Abstract

This study proposes a methodological approach to the redesign of a 1980s vehicle, the Lancia Beta HPE, integrating the TRIZ (Theory of Inventive Problem Solving) and the Industrial Design Structure (IDeS) frameworks within the design process. The redesign process focused on both the external morphology of the vehicle and its propulsion system, aligning the outcome with contemporary trends in market evolution, societal shifts, and environmental considerations. The objective of the project was to reinterpret stylistic elements that were typical of 1980s automotive design through a contemporary lens, while incorporating characteristics of the current aesthetic of electric vehicles (EVs). A pivotal element of the research involved a comparative stylistic analysis of past and present vehicle design languages. This facilitated the identification of design guidelines for adapting formal and stylistic details to the electric mobility paradigm, with emphasis on contemporary aesthetics and energy efficiency. The transition from internal combustion to electric propulsion necessitated a comprehensive re-evaluation of the vehicle’s key exterior features, encompassing the front end, body shape, and lighting systems, in order to reflect a novel ecological identity and convey technological advancement. In order to inform stylistic choices, an in-depth exploration of electric propulsion principles was conducted, leveraging AI-based tools such as GPT to support TRIZ-guided problem-solving.

1. Introduction

The transition to sustainable mobility has become a central concern in both industrial design and engineering. Among the most promising strategies is the integration of innovative design methodologies with advanced technologies, aiming to reduce environmental impact while preserving product efficiency and aesthetic value.

This approach aligns with recent comprehensive reviews that highlight the transformative potential of robust artificial intelligence throughout the mechatronic product development process [1].

In particular, the automotive sector has witnessed a surge in research exploring novel approaches to vehicle development, especially in the context of electric vehicles (EVs), which are increasingly viewed as a sustainable alternative to traditional internal combustion engine cars [2,3].

The optimal integration of battery packs represents a critical challenge in EV design, requiring careful consideration of cell type, physical arrangement, and weight-capacity trade-offs [4].

Beyond the vehicle itself, sustainable mobility is embedded within broader urban ecological transformation strategies. European initiatives such as the GREEN SURGE project highlight the need to integrate technology, green infrastructure, and social innovation to address climate change, resource efficiency, and well-being in urban environments [5]. This systemic perspective reinforces the importance of developing sustainable vehicle concepts aligned with future urban ecosystems.

Methodological frameworks such as IDeS (Industrial Design Structure) offer a systematic approach to product development, combining creativity with engineering rigour. This method has already proven effective in the design of sustainable mobility solutions, such as electric bicycles [6], and is adaptable to the redesign of legacy vehicles in light of contemporary needs. At the same time, TRIZ (Theory of Inventive Problem Solving) remains a valuable tool for structured innovation, particularly when enhanced by artificial intelligence (AI) technologies. Recent advancements, such as AutoTRIZ [7], automate TRIZ processes using large language models, broadening the scope and efficiency of design problem-solving.

In this context, systematic methods such as the Effect Solving Method (ESM) have been proposed to guide radical product innovation, offering a structured approach that improves the chances of success in areas such as wind turbine design [8].

Despite its strong potential for guiding systematic innovation, TRIZ adoption in practice is often hindered by methodological complexity and organisational learning barriers, as highlighted by industry-focused studies [9]. This evidence reinforces the importance of hybrid workflows where traditional engineering logic is supported by digital and AI-driven systems to facilitate operational usability and accelerate conceptual exploration.

In addition to AI-enhanced TRIZ methods, hybrid methodologies combining TRIZ with Quality Function Deployment (QFD) have proven to be effective in generating structured and innovative solutions. For instance, an extended House of Quality approach has been proposed to identify and prioritise contradictions between customer requirements and design parameters without relying on traditional TRIZ Function Analysis, enabling more efficient conceptual problem-solving and demonstrating measurable improvements in industrial system redesign [10].

Further contributions have expanded this hybrid perspective by integrating QFD with customer-oriented analytical tools such as Conjoint Analysis, as demonstrated in studies focused on small and medium-sized enterprises (SMEs). This combined use of QFD and Conjoint Analysis supports the translation of customer preferences into engineering specifications, reinforcing the connection between user expectations and innovative product development [11]. Together, these approaches underline how multi-method frameworks—linking TRIZ, QFD, and market-driven analysis—can effectively enhance creativity, structure decision-making, and improve the competitiveness of design processes within industrial and entrepreneurial contexts.

AI plays an increasingly relevant role in automotive design, not only by improving engineering processes but also by augmenting styling and concept generation [12]. Techniques such as generative design, digital twins, and machine learning allow for the optimization of vehicle components—such as chassis and propulsion systems—by simulating performance within defined constraints [13,14].

Recent empirical evidence shows that the adoption of AI technologies improves product development performance by reinforcing both internal and external knowledge-integration capabilities within R&D teams [15]. In parallel, AI enables a more effective incorporation of user expectations, energy-management strategies, and economic considerations into the design process [2], thereby supporting the development of intelligent, connected, and autonomous vehicles. Beyond technical enhancement, AI acts as a strategic driver for the evolution of mobility-related business models, fostering service-oriented value creation and sustainability-focused innovation—an emerging direction of particular relevance to electric mobility ecosystems [16].

Furthermore, AI enables a deeper integration of user expectations, energy management, and economic considerations [2], supporting the development of intelligent, connected, and autonomous vehicles. From a broader innovation perspective, AI also contributes to the evolution of mobility business models, enabling service-oriented value creation and sustainability strategies—an emerging paradigm particularly relevant to electric mobility ecosystems [16].

Nevertheless, the shift toward electric mobility must go beyond technical innovation. It requires a new design culture that harmonises aesthetics, ethics, and sustainability [17]. Recent perspectives also stress the necessity of embedding artificial intelligence within ethical and institutional frameworks that ensure accountability and responsible technological evolution. Collaborative initiatives between academia, industry, and civil institutions are being proposed as a way to foster safe and transparent AI integration within society, avoiding both technological overreach and stagnation [18].

Historical studies highlight how mobility paradigms evolve through technological and socio-cultural transformations [19], indicating that engineering innovation must be accompanied by a reconfiguration of the mobility ecosystem and user expectations. While electric vehicles can significantly reduce emissions, they still face challenges regarding full eco-efficiency, such as in battery production and energy lifecycle management [20]. Emerging solutions, including advanced battery management systems based on reduced-order models and eco-efficiency-oriented design practices, are increasingly being explored to improve sustainability in product development [21].

The relationship between design and engineering has long been central in the evolution of the automotive product, where these two disciplines converge to balance technological functionality with aesthetic expression. As highlighted by Da Silva and Dos Santos [22], the development of the automobile throughout the 20th and 21st centuries has been shaped by the progressive integration of design and engineering, establishing a multidisciplinary foundation that remains essential in contemporary mobility innovation.

In parallel, bio-inspired design and nature-driven engineering approaches are emerging as promising frameworks for vehicle innovation, offering performance, lightweighting, and energy-efficiency opportunities particularly suited to EV applications [23]. These approaches complement systematic innovation tools such as TRIZ, reinforcing the need for hybrid and interdisciplinary design methodologies.

In this evolving context, the present study contributes by applying a hybrid methodology—combining IDeS, TRIZ, and AI tools—to the redesign of an iconic 1980s vehicle. The objective is to reinterpret historical automotive design in a contemporary framework that embraces electric propulsion, sustainability principles, and advanced digital support tools. This approach demonstrates how past design heritage can be revitalised to meet current and future challenges in sustainable mobility.

From a market and consumer-behaviour perspective, product redesigns play a crucial role in sustaining brand engagement and stimulating public interest. Empirical studies on the automotive sector indicate that redesigned vehicles tend to generate greater consumer discussions and online word-of-mouth than entirely new models, highlighting the strategic relevance of revitalising existing designs through innovation [24]. This dynamic reinforces the value of reinterpreting heritage vehicles as a means to merge emotional attachment with sustainable technological transformation.

2. Materials and Methods

The present study adopts a hybrid methodology combining IDeS (Industrial Design Structure) and TRIZ (Theory of Inventive Problem Solving) to guide the redesign process.

