A Study on Performance Evaluation of Biodiesel from Grape Seed Oil and Its Blends for Diesel Vehicles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Production of Biodiesel

2.2. Blend Preparation

2.3. Smoke Test

2.4. Emission Analysis

2.5. Horsepower Test

2.6. Fuel Economy Test

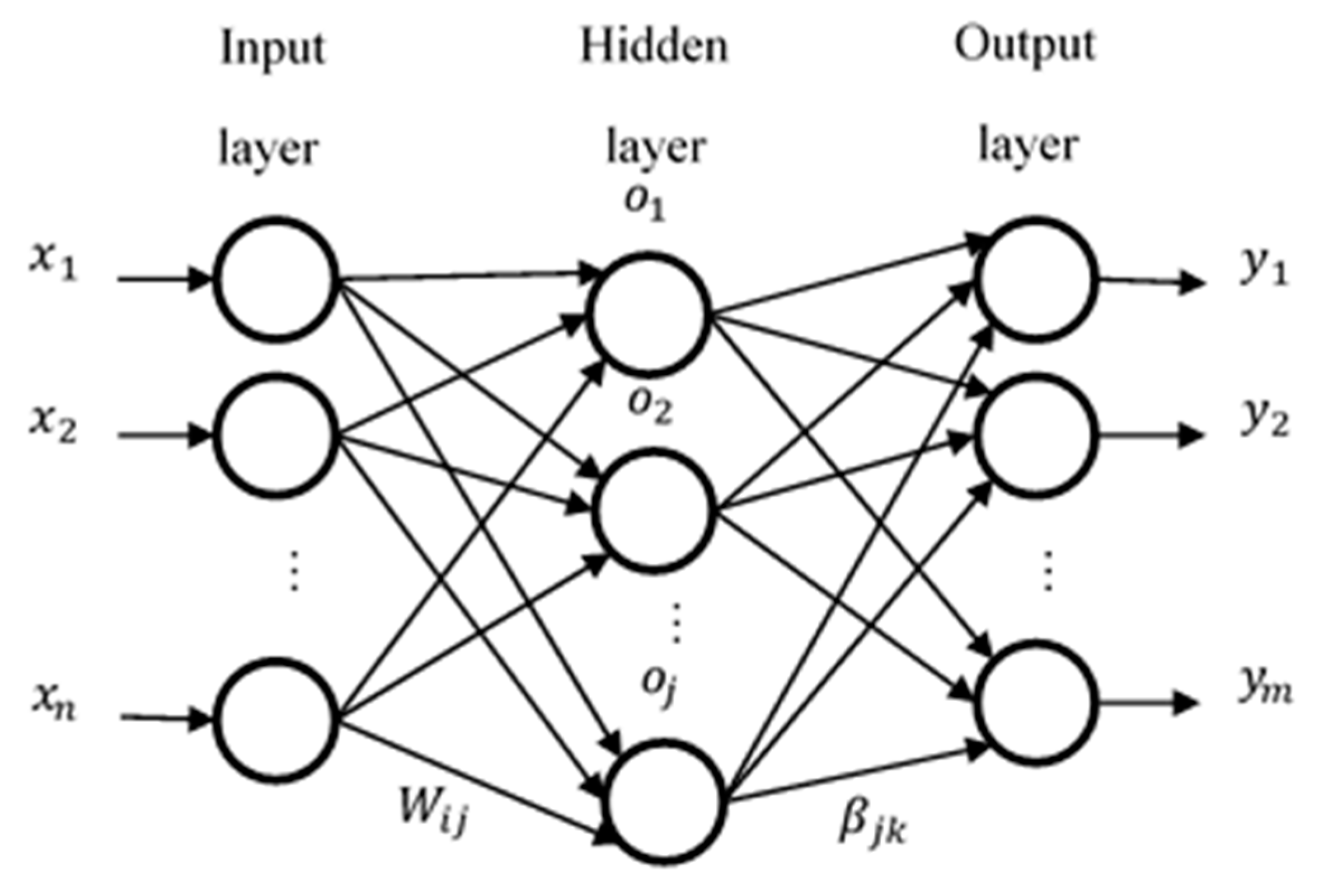

2.7. Optimization of Blend Ratio Using Artificial Methods

- Output weight

- Objective function

- Normalization

3. Results

- Fuel properties

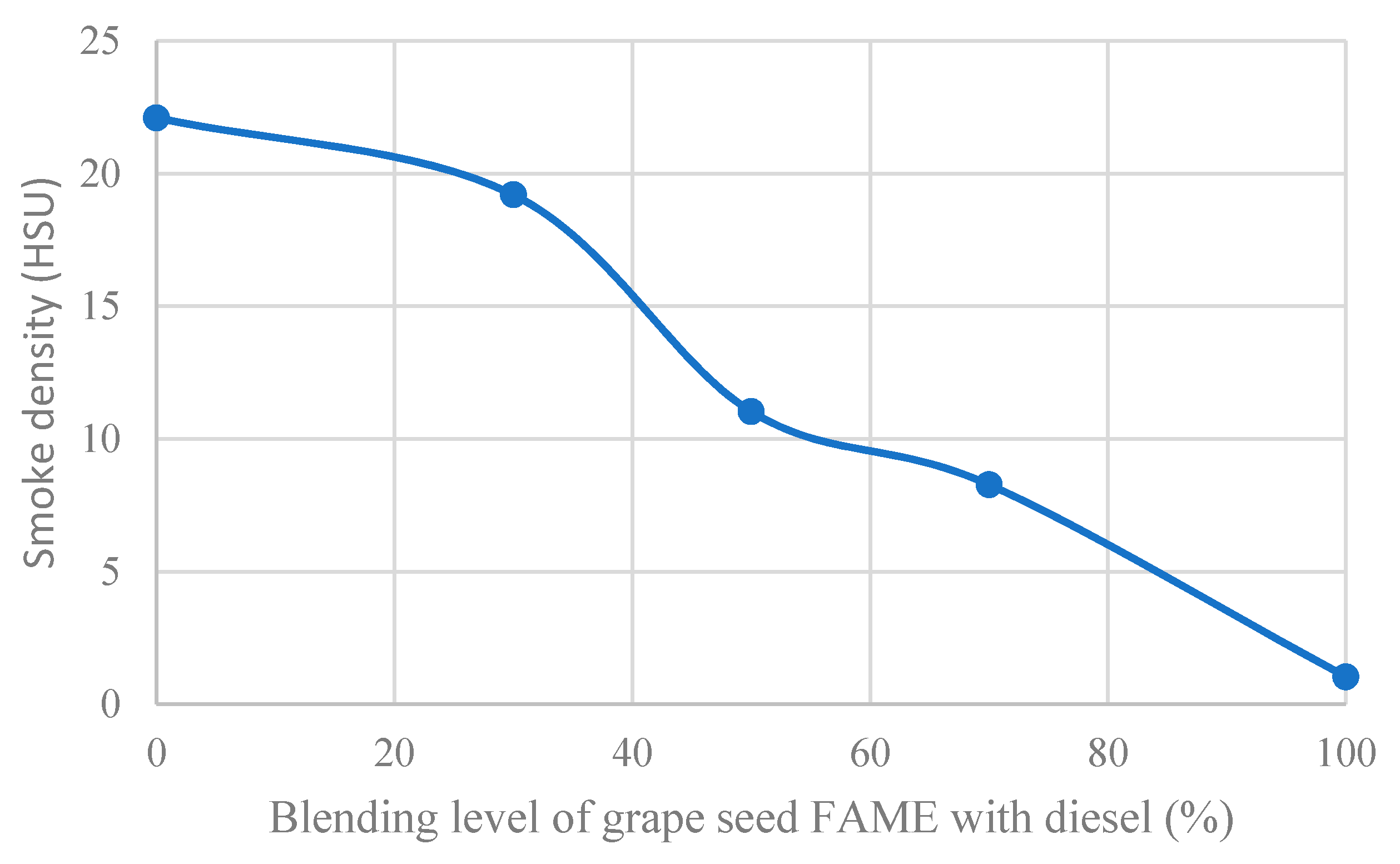

- Smoke opacity test

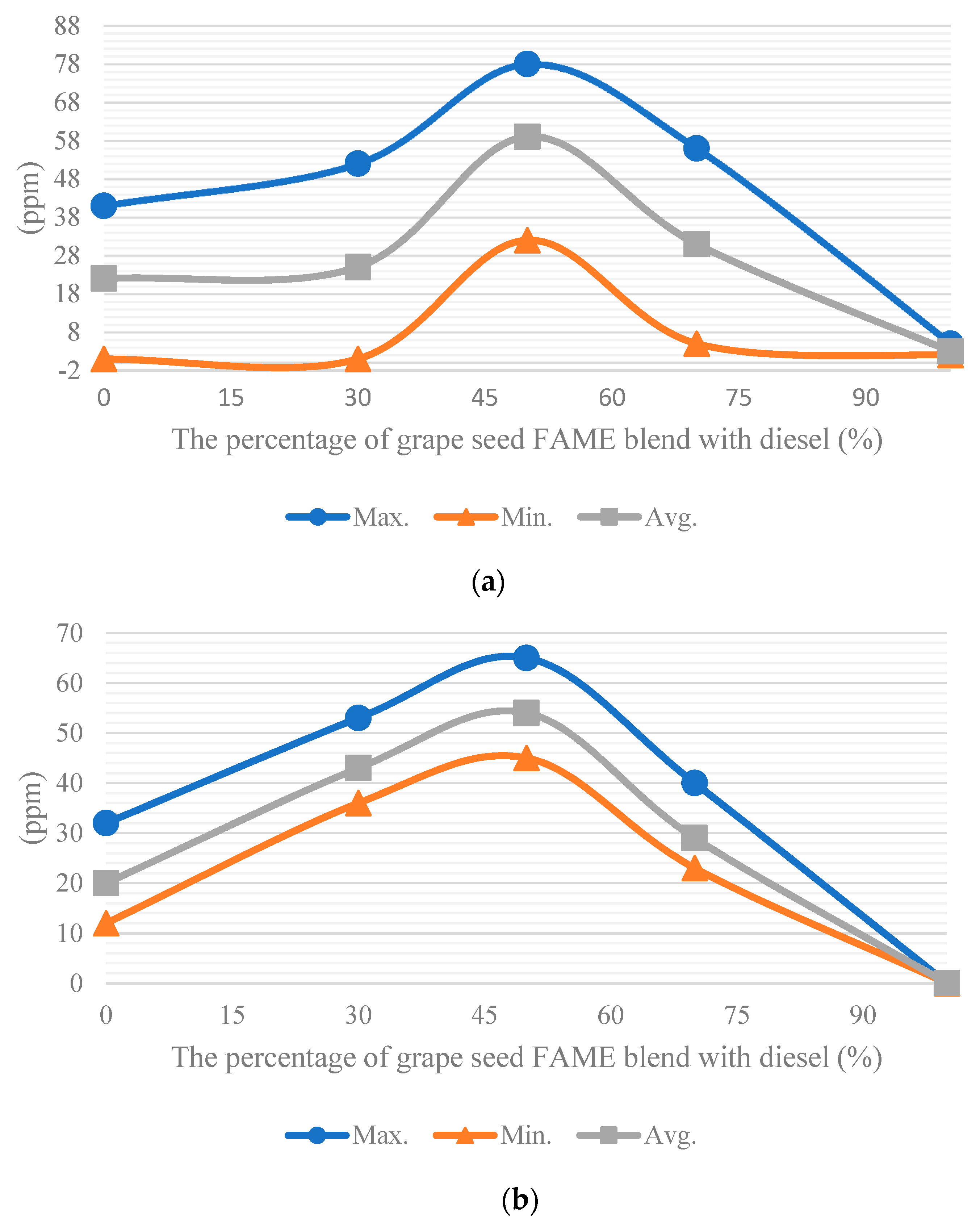

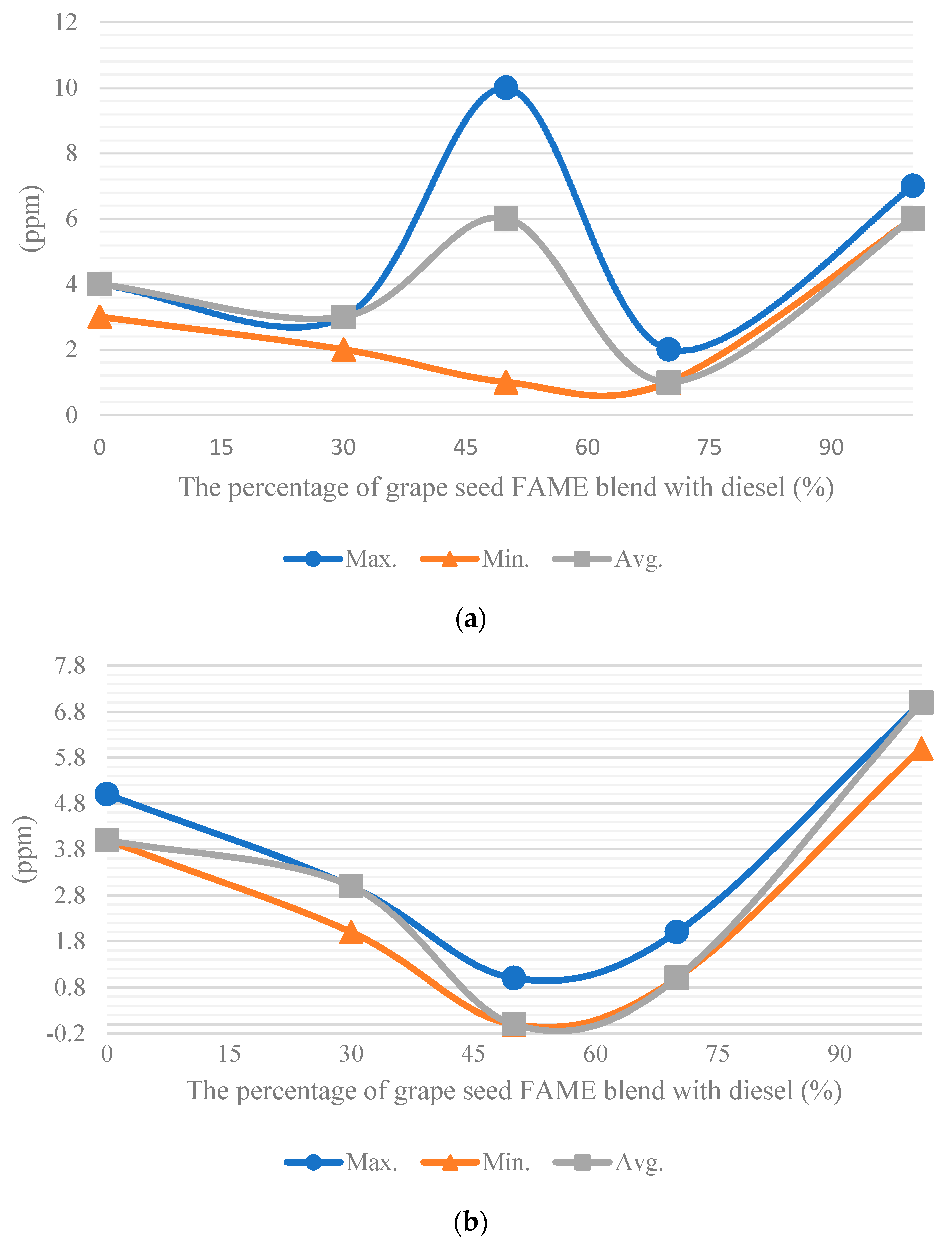

- HC emissions

- CO emissions

- NOx emissions

- Exhaust gas temperature

- Horsepower

- Fuel economy

- ELM Model Training and Testing

- Genetic Algorithm (GA) Optimization Results

