1. Introduction

In the past, stone masonry was a common structural material, and many buildings with architectural and historical value are the objects of studies for their preservation. In order to assess the present condition of these historical structures, a better understanding of their complex structural behavior is required. For buildings in seismic areas, the response to cyclic loads remains a critical issue. The identification of the main parameters that influence the structural capacity will allow for the development of appropriate solutions for conservation and possible reinforcement.

The safety assessment of old stone masonry walls has promoted the development of numerical models capable of representing their complex structural behavior under both axial and transverse loadings. Two fundamental numerical approaches towards masonry analysis are possible: the micro-modelling of the individual components and the macro-modelling as a homogeneous medium [

1].

Discontinuum or micro-models, where the joints and the units are explicitly modelled, have been developed using different numerical techniques: finite elements [

2]; discrete elements, [

3,

4]; limit analysis [

5]; discontinuous deformation analysis [

6]; finite/discrete element for dry walls [

7,

8] and unreinforced masonry [

9] or other rigid element models [

10]. All these involve polygonal or polyhedral units.

Discrete element models with circular particles were used to simulate the granular fill of masonry bridges [

11,

12] and old stone masonry [

13]. Recently, multi-level finite element modelling has also been applied to masonry, where the macro-model is constructed through the analysis at the micro-level of a representative volume element (RVE) and the adoption of homogenization techniques [

14].

In this work, a micro-modelling approach based on the discrete element method is adopted to study old stone masonry, due to their proven ability to simulate fracture processes through random particle assemblies representing quasi-brittle materials at the grain scale [

13,

15,

16,

17,

18,

19]. A similar micro-model approach based on the finite element method was proposed in [

20]. In this approach, both the stone units and the mortar are modelled through particles systems, the final structure formed by a system of particles, which have different properties according to the material they represent and interact through the contact interfaces [

13]. Particle models based on DEM are known to be computationally demanding due to the refined discretization that they require. In order to extend their applicability to structures of larger dimensions or to adopt more refined particle models, hybrid models have been proposed that couple a DEM particle discretization in the fracture zone with finite elements (FEM) in the linear elastic region [

15].

In this work, and in order to reduce the computational effort, a hybrid particle model is proposed where the stone units that are expected to remain in the elastic range are discretized by finite elements and only the particles at the stone boundary are kept, maintaining the initial stone surface roughness. In this way, the contact interaction is made independent of the finite element mesh, and only simplified particle/particle or particle/edge interactions are necessary. The proposed hybrid model has some similarities with the pinball method [

21], but in this work, the particle discretization is not associated with the element but with its boundary, and instead of a hierarchical sub-division, one adopts the refined particle discretization from the start of the simulation. By having the capacity to further refine the boundary, one can have a better description of the stress distribution along the finite element edges when compared to contact models which only allow for point/edge interactions, keeping the simplicity of the latter for large displacements when compared with the more sophisticated edge/edge type of contacts [

3,

4]. Several three-dimensional (3D) particle models have been proposed [

16,

17,

18,

19], but it is important to note that the 2D models are still competitive when applied to more complex geometries because the equivalent 3D models would require an excessive number of particles. Even if the fracture process is a 3D process, a 2D model remains an indispensable research tool, giving information that can be used in further understanding the structural behavior, safety assessment and the evaluation of reinforcement solutions. Further, the proposed model can be easily implemented in 3D.

The hybrid particle model proposed herein enhances the available capabilities for detailed analysis of traditional constructions of irregular or rubble masonry involving rough dry or mortared joints. The core principles of the particle model are briefly presented, followed by the description of the hybrid model in which the stone units have their interior discretized with finite elements while their boundary is represented by particles. The hybrid model is first applied in the analysis of uniaxial tensile and compression tests in order to verify that it leads to the same results of an all-particle model, namely, in the elastic phase, figures of rupture and pre-peak and post-peak behavior, while requiring less computer time.

The capacity of the particle model to analyze stone masonry structures is assessed in comparison with the experimental results of monotonic shear tests of dry masonry wall under different vertical loads [

22] which have been numerically studied using a finite element model, with a good match of the monotonic behavior [

23]. Finally, the capabilities of the proposed hybrid model are compared with the all-particle model predictions for rubble masonry analysis for uniaxial compression tests and for shear tests with an initial pre-compression axial force. These rubble wall panels have been experimentally studied for cyclic shear loading with an initial pre-compression load [

22].

