Abstract

Strengthening of electrodeposited Au-based materials is achieved by co-electrodeposition with TiO2 nanoparticles dispersed in a sulfide-based gold electrolyte. TiO2 content in the composite film is adjusted by concentration of the TiO2 in the gold electrolyte. Effects of the TiO2 content on surface morphology, crystalline structure and microstructure of the composite film are investigated. Mechanical properties of the Au–TiO2 composite films are evaluated by micro-Vickers hardness and micro-compression tests. The hardness increases from 135 to 207 HV when the TiO2 content is increased from 0 to 2.72 wt%. Specimens used in the micro-compression test are micro-pillars fabricated from the composite film, and the yield strength reaches 0.84 GPa by incorporating 2.72 wt% TiO2 into the film.

1. Introduction

Electrodeposition methods are widely applied in fabrication of micro-components used in miniaturized electronic devices such as microelectromechanical system (MEMS) devices. For instance, the proof mass and micro-springs in a highly-sensitive MEMS accelerometers are prepared by Au electrodeposition [1,2]. Au is used here because performance of a MEMS accelerometer is highly dependent on overall mass of the movable components, while miniaturization of the component is also required. Hence, Au (mass density = 19.32 g/cm3 at 298 K) becomes the ideal material to achieve requirements of high performance and miniaturization at the same time. On the other hand, Au has relatively weak mechanical strengths among materials commonly used in electronics, and this raises a concern on the structure stability of movable micro-structures composed of Au. Strengthening of the electrodeposited Au becomes an important task to ensure high structure stability of the movable micro-structures.

Co-electrodeposition of metal matrix composites (MMCs) is an effective and simple strategy to enhance a specific property of electrodeposited materials. Common reinforcement materials are nanoparticles (NPs) include oxides such as Al2O3 [3], TiO2 [4,5], and Cr2O3 [6], carbides like SiC [7] or graphitic materials like carbon nanofiber [8] and carbon nanotube [9], inorganic particles like phosphorus [10] and polymers like polyaniline [11]. For enhancing mechanical properties of electrodeposited Au while keeping the high mass density, the effects of oxide dispersion strengthening [12] could be readily applied by incorporating a small amount of oxide NPs into the electrodeposited film.

In this study, TiO2 NPs are introduced into the Au matrix composite by co-electrodeposition. Moreover, in consideration of the sample size effect [13], that is mechanical properties of metallic materials varied along with dimensions of the specimen used in the evaluation, the mechanical properties are evaluated by micro-compression test for application in miniaturized electronic devices.

2. Materials and Methods

Co-Electrodeposition of Au–TiO2 Composite Films

The base electrolyte was a non-cyanide sulfite-based commercial Au plating bath purchased from MATEX·JAPAN Co., Ltd., Shizuoka, Japan. The bath was composed of 18.13 g/L of Au(SO3)2 and additives including ethylenediaminetetraacetic acid (EDTA) and sodium gluconate with pH value of 7.5. 10, 30, and 50 g/L of TiO2 NPs (AEROXIDE® TiO2 P25, Evonik, Essen, Germany) were added into the base electrolyte to form Au–TiO2 composite films with different TiO2 contents. Cold-worked Cu plates were masked with polyimide tape into a single side with surface area of 10 × 10 mm2 as the working electrodes. Cu electrodes were treated with 1 M KOH and 1 M HCl for 1 min each at room temperature right before the electrodeposition. The counter electrode was a Pt plate with a total surface area of 40 × 10 mm2, and the reference electrode was Ag/AgCl(sat. KCl). The electrodeposition was conducted at 5 mA/cm2 using a potentiostat (1287A, Solartron, Leicester, UK). The TiO2 contained electrolyte was ultrasonicated for 30 min using a ultrasonicator (VS-100III, AS ONE, Osaka, Japan) right before the deposition to improve the dispersion of TiO2 NPs in the electrolyte. Temperature of the electrolyte was kept at 40 °C during the whole electrodeposition process.