The IDeS, developed at the University of Bologna, is a model that promotes product innovation by integrating engineering rigor with design creativity. The approach under discussion here extends beyond the confines of conventional design phases by incorporating planning, simulation, and numerical tools. The objective of this integration is to facilitate the creation of competitive and future-oriented solutions. The method integrates analytical engineering approaches with the exploratory and prototyping strength of industrial design, promoting both functionality and innovation.

Recent research in the automotive sector demonstrates the importance of structured design and development methodologies to ensure quality, performance, and industrial feasibility. For example, Six Sigma and lean design frameworks such as DMADV (Define–Measure–Analyse–Design–Verify) have proven effective in guiding product development from early concept stages to industrialisation while ensuring compliance with performance and cost constraints [25]. This supports the relevance of systematic approaches like IDeS in managing design complexity and ensuring traceable decision-making throughout the development cycle.

TRIZ, an acronym for “Theory of Inventive Problem Solving” which was introduced by Genrich Altshuller in the 1940s, is a systematic tool for solving engineering problems. The analysis of thousands of patents has resulted in the formulation of structured techniques, including the Contradiction Matrix, which is built on 39 engineering parameters and 40 inventive principles. These techniques are designed to address technical and physical contradictions. The application of additional tools, such as the Principle of Separation and Substance-Field (Su-Field) analysis, has been demonstrated to facilitate the resolution of design conflicts and the identification of system weaknesses.

It is evident that when IDeS and TRIZ are considered in unison, a complementary framework is provided. The IDeS methodology is predicated on engineering logic, while TRIZ supports inventive problem-solving through structured reasoning.