2. Hybrid Particle Model

2.1. Fundamentals

In the DEM, the domain is replaced by an assembly of discrete entities that interact with each other through contact points or contact interfaces. The ability to include finite displacements and rotations, including complete detachment, and to recognize new contacts as the calculation progresses are essential features. The forces acting on each entity are related to the relative displacements of each entity with respect to its neighbors (contacts) and to the entity deformation given its loads. At each step, given the applied forces, Newton’s second law of motion is invoked to obtain the new nodal points/particle positions. For a given nodal point/particle, the equations of motion, including local non-viscous damping, may be expressed as:

where

and

are, respectively, the total applied force and moment at time t including the exterior contact contribution,

and

are, respectively, the nodal point/particle mass and moment of inertia,

is the nodal point/particle acceleration and

is the nodal point/particle angular acceleration. The damping forces follow a local non-viscous damping formulation and are given by [

24]:

where

is the nodal point/particle velocity,

is the nodal point/particle angular velocity, α is the local non-viscous damping and the function

is given by:

The nodal point/particle forces applied at a given instant of time are defined by three parts:

where

are the external forces applied at the nodal point/particle,

are the external forces due to the contact interaction with neighboring entities which only occur at nodal points located at the stone units’ outer boundaries and at rigid particles and

are the internal forces due to the deformation of the associated triangular plane finite elements adopted in the discretization of each stone. The external forces due to contact interaction,

, are defined in the following section.

An explicit time marching calculation scheme based on the centered-difference algorithm is adopted [

15,

25,

26]. The proposed hybrid DEM/FEM model follows the principles defined for a particle DEM based model [

25,

26]. The main difference is that the hybrid contact interaction needs to be defined taking into account the inner FEM discretization, and the motion of the triangular finite element nodes also needs to be considered. The hybrid particle model only requires simple circular particle/wall or circular particle/circular particle interactions and adopts a simple contact interaction scheme based on spatial sorting [

27].

