1. Introduction

Milk and dairy products are vital sources of nutrition for millions of people around the world [

1]. The OECD/FAO report [

1] predicts that as incomes and populations increase around the world, more dairy products will be consumed over the medium term. Overall, per capita consumption is expected to increase by 0.4% per year by 2031 in high-income countries and by 2.0% and 1.5% per year in low-middle income and low-income countries, respectively [

1]. Northern Ireland (NI) is a small and largely rural region of the United Kingdom (UK), with a diverse farming structure. Dairy farms make up 10% of all farms but 31% of total agriculture output [

2]. The majority of milk produced in Northern Ireland is sold as internationally traded dairy products, and milk price is, therefore, strongly connected to global dairy commodity prices [

2]. This export dependency can leave Northern Ireland’s dairy farms exposed to the high levels of volatility experienced by global dairy commodity prices. For example, the price of milk rose from 20 pence per litre (ppl) in December 2015 to 52 ppl in December 2022, reverting to 37 ppl in December 2023 and then rising to 48 ppl in December 2024 [

3]. Output price variation, especially when combined with increased volatility in energy, fertiliser, and concentrate prices, has large effects on the profitability of dairy farms. In the UK, nitrogen fertiliser prices rose from £318/t in March 2021 to £911/t in March 2022 and fell back to £469/t in March 2023 and £365 in March 2024 [

4]. Agricultural diesel prices rose from £0.50/L in July 2020 to £1.22 in July 2022 and dropped to £0.78/L in July 2023 before rising to £0.83/L in July 2024, which has caused volatility in agricultural contractor prices [

5,

6]. The exceptional scale of recent price fluctuations has significantly complicated farm planning. Nevertheless, farm simulation models offer a valuable tool for exploring how changes in production levels, market prices, and policy impact farm performance and profitability [

7].

A number of dairy systems models have been developed internationally to simulate the farm-level technical and financial performance of milk production in a variety of geo-climatic contexts. The Moorepark Dairy Systems Model [

8] was established for simulating the many biological, physical, and economic processes in a typical Irish dairy farm. In the Netherlands, ref. [

9] developed the DairyWise whole-farm simulation model for intensive pasture- and indoor-based dairy systems. The DairyWise model is composed of several interacting sub-systems—livestock, feeding, manure management, soil, crops, nutrient cycling, energy use, greenhouse gas (GHG) emissions, and economics. The IDEA whole farm model [

10] was designed principally to provide detailed insight into optimal management on pasture-based dairy farms in New Zealand with a strong emphasis on exploring the biophysical and environmental interactions at farm level. e-Dairy [

11] was a whole-farm, stochastic, and dynamic simulation model developed to predict the biophysical and economic performance of grazing dairy systems.

The present study builds on this literature by developing a bio-economic dairy systems model explicitly designed to represent Northern Ireland’s production conditions. A bespoke dairy farm systems model was developed in preference to existing open-source alternatives, based on two primary considerations. First, a locally adapted model was required to accurately represent the environmental conditions, management practices, production systems, and policy contexts specific to Northern Ireland. Existing models are typically parameterized for different production environments, limiting their direct transferability and relevance to the Northern Irish context. Second, the development of a new model provided the flexibility to design, expand, and modify the model framework in line with evolving research objectives. This flexibility was necessary to incorporate novel traits, processes, and policy scenarios that could not be readily accommodated within the fixed structure of existing models. Developing an in-house model also ensured transparency in underlying assumptions and facilitated long-term capacity building within the research team.

While the model operates in a similar way to other dairy simulation models, a distinguishing feature of the AFBI model lies in its capacity to capture the diversity of dairy systems practiced in Northern Ireland, including fully indoor systems, mainly grass systems, and a large range of milk production yields per cow (5000 L to 11,000 L per cow per lactation). In this context, the model provides flexibility to simulate alternative calving profiles from year-round calving to seasonal spring or autumn calving systems, and allows for variations in grazing season lengths, conserved forage strategies, and rates of concentrate supplementation. In addition, the model is intended to explore how different dairy technologies, innovative management practices, and varying market or policy conditions influence technical and financial performance. This helps inform both farm advisors and policymakers about the potential benefits of alternative dairy farming approaches.

The aim of this paper is to describe a whole farm systems model for Northern Ireland dairy systems and to demonstrate its application by investigating the impact of varying market conditions on the profitability of three contrasting dairy systems.

This paper is structured as follows. First, the materials and methods outlines the model framework and defines the dairy systems under investigation. Next, the physical and financial results are presented, followed by a discussion that also considers the study’s limitations and areas for potential development. Finally, the paper concludes with key insights drawn from the research.

