Determination of Detection Probability and Localization Accuracy for a Guided Wave-Based Structural Health Monitoring System on a Composite Structure

Abstract

:1. Introduction

2. Methods: Reliability Assessment

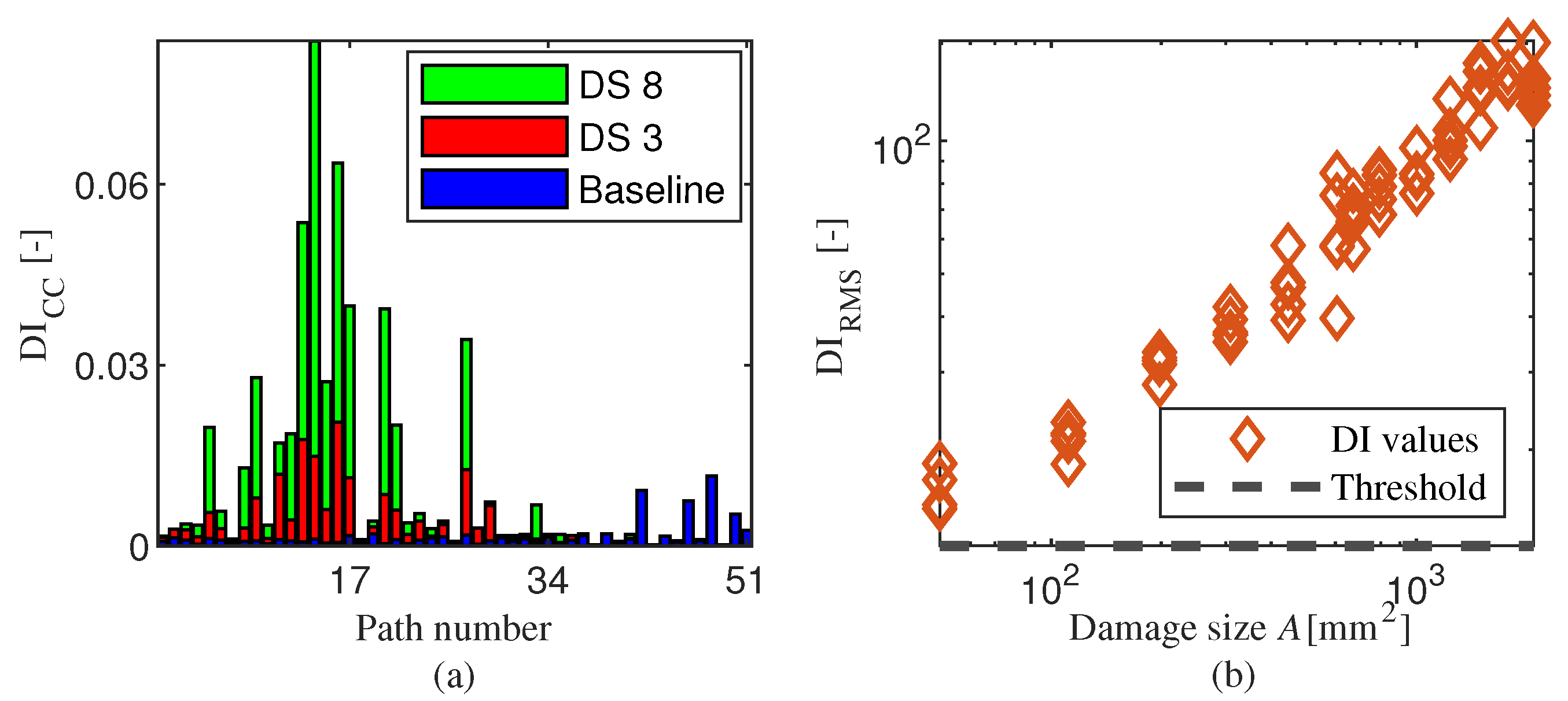

2.1. Level 1: Damage Detection

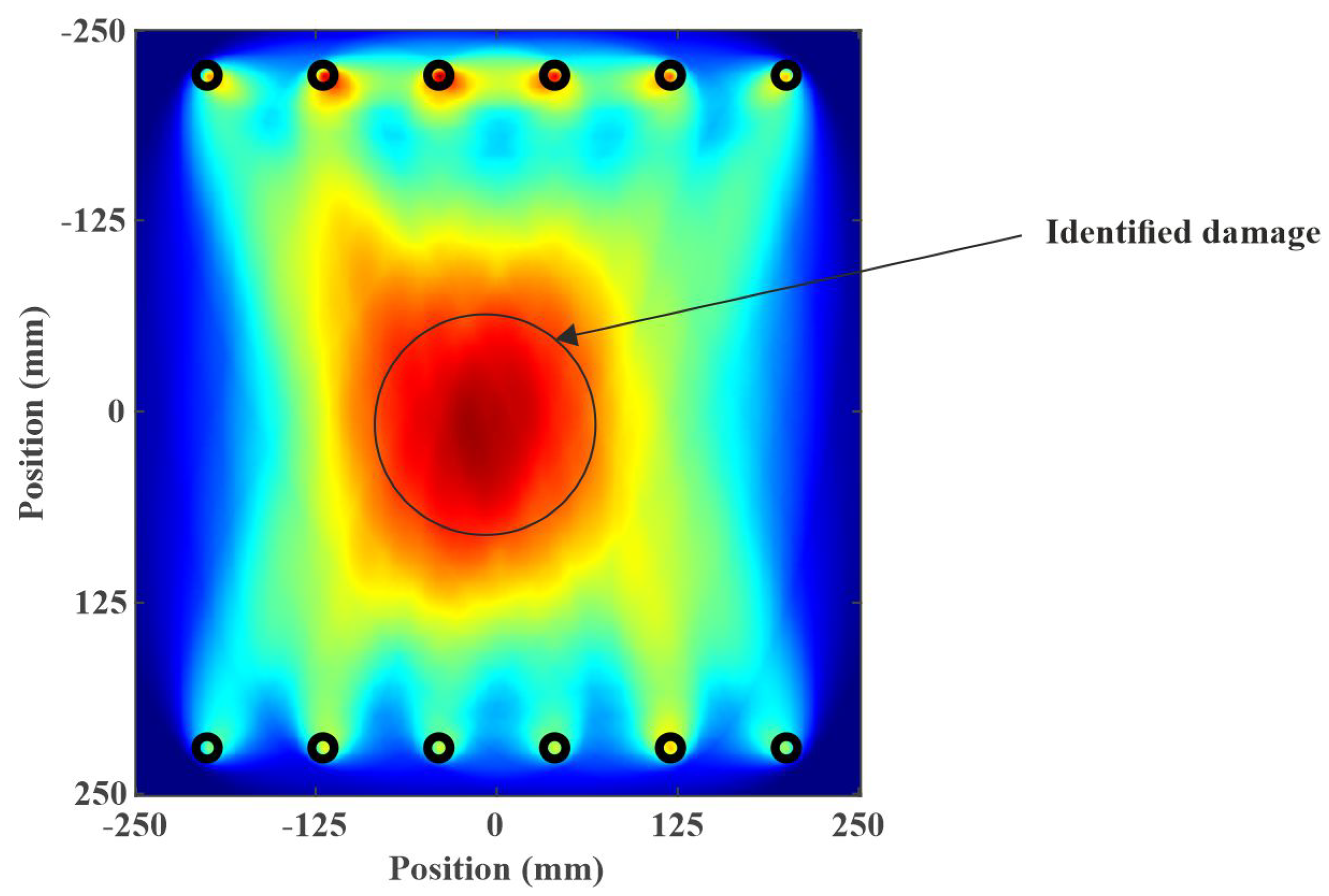

2.2. Level 2: Localization

2.3. POD Curve

2.4. Novel Method to Determine the Localization Accuracy