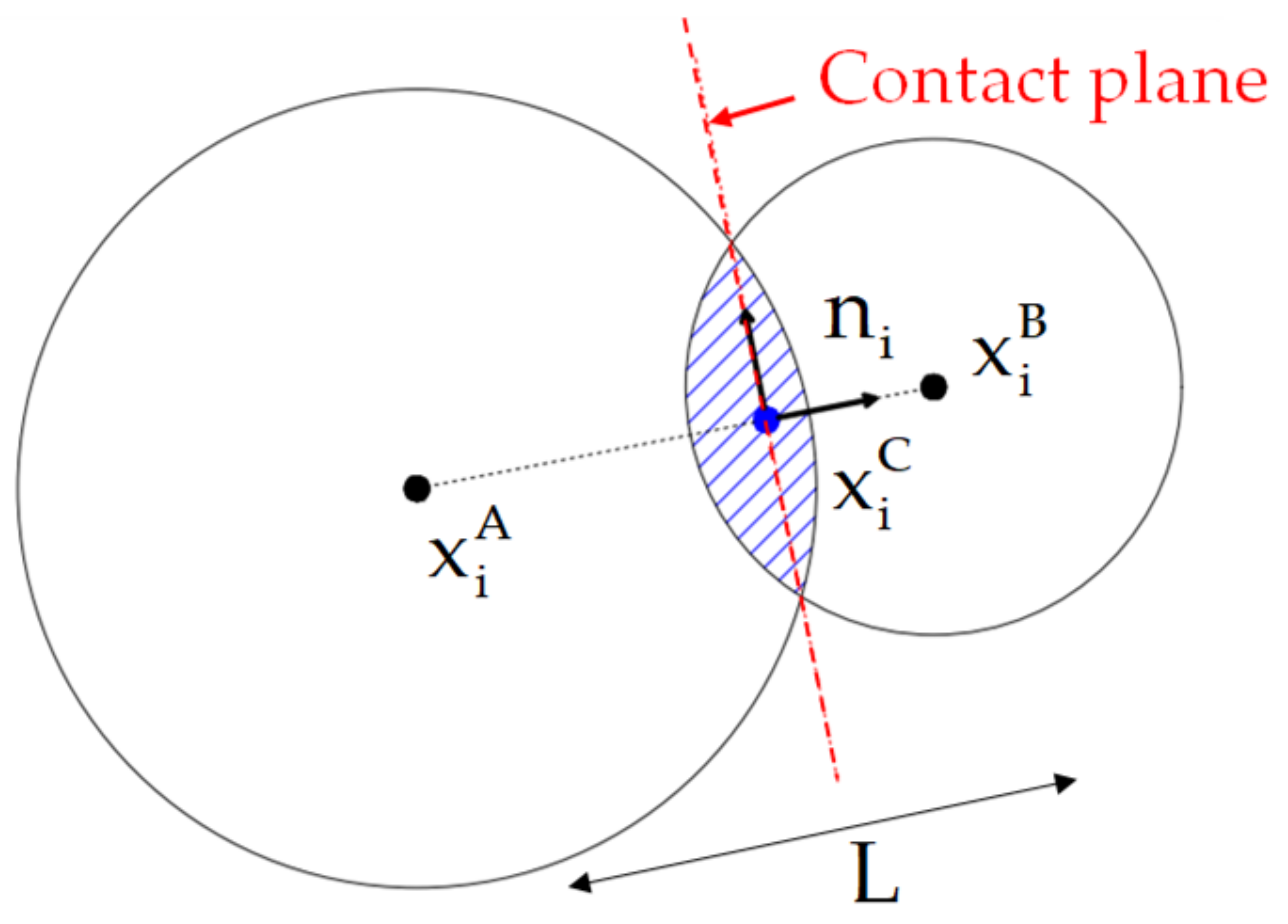

2.2. Hybrid Contact Model

Like in the traditional point contact model [

25,

26], the contact unit normal,

, is defined given the particles’ center of gravity and the inter-particle distance,

(

Figure 1):

The contact point location,

, is also defined in the same way as in the traditional particle model [

25,

26]:

where

is the contact overlap. The contact velocity of a given local contact point, which is the velocity of particle B relative to particle A, at the contact location is given by [

25,

26]:

Figure 1.

Contact model associated geometry.

Figure 1.

Contact model associated geometry.

If the particle under analysis is a traditional rigid particle, the contact velocity at the contact point is defined using the particle kinematics [

25,

26]:

where

is the permutation tensor. If the particle is a boundary particle associated with the edge of a given finite element, the contact velocity at the contact point is defined using the associated finite element nodal points kinematics and associated nodal shape functions:

where

is the shape function value associated with nodal point “

” of the corresponding triangular finite element,

, at the contact point location,

, and

is the velocity of nodal point “

” of the corresponding triangular finite element (see

Figure 2).

The triangular shape function values are defined in the traditional way according to the associated triangular areas (positive value clockwise; see

Figure 2):

The finite element boundary particles motion is defined in a similar manner, but the adopted shape functions are defined at the particle’s center of gravity instead of being defined at the contact location.

The contact displacement normal increment,

, stored as a scalar, and the contact displacement shear increment,

, stored as a vector, are given by:

Given the normal and shear stiffnesses of the local contact point, the normal and shear forces increments are obtained following an incremental linear law:

The resultant contact force at the local contact point is then given by:

If the particle under analysis is a traditional rigid particle, the contact force is transferred to the particle’s center of gravity through equilibrium conditions [

13,

26]. If the particle is a boundary particle associated with a finite element edge, the contact force is then transferred to the nodal points of the associated finite element triangle given the nodal shape functions. For the triangular plane finite element associated with particle A, the local contact forces are distributed to each nodal point according to:

A similar procedure can be found if the particle B is part of a finite element boundary.