4. Discussion

- Index of emission, which is the sum of the rankings of smoke opacity and HC, CO, and NOx emissions;

- Index of energy transfer, which is the sum of the rankings of heating value, exhaust gas temperature, and horsepower;

- Overall index, which entails the sum of rankings of all emissions, horsepower, and fuel economy.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Naik, S.; Goud, V.; Rout, P.; Dalai, A. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Aydogan, H.; Hirz, M.; Brunner, H. The use and future of biofuels. Int. J. Soc. Sci. 2014, 3, 12–21. [Google Scholar]

- U.S. Energy Information Administration. Short-Term Energy Outlook, July 2021; U.S. Energy Information Administration: Washington, DC, USA, 2021. [Google Scholar]

- Unpaprom, Y.; Tipnee, S.; Rameshprabu, R. Biodiesel from green alga Scenedesmus acuminatus. Int. J. Sustain. Green Energy 2015, 4, 1–6. [Google Scholar]

- Ogunkunle, O.; Ahmed, N.A. A review of global current scenario of biodiesel adoption and combustion in vehicular diesel engines. Energy Rep. 2019, 5, 1560–1579. [Google Scholar] [CrossRef]

- Baz, W.A.; Nawar, L.S.; Aly, M.M. Production of biofuel from sugarcane bagasse wastes using Saccharomyces cerevisiae. J. Exp. Biol. Agric. Sci. 2017. [Google Scholar] [CrossRef]

- Dworakowska, S.; Bednarz, S.; Bogdal, D. Production of Biodiesel from Rapeseed Oil. 1st World Sustainability Forum, 1–30 November 2011. Available online: www.wsforum.org (accessed on 6 July 2021).

- Ge, J.C.; Yoon, S.K.; Choi, N.J. Using Canola Oil Biodiesel as an Alternative Fuel in Diesel Engines: A Review. Appl. Sci. 2011, 7, 881. [Google Scholar] [CrossRef]

- Ashraful, A.M.; Masjuki, H.H.; Kalam, M.A.; Fattah, L.R.; Imtenan, S.; Shahir, S.A.; Mobarak, H.M. Production and comparison of fuel properties, engine performance and emission characteristics of biodiesel from non-edible vegetable oils: A review. Energy Convers. Manag. 2014, 80, 202–228. [Google Scholar] [CrossRef]

- Pramanik, K. Properties and use of jatropha curcas oil and diesel fuel blends in compression ignition engine. Renew. Energy 2003, 28, 239–248. [Google Scholar] [CrossRef]

- Fernández, C.; Solana, M.; Fiori, L.; Rodríguez, J.; Ramos, M.; Pérez, Á. From seeds to biodiesel: Extraction, esterification, transesterification and blending of Jatropha curcas oil. Environ. Eng. Manag. J. 2015, 14, 2855–2864. [Google Scholar]