2.1. IDeS Method

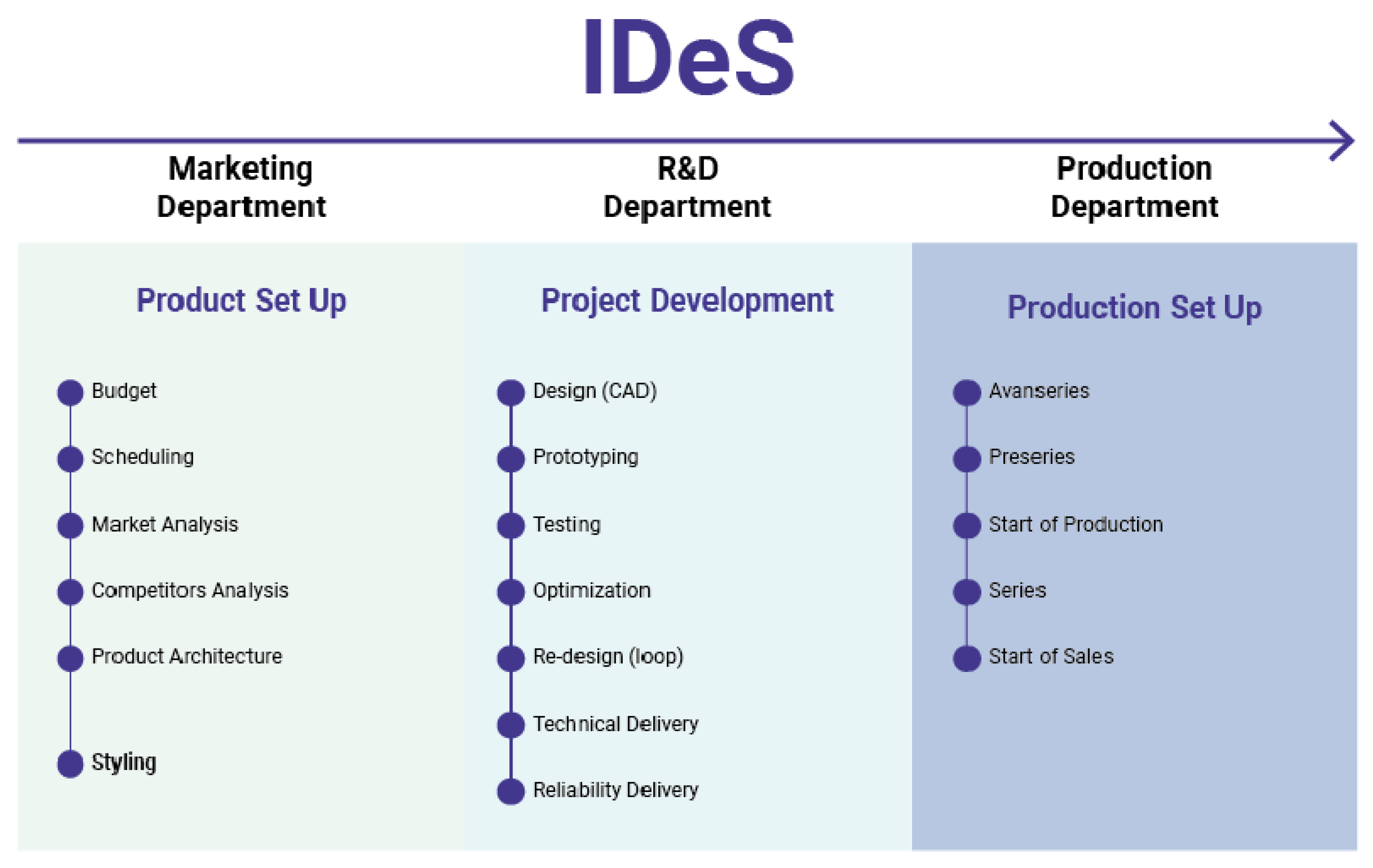

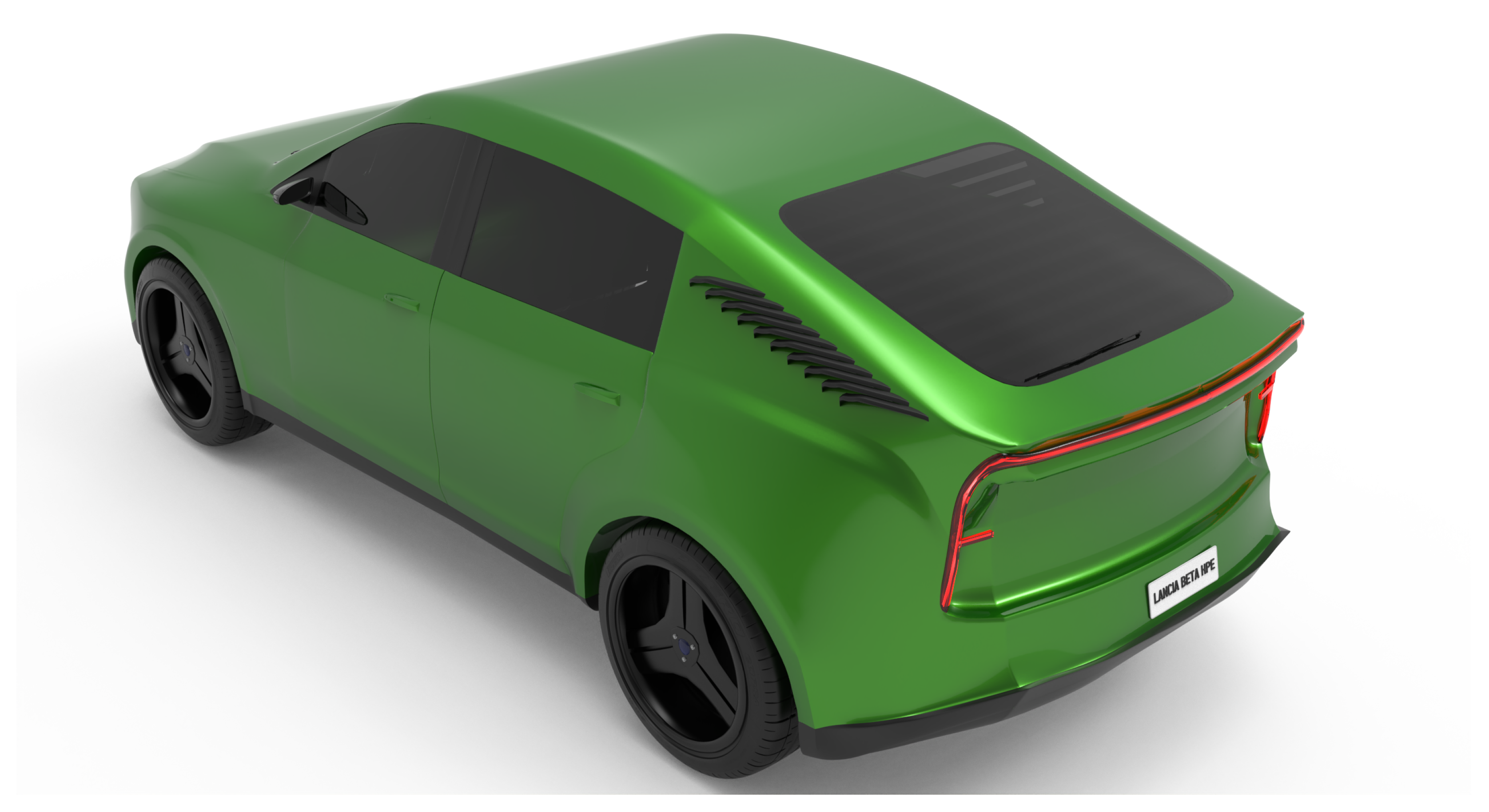

The Industrial Design Structure (IDeS) method is a systematic framework developed to support early-stage product development through the integration of design knowledge, customer requirements, and engineering constraints. By combining elements of Quality Function Deployment (QFD) and Design for Six Sigma (DFSS), the method enables designers to structure the design process in modular steps. The IDeS method is composed of a sequence of phases as shown in Figure 1 that guide the transition from functional analysis to design specifications and concept generation.

Figure 1.

IDeS Method Framework.

The IDeS method is comprised of three primary phases that guide the product development process from the initial conception to the preparatory phase preceding production. In the Product Set Up phase, the design context is defined through market analysis, cost evaluation, benchmarking and initial stylistic and functional choices. Subsequent to this, the Product Development phase ensues, wherein the conceptual framework is metamorphosed into a comprehensive technical design, which is then subjected to rigorous validation through prototyping and testing. The final phase, Production Set Up, is designed to prepare the product for large-scale manufacturing, ensuring its innovativeness and consistency with market objectives.

2.1.1. Environmental Analysis

In recent years, the automotive sector has experienced considerable changes in demographics, technology and regulation. In this context, it is imperative to draw a distinction between restyling and redesign, two concepts that are often conflated in discourse, it is explained in Table 1. The process of restyling involves the implementation of superficial alterations, including modifications to components such as bumpers, grilles, lights, and interiors, without compromising the vehicle’s fundamental structural integrity or its propulsion system. Conversely, the term ‘redesign’ denotes a more substantial revision, impacting efficiency, safety, performance, and environmental impact. Such a revision often involves structural modifications, updates to propulsion technology, and the introduction of new materials.

Table 1.

A schematic contrasting restyling vs. redesign, illustrating key differences.

The present paper focuses on the concept of redesign, as the vehicle under study—a 1970s model—requires extensive modernisation to remain competitive in the current market. However, in order to preserve its historical value, only some stylistic elements have been reinterpreted for contemporary tastes.

The automotive sector is undergoing a profound transformation, driven by environmental challenges, evolving mobility behaviors, technological progress, and new design paradigms. The Lancia Beta HPE redesign addresses these shifts by balancing heritage, digital innovation, and sustainability. Traditional vehicle classification based on body type has given way to segmentation by size, performance, and price. The new Beta HPE positions itself between the C and sporty D segments, blending saloon, coupé, and station wagon traits to meet contemporary demands for versatility and style. Market data from 2022–2023 show a 40.7% sales increase in March 2023, growth in alternative fuels (51.7%+), rising rental use, and steady motorisation growth [26,27]. Italy remains key, especially the North-East, with strong car attachment persisting post-pandemic [28]. Modern vehicle design transcends exterior form, emphasising digitalisation as seen in BMW XM (BMW, Spartanburg, USA), Audi Q8 e-tron (Audi, Bruxelles, Belgium), Mercedes EQ (Mercedes-Benz, Brema, Germany), and Lancia Ypsilon electric (Lancia (Stellantis), Saragozza, Spain). Key evolutions include digitised cabins (HUD, infotainment, steering controls), component simplification (1400 to 200 parts), new tech standards (ADAS, fast charging, battery recycling), and advanced human-machine interfaces [29].

Recent redesigns illustrate this approach: Ford Bronco (Ford Motor Company, Wayne, Michigan, USA 2020) merges modularity and off-road heritage with lightweight materials and digital tech; Land Rover Defender(Jaguar Land Rover (JLR), Nitra, Slovakia) evolves from rugged utility to premium SUV with fluid design and digital interiors [30]; Lamborghini Countach LPI 800-4 (Automobili Lamborghini S.p.A., Sant’Agata Bolognese, Italy 2023) modernises its wedge shape with hybrid tech, aerodynamic refinement, and LED lighting [29]. These cases demonstrate redesign as a conceptual evolution that preserves iconic DNA while embracing new technology and regulations.

Lancia Beta HPE(Lancia, Chivasso (Turin), Italy) embodies this with historic design cues (Aurelia, Flaminia, Stratos), evocative colours (“Vincenne blue,” “vibrant ochre”), functional reinterpretation of features like Venetian blinds, electric powertrain, digital interiors, enhanced ergonomics, and active safety. The project aligns with the European Green Deal’s 2035 petrol/diesel sales ban [31] and anticipates 2050 visions of autonomy, connectivity, and new mobility concepts.

2.1.2. Market Analysis

The market analysis for the restyling of the Lancia Beta HPE was structured according to the ‘six questions’ of Quality Function Deployment (QFD) to clearly define the target audience and the needs to be met.

This customer-centric approach is foundational to achieving a market orientation, which has been consistently linked to superior business performance and employee commitment [32].

The target audience consists of people with driving licences who are passionate about classic cars and loyal to the brand. The car is designed to be used throughout the day, both for short trips in the city and for long journeys, responding to the desire to drive a vehicle with a historic character and all modern comforts. Versatility is guaranteed by its ability to travel on paved roads and less regular terrain, offering space and comfort for passengers and luggage, with particular attention to the on-board experience and vehicle customisation.

Through the relative importance matrix Table 2, the key factors for the design were identified, with safety, recognisability and autonomy being the priorities. The interrelation matrix Table 3 further highlighted the most independent characteristics to focus on: safety, customisation, aerodynamics and technology. As a result, the design requirements for the redesign focus on these essential aspects, with the aim of creating a car that combines tradition and innovation, responding to the functional and emotional needs of the current and future market. After those analyses, the requirements requested for this project are: safety, familiarity, autonomy, personalisation, aerodynamics and technology.

Table 2.

Importance matrix, useful to identify the most important requirements against all the requirements. The numbers are 0 when the requirement in the column is less important than the requirement in the line, 1 when the requirements have the same importance, and 2 when the requirement in the column is more important than the requirement in the line.

Table 3.

Interrelation matrix, useful to identify the most independent requirements against all the requirements. The x value is a non-value, because a value can’t be more or less independent than itself.

2.1.3. Concurrent Analysis

The Lancia Beta HPE, a ‘coupé station wagon’ or ‘shooting brake’, marries sporty design with greater load capacity than a regular coupé. For market research, a benchmark was conducted on cars in segments C and D with this body type. Specific characteristics derived from the Beta HPE were considered, including length, height, width, boot capacity, engine power, top speed and acceleration. Only models with electric motors or innovative powertrains were included, in line with Lancia’s total electrification strategy from 2024.

In the course of the evaluation process, particular attention was paid to a number of key parameters, including but not limited to battery capacity, wheelbase length and rear-wheel drive. The latter was ultimately deemed to be the optimal configuration, on the grounds that it facilitates enhanced torque distribution, greater stability and more efficient use of space.

The TOP-FLOP analysis indicated that the BMW 4 Series Gran Coupé i4 eDrive35 (BMW, Munich, Germany) and Cupra Born (Cupra (Volkswagen Group), Zwickau, Germany) models demonstrated the greatest alignment with the stipulated requirements, while the Mazda MX30(Mazda Motor Corporation, Ujina (Hiroshima), Japan) exhibited the least optimal performance as shown in Table 4. The strategic positioning of the Beta HPE is guided by these results, which position it in direct competition with the most advanced vehicles in the segment.

Table 4.

Benchmarking and TOP–FLOP analysis.