2.3. Numerical Stability

When only a steady state solution is sought, a mass scaling algorithm is adopted in order to reduce the number of timesteps necessary to reach the desired solution. The nodal point masses/rigid particles are scaled so that the adopted centered-difference algorithm has a higher rate of convergence for a given loading step. The nodal point scaled mass/particle mass used in the calculations is set assuming a unit time increment,

, given the nodal point associated stiffness at a given time through:

The latter equation is the result of the application of Gershgorin’s theorem [

28], which guarantees that the highest frequency of a structural system is less than or equal to the ratio of the sum of the absolute values of a row of the stiffness matrix and the sum of the mass matrix row. An upper bound of the translation stiffness,

, associated with the finite element boundary particles contact model must be found at a given timestep:

where

indicates a summation along the “

” contacts associated with nodal point “

”,

and

are the contact normal and shear stiffnesses, respectively, and

is the shape function associated with nodal point “

” of the triangular plane finite element associated with the inter-particle contact. For the rigid particles, a similar numerical scheme is adopted [

13,

26].

2.4. Contact Stiffness and Strength

In the following numerical simulations, the normal and shear contact stiffnesses are given by the following expressions:

where

is the inter-particle distance,

is the out-of-plane thickness of the particle assembly and

is defined as the contact width, which is equal to the smallest diameter of the particles involved. For plane stress:

where

and

are the Young’s modulus and the Poisson’s ratio of the equivalent continuum material.

The total contact resistance (

) and the maximum cohesive force (

) are given as a function of the maximum tensile stresses (

) and the maximum cohesion stress (

) adopted at the contacts, and by the contact area, according to the following expressions:

2.5. Contact Constitutive Model

Figure 3 shows the bilinear softening contact model adopted in the normal and shear directions [

13,

26]. This contact model requires the definition of both the tensile fracture energy,

, and the shear fracture energy,

As presented in

Figure 3, from the moment that the strength values (tensile and shear) are reached, the maximum tensile contact force and/or maximum shear contact force are reduced based on the current contact damage value, which varies between 0 (without damage) and 1 (in which the contact is considered cracked, only working in compression under pure friction). If the cracking occurs due to tensile/shear damage, the contact is considered to be a tensile crack, and if the cracking occurs in compression/shear, then the contact is considered to be a shear crack.

2.6. Model Generation

After knowing the stone geometry and placement in the masonry wall (

Figure 4a), firstly, the space corresponding to the interior of each stone is discretized with inner particles (

Figure 4b). Following this, the space corresponding to the external domain of each stone, which corresponds to the laying mortar, is also discretized with particles (

Figure 4c). The hybrid PM particle model that is proposed requires a fourth step, in which each stone is discretized with finite elements and only the boundary stone particles are kept (

Figure 4) in order to maintain the initial boundary roughness characteristic of the initial all-particle model (

Figure 4).

By keeping the stone boundary particles present in the all-particle DEM model, the proposed hybrid model maintains, as closely as possible to a DEM all-particle model, the contact interaction of the stone units with the outer particles representing the mortar. To predict a similar response with the proposed hybrid model and the all-particle DEM model, two important issues need to be addressed: (i) both models should have a similar stone inner deformability, and (ii) in both models, the interaction of the stone boundary particles with the neighboring particles representing the mortar should be kept as close as possible.

The stone subdomains are considered deformable, either through the inner contacts, in an all-particle DEM model, or through an FE discretization, in the hybrid proposal. The proposed hybrid model allows for runtime reduction because it requires, for deformability purposes, a reduced number of finite elements when compared to the required number of inner particles and inner inter-particle contacts adopted in the all-particle DEM model (see

Figure 4c,d).

The adopted particle size distribution for the mortar and stone units should be chosen to be as close as possible to the real granular distribution of the material to be modelled. Due to computational restrictions, larger grain dimensions may be adopted. Regardless of the adopted grain size distributions for the mortar and stone units, in order to predict similar results to an all-particle DEM model, it is mandatory to keep the particle interlock that occurs between the particles representing the stone units and the particles representing the mortar, as occurs in the proposed hybrid model.

2.7. Model Parameters and Calibration Procedure

The elastic response associated with the proposed particle model is related with the elastic contact properties and of the equivalent continuum material and with the Young’s modulus and the Poisson’s coefficient of the triangular finite elements adopted in the inner discretization of each stone. The macroscopic strength response of the particle model requires the definition of five strength parameters associated with the contacts.