- Fernandez, C.M.; Ramos, M.J.; Perez, A.; Rodriguez, J.F. Production of biodiesel from winery waste: Extraction, refining and transesterification of grapeseed oil. Bioresour. Technol. 2010, 101, 7019–7024. [Google Scholar] [CrossRef]

- Samo, M.; Luliano, M. Enzymatic production of Biodiesel from Grapeseed oil. Chem. Eng. Trans. 2020, 80, 301–306. [Google Scholar]

- Sreedhar, C.; Prasad, B.D. Investigating on Use of Different Blends of White Grape Seed Biodiesel and Diesel on 4-Stroke Single Cylinder DI Diesel Engine. Int. J. Eng. Res. Appl. 2015, 5, 18–23. [Google Scholar]

- Karthikeyan, S.; Prathima, A.; Elango, A. An Environmental Effect of Vitis vinifera (Grape Seed Oil) Biofuel Blends in Marine Engine. Int. J. Mol. Sci. 2015, 44, 1856. [Google Scholar]

- Devan, P.K.; Mahalakshmi, N.V. A study of the performance, emission and combustion characteristics of a compression ignition engine using methyl ester of paradise oil–eucalyptus oil blends. Appl. Energy 2009, 86, 675–680. [Google Scholar] [CrossRef]

- Anand, B.; Saravanan, C.; Srinivasan, C. Performance and exhaust emission of turpentine oil powered direct injection diesel engine. Renew. Energy 2010, 35, 1179–1184. [Google Scholar] [CrossRef]

- Di, Y.; Cheung, C.; Huang, Z. Experimental investigation on regulated and unregulated emissions of a diesel engine fueled with ultra-low sulfur diesel fuel blended with biodiesel from waste cooking oil. Sci. Total. Environ. 2009, 407, 835–846. [Google Scholar] [CrossRef] [PubMed]

- Kaisan, M.U.; Pam, G.Y.; Kulla, D.M.; Kehinde, A.J. Effects of Oil Extraction Methods on Bio-diesel Production from Wild Grape Seeds: A Case Study of Soxhlet Extraction and Mechanical Press Engine Driven Expeller Methods. J. Altern. Energy Sources Technol. 2014, 6. [Google Scholar]

- Canaci, M.; Ozsezen, A.N.; Arcaklioglu, E.; Erdil, A. Prediction of performance and exhaust emissioms of a diesel engine fueled with biodiesel produced from waste frying palm oil. Expert Sys. Appl. 2009, 36, 9268–9280. [Google Scholar] [CrossRef]

- Thirumarimurugan, M.; Sivakumar, V.M.; Merly Xavier, A.; Prabhakaran, D.; Kannadasan, T. Preparation of biodiesel from Sunflower oil by transesterification. Int. J. Biochem. Bioinform. 2012, 2, 441. [Google Scholar] [CrossRef]

- Hoseinin, S.S.; Najafi, G.; Sadeghi, A. Chemical characterization of oil and biodiesel from Commom Purslane (Portulaca) seed as novel weed plant feedstock. Ind. Crop. Prod. 2019, 140, 111582. [Google Scholar] [CrossRef]

- Kamel, D.A.; Farag, H.A.; Amin, N.K.; Zatout, A.A.; Ali, R.M. Smart Utilization of Jatropha (Jatropha curcas Linnaeus) seeds for biodiesel production: Optimization and mechanism. Ind. Crop. Prod. 2018, 111, 407–413. [Google Scholar] [CrossRef]

- Mironeasa, S.; Leahu, A.; Codina, G.; Stroe, S.; Mironeasa, C. Grapeseed: Physico-chemical, structural charateristics and oil content. J. Agroaliment. Process. Technol. 2010, 16, 1–6. [Google Scholar]

- Fukuda, H.; Kondo, A.; Noda, H. Biodiesel fuel production by transesterification of oils. J. Biosci. Bioeng. 2001, 92, 405–416. [Google Scholar] [CrossRef]

- Oliveira, L.S.; Franca, A.S.; Camargos, R.R.; Ferraz, V.P. Coffee oil as a potential feedstock for biodiesel production. Bioresour. Technol. 2008, 99, 3244–3250. [Google Scholar] [CrossRef]

- Ramos, M.J.; Fernández, C.M.; Casas, A.; Rodríguez, L.; Pérez, Á. Influence of fatty acid composition of raw materials on biodiesel properties. Bioresour. Technol. 2009, 100, 261–268. [Google Scholar] [CrossRef]

- Rondon, A.; Aliaga, R.; Cuisano, J. Fuel Consumption and Emissions Analysis of a Light Vehicle Fuelled with Two Ethanol-Gasoline Blends in Urban Driving Conditions of Lima Metropolitan. World Electr. Veh. J. 2021, 12, 99. [Google Scholar] [CrossRef]

