Mapping the Surface Heat of Luminescent Solar Concentrators

Abstract

:1. Introduction

2. Experimental Section

2.1. Device Fabrication

2.2. Device Characterization

2.3. Ray-Tracing Simulation

3. Results and Discussion

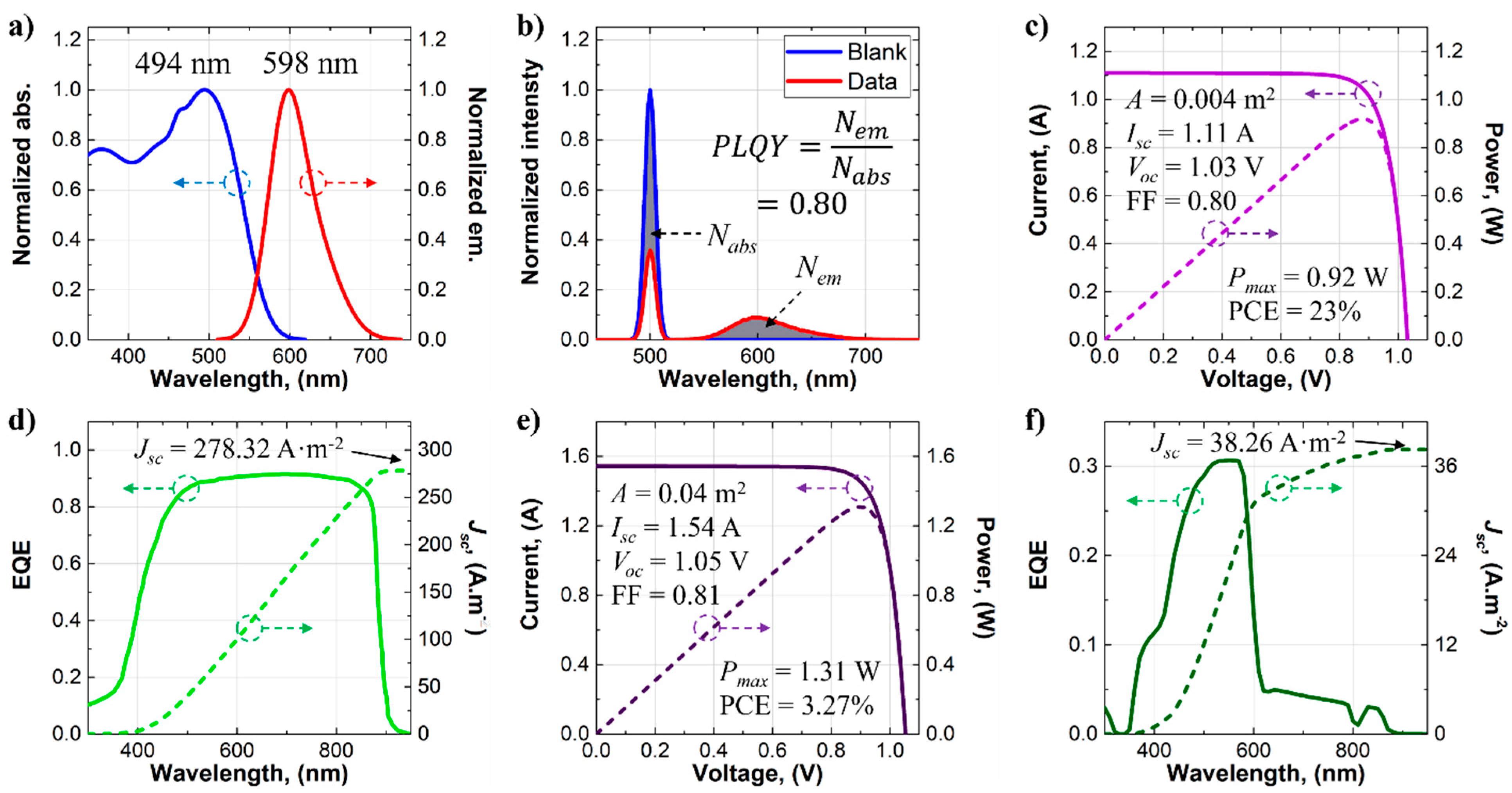

3.1. Spectroscopic and PV Properties

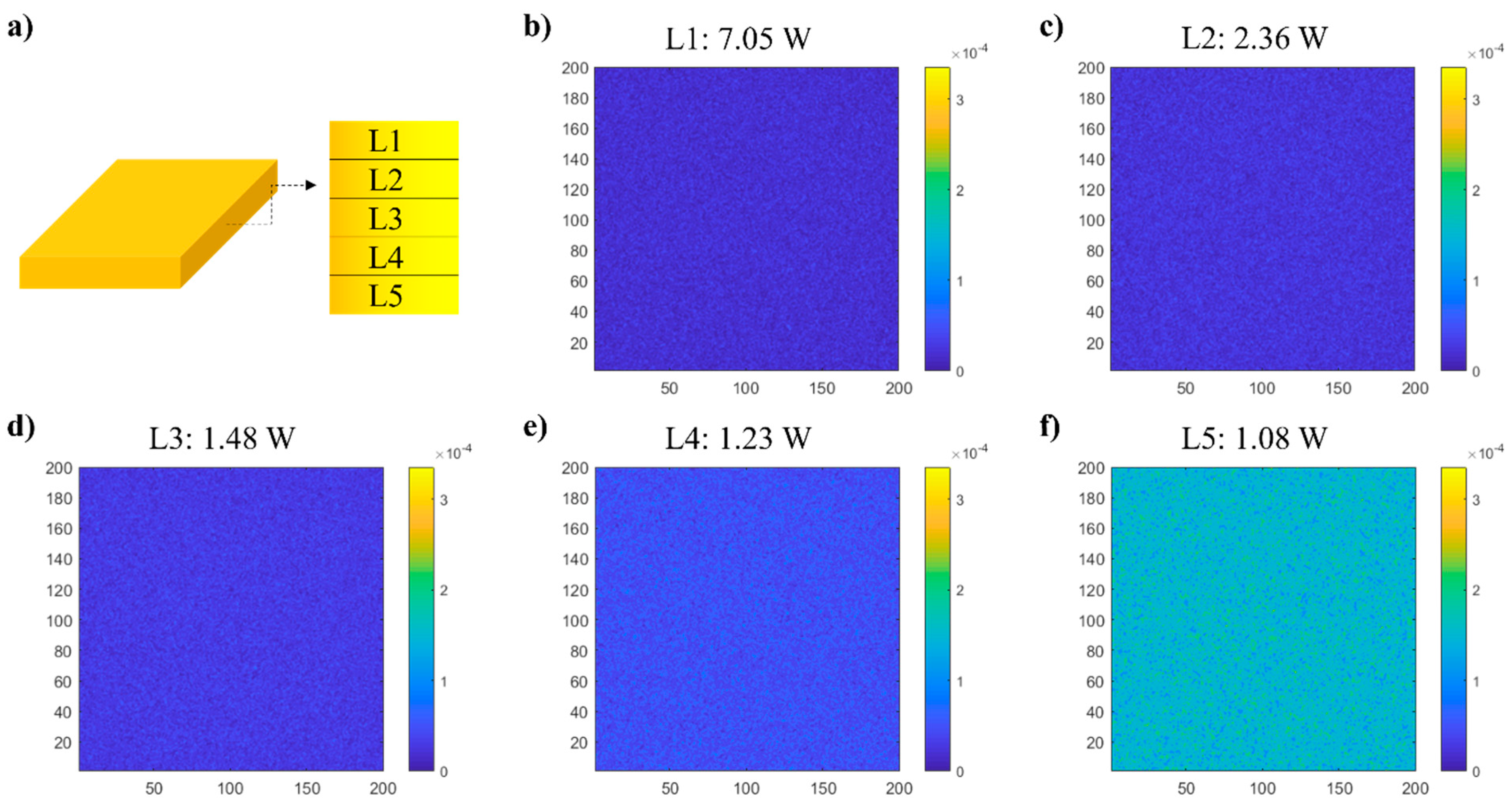

3.2. PT Properties

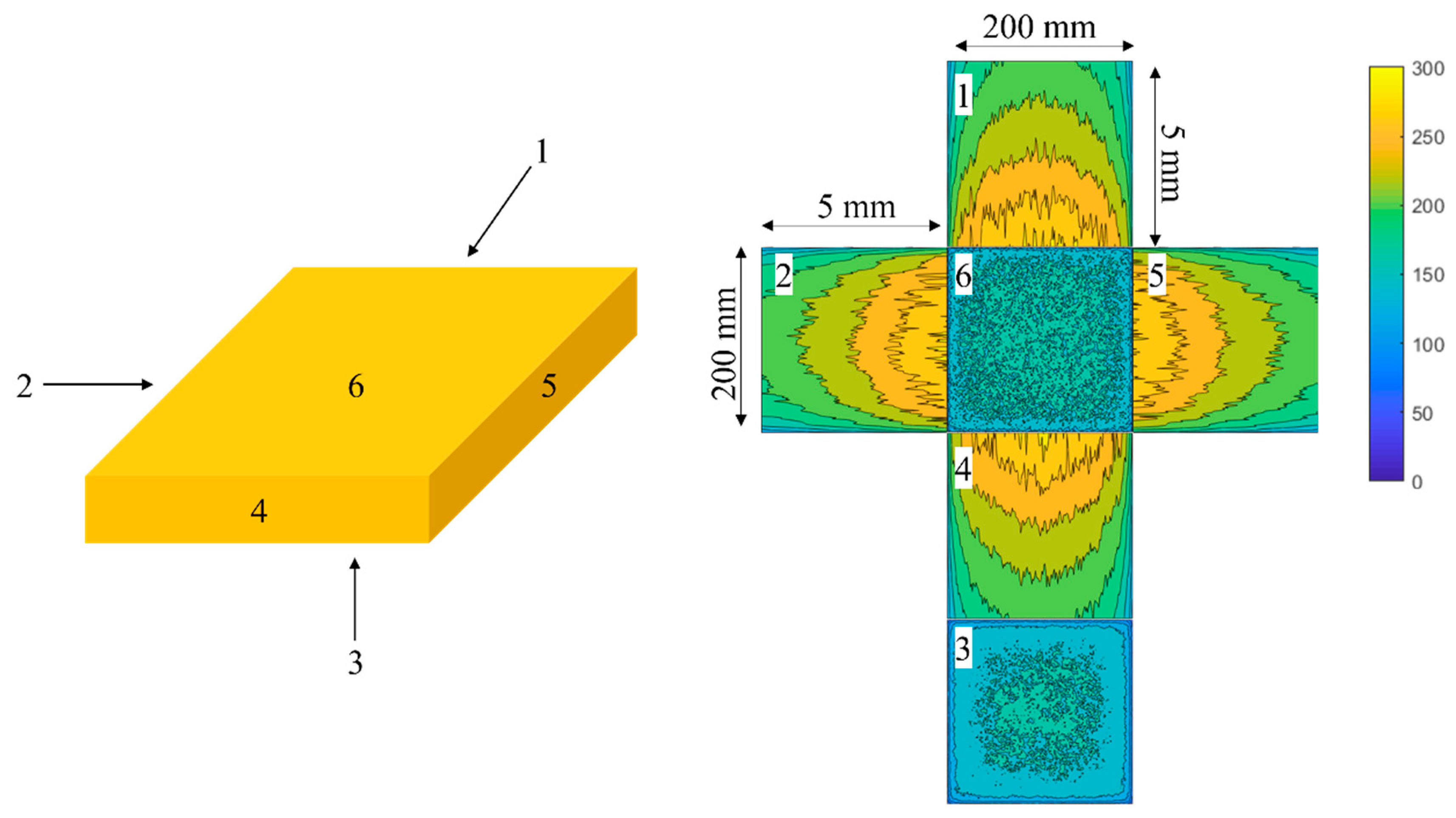

3.3. Surface Heatmap

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature and Abbreviations

| BIPV | building-integrated photovoltaics |

| DCJTB | 4-(dicyanomethylene)-2-tert-butyl-6-(1,1,7,7-tetramethyljulolidin-4-yl-vinyl)-4H-pyran |

| EQE | external quantum efficiency |

| FF | fill factor |

| GaAs | gallium arsenide |

| Isc | short-circuit current |