2. Materials and Methods

The Agri-Food and Biosciences Institute (AFBI) Dairy Systems Model is a whole farm, bio-economic simulation model that facilitates the technical and economic evaluation of grassland-based dairy cow production systems over an annual time horizon. It operates with a monthly time step and was developed in Microsoft Excel [

12]. The Excel platform has advantages such as accessibility, transparency, and flexibility, making it a dominant application for many bioeconomic models [

13]. The model is empirical and uses data from production research experiments to specify coefficients and production functions (e.g., grazed grass dry matter digestibility and energy content, liveweight gain and the monthly proportions of grazed grass and grass silage in the diet). Where alternative production functions are available, the model structure allows these to be used. A number of key assumptions underpin model operation. Firstly, the farmland area owned and the production system choices (e.g., annual milk yield, calving pattern) must be specified. Production systems modelled are based on an annual milk yield ranging from 5000 to 11,000 L and cows calving any month of the year.

Animals are categorised into three primary groups: lactating dairy cows (those currently producing milk), dry cows (not producing milk but approaching calving), and replacement heifers, which are further divided into calves (0–12 months old) and yearlings (13–24 months old). Each category is described based on the characteristics of an average animal in that group, such as milk production, body weight, weight changes, and feed consumption, with no assumption of variability within each group. The stocking rate is determined in line with existing agricultural policy, defined by the annual amount of organic nitrogen produced per hectare. This figure reflects the nitrogen excreted yearly by animals, with standard excretion rates of 100 kg N for dairy cows, 57 kg N for cattle aged 13–24 months, and 24 kg N for those aged 0–12 months. Under the Nitrates Directive in Northern Ireland, the maximum permissible nitrogen output is capped at 170 kg N/ha, although farms can apply for a derogation to increase this limit to 250 kg N/ha.

The farm’s usable agricultural land consists entirely of perennial ryegrass pastures, which are allocated between grazing and silage production. Overall forage availability is calculated from the farm’s total output of grazed grass and silage, measured in tonnes of dry matter (t DM). When necessary, additional concentrate feed is bought in, resulting in a diet made up of a combination of grazed grass, grass silage, and purchased concentrates. In Ireland, grazed grass represents the most cost-efficient source of feed energy, whereas the cost per unit of energy from grass silage and concentrates is typically fivefold and sevenfold higher, respectively [