2.2. TRIZ Method

Following the identification of technical contradictions related to engine parameters, utilising the WHAT-HOW matrix, the TRIZ method was employed to facilitate the identification of innovative solutions. This approach is predicated on the identification of contradictions between technical parameters and the utilisation of the contradiction matrix in conjunction with the 40 inventive principles, which serve to guide the generation of ideas to overcome these conflicts. While TRIZ provides a rigorous framework for resolving engineering contradictions and stimulating systematic innovation, its practical application is often hindered by methodological complexity and organisational learning barriers [9]. This reinforces the value of complementary tools and structured guidance to enhance accessibility and operational effectiveness during the problem-solving process.

In order to explore this complex engineering field in greater depth, General Purpose Technology (GPT) artificial intelligence technologies were used to broaden the perspective and gather relevant references. This choice is aligned with recent empirical findings demonstrating that AI adoption enhances product development performance by strengthening internal and external knowledge integration within R&D teams [15]. Furthermore, this practice is supported by literature reviews which identify AI as a key enabler for knowledge management and decision support in complex mechatronic development cycles [1]. This approach follows the emerging paradigm of AI-augmented research, where tools like GPT are used to make research work faster, more reliable, and more convenient, while maintaining critical human oversight for the interpretation of results [33]. The final interpretation of the results was guided by critical reflection and discussion with co-authors.

The technical analysis yielded several potential solutions, which can be summarised under the following themes: The following list comprises the key technological areas that are pertinent to this study: digital twin, battery cooling systems (BTMS), level 3 autonomous driving, thermal sensors, solid-state batteries, generative design, aerodynamic improvements, battery swapping, advanced segmentation, artificial intelligence for route estimation, LIDAR, lightweight materials (carbon fibre, natural fibres, aluminium, magnesium), regenerative braking, tyres, range extenders, user-vehicle interaction, ADAS systems and battery insulation. These elements represent the technological directions that, according to the TRIZ method, can assist in resolving the contradictions identified and promoting innovation in electric motor design.

Recent research has expanded the scope of TRIZ toward radical innovation design by integrating data-driven tools such as patent-based efficacy extraction, cluster analysis, and multilevel problem identification models. These approaches enhance the precision of contradiction analysis and accelerate the generation of breakthrough solutions by linking system-level challenges with specific technical effects [8].

In order to explore this complex engineering field in greater depth, General Purpose Technology (GPT) artificial intelligence technologies were used to broaden the perspective and gather relevant references. The final interpretation of the results was guided by critical reflection and discussion with co-authors.

2.3. Parameter Analysis

2.3.1. Safety

The subchapter brings the preliminary research phase for the vehicle redesign to a close. In terms of safety parameters, the focus is divided between active safety, which is concerned with accident prevention, and passive safety, which is concerned with damage reduction. As of 2022, the adoption of Advanced Driver Assistance Systems (ADAS) in Europe will become mandatory. These systems encompass a range of features, including intelligent speed adaptation, driver monitoring, automatic emergency braking, and lane keeping. The exploration of innovative optional technologies is also undertaken, including blind spot assistance, automatic parking, level 3 autonomous driving, advanced cybersecurity and driver unconsciousness warning systems. A particular focus has been placed on the domain of battery thermal management systems in electric vehicles (EVs). It is imperative to ensure adequate battery cooling in order to maintain the optimal temperature of the cells. This is crucial for enhancing the performance and durability of the battery. The most prevalent systems utilise coolants. This innovative solution is a closed-loop system that recovers heat from inside the vehicle in order to heat the passenger compartment. Heat pumps are utilised in this process, thus avoiding direct exchange with the outside environment. The Hyundai Ioniq 5 (Hyundai Motor Company, Ulsan, South Korea) case exemplifies the efficacy of this technology in reducing air conditioning consumption and enhancing component cooling. Despite the system’s complexity, it has been demonstrated to extend battery life and maintain optimal temperature, while also facilitating sustainable reuse of water as steam. The study concentrated on legally permitted level 3 autonomous driving, which permits the vehicle to drive autonomously in specific conditions (e.g., motorways), but with active driver control, supported by visual, audible or tactile notifications for control reassumption.

2.3.2. Engine

In evaluating the various propulsion technologies for vehicles, options such as electric motors, biofuels, e-fuels, hydrogen and traditional internal combustion methods were analysed. Life cycle analysis (LCA) has highlighted that internal combustion engines present greater challenges in terms of pollutant emissions and maintenance requirements during use. Conversely, electric vehicles present significant challenges, particularly in the production and recycling of batteries, due to the complexity of raw material management and waste treatment. Solid-state batteries are a particularly innovative and promising solution, offering higher energy density, superior safety and reduced charging times compared to traditional lithium batteries. It is evident that prominent corporations such as Toyota, NIO and Stellantis are allocating substantial resources to the development and implementation of this technology, with its imminent commercial introduction anticipated within the next few years. Stellantis offers the STLA Medium modular platform, dedicated to the C and E segments. This guarantees a range of up to 700 km with batteries from 87 to 104 kWh. The platform is accompanied by advanced recycling processes to reduce environmental impact through the recovery of precious materials. In order to achieve an enhancement in autonomy and efficiency, the incorporation of auxiliary systems is being contemplated. Such systems include the Range Extender, which employs alternative fuels to augment the range; regenerative braking, which facilitates the conversion of kinetic energy into electricity for the purpose of recharging the battery; and the Start&Stop system, which initiates the engine shutdown during periods of inactivity to minimise superfluous consumption. The electric motor selected is a brushless synchronous permanent magnet motor, which is renowned for its compact size, high efficiency, quiet operation and reduced heat generation due to the absence of brushes. These technological choices embody an integrated approach to the design of modern, sustainable and high-performance vehicles.

2.3.3. Customisation and Technology

Lancia has introduced the SALA (Sound Air Light Augmentation) system, which facilitates advanced interaction between driver, passengers and vehicle. Emerging technologies include the use of augmented and virtual reality on board, the integration of eye, voice, touch and gesture controls, as well as external LED panels to communicate with the surrounding environment. The field of artificial intelligence, in particular the application of machine learning, has enabled significant advances in personalising the user experience. This personalisation has been demonstrated to optimise consumption, whilst simultaneously ensuring safety and comfort. Stellantis plans to use over-the-air (OTA) updates to ensure the software is constantly updated, thereby enhancing human-vehicle interaction. The STLA Brain architecture has been designed to offer continuous digital services, supported by a cloud infrastructure provided by Amazon. This is connected to the STLA SmartCockpit, where the driver can interact through multimodal interfaces. DWPT (Dynamic Wireless Power Transfer) technology, when integrated into specific road sections, enables dynamic charging of electric vehicles, thereby increasing their range. Vehicle-to-Everything (V2X) communication systems represent a significant development in the field of transportation technology. These systems facilitate the real-time exchange of data between vehicles and various elements of the infrastructure, including other vehicles and the urban environment. The implementation of V2X technology has the potential to enhance mobility, safety and efficiency, making it a promising solution for the future of urban transportation.

2.3.4. Design

A technical analysis of the transition from internal combustion engine (ICE) vehicles to electric vehicles (EVs) reveals a significant transformation in body design. This transformation indicates that the project entails more than a mere restyling, but rather constitutes a substantial redesign. The primary distinctions can be attributed to aerodynamic requirements, energy efficiency, and component positioning. Electric vehicles (EVs) exhibit a variety of design features that contribute to a reduction in aerodynamic drag. These include more fluid shapes, the elimination or reduction of front grilles, and bonnets and doors with smooth lines that are optimised to reduce air resistance. The batteries, which are located in the floor pan, have a significant impact on both ground clearance and interior space, which is often greater than that observed in ICE vehicles. The front storage space has also been increased in size. The materials utilised are frequently chosen for their lightweight nature, with the objective of enhancing efficiency. Aesthetic embellishments, including LED lighting, wheel covers and solar panels, serve to underscore the innovative nature of the design. The utilisation of cameras in lieu of mirrors has been demonstrated to enhance visibility and optimise aerodynamics. A notable case study is the comparison between the Honda e (2023) and the Honda Civic (Honda Motor Co., Ltd., Suzuka, Japan) from the 1970s, which demonstrates a clear shift in dimensions, design, and functionality. While maintaining stylistic references, such as the rear curvature, the modern EV appears to have undergone a profound transformation, characterised by cleaner lines, greater height, new lighting systems and functional details aimed at emphasising sustainability, modernity and comfort.