| Jsc | short-circuit current density |

| LSC | luminescent solar concentrator |

| Nabs | number of absorbed photons |

| Nem | number of emitted photons |

| PCE | power conversion efficiency |

| PLQY | photoluminescence quantum yield |

| Pmax | maximum electric power |

| PT | photothermal |

| PV | photovoltaic |

| TIR | total internal reflection |

| Voc | open-circuit voltage |

References

- Osseweijer, F.J.W.; Hurk, L.B.P.v.d.; Teunissen, E.J.H.M.; Sark, W.G.J.H.M.v. A comparative review of building integrated photovoltaics ecosystems in selected European countries. Renew. Sustain. Energy Rev. 2018, 90, 1027–1040. [Google Scholar] [CrossRef]

- Alim, M.A.; Tao, Z.; Hassan, M.K.; Rahman, A.; Wang, B.; Zhang, C.; Samali, B. Is it time to embrace building integrated Photovoltaics? A review with particular focus on Australia. Sol. Energy 2019, 188, 1118–1133. [Google Scholar] [CrossRef]

- Kuhna, T.E.; Erban, C.; Heinrich, M.; Eisenlohr, J.; Ensslen, F.; Neuhaus, D.H. Review of technological design options for building integrated photovoltaics (BIPV). Energy Build. 2021, 231, 110381. [Google Scholar] [CrossRef]

- Debije, M.G.; Verbunt, P.P.C. Thirty years of luminescent solar concentrator research: Solar energy for the built environment. Adv. Energy Mater. 2012, 2, 12–35. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Zhang, Y.; Dong, R.; Luscombe, C.K. Review on the role of polymers in luminescent solar concentrators. J. Polym. Sci. A 2019, 57, 201–215. [Google Scholar] [CrossRef] [Green Version]

- Roncali, J. Luminescent solar collectors: Quo vadis? Adv. Energy Mater. 2020, 10, 2001907. [Google Scholar] [CrossRef]

- Zhao, Y.; Lunt, R.R. Transparent Luminescent Solar Concentrators for Large-Area Solar Windows Enabled by Massive Stokes-Shift Nanocluster Phosphors. Adv. Energy Mater. 2013, 3, 1143–1148. [Google Scholar] [CrossRef]

- Zhao, Y.; Meek, G.A.; Levine, B.G.; Lunt, R.R. Near-Infrared Harvesting Transparent Luminescent Solar Concentrators. Adv. Opt. Mater. 2014, 2, 606–611. [Google Scholar] [CrossRef]

- Yang, C.; Moemeni, M.; Bates, M.; Sheng, W.; Borhan, B.; Lunt, R.R. High-Performance Near-Infrared Harvesting Transparent Luminescent Solar Concentrators. Adv. Opt. Mater. 2020, 8, 1901536. [Google Scholar] [CrossRef]