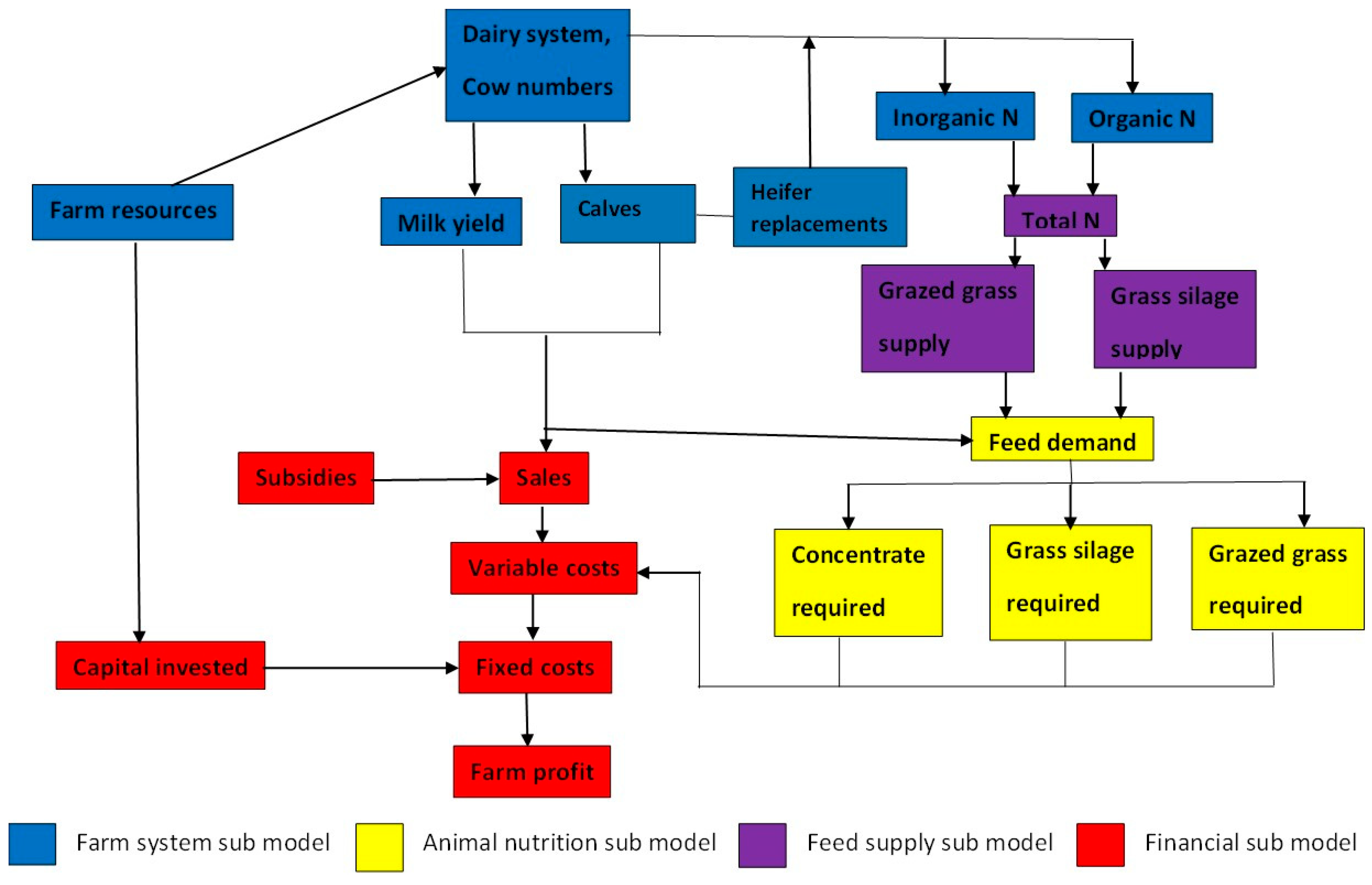

14]. Accordingly, forage feeds (grazed grass, grass silage) are prioritised over concentrates, according to their relative costs per unit of metabolizable energy. When animals are outdoors grazed grass is prioritised, and concentrates are used to fill any remaining energy gap according to the cow’s production level and DM intake capacity and reflecting the forage energy density. Similarly, when animals are indoors, grass silage is prioritised, and concentrate is used to fill the remaining energy gap. To prevent unrealistic assumptions, all user-defined inputs, such as dry matter digestibility, energy value of grazed grass, daily milk production, and the dietary balance between grazed grass and silage, are constrained within defined upper and lower limits. The overall model is made up of four interconnected sub models: farm system, animal nutrition, feed supply, and financial.

Figure 1 illustrates how these various components are linked within the model framework.

2.1. Farm System Sub-Model

The farm system sub-model represents the dairy cow production setup and, on a monthly basis, estimates animal populations, slurry generation, and housing requirements during the indoor season. Slurry output for this period is determined by daily slurry production per animal [

15], the size of each animal group, and the length of time the animals are kept indoors. The indoor housing period, defined at the input stage, depends on the availability of grazed grass (see

Section 2.3). Throughout the winter months, cows are housed in cubicle sheds and fed diets consisting of grass silage supplemented with concentrates.

2.2. Animal Nutrition Sub Model

The animal nutrition sub model calculates the energy needs and corresponding feed demands, comprising grazed grass, silage, and concentrate, for the simulated herd. This sub model follows an “animal-driven” approach, meaning that the animals’ energy requirements are defined first, based on user-specified production goals, and the necessary diet is then formulated to fulfil those needs. The Feed into Milk equations [

16] are used to determine the energy requirements for lactating and dry cows (

Table 1). The energy requirement is driven by the daily milk yield. Daily milk yields were obtained from the dairy herd at the AFBI research farm Hillsborough over a period of 10 years (2010–2020). These were split into lactation number (1–6) and yield bands (5000–7000, 7001–9000, 900+ L/lactation) and averaged to give a lactation curve and, therefore, daily milk yields for each lactation number in each yield band. A check on protein requirements and supply was undertaken as outlined by [

16].

2.3. Feed Supply Sub Model

The feed supply sub model simulates the forage production methods employed on the farm for both grazed grass and grass silage. Grass silage production is prioritised in the model, with the area needed for its production calculated first. The remaining land available for grazing is then determined by subtracting the silage area from the farm’s total land area for each month. The user can select from 1, 2, or 3 grass silage harvests. Silage yields are taken from [

17] and the equations are shown in

Table 2. The land area needed for grass silage is determined based on the silage demand calculated by the animal nutrition sub model. Once the specified number of grass silage harvests has been undertaken, the grass silage area becomes available for grazing. The total yearly grass yield (t DM/ha) on grazing land is calculated using a grass growth equation that depends on the applied organic and inorganic nitrogen rate (kg/ha). Annual grazed grass production was determined using the GrassCheck model which was adopted from the GrazeGro model [

18] across a range of N application rates. A quadratic equation was then developed to determine the annual yield based on N application rate (kg/ha) (

Table 2). Monthly distribution of the grass was as determined by the GrassCheck model; therefore, supply and demand for grazed grass is balanced on a monthly basis. Grass utilisation rate is set at 75% of the available forage DM produced [

19] but can be changed by the user.

The nitrogen applied on the grazing area is set by the user and is an important input, because it determines the stocking rate on the farm (

Figure 1). Nitrogen (N), phosphorous (P), and potassium (K) inputs for grass silage and P and K inputs for grazing are set according to the specifications of RB209 [

20] at a soil index of 2 for P and K. Slurry produced is allocated to first, second, and third harvest grass silage areas in the proportion 50%, 25%, and 25%, respectively. If only 2 grass silage harvests are selected by the user then slurry is proportioned at 50% each to first and second cut. The nutrient content of slurry is accounted for when calculating inorganic fertiliser requirements. The P and K available from organic manure is taken from RB209 [

20]. The availability of nitrogen from organic manure varies throughout the year due to different levels of nitrogen volatilization [

21] and is therefore set at 26% when applied in spring and 9% when applied in summer [

22].