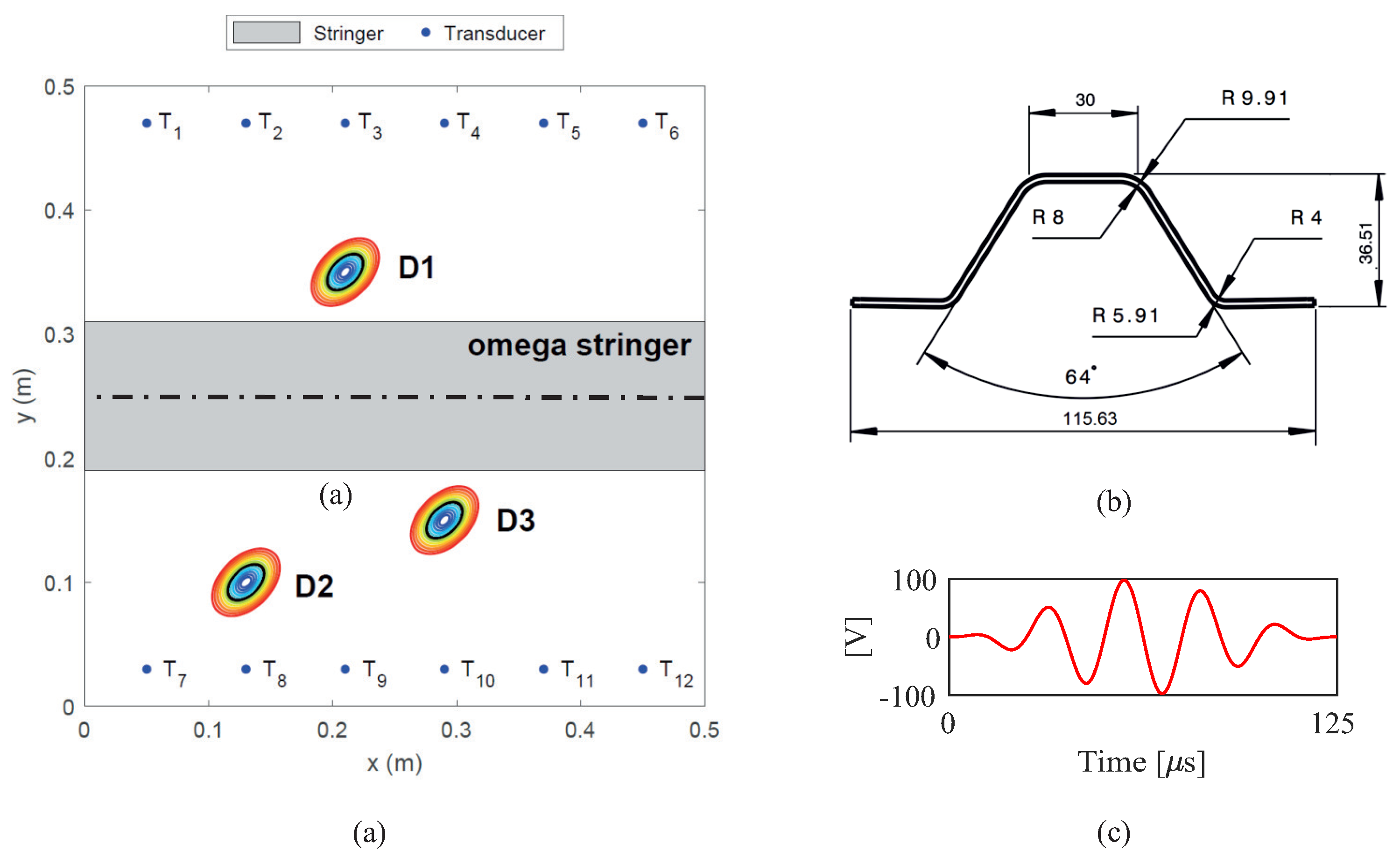

3. Materials: OGW Platform

3.1. Experimental Setup

3.2. Reference Damage

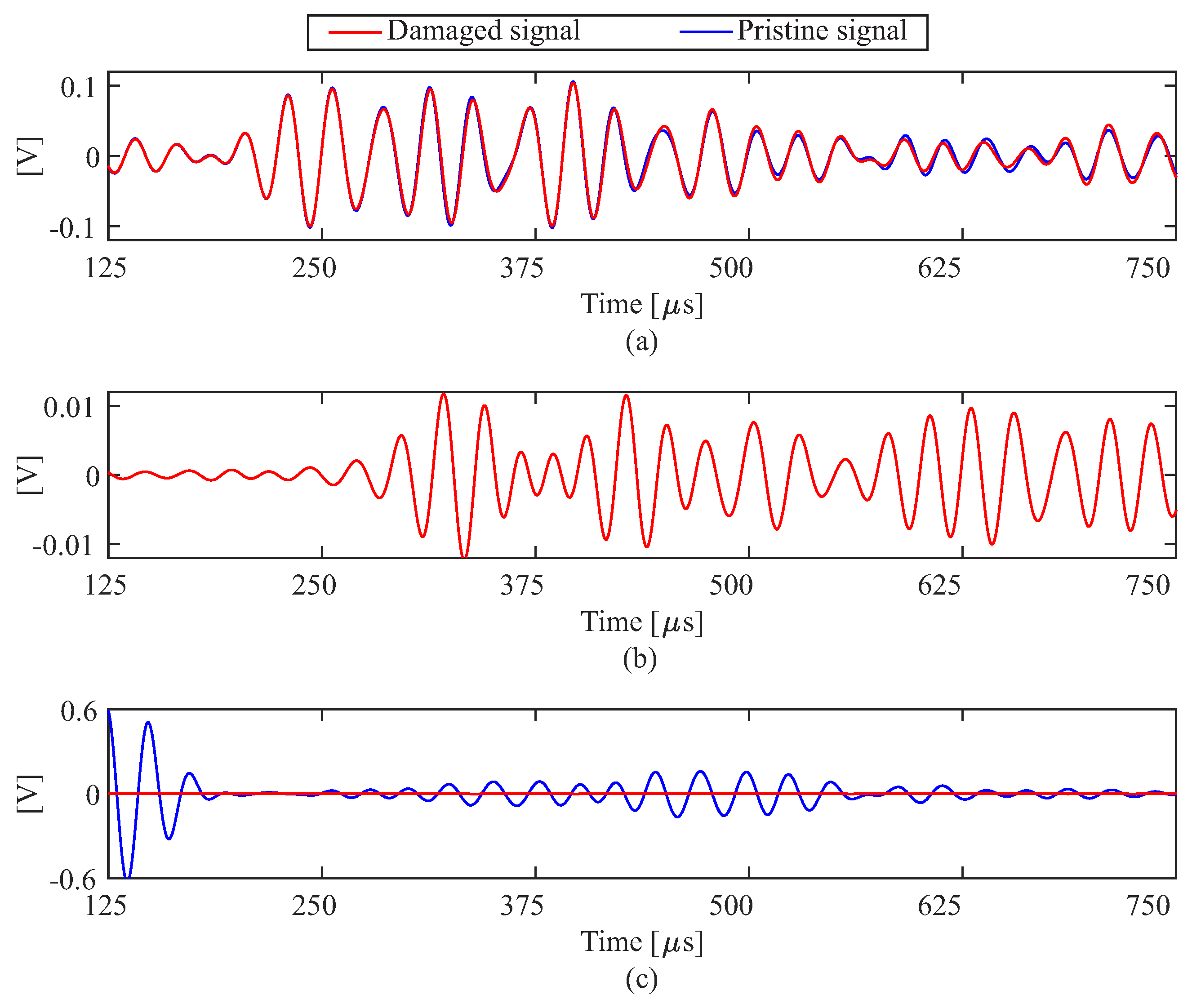

3.3. Raw Data

4. Results: Reliability Assessment

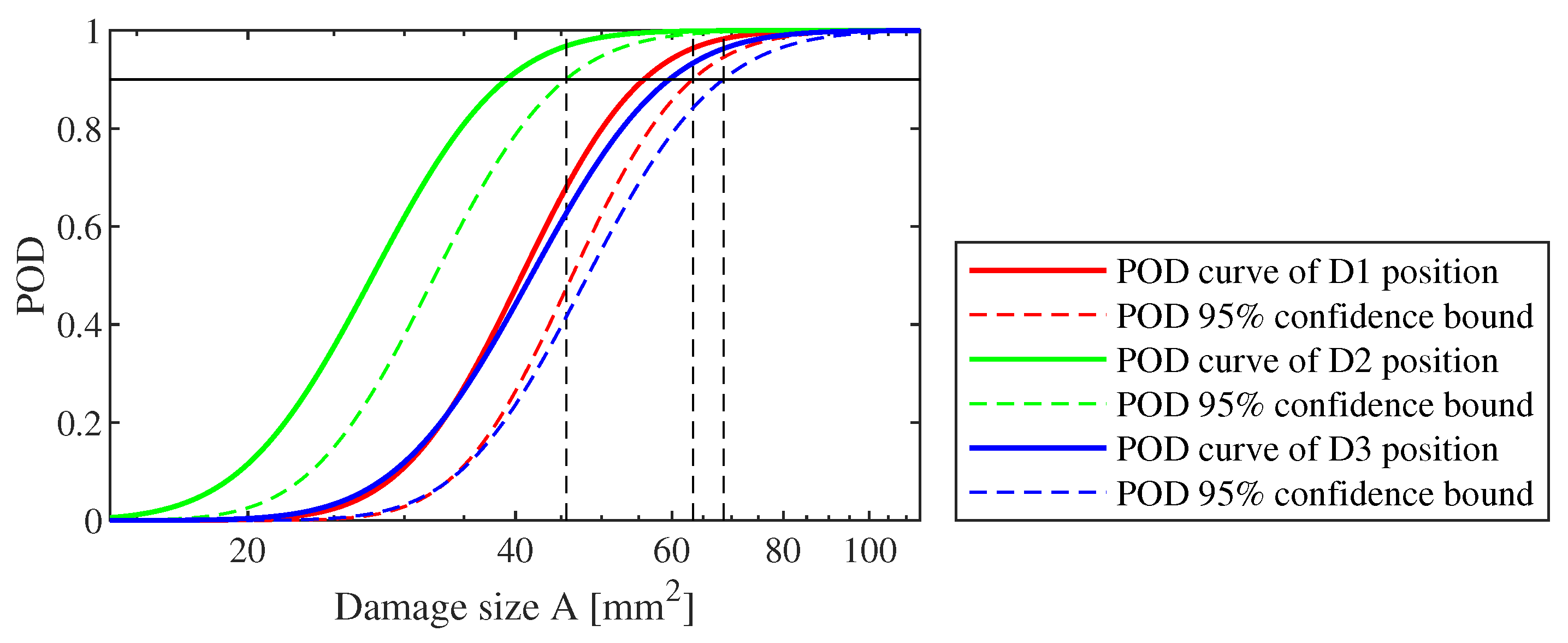

4.1. Probability of Detection

4.2. Localization Accuracy

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cawley, P. Structural health