Morphological Characteristics of Catalyst Layer Defects in Catalyst-Coated Membranes in PEM Fuel Cells

Abstract

1. Introduction

2. Experimental

2.1. Scope of Defect Analysis

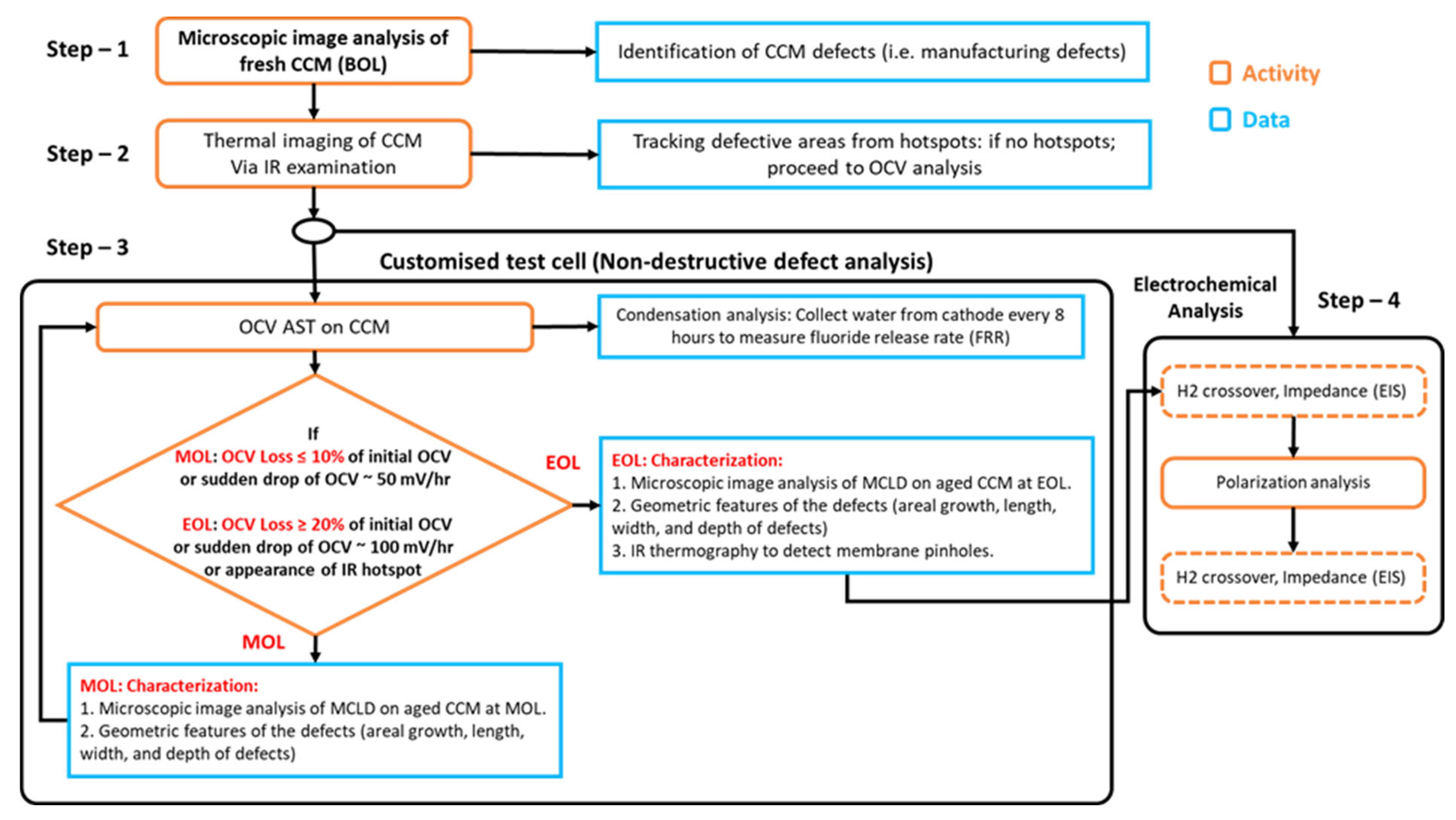

2.2. CCM Defect Analysis Framework

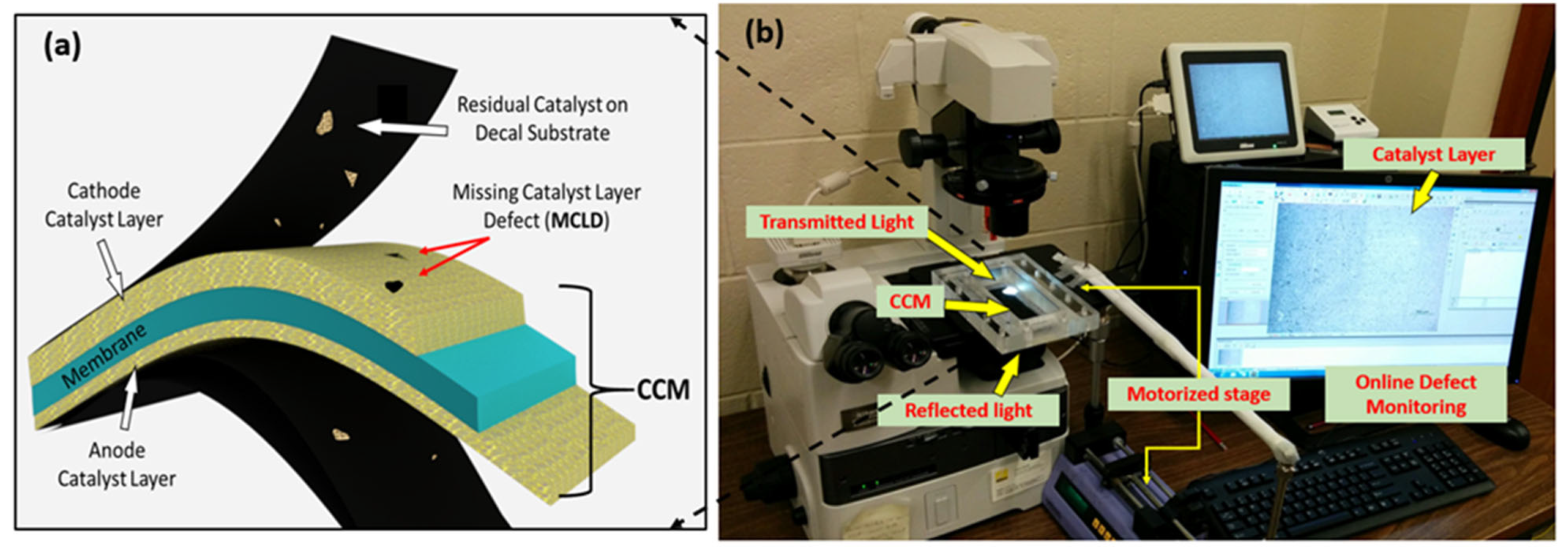

2.2.1. Microscopic Imaging

2.2.2. IR Thermography

2.2.3. Open Circuit Voltage-Accelerated Stress Test

- The test cell design involved transparent polycarbonate plates on the outside of two sets of lands and channels that were 2 mm wide and 1.5 mm deep [31]. This design allowed the user to monitor thermal changes on the electrode through IR thermography to easily identify leaks or pinholes.

- The test cells were operated using gaskets of varying thicknesses (0.5, 1, 3, 5, 6, and 8 mm) without gas flow plate lands or channels to prevent the compression and/or damage of the catalyst surface by lands/channels. The gaskets provided enough space for the membrane to swell without being damaged by the flow paths. A 6 mm thick gasket was found to yield the best results without any external damage to the catalyst layers. Overall, the use of this gasket ensured that defect (catalyst layer cracks) formation was caused solely by mechanical deformation due to membrane swelling in the presence of humidified gases rather than by mechanical deformation due to impinging land/channels.

- To provide an optimal electrical contact surface, a small portion of the anode and cathode GDL was extended to the end of the test cell to measure the potential difference (OCV) during the experiments. The OCV experiments were performed without hot pressing the GDL to the CCM. Since the GDL was not compressed and the CCM was not confined by the land/channels, the morphology of defects should not be affected by the GDL fibers and/or flow channel plate indentations. Therefore, the propagation of defects should be driven by the chemical and mechanical degradation caused by the reaction gases.

- A.

- MOL: Examination of the CCM surface during MOL by optical microscopy was conducted if the OCV dropped 10% or less below its initial value or the OCV dropped suddenly by ~50 mV/h. MOL image analysis included characterization of the geometric features of the defect.

- B.

- EOL: The experiment was terminated and EOL inspection of the CCM was conducted when the OCV dropped 20% or more below its initial value, the OCV dropped suddenly by ~100 mV/h, or if IR thermography detected any hotspots on the electrode. After characterization by optical microscopy and IR thermography were carried out, the aged CCM was subjected to electrochemical polarization analysis and H2 crossover measurements.