2.4. Financial Sub Model

The financial sub model estimates the expenses and revenues associated with the simulated system. It draws input quantities from the farm system, animal nutrition, and feed supply sub models. Default input prices are provided but can be adjusted by the user as needed.

Milk price is a function of the fat and protein content. To account for seasonal fluctuations in the Northern Ireland milk price the monthly deviations from the annual average for the years 2000 to 2020 was calculated [

3]. This information was then applied to determine the monthly milk price by modifying the user-defined annual average price. Monthly variable costs are computed using input prices, default values sourced from [

2,

5] alongside the quantities consumed. These variable costs cover items such as concentrates, fertiliser, lime, silage production (including contractor services, additives, and polythene), veterinary and medical expenses (e.g., anthelmintics, vet visits, treatment of sick animals, vaccinations), reseeding, straw, sawdust, slurry application, and milk replacer.

Fixed costs include overheads such as electricity, car, phone, land improvements, interest on loans, machinery and building maintenance and depreciation, professional fees (consultancy and accountant), and land rental. The cost of buildings was taken from [

5] based on a per-animal cost multiplied by the animal numbers on the farm. Building depreciation is calculated using the straight-line depreciation method over 30 years and the balance sheet valuation taken at the 15th year following construction. Machinery depreciation is calculated using the declining balance method with a 15% depreciation rate and the balance sheet valuation taken at the fifth year after purchase. Machinery owned by the farmer includes a tractor, telehandler, diet feeder, fertiliser sower, and topper. Other activities like harvesting grass silage, reseeding, and spreading slurry are performed by contractors and calculated in the variable costs. A working capital loan is assumed to cover half the variable costs with a repayment period of 1 year. A long-term loan is assumed to cover investments in land improvements, livestock housing, and machinery, with a repayment period of 20 years. A cost for water is not included because water for irrigation is not necessary in Northern Ireland and most farms have wells, and water is freely available. The cost to pump the water is included in electricity costs. If the total land area used exceeds the farmer’s owned land, land rental is treated as a cost; conversely, if less land is used than owned, rental is considered income. The model does not account for opportunity costs associated with owned land. Labour requirements are included and calculated using figures from [

5] for the different dairy systems. The key outputs from the AFBI Dairy Systems Model financial sub model are the monthly and annual cash flow and annual profit and loss account. All costs and margins are presented per farm, hectare, cow, and litre of milk sold.

2.5. Model Evaluation

Evaluation was conducted by “face validity” with “knowledgeable individuals” described by [

23,

24,

25]. This approach was necessary due to the absence of suitable datasets, independent from those used in model development, for quantitative validation. A number of ‘evaluation workshops’ were held with dairy researchers at AFBI Hillsborough and College of Agriculture and Rural Affairs (CAFRE) dairy advisors, similar to [

19,

26,

27]. These workshops focused on evaluating various scenarios by altering key factors such as land area, nitrogen application rates, input and milk prices, as well as performance metrics like forage production, milk output, and replacement rates. The evaluations focused on both verification of model equations and calculation processes and validation of model outputs against system benchmarks. Following a series of meetings that allowed for model adjustments, the evaluators concluded that the systems were realistically represented, both in terms of technical aspects, such as feed usage, stocking densities, and forage yields, and financial performance.

2.6. Model Application: Systems and Price Scenarios

The AFBI Dairy Systems Model was applied to examine how fluctuations in milk, concentrate, fertiliser, contractor, and electricity prices, along with changes in interest rates, impact the economic performance of three milk production systems used in Northern Ireland (Low, Medium, and High). The three systems reflect distinct genetic strains of Holstein Friesian cows. Specifically, Low comprises New Zealand-type strains focused on grazing efficiency, High comprises North American strains with a high genetic merit for milk production, while the Medium cow type balances moderate milk production potential with durability traits for grazing conditions. The systems varied in their input requirements, such as feed and herd size, and milk production levels; the impact this had on both physical and financial performance at the whole-farm scale was determined. Cow numbers were determined by aligning the livestock system with the available land, ensuring no need for renting land in or out. This was achieved through an iterative approach, adjusting animal numbers based on the level of inorganic nitrogen applied (as specified by the user) until the calculated land requirement matched the farmer’s owned land area. The number of cows differs since stocking rate is kept constant at 170 kg N/ha but feed requirements and replacement heifer numbers differ between the systems. The Low system had two silage harvests, whereas the Medium and High systems had three silage harvests in the year.

Table 3 shows some of the main input prices for the base price scenario. Calf rearing was similar for all systems; male calves were sold at 3 weeks of age and only female calves needed for replacements were kept.