monitoring: Closing the gap between research and industrial deployment. Struct. Health Monitor. 2018, 17, 1225–1244. [Google Scholar] [CrossRef] [Green Version]

- Farrar, C.R.; Worden, K. An introduction to structural health monitoring. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 303–315. [Google Scholar] [CrossRef] [PubMed]

- Su, Z.; Ye, L. Identification of Damage Using Lamb Waves: From Fundamentals to Applications; Springer Science & Business Media: Berlin, Germany, 2009; Volume 48, pp. 171–200. [Google Scholar]

- Mandache, C.; Genest, M.; Khan, M.; Mrad, N. Considerations on structural health monitoring reliability. In Proceedings of the International Workshop Smart Materials, Structures & NDT in Aerospace, Montreal, QC, Canada, 2–4 November 2011; Volume 24. [Google Scholar]

- Monaco, E.; Memmolo, V.; Ricci, F.; Boffa, N.D.; Maio, L. Guided waves based SHM systems for composites structural elements: Statistical analyses finalized at probability of detection definition and assessment. In Proceedings of the Health Monitoring of Structural and Biological Systems 2015, San Diego, CA, USA, 9–12 March 2015; International Society for Optics and Photonics: San Diego, CA, USA, 2015; Volume 9438, p. 1. [Google Scholar]