- Debije, M.G.; Rajkumar, V.A. Direct versus indirect illumination of a prototype luminescent solar concentrator. Sol. Energy 2015, 122, 334–340. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Zhang, Y. Luminescent solar concentrators performing under different light conditions. Sol. Energy 2019, 188, 1248–1255. [Google Scholar] [CrossRef]

- Papakonstantinou, I.; Portnoi, M.; Debije, M.G. The Hidden Potential of Luminescent Solar Concentrators. Adv. Energy Mater. 2021, 11, 2002883. [Google Scholar] [CrossRef]

- Slooff, L.H.; Bende, E.E.; Burgers, A.R.; Budel, T.; Pravettoni, M.; Kenny, R.P.; Dunlop, E.D.; Büchtemann, A. A luminescent solar concentrator with 7.1% power conversion efficiency. Phys. Status Solidi RRL 2008, 2, 257–259. [Google Scholar] [CrossRef] [Green Version]

- Goldschmidt, J.C.; Peters, M.; Bösch, A.; Helmers, H.; Dimroth, F.; Glunz, S.W.; Willeke, G. Increasing the efficiency of fluorescent concentrator systems. Sol. Energy Mater. Sol. Cells 2009, 93, 176–182. [Google Scholar] [CrossRef]

- Desmet, L.; Ras, A.J.; de Boer, D.K.; Debije, M.G. Monocrystalline silicon photovoltaic luminescent solar concentrator with 4.2% power conversion efficiency. Opt. Lett. 2012, 37, 3087–3089. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Olsen, J.; Nunez-Ortega, K.; Dong, W.-J. A structurally modified perylene dye for efficient luminescent solar concentrators. Sol. Energy 2016, 136, 668–674. [Google Scholar] [CrossRef]

- Mateen, F.; Li, Y.; Saeed, M.A.; Sun, Y.; Zhang, Y.; Lee, S.Y.; Hong, S.-K. Large-area luminescent solar concentrator utilizing donor-acceptor luminophore with nearly zero reabsorption: Indoor/outdoor performance evaluation. J. Lumin. 2021, 231, 117837. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Zhang, Y.; Li, Y.; Verduzco, R. High-performance hybrid luminescent-scattering solar concentrators based on a luminescent conjugated polymer. Polym. Int. 2021, 70, 475–482. [Google Scholar] [CrossRef]

- Xu, L.; Yao, Y.; Bronstein, N.D.; Li, L.; Alivisatos, A.P.; Nuzzo, R.G. Enhanced Photon Collection in Luminescent Solar Concentrators with Distributed Bragg Reflectors. ACS Photonics 2016, 3, 278–285. [Google Scholar] [CrossRef] [Green Version]

- Fahad, M.; Oh, H.; Jung, W.; Binns, M.; Hong, S.-K. Metal nanoparticles based stack structured plasmonic luminescent solar concentrator. Sol. Energy 2017, 155, 934–941. [Google Scholar] [CrossRef]

- Mateen, F.; Oh, H.; Kang, J.G.; Lee, S.Y.; Hong, S.-K. Improvement in the performance of luminescent solar concentrator using array of cylindrical optical fibers. Renew. Energy 2019, 138, 691–696. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Zhang, Y.; Dong, W. A Preliminary Investigation on the Photothermal Properties of Luminescent Solar Concentrators. Optics 2021, 2, 148–154. [Google Scholar] [CrossRef]

- Alam, H.; Ramakrishna, S. A review on the enhancement of figure of merit from bulk to nano-thermoelectric materials. Nano Energy 2013, 2, 190–212. [Google Scholar] [CrossRef]

- Twaha, S.; Zhu, J.; Yan, Y.; Li, B. A comprehensive review of thermoelectric technology: Materials, applications, modelling and performance improvement. Renew. Sustain. Energy Rev. 2016, 65, 698–726. [Google Scholar] [CrossRef]