2.2.4. Electrochemical Analysis

Polarization Analysis

Hydrogen Crossover Measurement by LSV and FER

3. Results and Discussion

3.1. Microscopic Investigation of Catalyst Layer Defects in CCMs

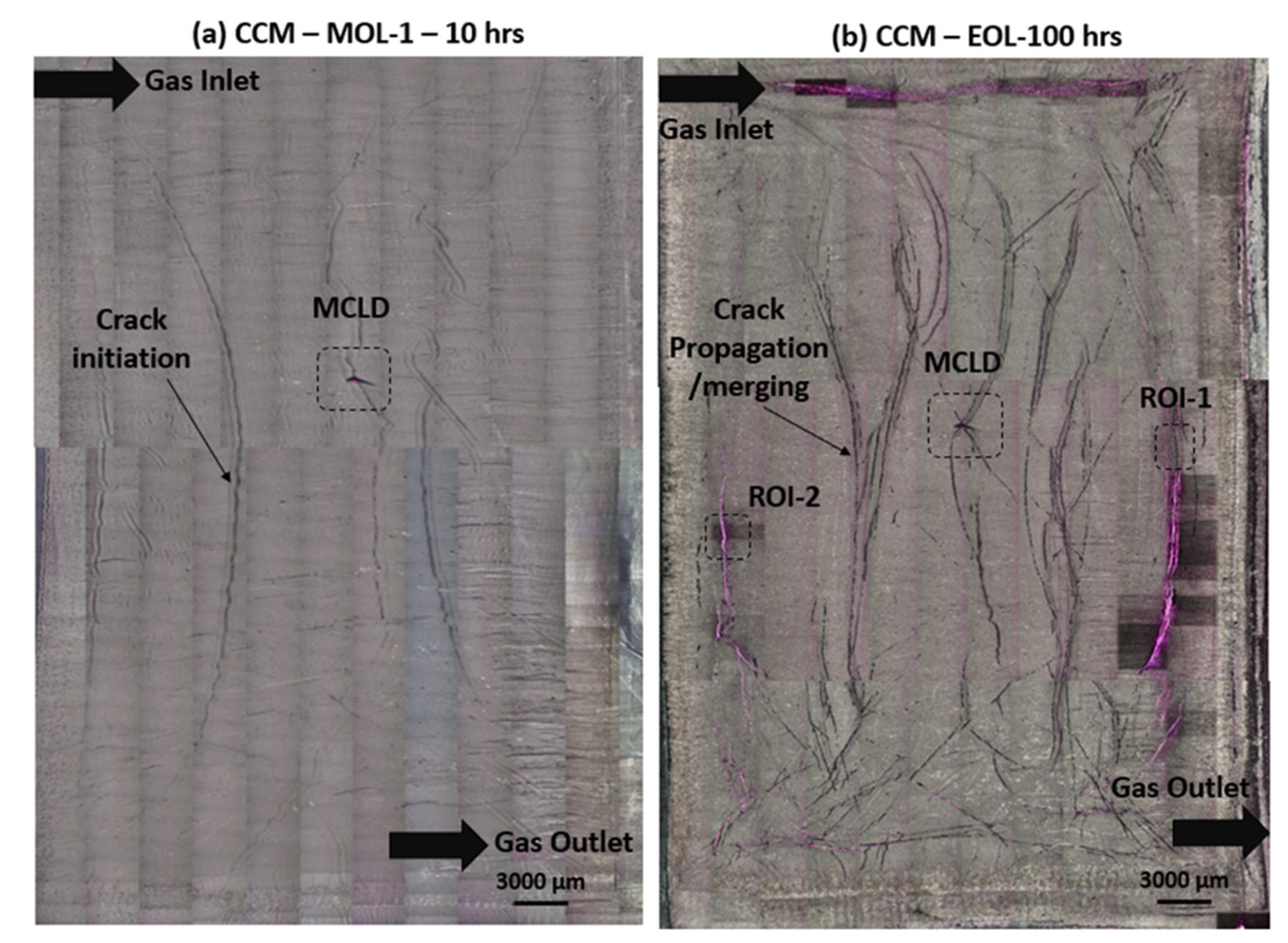

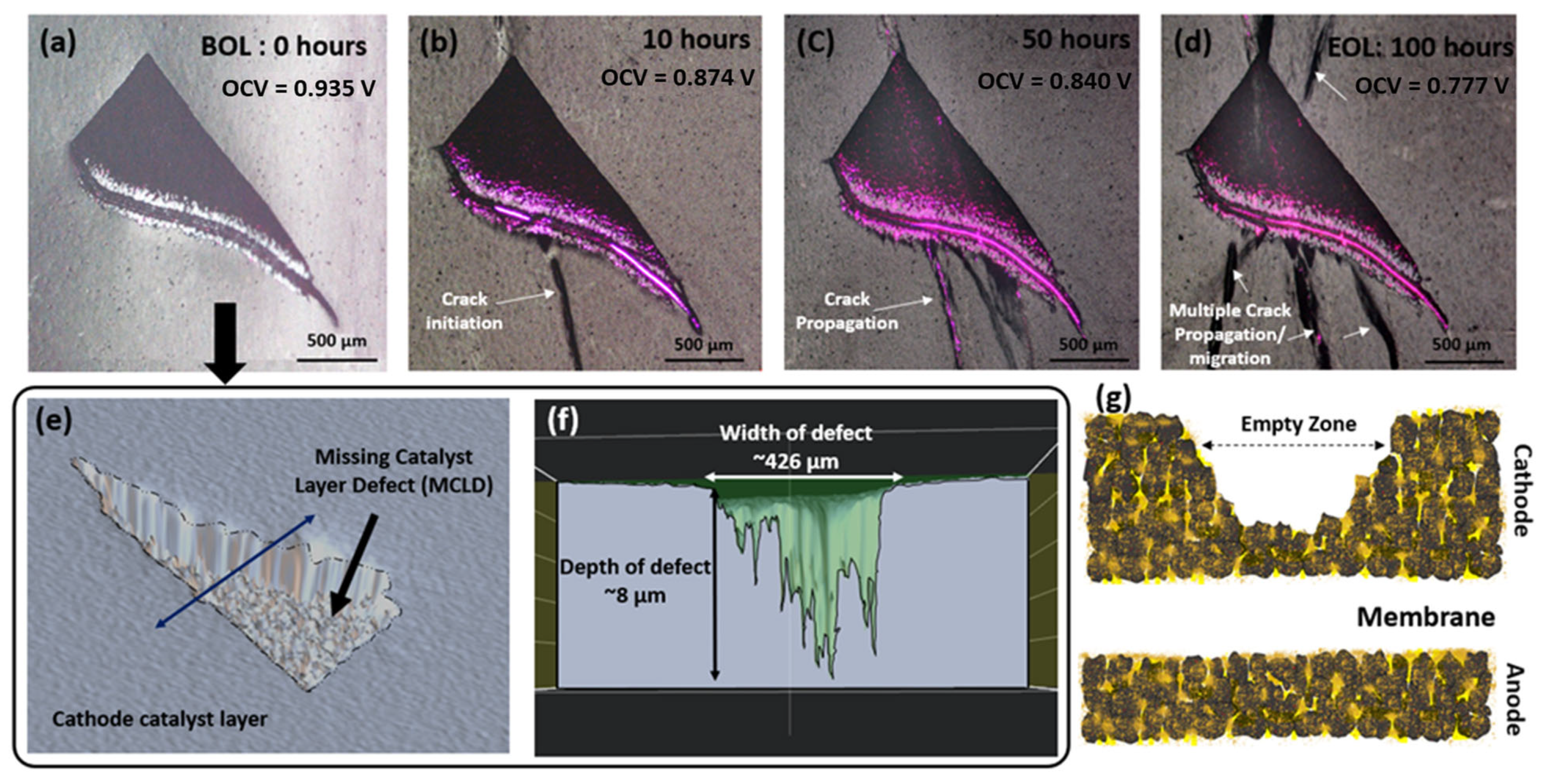

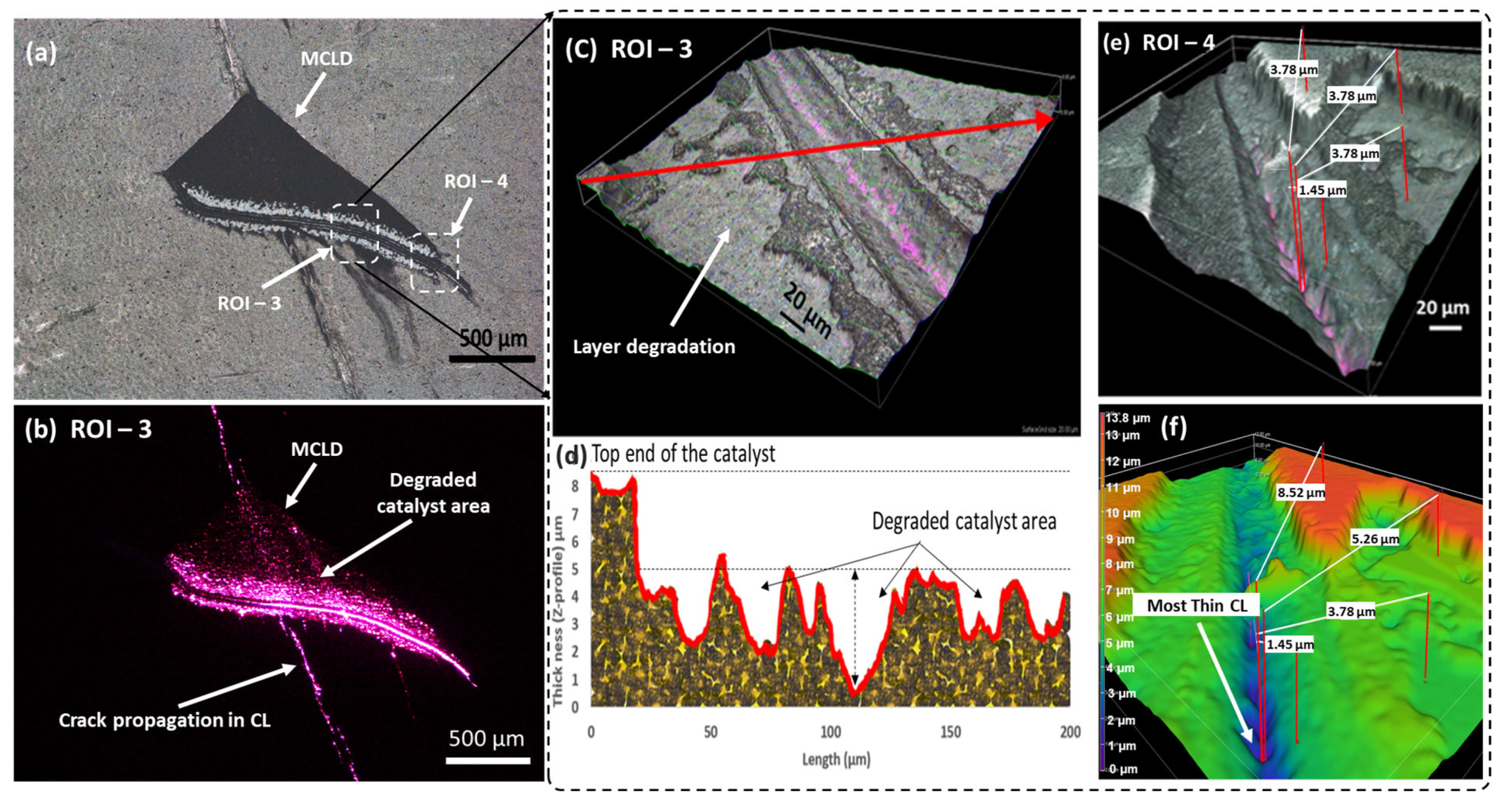

3.2. Degradation of Catalyst Layer Defect—MCLD

3.3. Degradation Mechanism of Catalyst Layer Defects

3.3.1. Surface Degradation (Chemical) of Catalyst Layer Defects

Catalyst Erosion

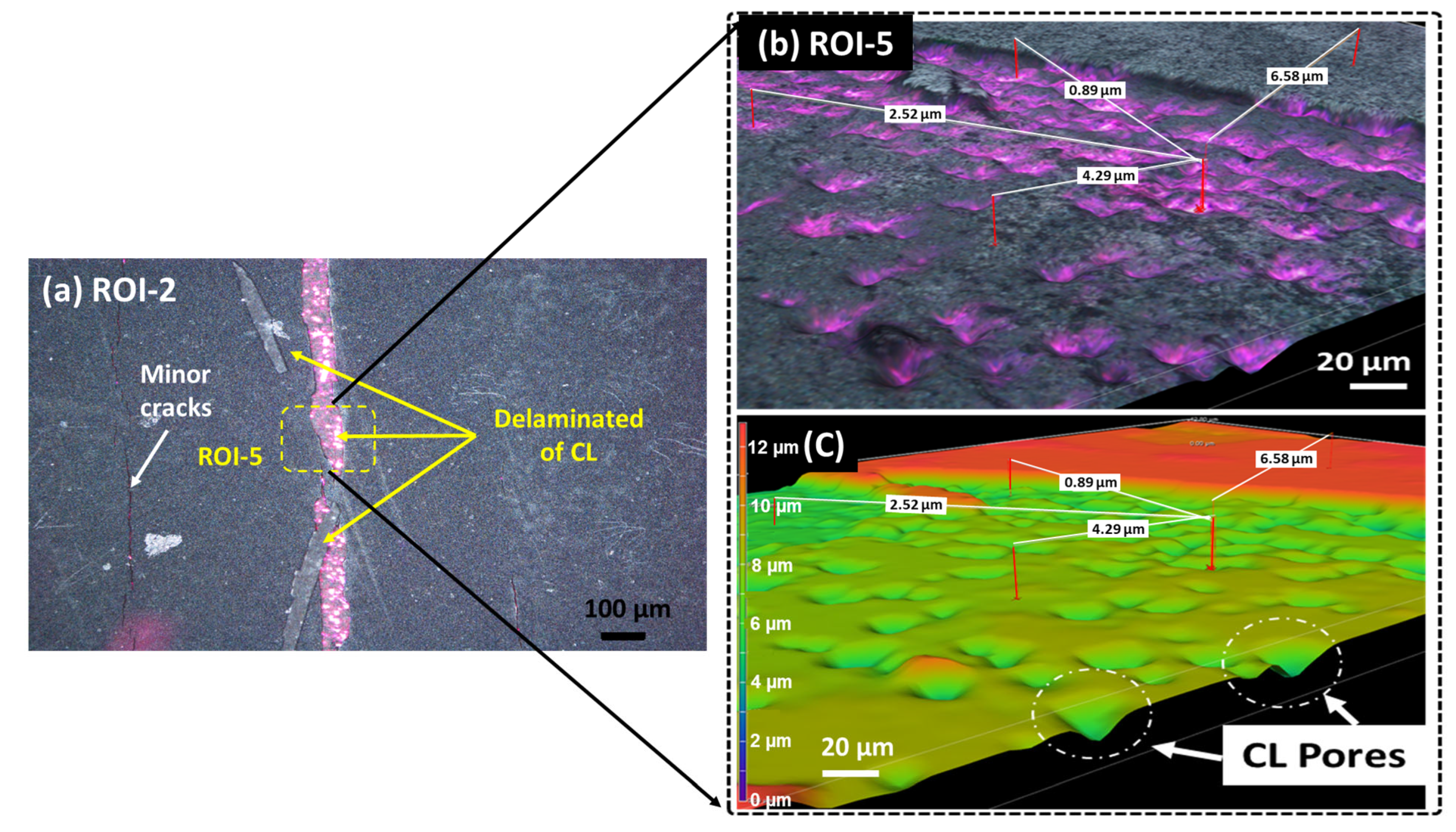

3.3.2. Mechanical Delamination of Catalyst Layers

3.4. Polarization Analysis

Hydrogen Crossover

3.5. Summary of Defect Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ACL | anode catalyst layer |

| AST | accelerated stress test |

| BOL | beginning-of-life |

| CCM | catalyst-coated membrane |

| CCL | cathode catalyst layer |

| DOE | Department of Energy |

| EOL | end-of-life |

| FER | fluoride emission rate |

| GDE | gas diffusion electrode |

| GDL | gas diffusion layer |

| LSV | linear sweep voltammetry |

| MCLD | missing catalyst layer defect |