- Grooteman, F. Damage detection and probability of detection for a SHM system based on optical fibres applied to a stiffened composite panel. In Proceedings of the International Conference on Noise and Vibration Engineering, Leuven, Belgium, 17–19 September 2012; pp. 3317–3330. [Google Scholar]

- Kelly, D.W.; Scott, M.L.; Thomson, R.S. Composite Aircraft Structures. In Modeling Complex Engineering Structures; American Society of Civil Engineers: Reston, VA, USA, 2007; pp. 247–274. [Google Scholar]

- Rentala, V.K.; Mylavarapu, P.; Gautam, J.P. Issues in estimating probability of detection of NDT techniques—A model assisted approach. Ultrasonics 2018, 87, 59–70. [Google Scholar] [CrossRef] [PubMed]

- Annis, C.; Bray, E.; Hardy, H.; Hoppe, P.M.S. Nondestructive Evaluation System Reliability Assessment; Handbook MIL-HDBK-1823A; United States Department of Defense, Wright-Patterson AFB: Dayton, OH, USA, 2009. [Google Scholar]

- Georgiou, G.A. PoD curves, their derivation, applications and limitations. Insight-Non-Destruct. Test. Cond. Monit. 2007, 49, 409–414. [Google Scholar] [CrossRef]

- Zhang, R.; Mahadevan, S. Fatigue reliability analysis using nondestructive inspection. J. Struct. Eng. 2001, 127, 957–965. [Google Scholar] [CrossRef]

- Cobb, A.C.; Michaels, J.E.; Michaels, T.E. Ultrasonic structural health monitoring: A probability of detection case study. AIP Conf. Proc. 2009, 1096, 1800–1807. [Google Scholar]

- Janapati, V.; Kopsaftopoulos, F.; Li, F.; Lee, S.J.; Chang, F.K. Damage detection sensitivity characterization of acousto-ultrasound-based structural health monitoring techniques. Struct. Health Monit. Int. J. 2016, 15, 143–161. [Google Scholar] [CrossRef]

- Gianneo, A.; Carboni, M.; Giglio, M. Feasibility study of a multi-parameter probability of detection formulation for a Lamb waves-based structural health monitoring approach to light alloy aeronautical plates. Struct. Health Monit. Int. J. 2016, 16, 225–249. [Google Scholar] [CrossRef]

- Mueller, I.; Fritzen, C.P. Inspection of piezoceramic transducers used for structural health monitoring. Materials 2017, 10, 71. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ihn, J.B.; Pado, L.; Leonard, M.S.; Olson, S.E.; DeSimio, M.P. Development and Performance Quantification of an Ultrasonic Structural Health Monitoring System for Monitoring Fatigue Cracks on a Complex Aircraft Structure; Technical Report; Air Force Research Lab Wright-Patterson Afb Oh: Dayton, OH, USA, 2011. [Google Scholar]

- Schneider, C.R.; Rudlin, J.R. Review of statistical methods used in quantifying NDT reliability. Insight-Non-Destruct. Test. Cond. Monit. 2004, 46, 77–79. [Google Scholar] [CrossRef]

- Tschöke, K.; Mueller, I.; Memmolo, V.; Moix-Bonet, M.; Moll, J.; Lugovtsova, Y.; Golub, M.; Venkat, R.S.; Schubert, L. Feasibility of Model-Assisted Probability of Detection Principles for Structural Health Monitoring Systems Based on Guided Waves for Fiber-Reinforced Composites. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 68, 3156–3173. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, H.; Sharif Khodaei, Z. Reliability assessment of SHM methodologies for damage detection. In Key Engineering Materials; Trans Tech Publ.: Stafa, Switzerland, 2016; Volume 713, pp. 244–247. [Google Scholar]

- Zhou, C.; Su, Z.; Cheng, L. Quantitative evaluation of orientation-specific damage using elastic waves and probability-based diagnostic imaging. Mech. Syst. Signal Process. 2011, 25, 2135–2156. [Google Scholar] [CrossRef]