- Champier, D. Thermoelectric generators: A review of applications. Energy Convers. Manag. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Zhang, Y. Regional measurements to analyze large-area luminescent solar concentrators. Renew. Energy 2020, 160, 127–135. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Y.; Zhang, Y.; Dong, W.-J. Improving the photostability of printed organic photovoltaics through luminescent solar concentrators. Opt. Mater. 2020, 108, 110194. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Sun, Y.; Ren, T. Spectral response of large-area luminescent solar concentrators. Appl. Opt. 2020, 59, 8964–8969. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, T.; Chu, B.; Li, W.; Su, Z.; Wu, H.; Yan, X.; Jin, F.; Gao, Y.; Liu, C. Highly efficient red OLEDs using DCJTB as the dopant and delayed fluorescent exciplex as the host. Sci. Rep. 2015, 5, 10697. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kurban, M.; Gündüz, B. Physical and optical properties of DCJTB dye for OLED display applications: Experimental and theoretical investigation. J. Mol. Struct. 2017, 1137, 403–411. [Google Scholar] [CrossRef]

- Lu, S.; Ji, L.; He, W.; Dai, P.; Yang, H.; Arimochi, M.; Yoshida, H.; Uchida, S.; Ikeda, M. High-efficiency GaAs and GaInP solar cells grown by all solid-state molecular-beam-epitaxy. Nanoscale Res. Lett. 2011, 6, 576. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Libra, M.; Petrík, T.; Poulek, V.; Tyukhov, I.I.; Kouřím, P. Changes in the Efficiency of Photovoltaic Energy Conversion in Temperature Range with Extreme Limits. IEEE J. Photovolt. 2021, 11, 1479–1484. [Google Scholar] [CrossRef]

- Debije, M.G.; Evans, R.C.; Griffini, G. Laboratory protocols for measuring and reporting the performance of luminescent solar concentrators. Energy Environ. Sci. 2021, 14, 293–301. [Google Scholar] [CrossRef]

- Gaigalas, A.K.; Wang, L. Measurement of the Fluorescence Quantum Yield Using a Spectrometer with an Integrating Sphere Detector. J. Res. Natl. Inst. Stand. Technol. 2008, 113, 17–28. [Google Scholar] [CrossRef] [PubMed]

- Tummeltshammer, C.; Brown, M.S.; Taylor, A.; Kenyon, A.J.; Papakonstantinou, I. Efficiency and loss mechanisms of plasmonic Luminescent Solar Concentrators. Opt. Express 2013, 21, A735–A749. [Google Scholar] [CrossRef] [PubMed]

- Breukers, R.D.; Smith, G.J.; Stirrat, H.L.; Swanson, A.J.; Smith, T.A.; Ghiggino, K.P.; Raymond, S.G.; Winch, N.M.; Clarke, D.J.; Kay, A.J. Light losses from scattering in luminescent solar concentrator waveguides. Appl. Opt. 2017, 56, 2630–2635. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Sun, Y.; Zhang, Y. Boosting the cost-effectiveness of luminescent solar concentrators through subwavelength sanding treatment. Sol. Energy 2020, 198, 151–159. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Zhang, Y.; Li, Y. Mapping the Surface Heat of Luminescent Solar Concentrators. Optics 2021, 2, 259-265. https://doi.org/10.3390/opt2040024

Sun Y, Zhang Y, Li Y. Mapping the Surface Heat of Luminescent Solar Concentrators. Optics. 2021; 2(4):259-265. https://doi.org/10.3390/opt2040024

Chicago/Turabian StyleSun, Yujian, Yongcao Zhang, and Yilin Li. 2021. "Mapping the Surface Heat of Luminescent Solar Concentrators" Optics 2, no. 4: 259-265. https://doi.org/10.3390/opt2040024

APA StyleSun, Y., Zhang, Y., & Li, Y. (2021). Mapping the Surface Heat of Luminescent Solar Concentrators. Optics, 2(4), 259-265. https://doi.org/10.3390/opt2040024