Surface morphology of the films was observed with a scanning electron microscope (SEM, S-4300 SE, Hitachi, Tokyo, Japan). The composition was determined by the energy dispersive X-ray analyzer (EDX, EMAX EX-250, Horiba, Kyoto, Japan) equipped in the SEM. The crystal structure was characterized through an X-ray diffractometer (XRD, Ultima IV, Rigaku, Tokyo, Japan).

Mechanical properties of the films were appraised by a micro-Vickers hardness testing machine (HMV-G20s, Shimadzu, Kyoto, Japan) at 50 g of load and micro-compression evaluation using a lab-designed micro-testing system. Specimens used in the micro-compression tests had a cuboidal pillar shape with dimensions of 20 µm in height and 10 × 10 µm2 square cross-section. The focus ion beam system (FIB, FB2100, Hitachi, Tokyo, Japan) was used to fabricate the micro-pillars. The pillar surface was further polished with low current Ga+ beams to allow observation of the microstructure through a scanning ion microscope (SIM) equipped in the FIB.

Micro-compression tests were conducted using a flat-topped indenter with a diameter of 50 μm on the top surface. Load resolution of this equipment was 10 μN, and the displacement resolution was 5 nm. More details of the micro-testing system are reported in a previous study [14]. A constant displacement rate of 0.05 μm/s was used in all micro-compression tests.

3. Results

3.1. Surface Morphology and Crystalline Structure

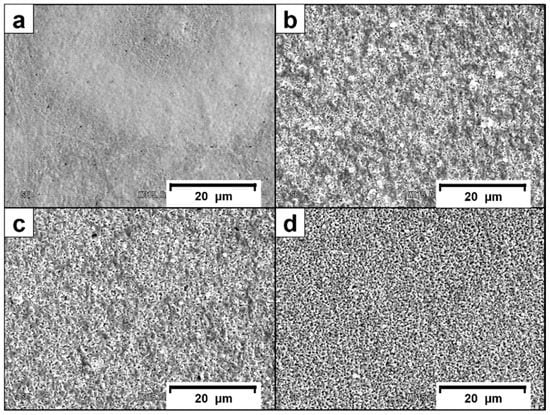

TiO2 concentration in the film was estimated from the proportion of Ti in the film by the EDX, which Ti signals detected by the EDX were assumed to be contributed by the TiO2 NPs only. From the estimation, TiO2 concentrations in films electrodeposited using the Au base electrolyte containing 0, 10, 30 and 50 g/L of the TiO2 NPs were 0, 1.45, 1.69, and 2.72 wt% TiO2 NPs, respectively. Surface morphology of the films are shown in Figure 1. Condensed structures were observed on surface of the pure Au film. Surfaces of the Au–TiO2 composite films were composed of nodule structures, which were different from that of the pure Au film. The difference is suggested to be originated from the applied potential to the working electrode, since galvanostatic electrodeposition was applied here and the electrical conductivity of TiO2 is lower than that of Au, then incorporation of TiO2 into the electrodeposited film would change the applied potential and eventually affect the nucleation of Au on the surface. In addition, TiO2 NPs adsorbed on the surface could also promote heterogeneous nucleation of Au. Hence, nodule structures were observed and size of the nodule visibly reduced due to the promoted Au nucleation.

Figure 1.

Surface morphology of electrodeposited (a) Au film and Au–TiO2 composite films containing (b) 1.45, (c) 1.69, and (d) 2.72 wt% TiO2.