- Liu, K.; Ma, S.; Wu, Z.; Zheng, Y.; Qu, X.; Wang, Y.; Wu, W. A novel probability-based diagnostic imaging with weight compensation for damage localization using guided waves. Struct. Health Monit. 2016, 15, 162–173. [Google Scholar] [CrossRef]

- Liu, B.; Liu, T.; Lin, Y.; Zhao, J. An aircraft pallet damage monitoring method based on damage subarea identification and probability-based diagnostic imaging. J. Adv. Transp. 2019, 2019, 2568736. [Google Scholar] [CrossRef]

- Liu, G.; Wang, B.; Wang, L.; Yang, Y.; Wang, X. Probability-based diagnostic imaging with corrected weight distribution for damage detection of stiffened composite panel. Struct. Health Monit. 2021, 14759217211033967. [Google Scholar] [CrossRef]

- Moix-Bonet, M.; Wierach, P.; Loendersloot, R.; Bach, M. Damage assessment in composite structures based on acousto-ultrasonics—Evaluation of performance. In Smart Intelligent Aircraft Structures (SARISTU); Springer: Berlin, Germany, 2016; pp. 617–629. [Google Scholar]

- Berens, A.P. NDE reliability data analysis. ASM Handb. 1989, 17, 689–701. [Google Scholar]

- Lewis, P.A. Distribution of the Anderson-Darling statistic. In Annals of Mathematical Statistics; Institute of Mathematical Statistics: Beachwood, OH, USA, 1961; pp. 1118–1124. [Google Scholar]

- Schubert Kabban, C.M.; Greenwell, B.M.; DeSimio, M.P.; Derriso, M.M. The probability of detection for structural health monitoring systems: Repeated measures data. Struct. Health Monit. 2015, 14, 252–264. [Google Scholar] [CrossRef]

- Moll, J.; Kexel, C.; Kathol, J.; Fritzen, C.P.; Moix-Bonet, M.; Willberg, C.; Rennoch, M.; Koerdt, M.; Herrmann, A. Guided waves for damage detection in complex composite structures: The influence of omega stringer and different reference damage size. Appl. Sci. 2020, 10, 3068. [Google Scholar] [CrossRef]

- Bach, M.; Pouilly, A.; Eckstein, B.; Bonet, M.M. Reference damages for verification of probability of detection with guided waves. In Structural Health Monitoring 2017; Destech Publications: Lancaster, PA, USA, 2017. [Google Scholar] [CrossRef]

- Moll, J.; Kathol, J.; Fritzen, C.P.; Moix-Bonet, M.; Rennoch, M.; Koerdt, M.; Herrmann, A.S.; Sause, M.G.; Bach, M. Open guided waves: Online platform for ultrasonic guided wave measurements. Struct. Health Monit. 2019, 18, 1903–1914. [Google Scholar] [CrossRef]

| D1 | D2 | D3 |

|---|---|---|

| 63.3 | 45.6 | 68.5 |

| D1 | D2 | D3 |

|---|---|---|

| 106 | 326 | 126 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bayoumi, A.; Minten, T.; Mueller, I. Determination of Detection Probability and Localization Accuracy for a Guided Wave-Based Structural Health Monitoring System on a Composite Structure. Appl. Mech. 2021, 2, 996-1008. https://doi.org/10.3390/applmech2040058

Bayoumi A, Minten T, Mueller I. Determination of Detection Probability and Localization Accuracy for a Guided Wave-Based Structural Health Monitoring System on a Composite Structure. Applied Mechanics. 2021; 2(4):996-1008. https://doi.org/10.3390/applmech2040058

Chicago/Turabian StyleBayoumi, Ahmed, Tobias Minten, and Inka Mueller. 2021. "Determination of Detection Probability and Localization Accuracy for a Guided Wave-Based Structural Health Monitoring System on a Composite Structure" Applied Mechanics 2, no. 4: 996-1008. https://doi.org/10.3390/applmech2040058

APA StyleBayoumi, A., Minten, T., & Mueller, I. (2021). Determination of Detection Probability and Localization Accuracy for a Guided Wave-Based Structural Health Monitoring System on a Composite Structure. Applied Mechanics, 2(4), 996-1008. https://doi.org/10.3390/applmech2040058