3. Stylistic Design Engineering (SDE)

The term ‘Stylistic Design Engineering’ (SDE) is employed to denote the phase of a project that is concerned with design. In this case, a comparative analysis was conducted on car models that, over time, have undergone significant redesigns while maintaining formal continuity and identity. The objective of this study was to ascertain the efficacy of stylistic strategies employed in the reinterpretation of historic vehicles, with a particular focus on the potential transposition of these approaches in the redesign of the Lancia Beta HPE (Lancia, Chivasso (Turin), Italy). The first case study examined the evolution of the Audi 100 C3 (Audi AG, Neckarsulm, Germany 1982) into the subsequent Audi A6 C7 (Audi AG, Neckarsulm, Germany, 2011), both of which belong to the E segment. The principal alterations encompassed the enhancement of aerodynamics and the redesign of the front end, characterised by the introduction of a more substantial grille and the integration of slimmer headlights. A substantial technological upgrade was implemented to align with the evolving expectations of users. A similar comparison was made between the Alfa Romeo Giulietta (Alfa Romeo, Cassino (Frosinone), Italy) of 1955 and that of 2010. The redesign saw the adoption of softer and more streamlined shapes, while retaining some iconic features, such as the front grille. The new version is distinguished by its contemporary proportions and dynamic styling, which reflect both the evolution of the target market and the company’s market positioning. The BMW 3 Series also demonstrates a consistent evolutionary trajectory between the 1975 and 2023 models. The front grille, a symbolic element of the brand, has undergone a reinterpretation in terms of both shape and materials. The stylistic intervention has been shown to affect the vehicle’s stance, proportions, aerodynamics and brightness, thereby making it more fluid and performant. Concurrently, an iconographic study was conducted on historic Lancia models, with particular emphasis on the 1978 Beta HPE. The analysis revealed recurring elements in the brand’s identity, including the chalice-shaped grille with central logo, the descending lines of the sides, the round headlights, and the essential geometries. According to the Chief Executive Officer, Luca Napolitano, these elements will form the basis of Lancia’s new stylistic identity. The Pu+Ra HPE concept car is the inaugural manifestation of this. The Lancia Beta HPE was distinguished by its harmonious integration of sportiness and practicality, making it well-suited for family use while also possessing a strong dynamic connotation. Its formal features are characterised by a square profile, a flat roof, side and rear blinds, a double belt line, flush door handles, and headlights integrated into a rounded grille. The rear is distinguished by the slightly protruding lights. Finally, future developments for the brand were taken into consideration. The new Ypsilon (2024), followed by Gamma and Delta, will represent the relaunch of the brand through electric and hybrid vehicles, with more robust designs that are consistent with the brand’s stylistic tradition. The new Gamma model will be a sports crossover, with power outputs of up to 350 hp and a range of up to 700 km. It will be based on the STLA Medium platform.

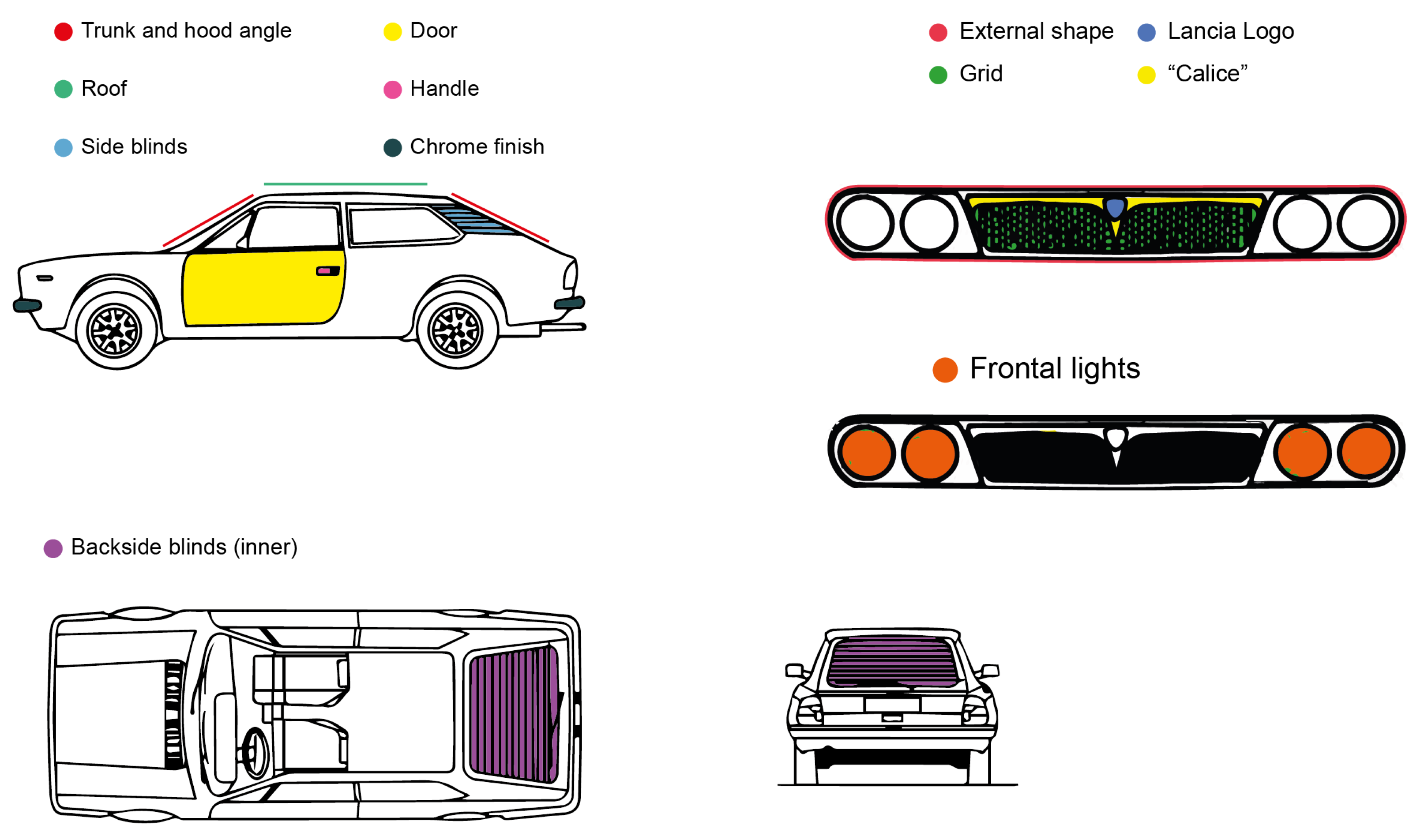

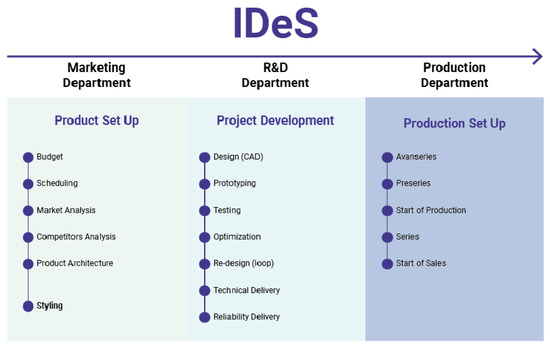

The analyses conducted (Figure 2) have enabled the establishment of a coherent framework for the development of a contemporary stylistic concept for the Lancia Beta HPE, founded upon a balance between technological innovation, historical identity, and formal recognizability.

Figure 2.

Analysis of Lancia Beta HPe looking at iconic elements.

