic continuum theories. Math. Mech. Solids 2025, 30, 1366–1392. [Google Scholar] [CrossRef]

- Li, A.; Deng, H.; Xiao, Y. Study of the Damage Evolution Process and Micromechanics Constitutive Model of Microcrystalline Limestone under Periodic Blasting Load. J. Mater. Civ. Eng. 2023, 35, 225–236. [Google Scholar] [CrossRef]

- Shi, Z.; Li, J.; Wang, J.; Chen, J.; Lin, H.; Cao, P. Experimental and numerical study on fracture characteristics and constitutive model of sandstone under freeze-thaw-fatigue. Int. J. Fatigue 2023, 166, 107236. [Google Scholar] [CrossRef]

- Tan, H.; Li, J.; Shi, Z.; Wang, M.; Wang, J.; Li, J. Damage evolution and failure characteristics of red sandstone with prefabricated crack under coupled dry-wet cycle-fatigue loading. Int. J. Fatigue 2023, 175, 107751. [Google Scholar] [CrossRef]

- Rong, G.; Huang, K.; Zhou, C.; Wang, X.; Peng, J. A new constitutive law for the nonlinear normal deformation of rock joints under normal load. Sci. China Technol. Sci. 2012, 55, 555–567. [Google Scholar] [CrossRef]

- Tang, H.; Zhu, M. Micro damage mechanics-based exponential power law acceleration of microscale damage and time-dependent crack propagation. Eng. Fract. Mech. 2020, 229, 106930. [Google Scholar] [CrossRef]

- Zhang, A.; Xie, H.; Zhang, Z.; Zhang, R.; Li, C.; Gao, M.; Ren, L.; Xie, J. Mechanical responses in rocks with different lithologies under mining loading-unloading: An insight by energy damage and ultrasonic characterization. Rock Mech. Rock Eng. 2024, 57, 10047–10069. [Google Scholar] [CrossRef]

- Li, S.; Zhang, J.; Chang, J.; Yang, H.; Yue, S.; Peng, J.; Chen, K.; Li, Y.; Ren, Z.; Chen, W. Quantitative calculation of the damage of carbonaceous mudstone during uniaxial compressive failure process under dry–wet cycling. Bull. Eng. Geol. Environ. 2025, 84, 190. [Google Scholar] [CrossRef]

- Li, S.; Huang, Z.; Huang, K.; Li, Y.; Peng, H.; Liang, Q.; Ma, K. Study on the evolution law and quantitative characterization of micro-crack propagation in the compressive failure process of rocks. Eng. Fail. Anal. 2024, 155, 107743. [Google Scholar] [CrossRef]

- Ashby, M.; Sammis, C. The damage mechanics of brittle solids in compression. Pure Appl. Geophys. 1990, 133, 489–521. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, Y.; Yang, R.; Li, J.; Chen, S.; Li, D. Study on dynamic mechanical characteristics of specimens with cavity under prestressing conditions. Eng. Fract. Mech. 2024, 312, 110602. [Google Scholar] [CrossRef]

- Deng, Z.; Min, J.; Jin, J.; Liu, S.; Wei, J. The macro-meso damage model for jointed rock mass under the sequential effects of freeze–thaw cycles and compressive shear load. Comput. Geotech. 2024, 174, 106644. [Google Scholar] [CrossRef]

- Liu, D.; He, M.; Cai, M. A damage model for modeling the complete stress-strain relations of brittle rocks under uniaxial compression. Int. J. Damage Mech. 2018, 27, 1000–1019. [Google Scholar] [CrossRef]

- Li, X.; Qi, C. A micro-macro dynamic compressive-shear fracture model under static confining pressure in brittle rocks. Int. J. Impact Eng. 2018, 122, 109–118. [Google Scholar] [CrossRef]

| /GPa | /(MPa·m1/2) | /° | /mm | /° | /mm | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.16 | 0.196 | 0.575 | 1191 | 0.0659 | 45 | 0.26 | 2.1 | 0 | 0.16 | 0.559 | 6.325 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Yang, H.; Li, Y.; Liu, X.; Tan, J.; Guo, Y.; Liang, Q.; Shen, Y.; Wei, X.; Ma, C. A Damage Constitutive Model for Rock Considering Crack Propagation Under Uniaxial Compression. Modelling 2025, 6, 116. https://doi.org/10.3390/modelling6040116

Li S, Yang H, Li Y, Liu X, Tan J, Guo Y, Liang Q, Shen Y, Wei X, Ma C. A Damage Constitutive Model for Rock Considering Crack Propagation Under Uniaxial Compression. Modelling. 2025; 6(4):116. https://doi.org/10.3390/modelling6040116

Chicago/Turabian StyleLi, Shengnan, Hao Yang, Yu Li, Xianglong Liu, Junhao Tan, Yuecheng Guo, Qiao Liang, Yaqian Shen, Xingxing Wei, and Chenzhen Ma. 2025. "A Damage Constitutive Model for Rock Considering Crack Propagation Under Uniaxial Compression" Modelling 6, no. 4: 116. https://doi.org/10.3390/modelling6040116

APA StyleLi, S., Yang, H., Li, Y., Liu, X., Tan, J., Guo, Y., Liang, Q., Shen, Y., Wei, X., & Ma, C. (2025). A Damage Constitutive Model for Rock Considering Crack Propagation Under Uniaxial Compression. Modelling, 6(4), 116. https://doi.org/10.3390/modelling6040116