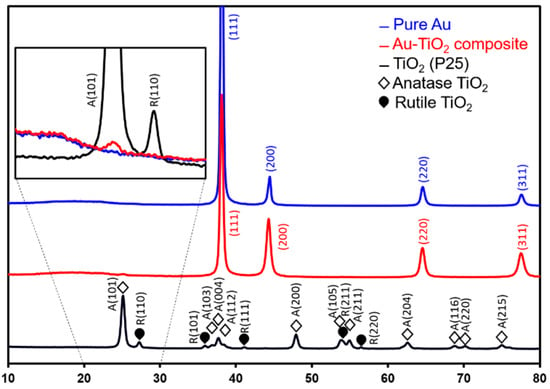

XRD spectra of the TiO2 NPs, pure Au and Au–TiO2 composite films (2.72 wt% TiO2) are shown in Figure 2. Typical face-centered cubic (FCC) Au characteristic peaks were identified in both Au and Au–TiO2 composite films. The anatase TiO2 (101) peak at 2θ = 25.1° also appeared in XRD patterns of the Au–TiO2 composite film containing 2.72 wt% TiO2 (inset of Figure 2). This result confirmed incorporation of TiO2 NPs into the Au matrix, forming a Au–TiO2 MMCs film. In addition, the peak intensity ratio of FCC-Au (111) peak to other peaks was lower for the Au–TiO2 composite film when compared with the pure gold film. This result again revealed the promoted heterogeneous nucleation of Au after adsorption of TiO2 NPs on surface of the working electrode, because (111) orientation is the preferred nucleation orientation for Au and the intensity reduced when the heterogeneous nucleation is promoted.

Figure 2.

XRD spectra of Au, TiO2 NPs, and the Au–TiO2 composite film. The inset shows zoomed spectra of 2θ = 20° to 30°.

Average grain size of Au in the film was evaluated by averaging the weighted grain size values of primary (111) to quaternary (311) X-ray diffraction peaks from the Scherrer equation. The Scherrer equation is defined as follows:

where τ is the mean size of the ordered domain, Κ is the shape factor, λ is the wave length of incident X-ray beam (approximate to be 1.54 × 10−10 m), D is the full width at half maximum of the diffraction peak, and θ is the Bragg diffraction angle.

Average grain size of Au in the film without TiO2 NPs was 20.4 nm while that of the 2.72 wt% TiO2 Au–TiO2 composite film was 16.3 nm. The decrease in the average grain size indicated grain refinement caused by incorporation of the TiO2 NPs, which demonstrated the effect of promoted Au nucleation when adding TiO2 NPs into the electrolyte.

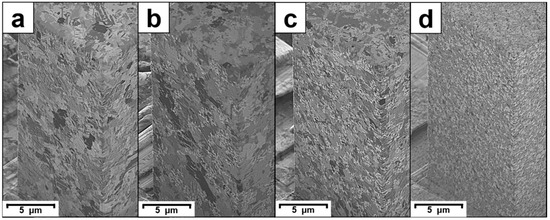

Figure 3 shows microstructure of the electrodeposited films from SIM images of the as-fabricated micro-pillars. White spots on surface of the micro-pillars illustrated the portion that is TiO2-rich (Figure 3b–d). Total amount of the TiO2-rich portion increased with an increase in TiO2 content in the micro-pillar.

Figure 3.

Scanning ion microscope (SIM) images showing microstructure of the (a) Au micro-pillars and Au–TiO2 composite micro-pillars containing (b) 1.45, (c) 1.69, and (d) 2.72 wt% of TiO2.

3.2. Mechanical Properties of Au–TiO2 Composite

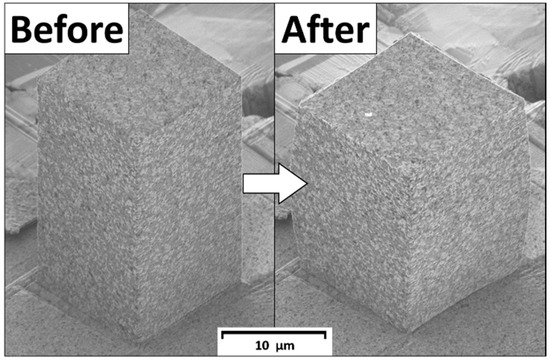

All micro-pillars showed ductile deformation and deformed to a barrel-shape after the micro-compression test. Figure 4 shows SIM images of the 2.72 wt% TiO2 Au–TiO2 composite micro-pillar before and after the micro-compression test. This deformation behavior is typical for micro-pillars composed of polycrystals [15].