- Huang, G.B.; Zhu, Q.Y.; Siew, C.K. Extreme learning machine: Theory and applications. Neurocomputing 2006, 70, 489–501. [Google Scholar] [CrossRef]

- Penrose, R. A generalized inverse for matrices. In Proceedings of the Cambridge Philosophical Society; Cambridge University Press: Cambridge, UK, 1955; pp. 406–413. [Google Scholar]

- Huang, G.B.; Wang, D.H.; Lan, Y. Extreme learning machines: A survey. Int. J. Mach. Learn. Cybern. 2011, 2, 107–122. [Google Scholar] [CrossRef]

- ASTM International. ASTM International. ASTM D6751-20a: Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels. In Annual Book of ASTM Standards; American Society of Testing Materials: West Conshohocken, PA, USA, 2020; Available online: www.astm.org (accessed on 7 June 2021).

- Deng, B.; Li, Q.; Chen, Y.; Li, M.; Liu, A.; Ran, J.; Xu, Y.; Liu, X.; Fu, J.; Feng, R. The effect of air/fuel ratio on the CO and NOx emissions for a twin-spark motorcycle gasoline engine under wide range of operating conditions. Energy 2018, 169, 1202–1213. [Google Scholar] [CrossRef]

- Elango, T.; Senthilkumar, T. Performance and emission characteristics of CI engine fueled with non-edible vegetable oil and biodiesel blends. J. Eng. Sci. Technol. 2011, 6, 240–250. [Google Scholar]