| MEA | membrane electrode assembly |

| MOL | middle-of-life |

| OCV | open-circuit voltage |

| PEMFC | polymer electrolyte membrane fuel cell |

| RH | relative humidity |

| ROI | region of interest |

References

- Miller, R.G.; Sorrell, S.R. The Future of Oil Supply. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130179. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yiheng, P.; Hui, X.; Martinez, A.; Chen, K.S. PEM Fuel Cell and Electrolysis Cell Technologies and Hydrogen Infrastructure Development: A Review. Energy Environ. Sci. 2022, 15, 288–2328. [Google Scholar] [CrossRef]

- Sung, W.; Song, Y.; Yu, K.; Lim, T. Recent Advances in the Development of Hyundai Kia’s Fuel Cell Electric Vehicles. SAE Int. J. Engines 2018, 3, 768–772. [Google Scholar] [CrossRef]

- Clean Hydrogen Joint Undertaking. Clean Hydrogen; Clean Hydrogen Joint Undertaking: Brussels, Belgium, 2022. [Google Scholar]

- Yuan, X.Z.; Nayoze-Coynel, C.; Shaigan, N.; Fisher, D.; Zhao, N.; Zamel, N.; Gazdzicki, P.; Ulsh, M.; Friedrich, K.A.; Girard, F.; et al. A Review of Functions, Attributes, Properties and Measurements for the Quality Control of Proton Exchange Membrane Fuel Cell Components. J. Power Sources 2021, 491, 229540. [Google Scholar] [CrossRef]