In the Low system, calving occurred in spring, with 25% of cows calving in February, 50% in March, and 25% in April. All cows were dry during December and January, and each produced 6000 L of milk per lactation. From March to October, cows were kept outdoors and fed a diet of grazed grass supplemented with concentrate. During the indoor period, from November to February, their diet consisted of grass silage and concentrate [

28,

29,

30]. In the Medium system, calving was split between spring and autumn, with 25% of cows calving in March, 25% in April, 25% in September, and the remaining 25% in October. Each cow produced 8000 L of milk per lactation. From April to September, cows were grazed outdoors on a diet of fresh grass and concentrate, while from October to March, they were housed indoors and fed grass silage along with concentrate [

28,

29]. In the High system, calving occurred continuously throughout the year, with 8.3% of cows calving each month. Each cow produced 10,000 L of milk per lactation. Lactating cows were kept indoors year-round and fed a diet of grass silage and concentrate, while only dry cows and replacement heifers grazed outdoors, receiving grazed grass along with concentrate [

28,

29]. Dry cows were treated similarly for all systems, with the diet being either grazed grass or grass silage depending on the time of year. The effect of changing milk, concentrate, fertiliser, contractor, and electricity prices and interest rate by 10% on net profit was investigated.

3. Results

Table 4 presents the main physical results for the systems investigated. The grazing area and silage area was largest and smallest, respectively, for the Low system and smallest and largest, respectively, for the High system. As a proportion of total annual feed budget, intake of grazed grass was 53%, 34%, and 11% for the Low, Medium and High systems, respectively. Grass silage intake as a proportion of total intake was 33%, 45%, and 63% for the Low, Medium and High systems, respectively. Concentrate intake as a proportion of total intake was 13%, 20%, and 26% for the Low, Medium, and High systems, respectively. This resulted in total concentrate consumed per cow being 55% lower for the Low system compared to the Medium system and 44% higher for the High system compared to the Medium system. The amount of inorganic nitrogen applied per hectare for the grazing and silage areas was largest for the Low system and smallest for the High system. The number of cows in each system was similar, but the Low system had the highest number, with the High system having the lowest. However, total milk produced per farm was 21% lower for the Low system compared to the Medium system and 22% higher for the High system compared to the Medium system.

Table 5 presents baseline financial results for the systems investigated. Overall, the most profitable system was the Medium system. Milk sales were highest in the High system. Total output was 19% lower in the Low system compared to the Medium system and 16% higher in the High system compared to the Medium system. However, total variable costs were lowest for the Low system and highest for the High system. Accordingly, gross margin was 11% lower for the Low system compared to the Medium system and 0.1% higher for the High system compared to the Medium system. Fixed costs were 6% higher and 7% lower in the High and Low systems, respectively, compared to the Medium system, resulting in the net profit being greater for the Medium system compared to the Low and High systems. The net profit per ha and cow were highest for the Medium system and lowest for the Low system. However, the net profit per litre was highest for the Low system and lowest for the High system. The net cash flow was highest for the Medium system and lowest for the Low system.

Table 6 shows the effect of changing milk, concentrate, fertiliser, contractor, and electricity prices and interest rate on net profit.