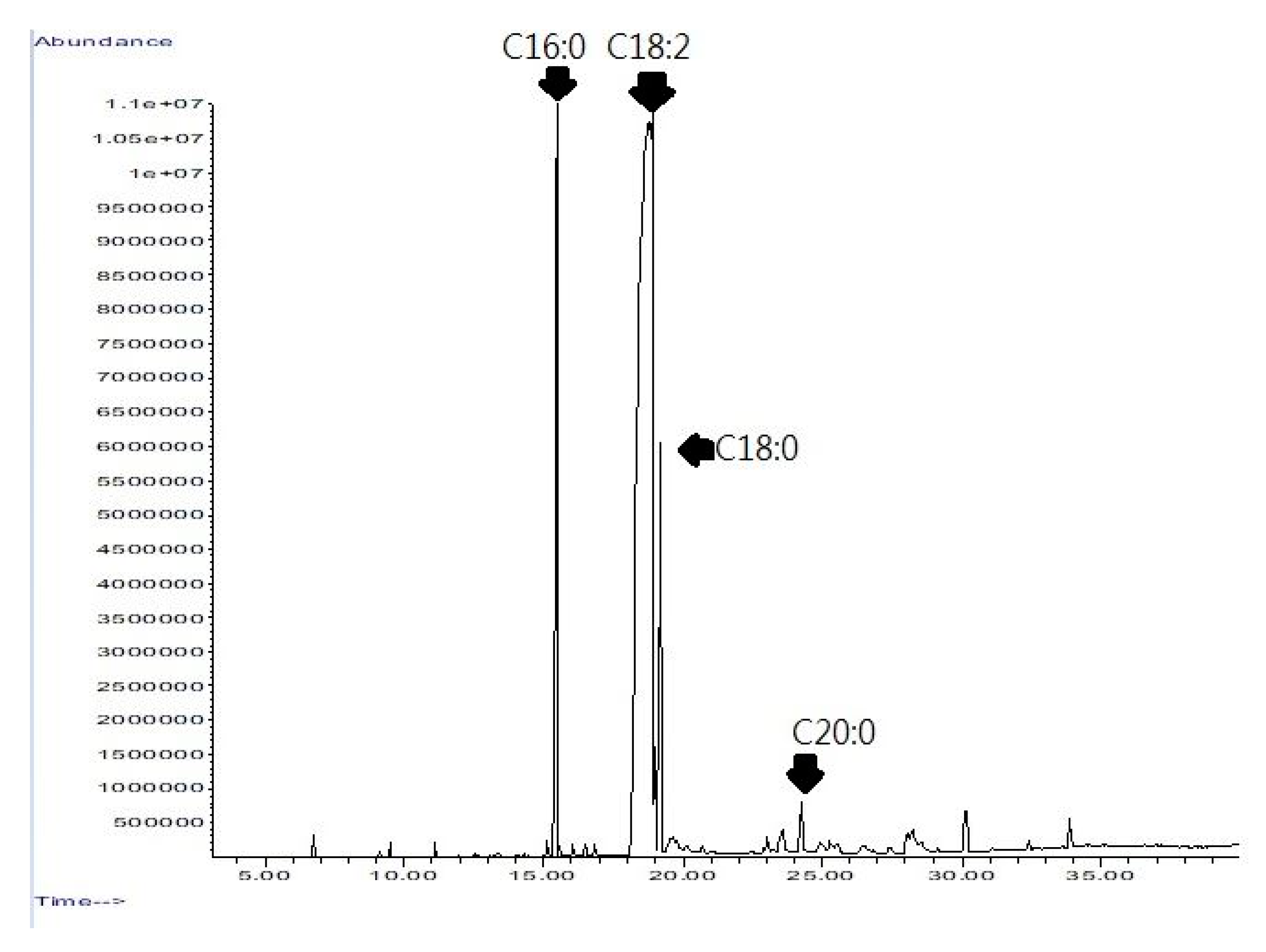

| Fatty Acid Fragment of Methyl Ester | GS FAME |

|---|---|

| Palmitic acid (C16:0) | 13.39 |

| Stearic acid (C18:0) | 5.60 |

| Linoleic acid (C18:2) | 80.17 |

| Arachidic acid (C20:0) | 0.84 |

| Blend | Blend Ratio |

|---|---|

| I | B0 (100% DI) |

| II | B30 (30% GS + 70% DI) |

| III | B50 (50% GS + 50% DI) |

| IV | B70 (70% GS + 30% DI) |

| V | B100 (100% GS) |

| Model | Daihatsu Rocky 2.8 Diesel Hardtop |

|---|---|

| Engine type | Naturally aspirated, in-line 4-cylinder |

| Fuel system | Diesel indirect injection |

| Maximum power | 54 kW @ 3600 rpm |

| Maximum torque | 170 Nm @ 2200 rpm |

| Bore × stroke | 92.0 mm × 104.0 mm |

| Engine size (displacement) | 2765 cc |

| Compression ratio | 21.5:1 |

| 70% Rated Engine Speed | High Idle Speed | Low Idle Speed | |||||

|---|---|---|---|---|---|---|---|

| Hold | Wait | Hold | Read | Wait | Hold | Read | |

| Time(s) | 30 | 15 | 15 | 30 | 15 | 15 | 30 |

| Weight | Value |

|---|---|

| 1.5 | |

| 1.0 | |

| 3.0 | |

| 1.0 | |

| 2.0 | |

| 1.0 |

| Properties | Grape Seed FAME | Diesel |

|---|---|---|

| Viscosity at 25 °C (mm2/s) | 7.47 | 5.5–24 |

| Cetane number | 47 | 45–50 |

| Heating value (J/g) | 39,440.97 | 47,424.79 |

| Blend | Brake (rpm) | Speed (km/h) | Horsepower (kW) | Torque (Nm) |

|---|---|---|---|---|

| B0 | 331.79 | 20.65 | 5.33 | 153.38 |

| B30 | 315.08 | 19.61 | 4.53 | 137.60 |

| B50 | 335.34 | 20.88 | 4.74 | 134.96 |

| B70 | 329.27 | 20.50 | 4.75 | 137.86 |

| B100 | 325.47 | 20.26 | 4.84 | 142.08 |

| Blend | Fuel Economy (km/L) |

|---|---|

| B0 | 4.42 |

| B30 | 4.02 |

| B50 | 3.74 |

| B70 | 5.41 |

| B100 | 3.35 |

| 1 | 2 | 3 | 4 | 5 | ||

|---|---|---|---|---|---|---|

| Biodiesel ratio (vol.%) | 0 | 30 | 50 | 70 | 100 | |

| Maximum power at minimum engine speed (kw) | 5.33 | 4.53 | 4.74 | 4.75 | 4.84 | |

| Smoke opacity (HSU) | 22.1 | 18 | 11.5 | 7.5 | 1.03 | |

| HC at high idle speed (ppm) | 22 | 25 | 59 | 31 | 3 | |

| HC at low idle speed (ppm) | 20 | 43 | 54 | 29 | 0 | |

| CO at high idle speed (%) | 0.4 | 0.55 | 0.66 | 0.63 | 0.11 | |

| CO at low idle speed (%) | 0.06 | 0.08 | 007 | 0.07 | 0.11 | |

| at high idle speed (ppm) | 4 | 3 | 6 | 1 | 6 | |

| at low idle speed (ppm) | 4 | 3 | 0 | 1 | 7 | |

| Fuel economy (km/L) | 4.42 | 4.02 | 3.74 | 5.41 | 3.35 |

| Data Set No. | 1 | 2 | 3 | 4 | 5 | |

| Biodiesel ratio (vol.%) | 0 | 30 | 50 | 70 | 100 | Average of E for each index (10−9%) |

| Maximum power at minimum engine speed (10−9%) | −0.0066 | −0.0066 | 0.2190 | −0.0998 | 0.1100 | 0.0432 |