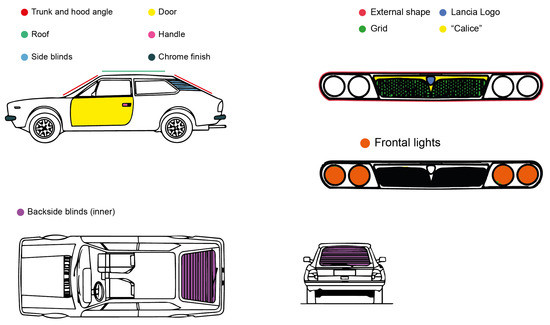

3.1. Sketch and 2D Analysis

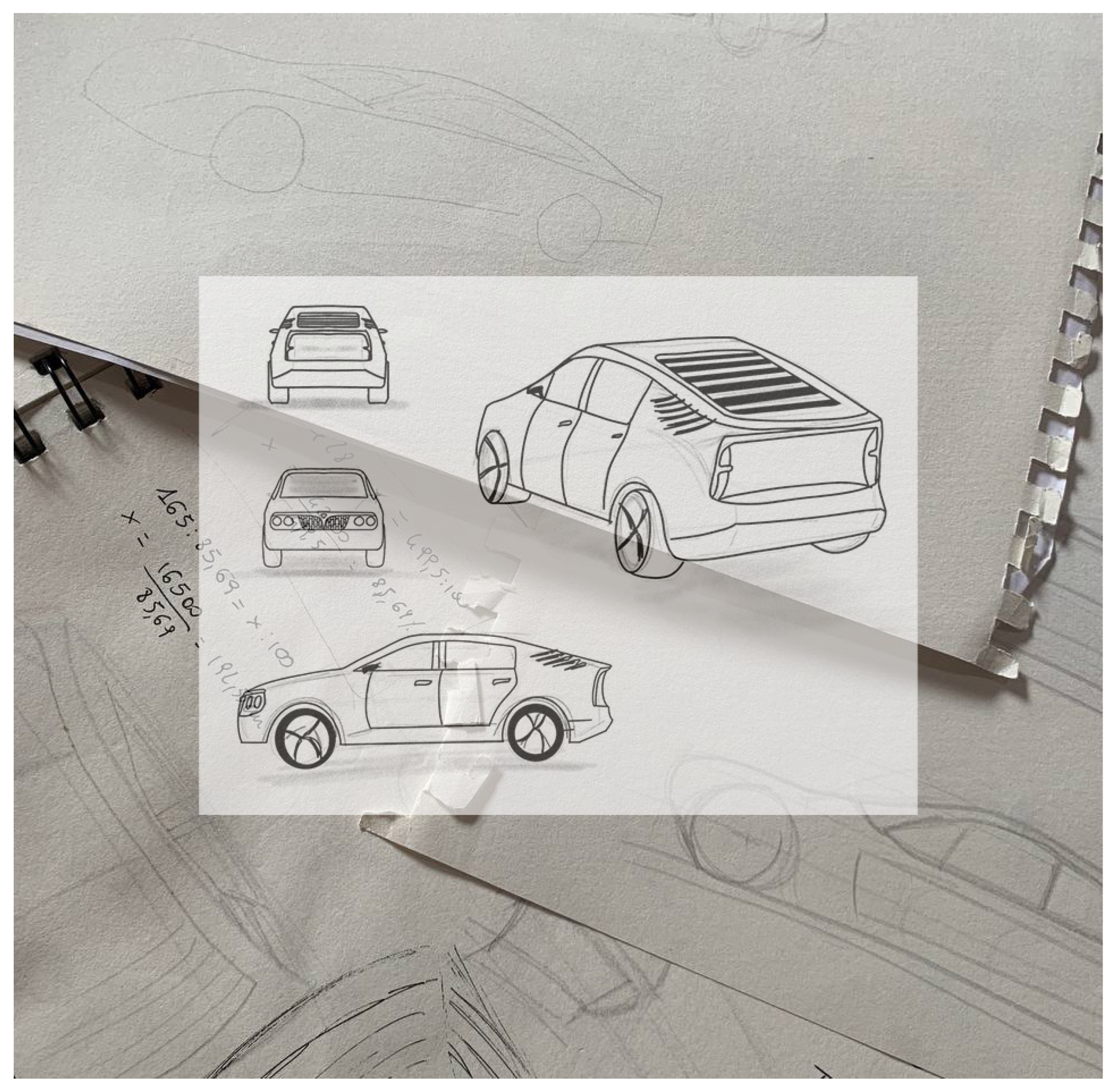

At this stage of the design process, the primary objective was to define the general morphology and stylistic details of the vehicle through an initial graphic exploration. A substantial number of freehand and iPad sketches (Figure 3) were produced, enabling the exploration of divergent stylistic directions that were found to be consistent with the findings of the historical and market analysis conducted previously. This exploratory process proved fundamental in selecting a proposal that could combine the brand’s values with a contemporary aesthetic, leading to the definition of the reference sketch.

Figure 3.

Sketches of Lancia Beta HPe.

This design was then developed into a complete set of two-dimensional drawings, which were necessary for the subsequent creation of a 3D model. The technical blueprint was created using AutoCAD 2023, with the typical proportions of C and D-segment vehicles currently on the market being taken into account. This enabled the concept vehicle to be positioned in an intermediate range between sportiness and functionality, in line with contemporary market expectations.

The configuration that has been selected corresponds to that of a compact sports SUV, characterised by dynamic lines and compact dimensions. This configuration facilitates the vehicle’s ability to deliver high performance on the road while simultaneously ensuring the comfort and versatility of use, even in the context of extra-urban routes or extended journeys.