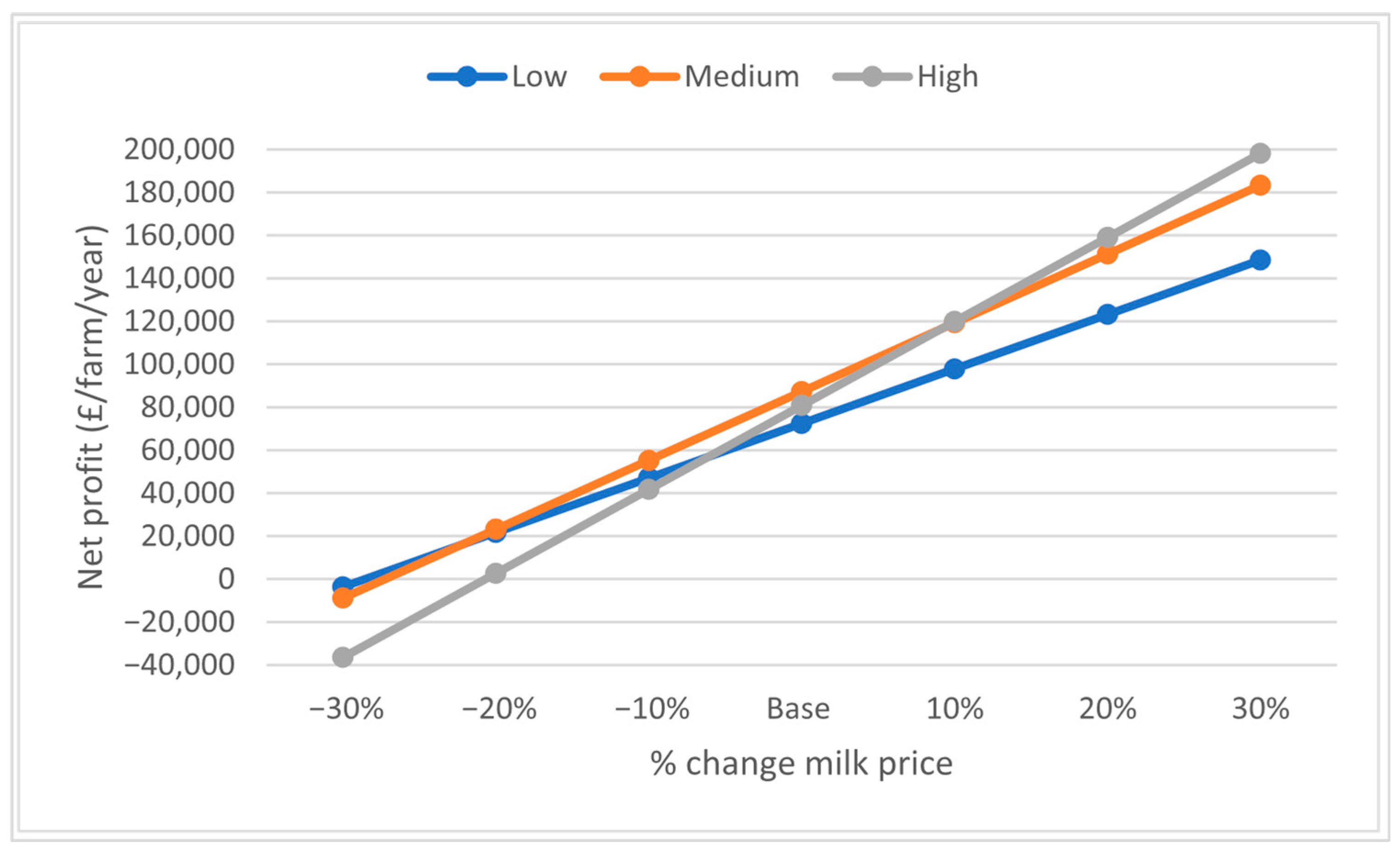

Table 6 shows the effect of a 10% change, but these are cumulative, i.e., for 20% multiply by two, for 30% multiply by three. A 10% shift in milk price resulted in net profit changes of 35%, 37%, and 48% for the Low, Medium, and High systems, respectively.