One of the main disadvantages of particle models is that it is not possible to devise analytical expressions for the elastic and strength contact properties. For this reason, it is necessary to calibrate them based on experimental results. In general, uniaxial compression, uniaxial tensile, splitting or bending tests are adopted.

Figure 5 shows the final crack patterns for a given mortar under different elementary tests. In order to have a more thorough calibration, one should know not only the peak values but also the full stress/deformation curve and the full details of the loading equipment.

In masonry micro-modelling based on the finite element method, complex cohesive contact models have been devised including cyclic behavior [

29]. Nevertheless, it is complex to reproduce all the phenomena with a macroscopic constitutive law. As mentioned in [

23], the cyclic model proposed in [

29] requires a significant number of parameters and experiences severe convergence difficulties upon a large number of cycles or large displacements. With a particle model approach, where the physical particle interactions and the material randomness associated with the grain structure are taken directly into account, the failure phenomena are an emergent property, and the development of cracks and rupture surfaces appears naturally as part of the simulation process given its discrete nature. From our point of view, this advantage compensates the need for calibration under simple tests.

4. Discussion and Conclusions

Particle models, by taking directly into account the physical particle interactions and the material randomness associated with the grain structure, are able to predict complex macroscopic failure phenomena, and the development of cracks and rupture surfaces appears naturally as part of the simulation process given its discrete nature. These advantages clearly compensate for the fact that these types of models require a previous parameter calibration procedure using fundamental tests. The particle model can be interpreted as being a synthetic material that mimics the real material, which is calibrated using fundamental testing and then adopted in larger models [

26].

For the above-mentioned reasons, particle models show great potential to handle particular masonry problems, namely, the study of traditional masonry structures with irregular stones, 3-leaf walls or rubble masonry. The computational resources available today allow for the detailed representation of materials by means of discrete element particle models, which have become a powerful tool to investigate the fundamental behavior of materials and structures.

Nevertheless, it is important to reduce the computational effort associated with particle models, and for this reason, a hybrid DEM/FEM particle model is proposed here, where the stone units that are expected to remain in the elastic range are discretized by finite elements. With the proposed model, only the particles at the stone boundary are kept, maintaining the initial stone surface roughness. This enhancement, as shown, allows for more refined discretization to be adopted in particle models, with a granulometry closer to the mortar/stone element, or for the possibility of applying particle models to larger structures.

The results that are presented, namely, the uniaxial tests in small samples and the uniaxial tests and shear tests in rubble masonry, clearly show the relevance of the proposed enhancements. The results presented show the relevance of keeping the outer particle boundaries adopted in the stone’s discretization in order to maintain the particle interactions that are present in an all-particle model. It is shown that it is only possible to predict a response similar to that predicted with an all-particle model by using the proposed hybrid FEM/DEM model, namely, the final crack patterns, crack evolution and overall response. It is also shown that, for the rubble masonry examples, the hybrid FEM/DEM allows for a significant computational run time reduction of around 40% and of around 20% to 25% for the small uniaxial tests that are presented.

The hybrid DEM/FEM particle model is also adopted in shear tests of dry masonry walls under different pre-compressions values. This type of walls can be modelled with a smooth contact joint either with polygonal DEM models [

3,

4] or with FEM models [

23,

29], which are computationally less demanding. Nevertheless, the presented numerical studies clearly show that the proposed model is able to handle large displacements, which is an important feature when adopting a micro-modelling approach. Additionally, there is the potential to adopt the developed particle model in the assessment of the stone surface roughness in the overall wall response. As mentioned, the boundary surface can be chosen independently from the FE discretization mesh, and the interactions are simple particle/particle and particle/wall, which allows for the proposed model to be applied in non-convex stones.

At present, the proposed particle model requires elastic behavior in the stones, which, for rubble-stone masonry walls built with hydrated air lime mortar [

30], may be sufficient. However, for stronger mortars, it may be relevant to include the nonlinear behavior in some of the stones. Developments are being undertaken to allow for a switch from the hybrid FE model to the full DE on a given stone if a given limit stress state is reached. The presented results clearly show that keeping the outer boundary particles is one of the key ingredients in order to have a smooth transition between models. With the proposed hybrid model, it is also possible to represent some stones where nonlinearity is expected with an all-particle DEM model.