- U.S. Department of Energy; Energy Efficiency & Renewable Energy. Pathway to Commercial Success: Technology and Products Supported by the Fuel Cell Technology Office; U.S. Department of Energy: Washington, DC, USA, 2015. [Google Scholar]

- U.S. Department of Energy; Energy Efficiency & Renewable Energy; Fuel Cell Technologies Office. Manufacturing Cost Analysis of Polymer Electrolyte Membrane (PEM) Fuel Cell Systems for Material Handling Applications; U.S. Department of Energy: Washington, DC, USA, 2017. [Google Scholar]

- Shangguan, Z.; Li, B.; Ming, P.; Zhang, C. Understanding the Functions and Modifications of Interfaces in Membrane Electrode Assemblies of Proton Exchange Membrane Fuel Cells. J. Mater. Chem. A 2021, 9, 15111–15139. [Google Scholar] [CrossRef]

- Xie, M.; Chu, T.; Wang, T.; Wan, K.; Yang, D.; Ki, B.; Ming, P.; Zhang, C. Preparation, Performance and Challenges of Catalyst Layer for Proton Exchange Membrane Fuel Cell. Membranes 2021, 11, 879. [Google Scholar] [CrossRef]

- Song, J.M.; Suzuki, S.; Uchida, H.; Watanabe, M. Preparation of High Catalyst Utilization Electrodes for Polymer Electrolyte Fuel Cells. Langmuir 2006, 22, 6422–6428. [Google Scholar] [CrossRef] [PubMed]

- Shukla, S.; Domican, K.; Karan, K.; Bhattacharjee, S.; Secanell, M. Electrochimica Acta Analysis of Low Platinum Loading Thin Polymer Electrolyte Fuel Cell Electrodes Prepared by Inkjet Printing. Electrochim. Acta 2015, 156, 289–300. [Google Scholar] [CrossRef]

- Lin, R.; Cai, X.; Zeng, H.; Yu, Z. Stability of High-Performance Pt-Based Catalysts for Oxygen Reduction Reactions. Adv. Mater. 2018, 30, 1705332. [Google Scholar] [CrossRef]

- Hwang, D.S.; Park, C.H.; Yi, S.C.; Lee, Y.M. Optimal Catalyst Layer structure of Polymer Electrolyte Membrane Fuel Cell. Int. J. Hydrog. Energy 2011, 36, 9876–9885. [Google Scholar] [CrossRef]

- Mandal, M.; Valls, A.; Gangnus, N.; Secanell, M. Analysis of Inkjet Printed Catalyst Coated Membranes for Polymer Electrolyte Electrolyzers. J. Electrochem. Soc. 2018, 165, 543–552. [Google Scholar] [CrossRef]