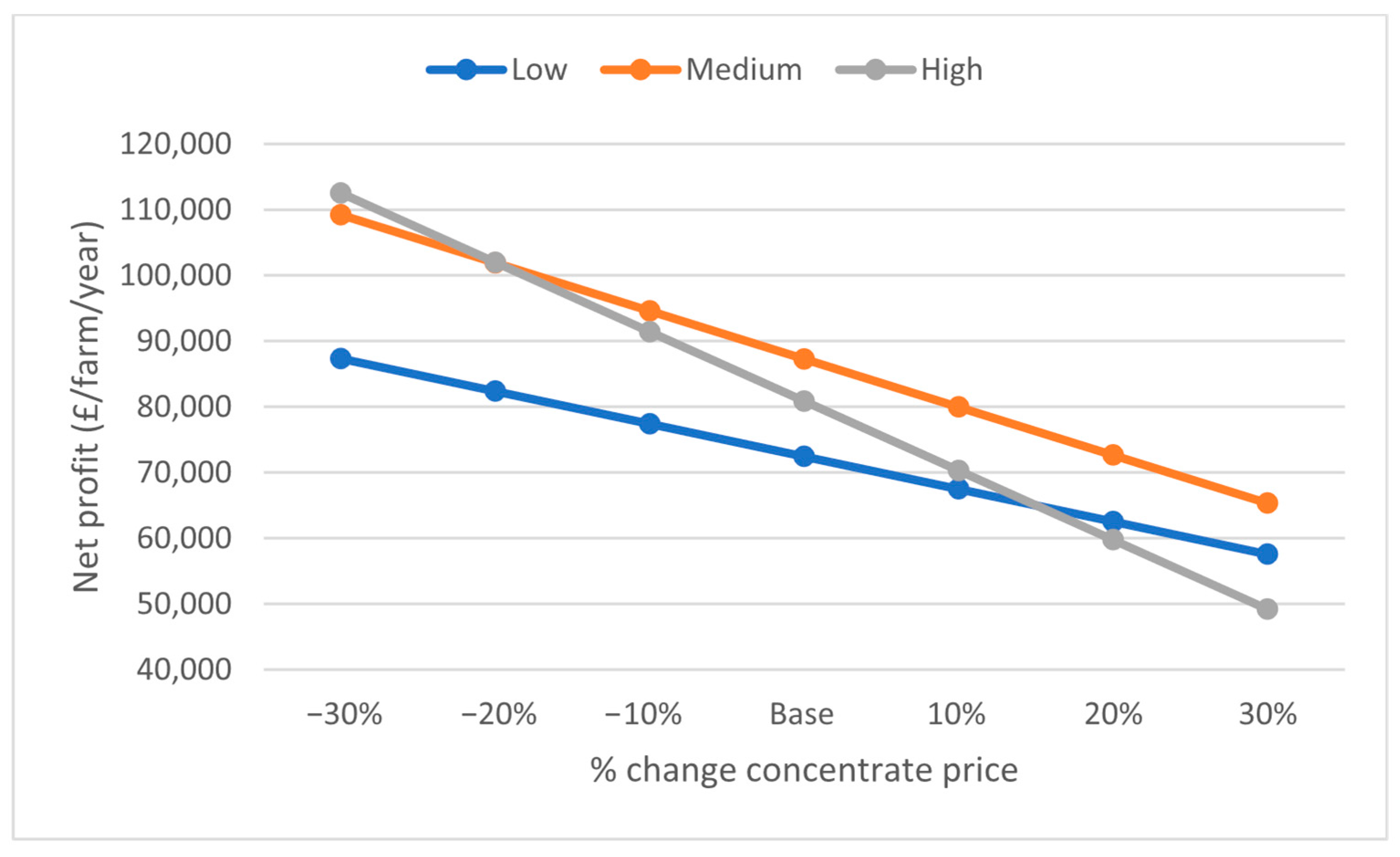

Figure 2 shows that a 10% decrease in milk price makes the High system the least profitable and a 10% increase makes it slightly more profitable than the Medium system. A 20% decrease in milk price makes the Low system nearly as profitable as the Medium system and a 30% decrease in milk price makes the Low system the most profitable. A 10% shift in concentrate price resulted in net profit changes of 7%, 8%, and 13% for the Low, Medium, and High systems, respectively.

Figure 3 shows that a 20% increase in concentrate price results in the High system becoming the least profitable, and a 20% decrease makes it slightly more profitable than the Medium system. A 10% shift in fertiliser price resulted in net profit changes of 2.3%, 2.2%, and 2.6% for the Low, Medium, and High systems, respectively. A 10% shift in contractor price resulted in net profit changes of 4.6%, 5.5%, and 9.2% for the Low, Medium, and High systems, respectively. A 10% shift in electricity price resulted in net profit changes of 1.3%, 1.2%, and 1.4% for Low, Medium, and High systems, respectively. A 10% shift in interest rate resulted in net profit changes of 3.7%, 3.7%, and 4.4% for the Low, Medium, and High systems, respectively.

4. Discussion

This paper outlined the development, assessment, and use of a new bio-economic simulation model for dairy farming systems. It detailed how the farm system, animal nutrition, feed supply, and financial sub models interact within the overall framework. The model was evaluated and shown to effectively reflect dairy production practices in Northern Ireland. Additionally, the paper demonstrated the model’s application by analysing how changes in milk price, concentrate costs, fertiliser expenses, contractor fees, electricity prices, and interest rates affect the profitability of three different dairy systems.

As with all simulation models the results shown are a simulation of changes on a farm and every individual farm is slightly different (farmer’s skills, breed of cows, infrastructure). Therefore, the results should not be treated as the exact profitability possible, but rather as indicating the relativity in profitability between the systems.

4.1. Applications of Model

At baseline prices, the Medium system was more profitable than the Low and High systems, with the High system being more profitable than the Low system. Increased sales revenue from moving from Low to Medium (£67,932) more than compensated for the additional input costs required (£53,107). In contrast, the extra input costs switching from Medium to High (£73,600) exceeded the gain in sales revenue (£67,184). This finding is consistent with the results of [

31] regarding the financial advantages of moderate input systems under Northern Irish conditions. Feed costs as a percentage of variable costs were on average 77% across all systems (75% Low, 78% Medium, 79% High). Other studies have found similar levels for feed costs as a percentage of variables costs [

32]. The vet/med/AI costs are highest in the High system, because the cows are more prone to health issues such as displaced abomasum and ketosis, while lower fertility performance (conception rates) increases insemination costs [

28,

29,

30].

The results showed that changes in milk price have a large effect on net profit, with the High system being most affected due to its output intensity.

Figure 2 shows how sensitive the systems were to milk price changes and how a change in milk price can change the ranking of the systems in terms of profitability. Variations in concentrate price had the greatest impact on the High system and the least on the Low system, highlighting the differing reliance on concentrate feed within each system. This is similar to what was found by [

29].

Figure 3 shows how changing concentrate price can affect the ranking of the systems in terms of profitability. These results would imply that if concentrate prices are decreasing and milk prices are increasing farmers can profitably feed more concentrate and increase milk output. However, in the short run there is limited flexibility for farmers to switch between systems due to the investments in cow genetics and farm infrastructure (both being different between the systems) that would be required.