Figure 4.

SIM images of the Au–TiO2 (2.72 wt%) micro-pillar before and after the micro-compression test.

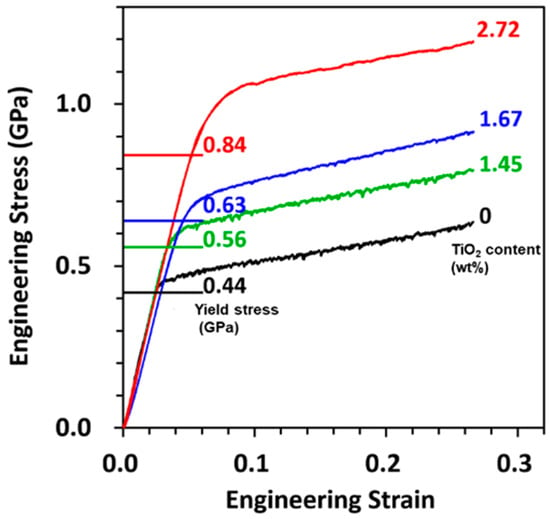

Yield strengths (σy) of the micro-pillars were obtained from the engineering strain–stress curves shown in Figure 5. Micro-Vickers hardness (HV), σy, HV to σy coefficient (HV/σy), and theoretical mass density of the composites are summarized in Table 1. Theoretical mass density of the films was calculated from the TiO2 NPs content and densities of pure Au and TiO2. The HV increased from 135 to 207 HV, and the σy increased from 0.44 to 0.84 GPa due to its having 2.72 wt% of TiO2 in the Au matrix. The strengthening was mostly contributed by the oxide dispersion strengthening. The HV/σy’s were all close to three, and the ratio decreased as the σy increased. The HV/σy is commonly known as the Tabor factor. The value and the decreasing trend observed in this study both corresponded well with the behavior of close-packed structure metals reported in the literature [16]. Mass density of 2.72 wt% TiO2 content Au–TiO2 composite was 98% of that pure Au while the σy increased by almost 91%.

Figure 5.

Engineering strain–stress curves of all micro-pillars.

Table 1.

TiO2 content, micro-Vickers hardness (HV), yield strength (σy), HV to σy coefficient (HV/σy), and mass density of the pure Au and Au–TiO2 composite films.

4. Conclusions

In this work, Au–TiO2 composite films were fabricated by the co-electrodeposition method, and the mechanical properties were evaluated by micro-Vickers hardness and micro-compression tests. XRD spectrum of the films indicated grain refinement in the electrodeposited Au after incorporation of TiO2 NPs into the film. Vickers hardness of the Au-based film was enhanced from 135 to 207 Hv by incorporating 2.72 wt% of TiO2 into the film, and yield strength of the micro-pillar reached 0.84 GPa. The yield strength was improved by ~91% and the mass density reduced by only ~2% when compared with those of pure gold. In conclusion, the Au–TiO2 composite possesses high strength with high mass density, which is promising for miniaturized electronic devices requiring low Brownian noise with high structure stability.

Author Contributions

Conceptualization, Y.-A.C., T.-F.M.C. and M.S.; Methodology, Y.-A.C., T.-F.M.C.; Validation, C.-Y.C., D.Y., H.I.; Formal analysis, Y.-A.C., C.-Y.C.; Investigation, Y.-A.C.; Resources, M.S.; Data curation, Y.-A.C.; Writing—original draft preparation, Y.-A.C.; Writing—review and editing, Y.-A.C., T.-F.M.C., M.S.; Visualization, Y.-A.C.; Supervision, T.-F.M.C. and M.S.; Project administration, K.M. (Katsuyuki Machida) and M.S.; Funding acquisition, K.M. (Kazuya Masu) and M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the New Energy and Industrial Technology Development Organization (NEDO), and is supported by JST CREST Grant Number JPMJCR1433.

Conflicts of Interest

On behalf of all of the co-authors, the corresponding author states that there is no conflict of interest.