| Smoke opacity (10−9%) | −0.3930 | 2.0800 | −8.100 | 5.5500 | −63.2000 | −12.8126 |

| HC at high idle speed (10−9%) | 1.2800 | −3.230 | −0.281 | 0.4960 | −52.7000 | −10.8870 |

| HC at low idle speed (10−9%) | −0.0400 | 0.5420 | −4.960 | 4.0400 | 0.0268 | −0.0782 |

| CO at high idle speed (10−9%) | 0.6910 | −1.140 | 0.8940 | 1.5000 | −7.4800 | −1.1070 |

| CO at low idle speed (10−9%) | −1.0300 | 2.5500 | 100.00 | −0.0363 | −0.1530 | 20.2661 |

| at high idle speed (10−9%) | −0.468 | 1.3000 | 6.1800 | −33.800 | 2.7600 | −4.8056 |

| at low idle speed (10−9%) | −1.0200 | 3.3200 | −0.025 | −20.100 | 4.2300 | −2.7190 |

| Fuel economy (10−9%) | 0.749 | −2.710 | 2.650 | 0.716 | 1.320 | 0.5450 |

| Average of E of individual dataset (10−9%) | −0.0271 | 0.301 | 10.7 | −4.64 | −12.8 | −1.2932 |

| Result No. | Ratio (%) | Fitness |

|---|---|---|

| 1 | 73.66965627 | −340.5590531 |

| 2 | 73.66733668 | −340.5590531 |

| 3 | 73.67026635 | −340.5590531 |

| 4 | 73.66891823 | −340.5590531 |

| 5 | 73.66715099 | −340.5590531 |

| 6 | 73.67054817 | −340.559053 |

| 7 | 73.67025633 | −340.5590531 |

| 8 | 73.67140711 | −340.559053 |

| 9 | 73.66666093 | −340.5590531 |

| 10 | 73.66868675 | −340.5590531 |

| 11 | 73.66823657 | −340.5590531 |

| 12 | 73.67123271 | −340.559053 |

| 13 | 73.66857724 | −340.5590531 |

| 14 | 73.66904511 | −340.5590531 |

| 15 | 73.66702082 | −340.5590531 |

| 16 | 73.66861278 | −340.5590531 |

| 17 | 73.66787028 | −340.5590531 |

| 18 | 73.66616498 | −340.559053 |

| 19 | 73.66541996 | −340.559053 |

| 20 | 73.66661274 | −340.5590531 |

| Average | 73.66848405 | −340.55905 |

| Biodiesel Ratio (%) | 0 | 30 | 50 | 70 | 73.76 | 100 | Average |

|---|---|---|---|---|---|---|---|

| Fitness | −272.179 | −320.565 | −335.865 | −339.545 | −340.559 | −331.180 | −319.867 |

| Parameter | B0 | B30 | B50 | B70 | B100 |

|---|---|---|---|---|---|

| Heating value | 2 | 1 | 4 | 5 | 7 |

| Smoke opacity | 7 | 6 | 3 | 2 | 1 |

| HC emissions | 2 | 4 | 5 | 3 | 1 |

| CO emissions | 2 | 3 | 5 | 4 | 1 |

| NOx emissions | 6 | 3 | 5 | 1 | 7 |

| Exhaust gas temperature | 1 | 4 | 7 | 3 | 2 |

| Horsepower | 1 | 7 | 5 | 4 | 3 |

| Fuel economy | 4 | 5 | 6 | 3 | 7 |

| Parameter | B0 | B30 | B50 | B70 | B100 |

|---|---|---|---|---|---|

| Emission | 17 | 16 | 18 | 10 | 10 |

| Energy transfer | 4 | 12 | 16 | 12 | 12 |

| Overall index | 22 | 28 | 29 | 17 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fadairo, A.; Ip, W.F. A Study on Performance Evaluation of Biodiesel from Grape Seed Oil and Its Blends for Diesel Vehicles. Vehicles 2021, 3, 790-806. https://doi.org/10.3390/vehicles3040047

Fadairo A, Ip WF. A Study on Performance Evaluation of Biodiesel from Grape Seed Oil and Its Blends for Diesel Vehicles. Vehicles. 2021; 3(4):790-806. https://doi.org/10.3390/vehicles3040047

Chicago/Turabian StyleFadairo, Adebayo, and Weng Fai Ip. 2021. "A Study on Performance Evaluation of Biodiesel from Grape Seed Oil and Its Blends for Diesel Vehicles" Vehicles 3, no. 4: 790-806. https://doi.org/10.3390/vehicles3040047

APA StyleFadairo, A., & Ip, W. F. (2021). A Study on Performance Evaluation of Biodiesel from Grape Seed Oil and Its Blends for Diesel Vehicles. Vehicles, 3(4), 790-806. https://doi.org/10.3390/vehicles3040047