Fertiliser prices have varied substantially over the last 5 years [

4]. However, this study found changes in fertiliser price had a modest effect on net profit, because fertiliser expenditure comprised a relatively small proportion of total variable costs (16%, 13%, and 10% for the Low, Medium, and High systems, respectively). With increasing fertiliser prices, farmers may be inclined to reduce fertiliser usage; however, this may not improve profitability, because it could reduce the stocking rate of the farm or lead to the purchase of more expensive feeds to maintain production [

33]. The study showed that changes in contractor prices had the largest impact on the net profit of the High system and a 10% change in contractor prices had a larger effect on net profit than a 10% change in fertiliser prices across all systems. Changes in electricity prices and interest rates were found to have a small effect on the net profit of the dairy systems investigated due to their lower percentage share of costs.

On a farm of this size in Northern Ireland, labour would normally consist of unpaid labour mainly from the farmer or family members. However, when labour requirements were calculated, considerable differences were found across the three systems, with the labour requirement per cow being lower for the Low system (1 labour unit) compared to the High (2 labour units) and Medium systems (1.5 labour units) due to the variability in milking, feeding, replacement heifer rearing, and management time required for each system [

5,

34]. When the full cost of unpaid family labour [

35] was included in the baseline scenario the ranking of the systems changed, however, the Medium system was still the most profitable. The profitability for the Low, Medium, and High systems was, £45,272, £46,614, and £26,863, respectively. Whilst for the Low system, the labour required per cow was lower, there are likely to be periods of very high labour demand (calving), whereas for the Medium and High systems, the labour demands would be more constant throughout the year.

4.2. Innovations of Approach

Several whole-farm systems models have been described in the previous literature [

8,

9,

36,

37,

38]; however, the originality of the AFBI Dairy Systems Model lies in its ability to model a wide range of dairy production systems practiced in Northern Ireland. This covers a spectrum of milk yields, calving profiles, grazing season lengths, replacement rates, and quantities of purchased feed. The model allows the user to better understand how nitrogen application rate, grazing season length, calving profile, milk yield and replacement rate affect the demands for grazed grass, grass silage, and concentrate and, therefore, costs of production and overall profitability. This enables researchers to deepen their understanding of dairy production systems, which can inform improvements aimed at increasing profitability. As a result, the model serves as a valuable tool for assessing the economic effects of different policy options and market scenarios on the financial performance of dairy systems. Moreover, production system adaptations such as altering stocking rates, replacement heifer rates, and grazing season lengths can also be evaluated. While the model is built using production data from Northern Ireland, its parameters are adaptable to suit other temperate grassland environments where animal performance or feeding practices may vary from those used in this study. The model’s flexible design makes it suitable for examining the effects of changing input and output prices, as well as variations in performance.

4.3. Limitations of Approach

The model created is deterministic, meaning it does not capture the variability in production within the systems being simulated, for example, fluctuations in milk yield, energy requirements, or weather extremes that influence grazing periods and forage yields. Several dairy system modelling studies [

8,

39] have incorporated stochastic methods, often building on a deterministic foundation. As such, evolving this model into a stochastic version represents a potential future enhancement of the current framework. Other potential model extensions could capture the dynamics of farm system adjustments over longer planning horizons and representing heterogeneity in animal performance rather than relying on group averages. While we acknowledge the value of these possible future developments, we suggest that, for the purposes of analysing the current scenarios, such enhancements would likely offer only limited additional insights while substantially increasing model complexity.

5. Conclusions

The AFBI Dairy Systems Model has demonstrated its capability to capture the complexity of dairy production systems in Northern Ireland and their responsiveness to price fluctuations. Financial outcomes across all systems were notably affected by changes in milk and concentrate prices, while they showed comparatively little sensitivity to shifts in fertiliser, contractor, and electricity prices and interest rates. The profitability of a low-output system was less exposed to variations in prices; in contrast, a high-output system was very exposed to variations in prices. Overall, a medium-input system was the most profitable across the majority of price scenarios investigated.

However, because a farmer’s overarching decision regarding system type (Low, Medium, or High) involves substantial investment in cow genetics tailored to that system, switching between systems is both costly and slow. Such adjustments typically require several years, raising important questions about optimal pathways for transition. Within a given system, flexibility is also constrained, as nutrition strategies must be closely aligned with the chosen cow genetics. For example, reducing concentrate supplementation in high-yielding systems is likely to compromise animal welfare, particularly in relation to health and fertility, whereas increasing concentrate feeding in low-input systems may be uneconomic, given the limited milk yield response of cows selected for such systems. Research examining adaptation both within and across systems therefore constitutes a promising area for future investigation.

Additionally, it is anticipated that the model will be used to explore the effect on profitability of different dairy systems (milk yields, calving season, replacement rates), new farm practices (zero grazing, alternative forages), different markets (changes in milk payment system), and policy conditions (restrictions on stocking rates) providing both farm advisors and policymakers with a holistic analysis of alternative dairy farming strategies.