- Pak, C.; You, D.J.; Choi, K.H.; Chang, H. High performance membrane electrode assemblies by optimization of processes and supported catalysts. In Hydrogen Energy: Challenges and Perspectives; InTech: New York, NY, USA, 2012; Chapter 10. [Google Scholar] [CrossRef]

- Sing, R.; Sing, A.; Sing, T. Factors Influencing the Performance of PEM Fuel Cells: A Review on Performance Parameters, Water Management, and Cooling Techniques. Int. J. Energy Res. 2021, 46, 3810–3842. [Google Scholar] [CrossRef]

- Jung, C.Y.; Kim, W.J.; Yi, S.C. Optimization of Catalyst Ink Composition for the Preparation of a Membrane Electrode Assembly in a Proton Exchange Membrane Fuel Cell Using the Decal Transfer. Int. J. Hydrog. Energy 2012, 37, 18446–18454. [Google Scholar] [CrossRef]

- Kundu, S.; Fowler, M.W.; Simon, L.C.; Grot, S. Morphological Features (Defects) in Fuel Cell Membrane Electrode Assemblies. J. Power Sources 2006, 157, 650–656. [Google Scholar] [CrossRef]

- Tavassoli, A.; Lim, C.; Kolodziej, J.; Lauritzen, M.; Knights, S.; Wang, G.; Kjeang, E. Effect of catalyst layer defects on local membrane degradation in polymer electrolyte fuel clls. J. Power Sources 2016, 322, 17–25. [Google Scholar] [CrossRef]

- Li, P.; Qiu, D.; Peng, L.; Shen, S.; Lai, X. Analysis of Degradation Mechanism in Unitized Regenerative Fuel Cell under the Cyclic Operation. Energy Convers. Manag. 2022, 254, 115210. [Google Scholar] [CrossRef]

- Ulsh, M.; Sopori, B.; Aieta, N.V.; Bender, G. Challenges to High-Volume Production of Fuel Cell Materials: Quality Control. Electrochem. Soc. 2012, 50, 919–926. [Google Scholar] [CrossRef]

- Bender, G.; Felt, W.; Ulsh, M. The Spatial Performance Effect of Electrode Defects in PEMFC. ECS 2012, 13, 1588. [Google Scholar] [CrossRef]

- Park, I.S.; Li, W.; Manthiram, A. Fabrication of Catalyst-Coated Membrane-Electrode Assemblies by Doctor Blade Method and Their Performance in Fuel Cells. J. Power Sources 2010, 195, 7078–7082. [Google Scholar] [CrossRef]

- Yılmaztürk, S.; Gümüşoğlu, T.; Arı, G.A.; Öksüzömer, F.; Deligöz, H. Fabrication and performance of catalyst-coated membranes by layer-by-layer deposition of catalyst onto Nafion for polymer electrolyte membrane fuel cells. J. Power Sources 2012, 201, 88–94. [Google Scholar] [CrossRef]

- Ren, H.; Meng, X.; Lin, Y.; Shao, Z. Structural Stability of Catalyst Ink and Its Effects on the Catalyst Layer Microstructure and Fuel Cell Performance. J. Power Sources 2022, 517, 230698. [Google Scholar] [CrossRef]

- Sassin, M.B.; Garsany, Y.; Gould, B.D.; Swider-Lyons, K.E. Fabrication Method for Laboratory-Scale High-Performance Membrane Electrode Assemblies for Fuel Cells. Anal. Chem. 2017, 89, 511–518. [Google Scholar] [CrossRef]

- Knowles, M.; Baglee, D.; Morris, A.; Ren, Q. The State of the Art in Fuel Cell Condition Monitoring and Maintenance. World Electr. Veh. J. 2011, 4, 487–494. [Google Scholar] [CrossRef]

- Rankov, V.; Locke, R.J.; Edens, R.J.; Barber, P.R.; Vojnovic, B. An Algorithm for Image Stitching and Blending. Three-Dimens. Multidimens. Microsc. Image Acquis. Process. XII 2005, 5701, 190. [Google Scholar] [CrossRef]

- Tian, T.; Tang, J.; Chen, Y.; Tan, J.; Li, S.; Pan, M. Study on Accelerated Stress Test for Fuel Cell Lifetime. Int. J. Electrochem. Sci. 2018, 13, 2022–2032. [Google Scholar] [CrossRef]

- Yuan, X.Z.; Li, H.; Zhang, S.; Martin, J.; Wang, H. A Review of Polymer Electrolyte Membrane Fuel Cell Durability Test Protocols. J. Power Sources 2011, 196, 9107–9116. [Google Scholar] [CrossRef]

- Arcot, M.P.; Zheng, K.; Mcgrory, J.; Fowler, M.W.; Pritzker, M.D. Investigation of Catalyst Layer Defects in Catalyst-Coated Membrane for PEMFC Application: Non-Destructive Method. Int. J. Energy Res. 2018, 42, 3615–3632. [Google Scholar] [CrossRef]