References

- Yamane, D.; Konishi, T.; Matsushima, T.; Machida, K.; Toshiyoshi, H.; Masu, K. Design of sub-1g microelectromechanical systems accelerometers. Appl. Phys. 2014, 104, 074102. [Google Scholar] [CrossRef]

- Masu, K.; Machida, K.; Yamane, D.; Ito, H.; Ishihara, N.; Chang, T.F.M.; Sone, M.; Shigeyama, R.; Ogata, T.; Miyake, Y. CMOS-MEMS based microgravity sensor and its application. ECS Trans. 2020, 97, 91–108. [Google Scholar] [CrossRef]

- Chiu, S.Y.; Chung, S.T.; Lin, C.Y.; Tsai, W.T. Electrodeposition of Ni-Al2O3 composite coatings employing supercritical CO2 baths. Surf. Coat. Technol. 2014, 247, 68–73. [Google Scholar] [CrossRef]

- Imbaby, M.F.; Jiang, K. Stainless steel–titania composite micro gear fabricated by soft moulding and dispersing technique. Microelectron. Eng. 2010, 87, 1650–1654. [Google Scholar] [CrossRef]

- Parida, G.; Chaira, D.; Chopkar, M.; Basu, A. Synthesis and characterization of Ni-TiO2 composite coatings by electro-co-deposition. Surf. Coat. Technol. 2011, 205, 4871–4879. [Google Scholar] [CrossRef]

- Srivastava, M.; Balaraju, J.N.; Ravishankar, B.; Rajam, K.S. Improvement in the properties of nickel by nano-Cr2O3 incorporation. Surf. Coat. Technol. 2010, 205, 66–75. [Google Scholar] [CrossRef]

- Maurin, G.; Lavanant, A. Electrodeposition of nickel/silicon carbide composite coatings on a rotating disc electrode. J. Appl. Electrochem. 1995, 25, 1113–1121. [Google Scholar] [CrossRef]

- Arai, S.; Endo, M. Carbon nanofiber–copper composite powder prepared by electrodeposition. Electrochem. Commun. 2003, 5, 797–799. [Google Scholar] [CrossRef]

- Arai, S.; Saito, T.; Endo, M. Cu–MWCNT composite films fabricated by electrodeposition. J. Electrochem. Soc. 2010, 157, D147–D153. [Google Scholar] [CrossRef]

- Graydon, J.W.; Kirk, D.W. Suspension Electrodeposition of Phosphorus and Copper. J. Electrochem. Soc. 1990, 137, 2061–2066. [Google Scholar] [CrossRef]

- Hu, C.C.; Chen, E.; Lin, J.Y. Capacitive and textural characteristics of polyaniline-platinum composite films. Electrochim. Acta 2002, 47, 2741–2749. [Google Scholar] [CrossRef]

- Ibrahim, I.A.; Mohamed, F.A.; Lavernia, E.J. Particulate reinforced metal matrix composites—A review. J. Mater. Sci. 1991, 26, 1137–1156. [Google Scholar] [CrossRef]

- Greer, J.R.; Oliver, W.C.; Nix, W.D. Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 2005, 53, 1821–1830. [Google Scholar] [CrossRef]

- Takashima, K.; Higo, Y.; Sugiura, S.; Shimojo, M. Fatigue crack growth behavior of micro-sized specimens prepared from an electroless plated Ni-P amorphous alloy thin film. Mater. Trans. 2001, 42, 68–73. [Google Scholar] [CrossRef]

- Chen, C.Y.; Yoshiba, M.; Nagoshi, T.; Chang, T.F.M.; Yamane, D.; Machida, K.; Masu, K.; Sone, M. Pulse electroplating of ultra-fine grained Au films with high compressive strength. Electrochem. Commun. 2016, 67, 51–54. [Google Scholar] [CrossRef]

- Zhang, P.; Li, S.X.; Zhang, Z.F. General relationship between strength and hardness. Mater. Sci. Eng. A 2011, 529, 62–73. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).