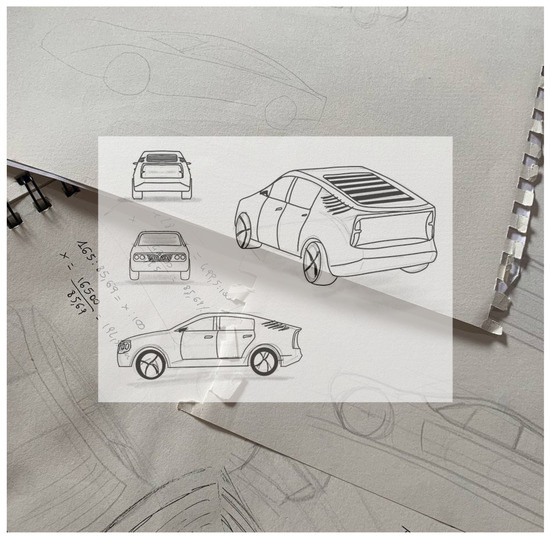

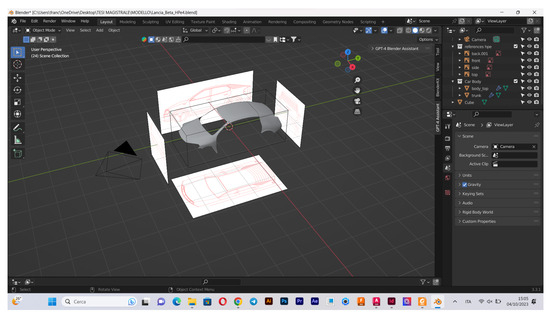

3.2. 3D Model

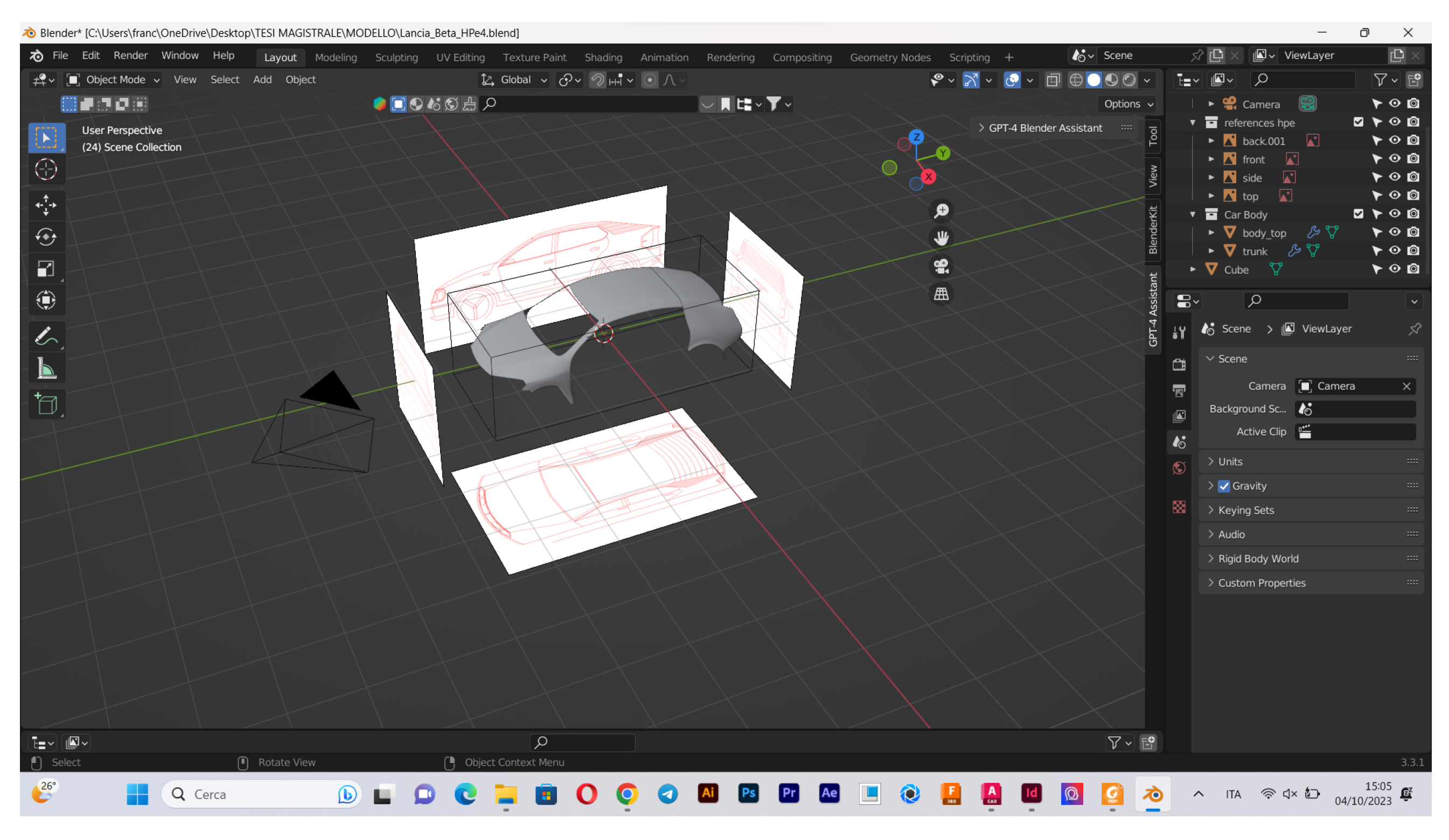

The three-dimensional modelling (Figure 4) of the vehicle was conducted utilising Blender, a widely utilised open-source software in the 3D graphics sector. This choice enabled a particularly fluid and flexible modelling approach, ensuring a high degree of control over the model’s surfaces. In particular, the Subdivision Surface modifier was utilised, which facilitates the iterative subdivision of the original mesh into denser surfaces, thereby enhancing the visual rendering of the model without unduly encumbering the creative process.

Figure 4.

3D model realised in Blender, using 2D drawings as starting point for the model.

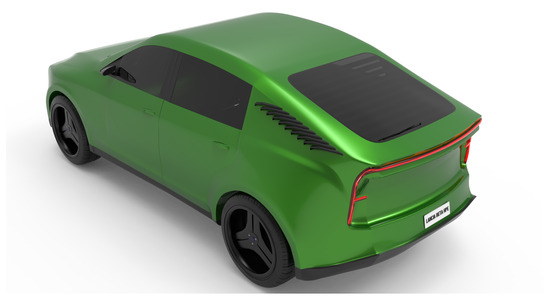

Despite the fact that mesh-based modelling is less accurate than NURBS-based modelling (which is particularly suitable for engineering applications or components with strict dimensional tolerances), it proved to be extremely effective in the stylistic representation of the vehicle. Furthermore, Blender incorporates internal rendering engines (Cycles in Figure 5 and Eevee) that are capable of generating high-quality renders, rendering the software particularly suitable for photorealistic visualisation of modelled concepts (Figure 6).

Figure 5.

Cycles rendering realized in Blender.

Figure 6.

Rendering of the car in another perspective, rear part.

4. Results

4.1. Approach and Methodology

- The approach outlined in this study supports the idea that employing a structured design methodology can lead to the development of innovative and technically sound solutions;

- The proposed method allowed for the definition of a complete vehicle concept, merging aesthetic and engineering requirements into a cohesive and traceable design workflow.

4.2. Learning Outcomes and Technological Integration

- A key result of the process was the incremental learning gained from using non-traditional tools and techniques;

- The integration of generative artificial intelligence, particularly language models like GPT, was shown to be effective in assisting the early exploratory and research stages of a highly complex design process;

- These findings suggest that innovative technologies can act as catalysts, enabling creativity and technical advancements rather than restricting them.

4.3. Role of Sketch Quality in the Final Outcome

- The quality and accuracy of the initial sketch significantly influence the effectiveness of subsequent design phases;

- A well–defined sketch provides an early spatial and stylistic framework, helping to clarify key proportional relationships such as vehicle dimensions, stance, and segment classification;

- By establishing the core design intent from the outset, the sketch acts as a conceptual reference that guides 2D blueprint development and later 3D modelling stages, resulting in a more coherent and mature final form;

- Conversely, a low–fidelity sketch may lead to ambiguity in proportions and character definition, requiring additional refinement later in the process and potentially limiting the fidelity of the final outcome;

- These findings confirm that the sketch is not only a creative artefact but also a structural design tool that supports precision, consistency, and traceability throughout the development workflow.

4.4. 3D Modelling and Tool Integration

- The project also led to the enhancement and expansion of 3D modeling skills, combining advanced software techniques with the exploration of new tools and command;

- This hybrid approach led to a more accurate and detailed final representation of the product, staying true to the original design intent.

5. Discussion

The findings of this study corroborate the efficacy of a structured approach to the design process, underscoring the notion that a meticulously delineated methodology can precipitate the conception of innovative and technologically proficient solutions. In particular, the integration of generative artificial intelligence, such as GPT-type language models, has demonstrated considerable efficacy in facilitating the preliminary stages of exploration and research, which are hallmarks of a complex design process. This suggests that innovative technologies should not be regarded as constraints, but rather as catalysts that promote creativity and technical progress. Moreover, the project contributed significantly to the expansion of skills in the field of 3D modelling, integrating the advanced use of established software with the exploration of new tools and commands. This hybrid approach facilitated the acquisition of a final representation of the product that was not only more accurate but also more faithful to the initial design intent. These results align with the findings of previous studies that emphasise how the adoption of innovative technologies can amplify creative potential and improve the quality of the design process. These findings suggest that the integration of advanced techniques and non-traditional tools has the potential to further evolve the design of complex products. It is recommended that future research endeavours focus on investigating the long-term impact of these methodologies and their application in other design contexts. This will facilitate a comprehensive understanding of their potential and challenges.

Author Contributions

Conceptualization, F.G. and L.F.; methodology, F.G., L.F. and G.D.; software, F.G. and G.G.; validation, F.G. and L.F.; formal analysis, F.G.; investigation, F.G.; resources, L.F.; data curation, F.G.; writing—original draft preparation, F.G.; writing—review and editing, F.G.; visualization, F.G.; supervision, L.F., G.D. and G.G.; funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

This research is based on conceptual and methodological development carried out during the authors’ academic thesis. It includes references to internal student works and previous teaching materials. The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

During the preparation of this manuscript/study, the author(s) used ChatGPT (OpenAI, GPT-4, 2025) for the purposes of generating data and analyse them. The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Nussgen, A.; Degen, R.; Irmer, M.; Richter, F.; Bostrom, C.; Ruschitzka, M. Leveraging Robust Artificial Intelligence for Mechatronic Product Development—A Literature Review. Int. J. Intell. Sci. 2024, 14, 1–21. [Google Scholar] [CrossRef]

- Muratori, M. Transforming Energy Through Sustainable Mobility: Electric Vehicles—A Sustainable Solution for Transportation Systems; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2023. Available online: https://docs.nrel.gov/docs/fy24osti/91331.pdf (accessed on 6 November 2025).