- Pestrak, M.; Li, Y.; Case, S.W.; Dillard, D.A.; Ellis, M.W.; Lai, Y.-H.; Gittleman, C.S. The Effect of Mechanical Fatigue on the Lifetimes of Membrane Electrode Assemblies. J. Fuel Cell Sci. Technol. 2010, 7, 41009. [Google Scholar] [CrossRef]

- Singh, Y.; Orfino, F.P.; Dutta, M.; Kjeang, E. 3D Failure Analysis of Pure Mechanical and Pure Chemical Degradation in Fuel Cell Membranes. J. Electrochem. Soc. 2017, 164, F1331–F1341. [Google Scholar] [CrossRef]

- Reshetenko, T.V.; Bender, G.; Bethune, K.; Rocheleau, R. Application of a Segmented Cell Setup to Detect Pinhole and Catalyst Loading Defects in Proton Exchange Membrane Fuel Cells. Electrochim. Acta 2012, 76, 16–25. [Google Scholar] [CrossRef]

- Gunji, H.; Eguchi, M.; Sekine, F.; Tsutsumi, Y. Gas-Leak-Induced Pinhole Formation at Polymer Electrolyte Membrane Fuel Cell Electrode Edges. Int. J. Hydrog. Energy 2017, 42, 562–574. [Google Scholar] [CrossRef]

- Kreitmeier, S.; Michiardi, M.; Wokaun, A.; Büchi, F.N. Factors Determining the Gas Crossover through Pinholes in Polymer Electrolyte Fuel Cell Membranes. Electrochim. Acta 2012, 80, 240–247. [Google Scholar] [CrossRef]

- Mu, S.; Zhao, P.; Xu, C.; Gao, Y.; Pan, M. Detaching Behaviors of Catalyst Layers Applied in PEM Fuel Cells by Off-Line Accelerated Test. Int. J. Hydrog. Energy 2010, 35, 8155–8160. [Google Scholar] [CrossRef]

- Mu, S.; Xu, C.; Gao, Y.; Tang, H.; Pan, M. Accelerated Durability Tests of Catalyst Layers with Various Pore Volume for Catalyst Coated Membranes Applied in PEM Fuel Cells. Int. J. Hydrog. Energy 2010, 35, 2872–2876. [Google Scholar] [CrossRef]

- Kai, Y.; Kitayama, Y.; Omiya, M.; Uchiyama, T.; Kato, M. Crack Formation on Membrane Electrode Assembly (MEA) Under Static and Cyclic Loadings. J. Fuel Cell Sci. Eng. Technol. 2012, 10, 143. [Google Scholar] [CrossRef]

- Meyer, Q.; Mansor, N.; Iacoviello, F.; Cullen, P.L.; Jervis, R.; Finegan, D.; Tan, C.; Bailey, J.; Shearing, P.R.; Brett, D.J.L. Electrochimica Acta Investigation of Hot Pressed Polymer Electrolyte Fuel Cell Assemblies via X-ray Computed Tomography. Electrochim. Acta 2017, 242, 125–136. [Google Scholar] [CrossRef]

| CCM-1 | CCM-2 | CCM-Baseline | ||||||

|---|---|---|---|---|---|---|---|---|

| Number of MCLD | 1 | 1 | No defects | |||||

| % Growth of Defect | MOL-1 | MOL-2 | EOL | - | - | |||

| 5.9% | 11.2% | 1.3% | ||||||

| OCV (V) | BOL | EOL | BOL | EOL | BOL | EOL | ||

| 0.937 | 0.776 | 0.923 | 0.820 | 0.968 | 0.909 | |||

| H2 Crossover (mA/cm2) | 3.13 | 5.42 | 3.32 | 3.95 | 3.25 | 3.46 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arcot, M.P.; Cronin, M.; Fowler, M.; Pritzker, M. Morphological Characteristics of Catalyst Layer Defects in Catalyst-Coated Membranes in PEM Fuel Cells. Electrochem 2023, 4, 1-20. https://doi.org/10.3390/electrochem4010001

Arcot MP, Cronin M, Fowler M, Pritzker M. Morphological Characteristics of Catalyst Layer Defects in Catalyst-Coated Membranes in PEM Fuel Cells. Electrochem. 2023; 4(1):1-20. https://doi.org/10.3390/electrochem4010001

Chicago/Turabian StyleArcot, Muneendra Prasad, Magnus Cronin, Michael Fowler, and Mark Pritzker. 2023. "Morphological Characteristics of Catalyst Layer Defects in Catalyst-Coated Membranes in PEM Fuel Cells" Electrochem 4, no. 1: 1-20. https://doi.org/10.3390/electrochem4010001

APA StyleArcot, M. P., Cronin, M., Fowler, M., & Pritzker, M. (2023). Morphological Characteristics of Catalyst Layer Defects in Catalyst-Coated Membranes in PEM Fuel Cells. Electrochem, 4(1), 1-20. https://doi.org/10.3390/electrochem4010001