- Van Mierlo, J.; Berecibar, M.; El Baghdadi, M.; De Cauwer, C.; Messagie, M.; Coosemans, T.; Jacobs, V.A.; Hegazy, O. Beyond the State of the Art of Electric Vehicles: A Fact-Based Paper of the Current and Prospective Electric Vehicle Technologies. World Electr. Veh. J. 2021, 12, 20. [Google Scholar] [CrossRef]

- Pierri, E.; Cirillo, V.; Vietor, T.; Sorrentino, M. Adopting a Conversion Design Approach to Maximize the Energy Density of Battery Packs in Electric Vehicles. Energies 2021, 14, 1939. [Google Scholar] [CrossRef]

- Hansen, R.; Rall, E.; Rolf, W.; Pauleit, S.; Erlwein, S.; Fohlmeister, S.; Santos, A.; Luz, A.; Branquinho, C.; Santos-Reis, M.; et al. Advanced Urban Green Infrastructure Planning and Implementation: Innovative Approaches and Strategies from European Cities; GREEN SURGE Project, European Union FP7; University of Copenhagen: Copenhagen, Denmark, 2016. [Google Scholar] [CrossRef]

- Frizziero, L.; Liverani, A.; Donnici, G.; Giuliano, I.; Picciariello, M.G.; Tucci, M.L.; Reimer, D.; Ali, A. Application of IDeS (Industrial Design Structure) to Sustainable Mobility: Case Study of an Innovative Bicycle. Inventions 2021, 6, 22. [Google Scholar] [CrossRef]

- Jiang, S.; Li, W.; Qian, Y.; Zhang, Y.; Luo, J. AutoTRIZ: Automating Engineering Innovation with TRIZ and Large Language Models. Adv. Eng. Inform. 2025, 65, 103312. [Google Scholar] [CrossRef]

- Wang, K.; Tan, R.; Peng, Q.; Sun, Y.; Li, H.; Sun, J. Radical innovation of product design using an effect solving method. Comput. Ind. Eng. 2021, 151, 106970. [Google Scholar] [CrossRef]

- Ilevbare, I.M.; Probert, D.; Phaal, R. A review of TRIZ, and its benefits and challenges in practice. Technovation 2013, 33, 30–37. [Google Scholar] [CrossRef]

- Al-Dwairi, A.; Al-Araidah, O.; Hamasha, S. An Integrated QFD and TRIZ Methodology for Innovative Product Design. Designs 2023, 7, 132. [Google Scholar] [CrossRef]

- Kosasih, W.; Salomon, L.L.; Halim, A.D. Integration of Conjoint Analysis and QFD for New Product Development in Manufacturing Small and Medium Enterprises (Case Study: A Food Company). IOP Conf. Ser. Mater. Sci. Eng. 2020, 847, 012017. [Google Scholar] [CrossRef]

- Thangavelu, J. Artificial Intelligence in Engineering Design: Enhancing Creativity and Efficiency. ESP Int. J. Adv. Sci. Technol. 2024, 2, 29–39. [Google Scholar]

- De la Tejera, J.A.; Ramirez-Mendoza, R.A.; Bustamante-Bello, M.R.; Orta-Castañón, P.; Arce-Saenz, L.A. Overview of an AI-Based Methodology for Design: Case Study of a High-Efficiency Electric Vehicle Chassis for the Shell Eco-Marathon. In Proceedings of the International Symposium on Electromobility (ISEM 2023), Monterrey, Mexico, 13–15 November 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Ibrahim, M.; Rassõlkin, A.; Vaimann, T.; Kallaste, A. Overview on Digital Twin for Autonomous Electrical Vehicles Propulsion Drive System. Sustainability 2022, 14, 601. [Google Scholar] [CrossRef]

- Yin, L.; Zhu, S.; Zhou, J. AI Technology Adoption, AI Knowledge Integration and AI Product Development Performance. In Service Science; Wang, Z., Wang, S., Xu, H., Eds.; Springer Nature: Singapore, 2023; pp. 351–359. [Google Scholar] [CrossRef]

- Naeem, R.; Kohtamäki, M.; Parida, V. Artificial intelligence enabled product service innovation: Past achievements and future directions. Rev. Manag. Sci. 2024, 19, 2149–2192. [Google Scholar] [CrossRef]

- Mausbach, A.G. Paradigm Shift: The Aesthetic of the Automobile in the Age of Sustainability. Ph.D. Thesis, Intelligent Mobility Design Centre, Royal College of Art, London, UK, 2010. Available online: https://researchonline.rca.ac.uk/1164/ (accessed on 21 September 2023).

- Stahl, B. Embedding responsibility in intelligent systems: From AI ethics to responsible AI ecosystems. Sci. Rep. 2023, 13, 7586. [Google Scholar] [CrossRef]

- Beaume, R.; Midler, C. From technology competition to reinventing individual ecomobility: New design strategies for electric vehicles. Int. J. Automot. Technol. Manag. 2009, 9, 174–190. [Google Scholar] [CrossRef]

- Xia, X.; Li, P. A review of the life cycle assessment of electric vehicles: Considering the influence of batteries. Sci. Total Environ. 2022, 814, 152870. [Google Scholar] [CrossRef] [PubMed]

- Sheng, I.L.S.; Teoh, K.-S. Eco-Efficient Product Design Using Theory of Inventive Problem Solving (TRIZ) Principles. Am. J. Appl. Sci. 2010, 7, 852–858. [Google Scholar] [CrossRef]

- Da Silva, D.M.; dos Santos, C. Thinking the Automobile: A Design and Engineering Intention. Converg. J. Res. Arts Educ. 2022, 15, 111–119. [Google Scholar] [CrossRef]

- Sareh, P. Inspired by nature, refined by numbers: Formal-functional bioinspiration and intelligent computation in vehicle design. R. Soc. Open Sci. 2025, 12, 241742. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Zhang, J.; Liu, H.; Liang, L. The effect of online and offline word-of-mouth on new product diffusion. J. Strateg. Mark. 2014, 22, 177–189. [Google Scholar] [CrossRef]

- Baptista, A.; Silva, F.J.G.; Campilho, R.D.S.G.; Ferreira, S.; Pinto, G. Applying DMADV on the industrialization of updated components in the automotive sector: A case study. Procedia Manuf. 2020, 51, 1332–1339. [Google Scholar] [CrossRef]

- ANFIA. Il Futuro del Settore Automotive: Sfide e Opportunità per i Fornitori Italiani Verso il 2030; ANFIA: Torino, Italy, 2021; Available online: https://www.anfia.it/images/pubblicazioni/documenti/20_11_Il_futuro_del_settore_auto_ANFIA_RB_S_P.pdf (accessed on 15 September 2023).

- ANFIA. Focus Italia Mercato Autovetture; ANFIA: Torino, Italy, 2023; Available online: https://www.anfia.it/it/attivita/studi-e-statistiche/focus-dossier-pubblicazioni/immatricolazioni/italia/focus-italia-mercato-autovetture-dicembre-2023 (accessed on 15 September 2023).

- ISFORT. 19° Rapporto Sulla Mobilità Degli Italiani. Available online: https://www.isfort.it/wp-content/uploads/2022/12/19-Rapporto_mobilita_italiani_Sintesi.pdf (accessed on 15 September 2023).

- ACI Studi e Ricerche—Centro Documentazione e Dati e Statistiche. ACI Studi e Ricerche. Available online: https://www.aci.it/laci/studi-e-ricerche.html (accessed on 15 September 2023).

- Ansa, A. Land Rover Defender by E.C.D. Automotive Design—Novità e Anticipazioni. Agenzia ANSA. 2023. Available online: https://www.ansa.it/canale_motori/notizie/prove_novita/2023/01/30/land-rover-defender-by-e.c.d.-automotive-design_af30f391-6897-4d60-93ea-29e46a5ee6ad.html (accessed on 15 September 2023).

- Parlamento Europeo. Il Divieto di Vendita per le Nuove Auto a Benzina e Diesel Nell’UE dal 2035. European Parliament. 2023. Available online: https://www.europarl.europa.eu/news/it/headlines/economy/20221019STO44572/il-divieto-di-vendita-per-le-nuove-auto-a-benzina-e-diesel-nell-ue-dal-2035 (accessed on 15 September 2023).

- Jaworski, B.J.; Kohli, A.K. Market Orientation: Antecedents and Consequences. J. Mark. 1993, 57, 53–70. [Google Scholar] [CrossRef]

- Burger, B.; Kanbach, D.K.; Kraus, S.; Breier, M.; Corvello, V. On the Use of AI-Based Tools like ChatGPT to Support Management Research. Eur. J. Innov. Manag. 2023, 26, 233–241. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).